Patents

Literature

116results about How to "Expedited drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radio frequency textile drying machine

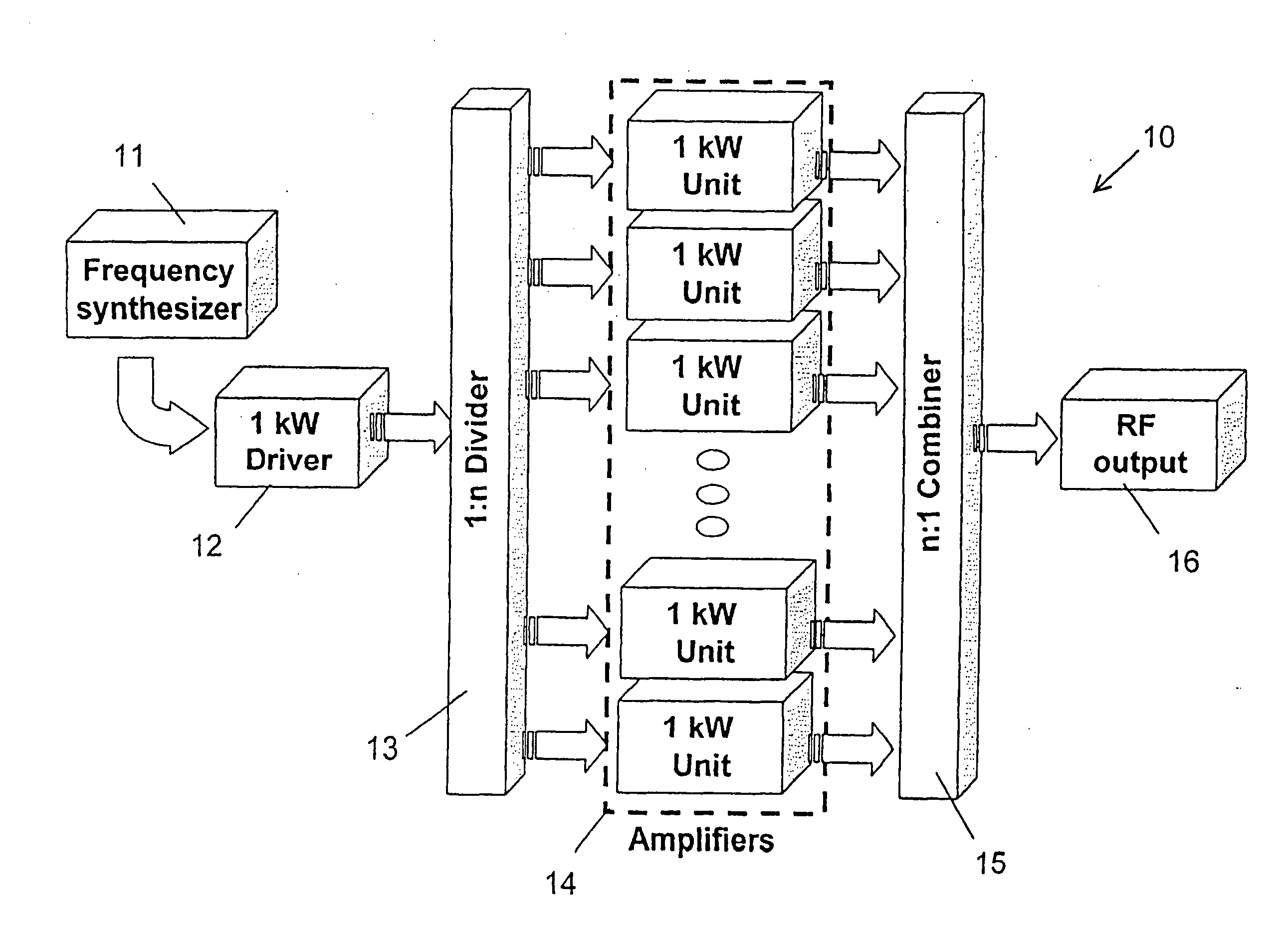

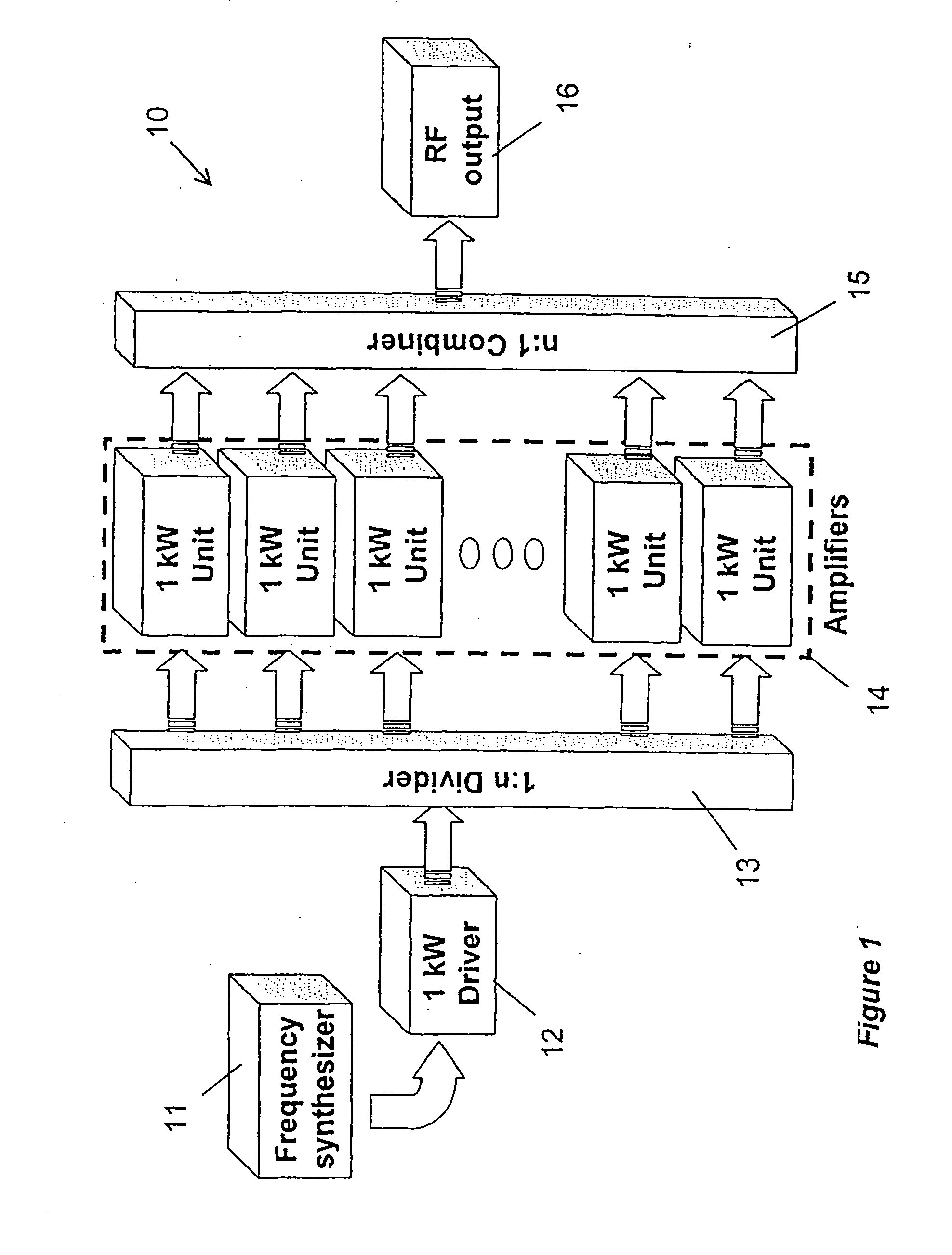

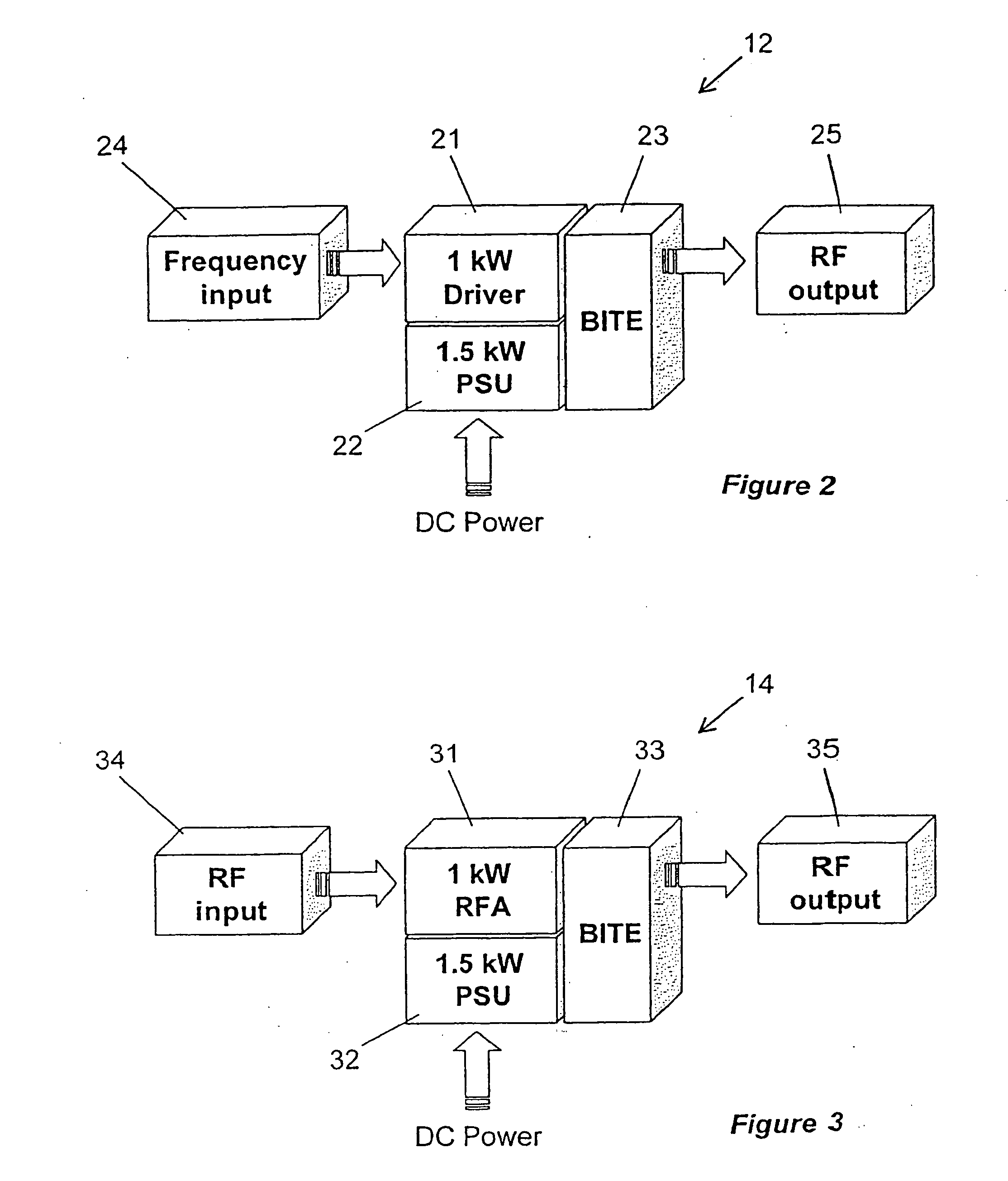

InactiveUS20070045307A1Reduce maintenance costGood efficiencyDielectric heatingDrying solid materials with heatRadio frequencySolid-state

A textile drying machine comprises a tank for receiving textiles with a spindle inside the tank for supporting the textiles, and a solid-state radio frequency generator. The generator is connected to the spindle and the tank is earthed so that when the generator is operated an oscillating electric field is generated between the spindle and the tank, and hence applied to textiles on the spindle. The electric field heats water molecules in the textiles by molecular vibration so that evaporation occurs, and the water vapor is removed from the tank by an extractor fan. The machine may also be used to dye the textiles prior to drying, thus providing an integrated dyeing / drying machine.

Owner:FALMER INVESTMENTS LTD

Method of drying book and similar paper-based materials

InactiveUS7007405B2Easy to handleSimple methodDrying using combination processesDrying solid materials with heatPaper basedMoisture

Owner:USTAV CHEMCH PROCESU AKADE VEDCESKE REPUBLIKY

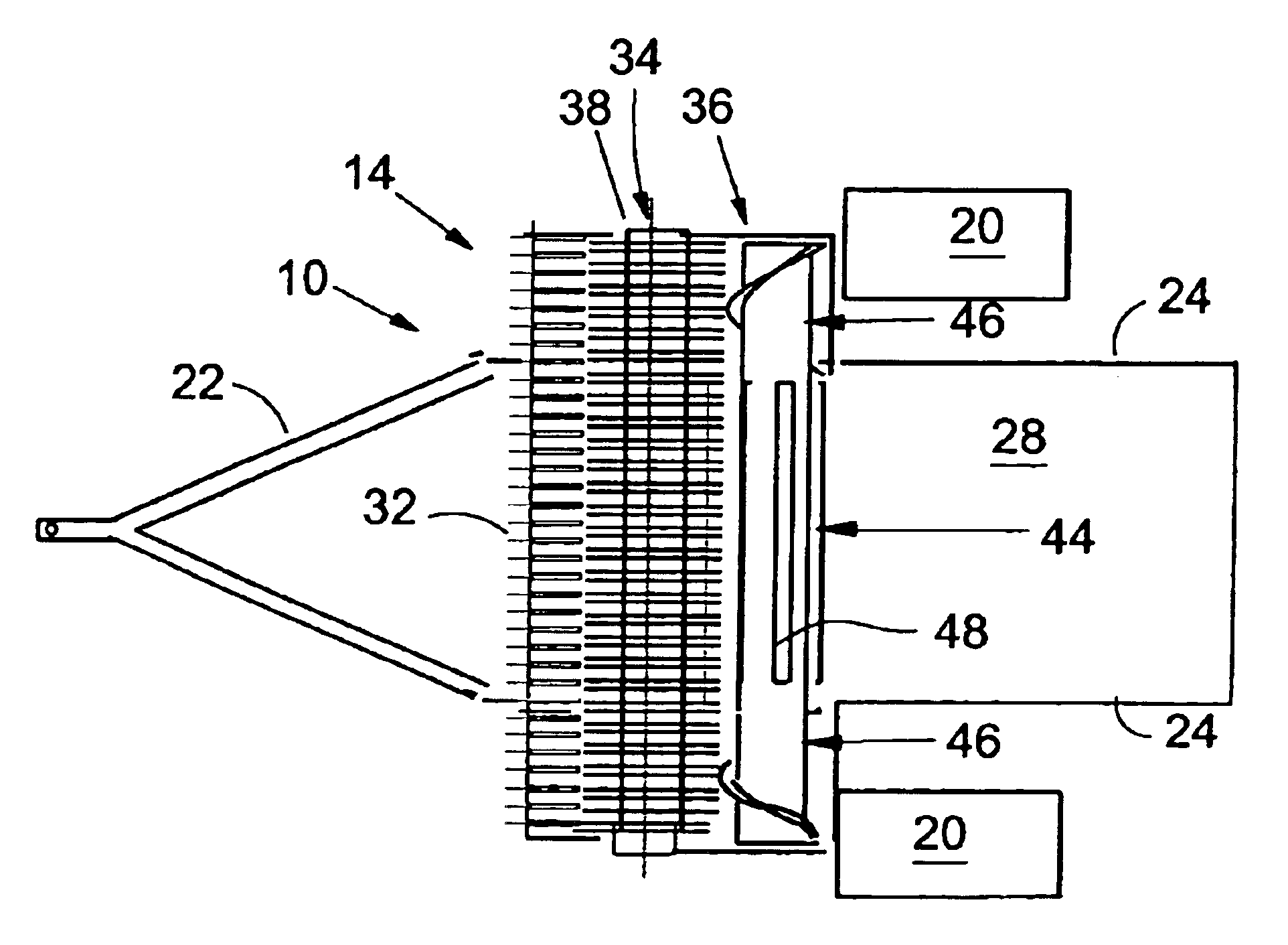

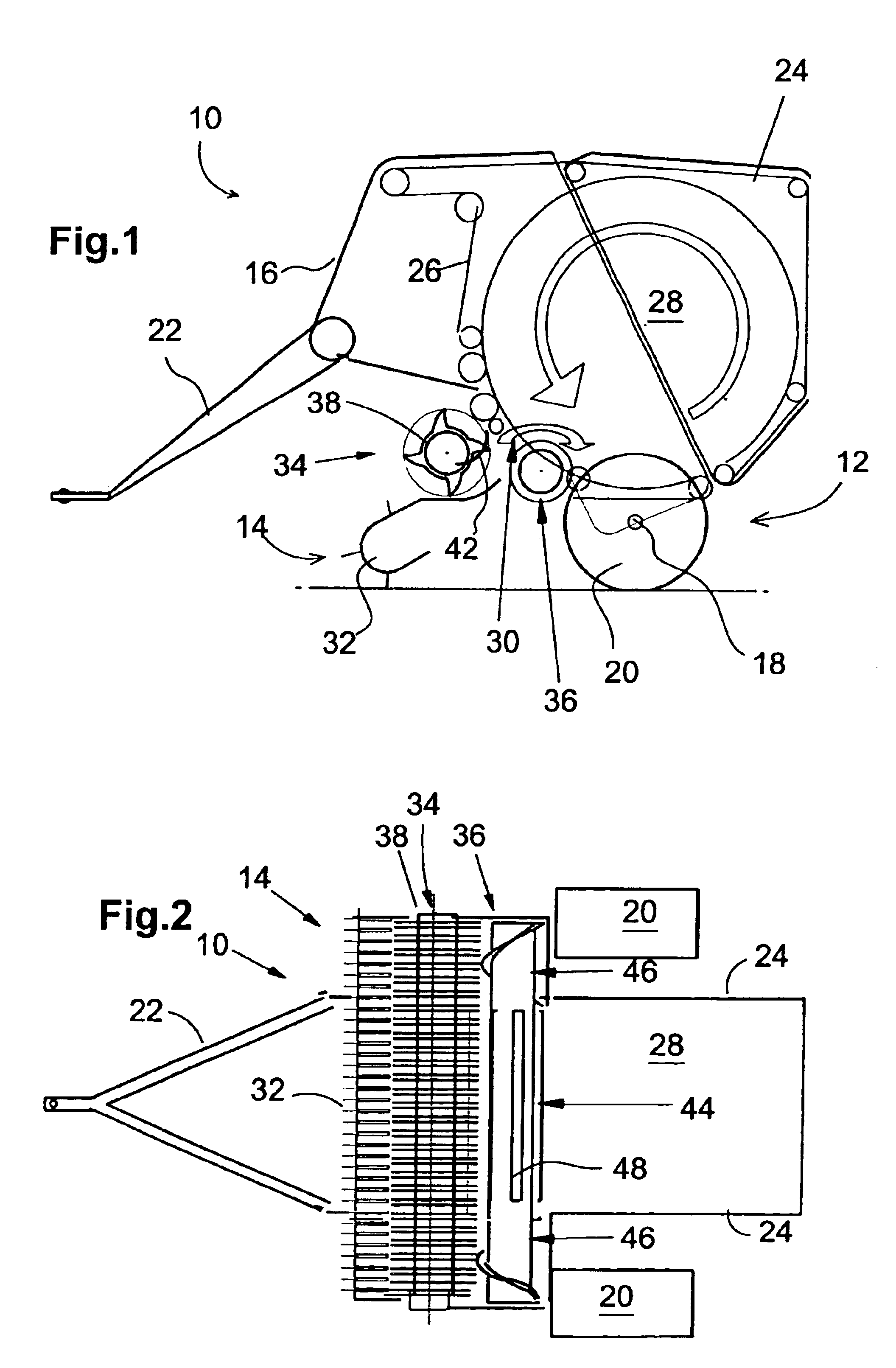

Baler

A large round baler is equipped with a plurality of components for delivering crop to an inlet of a baling chamber of a large round baler. These components have a width which is substantially wider than the baling chamber inlet and include a crop take-up device and a crop processing arrangement, such as a cutter head, that receives crop from the crop take-up device. The crop processing arrangement delivers the processed crop to a transverse conveyor, which narrows the stream of crop to the width of the baling chamber inlet.

Owner:DEERE & CO

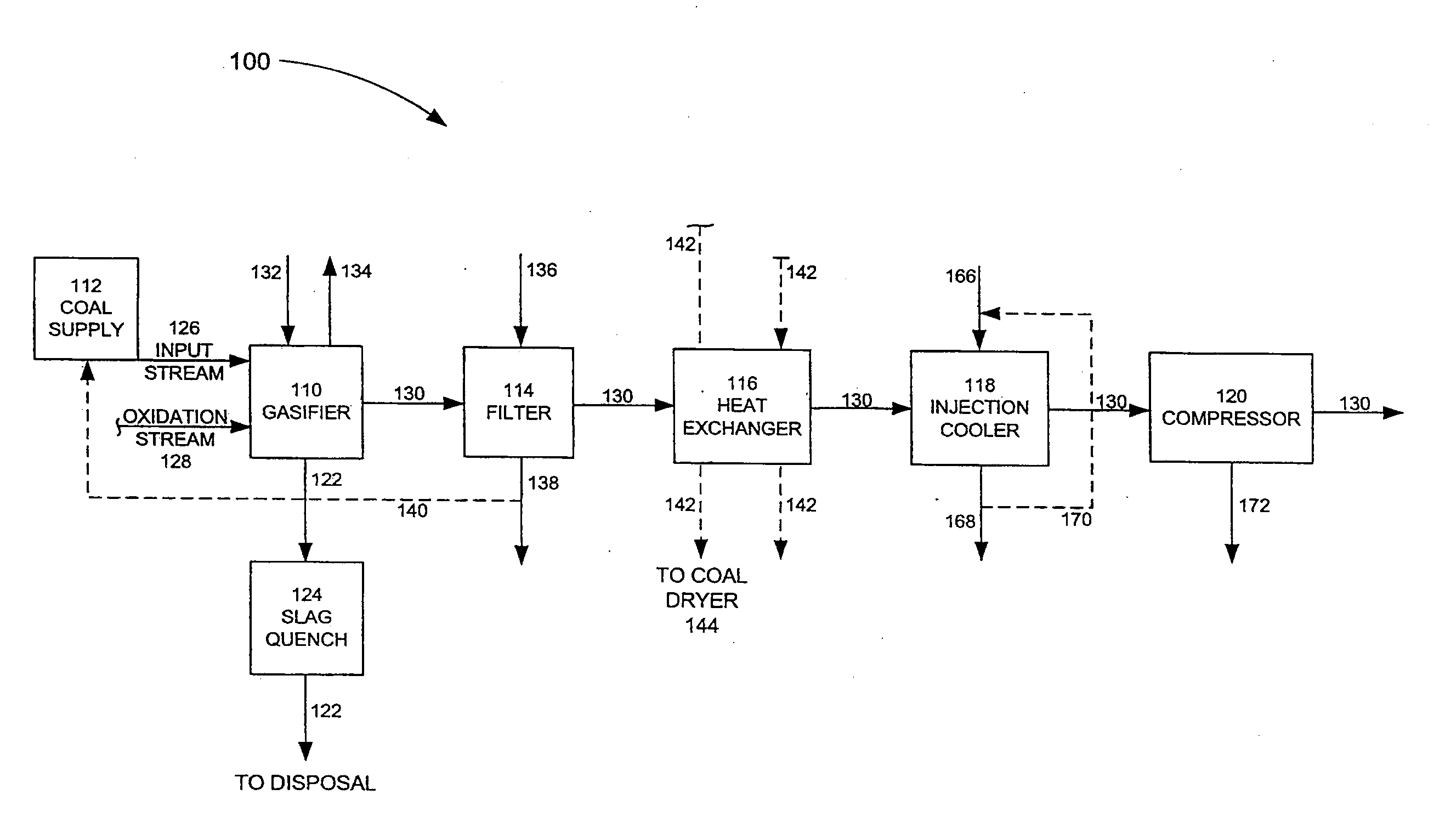

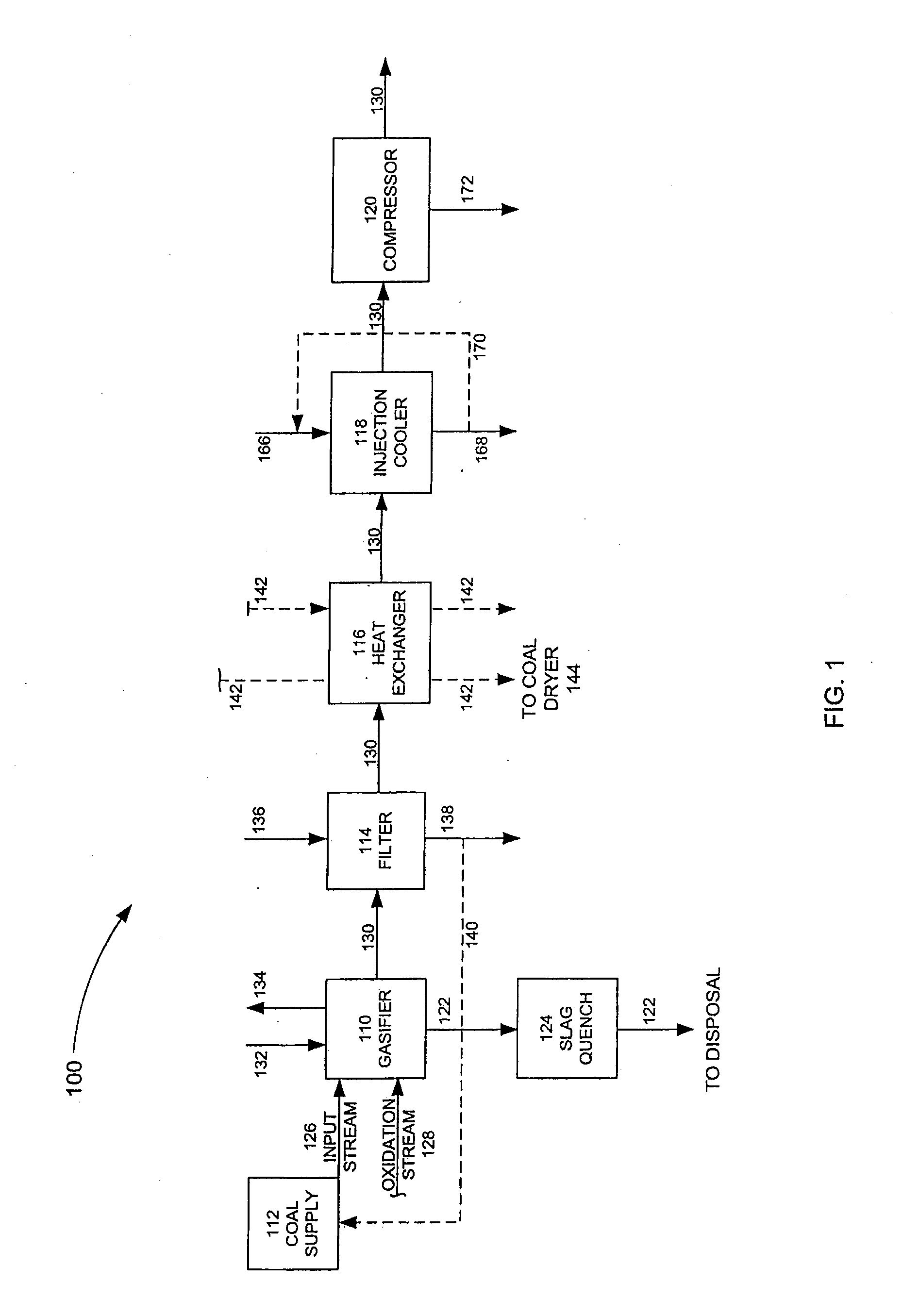

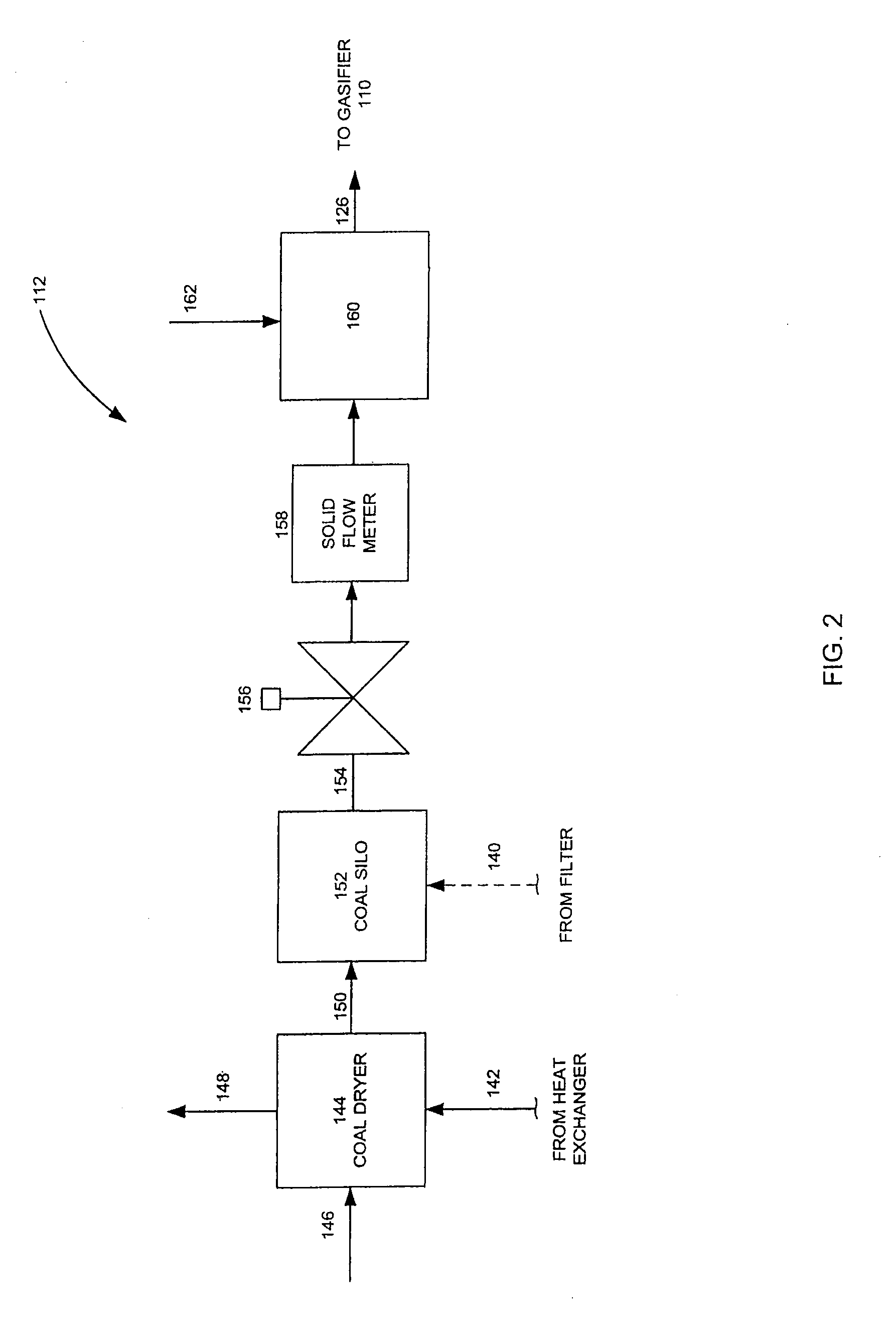

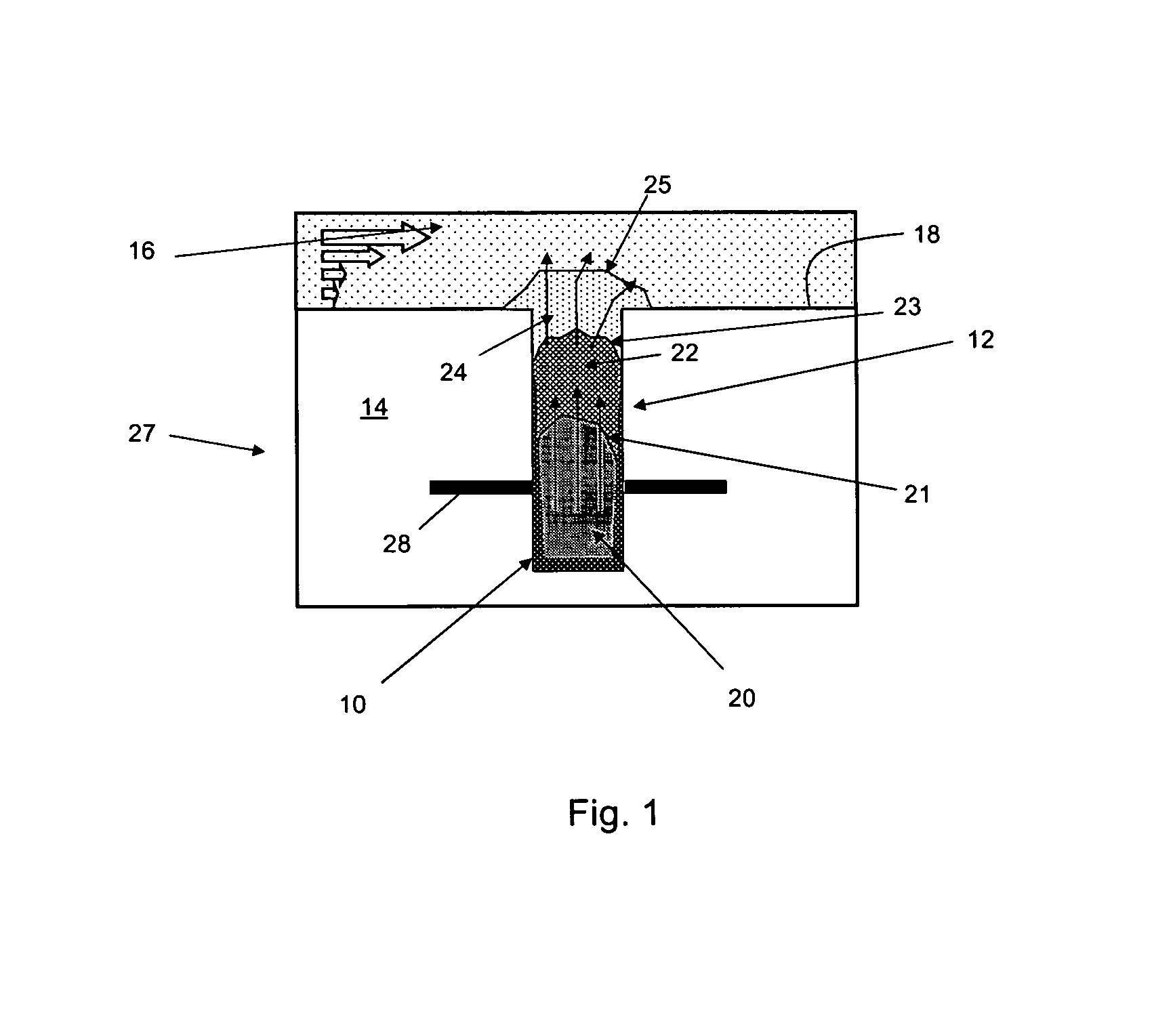

Atmospheric pressure gasification process and system

InactiveUS20110173885A1Reduce and prevent leakage of gasImprove efficiencyGasifier feeding meansGas generation devicesCombustorFuel distribution

A fuel supply system for supplying pulverized feedstock to a gasifier includes a feedstock storage apparatus for storing pulverized feedstock. The feedstock storage apparatus operates at a first pressure. The fuel supply system also includes a mechanical conveyance apparatus linking the feedstock storage apparatus to a fuel distribution apparatus. The mechanical conveyance apparatus is operable to continuously convey the pulverized feedstock from the feedstock storage apparatus to the fuel distribution apparatus at a first flow rate. The fuel distribution apparatus operates at a second pressure that is greater than the first pressure. The fuel distribution apparatus includes at least one outlet communicably connected to at least one burner on the gasifier for transferring pulverized feedstock from the fuel distribution apparatus to the at least one burner.

