Method for drying wood and an apparatus for the implementation thereof

A wood drying technology, which is applied in the direction of wood drying, drying gas arrangement, and drying of solid materials without heating, can solve the problems of poor wood drying quality, uneven length, energy consumption, etc., to strengthen wood drying treatment and improve vacuum Build rate and vacuum degree, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

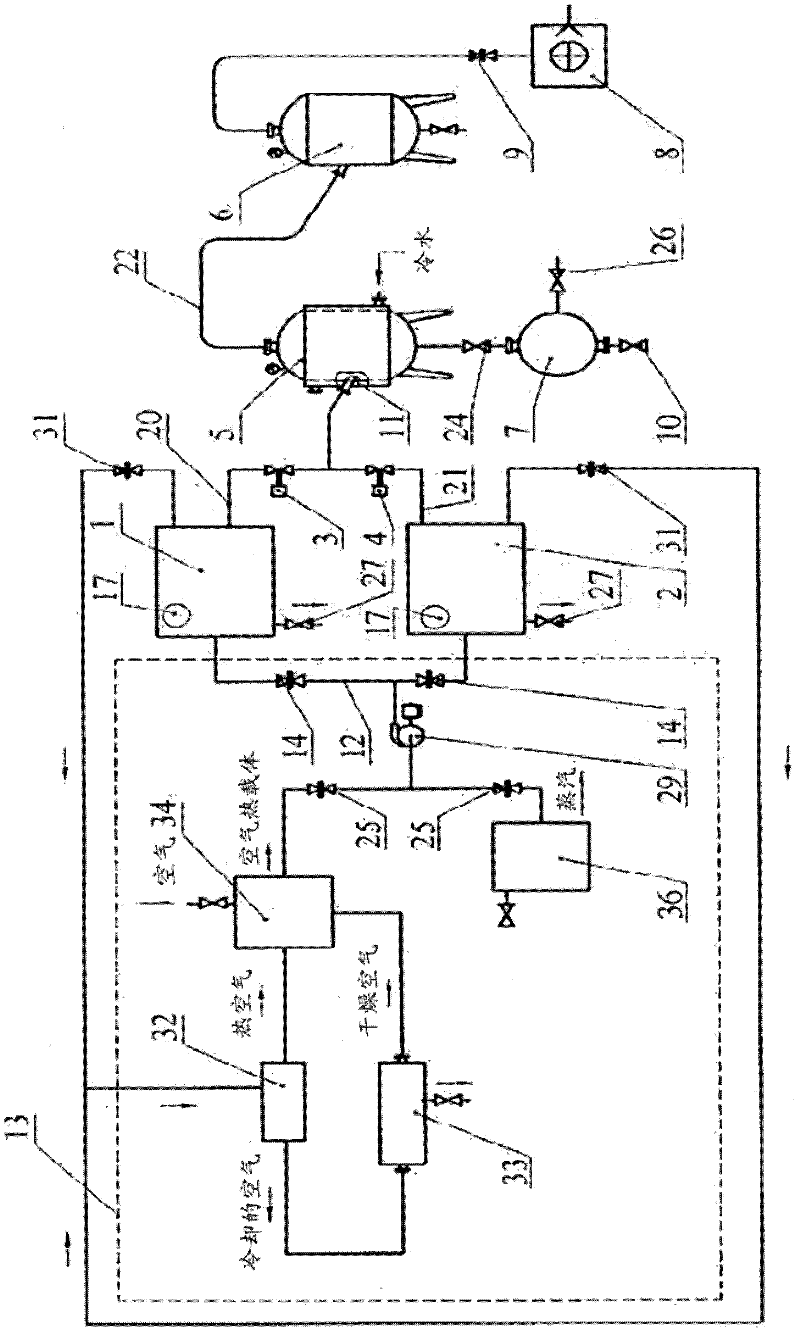

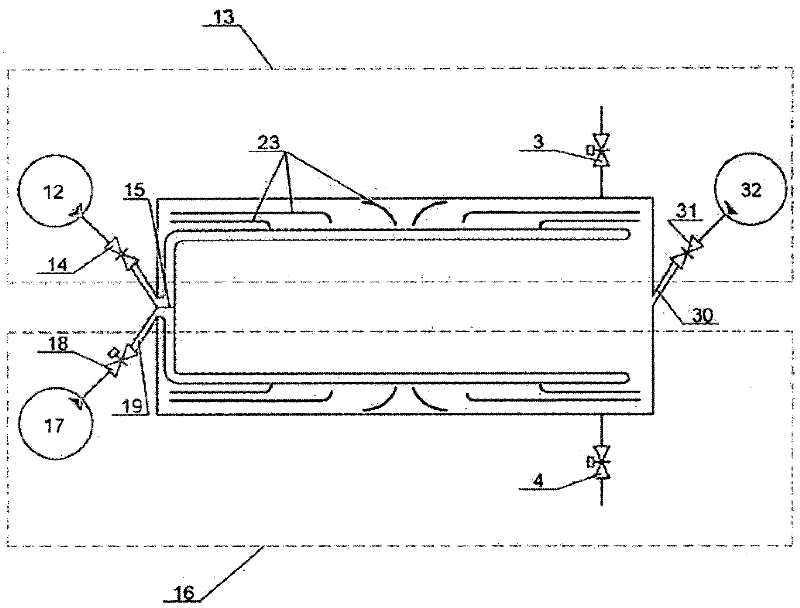

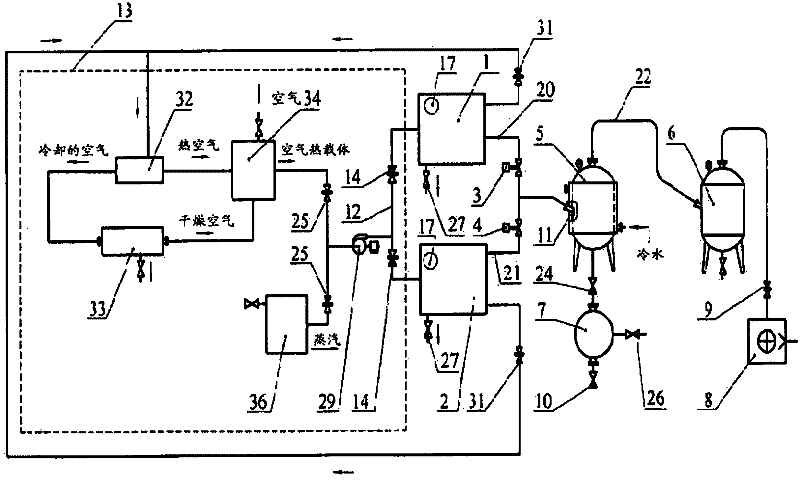

[0049] The block arrangement of the device and the arrangement of the elements of the drying chamber comprise a drying chamber 1 , 2 connected to a cooled vacuum receiver 5 via lines 20 , 21 and quick response valves 3 , 4 . At the inlet of the receiver 5, a helical guiding means 11 is installed. The receiver 5 is connected in series to the second vacuum receiver 6 and the vacuum pump 8 through a line 22 and a vacuum lock 9 , and the receiver 5 is connected to the air lock chamber 7 through a line and a connection valve 24 . The air lock chamber 7 is equipped with a drain cock 10 and a vent cock 26 . The drying chambers 1 , 2 are connected to a heating medium supply line 12 . The heating medium supply line is connected to a system 13 for heating medium preparation, said system 13 comprising: a steam generator or boiler room for supplying steam at a pressure of not more than 0.07MPa gauge at 100°C to 115°C; and a gas generator 34 for preparing heat recovery air to a preset te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com