Patents

Literature

184results about How to "Many problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

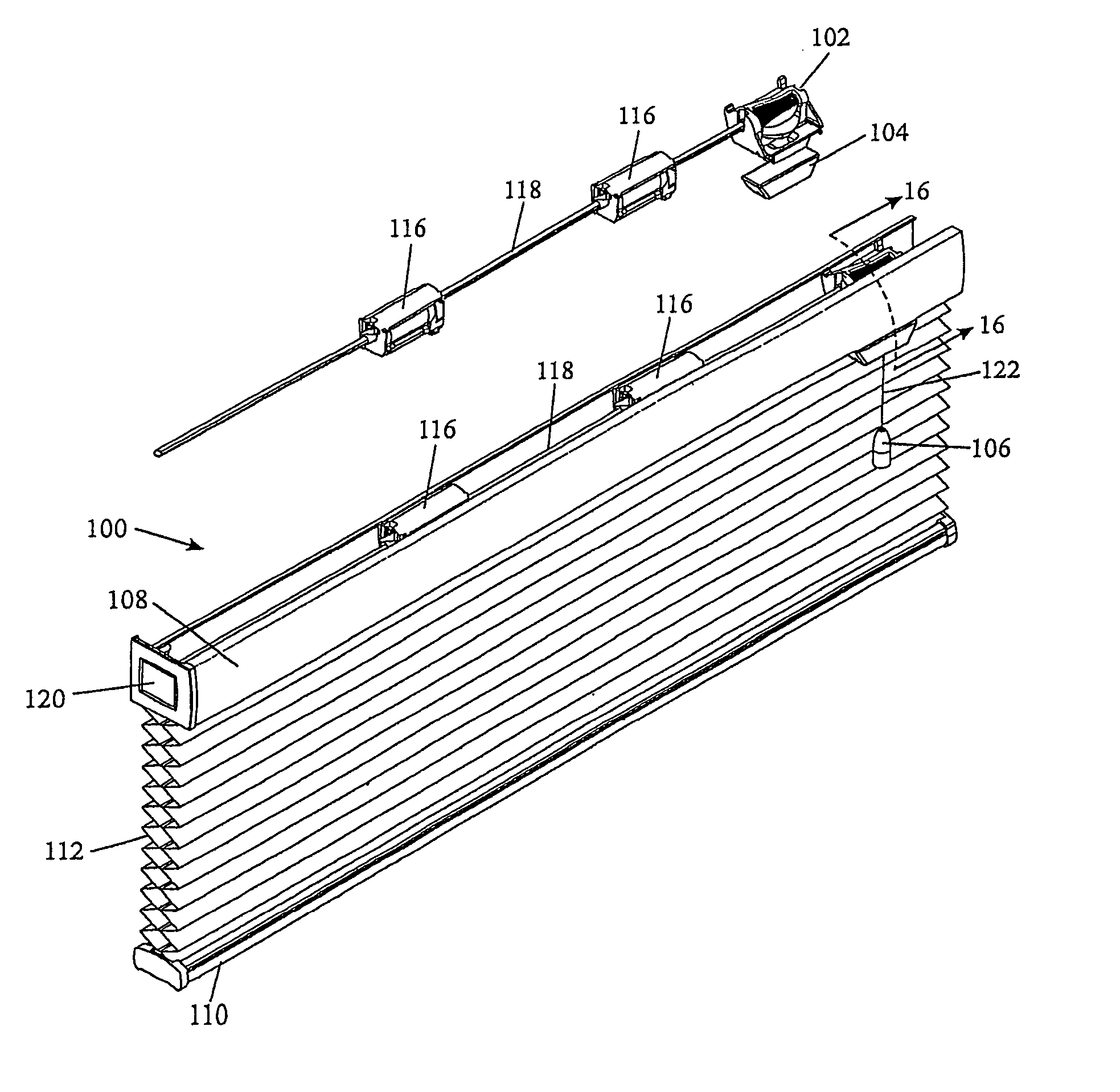

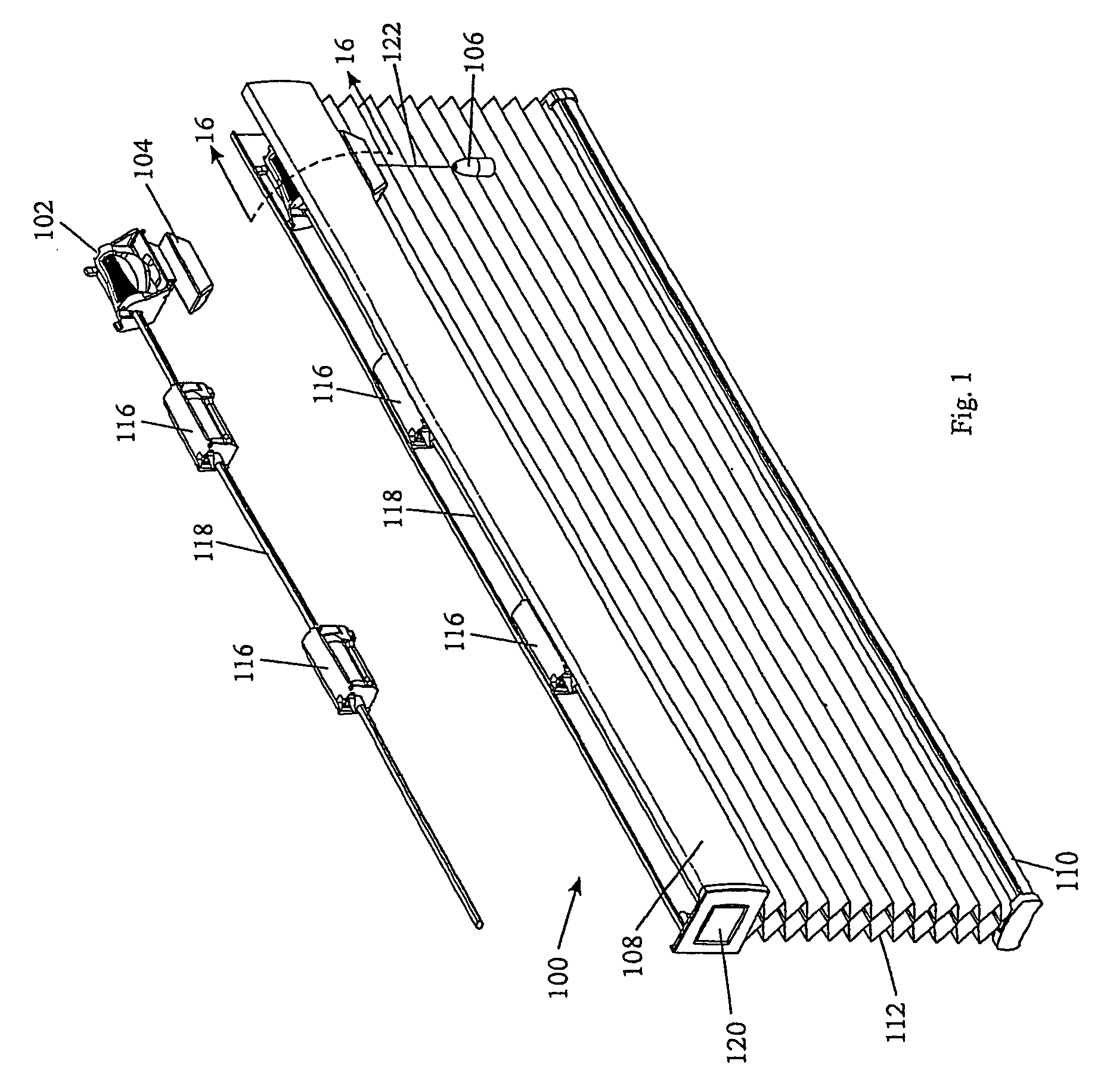

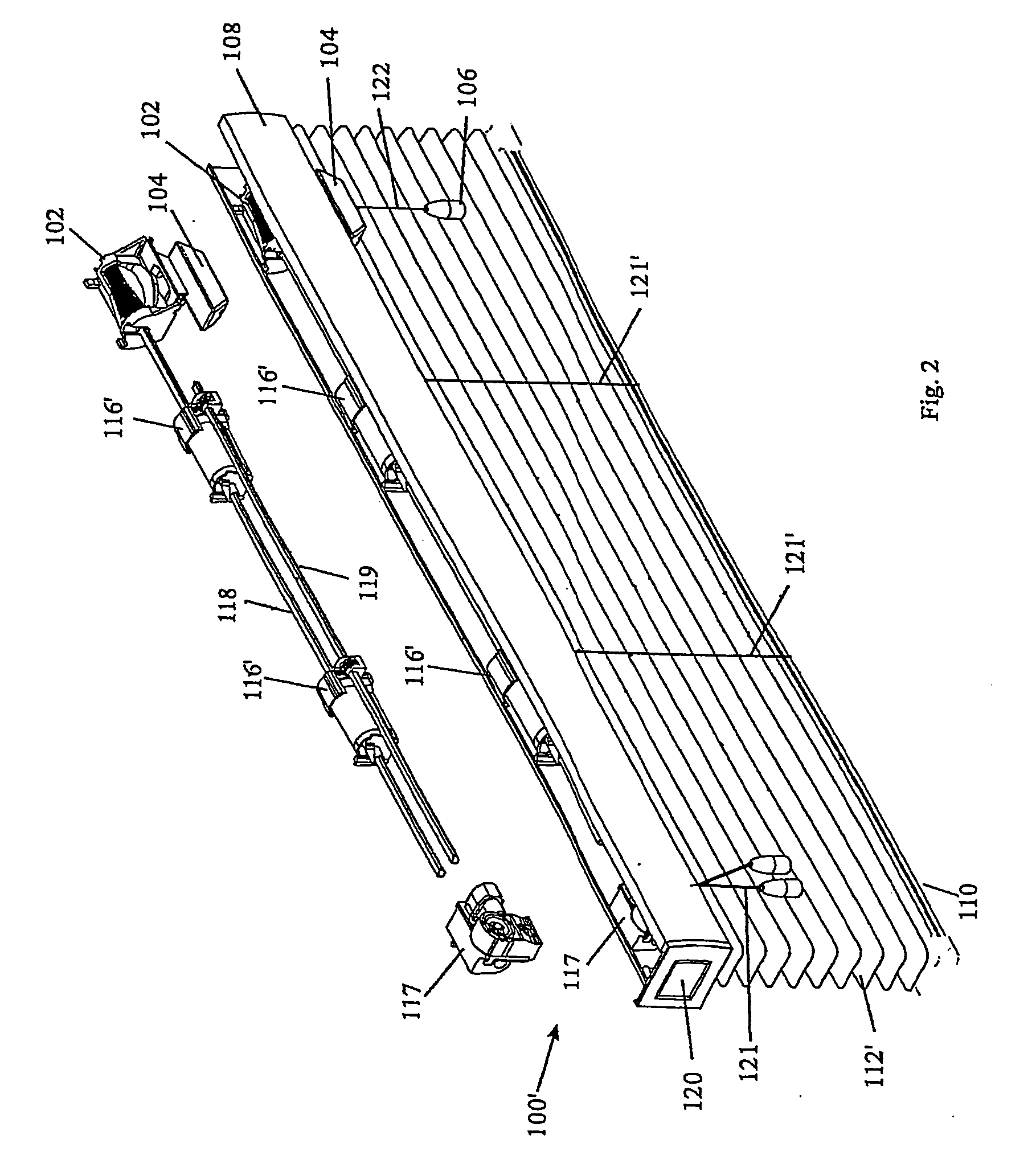

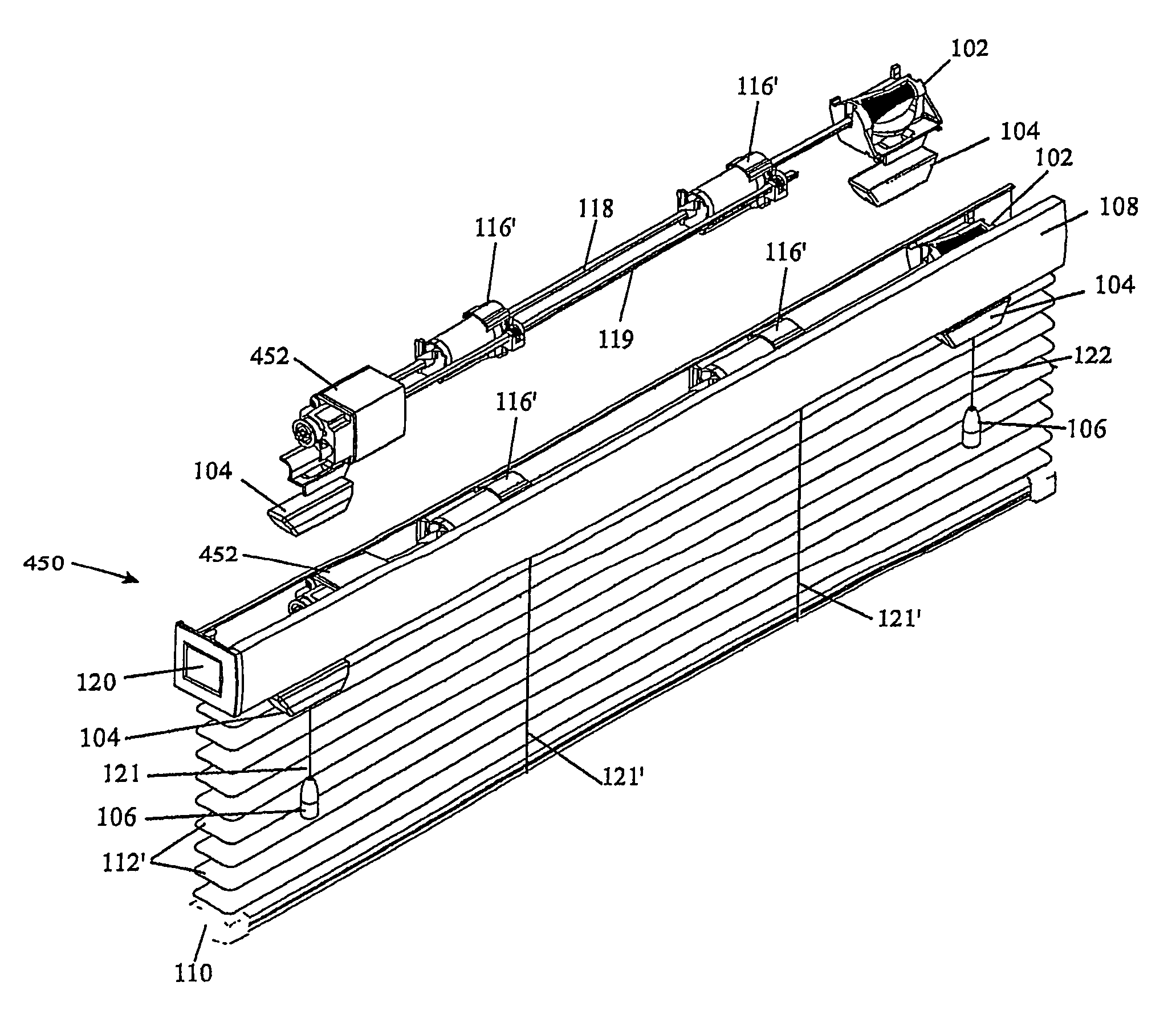

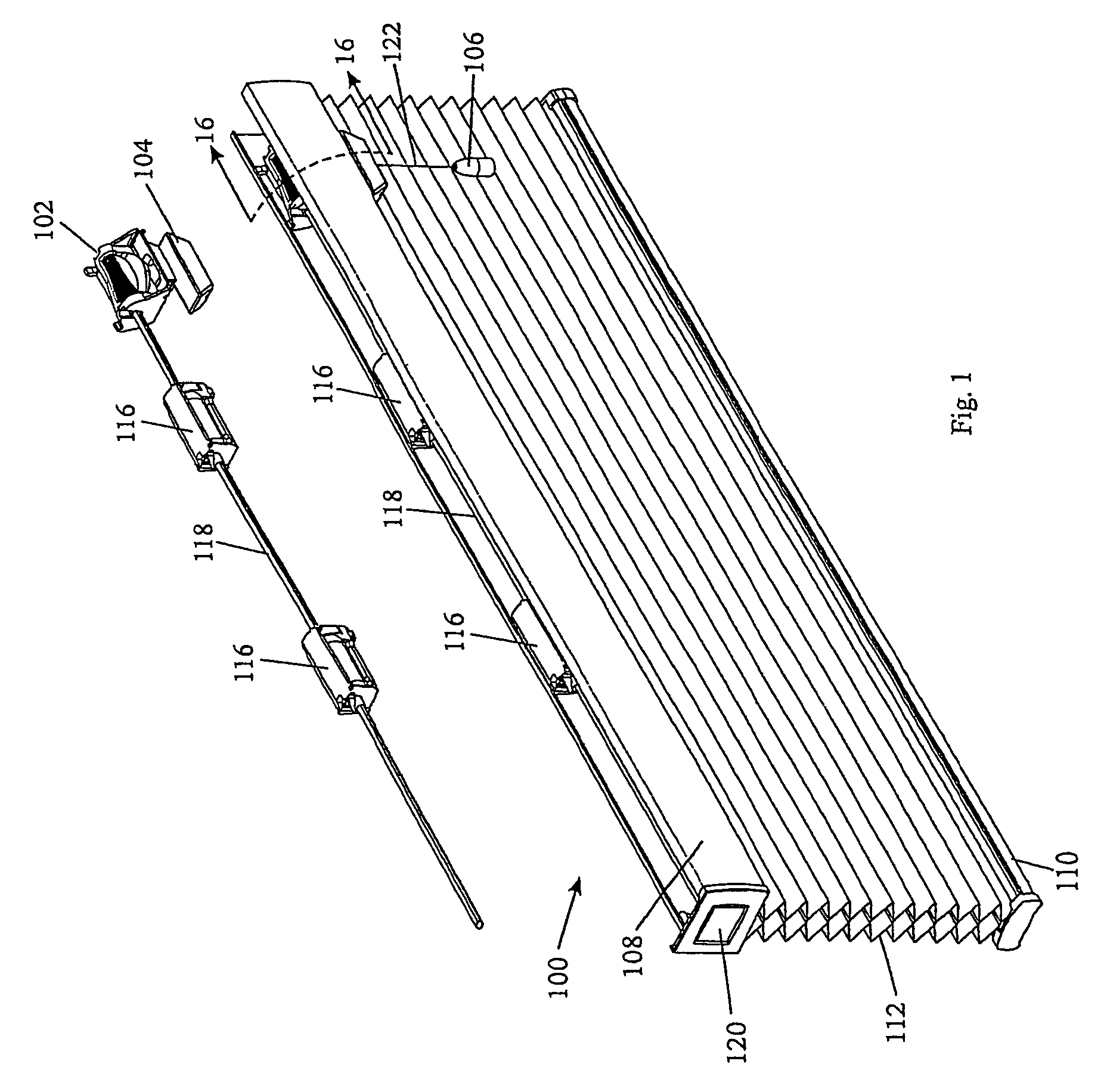

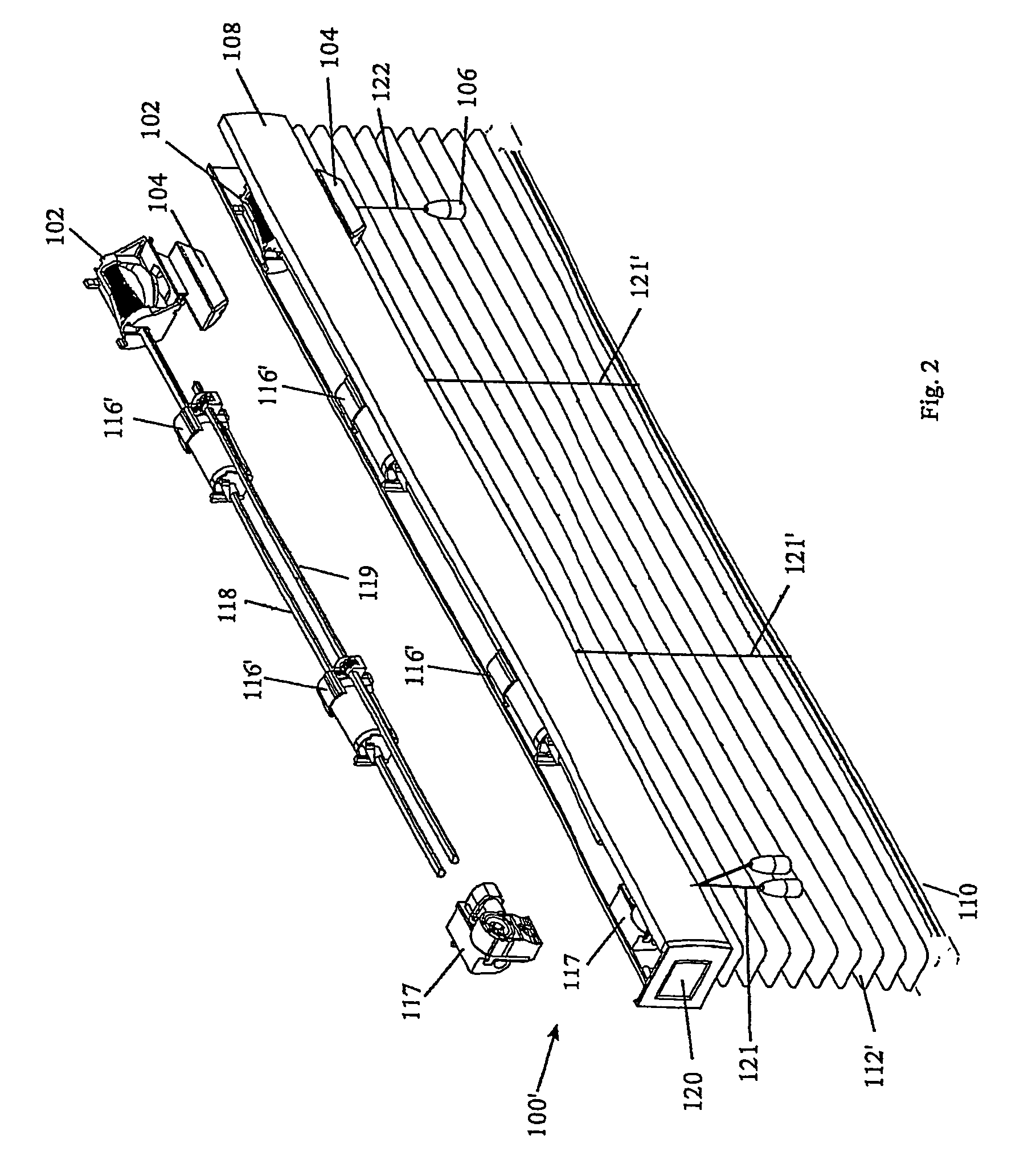

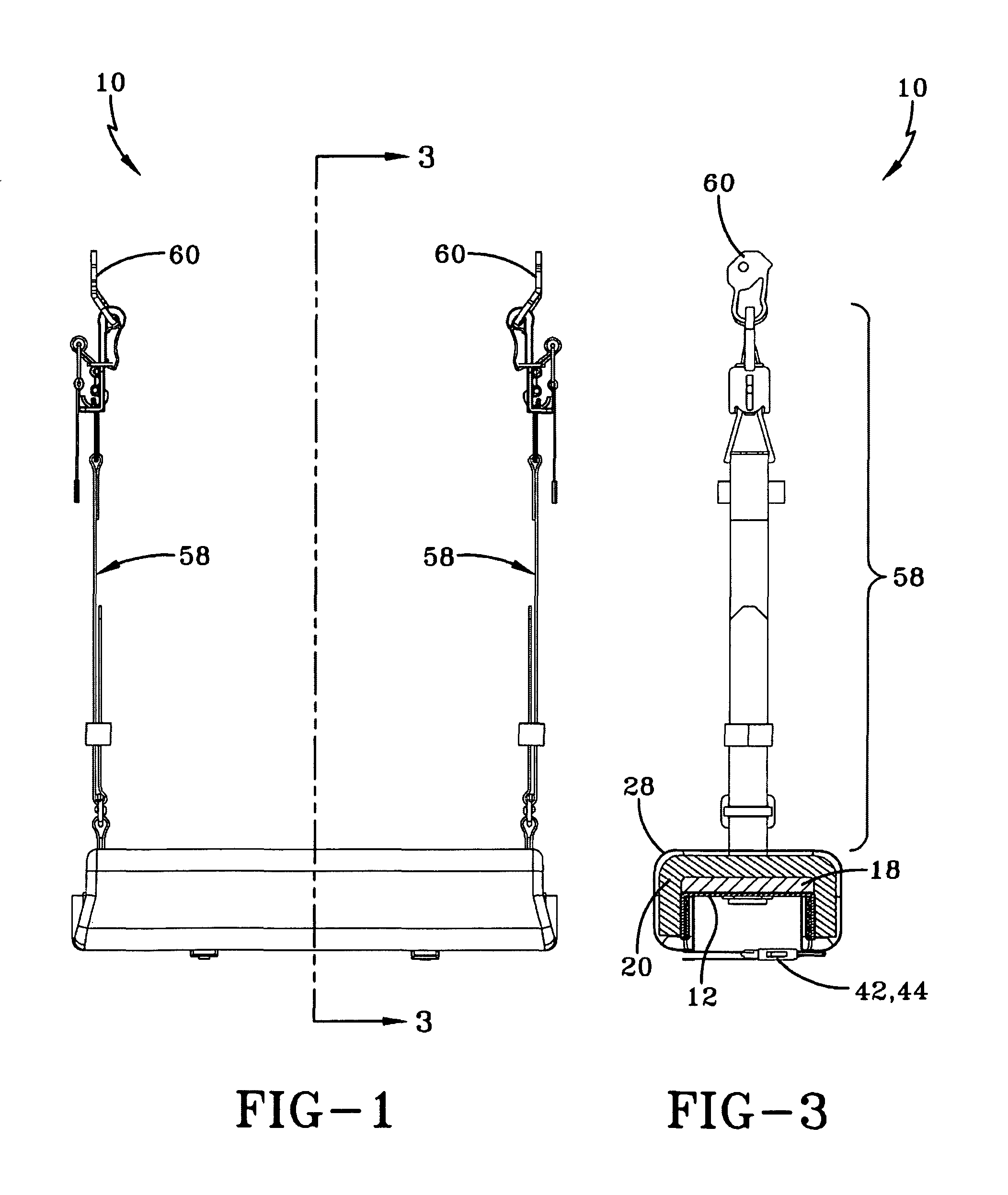

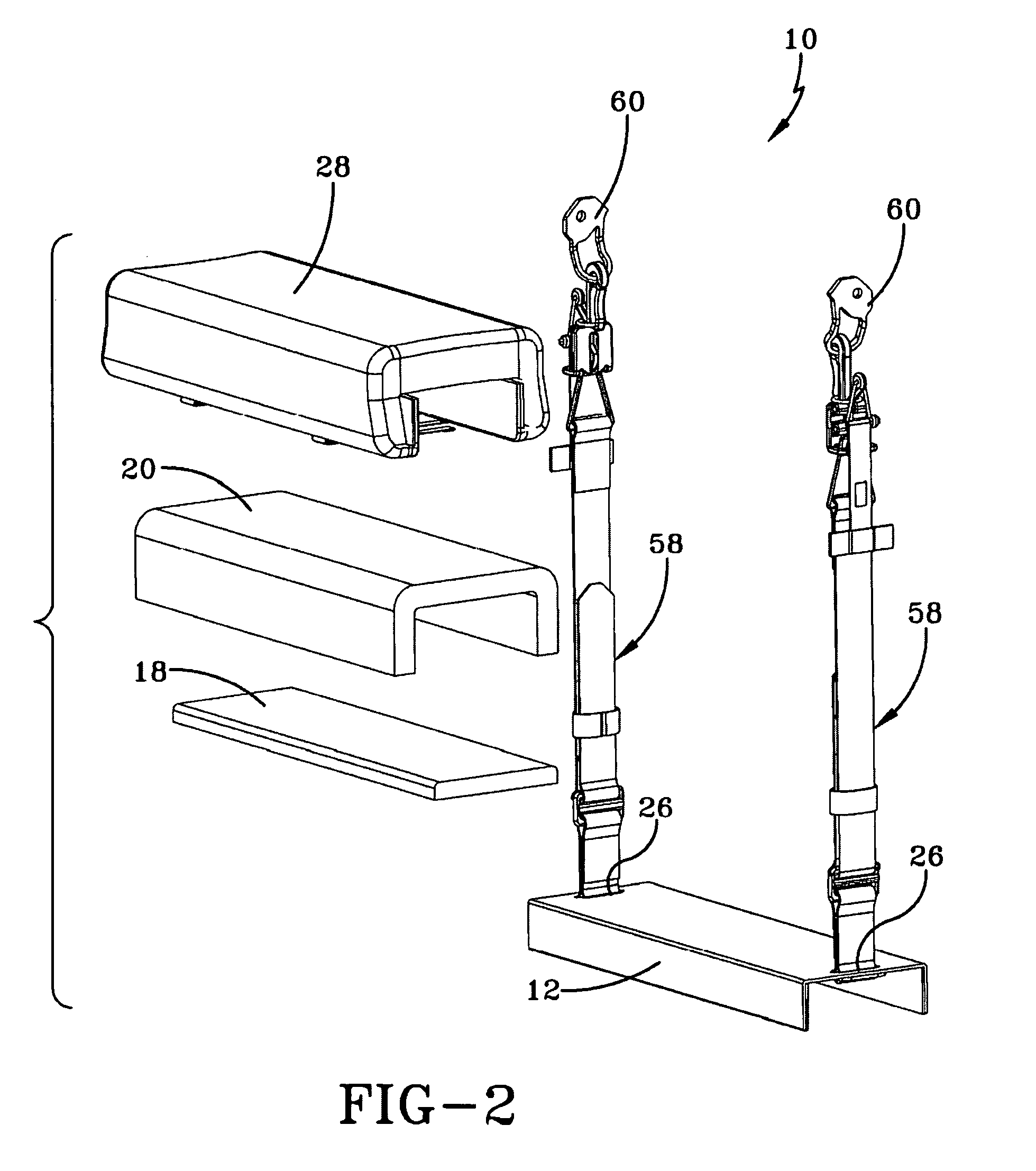

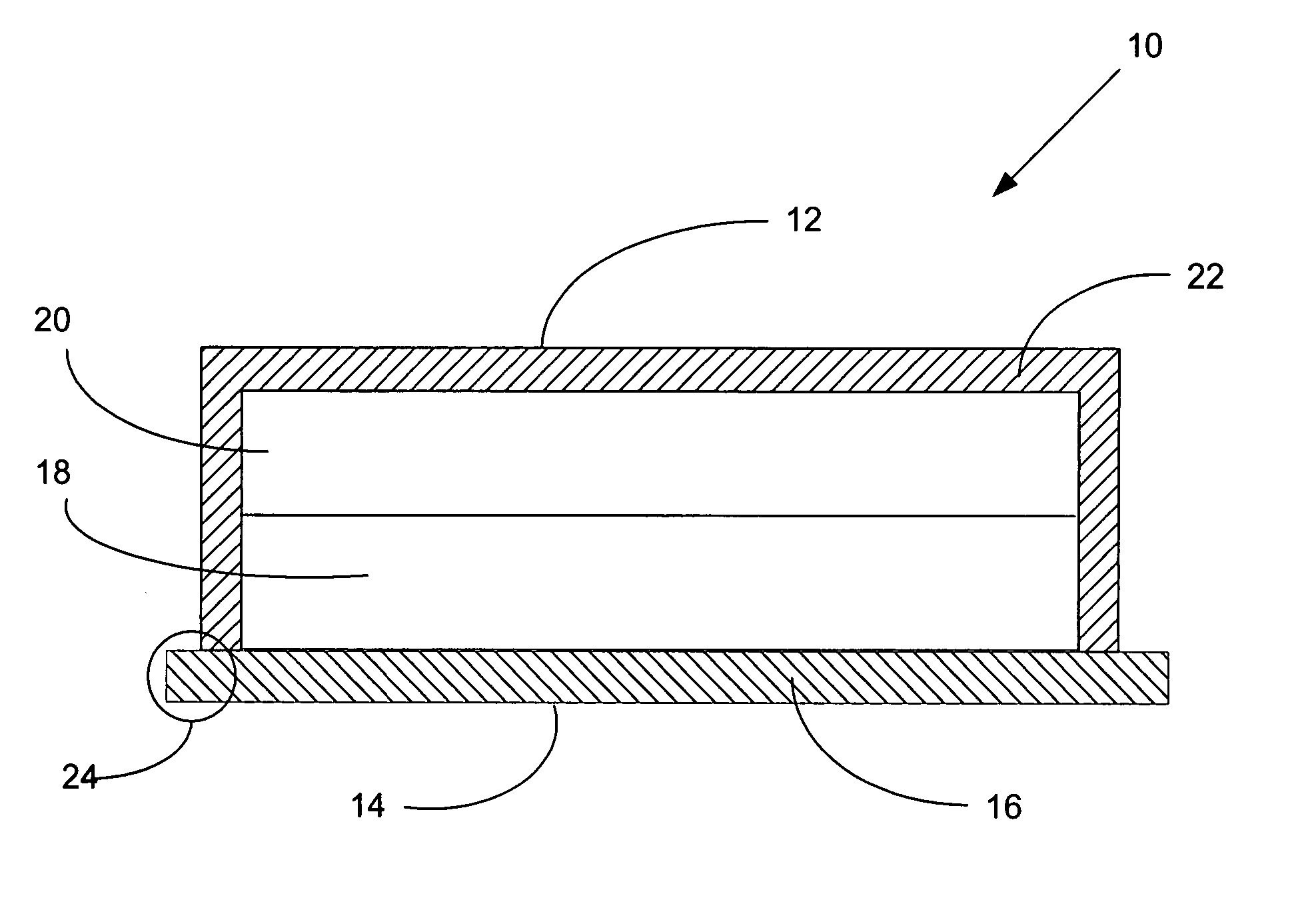

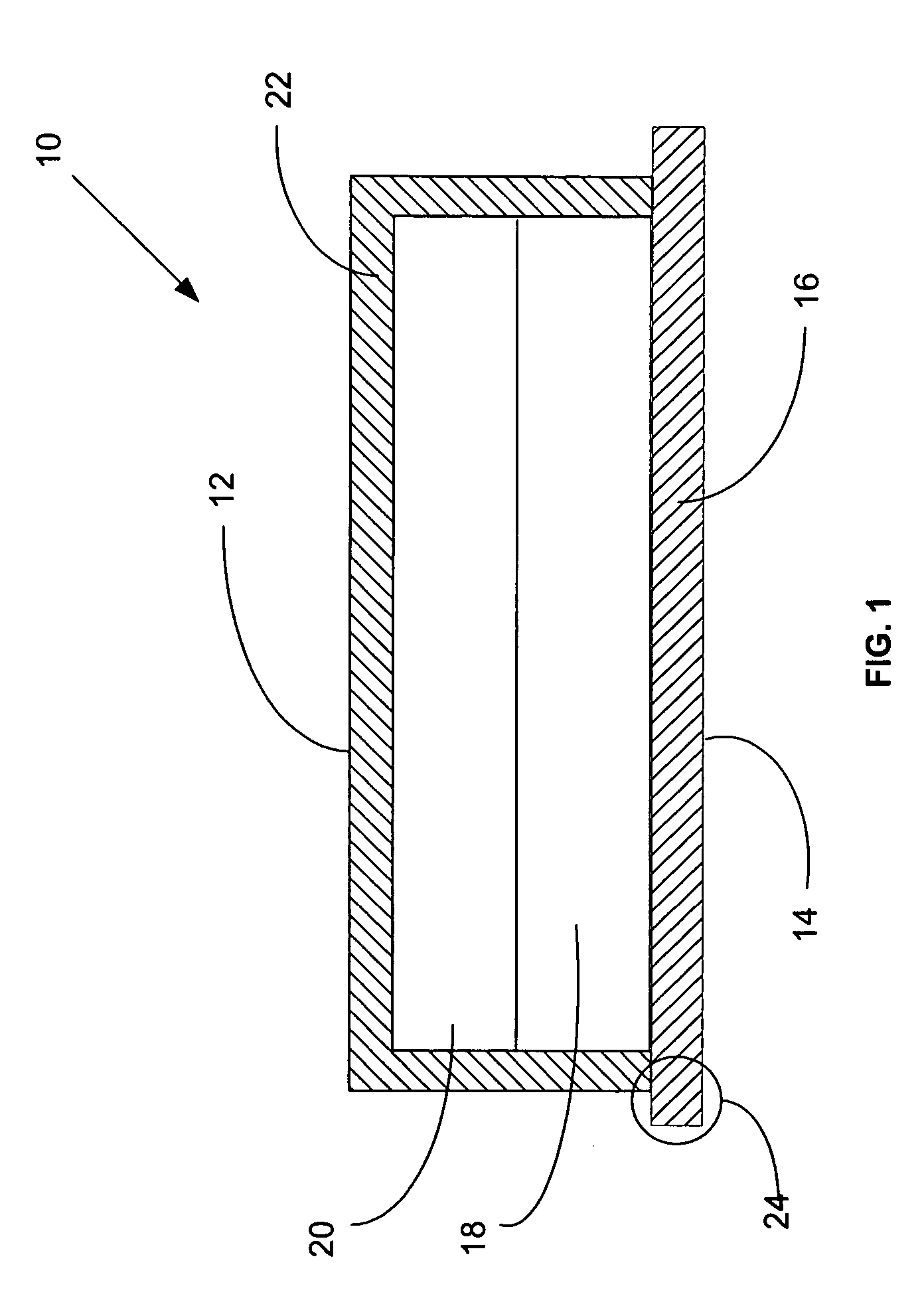

Drive for coverings for architectural openings