Owner:HATCH LTD

Magnesium alloy surface chemical cleaning process and cleaning liquid

This invention relates to chemical cleaning process and agents for magnesium alloy. The chemical cleaning agents comprises phosphoric-sulfuric acid aqueous solution as washing agent at some ratio and alkali solution as cleaning agent. The chemical cleaning process is carried out by immersing parts without oily stain in acid solution for a fixed time, then washing them in water and immersing them in alkali solution for a fixed time, finally, washing them in water so as to remove settlings or remains due to oxidizing, eroding, mold parting agent for compression casting, chemical conversion film, etc. It can be used as pre-treatment for chemical or electrochemical protective process to provide clean surface. It processes effectively with good quality, easy operation, and stable solutions. The solutions do not contain hexavalent chromium and fluoride so as to wastes treatment, and can be used in industrial production.

Owner:杨景林

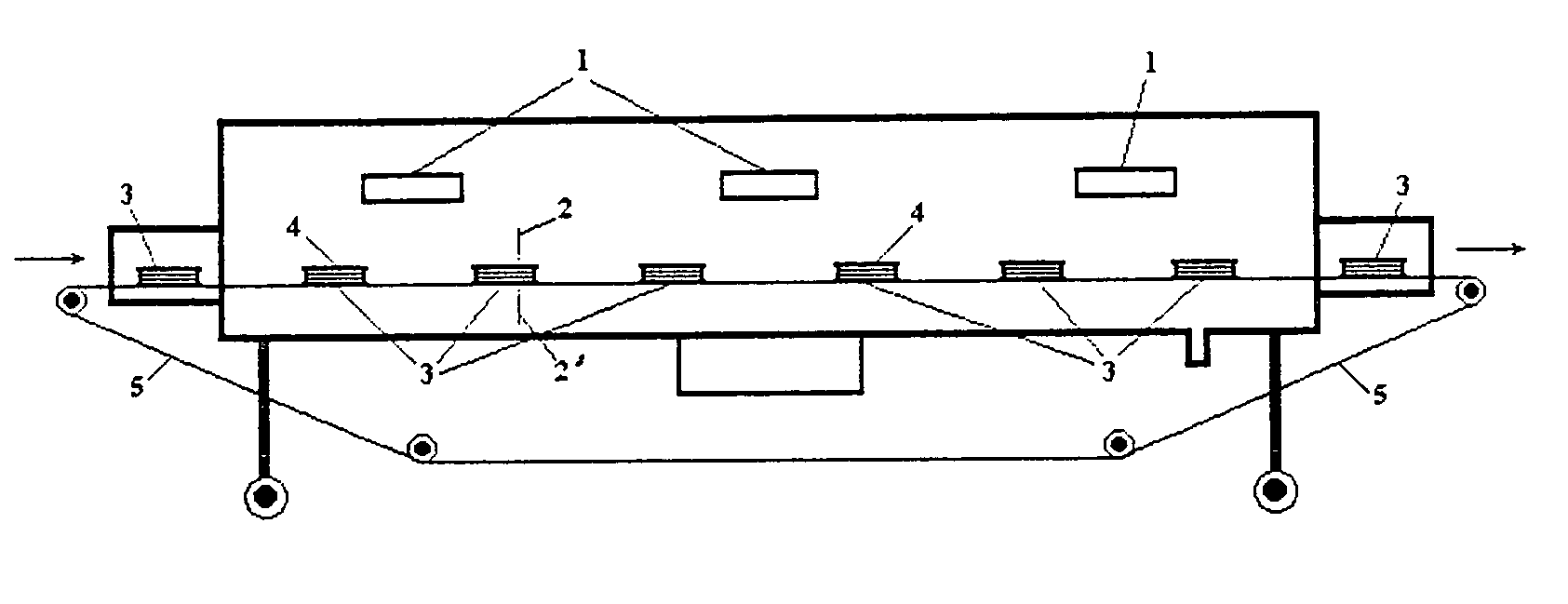

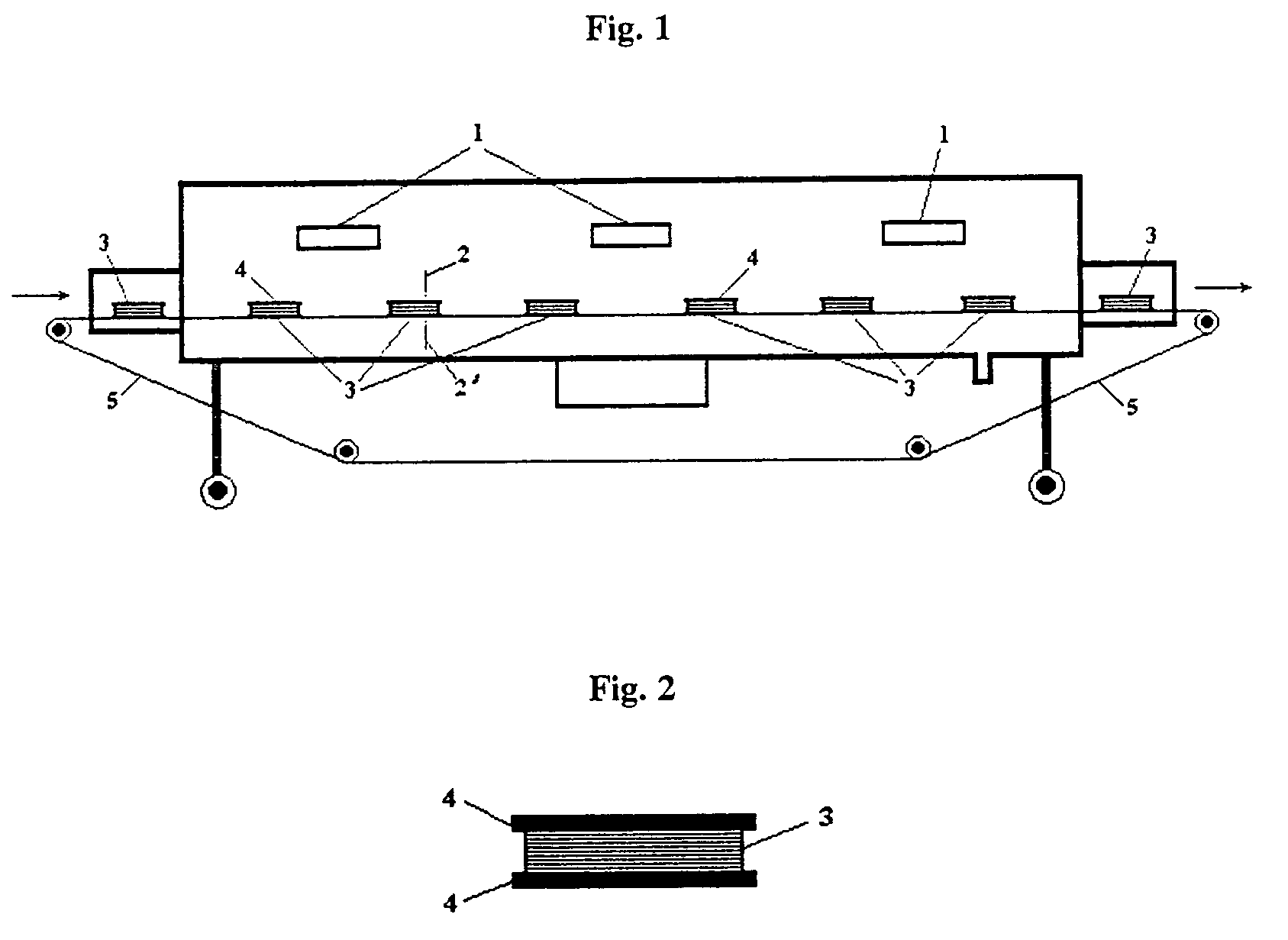

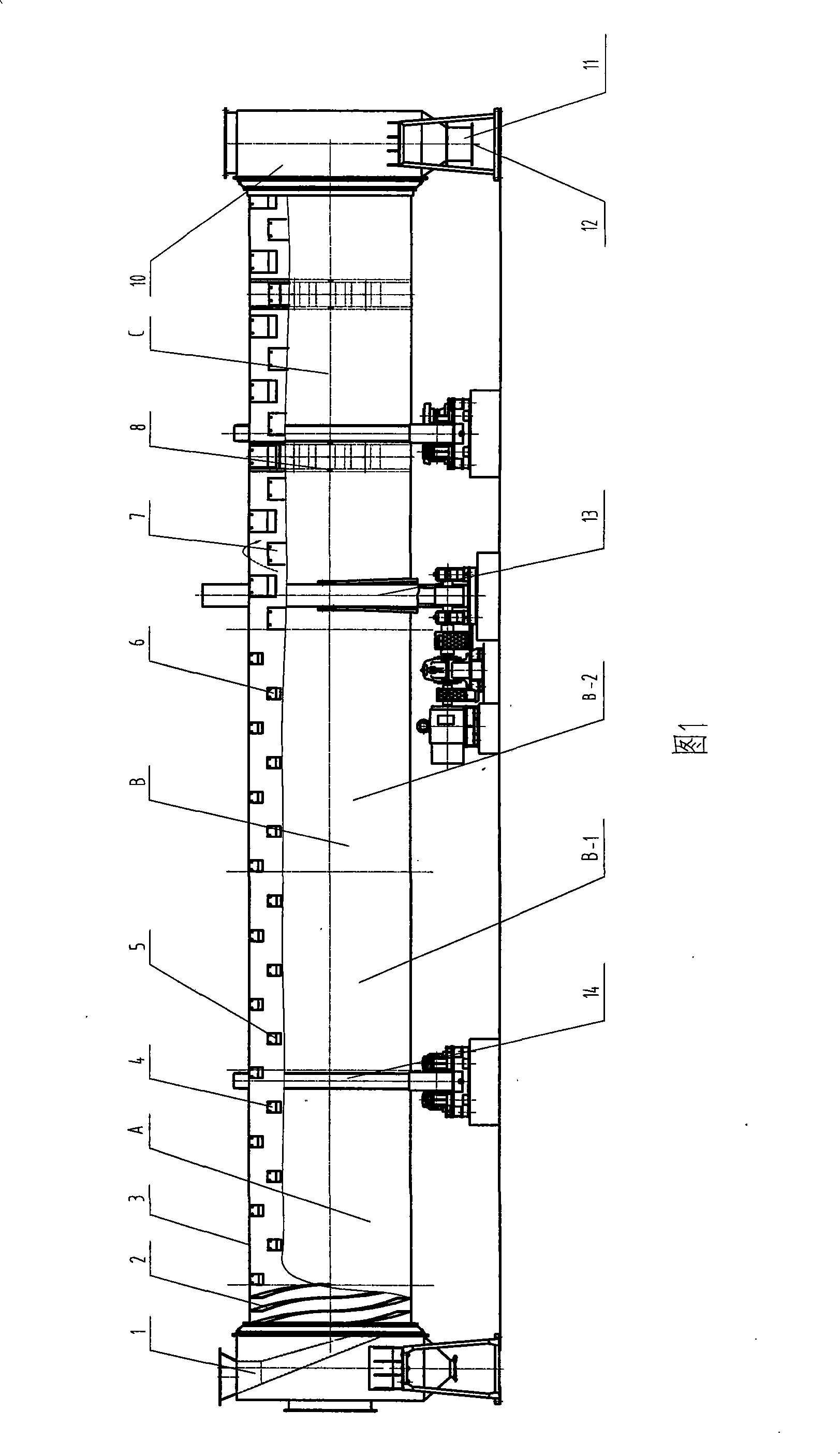

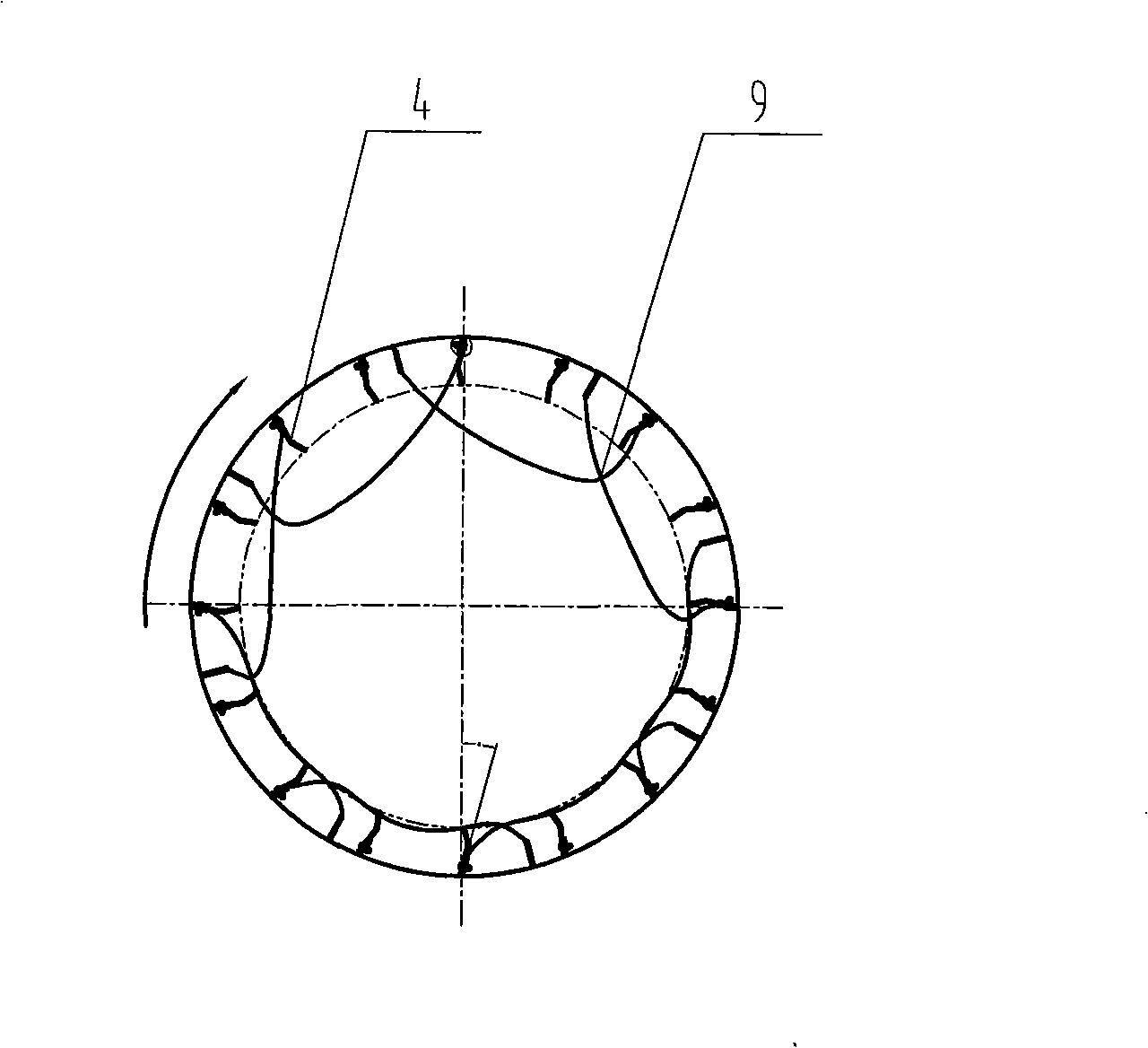

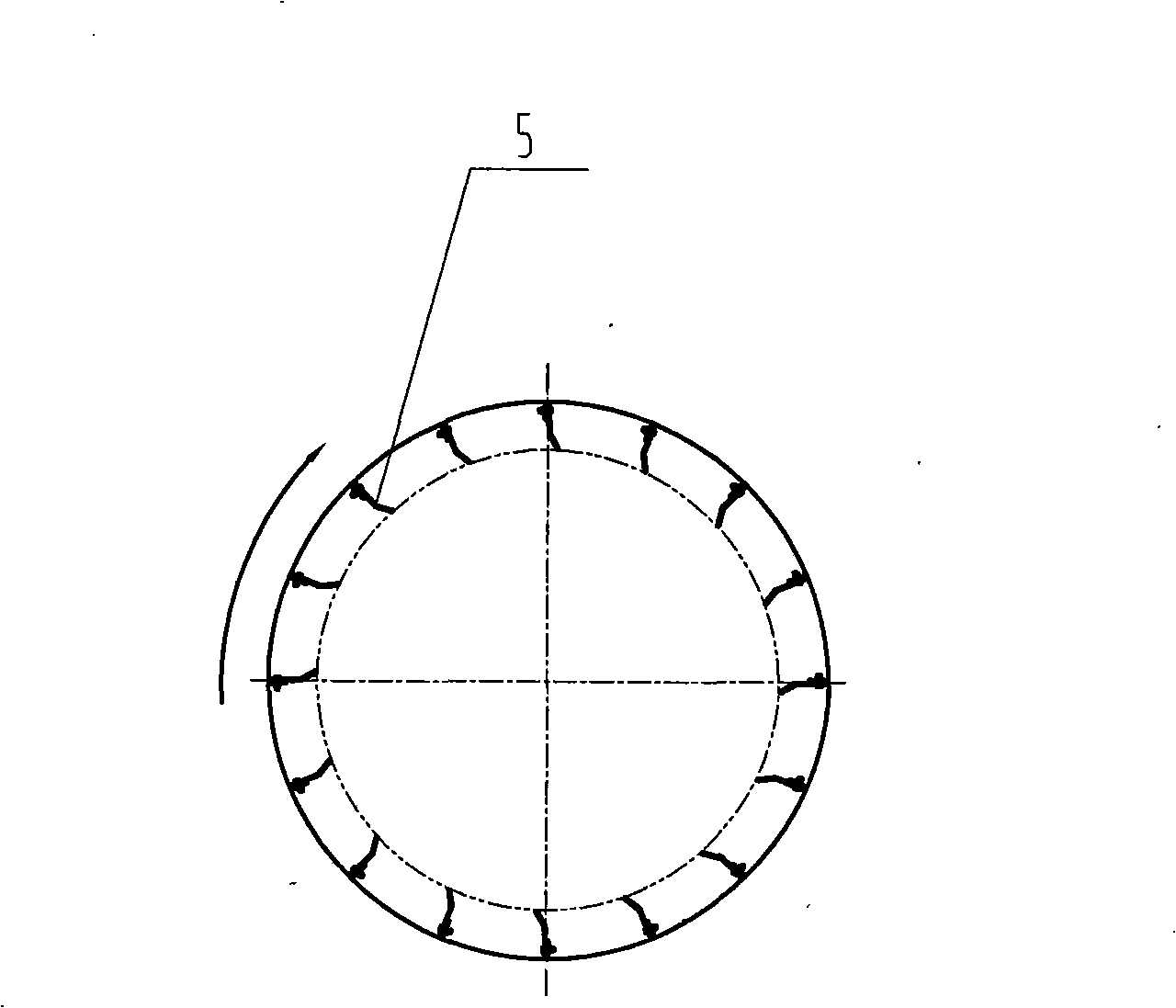

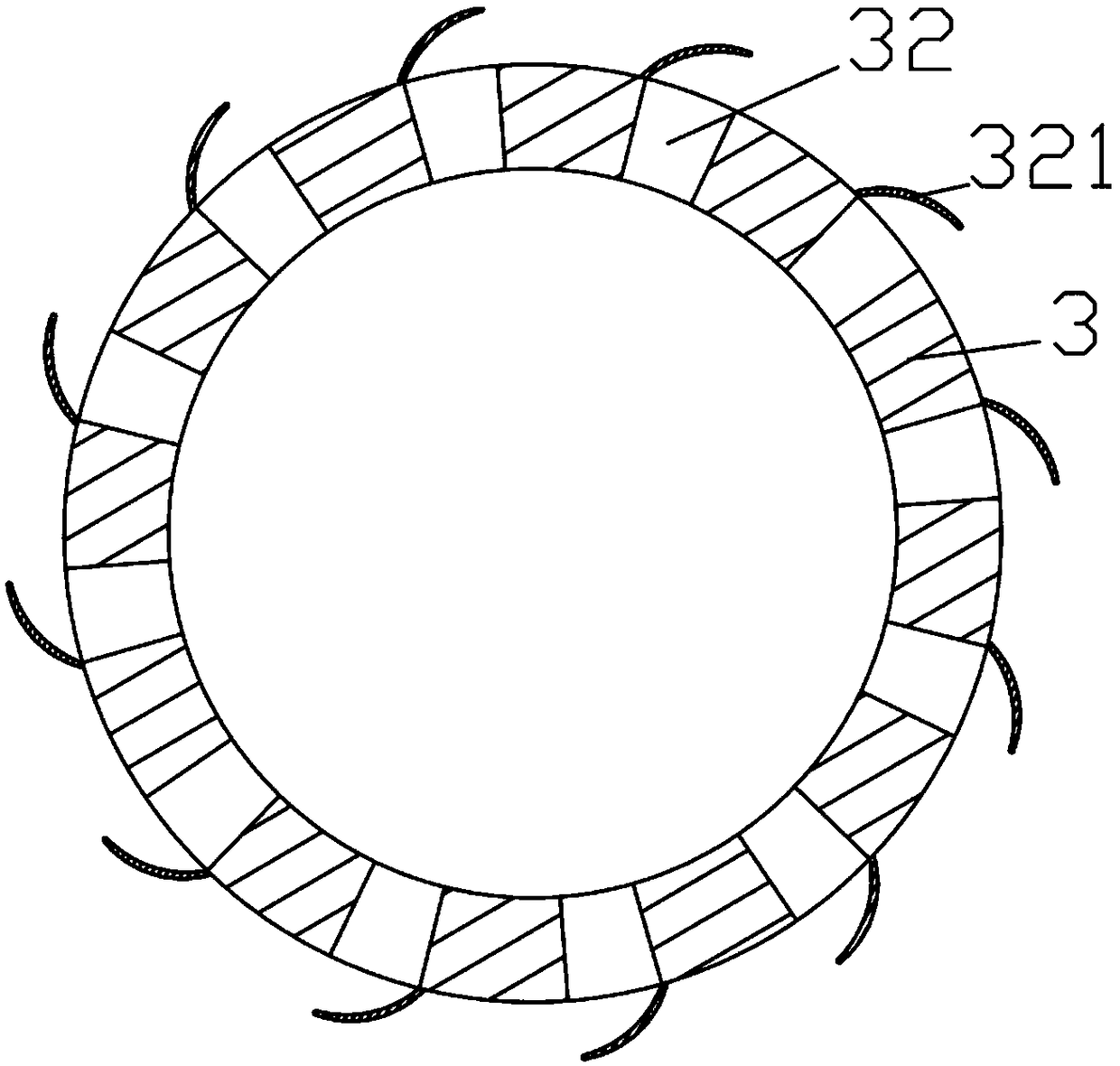

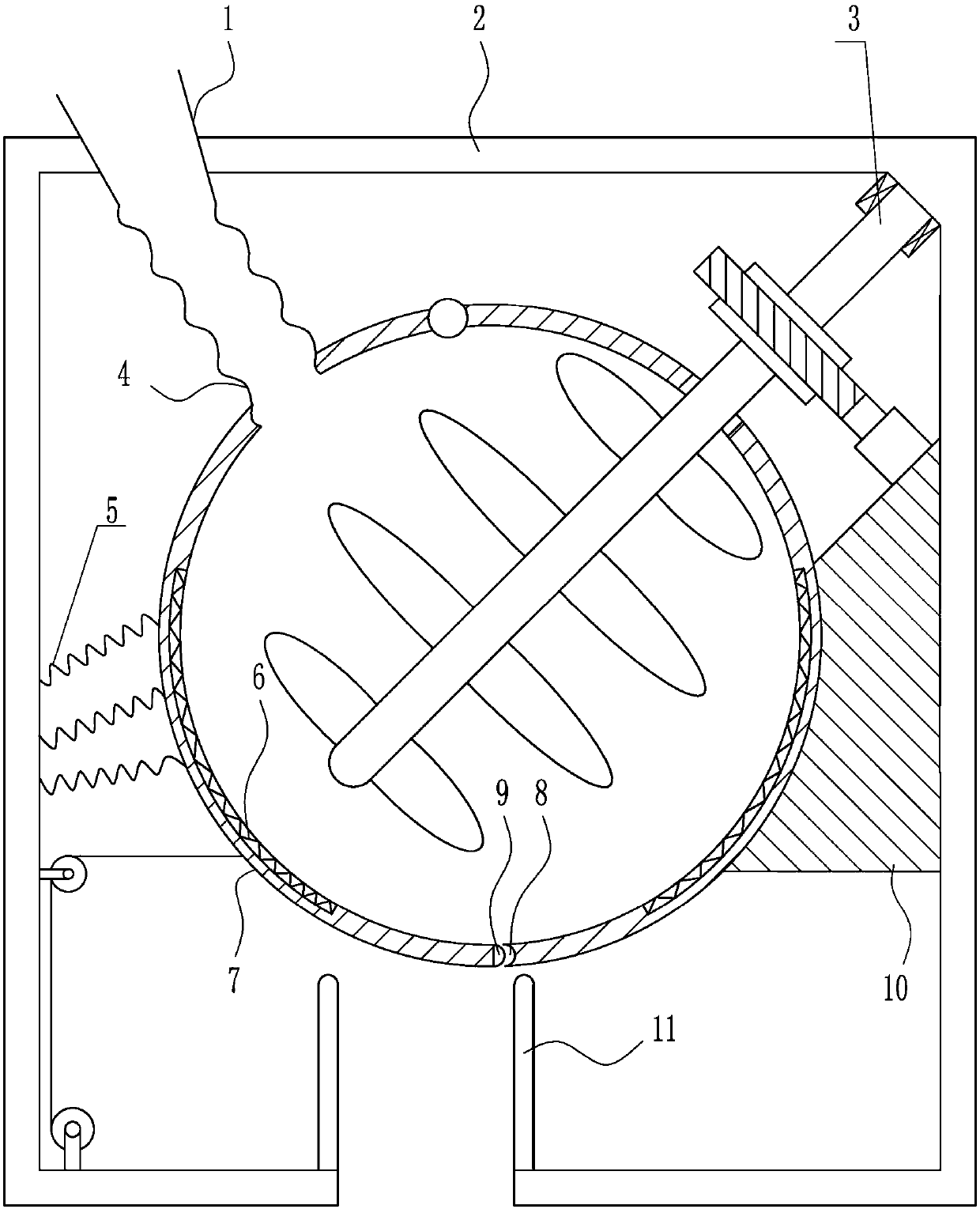

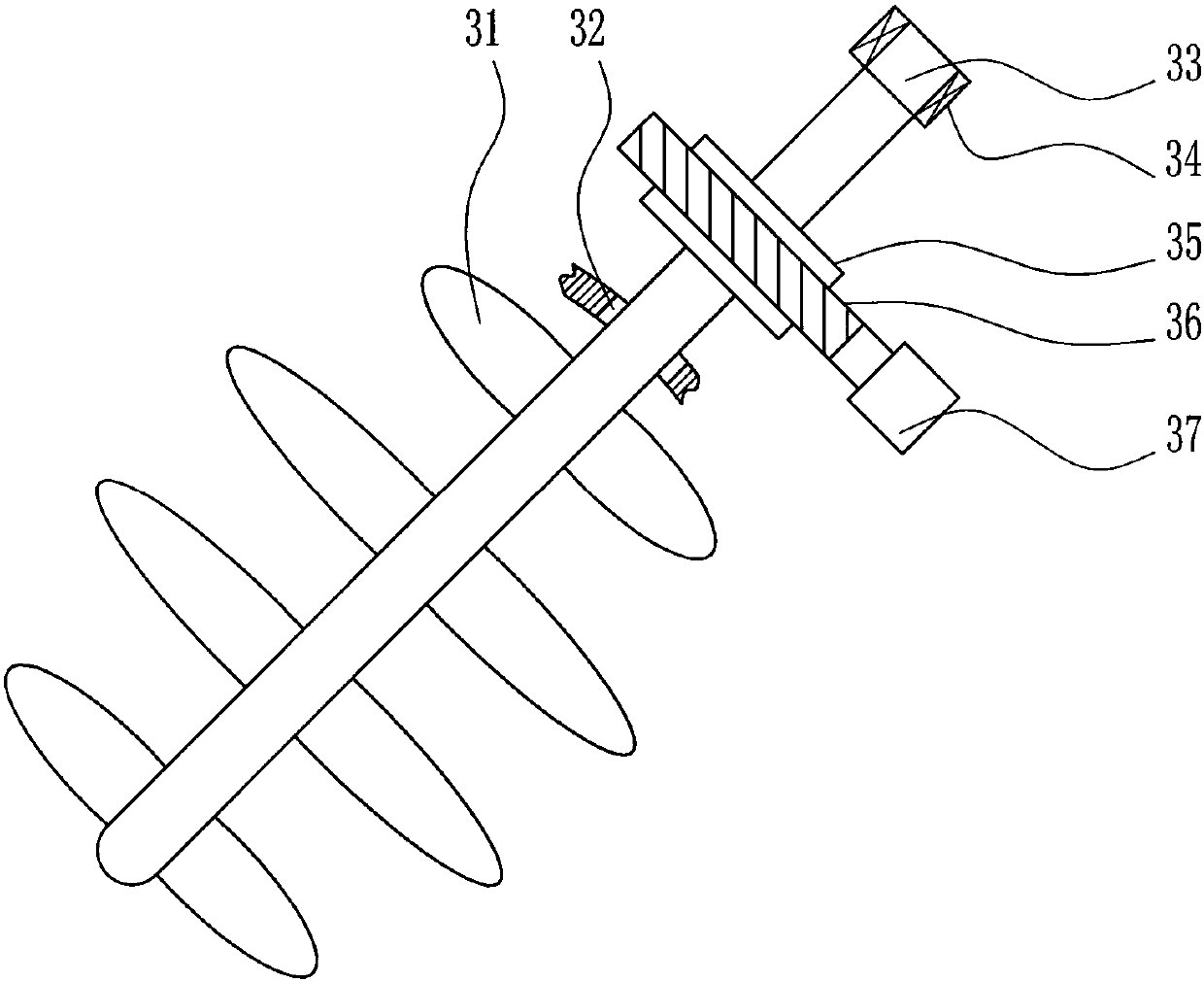

Rotary drying device suitable for high moisture material

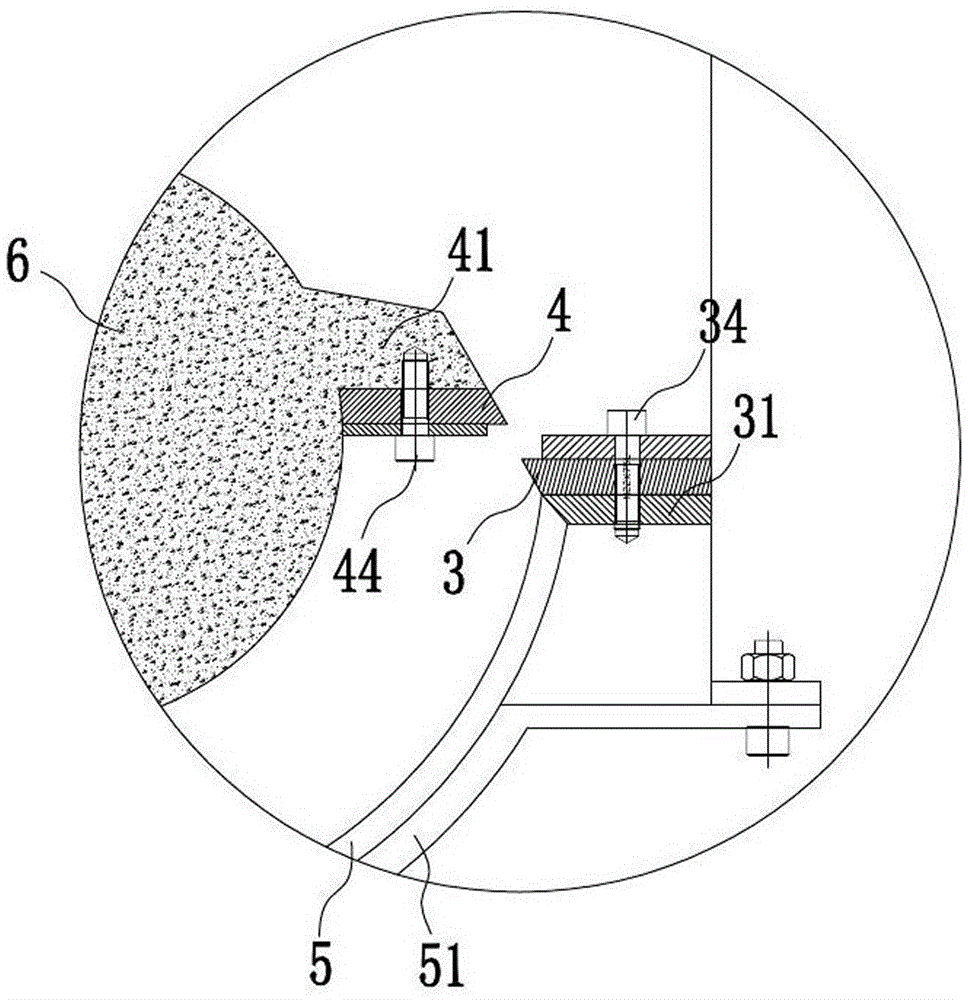

ActiveCN101334232AReduce equipment investment and floor spaceShort processing cycleDrying machines with non-progressive movementsEnergy consumptionMoisture

The invention provides a rotary type dryer which is suitable for high moisture materials. The dryer comprises a cylinder body, a driving device and a riding wheel device; a preheating zone, a baking zone and a drying zone are successively divided in an inner cavity of the cylinder body from head to tail; a plurality of lifting blades I rearward inclined with the bus of the cylinder body, a lifting blade II perpendicular to the bus of the cylinder body, a lifting blade III frontward inclined with the bus of the cylinder body and a lifting blade IV rearward inclined with the bus of the cylinder body are respectively arranged on the inner walls of the cylinder bodies of the preheating zone, the front zone and rear zone of the baking zone and the drying zone, and a plurality of the gammadia lifting blades with crisscross brackets are arranged in the cylinder body of the drying zone; a plurality of arch breaking chains, the two ends of which are fixed with the inner wall of the cylinder body, are arranged on the inner wall of the cylinder body. The rotary type dryer has the advantages that the dry processing can be directly performed to the high moisture materials, the equipment investment and the occupied area are effectively reduced, the processing period is shortened, the secondary pollution is avoided, the energy consumption and the operating cost are decreased, the moisture content can be decreased to 3 to 5 percent after the dry processing, and the dry processing effect is good.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

