Treatment system for boiler feedwater

A technology of treatment system and make-up water, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Unfavorable environmental protection and other problems, to achieve the effect of reducing chemical self-water consumption and industrial wastewater production, reducing floor space and equipment investment, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

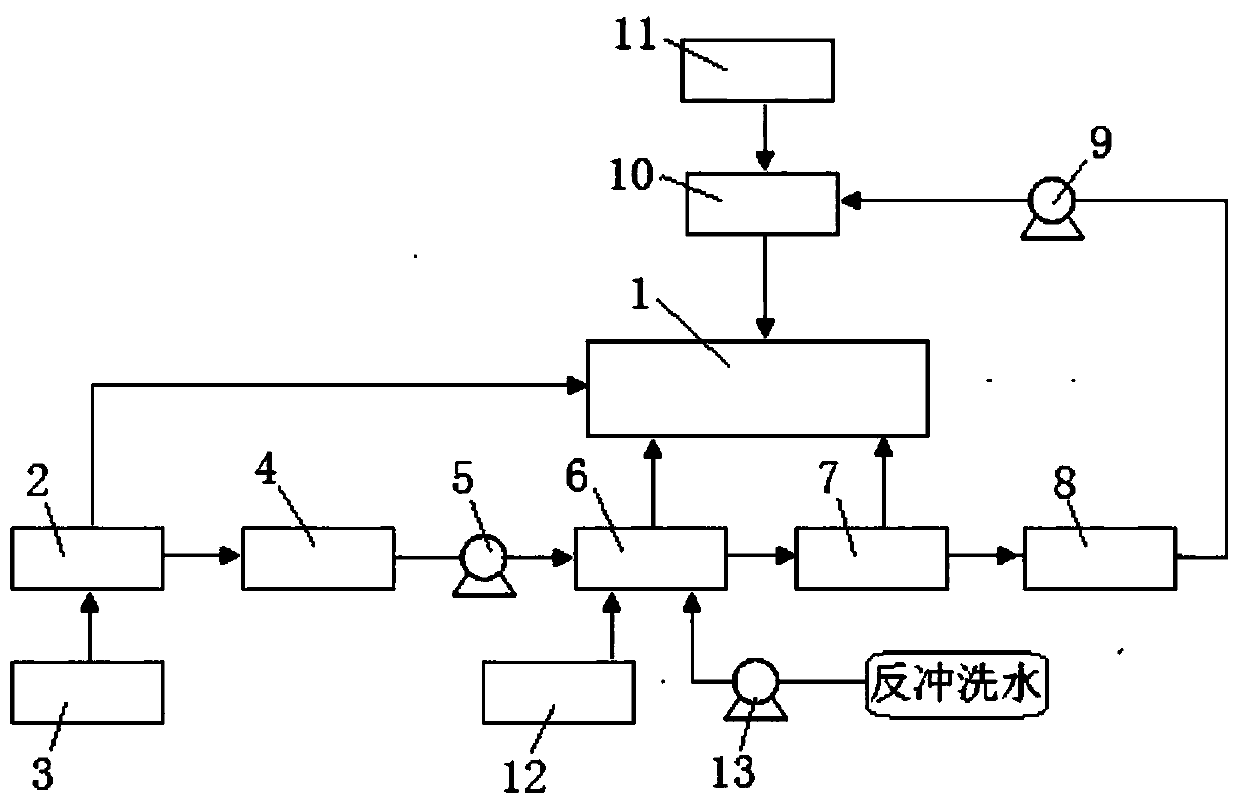

[0012] The present invention is used for the treatment system of boiler make-up water such as figure 1 As shown, it includes industrial wastewater discharge pool 1, coagulation clarification tank 2, coagulation storage and dosing equipment 3, No. 1 water tank 4, filter 6, electric adsorption equipment 7, No. 2 water tank 8, backwash water pipeline, empty A press 12, a backwash water pump 13, a desalination unit 10 and a control unit. The coagulation storage and dosing equipment 3 is connected to the coagulation and clarification tank 2, the coagulation and clarification tank 2 is connected to the No. 1 water tank 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com