Preparation method of nanometer iron-based soft magnetic block

A nano-iron and soft magnetic technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of limited product composition, poor adaptability of flux, low strength, etc., and achieve clear interlayer interface characteristics and organization The effect of compact structure and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

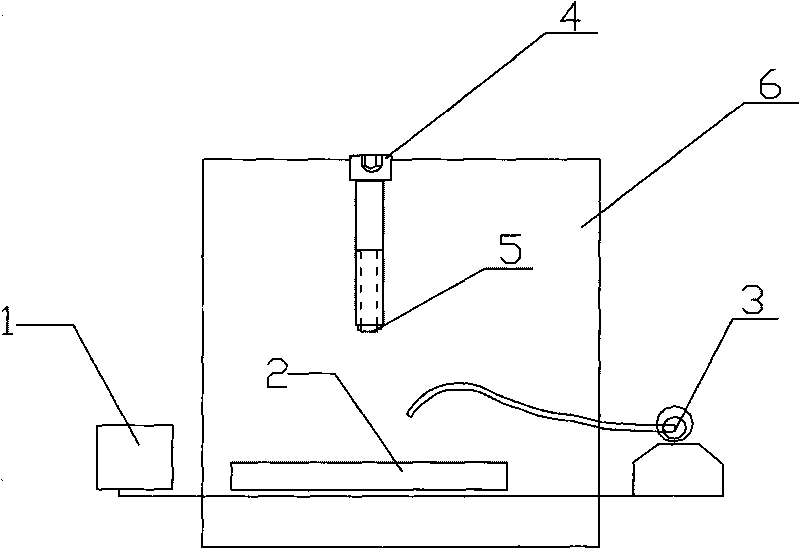

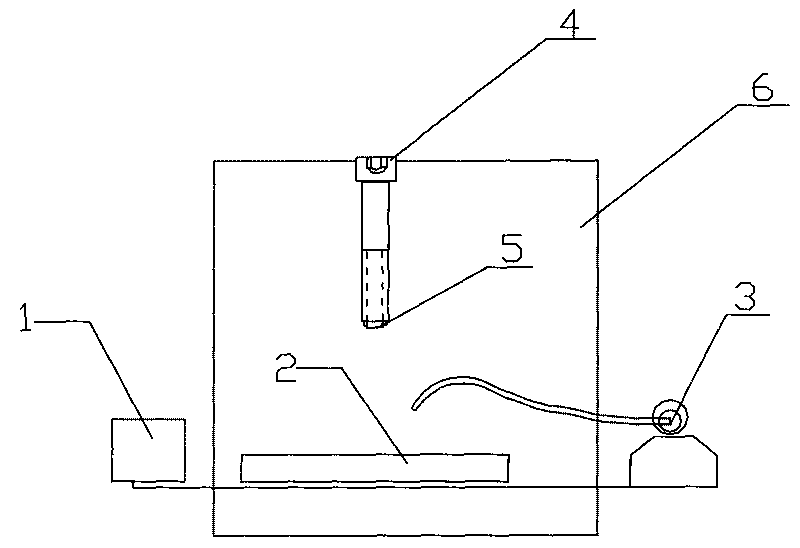

[0034]Take Fe, Si, B, Cu, Nd elements, according to the weight ratio of 0.735:0.135:0.09:0.01:0.03, use the mechanized alloy method to make nano powder, the powder diameter is 30-50nm; use PRO-E to make a three-dimensional ring image, the section It is a rectangle, the size of the ring is 200mm, and the size of the rectangle is 50mm×50mm. Then the process parameters are decomposed through the interface software, and the control information and powder are sent to the laser processing platform 2, and the thickness of the powder layer is 0.1 mm. Under the signal control of the computer 1, the feeder 3 and the laser 4 work together to feed and sinter layer by layer in an orderly manner until the shape of the nano-iron-based soft magnetic block to be prepared is fired. 1KW CO2 fast axial flow laser working parameters: spot diameter d=1mm, focal length l=120mm, beam mode TEM00. The laser scanning speed is 10mm / s, the laser power is 100W, and the scanning interval is 0.6mm.

Embodiment 2

[0036] According to the preparation method of laser sintering rapid prototyping materials disclosed in the patent [200510020015.5], firstly, the phenolic resin or epoxy resin used as the binder is crushed to within 50 μm; then the metal Fe, Si, B, Cu, The Nd element is added into the ball mill according to the weight ratio of 0.735:0.135:0.09:0.01:0.03 and the pulverized binder, and mixed evenly; the alloy powder is taken out and sent to the high-energy ball mill for pulverization, so that the diameter of the powder is 30-50nm. Make a three-dimensional ring image through AutoCAD, the section is rectangular, the size of the ring is 5mm, and the size of the rectangle is 3mm×3mm. Then the process parameters are decomposed through the interface software, and the control information and powder are sent to the laser processing platform 2, and the thickness of the powder layer is 0.4mm. Under the signal control of the computer 1, the feeder 3 and the laser 4 work together to feed and...

Embodiment 3

[0038] According to the preparation method of laser sintering rapid prototyping materials disclosed in the patent [200510020015.5], firstly, the phenolic resin or epoxy resin used as the binder is crushed to within 50 μm; then the metal Fe, Co, Mo, Dy, The element B is put into a high-energy ball mill for crushing with the pulverized binder in a weight ratio of 0.63:0.095:0.02:0.005:0.25, so that the diameter of the powder is 30-50nm. Make a three-dimensional hollow frame image by software, the section is rectangular, the frame size is 100mm×100mm, and the rectangle size is 30mm×30mm. After the process parameters are decomposed by the interface software, the control information is generated and sent to the laser processing platform 2 together with the powder, and the thickness of the powder layer is 0.5mm. Under the signal control of the computer 1, the feeder 3 and the laser 4 work together to feed and sinter layer by layer in an orderly manner until the shape of the nano-iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com