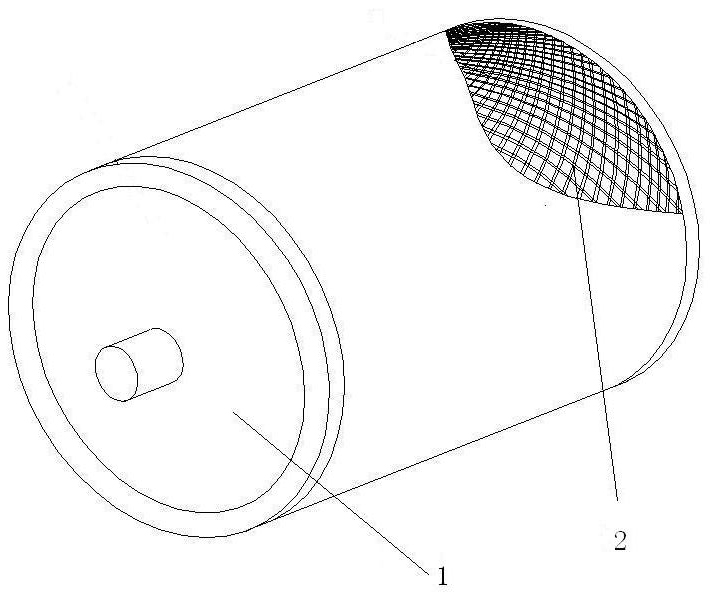

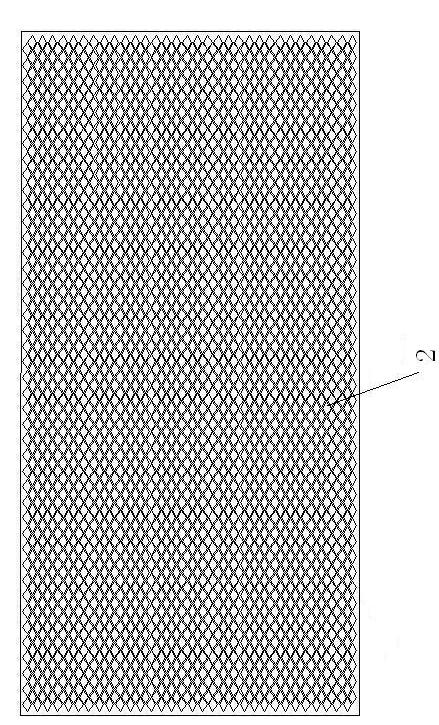

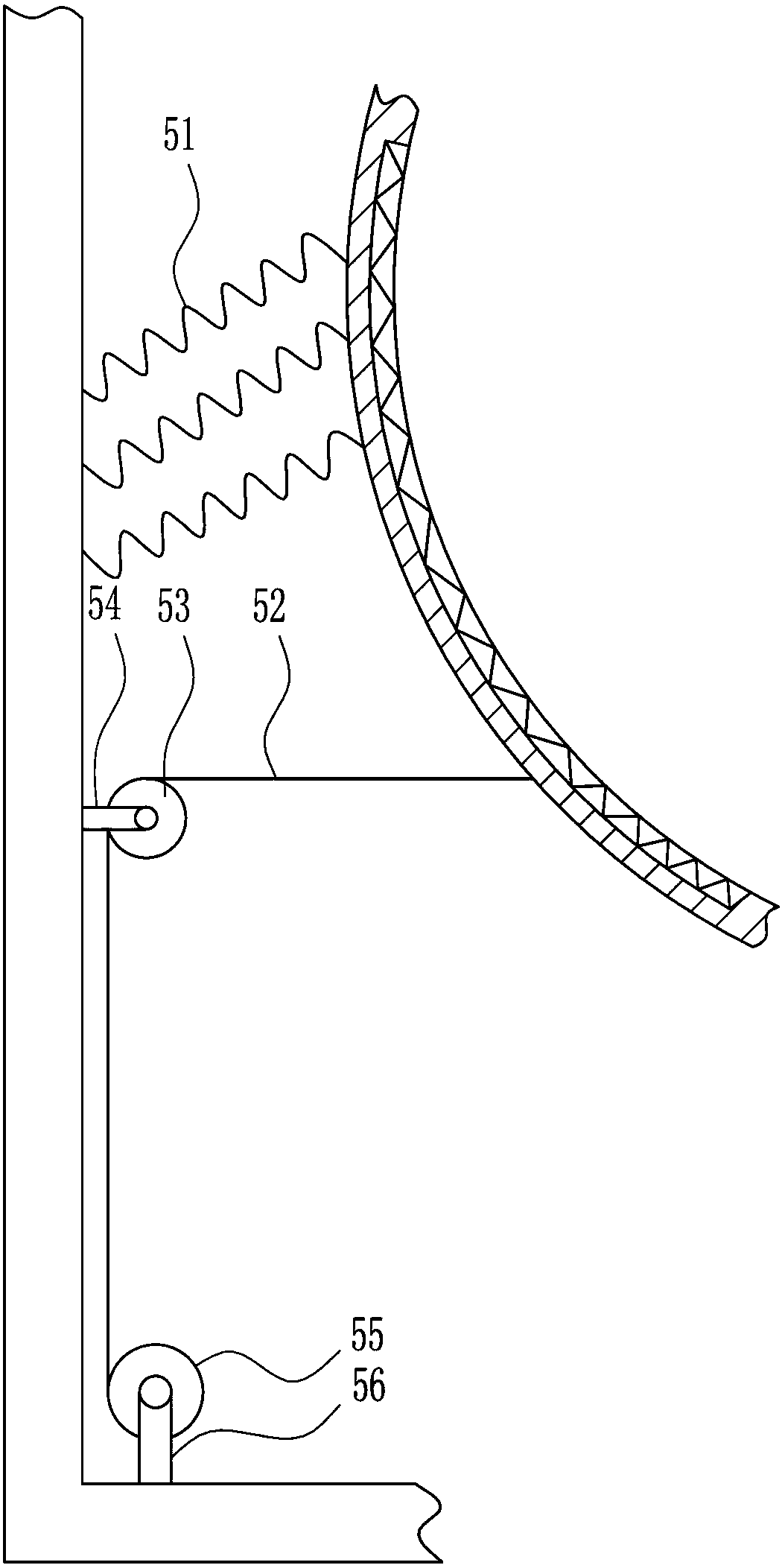

Manufacturing method and device of heat-sealed type grid tea leaf and coffee filter paper

The invention relates to a manufacturing method of heat-sealed type grid tea leaf and coffee filter paper and a grid device of a circular net forming device of a paper-making machine for the manufacturing method. The device comprises a circular net cage, a grid forming net, a couch roller, a net cloth blanket, a cleaning cylinder and a frame, wherein the grid forming net is sheathed outside the circular net cage, ad the couch roller is matched with the circular net cage. The method comprises the following steps of: (a) enabling 20%-50% of softwood pulp and 50%-80% of polypropylene fiber short yarn to constitute hot-melt fiber pulp, and enabling the hot-melt fiber pulp to form a wet paper page with a heat sealing function in an oblique net forming device; and (b) enabling 0-60% of abaca and 40-100% of the softwood pulp to constitute long fiber pulp of natural fiber, forming the long fiber pulp of the natural fiber in the grid device of the circular net forming device of the paper-making machine and forming the wet paper page with grid lines. The device has the advantages of high strength, better heat sealing strength, higher air permeability and fast leaching speed, and is suitable for packaging bagged tea and coffee with large packaging capacity.

Owner:杭州新华纸业有限公司

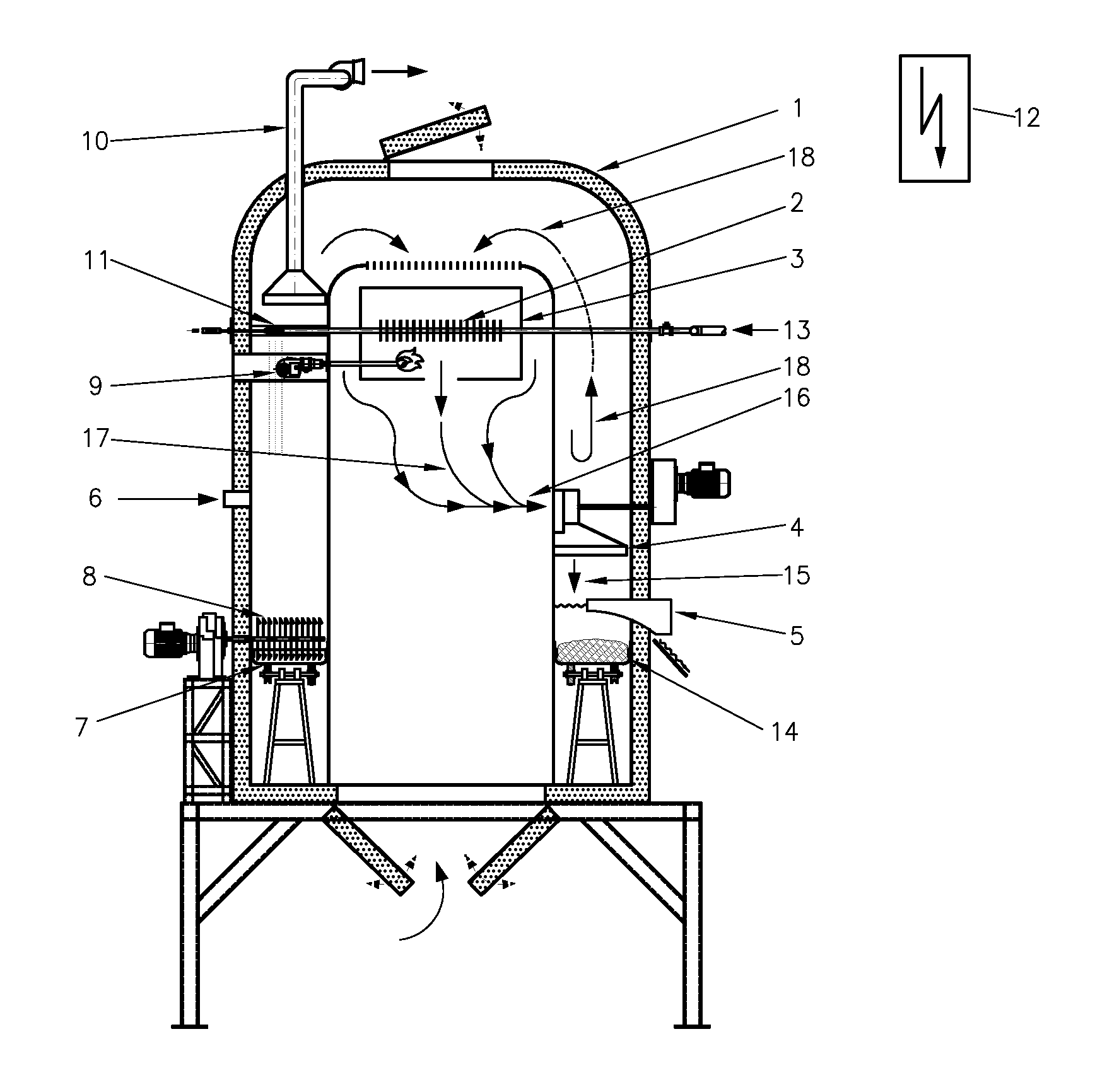

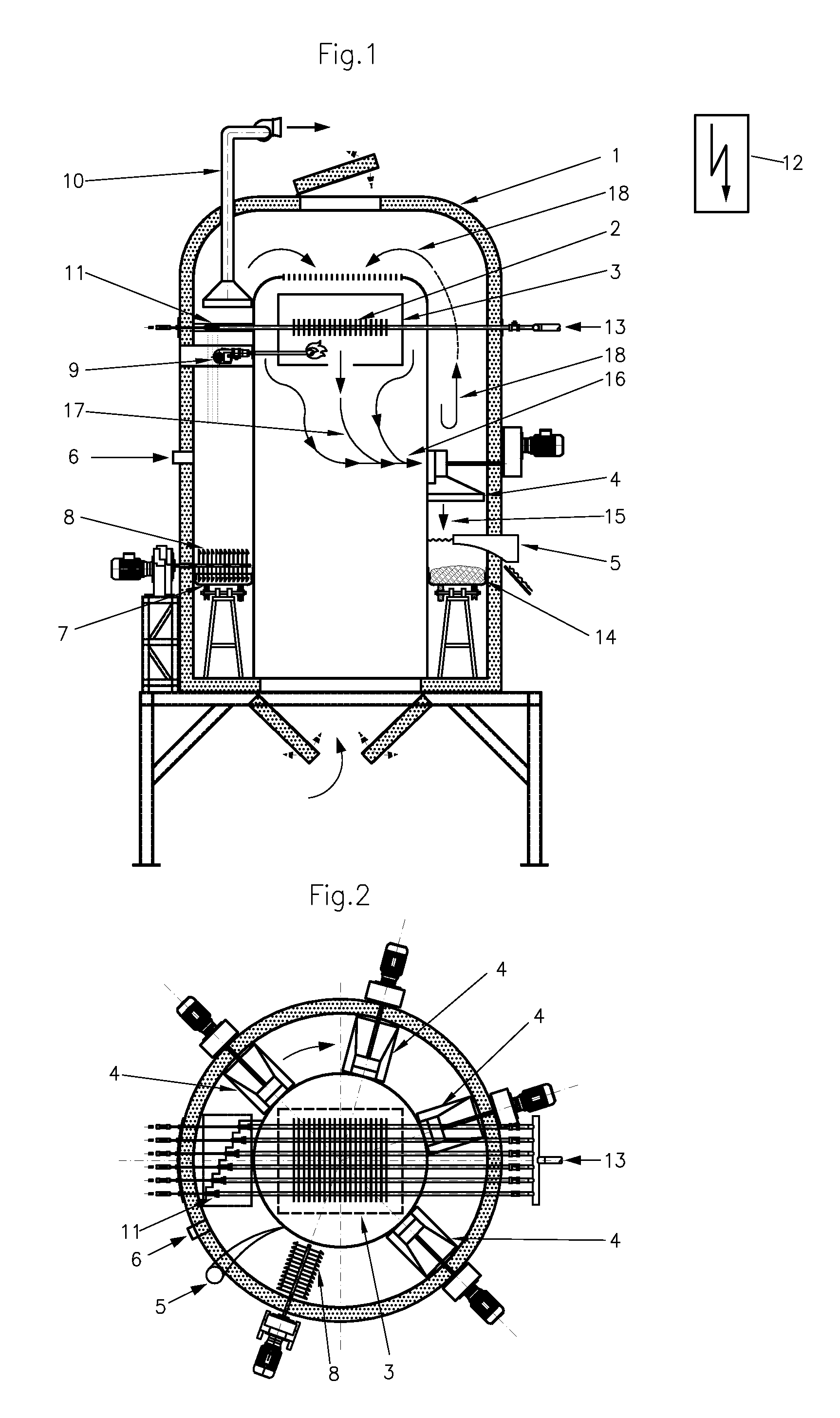

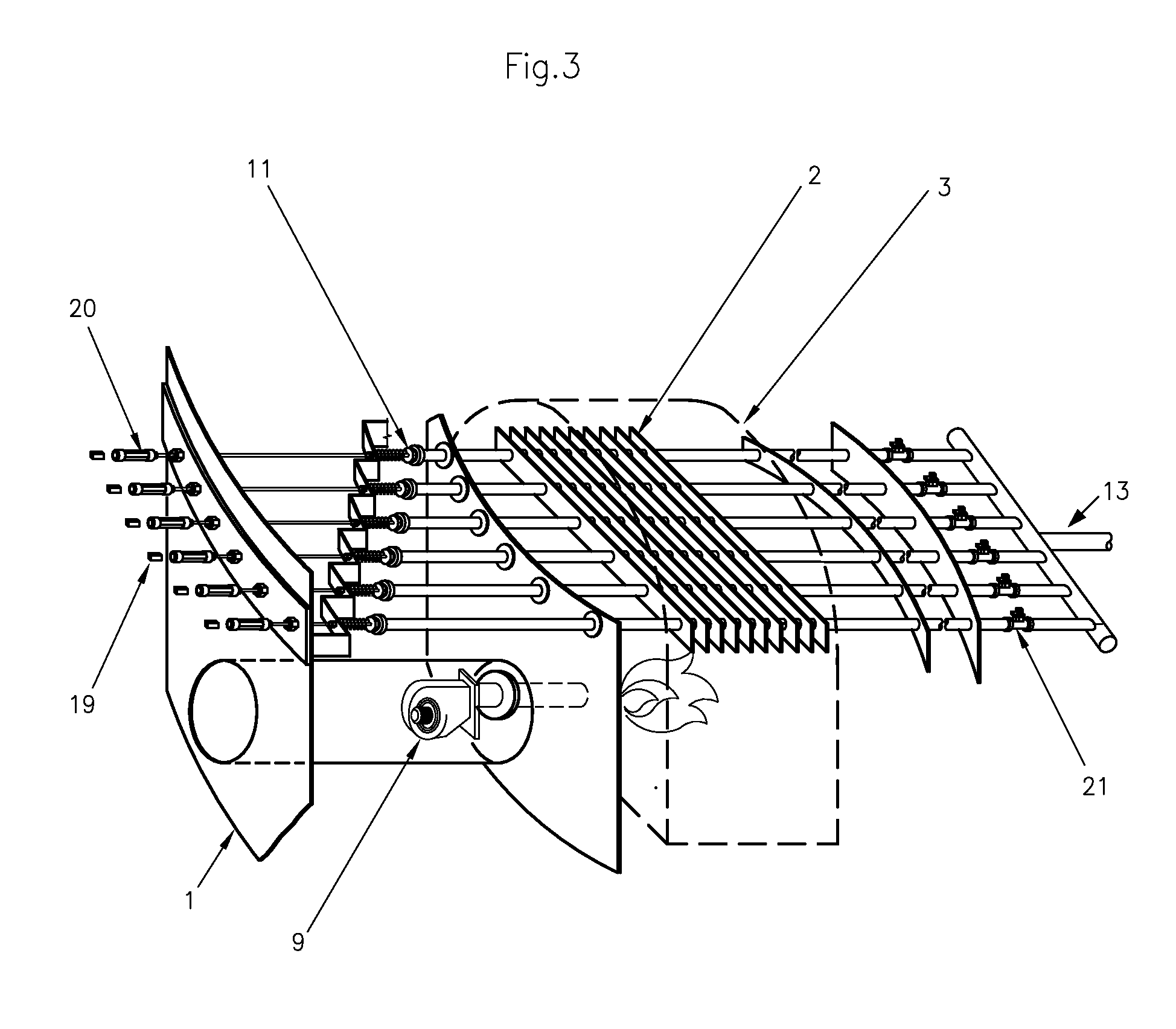

Method of processing and drying waste in a cyclic continuous process

InactiveUS20130019493A1Reduce water pollutionLow disposal costDrying using combination processesSludge treatment by de-watering/drying/thickeningCyclic processMoisture

The present invention is directed to a device for drying waste in a continuous cyclic process. The invention is further directed to a method for drying waste in a continuous cyclic process in the device of the invention, wherein the raw waste entering the system is at a vast range of moisture contents between 99% and 75%.

Owner:DST DRYING SLUDGE TECH

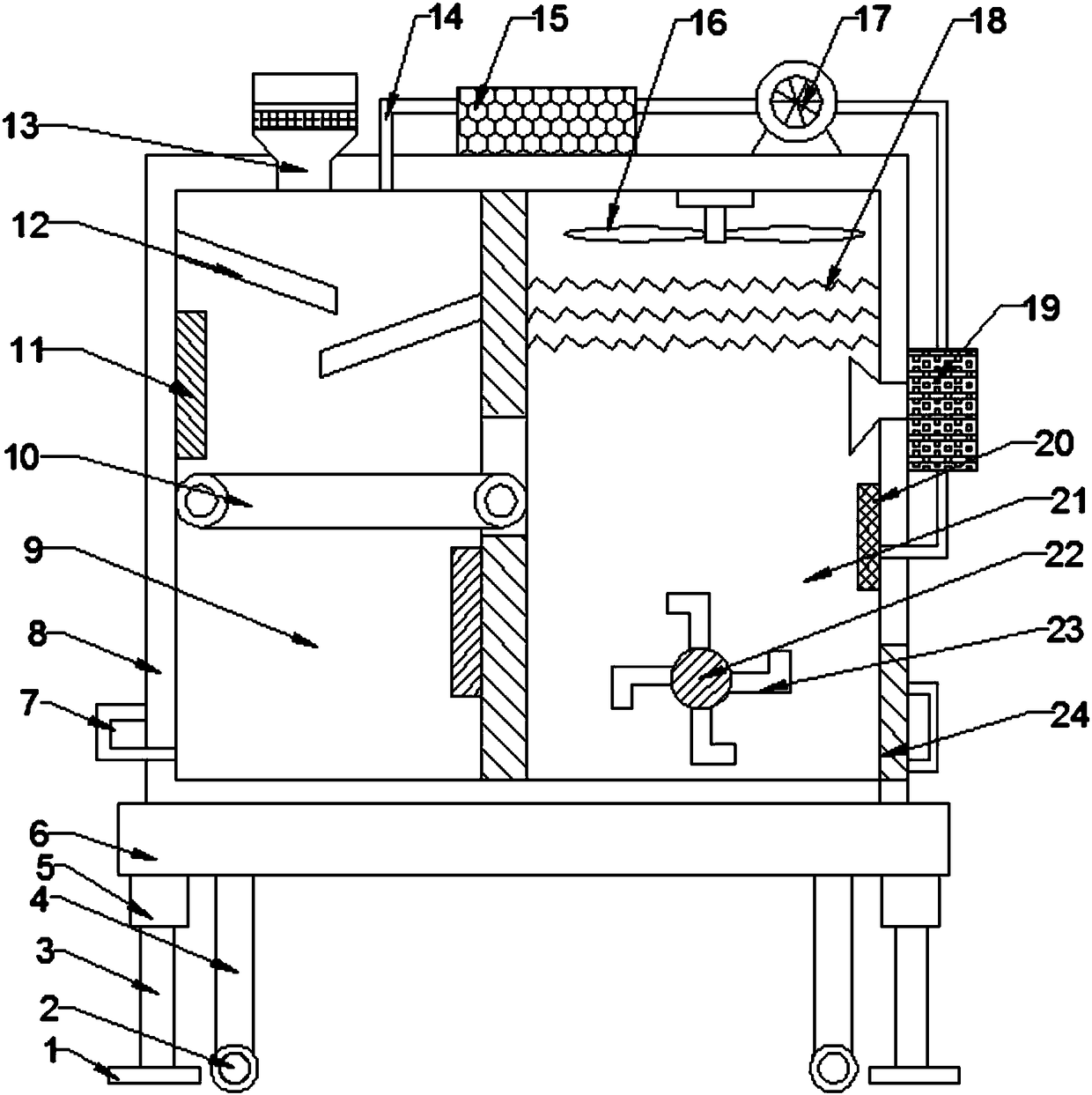

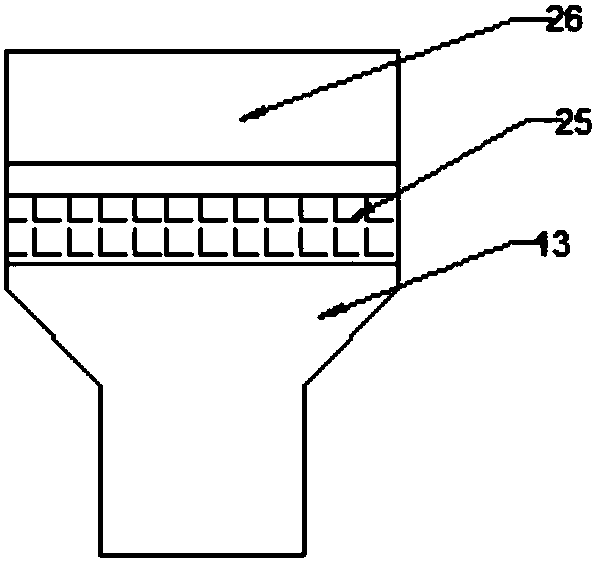

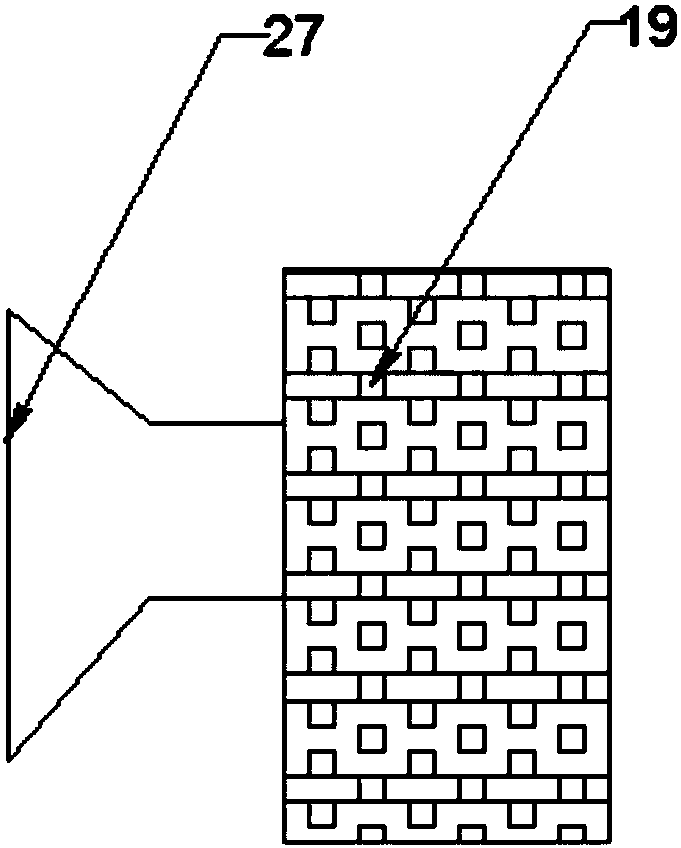

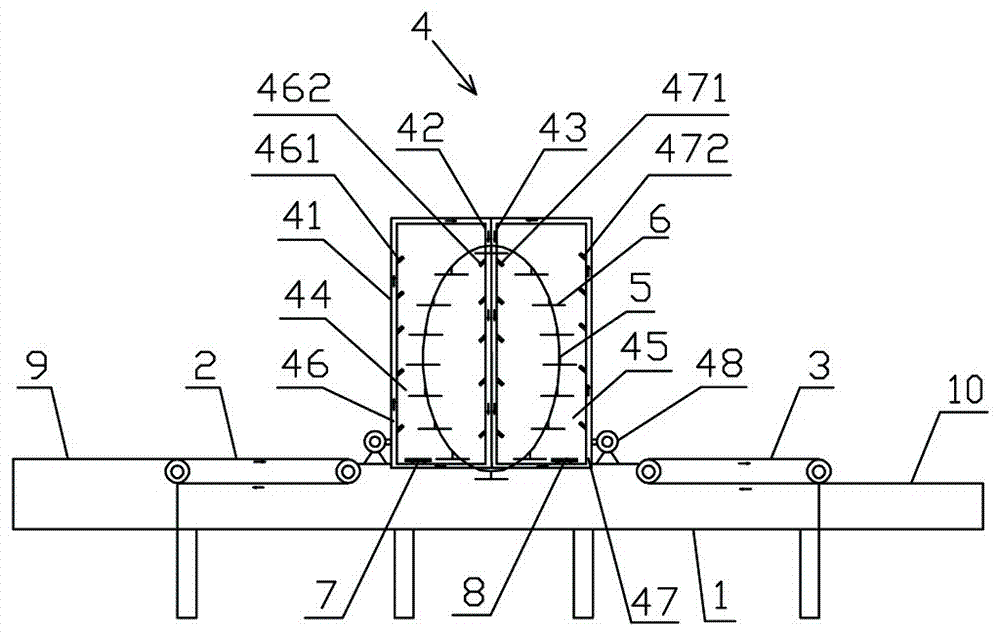

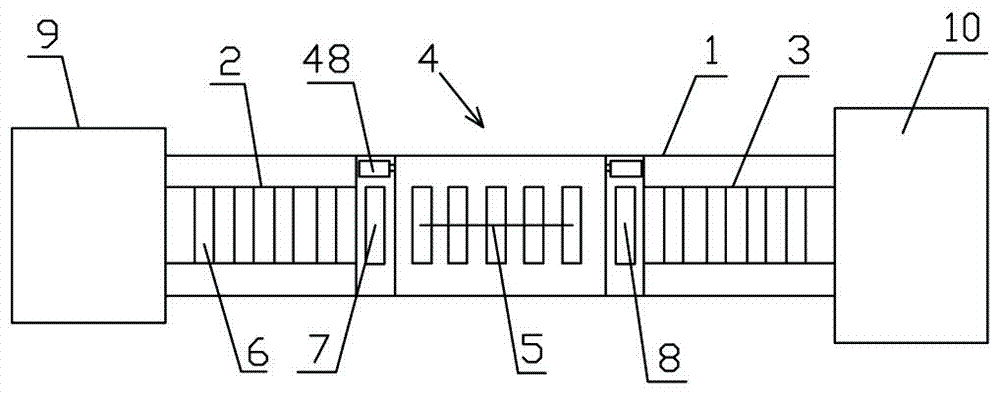

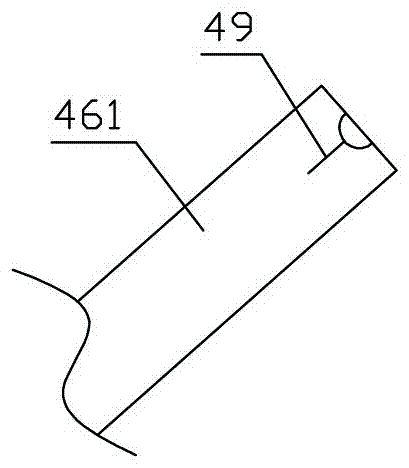

Agricultural grain drying treatment equipment

InactiveCN108168252AKeep dryEasy dischargeFood processingClimate change adaptationMicrowaveAgricultural engineering

