Manufacturing method and device of heat-sealed type grid tea leaf and coffee filter paper

A heat-sealing and grid technology, which is applied in the papermaking industry, can solve the problems of unresolved filter paper, increase quantitative and other problems, and achieve the effects of high air permeability, fast leaching speed, and good heat-sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] Example.

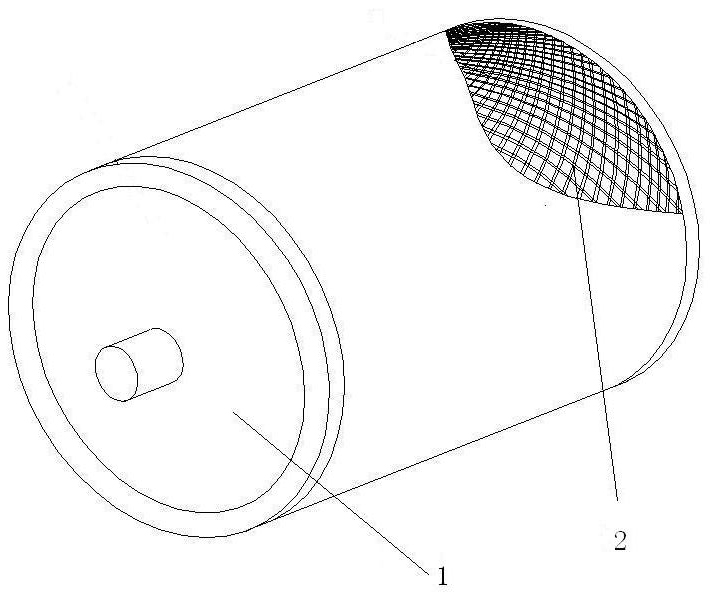

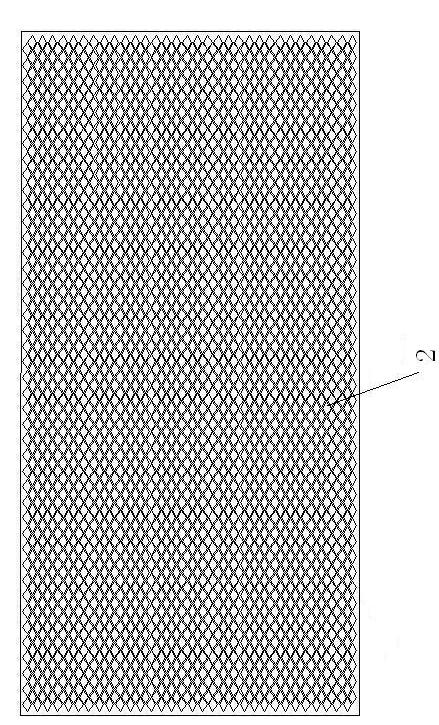

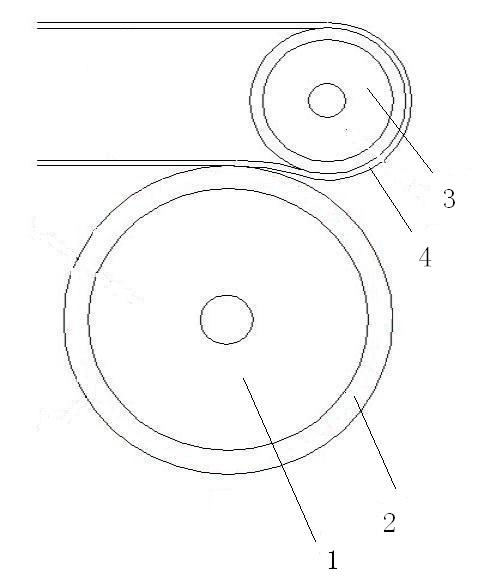

[0026] Such as Figure 1-Figure 4 As shown, the grid device of the cylinder former of the paper machine includes a cylinder cage 1 , a grid forming wire 2 , a couch roll 3 , a mesh felt 4 , a cleaning drum 5 and a frame 6 .

[0027] The cleaning cylinder 5 is fixed on the frame 6 by bolts, and clear water is placed in the cleaning cylinder 5, which can wash the cylinder cage 1 and the grid forming net 2 to reduce dust and impurities on the grid forming net 2 and improve product quality. Offer hole on the cleaning cylinder 5, the rotary mesh cage 1 is installed in the hole, and the bottom of the rotary mesh cage 1 is soaked in water. When the rotary screen cage 1 rotates, the part of the rotary sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com