Rock sample drying apparatus and its drying box structure

A drying equipment and drying oven technology, applied in non-progressive dryers, lighting and heating equipment, preparation of samples for testing, etc., can solve the problems of inconvenient installation, overhaul, maintenance, complicated mechanism configuration, poor explosion-proof measures, etc. To achieve the effect of simple structure, low manufacturing cost and environmental purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

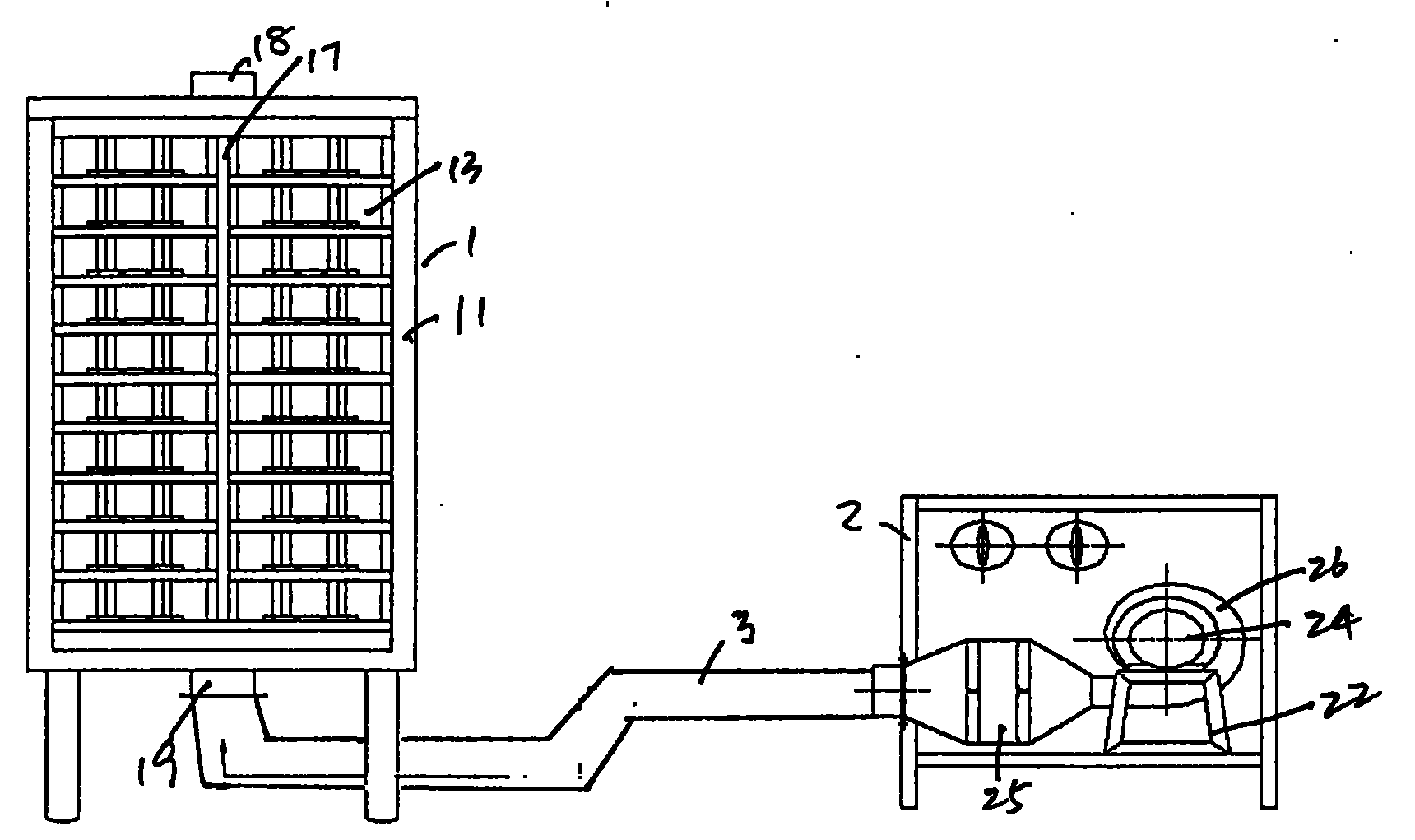

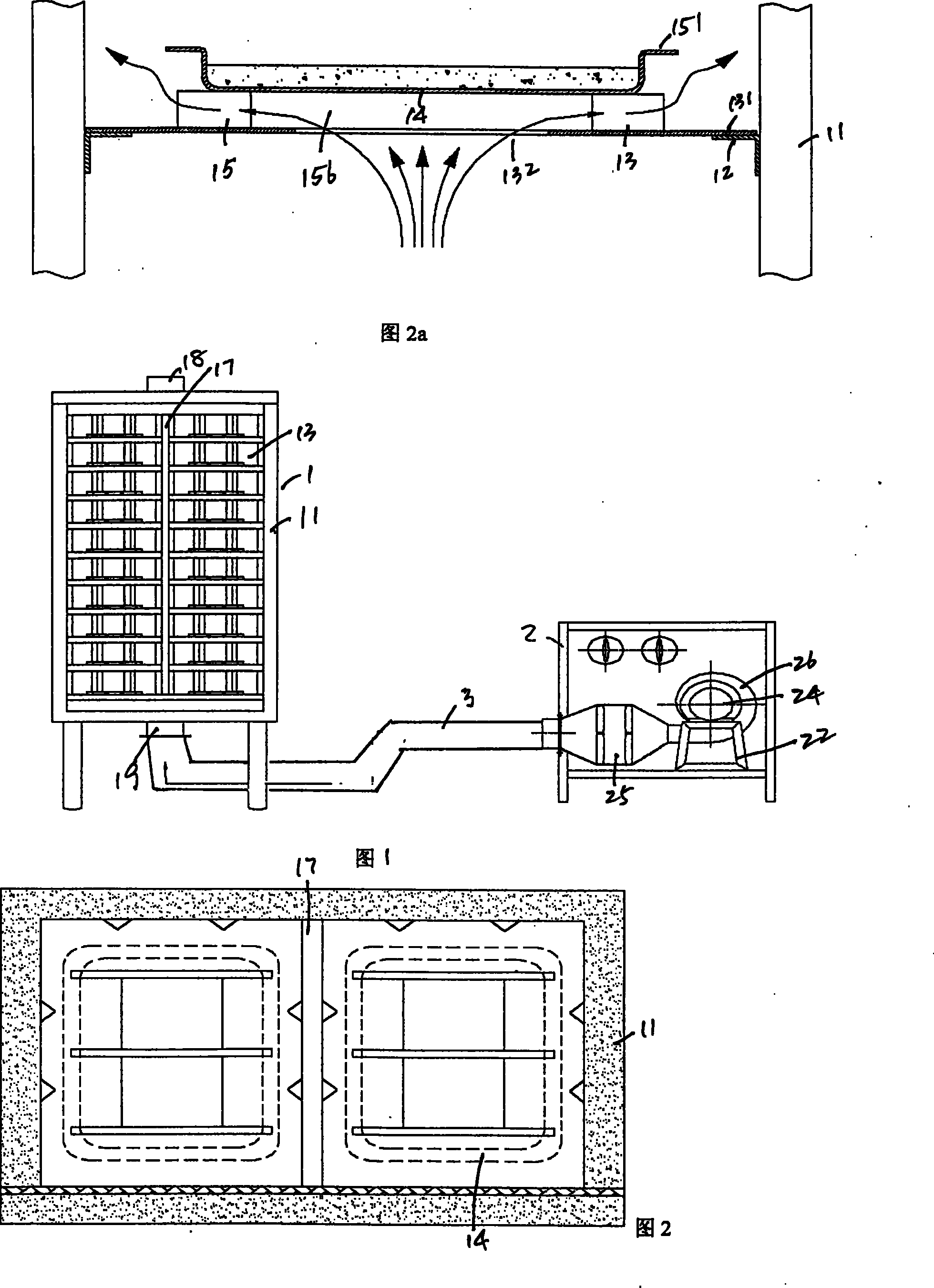

[0029] Please refer to Figure 1-2, a rock sample drying equipment and its drying box structure,

[0030] The rock sample drying equipment includes a drying box 1, wherein the drying box is connected with a hot air device 2 for conveying hot air through a high-temperature-resistant insulated air supply pipe 3; the drying box 1 is composed of a The box body 11 of the first layer and 13 groups of drawers arranged in series in several layers are arranged in the box body; there is a gap for air flow to pass between the drawer group and the box body, and a gap for air flow to pass between the drawers of each layer; Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com