The invention provides agricultural grain drying treatment equipment and belongs to the field of agriculture. The equipment comprises a supporting device and a drying treatment device; a pre-drying cavity is formed in the left side of an inner cavity of a box, and a drying cavity is formed in the right side of the inner cavity of the box; feed baffles are arranged on the upper side of an inner cavity of the pre-drying cavity; a conveying belt is arranged in the inner cavity of the pre-drying cavity; electric heating wires are arranged below a fan; a discharging cover plate is hinged to the bottom of the right side of the box; and a microwave generator is fixedly arranged on the right side of the box, and the side surface of the microwave generator is connected with the pre-drying cavity through a microwave conveying pipe. According to the agricultural grain drying treatment equipment, by arranging the electric heating wires below the fan, the function for drying grains in an air blasting mode is achieved; by arranging rotating claws on a rotary shaft, the function that the grains are stirred to facilitate drying of the grains and discharging of dried grains is achieved; and the equipment has the characteristics of being simple in structure, high in practicability and good in drying treatment effect.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

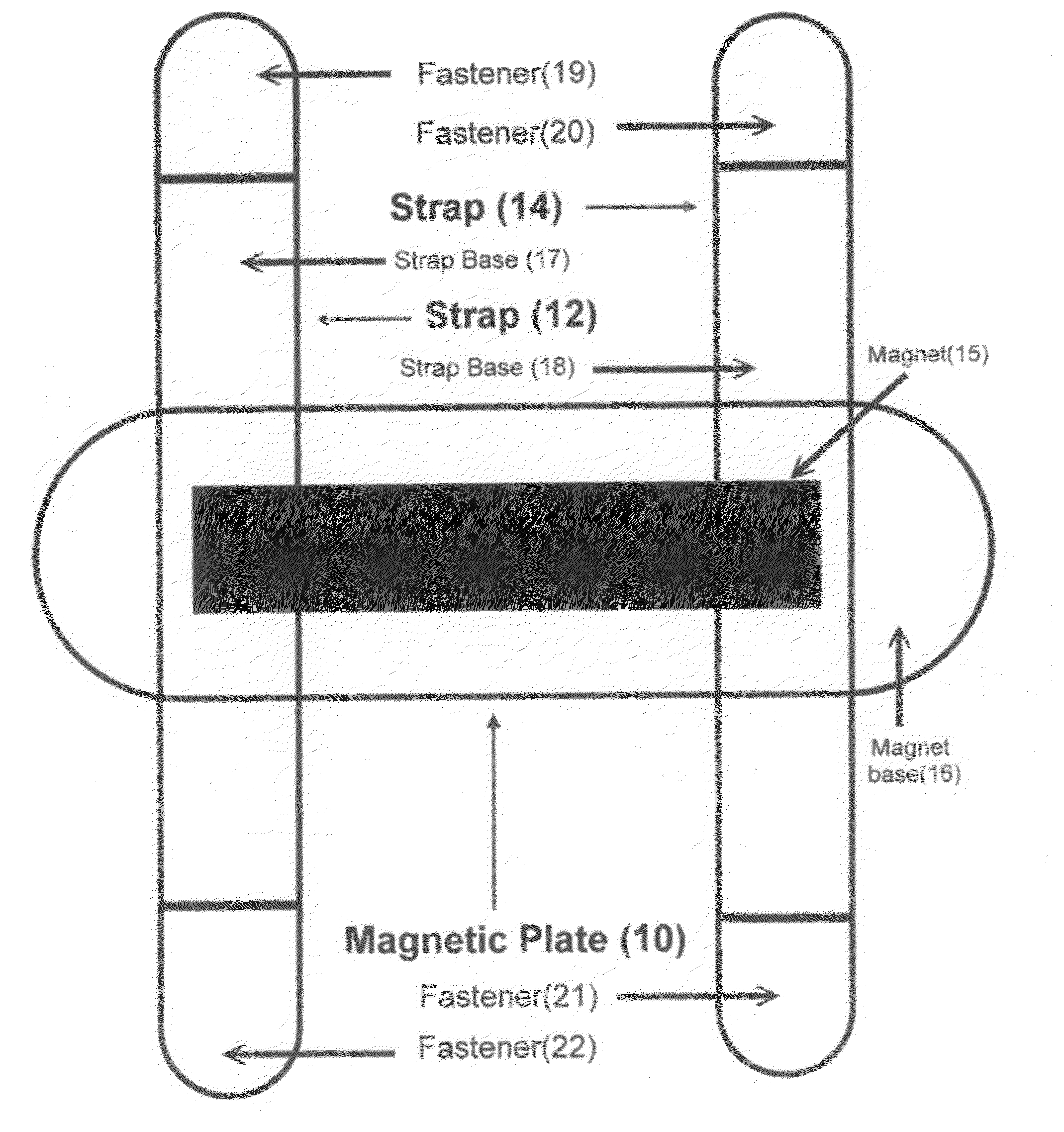

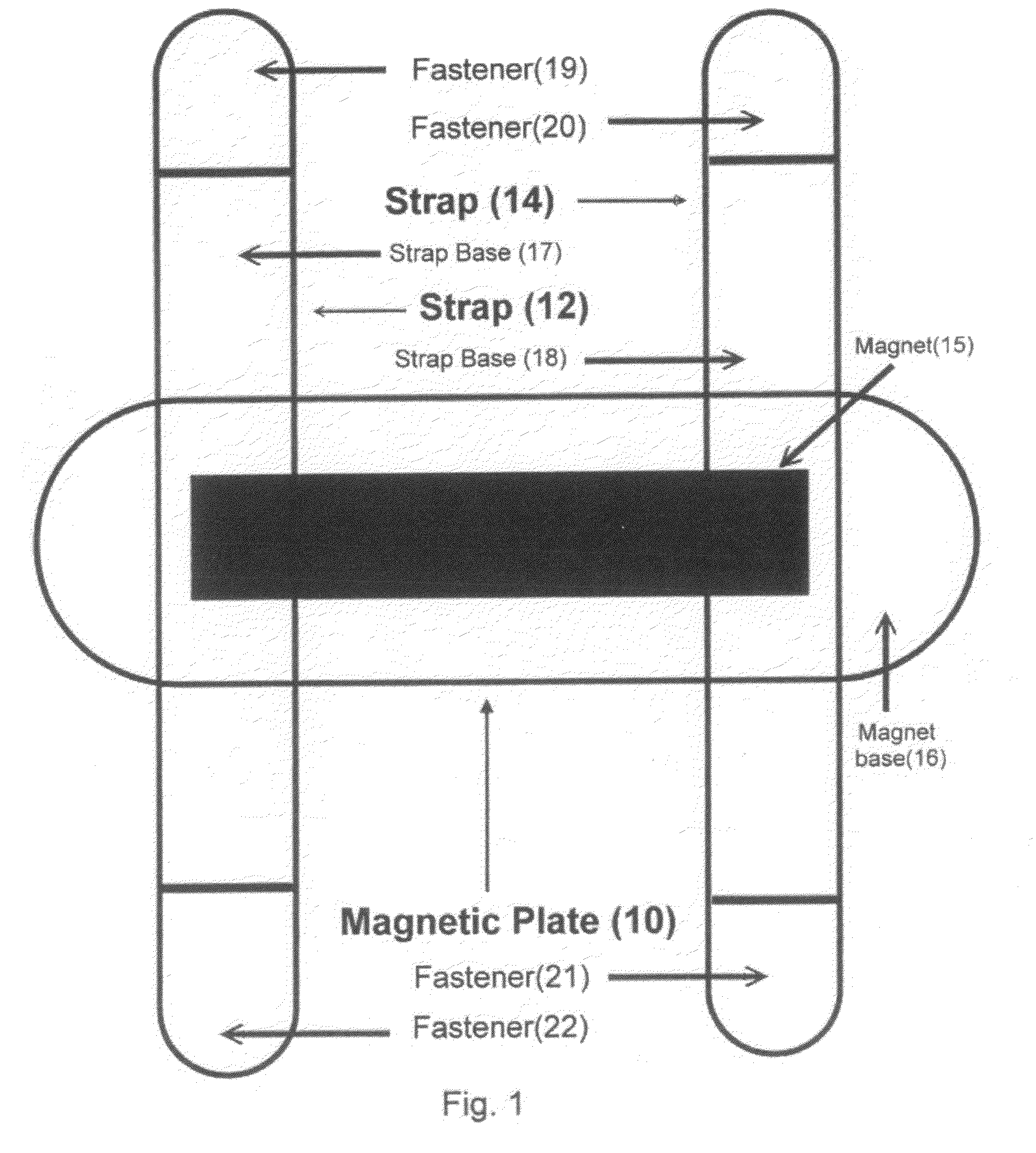

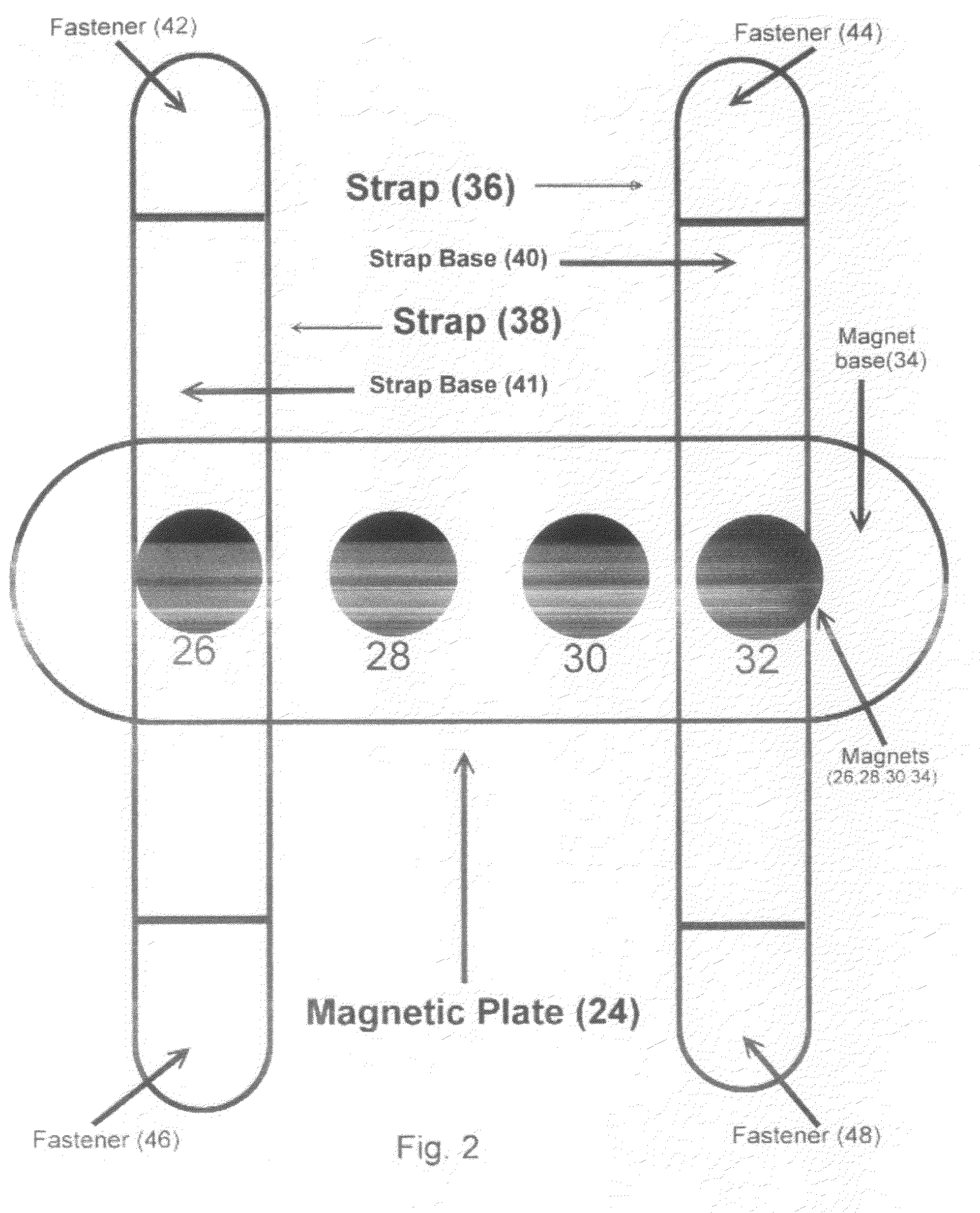

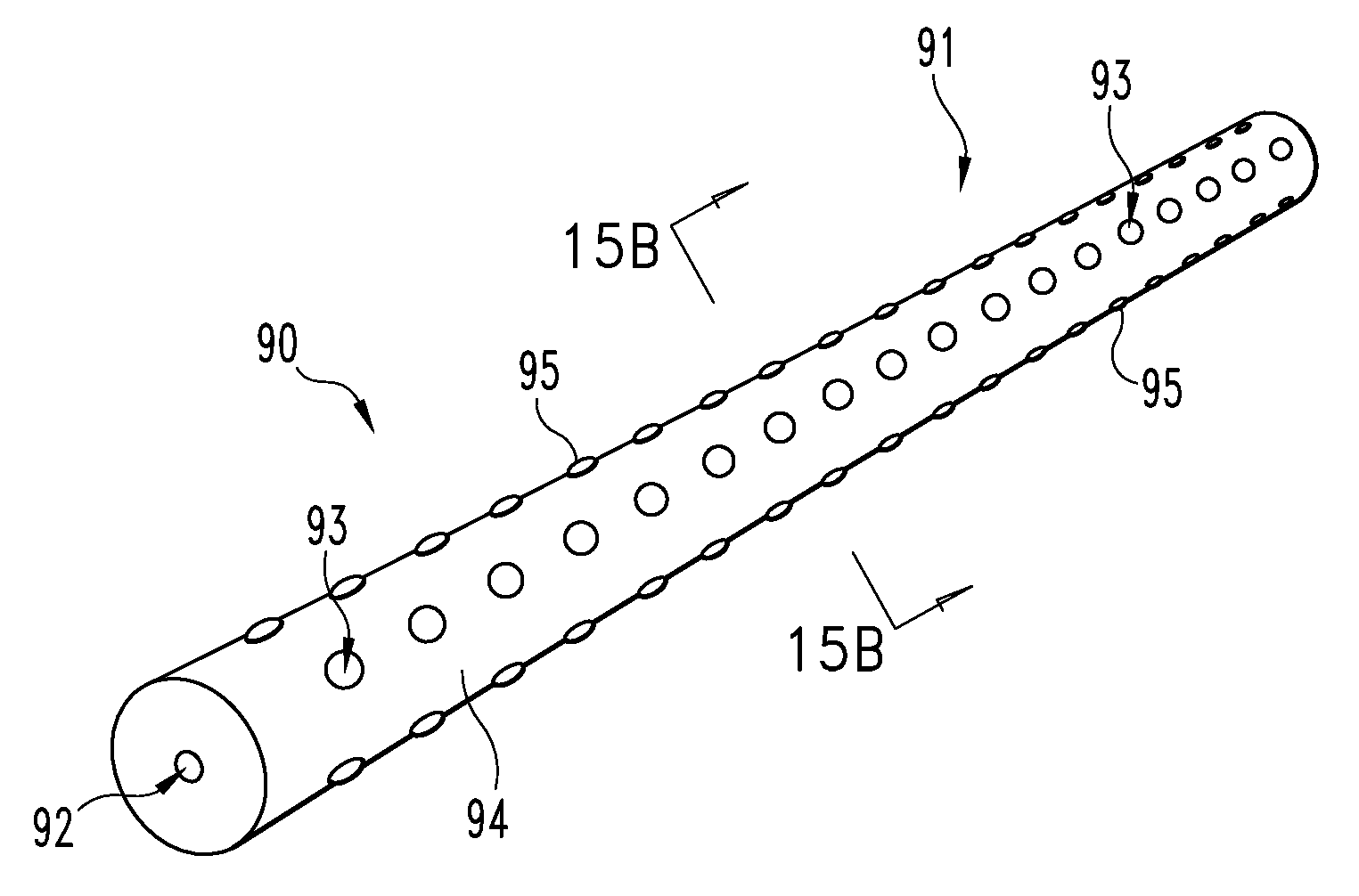

Magnetic shoe-drying apparatus

InactiveUS20100064544A1Accelerated dryingExpedited drying processAgriculture tools and machinesPicture framesLaundryMagnet

A magnetic shoe-drying apparatus is to improve shoe drying in a conventional laundry dryer. The apparatus is comprised of a magnet plat and at least one strap. The straps are to fasten a wet shoe onto the magnetic plate and the magnetic plate serves as a way to stick the shoe to the drum, inside a laundry, so that the shoe will not tumble when the dryer is in operation. Several pieces of the apparatus can be placed in the dryer and hence several wet shoes can be dried simultaneously. Wet clothes can also be dried together with wet shoes using this apparatus.

Owner:LUONG HUAN V +1

Cloth dyeing machine

ActiveCN108660646AQuick drying processAvoid wastingTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forcePulp and paper industryTherapeutic effect

The invention discloses a cloth dyeing machine. The machine comprises a box, a dyeing cylinder arranged in the box and a base arranged at the bottom of the box, and a top cover detachably connected with the top of the box is arranged at the top of the box; the dyeing cylinder is arranged at the bottom of the box, a drying device is arranged above the dyeing cylinder, an automatic lifting device isarranged on the base and connected with a bearing plate, and a rotatable loading box is arranged below the bearing plate. According to the cloth dyeing machine, dyed cloth can be quickly dried, the drying treatment effect is improved, dyeing liquid during drying treatment can be recycled, the situation is avoided that a large amount of dyeing liquid is wasted, and the cloth dyeing machine is highin practicability and beneficial to environmental protection.

Owner:南通东晨服饰有限公司

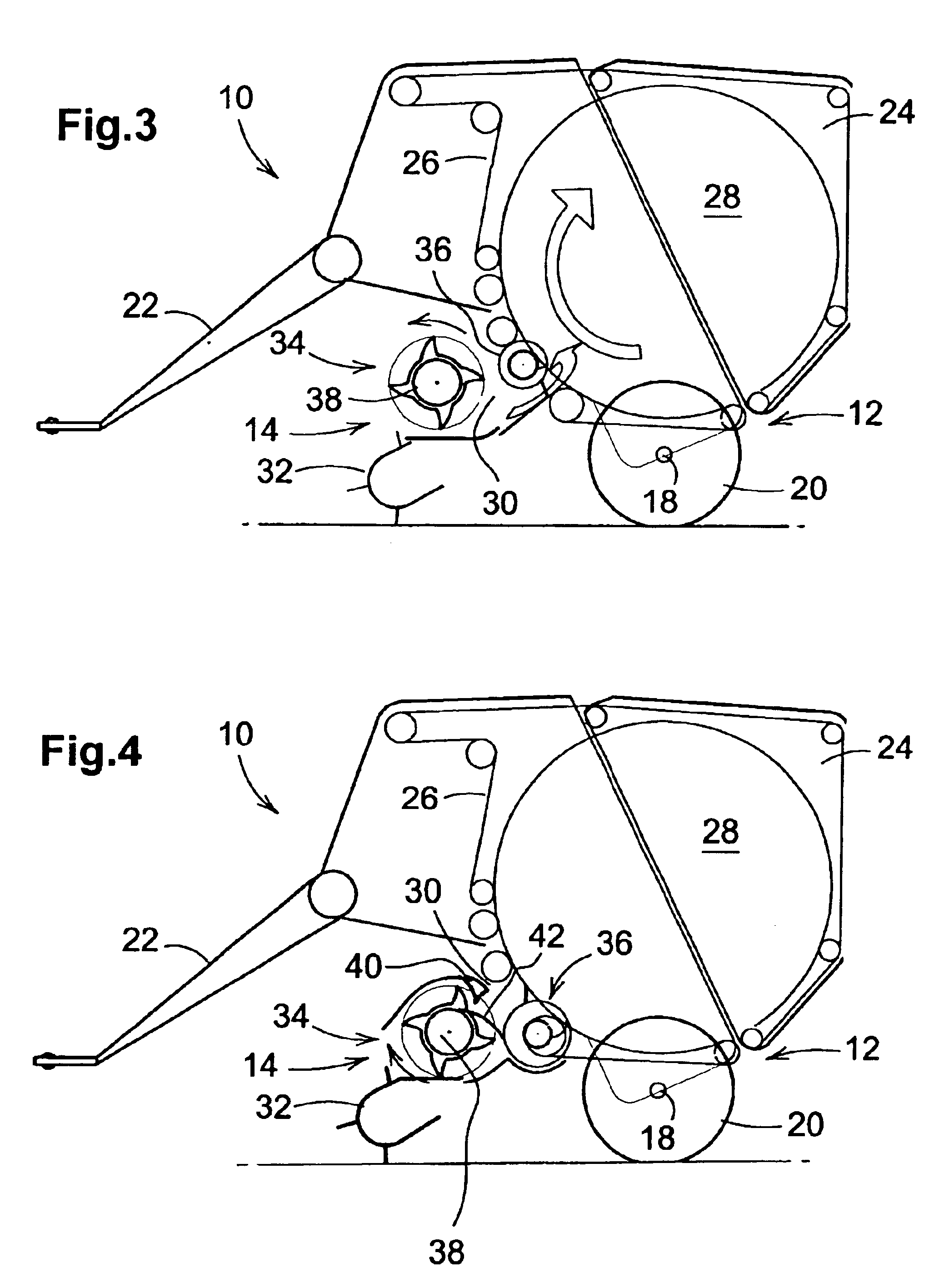

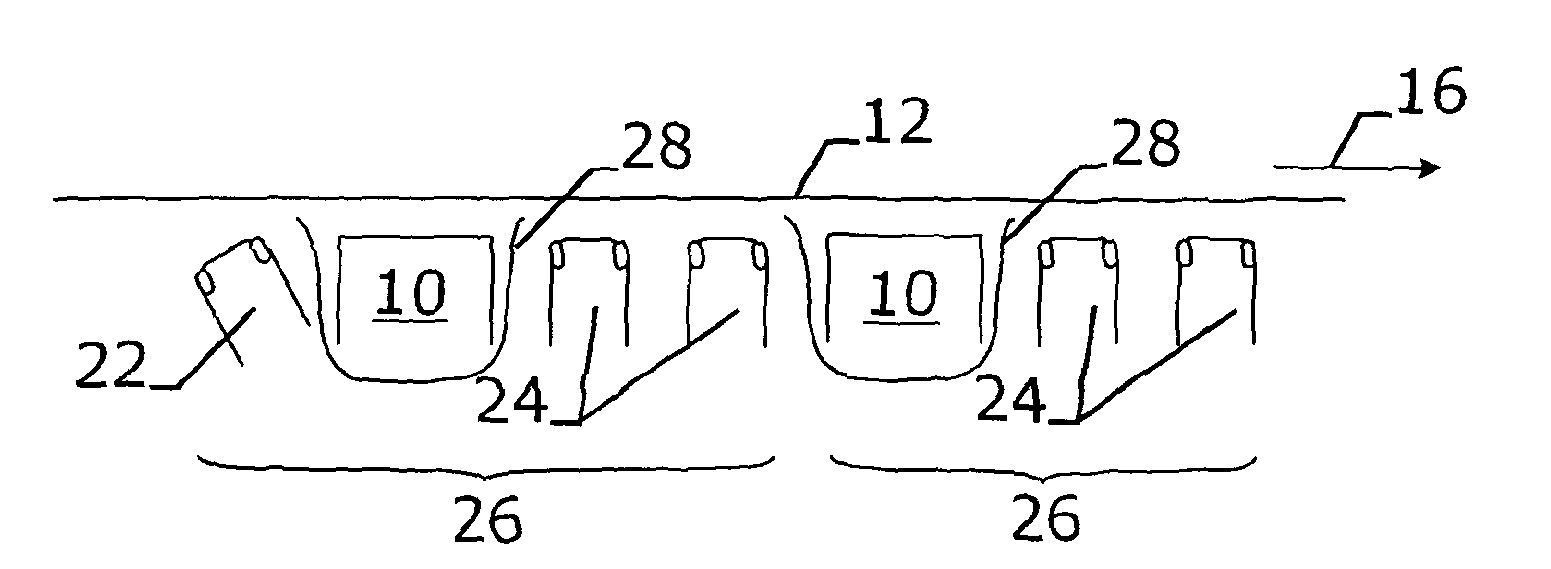

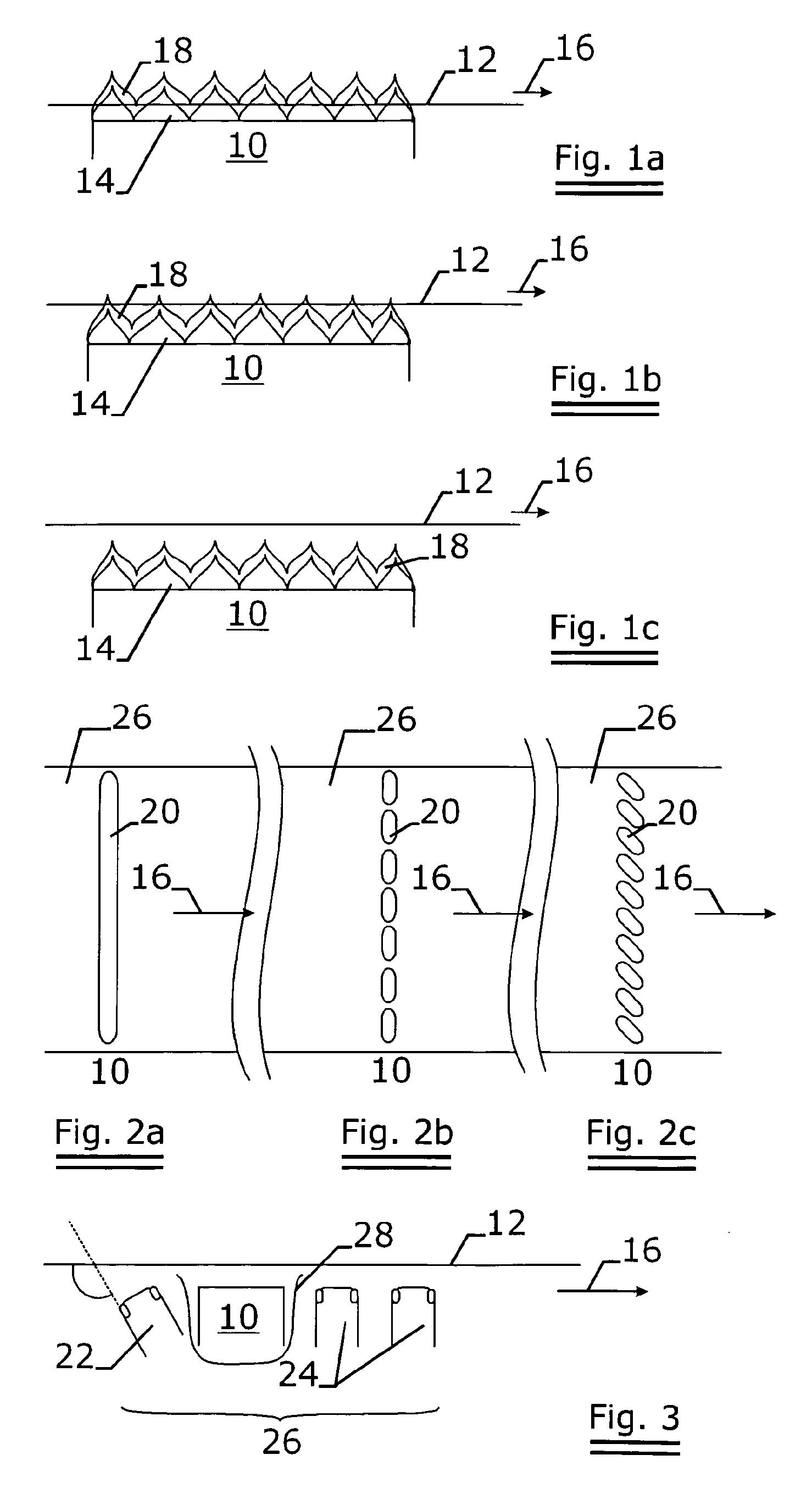

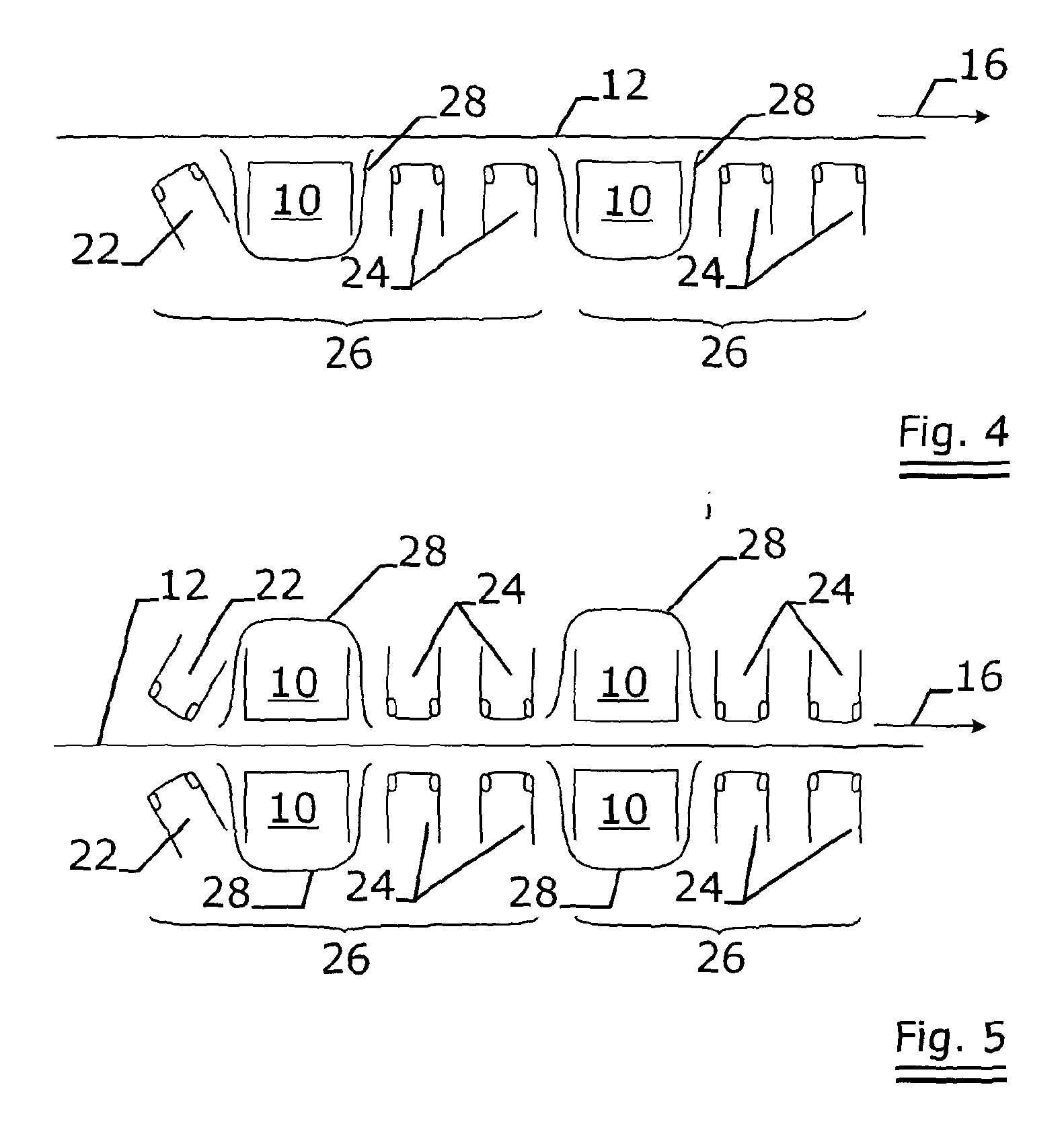

Flame Dryer

InactiveUS20090007453A1Increase productionIncrease flexibilityDrying solid materials with heatDryer sectionEnergy transferCombustor

The object of the invention is an dryer in the dryer section (26) of a machine for treating or producing a web (12). This drying section (26) has, amongst other things, a burner assembly (10), wherein this burner assembly (10) is adapted to produce a flame (14) and exhaust gases (18). Either said flame (14) or the exhaust gases (18) or both are in direct contact with the web (12) to be dried. The flame (14) or the exhaust gases (18) or both cover the maximum width of the web (12) to be dried and this at a temperature exceeding 600° C., e.g. above 700° C., e.g. 800° C., preferably 1000° C. and more. By applying such a high temperature to the web (12) to be dried, one achieves a large temperature difference, resulting in a better heat transfer Considering the theoretical equation of heat transfer qx=kx. Ax.DTx, it is evident that because of the large temperature difference, the dimensions of the system can be reduced and / or the efficiency of the drying process can be refined. A further advantage of the higher energy transfer is that the drying process is accelerated and that the web can pass the dryer at high speeds.