ActiveUS20060118248A1Many problemEliminate needExtensible doors/windowsCurtain accessoriesLinear motionEngineering

A cord drive mechanism to convert linear motion to circular motion for use in coverings for architectural openings. Various controls are used to provide a braking force on the cord. Some of the embodiments incorporate a capstan.

Owner:HUNTER DOUGLAS INC

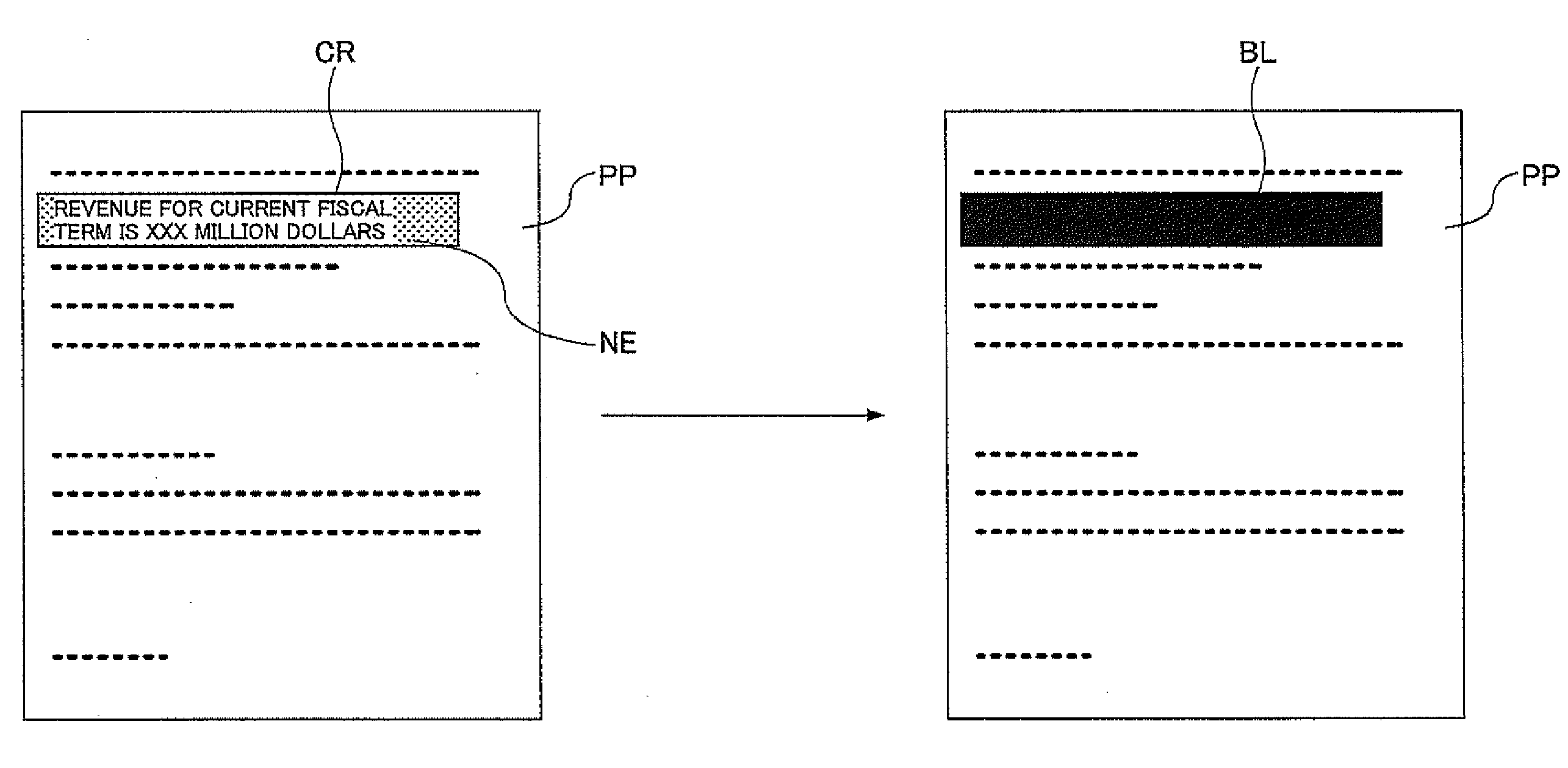

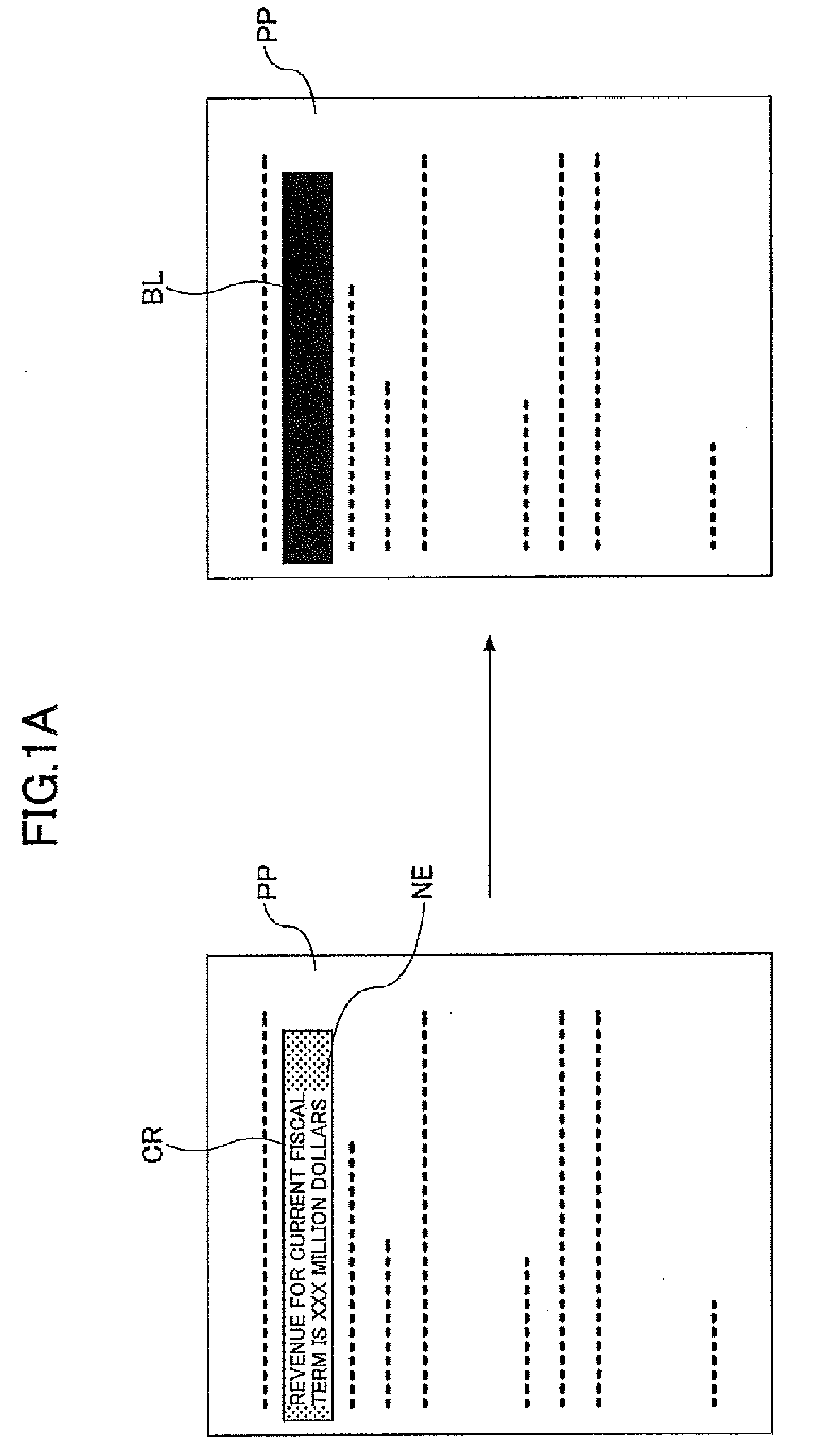

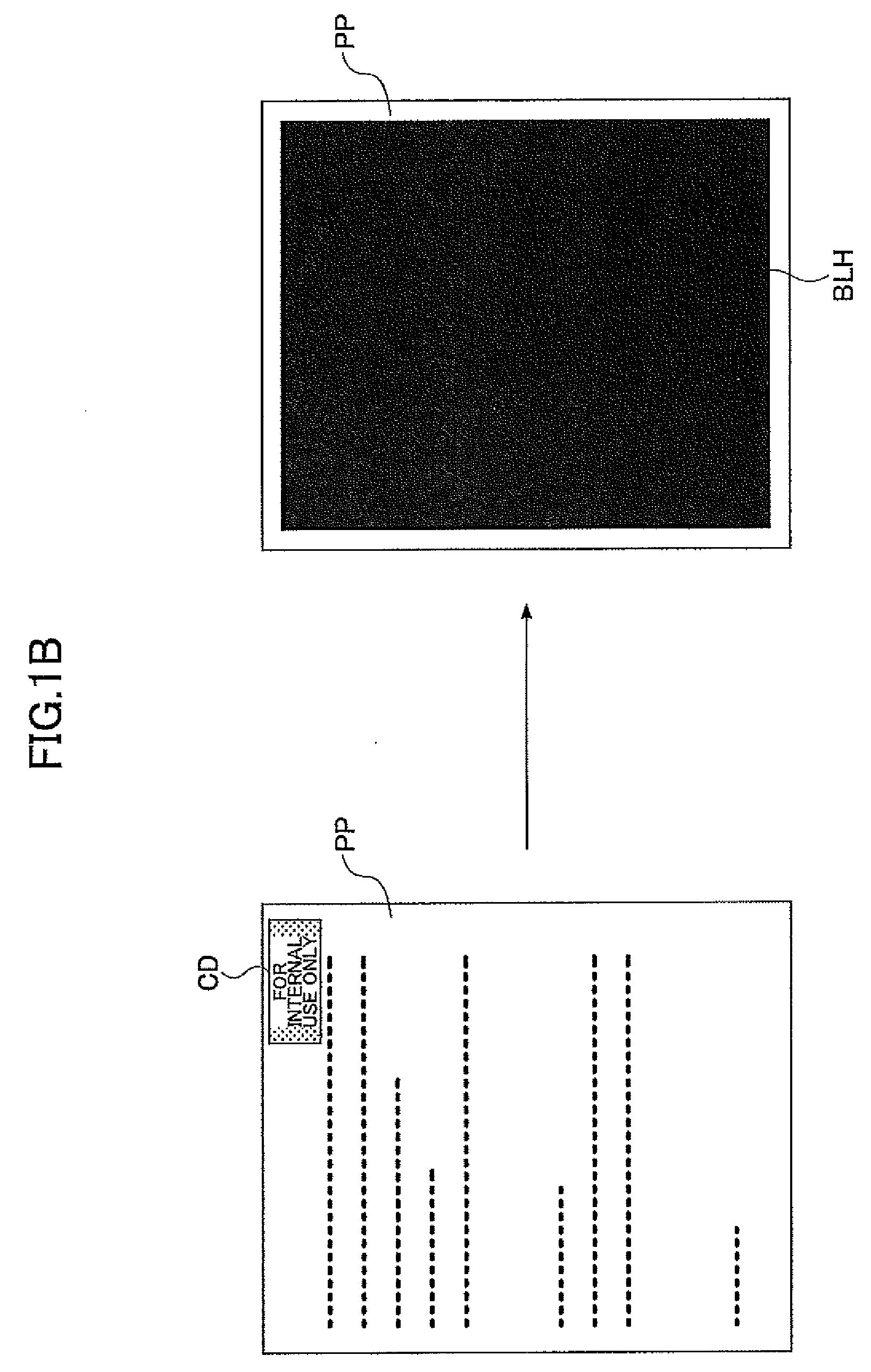

Image Forming Apparatus for Use in Backside Printing

InactiveUS20090066987A1Reduce amountLeakage of confidential informationElectrographic process apparatusDigital output to print unitsImage recordingComputer graphics (images)

An image forming apparatus includes an image obtaining unit configured to generate a document image for superimposition printing in response to an image requested to be printed or acquire the document image for superimposition printing from a source that requests printing, and an image recording unit configured to record the document image for superimposition printing as data associated with a paper sheet on which the requested image is printed.

