Rotary drying device suitable for high moisture material

A rotary, high-moisture technology, applied in dryers, non-progressive dryers, drying and other directions, can solve problems such as inability to dry operations, shorten processing cycles, reduce energy consumption and operating costs, and avoid two The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0017] In the embodiment of the present invention, a high-moisture rotary dryer with a cylinder body length of 22 m and a diameter of 3 m is taken as an example.

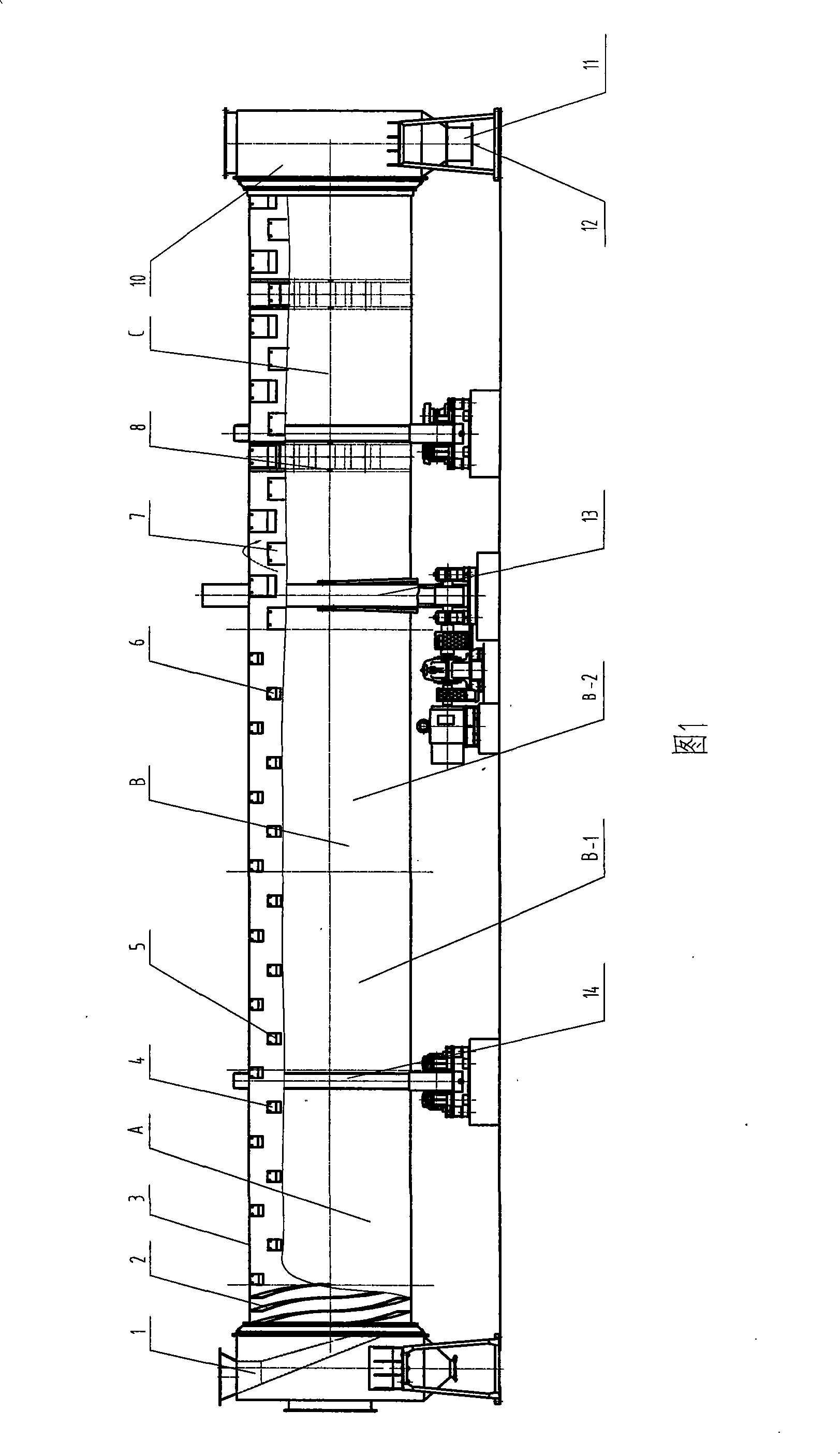

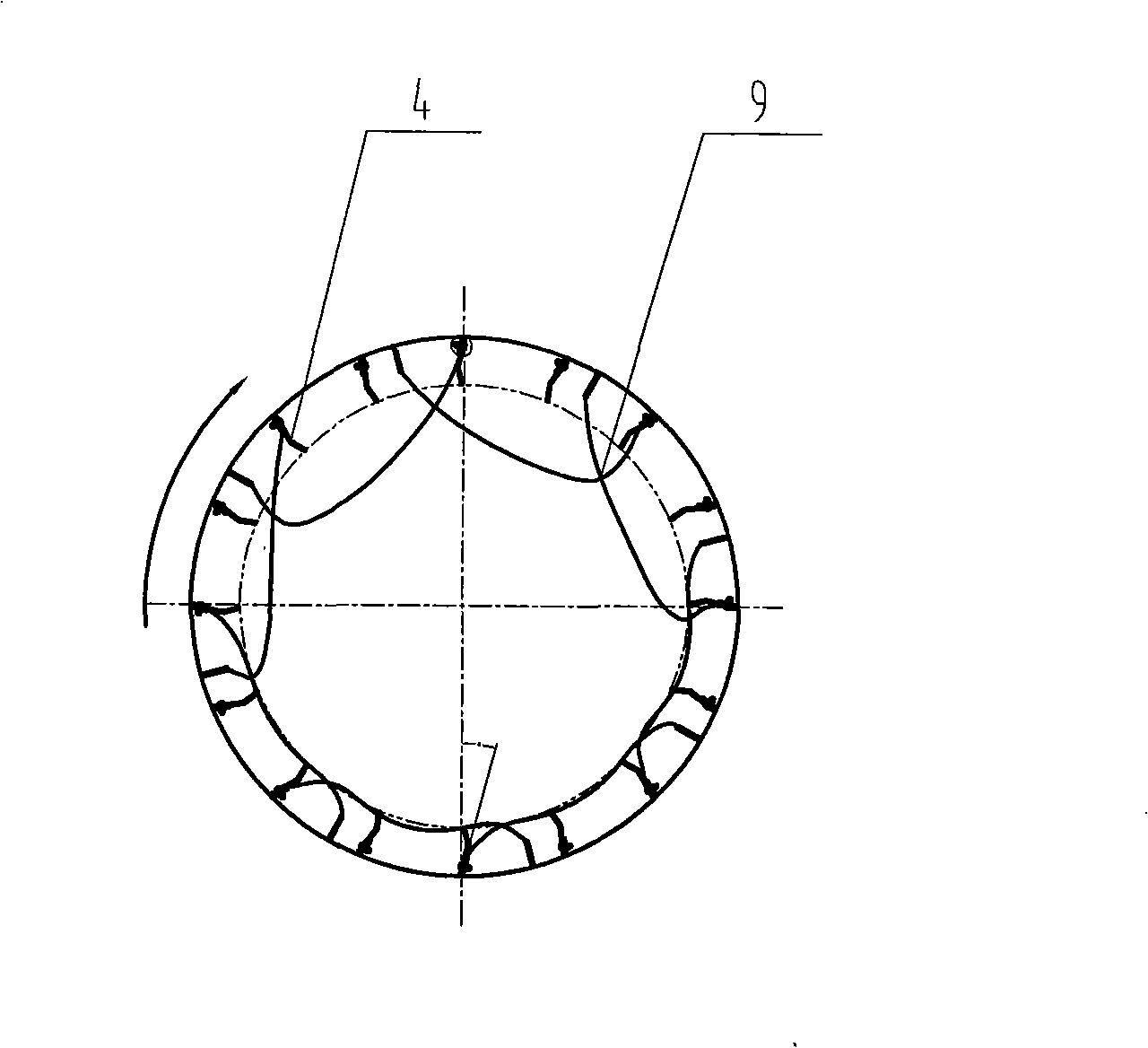

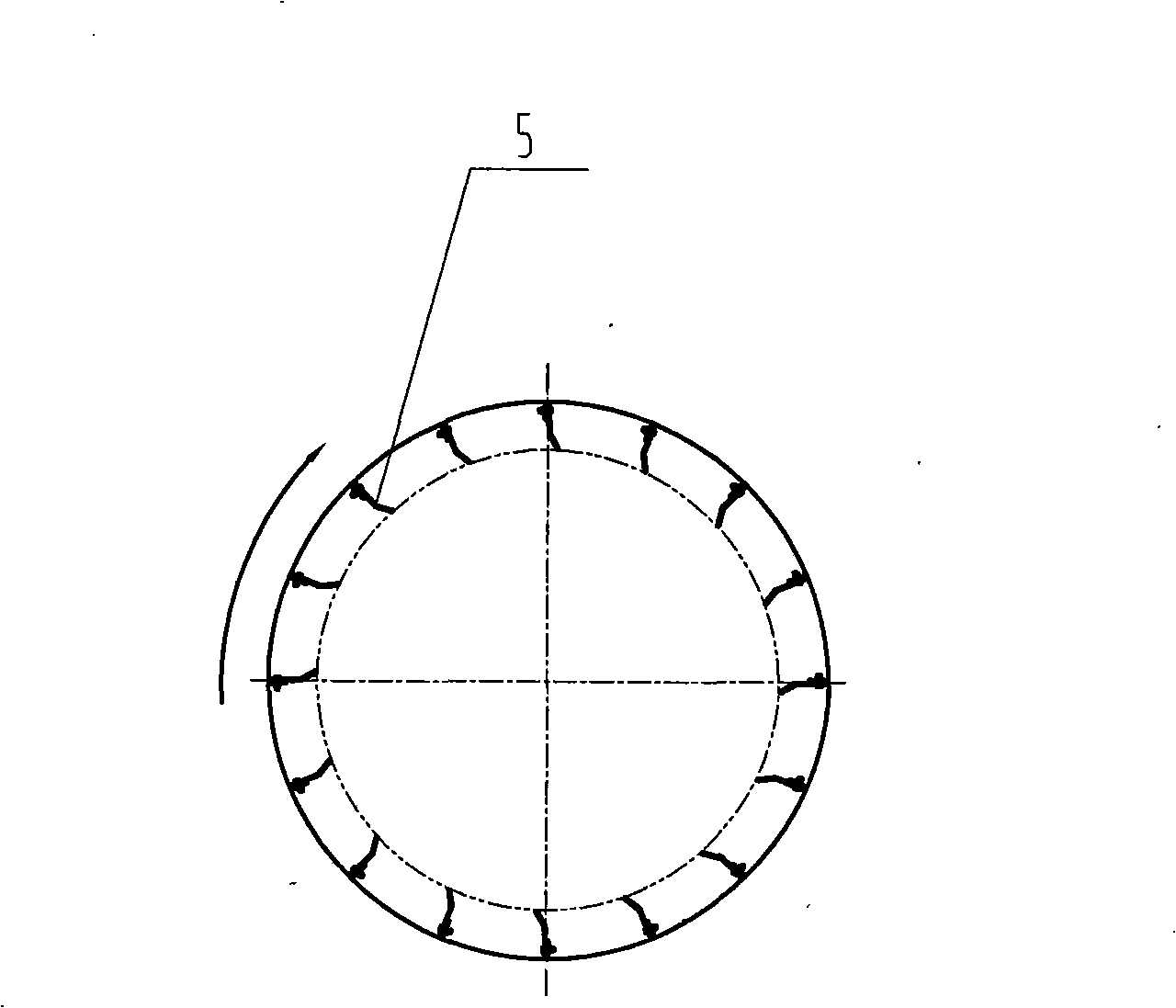

[0018] The high-moisture rotary dryer described in the embodiment of the present invention includes a cylinder body 3, a transmission device 13, and a supporting roller device 14; At an angle of 3°, the rotary power of the cylinder body 3 is provided by the transmission device 13 . A feed port 1 and a feed screw 2 are provided at the head end of the cylinder body 3 , and a discharge port 12 , a discharge valve 11 and a discharge cover 10 are provided at the tail end. The inner cavity of the cylinder body 3 is sequentially divided into a 3.1m long preheating zone A, a 10.5m long drying zone B and a 6.5m long drying zone C from the beginning to the end (that is, the feed end to the discharge en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com