Owner:NV BEKAERT SA +1

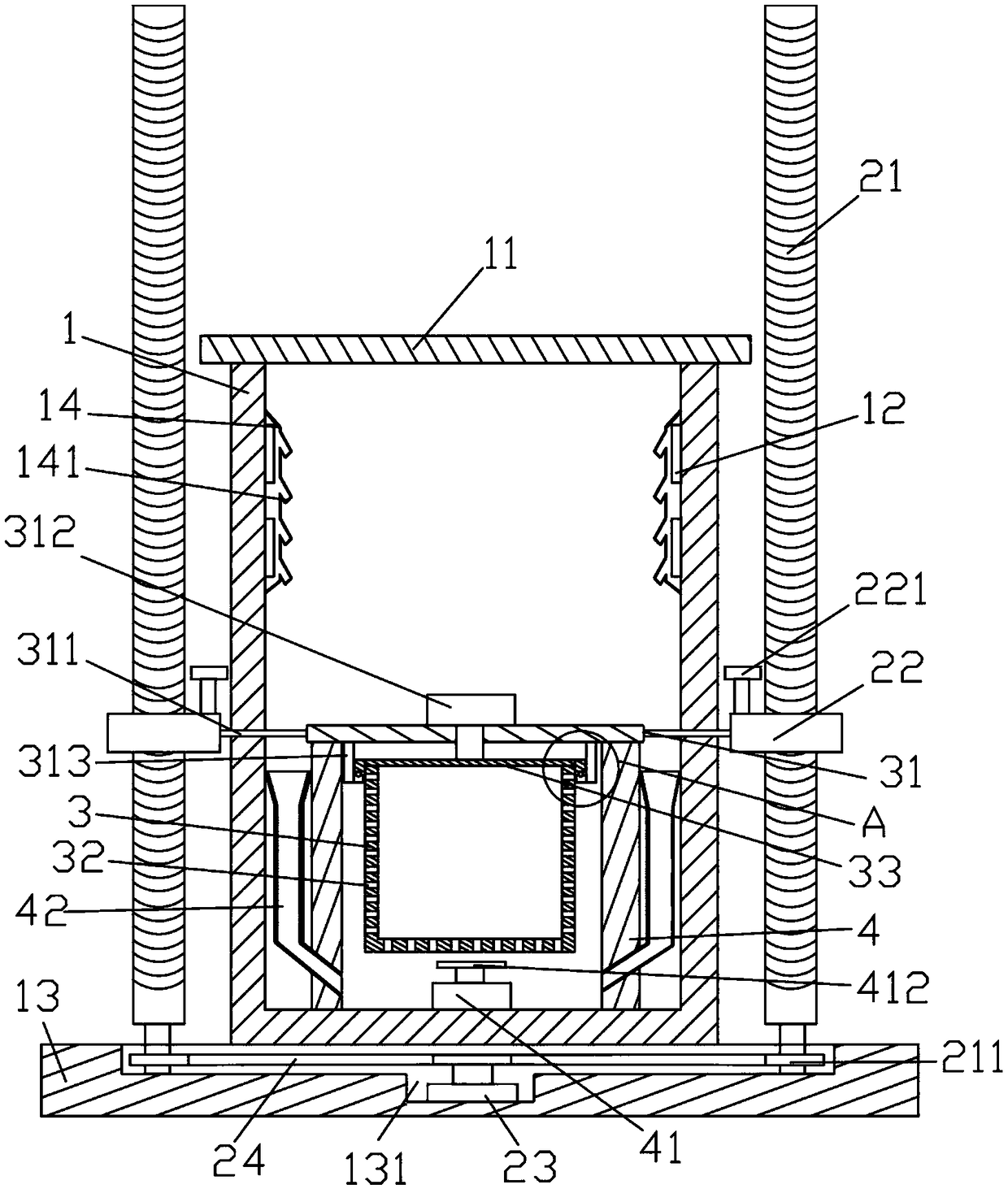

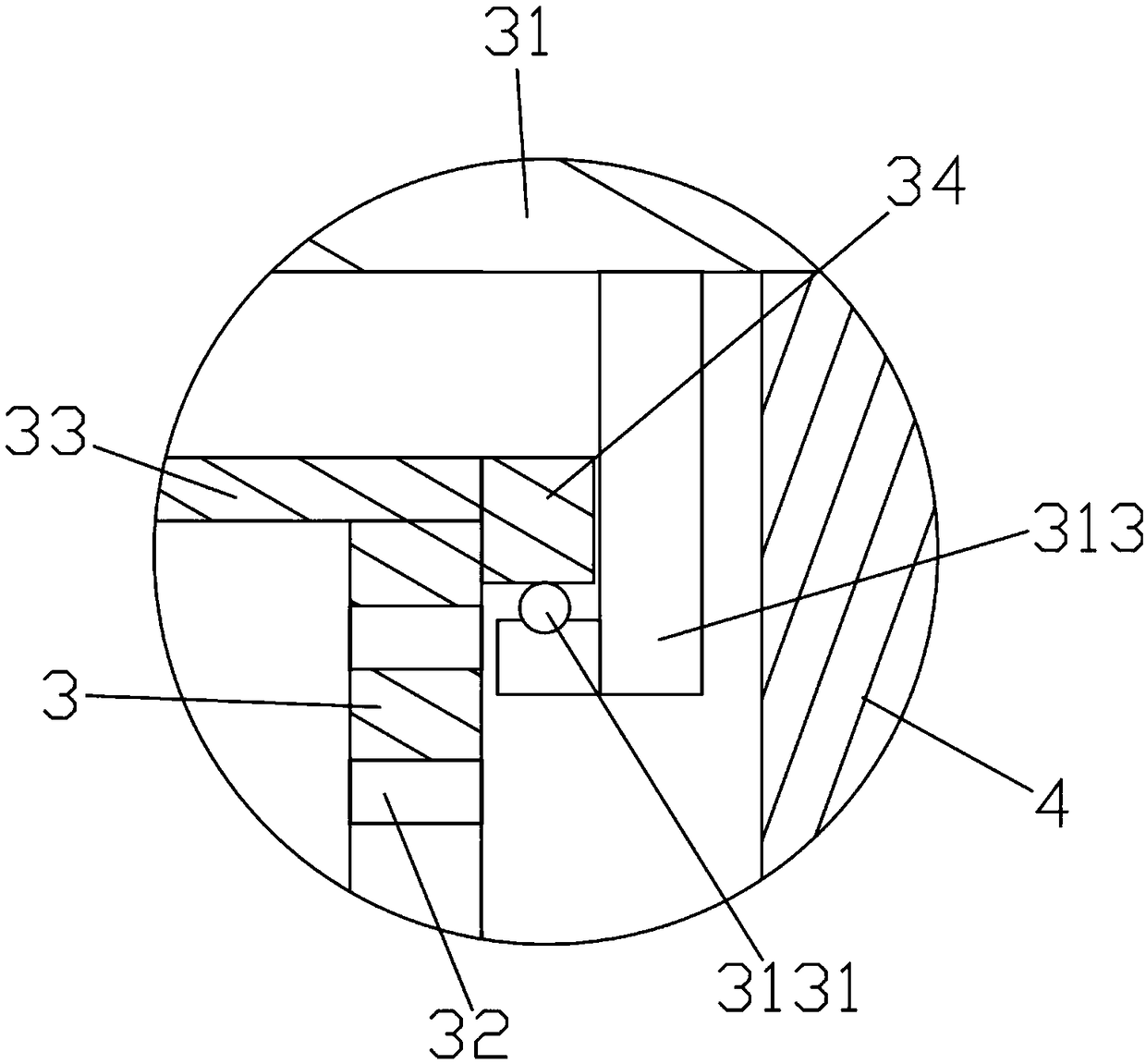

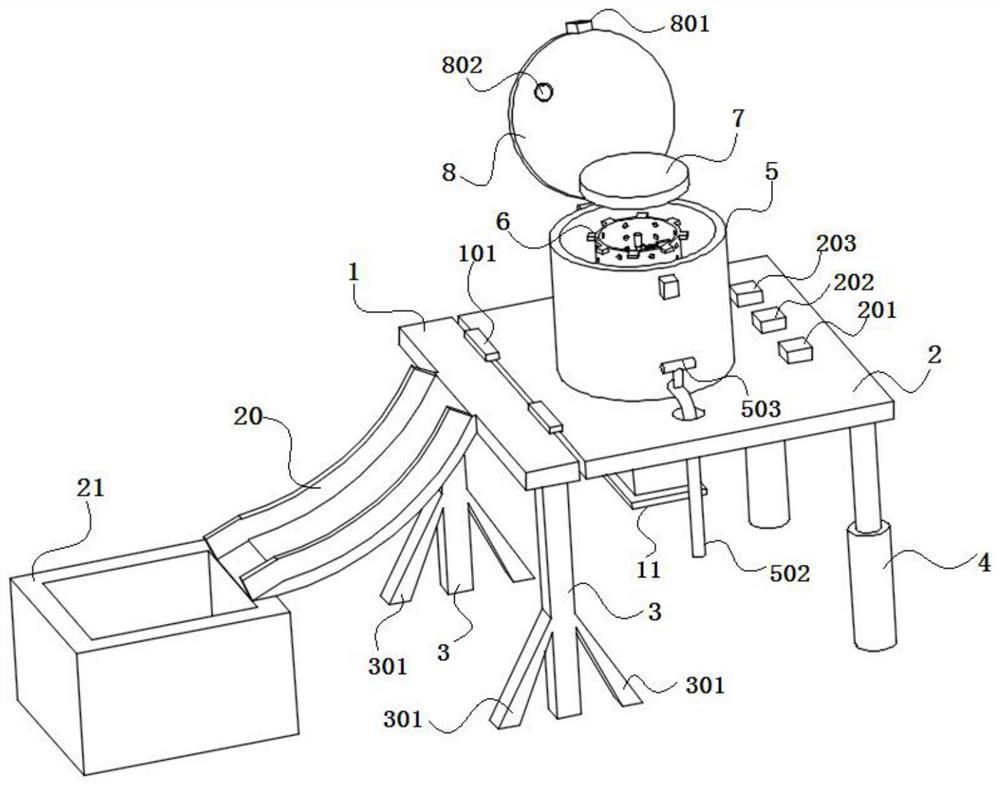

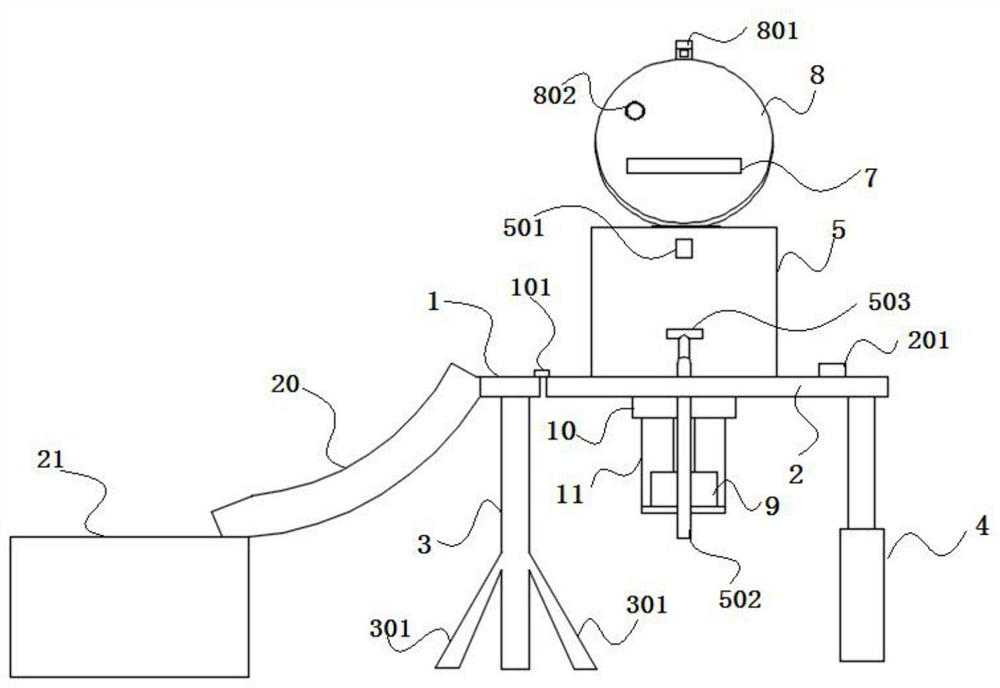

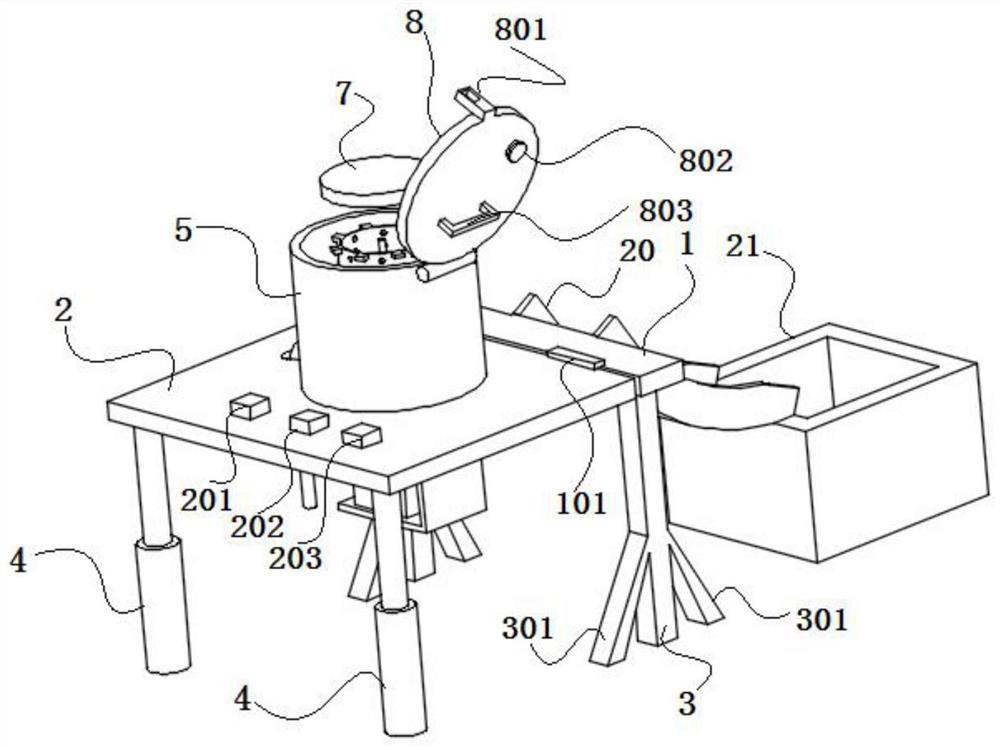

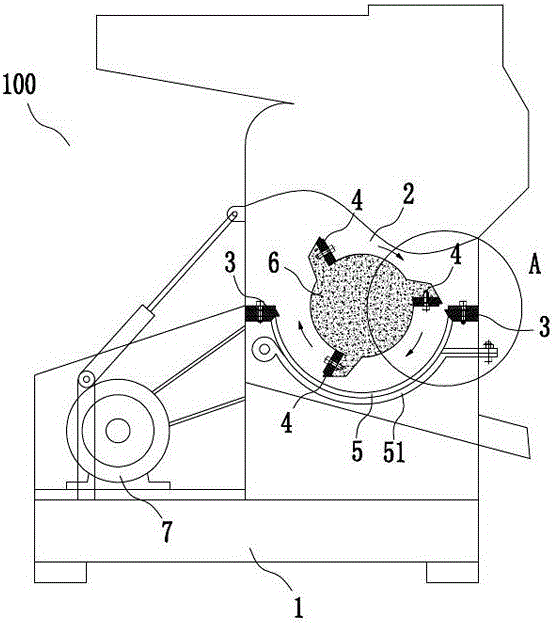

Centrifugal drying treating device for chemical production

InactiveCN111928587AEasy to take outImprove work efficiencyDrying solid materials without heatHollow article cleaningElectric machineryProcess engineering

The invention discloses a centrifugal drying treating device for chemical production, and relates to the technical field of chemical production. The device comprises a supporting fixing module, a centrifugal drying module and a raw material bearing module. The supporting fixing module comprises a first slab, a second slab, supporting legs, an electric stretchable rod and an L-shaped fixing plate.The centrifugal drying module comprises an outer cylinder, a centrifugal cylinder, a centrifugal shaft, a top cover, a protective cover and a motor. The raw material bearing module comprises an arc sliding way and a raw material bearing box. By arranging the supporting fixing module, the centrifugal drying module and the raw material bearing module, the problems that in the prior art, raw materials are not conveniently poured out from the centrifugal cylinder; dehydration is performed only through centrifugal force, and the drying efficiency is low; in the centrifugal process, raw materials are likely to be stuck and stacked on the cylinder wall, and raw material centrifugal drying is not thorough is caused are solved. Raw materials are more easily taken out after raw materials are centrifuged, dried and dehydrated, the working efficiency is improved, raw materials can be easily scraped down when stuck to the centrifugal cylinder wall, and the raw materials are centrifuged and dried more thoroughly.

Owner:合肥德纳达信息科技有限公司

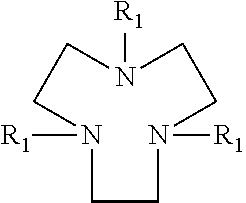

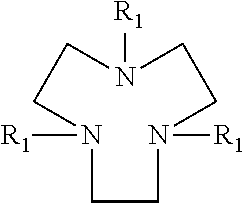

Drier for auto-oxidisable coating compositions

ActiveUS20140342163A1Expedited drying processLow costOrganic chemistryDrying solid materials with heatDesiccantHeteroatom

A mixture for use as a drier for air-drying an auto-oxidizable resin composition, said mixture comprising : 1,4,7-trialkyl-1,4,7-triazacyclononane (L); and, a manganese salt having the general formula Mn2+[X]n, wherein anion X is selected from PF6−, SbF6−, AsF6−, BF4−, B(C6F5)4−, Cl−, Br−, I−, NO3−, or R2COO− in which case n=2, or the anion X is SO42− in which case n=1, and wherein R2 is C1-C20 alkyl optionally substituted with heteroatoms, C6-C20 aryl optionally substituted with heteroatoms, or a polymeric residue; wherein the 1,4,7-trialkyl-1,4,7-triazacyclononane (L) is present in the mixture in an amount such that the molar ratio of L:Mn is at least 1.25:1 and more preferably at least 1.5:1.

Owner:AKZO NOBEL COATINGS INT BV

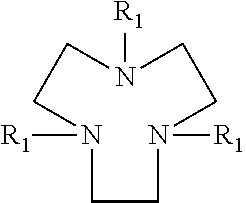

Plastic shoe tree crusher, shoe tree crushing production line and crushing method

ActiveCN105690601AIncrease crushing outputReduce laborPlastic recyclingGrain treatmentsProduction lineEngineering

The invention discloses a plastic shoe tree crusher, a shoe tree crushing production line and a crushing method. The plastic shoe tree crusher comprises a rack, a crushing cavity, fixed cutters, movable cutters, a discharging screen, a movable cutter rolling disc and a motor. The movable cutter rolling disc is arranged in the crushing cavity. A plurality of rows of movable cutter grooves are formed in the movable cutter rolling disc in the radial direction. Each row of movable cutter grooves are provided with a plurality of movable cutter bases distributed in a staggered manner. The movable cutters are fixedly arranged in the movable cutter bases, and the cutting edges of the movable cutters are higher than the outer surface of the movable cutter rolling disc. One fixed cutter base is arranged at the front end of the crushing cavity, one fixed cutter base is arranged at the rear end of the crushing cavity, the fixed cutters are fixedly arranged in the fixed cutter bases, and the cutting edges of the fixed cutters are higher than the inner surface of the crushing cavity. The motor is used for driving the movable cutter rolling disc to rotate, and the discharging screen is arranged at the lower end of the crushing cavity. In the movable cutter rolling disc rotating process, shoe tree crushing is caused due to gaps between the cutting edges of the movable cutters and the cutting edges of the fixed cutters, and crushed shoe tree materials pass through the discharging screen and then are output. According to the plastic shoe tree crusher, the shoe tree crushing production line and the crushing method, the crushing yield is high, the manual work is little, the crushing cost is low, and plastic shoe trees with metal can be directly crushed.

Owner:DONGGUAN JIANFA SHOE MATERIAL CO LTD

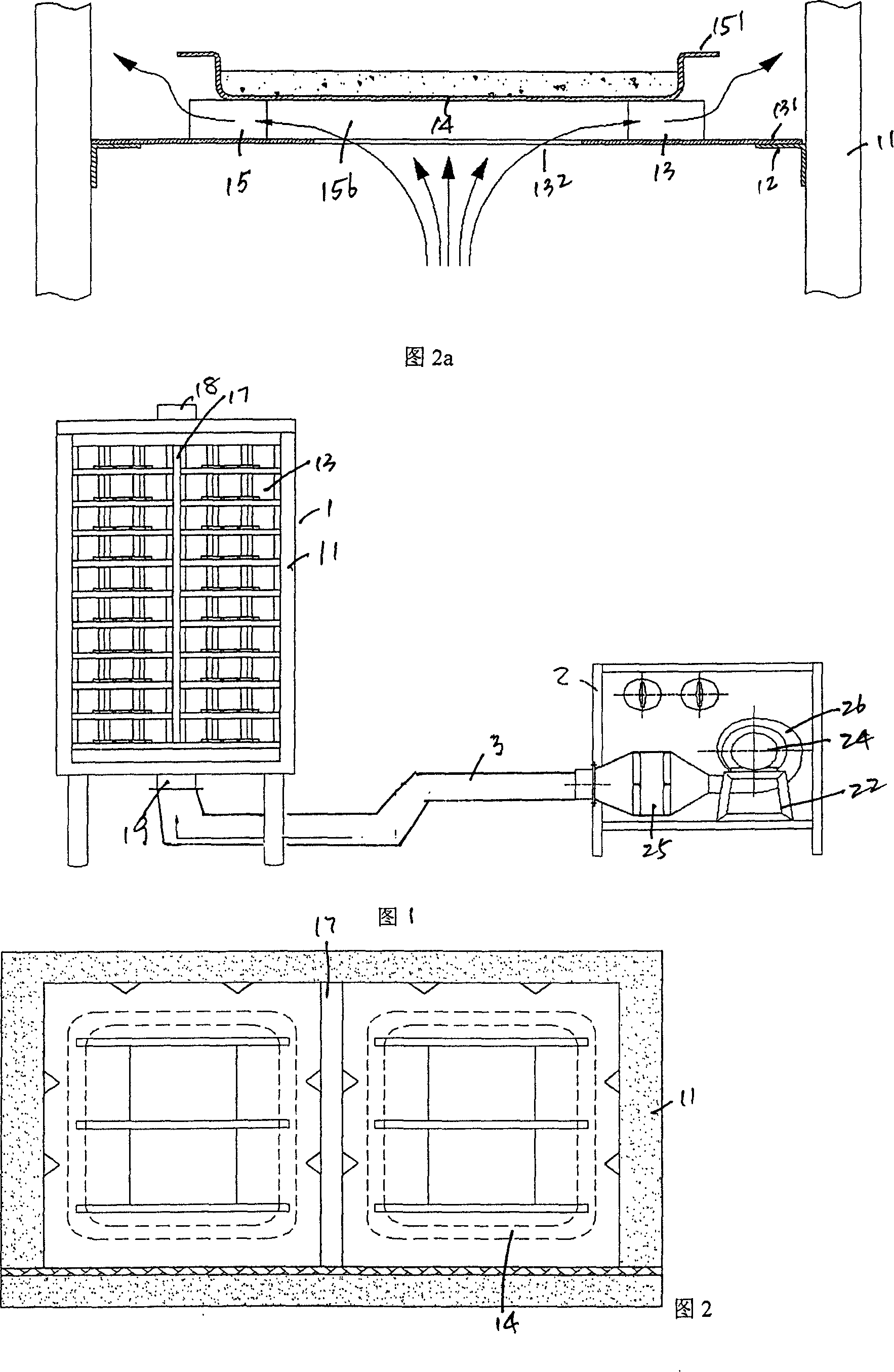

Method for drying wood and an apparatus for the implementation thereof

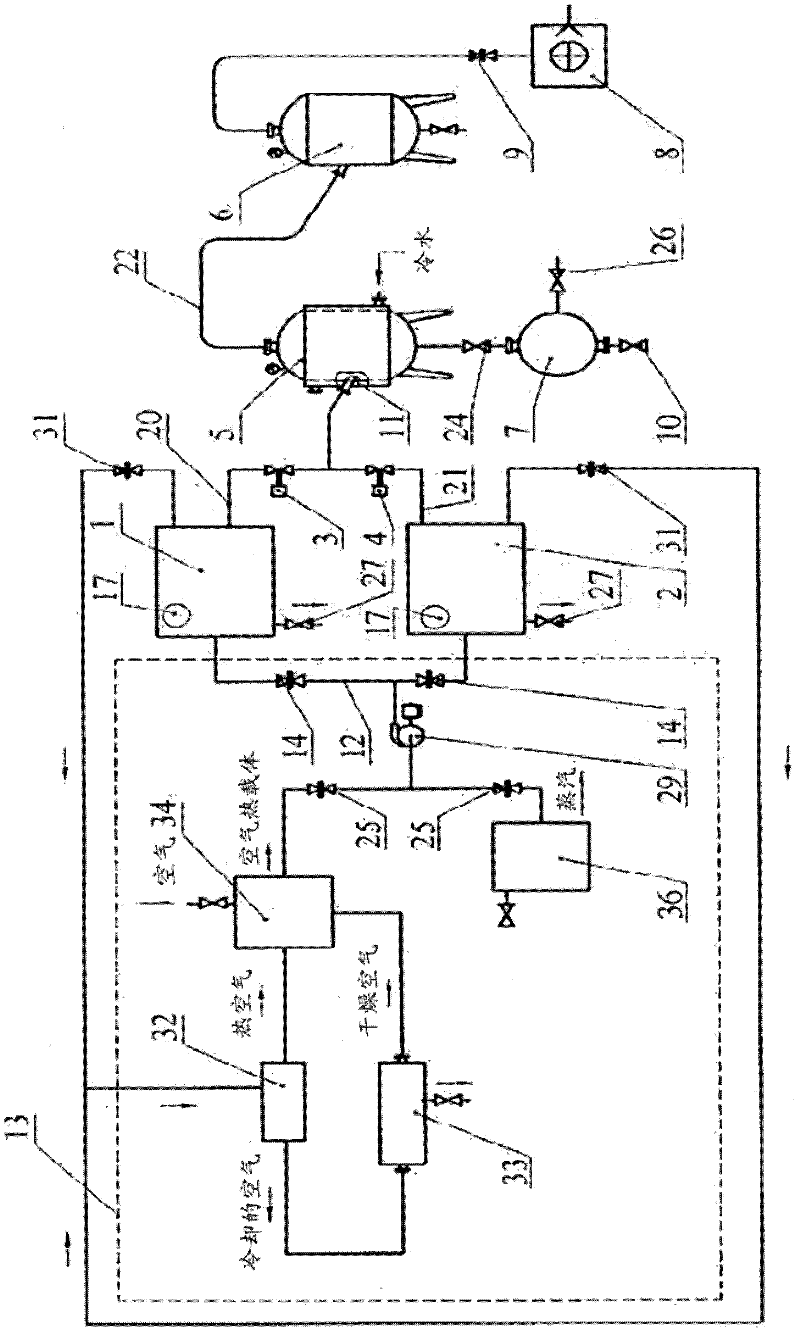

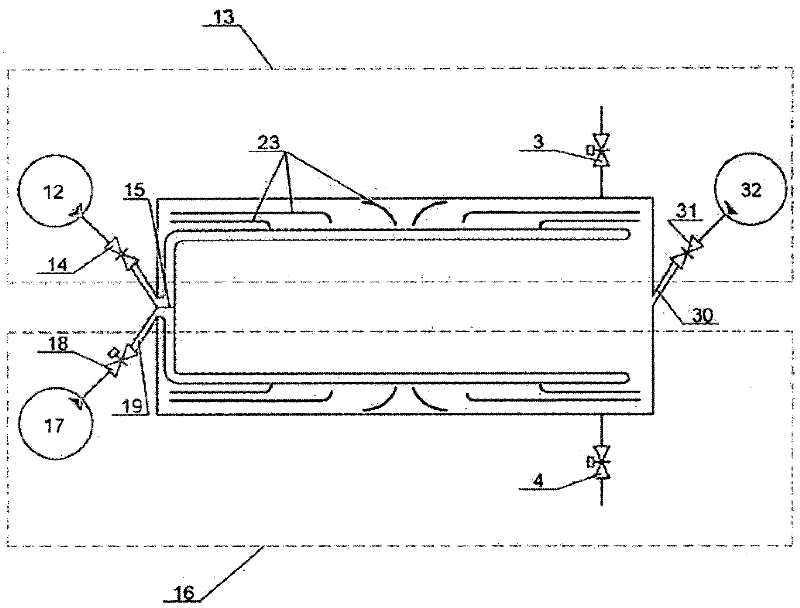

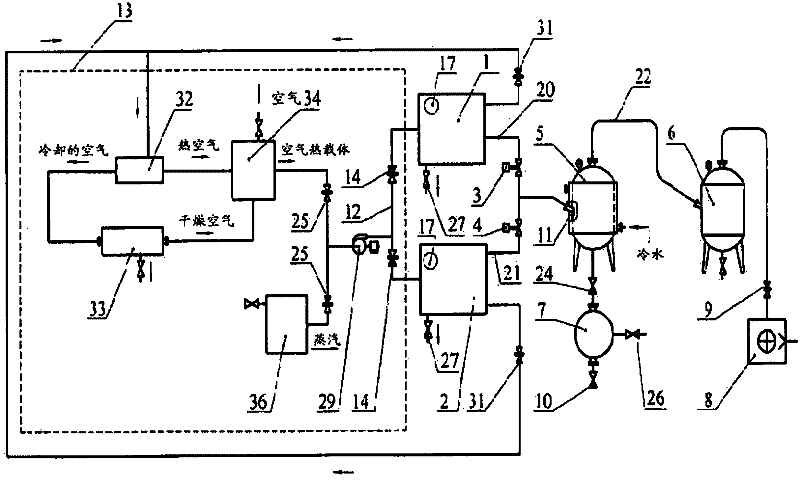

InactiveCN102348947AIncrease speedIncrease vacuumDrying using combination processesDrying solid materials without heatHeat carrierAtmospheric air

The invention relates to the field of wood processing. The drying method consists of the repeated alternation of the cycles of blowing air heat-carrier over the wood at atmospheric pressure while heating the wood to an average volume temperature of 80-100 DEG C, applying a pulsed rapid vacuum with a working pressure of not more than 50 mm Hg over a time of up to 10 s with free moisture being forced out without the phase transformation of the water into vapour until a constant temperature of the wood is established, and relieving the vacuum to atmospheric pressure by supplying air heat-carrier, the wood being blown over and the vacuum relieved using air heat-carrier with a temperature of 150-300 DEG C at an excess pressure of not more than 0.07 MPa.; The apparatus for implementing this method for drying wood includes two drying chambers connected to a cooled receiver by pipes having fast-acting valves, said cooled receiver being connected in series to a second receiver and to a vacuum pump by means of a pipe with a vacuum seal. The first receiver is fitted with spiral guides for streams of vapour-droplet medium along a tangent to the inside diameter of the receiver shell. The drying chambers are connected to a heat-carrier preparation and delivery system.