Owner:RICOH KK

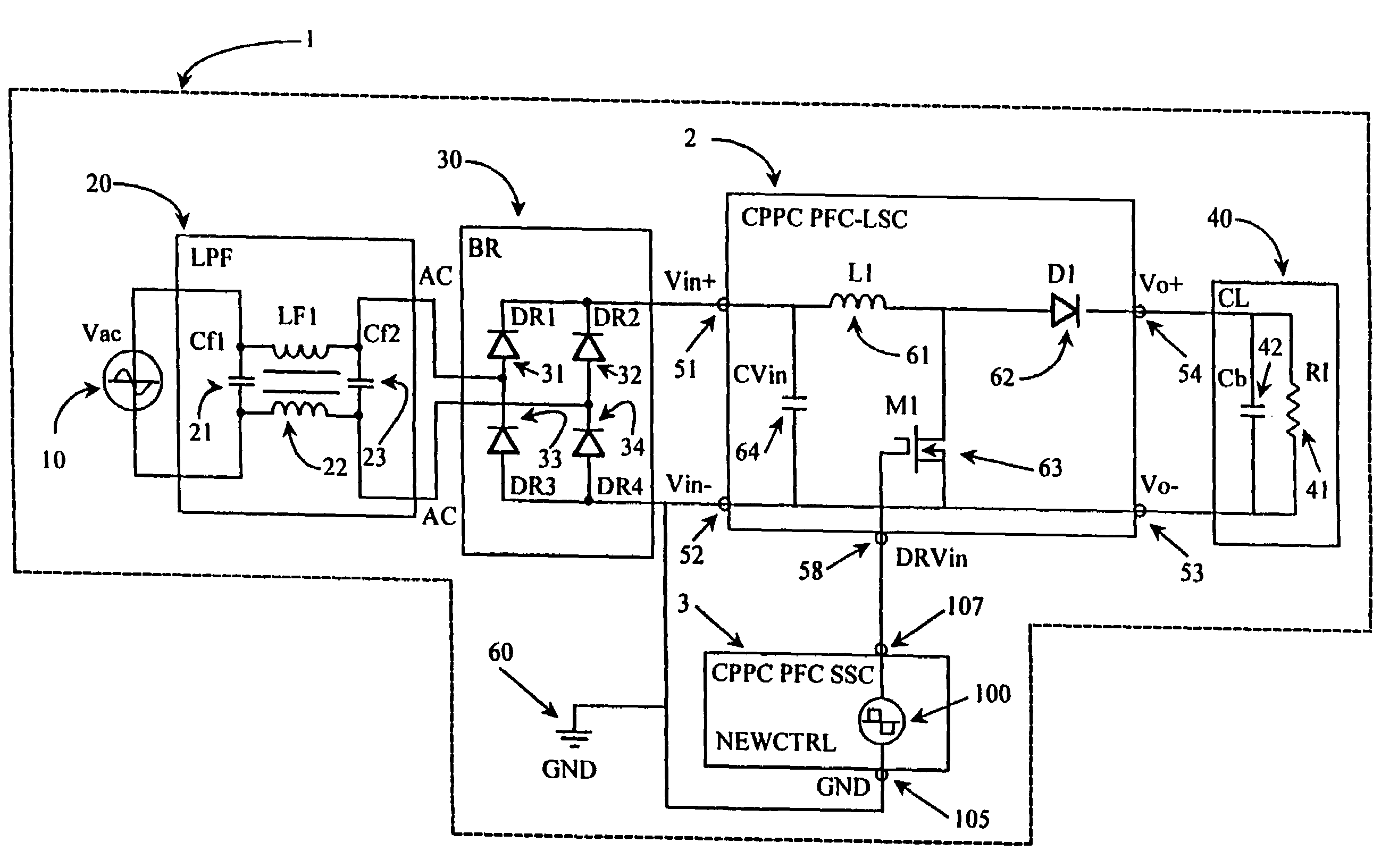

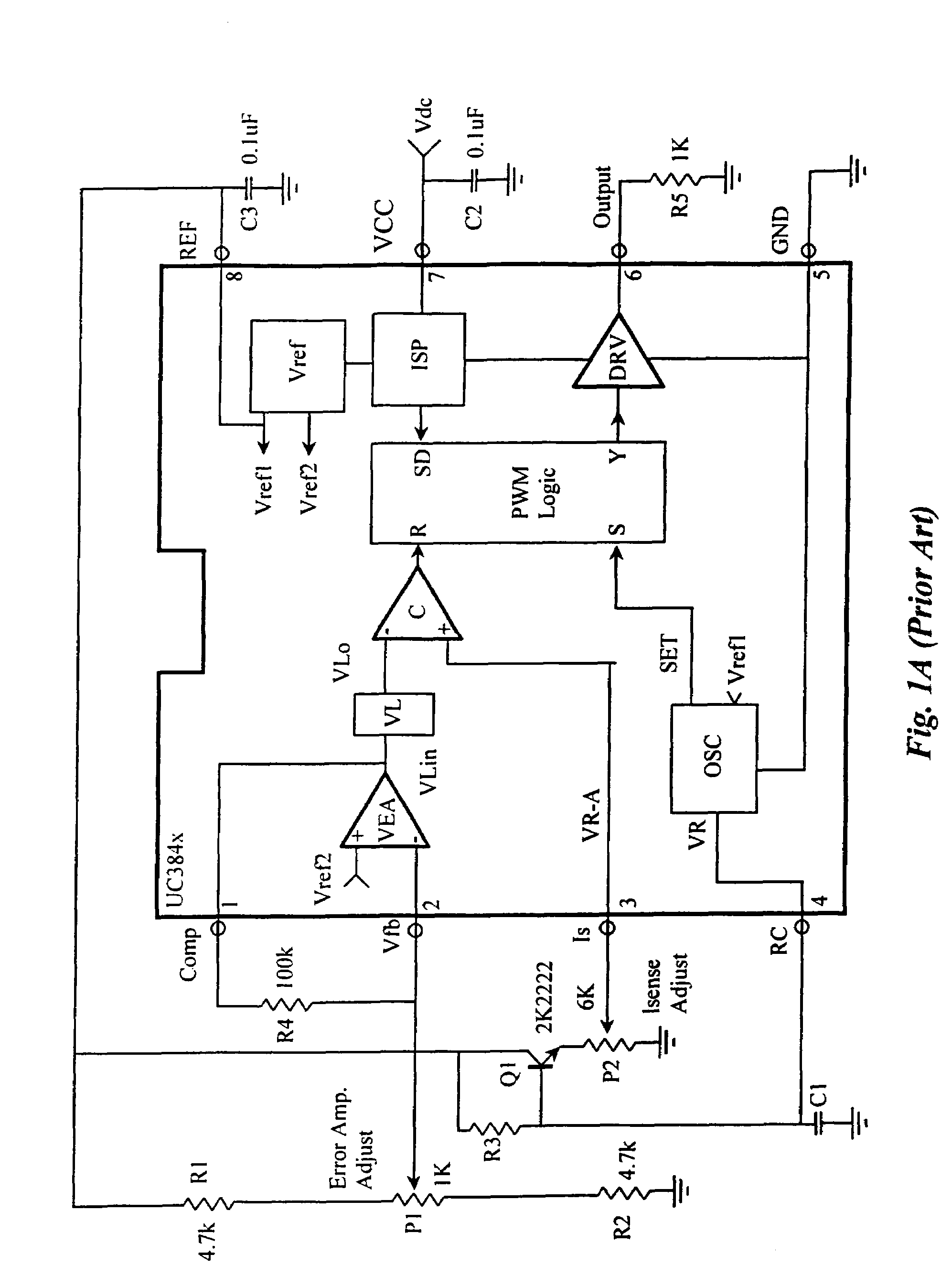

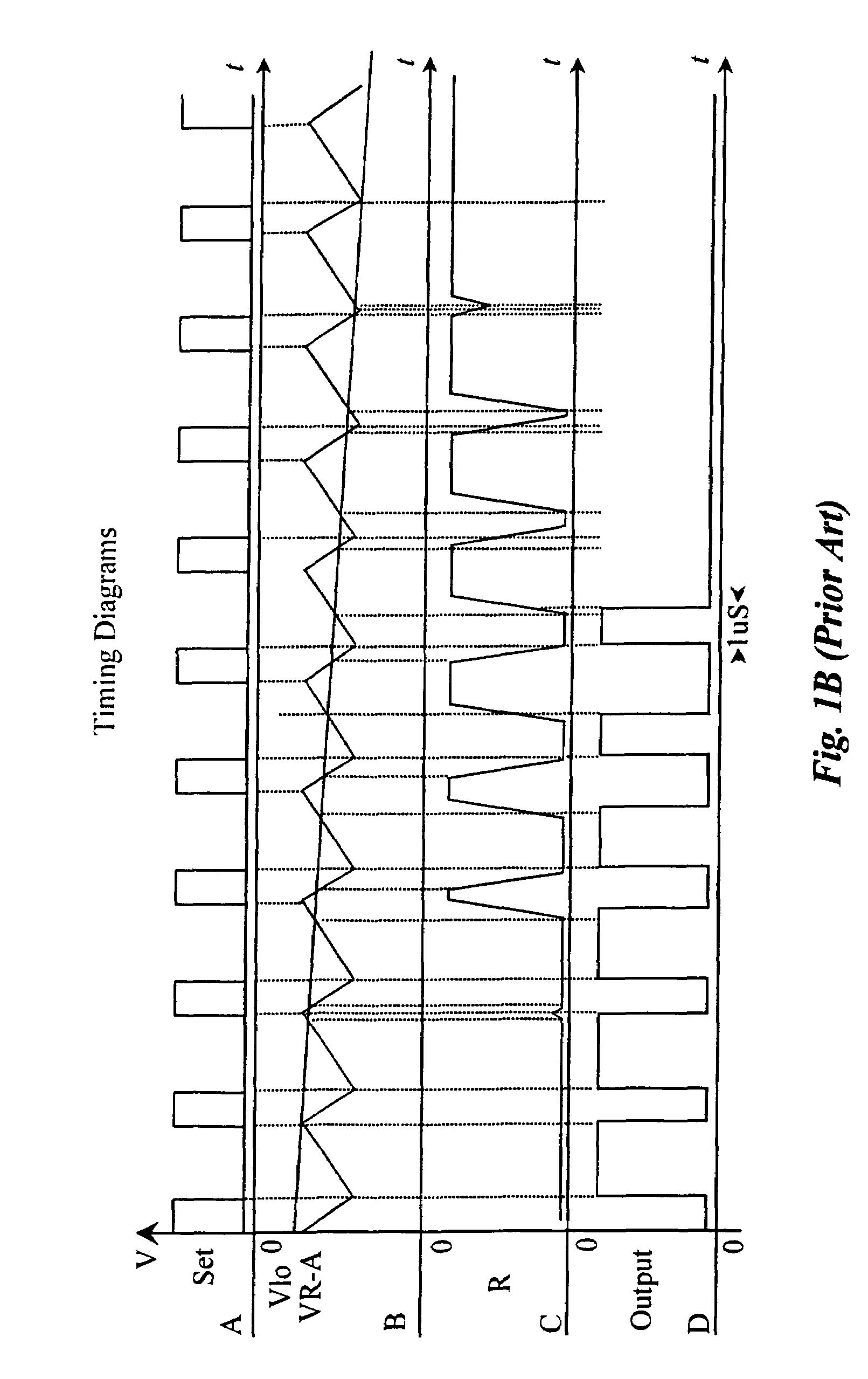

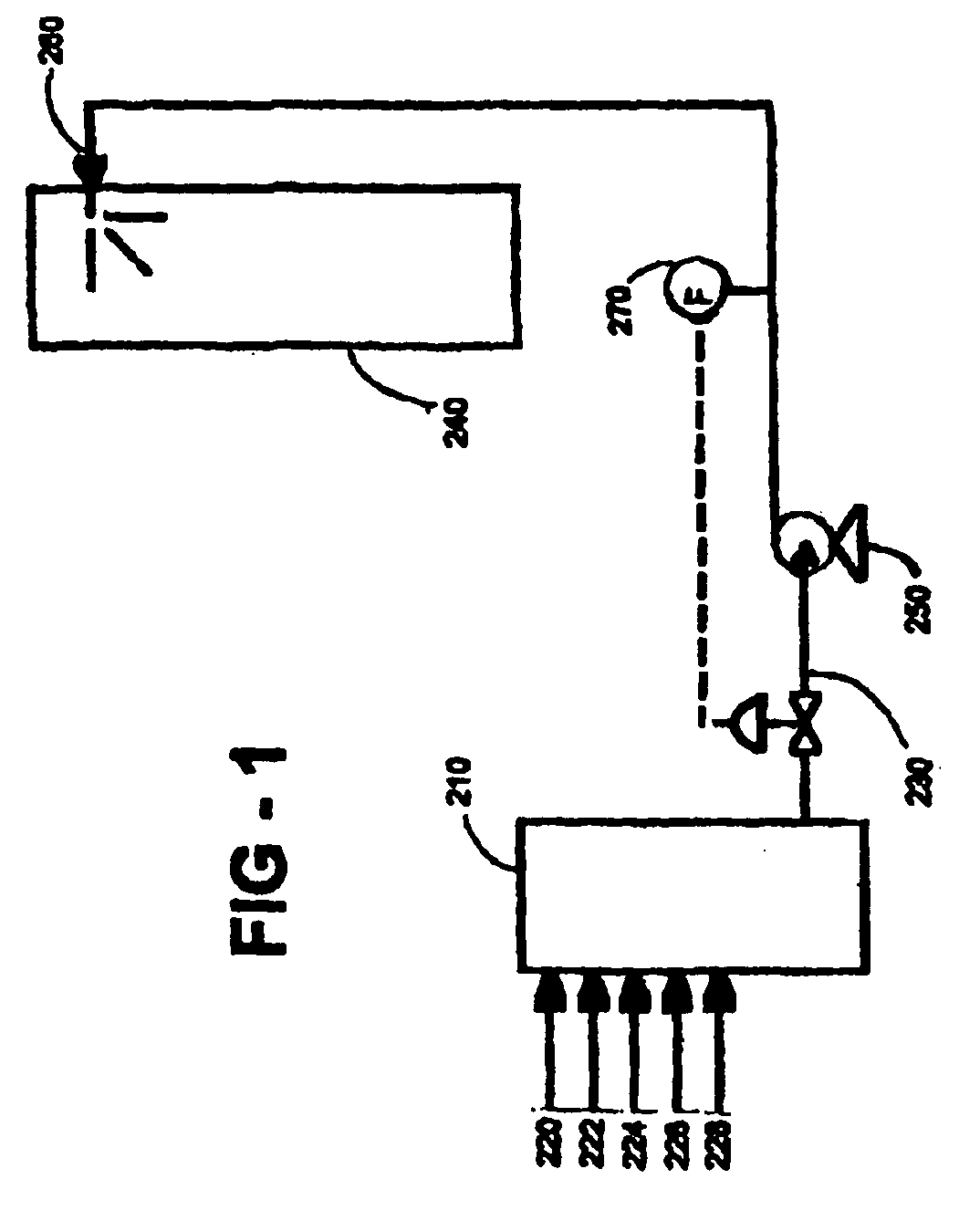

Method and system for power factor correction using constant pulse proportional current

InactiveUS7391630B2High performanceReduce problemAc-dc conversion without reversalEfficient power electronics conversionPower factor correctorPwm controller

A Power Factor Correction (PFC) system providing near unity power factor for an AC power source (VAC) connected to a complex load. The system includes a bridge rectifier, boost or buck-boost converter, complex load, and pulse width modulation (PWM) controller to provide pulses with variable duty cycle to a power switch. The invention is a constant pulse proportional current (CPPC) PWM controller that generates trains of pulses constant in frequency and duty cycle for one semi-cycle of the VAC. The duty cycle of the driving signal is modified by applying open-loop correction signals to summing nodes of PWM circuits. Since the PWM provides a constant train of driving pulses with constant duty cycle for one semi-cycle of the VAC, the current absorbed by the converter is contingent and linearly proportional to the voltage. Thus, the output current follows the voltage resulting in a power factor of near unity.

