Intelligent shoe sole drying production system and production technology thereof

A technology of production system and production process, which is applied in the field of intelligent shoe sole drying production system and its production process, can solve the problems of hard, insufficient and occupied working environment, and achieve more uniform and sufficient drying treatment and good drying The effect of processing operations, saving occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

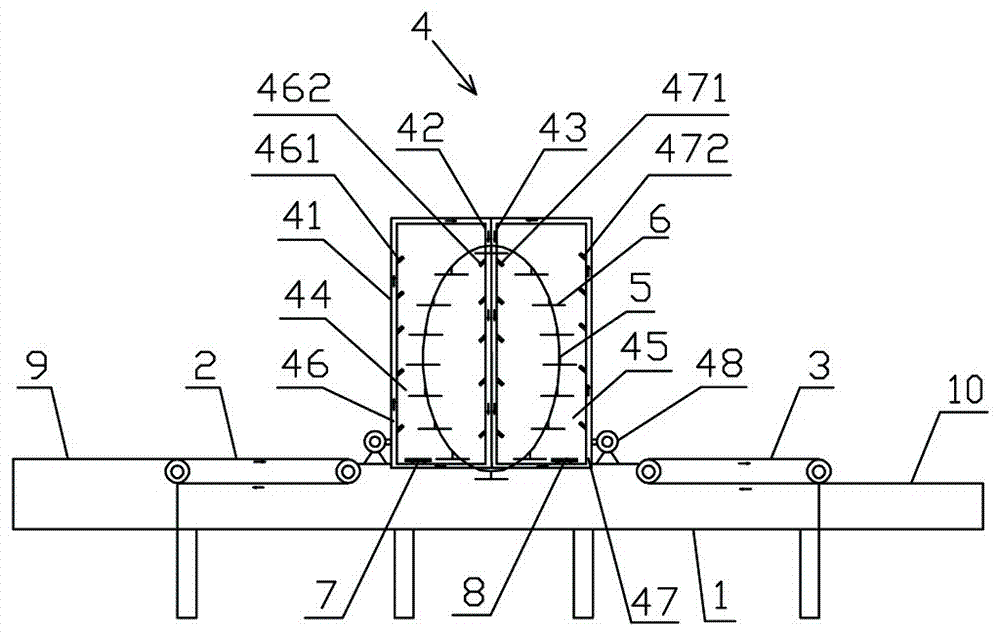

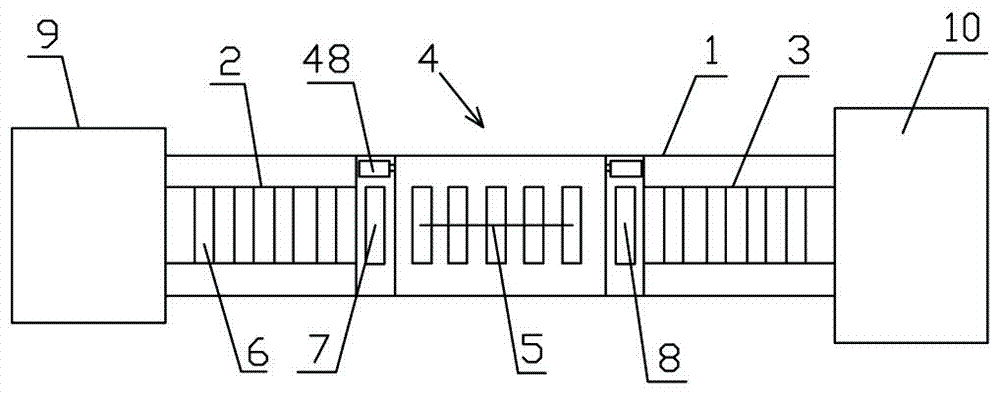

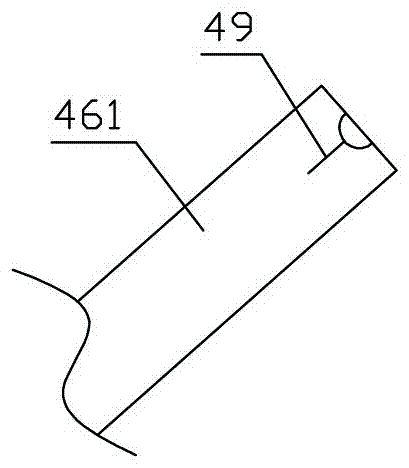

[0027] Such as figure 1 , figure 2 and image 3 As shown, an intelligent shoe sole drying production system includes a console 1, the left and right sides of the console 1 are respectively provided with a first conveyor chain 2 and a second conveyor chain 3, the first and second The conveying chains (2, 3) are conveyed and arranged along the horizontal direction respectively, and the conveying directions of them (2, 3) are the same. The middle part of the operating table 1 is provided with a drying mechanism 4, and the drying mechanism 4 is provided with a third conveying chain 5 arranged along the up and down direction, and the first, second and third conveying chains (2 , 3, 5) are respectively detachably fitted with a number of delivery carriers 6 for transporting shoe soles; the operating table 1 on both sides of the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com