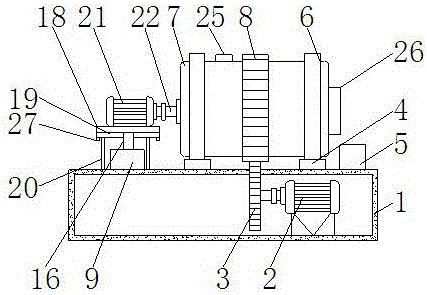

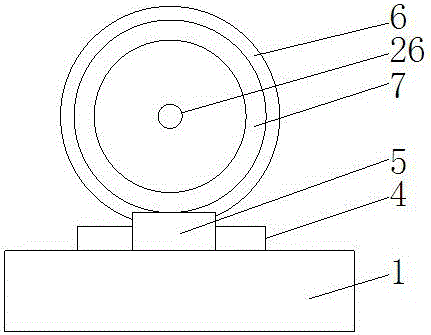

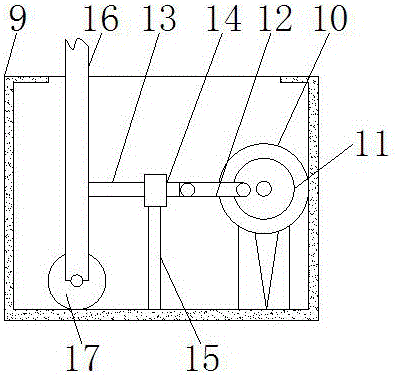

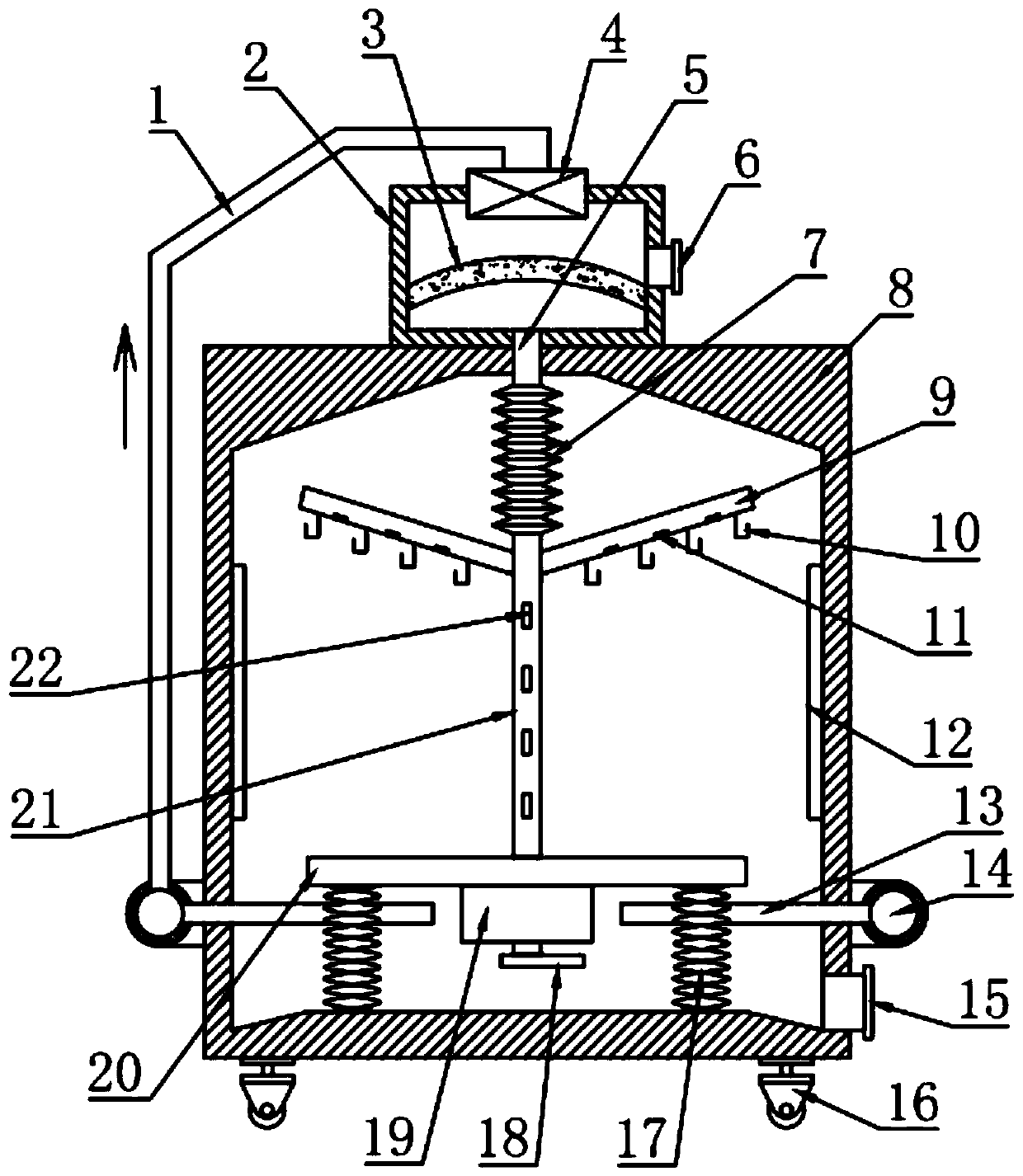

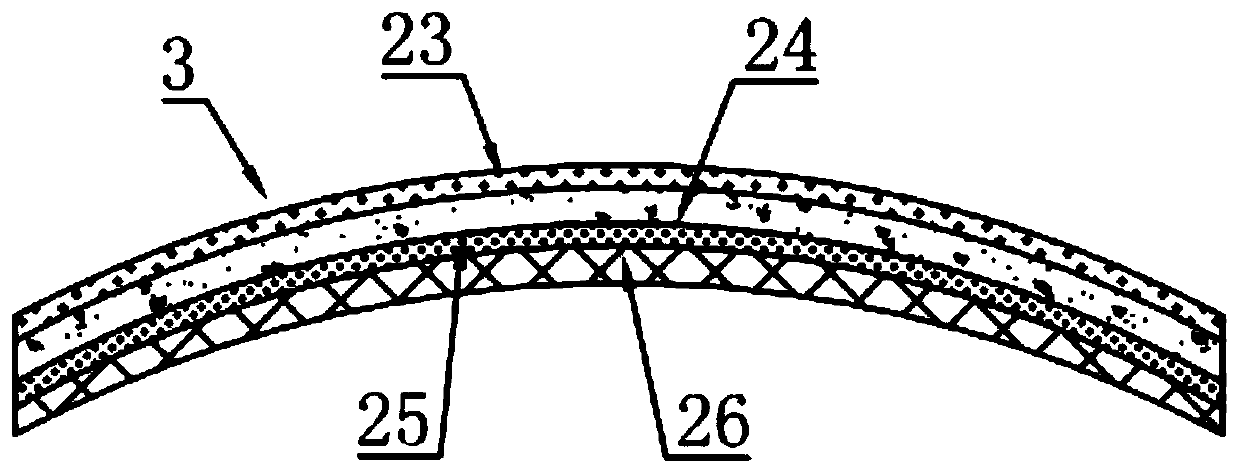

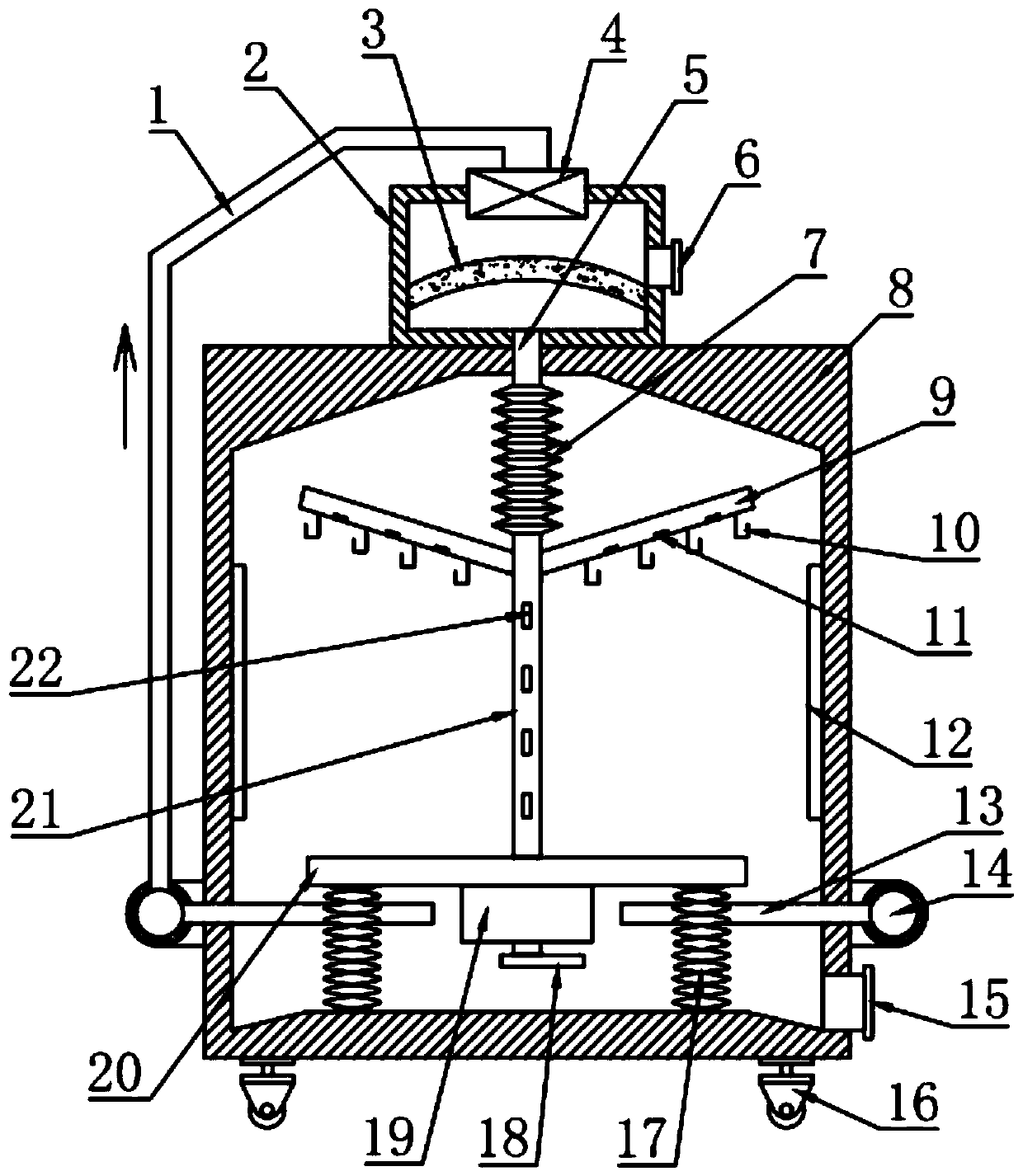

Chemical material drying treatment device with stir-fry function

ActiveCN106369964AExpedited drying processIncrease the heating areaDrying machines with non-progressive movementsDrying solid materialsCouplingElectric machinery

The invention discloses a chemical material drying treatment device with the stir-fry function. The device comprises a base, a first motor is fixedly mounted at the bottom of an inner cavity of the base, an output shaft of the first motor is fixedly provided with a gear through a coupler, the top of the gear penetrates the top of the base and extends to the outer portion of the base, two damping blocks are fixedly mounted on the top of the base, a controller is fixedly mounted on the right side of the top of the base, fixing rings are fixedly mounted on the tops of the damping blocks, and a rotating cylinder is movably connected with the interiors of the fixing rings. According to the chemical material drying treatment device with the stir-fry function, through improvement of a power box, the effect of quickening the chemical material drying treatment is achieved, and therefore the heating area of the chemical materials is larger, the drying efficiency of the chemical materials is improved, the drying time is shortened, a user conveniently use the device, meanwhile, the drying cost is saved, and the work efficiency of the drying treatment device is greatly improved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

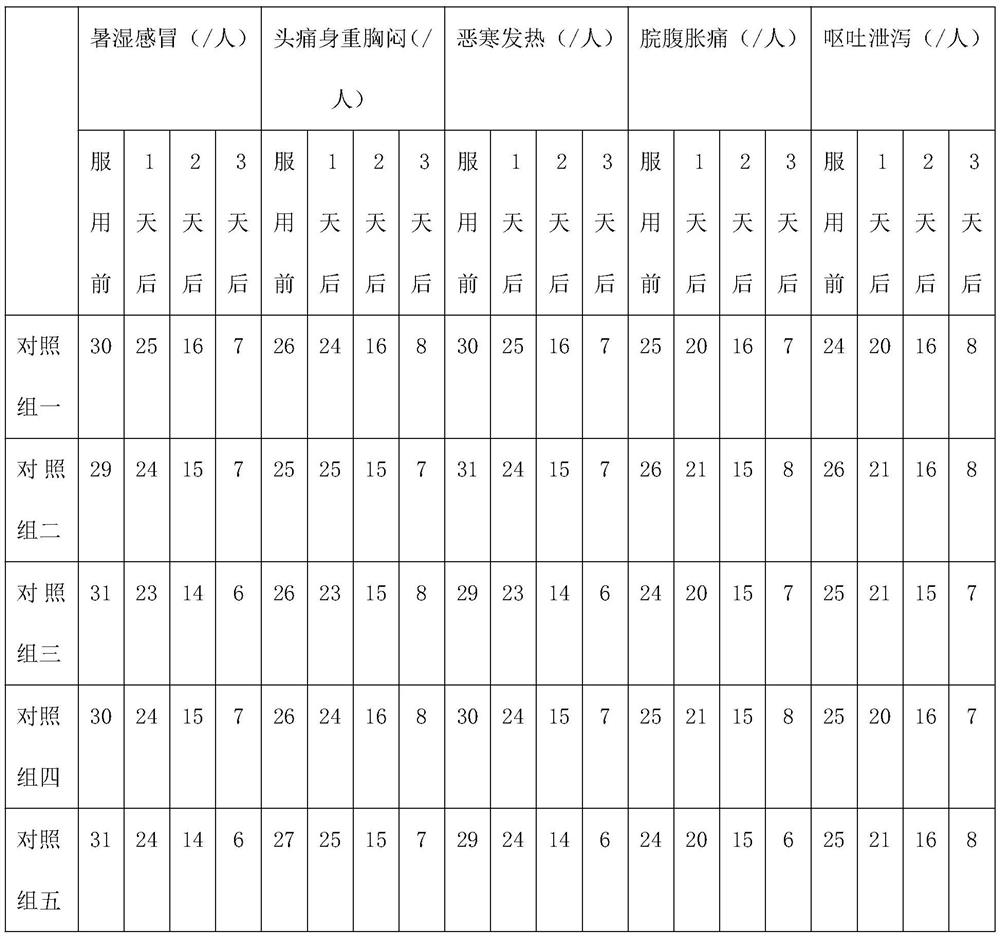

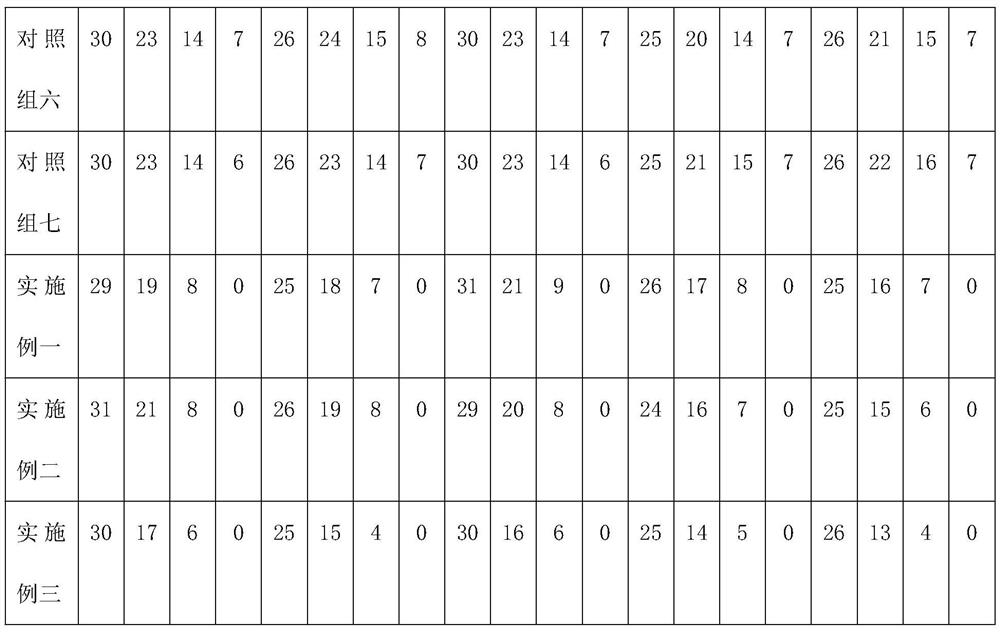

Traditional Chinese medicine pills with effects of regulating qi-flowing and removing dampness and preparation method of traditional Chinese medicine pills

InactiveCN111714613AGuaranteed efficacyStrengthen the function of regulating qi and dehumidificationAntinoxious agentsPill deliveryOfficinalisWolfiporia extensa

The invention discloses traditional Chinese medicine pills with effects of regulating qi-flowing and removing dampness and a preparation method of the traditional Chinese medicine pills, and relates to the technical field of traditional Chinese medicines. The traditional Chinese medicine pills are prepared from the following raw material: herba pogostemonis, herba eupatorii, rhizoma atractylodis,fructus amomi, semen alpiniae, herba meliloti suaveolentis, folium perillae, radix angelicae, bighead atractylodes rhizomes, pericarpium citri tangerinae, fructus crataegi, radix aucklandiae, pinelliaternate, cortex magnoliae officinalis, poria cocos, radix platycodi, radix glycyrrhizae, pericarpium arecae, fructus jujubae, sucus zingberis, camellia oil and xylitol. The herba eupatorii, rhizoma atractylodis, fructus amomi, semen alpiniae, herba meliloti suaveolentis, fructus crataegi, radix aucklandiae and camellia oil in the formula can effectively enhance the functions of regulating qi-flowing and removing dampness of the Huoxiang Zhengqi Wan; the cooperating effect of the medicines is better, the medicine effect durability can be prolonged, human digestion and absorption are facilitated, the taste is better, and the effect of extracting effective substances in the raw material percolation and decoction are effectively enhanced; the effective components in the raw material are better in utilization effect, the medicine effect loss is reduced, and the medicine utilization rate is higher; and the temperature gradient type rolling drying treatment is adopted, so that the drying treatment effect is better, and the medicine effect durability can be improved.

Owner:NANJING TONGRENTANG PHARM CO LTD

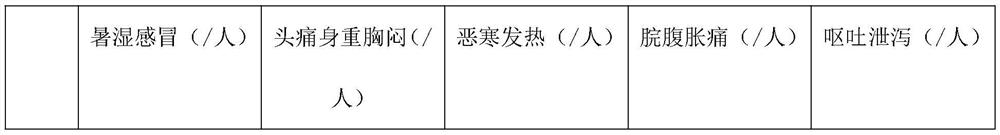

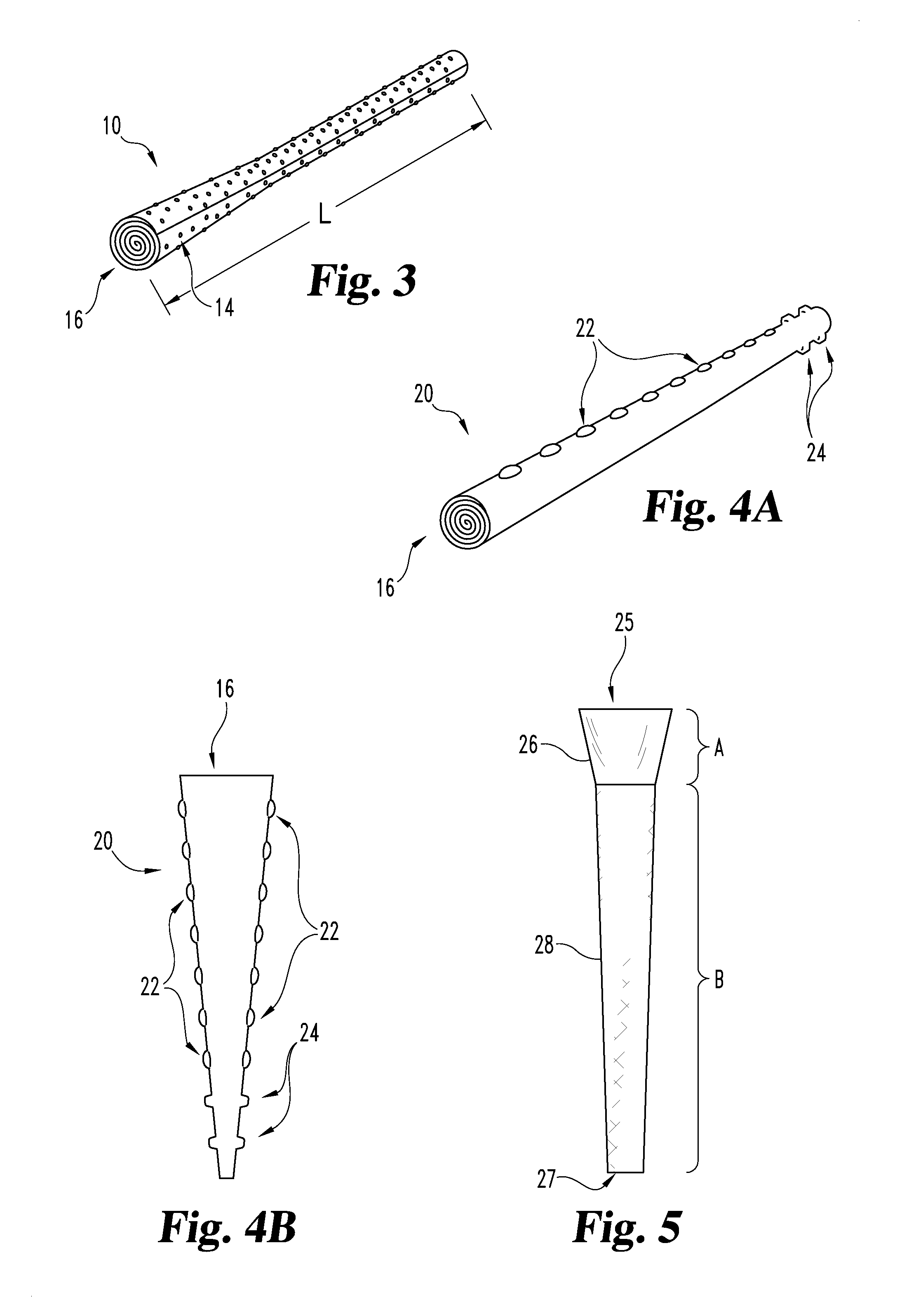

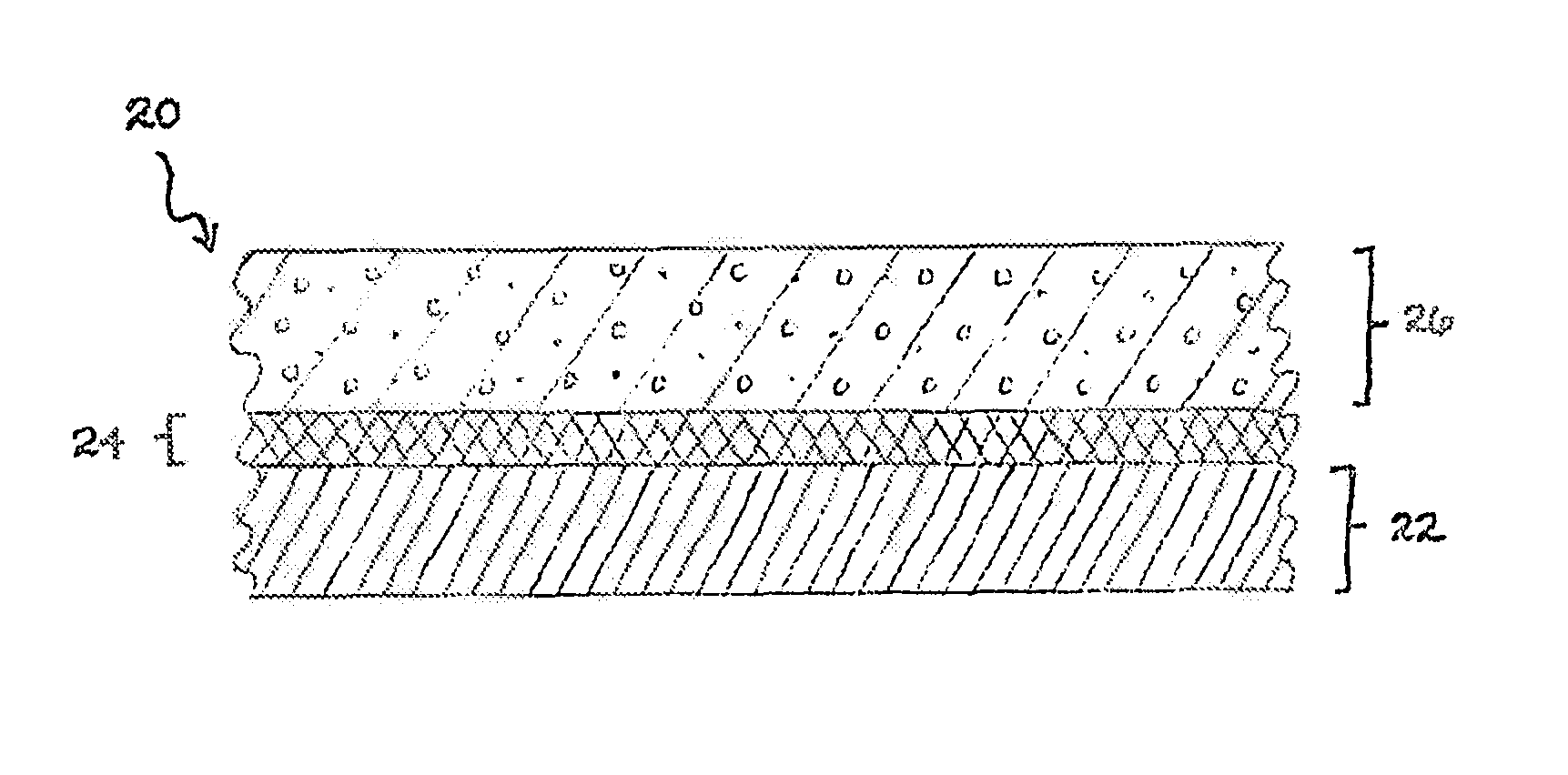

Volumetric grafts for treatment of fistulae and related methods and systems

ActiveUS9456813B2Easy to closeImprove uniformitySurgeryWound drainsCell-Extracellular MatrixECM Protein

Described are devices, methods, and systems useful in the treatment of fistulae, and in certain embodiments those having openings extending into the alimentary canal, such as anorectal fistulae. Illustratively, an anorectal fistula can be treated by placing a volumetric construct within the primary opening of the fistula. In certain embodiments, the volumetric construct can include a rolled remodelable material processed to form a substantially unitary body. Advantageous such remodelable materials can include collagenous extracellular matrix materials, such as small intestine submucosa.