Owner:PF1

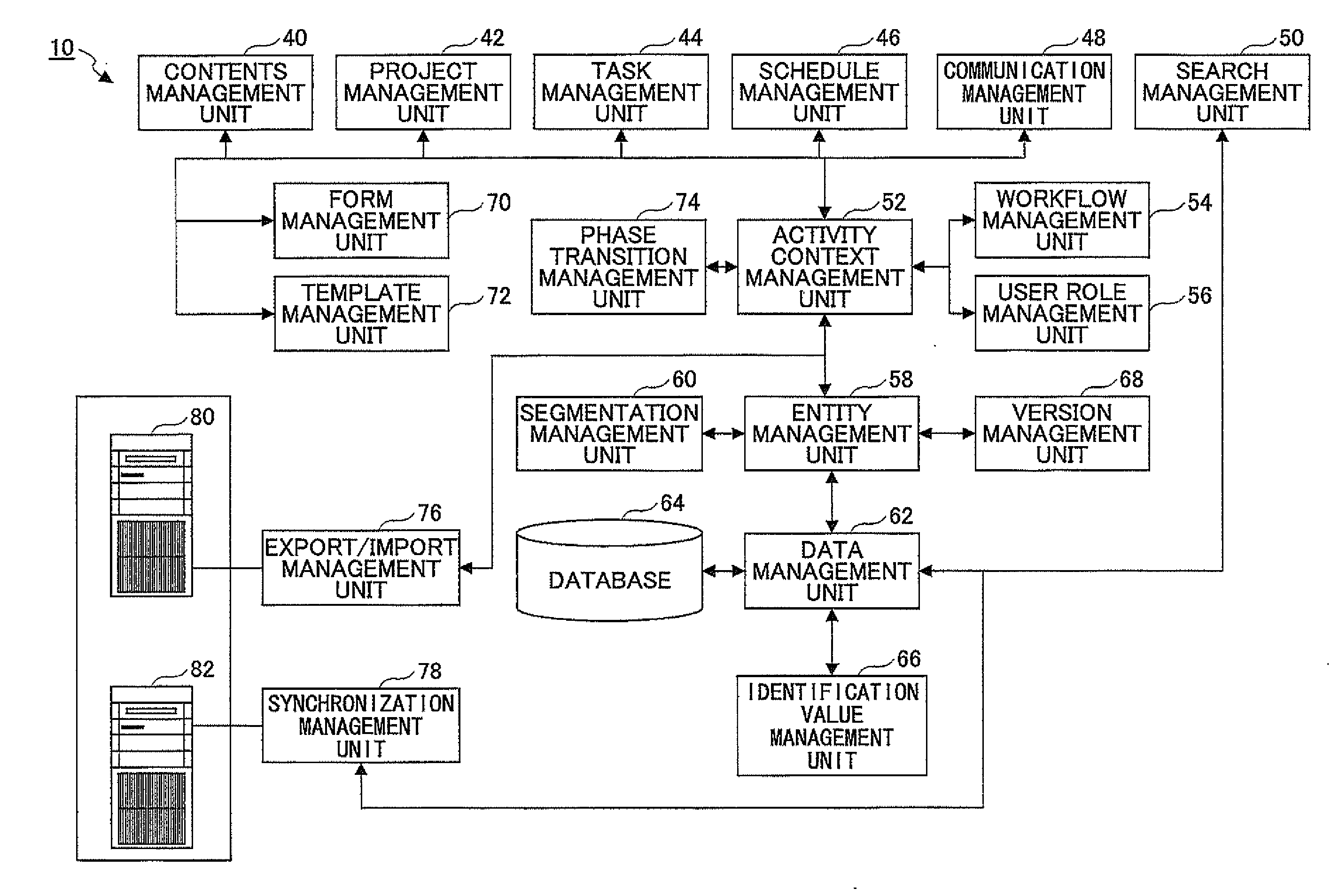

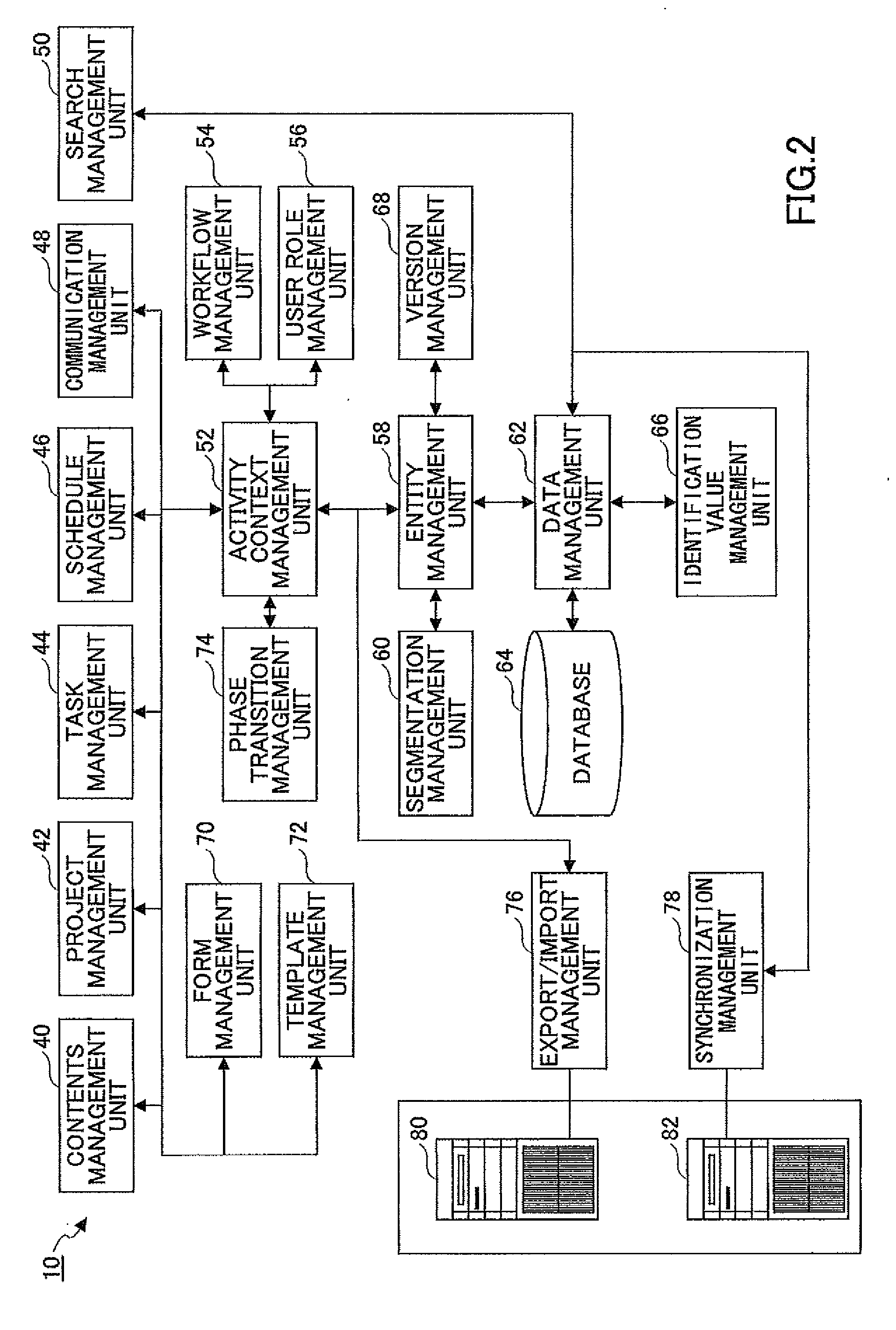

System for assisting collaborative activity

InactiveUS20090235182A1Eliminate the problemMany problemDigital computer detailsOffice automationContext managementManagement unit

A system for assisting a collaborative activity includes a plurality of work interfaces, a role management unit, a workflow management unit, a collaborative activity registration unit, and an activity context management unit situated between the plurality of work interfaces and the collaborative activity registration unit to receive entered information from one of the work interfaces, to associate shared information contained in the entered information with user information provided by the role management unit and an activity content provided by the workflow management unit to create collaborative activity information, and to cause the collaborative activity registration unit to register the collaborative activity information.