Owner:COOK BIOTECH

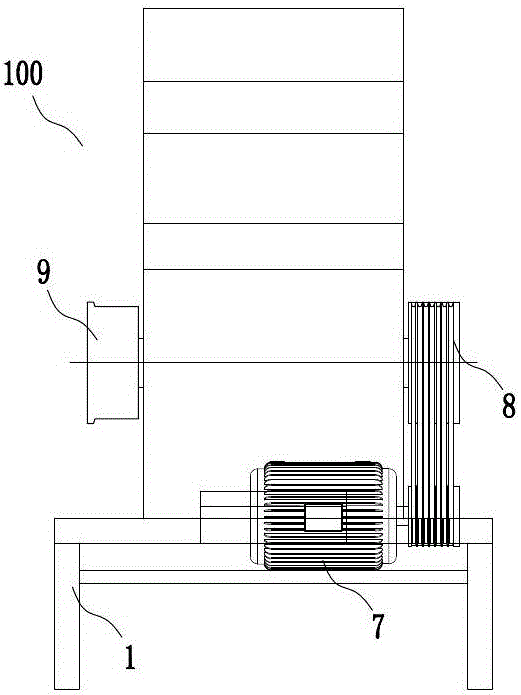

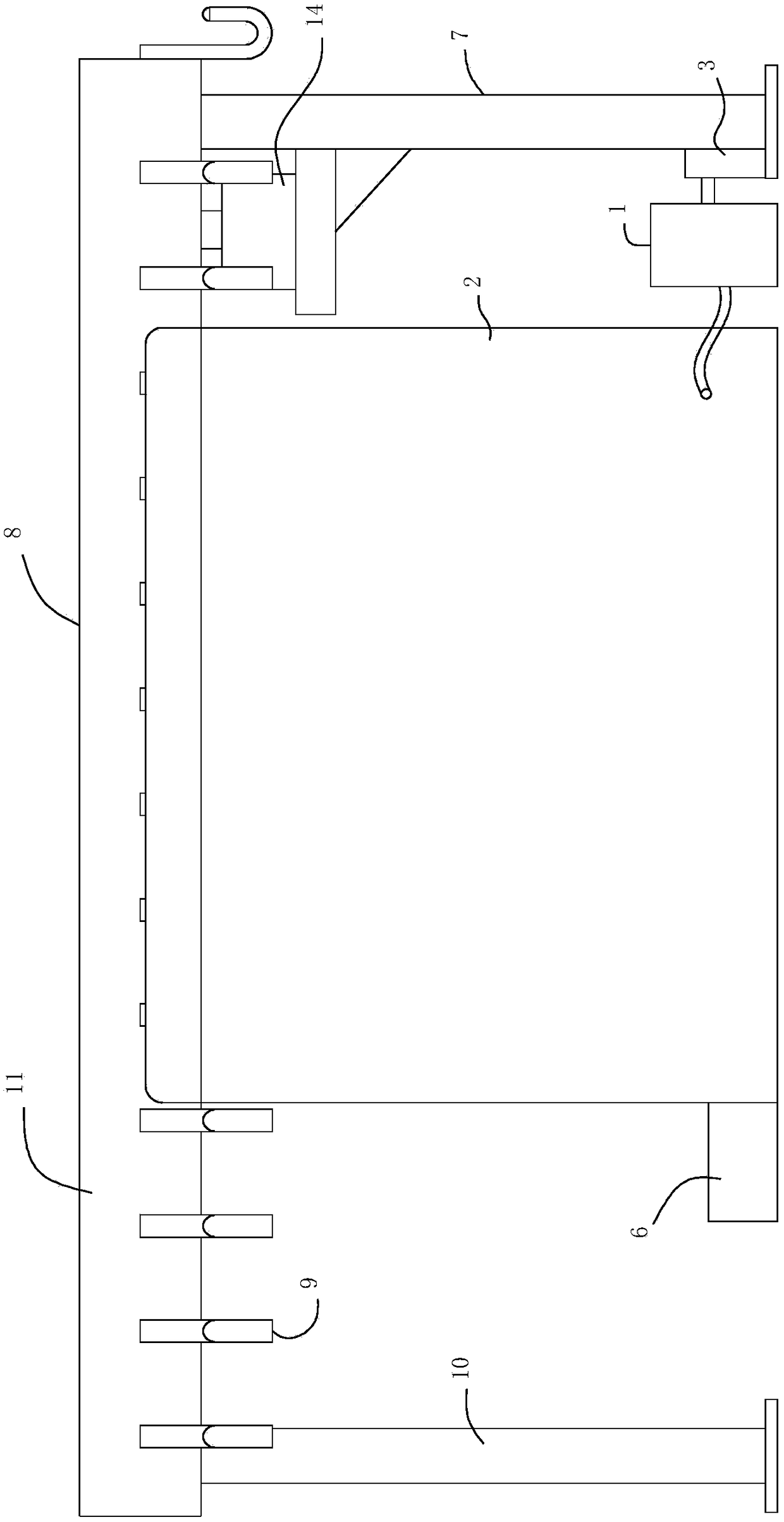

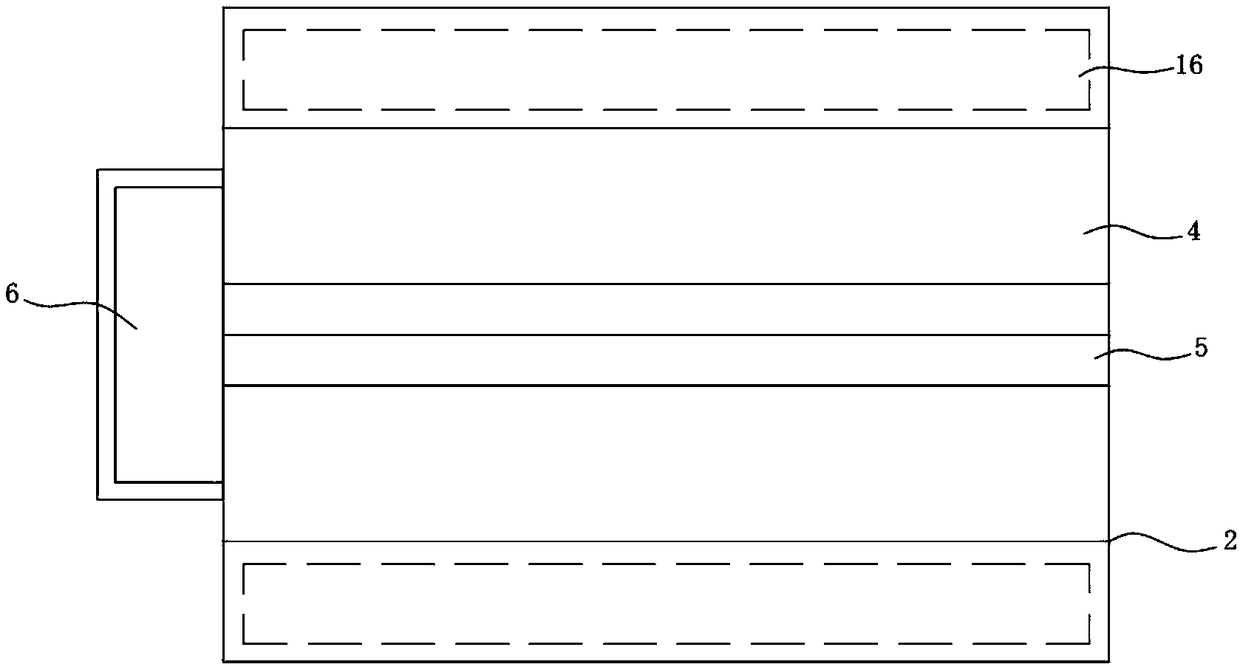

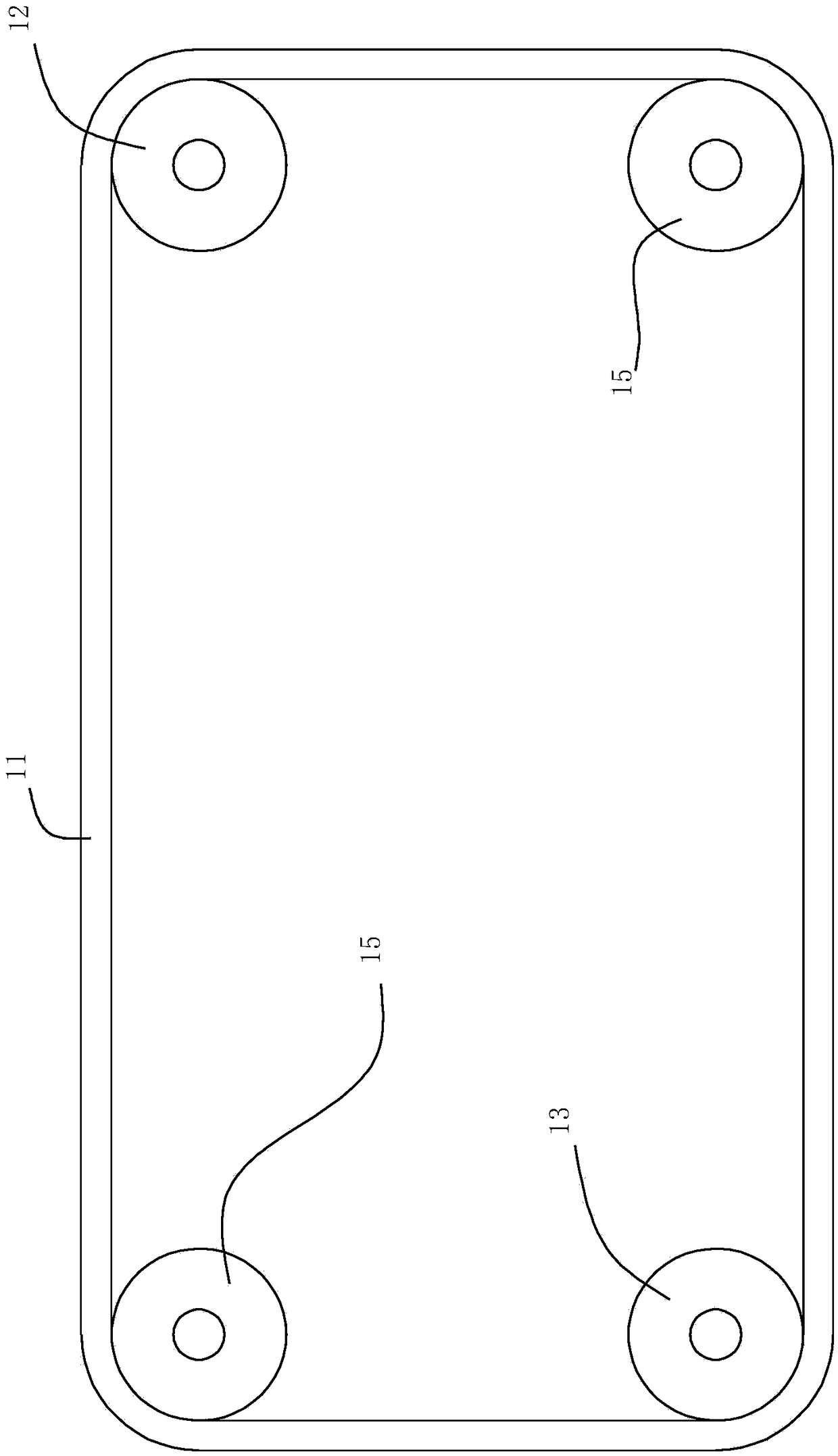

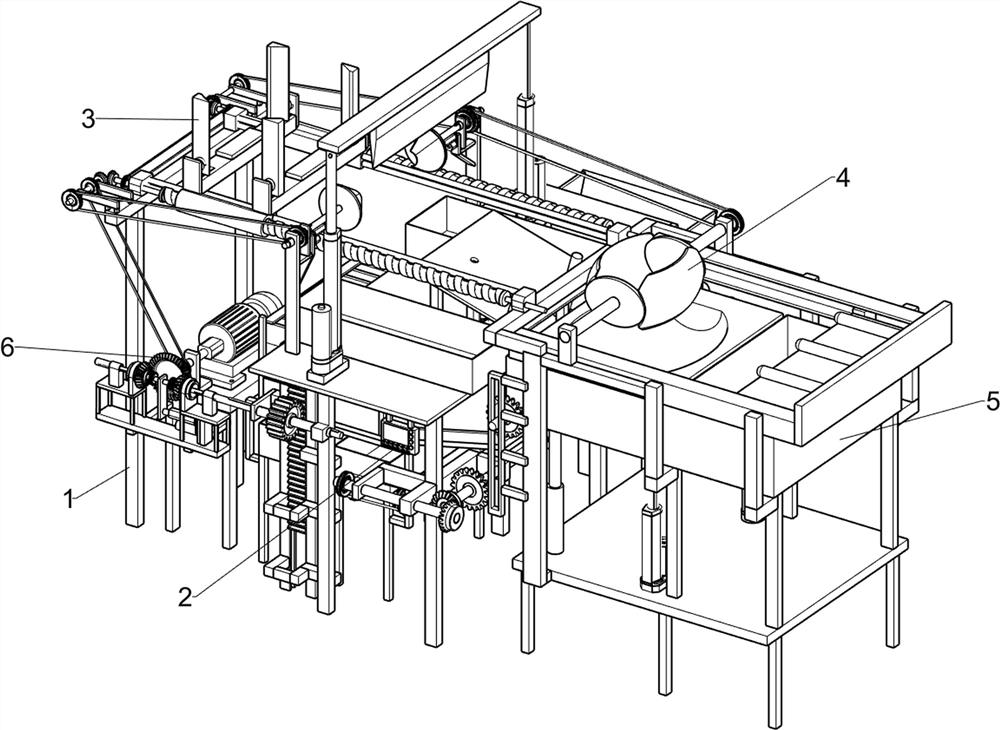

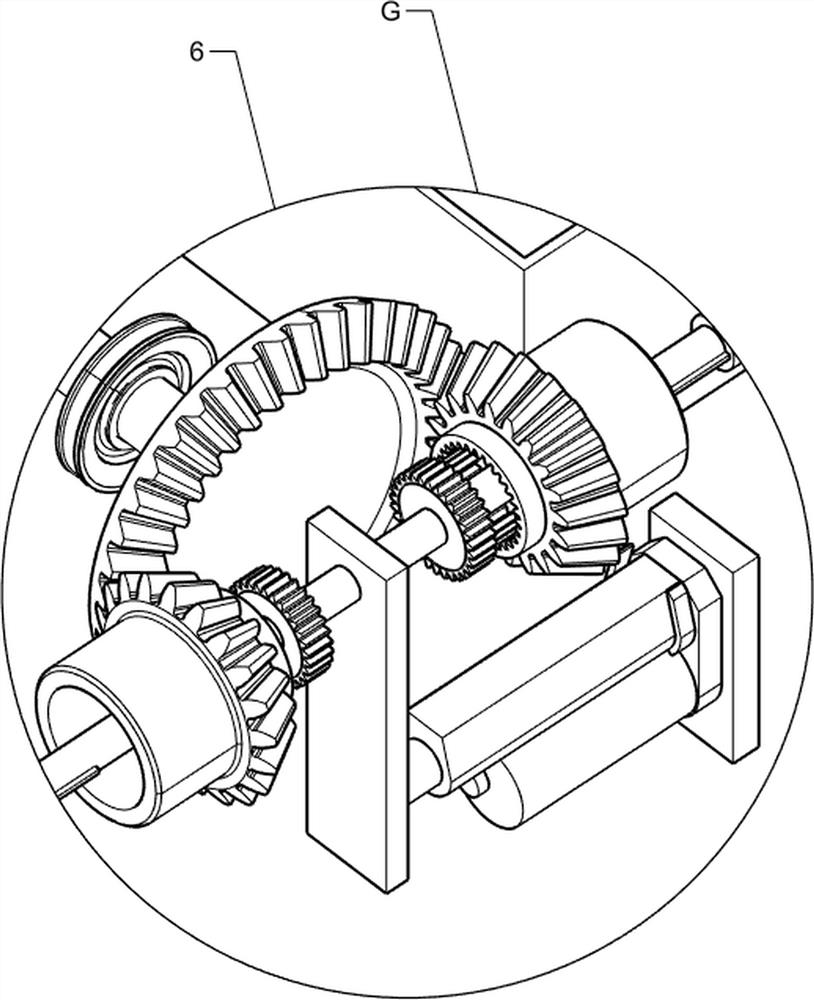

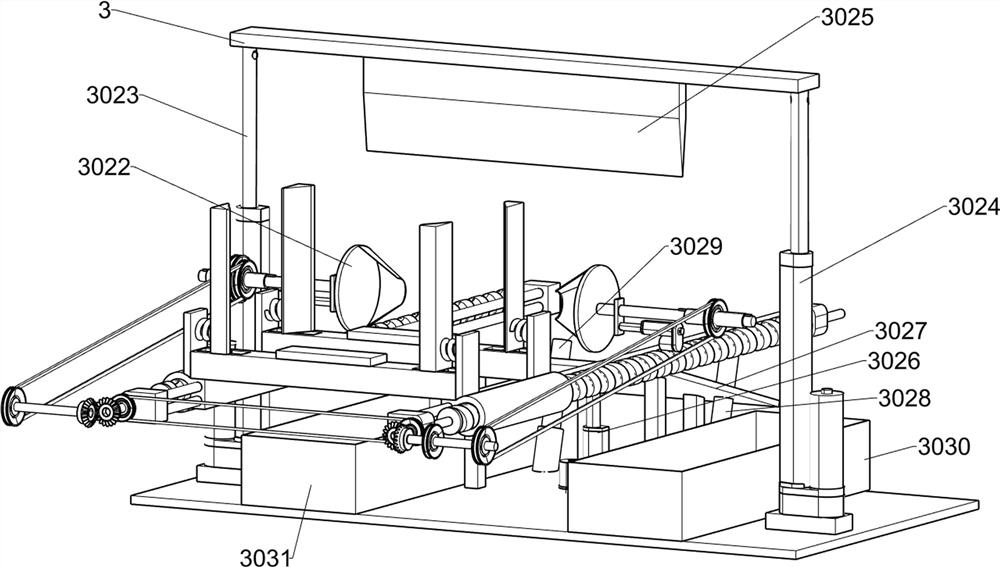

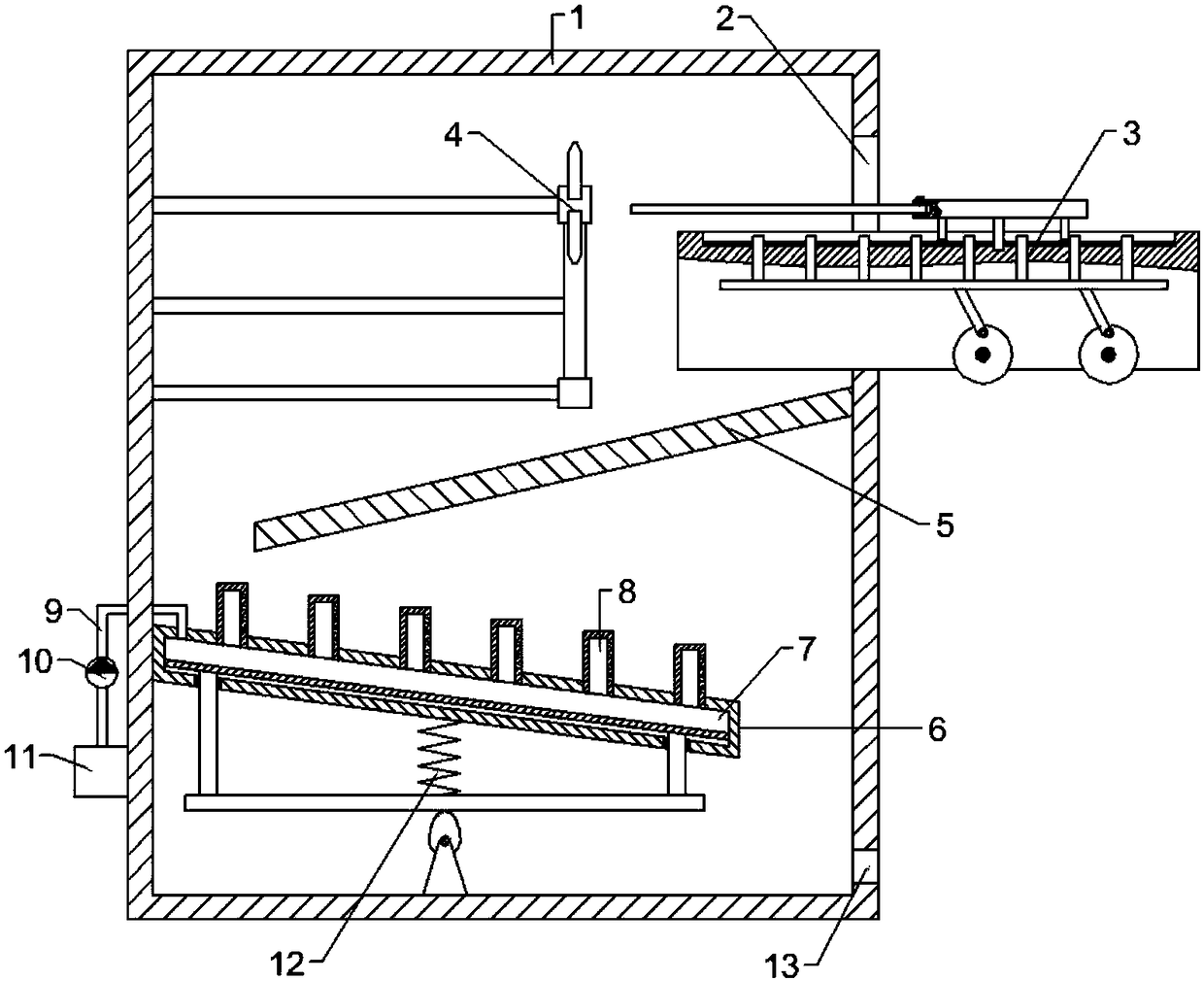

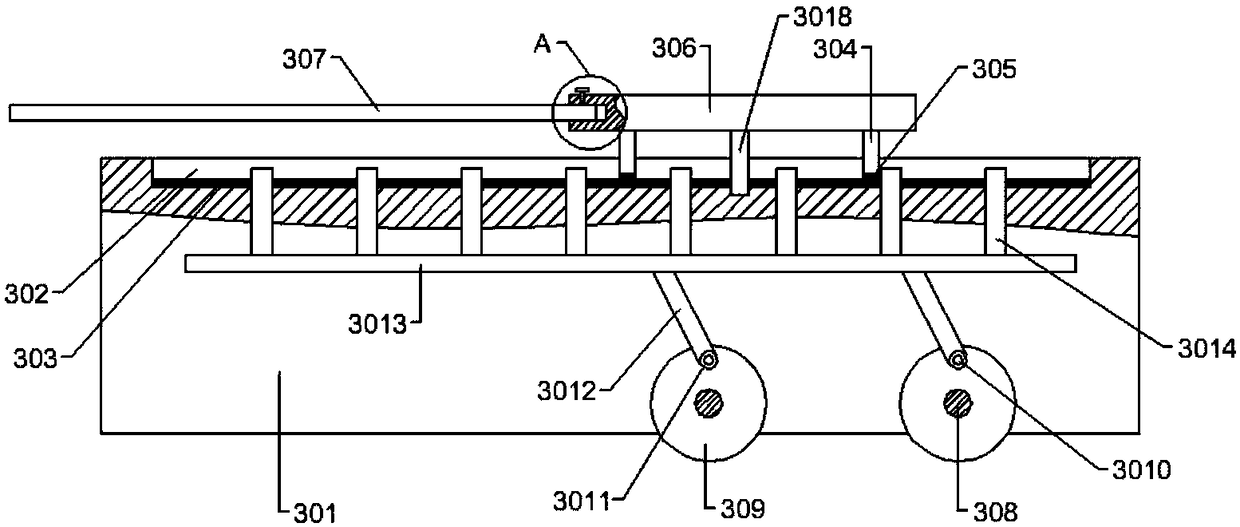

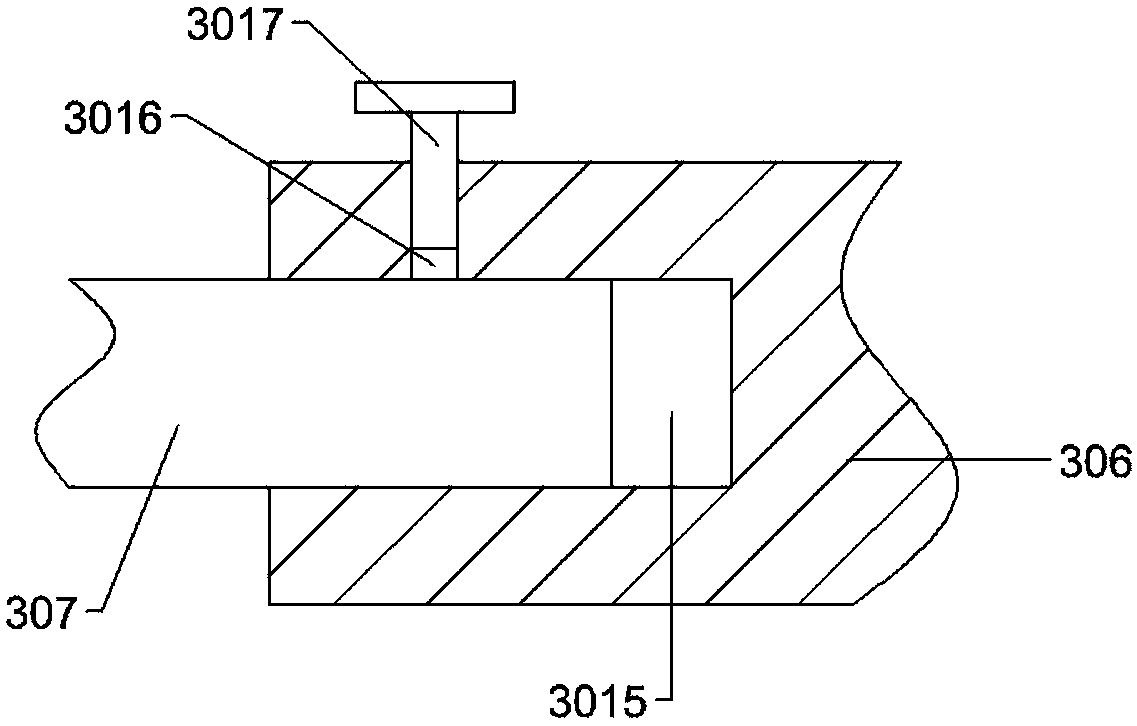

Intelligent shoe sole drying production system and production technology thereof

PendingCN107314655AReduce occupancyEasy to dryDrying gas arrangementsDrying machines with progressive movementsAdhesive glueProcess engineering

Owner:FUJIAN TIEGONG INTELLIGENT ROBOT CO LTD

Sausage casing dryer

PendingCN108870941AEven contactExpedited drying processDrying gas arrangementsSausage casingsAir pumpEngineering

The invention relates to sausage casing processing equipment, in particular to a sausage casing dryer and belongs to the field of sausage casing processing. The sausage casing dryer is reasonable in structure design and convenient to operate by an operator. According to the sausage casing dryer, an air heating chamber heats air pumped by an air pump, the heated air enters a drying chamber and is blown to a drying channel through a blowhole, the sausage casings pass through the drying channel under the action of a swing mechanism, the air flow exhausted by the blowhole dries the sausage casingsrapidly, and the sausage casing drying efficiency is improved. Hooks are arranged on the swing mechanism and used for hanging the sausage casings, during actual operation, the operator only needs tohang the undried sausage casings on the hooks, then the dried sausage casings are taken down from the hooks, the labour intensity of the operator is reduced, and the sausage casing drying operation isconvenient.

Owner:浙江亚泰生物科技有限公司

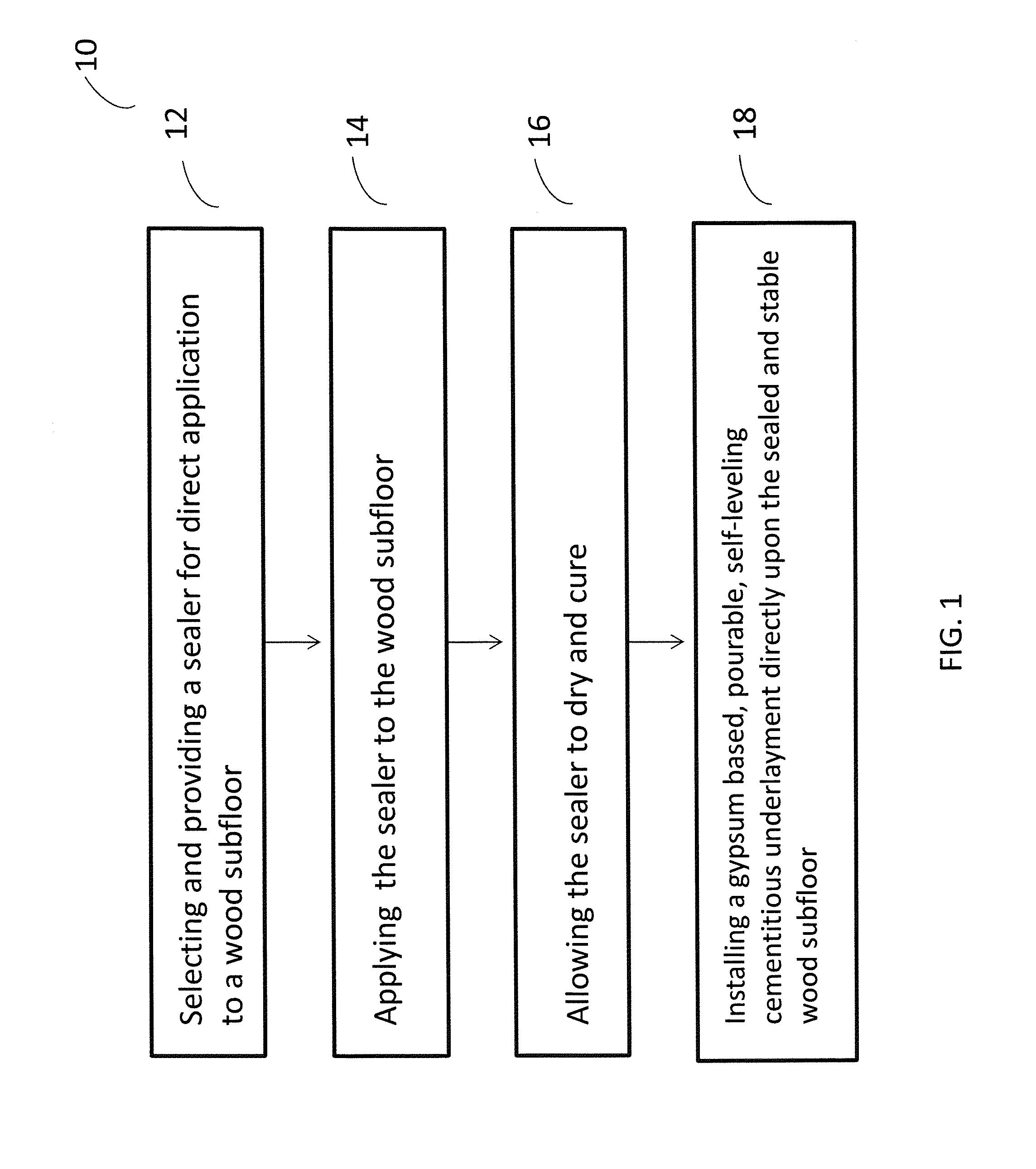

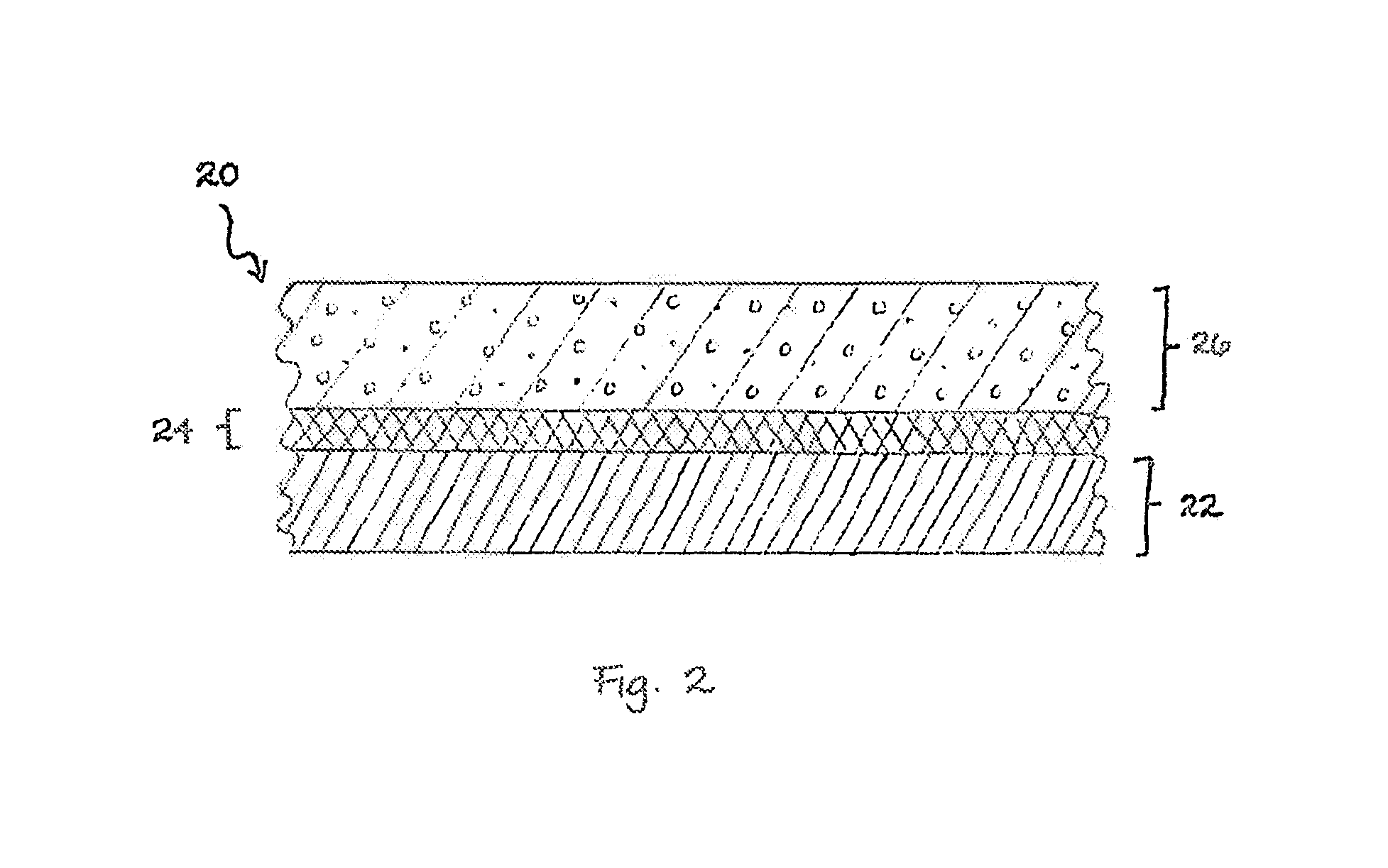

Method for sealing wood subfloors

ActiveUS8898994B1Improve a flooring systemLow costBuilding repairsBuilding material handlingEngineeringSealant

A method of applying a flooring system on a wood subfloor, including providing a sealer for direct application to the wood subfloor; applying the sealer to the wood subfloor; and allowing the sealer to dry and cure, forming a sealed and stable wood subfloor.

Owner:UNITED STATES GYPSUM CO

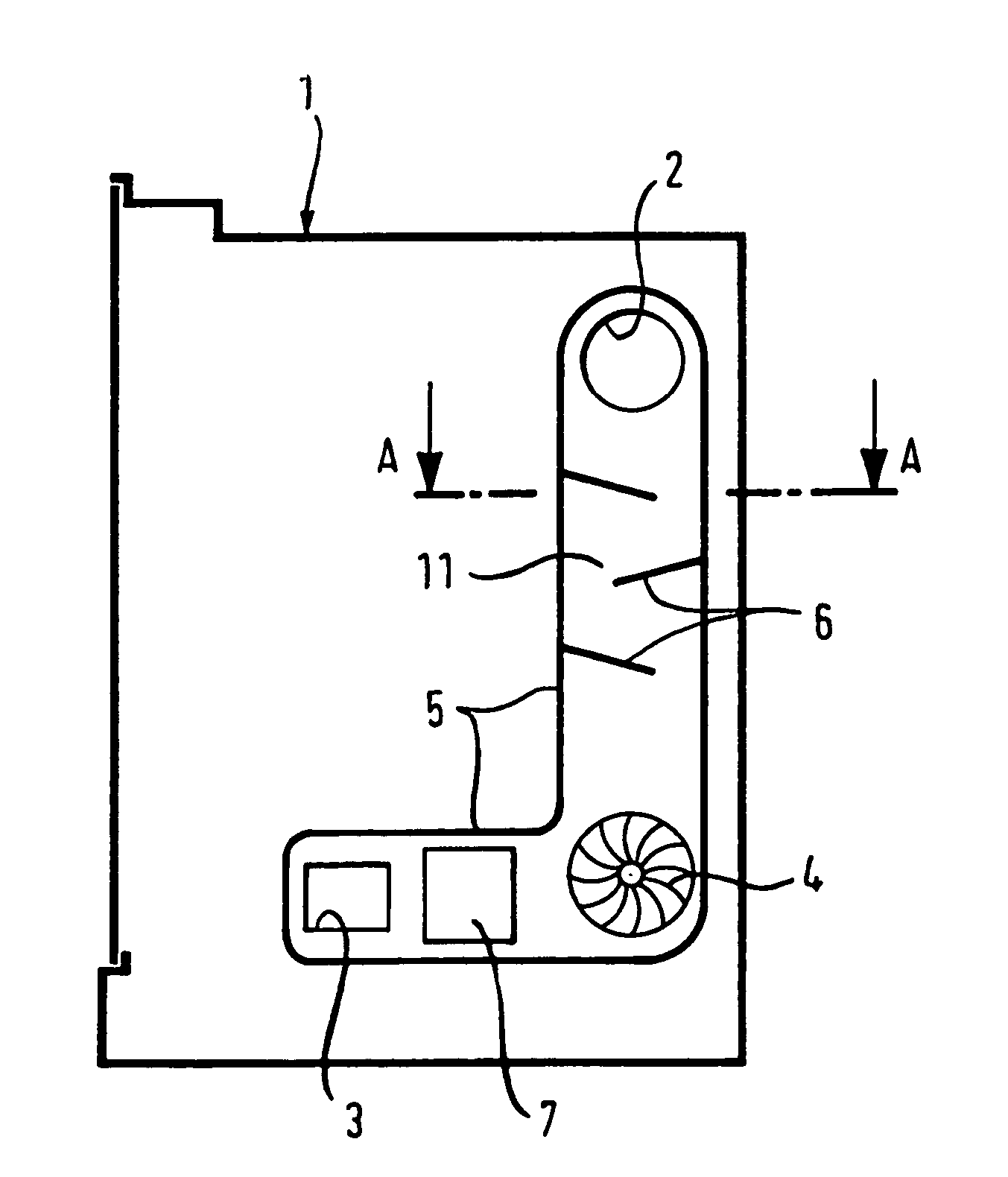

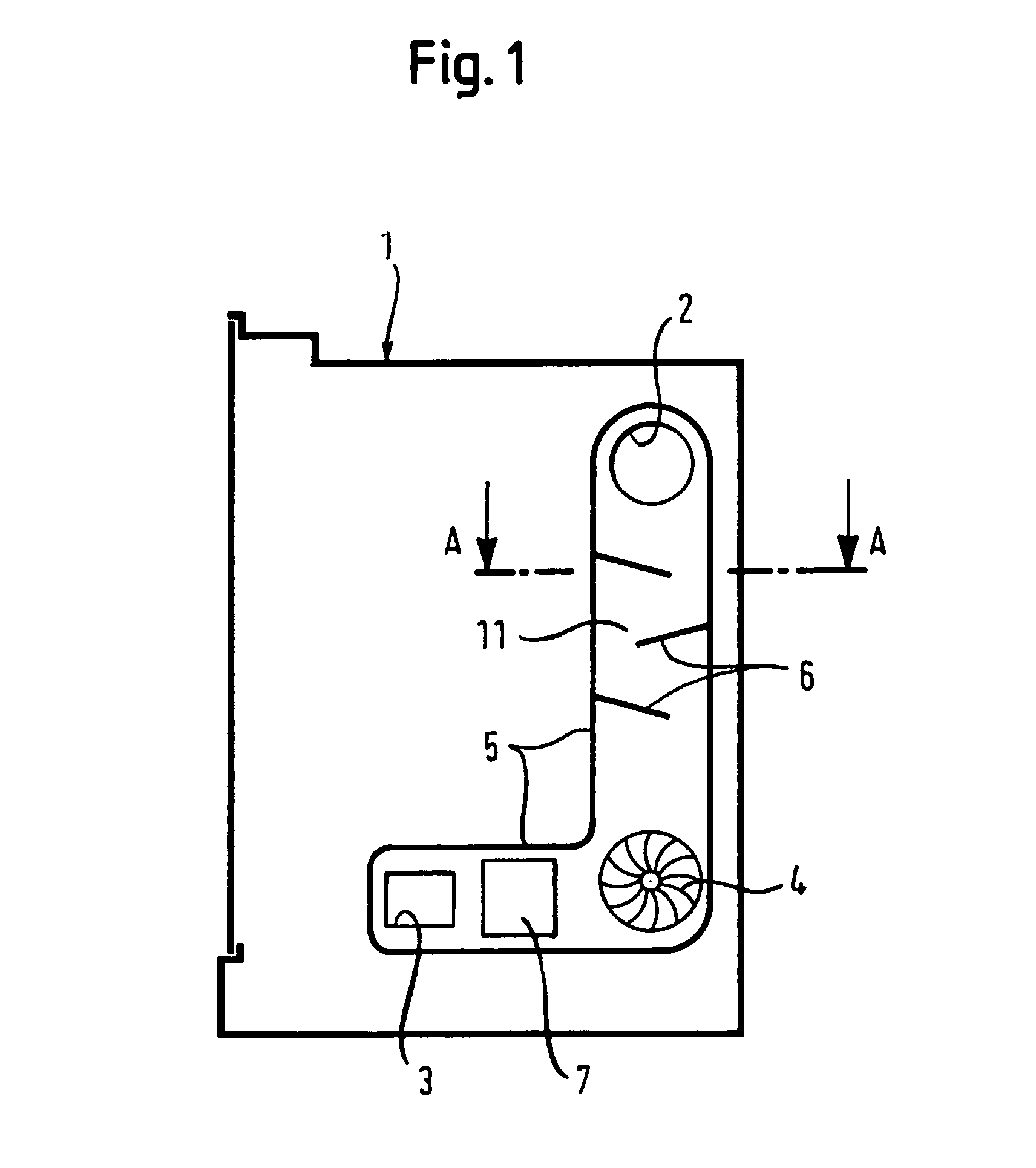

Dishwasher comprising a drying apparatus

ActiveUS8887742B2Good hygroscopicityExpedited drying processTableware washing/rinsing machine detailsCleaning using liquidsAir cycleEngineering

A drying apparatus that allows the wet washed dishes located in the washing container to be dried quickly from an economic and hygienic point of view is provided. The drying apparatus for drying washed dishes is disposed inside a dishwasher and circulates exclusively the air located in a washing container of the dishwasher. The drying apparatus is provided with a suction port for introducing the air from the washing container into the drying apparatus, a blow-out port for discharging the air from the drying apparatus into the washing container, a conveying section between the suction port and the blow-out port, and a fan for conveying the air from the suction port to the blow-out port via the conveying section with the conveying section having a condensing section with at least one wall operable as a condensing surface upon which the humidity contained in the air condenses.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

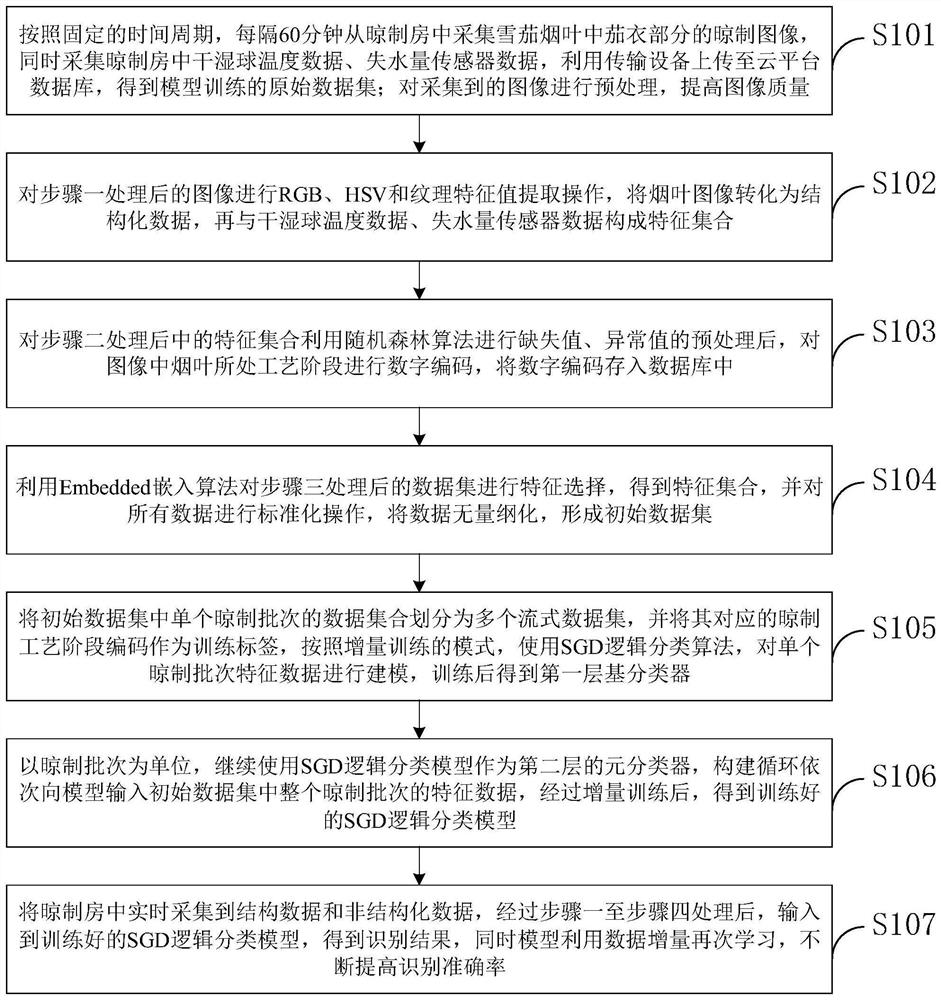

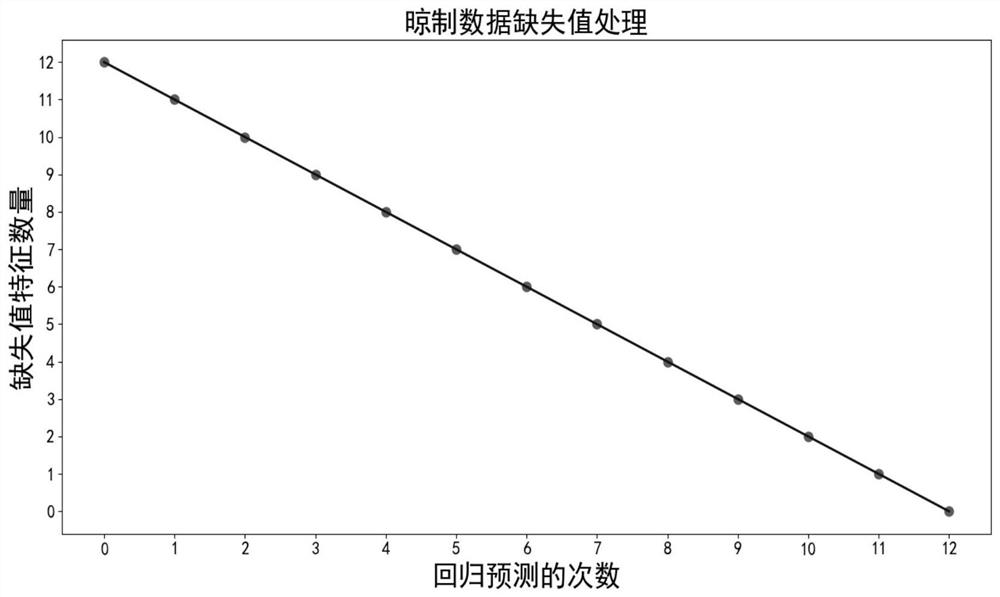

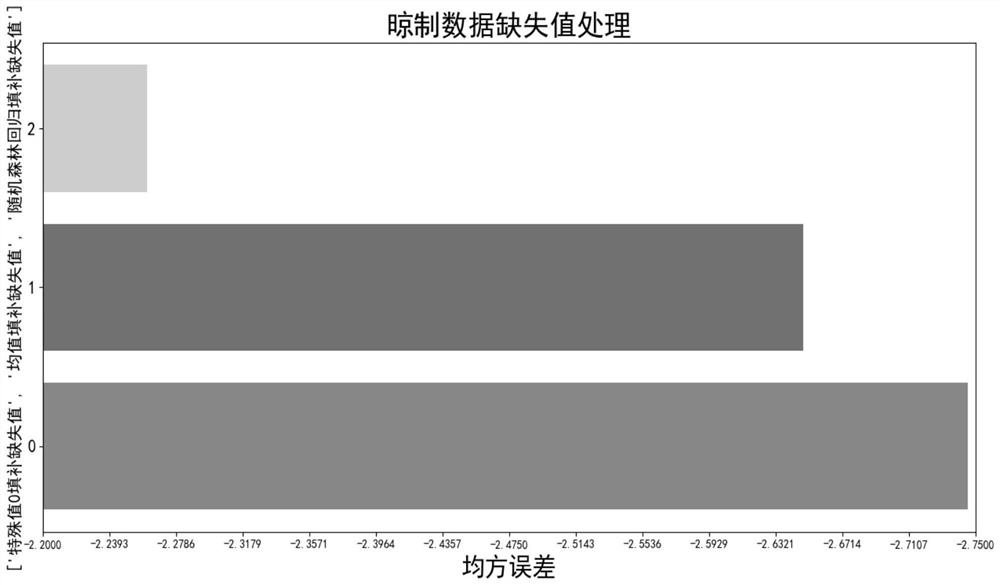

Cigar tobacco leaf air-curing process stage identification method based on incremental learning

PendingCN114359697AImprove training efficiencySolve the noise problemCharacter and pattern recognitionEngineeringIncremental learning

The invention belongs to the technical field of tobacco leaf air-curing, discloses a cigar tobacco leaf air-curing process stage identification method based on incremental learning, and provides a fusion model for identifying a tobacco leaf air-curing process stage by adopting an incremental learning mode based on an SGD logic classification algorithm. According to the model, data can be subjected to preprocessing and feature selection in combination with airing data characteristics collected by an airing room, and through an incremental training learning mode, the accuracy of judging the airing process stage is gradually improved, the tobacco airing process is optimized, the working pressure of tobacco growers is relieved, and the economic benefits of tobacco are improved. According to the method, a large amount of effective information is filled for tobacco leaf data features, the subsequent model prediction accuracy is improved, the problem of a large amount of noise in air-curing data is solved, and the model training efficiency is improved; the air-curing process stage is rapidly judged in real time, and meanwhile, the model learns again by utilizing subsequent data increment, so that the tobacco air-curing process is improved, and remote, intelligent and accurate air-curing is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Raw material preparation device of meal replacement powder

InactiveCN112369616ARealize half-cut and complete deliveryAchieve removalFruit stoningFood treatmentNutritive valuesMeal replacement

The invention relates to the field of meal replacement powder, in particular to a raw material preparation device of meal replacement powder. The technical problem is to provide a raw material preparation device of meal replacement powder. According to the technical scheme, the raw material preparation device of meal replacement powder comprises a head and tail removal system, a kernel removal system, a slicing and grinding system and the like, wherein a second collection tank is arranged below one end of the slicing and grinding system. By combining the high nutritional value of apples, the raw material preparation device can be used for designing preparation of apple meal replacement powder, a conventional method for treating apple raw materials, namely directly grinding apples and performing air-drying and powdering, is overcome, the influence of apple kernels on the meal replacement powder is taken into consideration, and the quality of the meal replacement powder is improved; thekernel-removed apples are sliced to accelerate the air-drying treatment of apples, and the situation that the prior art cannot perform kernel removal treatment after head and tail end removal of apples can be changed.

Owner:段梦洒

Tea leaf quantitative drying device

ActiveCN107560369AEvenly heatedImprove drying effectPre-extraction tea treatmentDrying solid materialsAgricultural engineeringMachining

The invention relates to a drying device, in particular to a tea leaf quantitative drying device. The technical effect that the tea leaf quantitative drying device is provided is achieved. In order toachieve the technical effect, the provided tea leaf quantitative drying device comprises a first feeding hopper, a frame, a uniform stirring mechanism, a hose and the like. A mounting base is arranged on the inner right wall of the frame. A drying trough is mounted on the left side of the mounting base. The uniform stirring mechanism is arranged at the top of the mounting base. The first feedinghopper is arranged on the left side of the top of the frame. The top of the drying trough is rotationally connected. A clamping block is arranged on the left side of the bottom of the drying trough. Aclamping groove is formed in the right side of the bottom of the drying trough. The clamping block is matched with the clamping trough. The hose is connected with the left side of the top of the drying trough. The effect of charging tea leaves properly can be achieved, the falling tea leaves are subjected to radiating treatment through cooling blades, subsequent machining is facilitated, the tealeaves can be quantitatively charged into the drying trough each time through the tea leaf quantitative drying device, charging is facilitated, and the drying effect is optimal.

Owner:WU YI STAR TEA IND

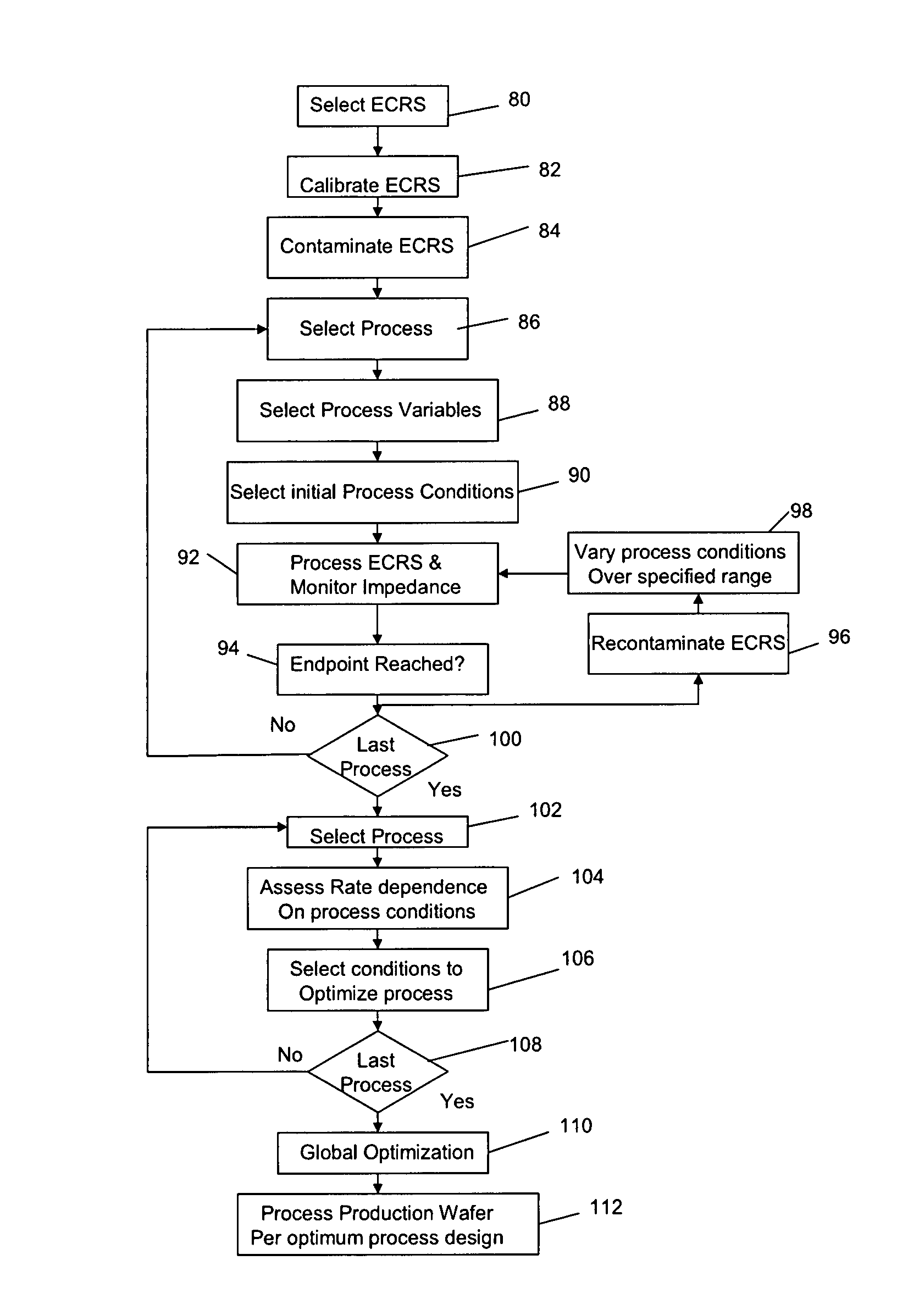

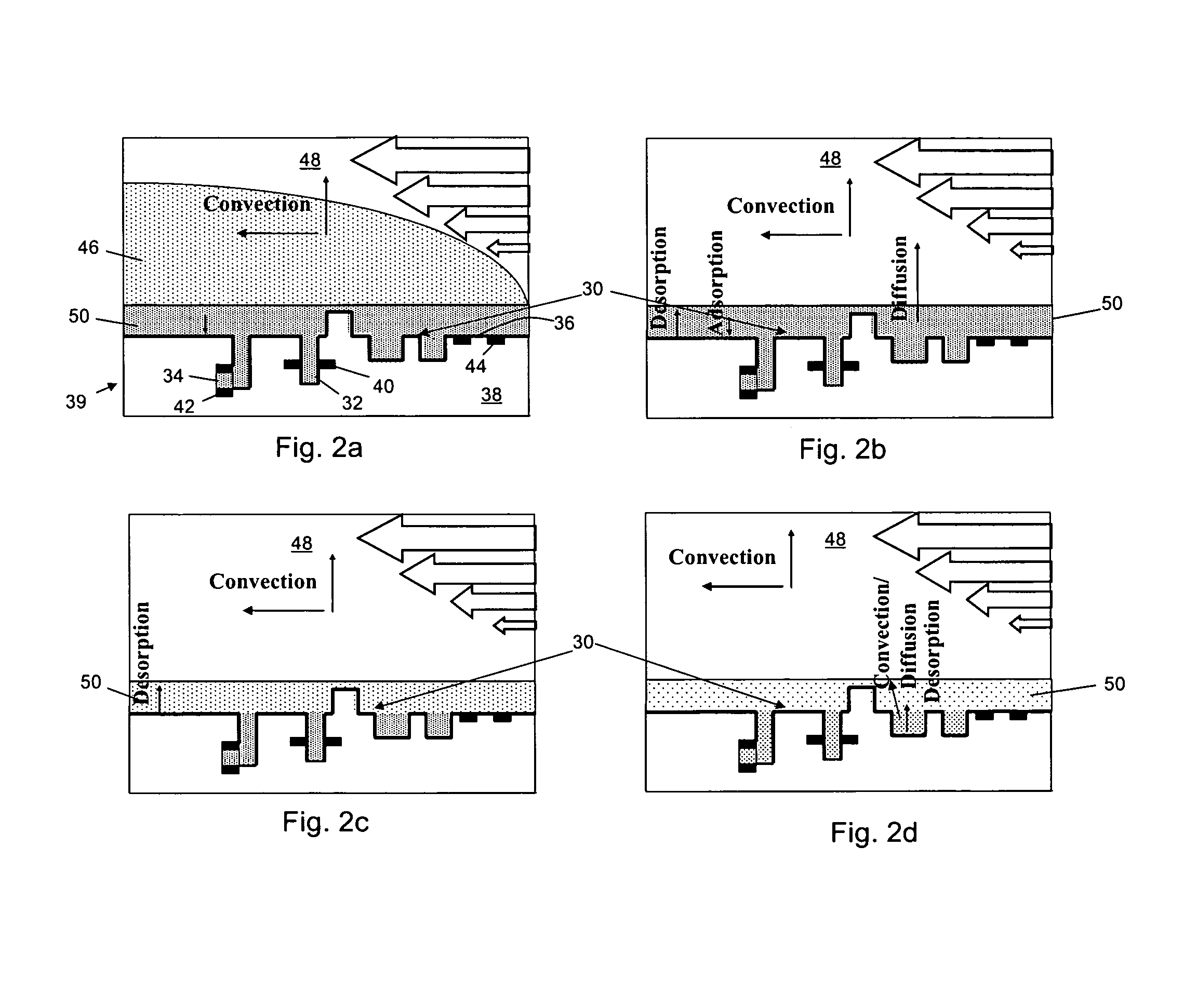

Method of design optimization and monitoring the clean/rinse/dry processes of patterned wafers using an electro-chemical residue sensor (ECRS)

InactiveUS7932726B1Improve cleanlinessAccelerated rinseSemiconductor/solid-state device manufacturingFault locationElectricityMicro devices

A method of improving the clean, rinse and dry processes during the manufacture of ICs, MEMS and other micro-devices to conserve solution and energy while completing the process within a specified time. An electro-chemical residue sensor (ECRS) provides in-situ and real-time measurement of residual contamination on a surface or inside void micro features within the sensor representative of conditions on production wafers. The measured impedance can be used to determine what process variables and specifically how process conditions affect the rate of change of the measured impedance. The in-situ measurements are used to design and optimize a production process and / or to monitor the production run in real-time to control the process conditions and transfer of a patterned wafer through the processes.

Owner:ENVIRONMENTAL METROLOGY CORP

Equal-length cutting equipment for medicine processing based on parallel feeding principle

InactiveCN108326921ARealize equidistant movementGuaranteed equally spaced truncationDrying gas arrangementsMetal working apparatusEngineeringCircular disc

The invention provides equal-length cutting equipment for medicine processing based on a parallel feeding principle. The equal-length cutting equipment comprises a shell, wherein an opening is formedin the right side wall of the shell, a parallel feeding device is arranged at the opening part, and the left part of the parallel feeding device penetrates through the opening and enters the shell; acutting device is arranged in the shell; the lower side of the cutting device is provided with a guide plate, the guide plate is obliquely arranged towards the left lower part, and a drying device isarranged below the guide plate; and the drying device comprises an oblique plate. The equal-length cutting equipment has the beneficial effects that first, a moving plate is driven to make circular path movement by a disc through a support column; when one pushing plate acts on a baffle, the baffle is driven to move towards the left side for a certain length, the pushing plate is then separated from the baffle, the next pushing plate acts on the baffle, and the baffle is driven to move leftwards; and through repeated operation in this way, the equal-distance movement of a mounting plate can berealized, and the equal-length cutting of medicines can be ensured.

Owner:葛润生

Rock sample drying apparatus and its drying box structure

ActiveCN1936534ASignificant advantagesSignificant beneficial effectPreparing sample for investigationDrying machines with non-progressive movementsEngineeringDry box

This invention relates to a rock drying device including a drying box and a hot air device feeding hot air to the drying box via a high-temperature insulation feeding pipeline, in which, the drying box is composed of a box with heat-preservation layer and a drawer set of column layers in the box with gaps between the drawer set and the box for gas flow passing through and gaps are remained among layers of the drawers for gas flow passing through, a hot air inlet is set at the middle of the bottom of the drawers, the hot air device is set in a frame formed by a fan driven by a blowout motor connected with a heater meeting the preset heating temperature, said heater is connected with the box by the high temperature pipeline and the box, an intake pipeline is connected with the fan.

Owner:天津开发区利达科技发展有限公司

Intelligent household clothes fast environment-friendly drying device

ActiveCN109853202AEasy to handleQuick drying processTextiles and paperLaundry driersTemperature controlPulp and paper industry

The invention relates to the field of intelligent household equipment, in particular to an intelligent household clothes fast environment-friendly drying device. The device comprises a machine body, amounting plate is arranged on the lower portion of the inner side of the machine body, and a plurality of supporting springs are arranged on the outer ring of the bottom of the mounting plate; a double-axial-extension motor is fixedly arranged in the middle of the bottom of the mounting plate, and an output shaft at the upper side of the double-axial-extension motor is connected with a central pipe; a plurality of clothes hanging pipes are arranged on the upper portion of the center pipe in the circumferential direction, and an air inlet cylinder is further arranged at the top of the machinebody; the top of the air inlet cylinder is provided with a temperature control air heater, and an air inlet of the temperature control air heater is connected with a circulating pipe; the other end ofthe circulating pipe is communicated with an annular pipe, and a plurality of branch air pipes are arranged on the inner side of the annular pipe in the circumferential direction; an air inlet pipe is arranged at the bottom of the air inlet cylinder, and the lower end of the air inlet pipe is connected with the central pipe through an elastic corrugated pipe. The device is novel in structural design, good in clothes drying treatment effect, high in efficiency, capable of saving energy, environmentally friendly and beneficial to popularization.

Owner:孙雪东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com