Owner:RICOH KK

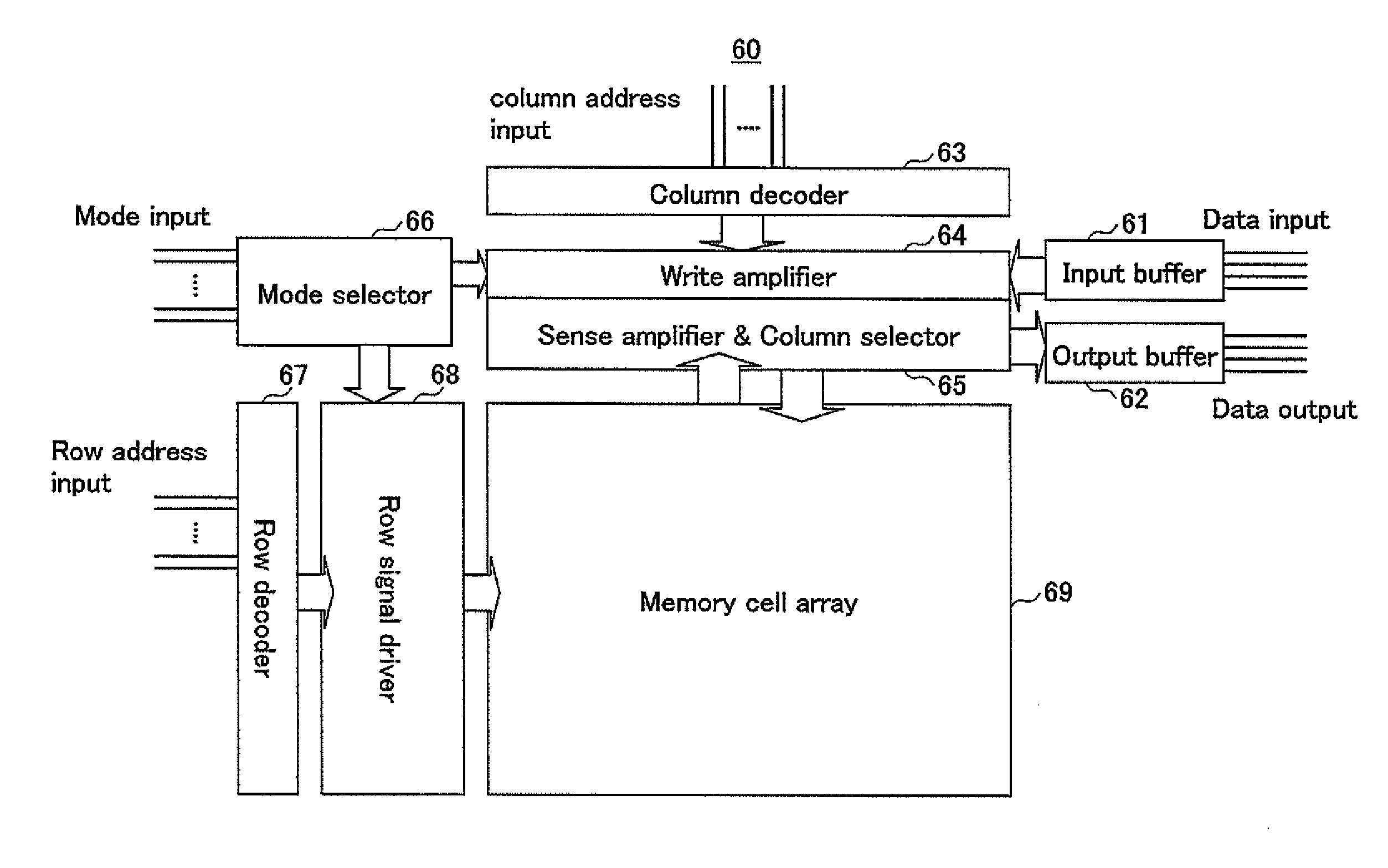

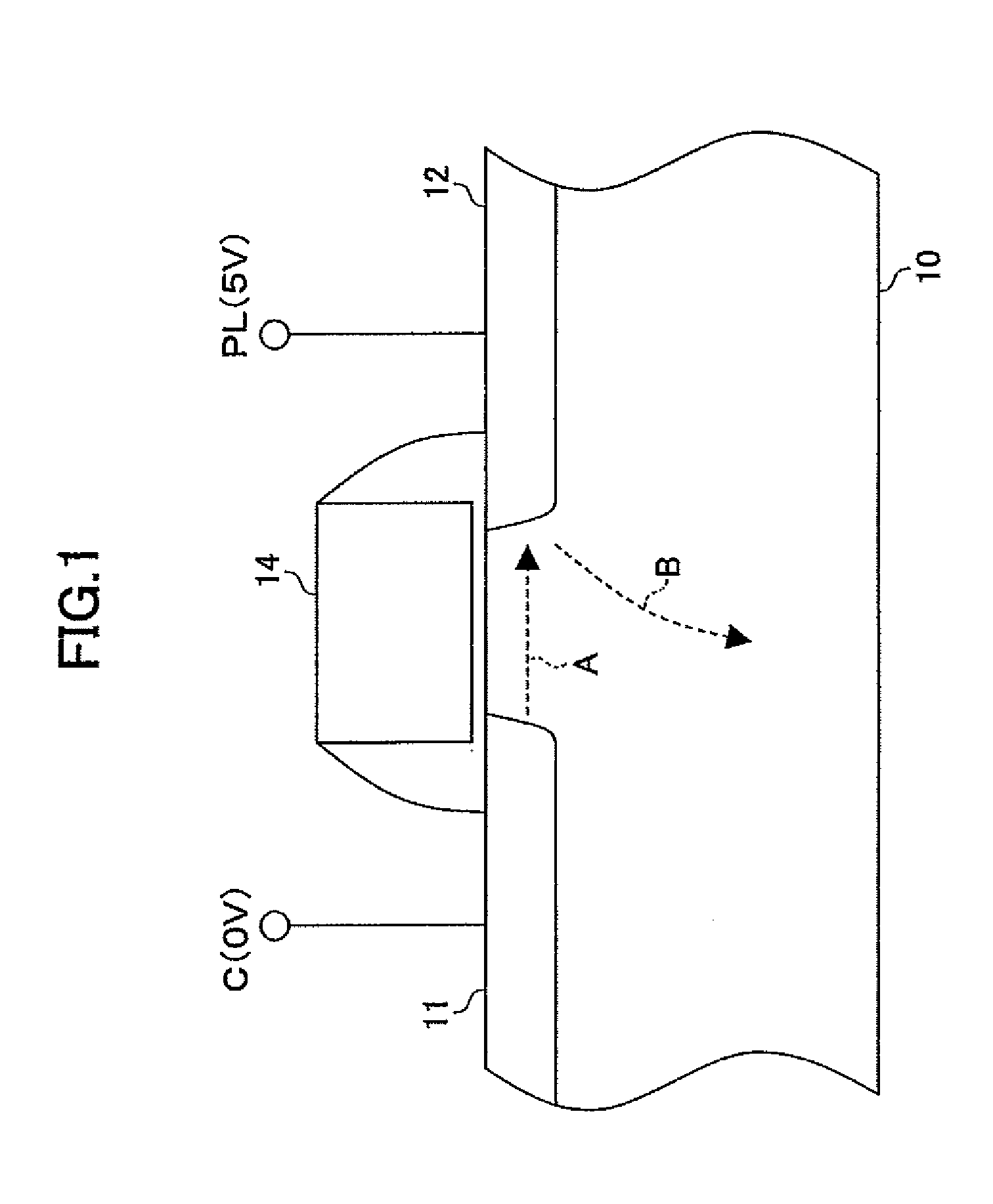

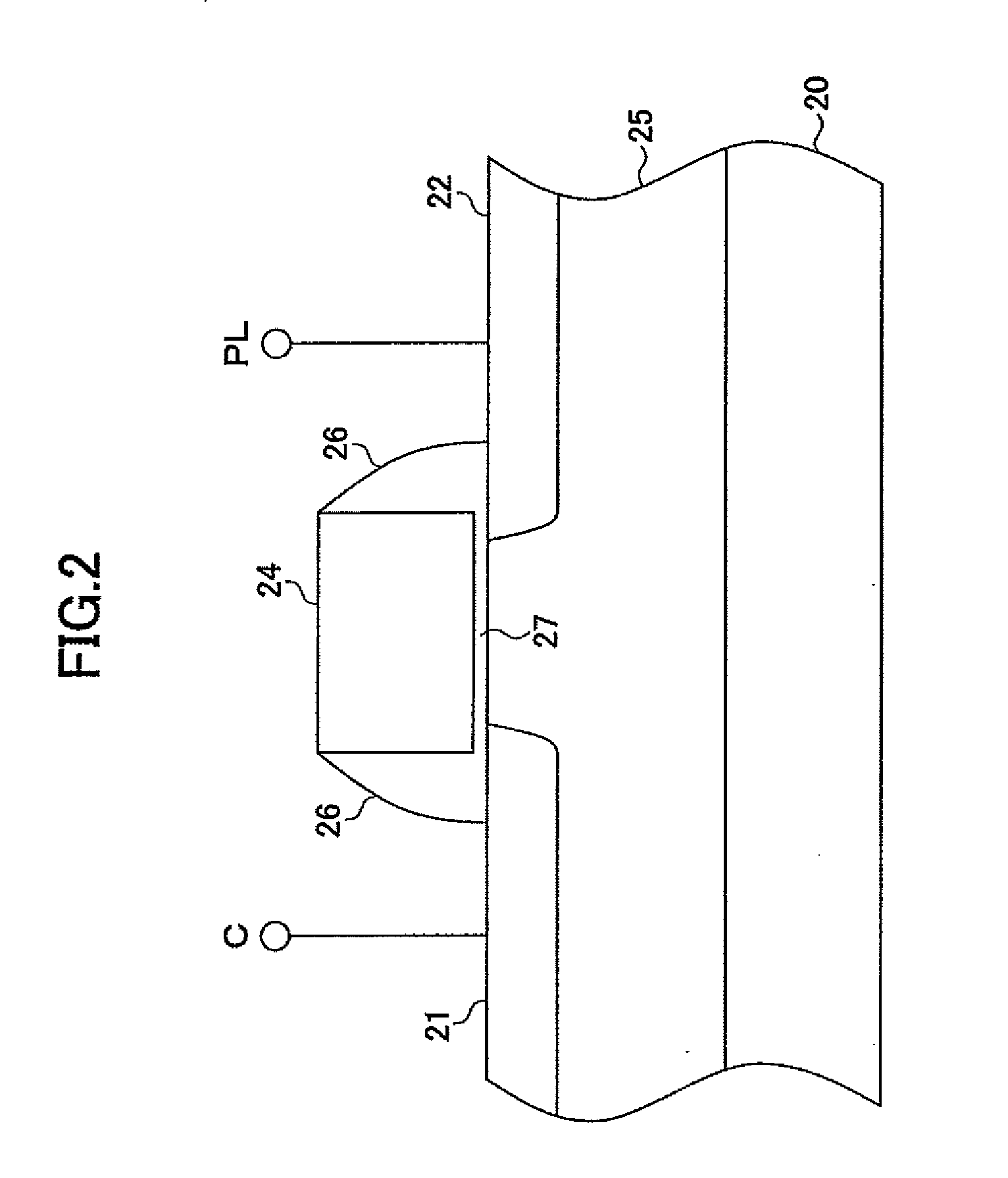

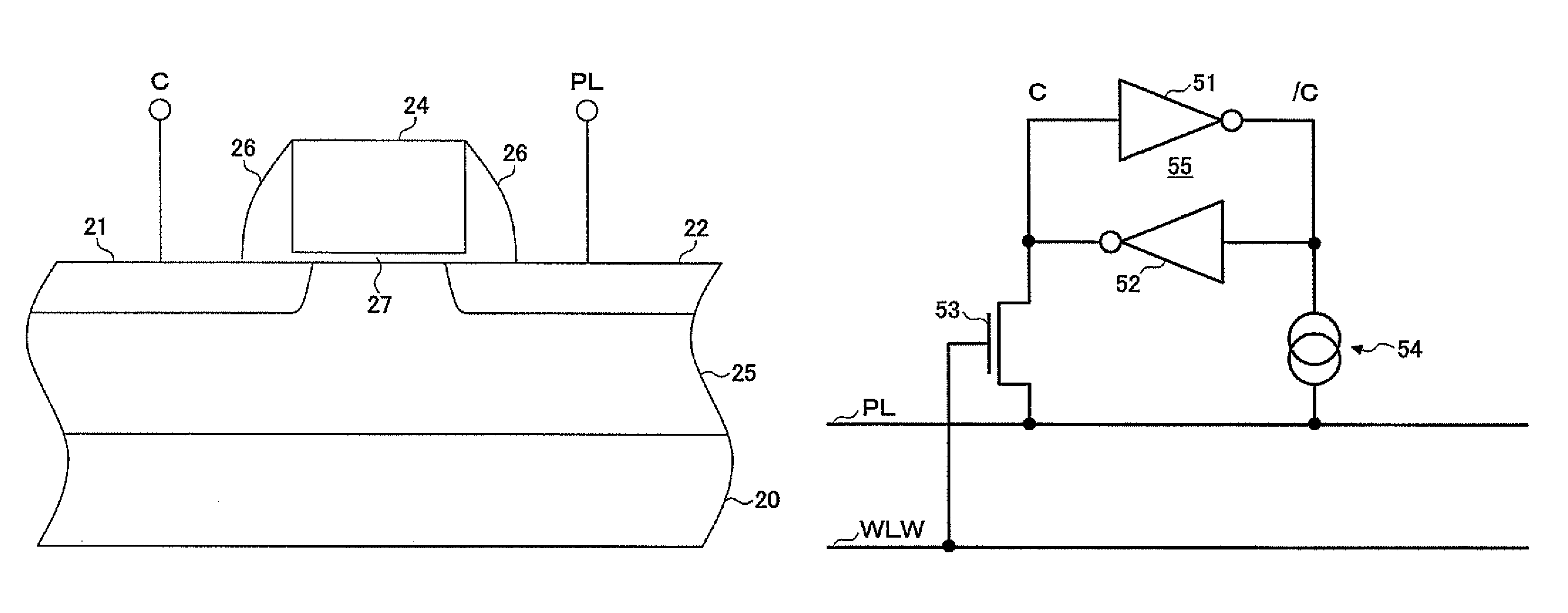

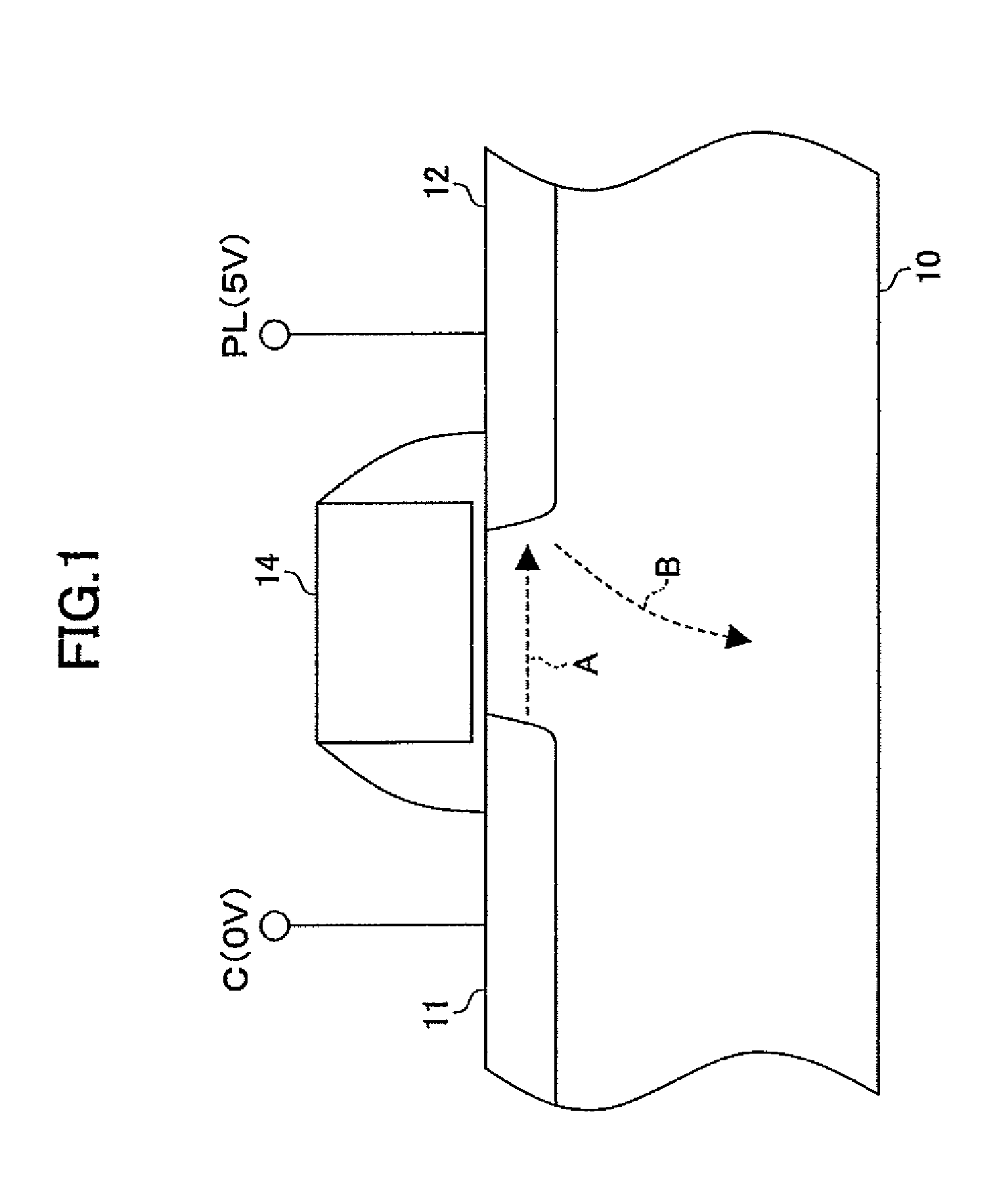

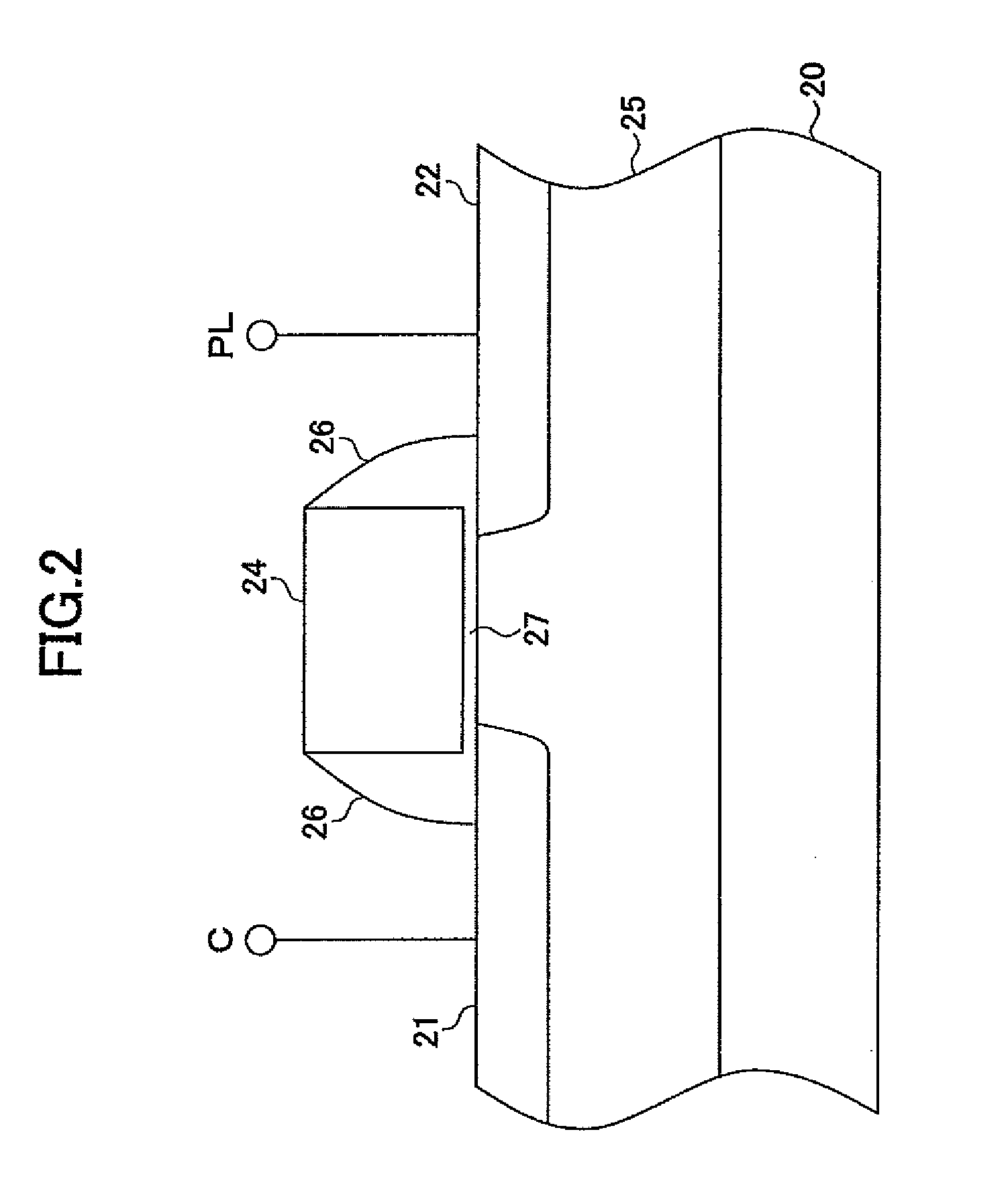

Nonvolatile semiconductor memory circuit utilizing a mis transistor as a memory cell

ActiveUS20090316477A1Lower threshold voltagePotential differenceSolid-state devicesSemiconductor/solid-state device manufacturingHemt circuitsMemory circuits

A memory circuit includes a latch having a first node and a second node to store data such that a logic level of the first node is an inverse of a logic level of the second node, a MIS transistor having a gate node, a first source / drain node, and a second source / drain node, the first source / drain node coupled to the first node of the latch, and a control circuit configured to control the gate node and second source / drain node of the MIS transistor in a first operation such that a lingering change is created in transistor characteristics of the MIS transistor in response to the data stored in the latch, wherein the MIS transistor includes a highly-doped substrate layer, a lightly-doped substrate layer disposed on the highly-doped substrate layer, diffusion regions formed in the lightly-doped substrate layer, a gate electrode, sidewalls, and an insulating film.

Owner:NSCORE

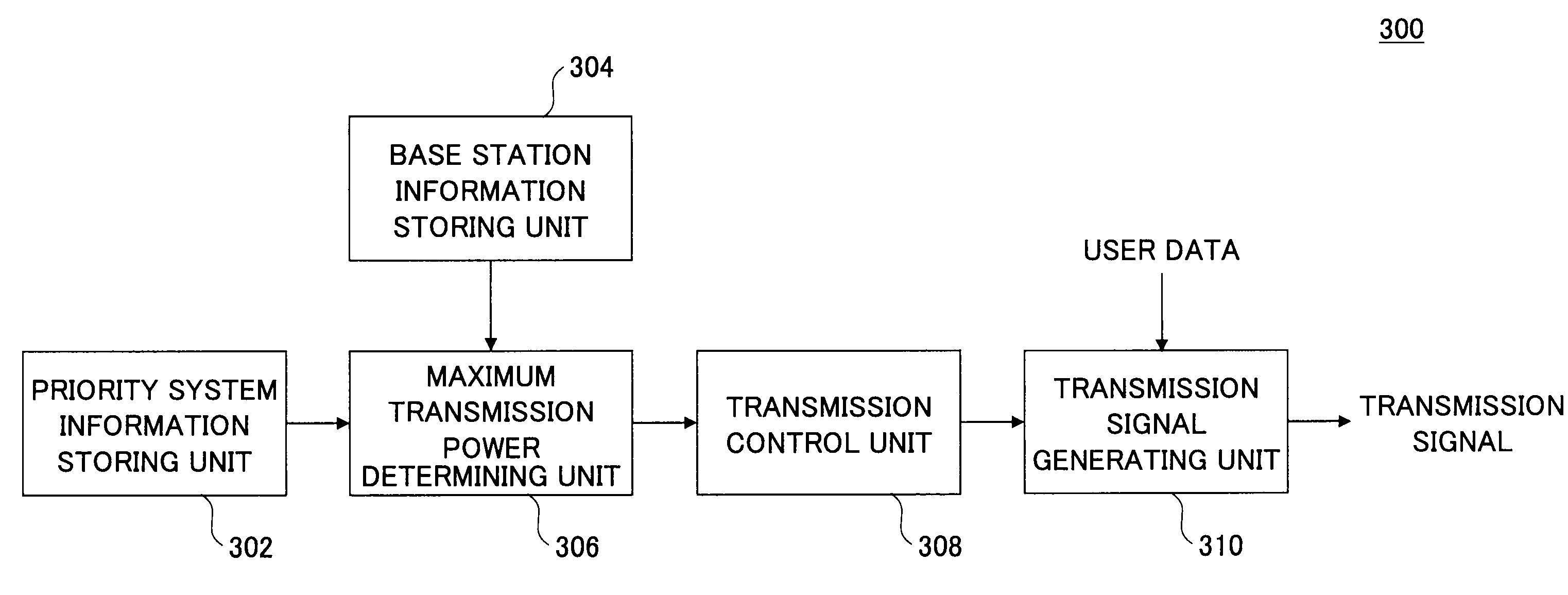

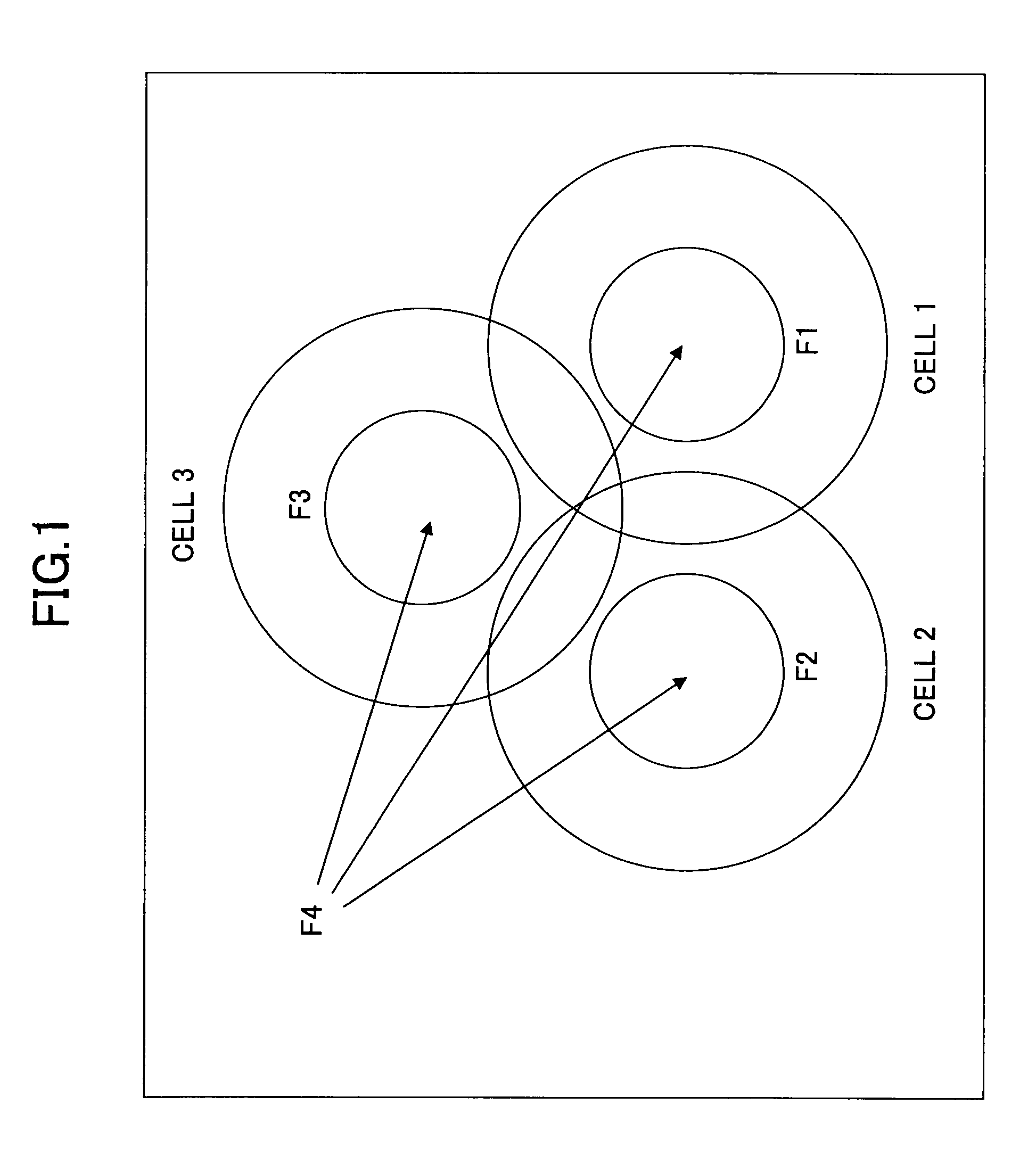

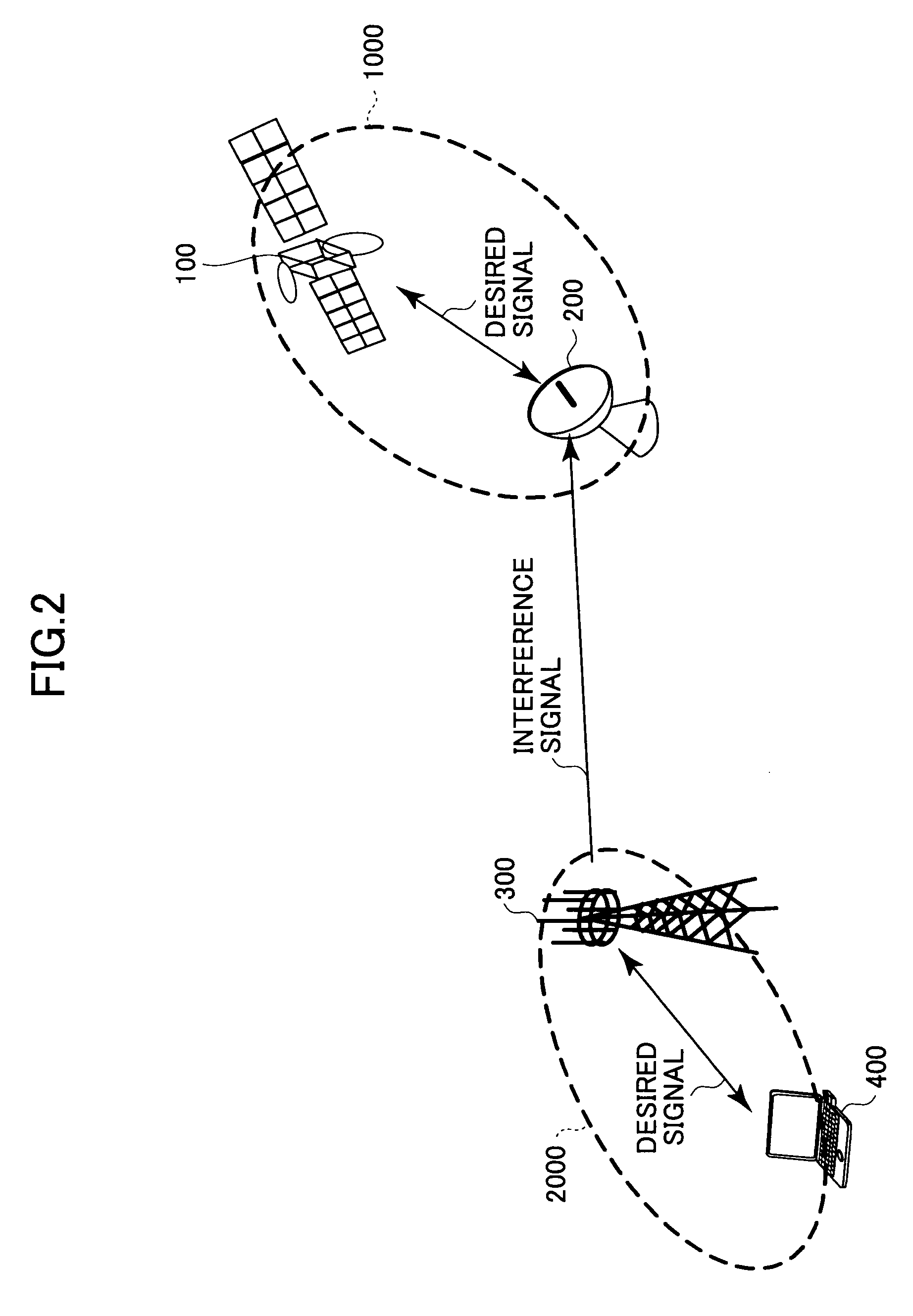

Base station, receiving device, mobile terminal, and frequency sharing method

InactiveUS20090088083A1Many problemEnergy efficient ICTPower managementCommunications systemEngineering

A disclosed base station is used in a first wireless communication system using a first frequency band that is the same as or adjacent to a second frequency band used by a second wireless communication system, and includes a propagation loss estimation unit configured to estimate propagation loss of a signal in the first frequency band when the signal arrives at a receiving device of the second wireless communication system; a frequency difference calculation unit configured to calculate a frequency difference between the first frequency band and the second frequency band; a maximum transmission power determining unit configured to determine maximum transmission power based on the estimated propagation loss and the calculated frequency difference; and a transmission control unit configured to transmit a signal with transmission power less than or equal to the maximum transmission power determined by the maximum transmission power determining unit.

Owner:NTT DOCOMO INC

Nonvolatile semiconductor memory circuit utilizing a MIS transistor as a memory cell

ActiveUS7821806B2Many problemReduce adverse effectsSolid-state devicesRead-only memoriesHemt circuitsMemory circuits

A memory circuit includes a latch having a first node and a second node to store data such that a logic level of the first node is an inverse of a logic level of the second node, a MIS transistor having a gate node, a first source / drain node, and a second source / drain node, the first source / drain node coupled to the first node of the latch, and a control circuit configured to control the gate node and second source / drain node of the MIS transistor in a first operation such that a lingering change is created in transistor characteristics of the MIS transistor in response to the data stored in the latch, wherein the MIS transistor includes a highly-doped substrate layer, a lightly-doped substrate layer disposed on the highly-doped substrate layer, diffusion regions formed in the lightly-doped substrate layer, a gate electrode, sidewalls, and an insulating film.

Owner:NSCORE

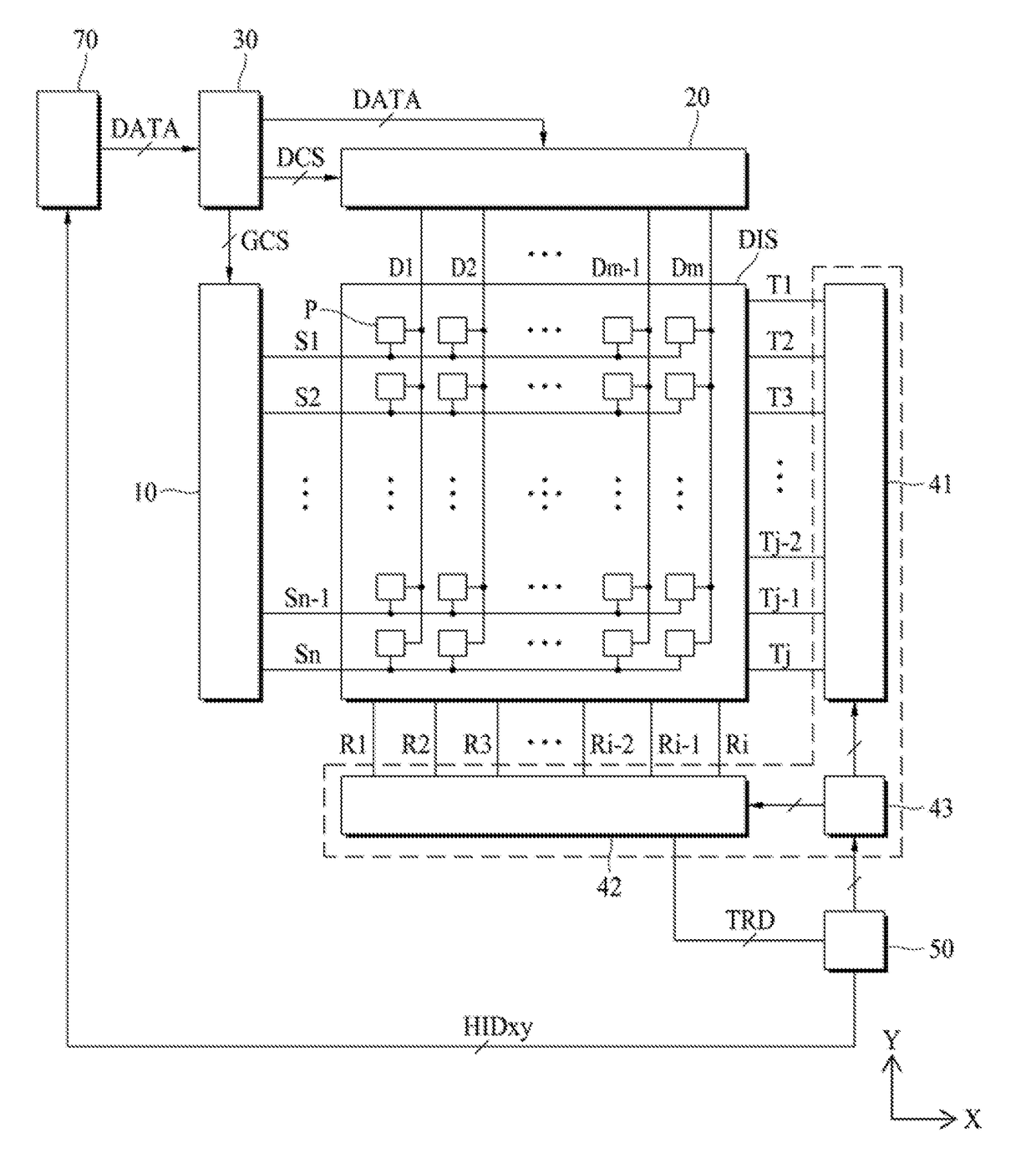

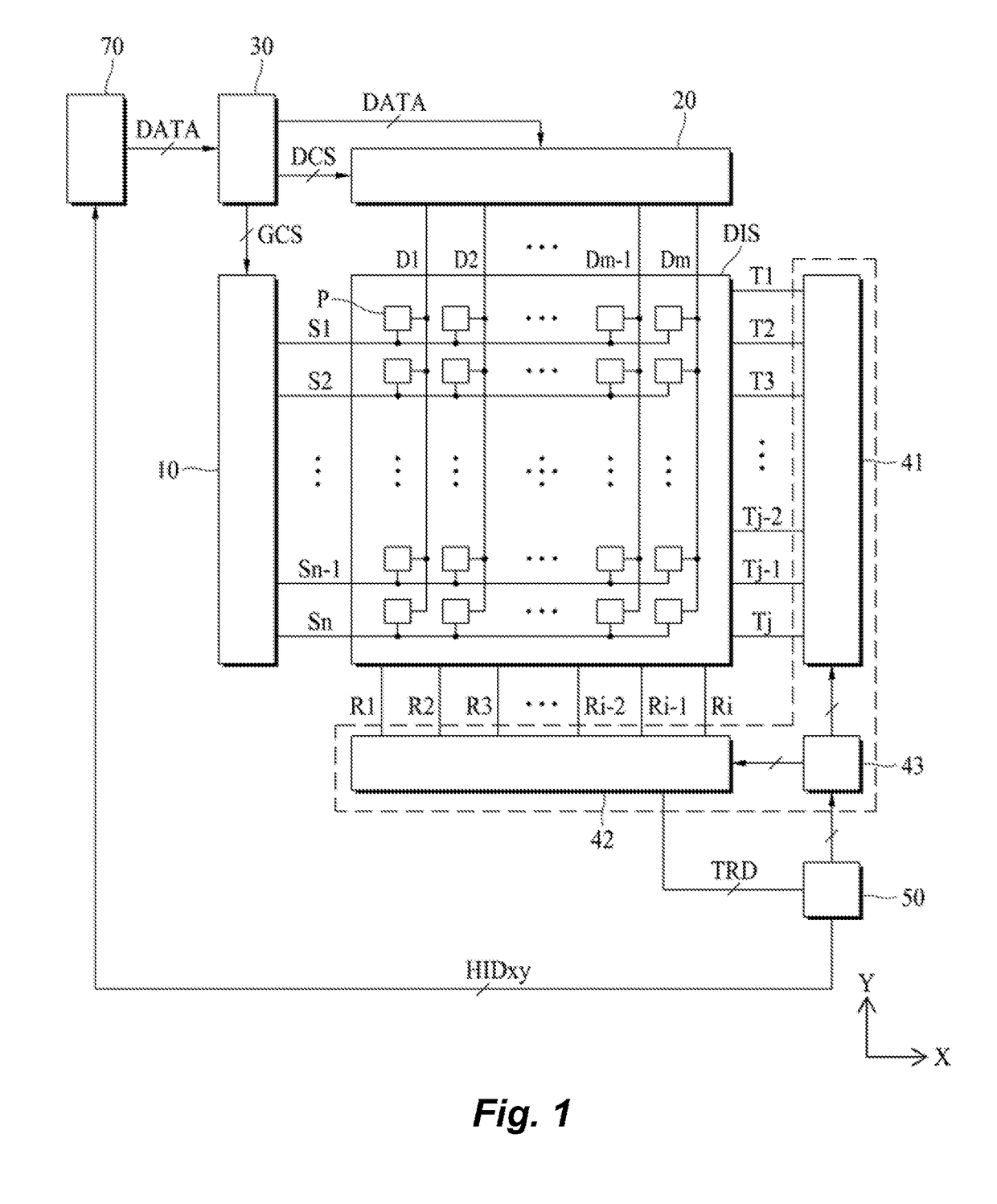

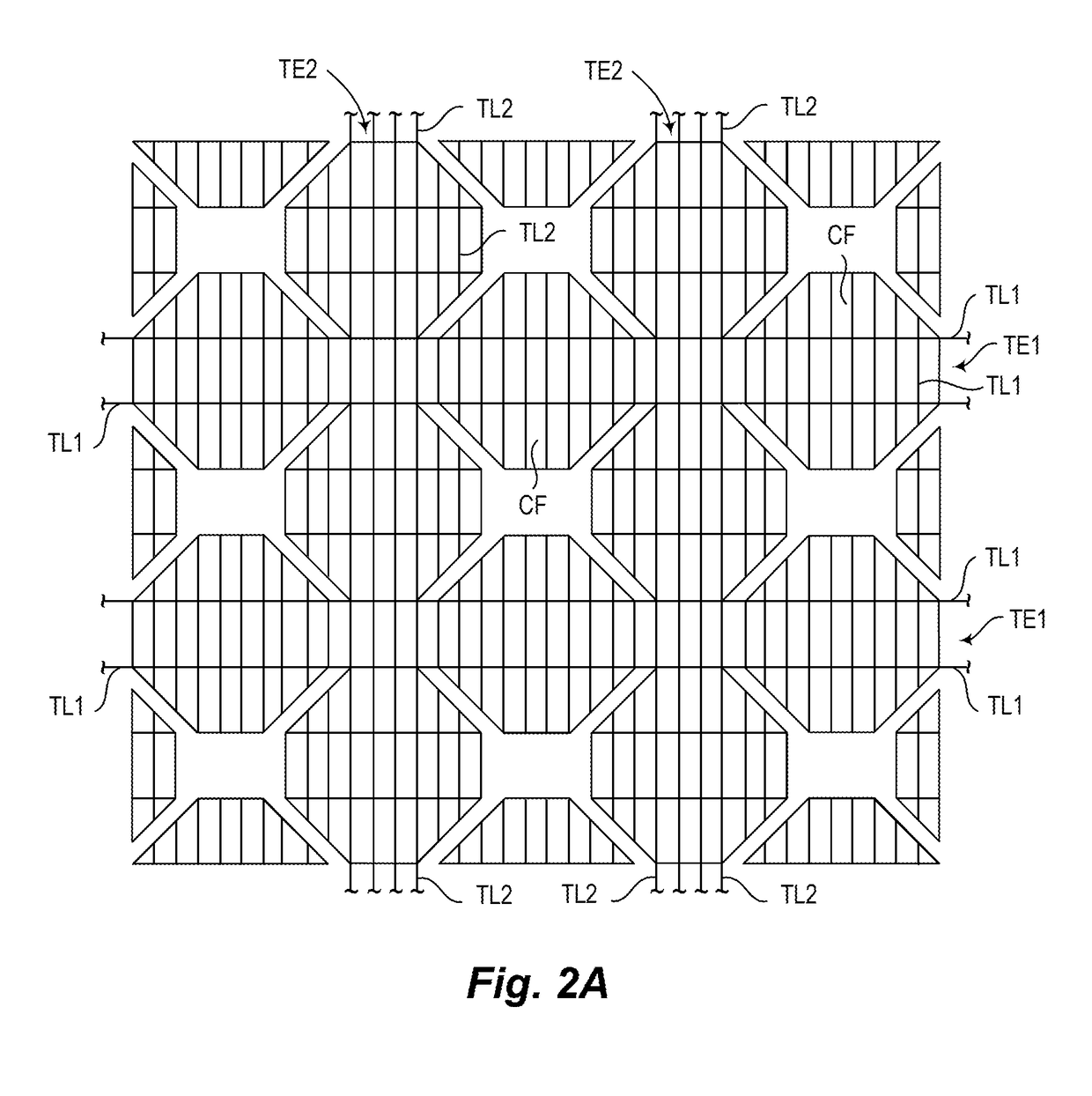

Display device including touch screen function

ActiveUS20170090634A1Many problemLuminance can be restrainedStatic indicating devicesSolid-state devicesDisplay deviceEngineering

Disclosed is a an in-cell type display device including a touch screen function which is capable of preventing a luminance from being changed in accordance with a viewing angle, and omitting a process of connecting touch electrodes provided in an upper substrate with Tx driver and Rx driver connected with a lower substrate, wherein the display device includes a lower substrate, a thin film transistor layer including thin film transistors provided on the lower substrate, an encapsulation layer provided on the thin film transistor layer, color filters provided on the encapsulation layer, a black matrix provided between the color filters and provided on the encapsulation layer, and first touch electrodes overlapped with the black matrix.

Owner:LG DISPLAY CO LTD

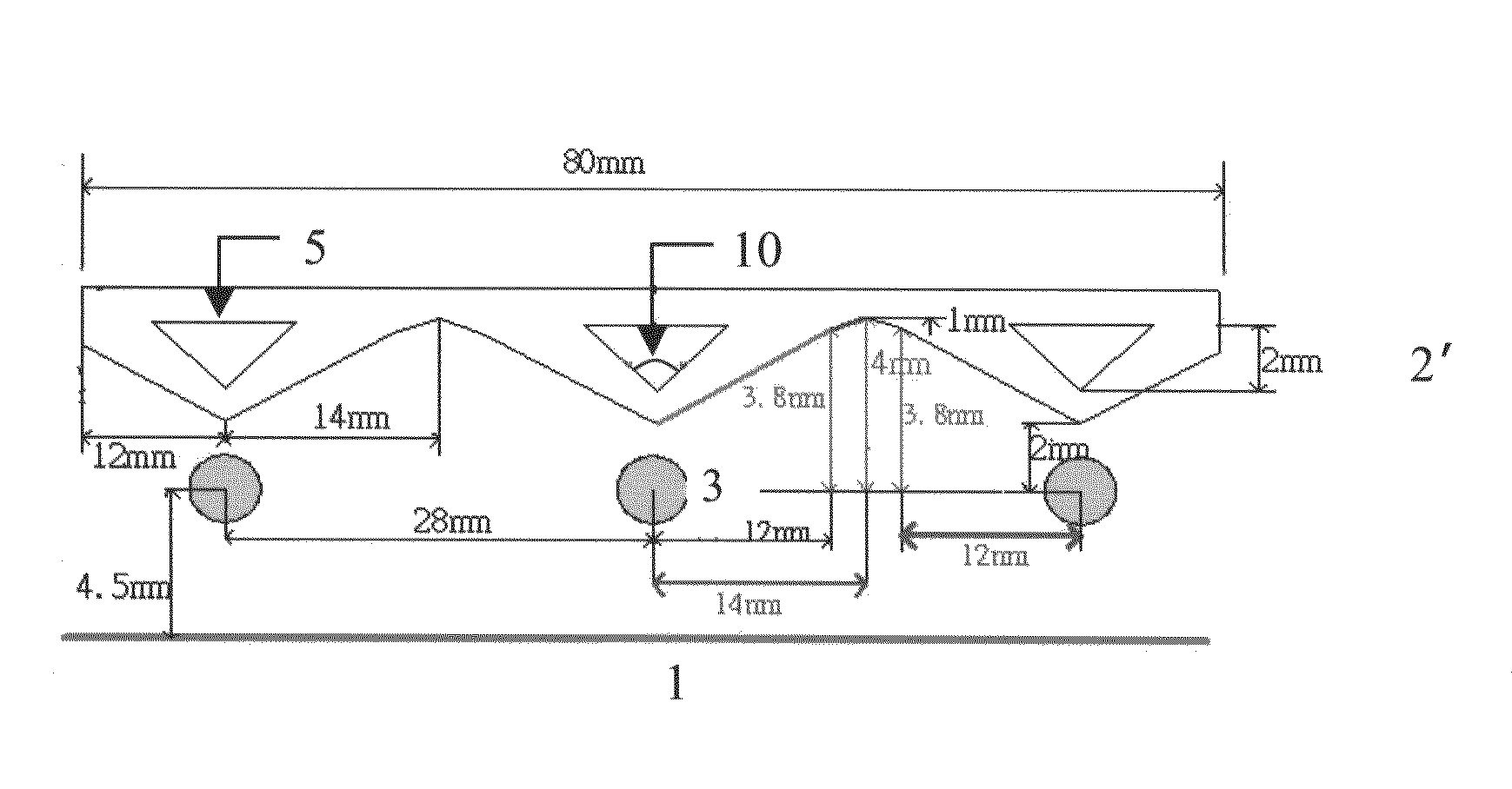

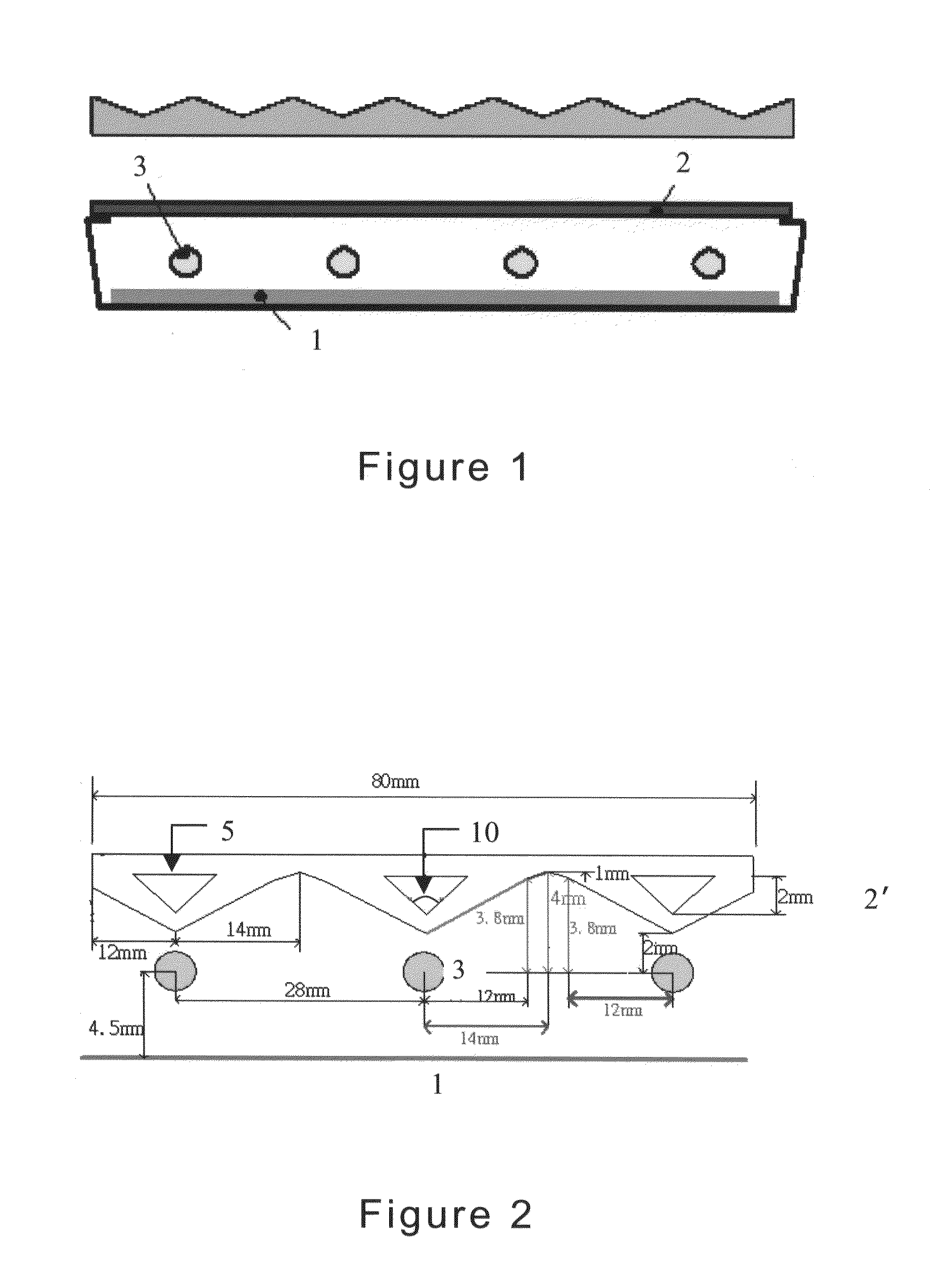

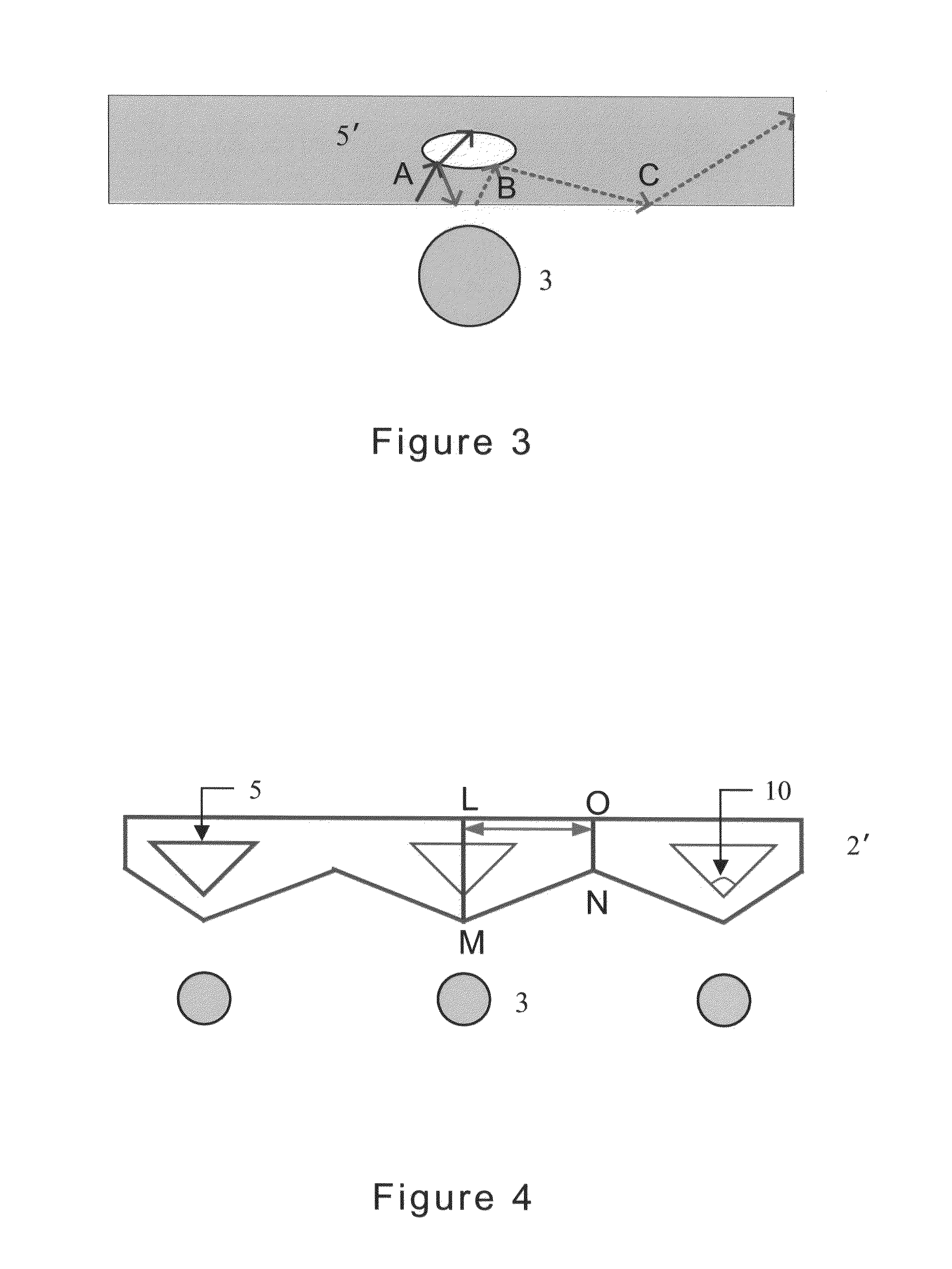

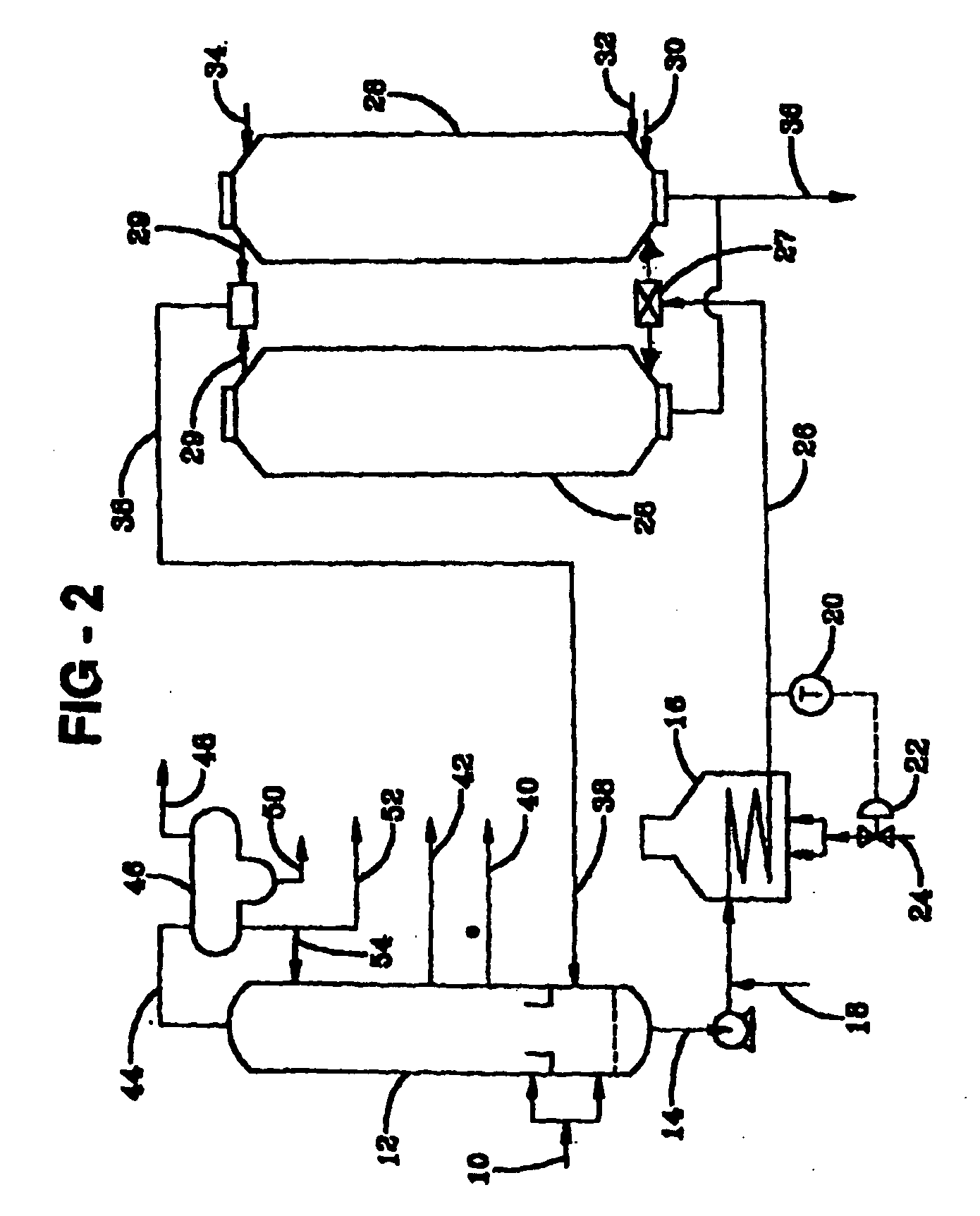

Bottom lighting backlight module having uniform illumination and process for manufacturing the same

InactiveUS7374312B2High temperature enduranceNo surface roughnessMeasurement apparatus componentsNon-linear opticsDiffusionEffect light

The present invention provides a bottom lighting backlight module comprising: a light reflecting plate, a plurality of light sources such as lamp and LED; and a diffusion sheet; wherein said diffusion sheet has an excavated structure of shape with cross-section of an inverted triangle having a specific apex angle ranging from 110 degrees to 130 degrees. Some of the light incident on the excavated structure inside the diffusion sheet can be totally reflected and redirected sideways, so that it is possible to reduce the local brightness for area around each light source but significantly improve the evenness of brightness for the whole module.

Owner:NAT CHIAO TUNG UNIV +1

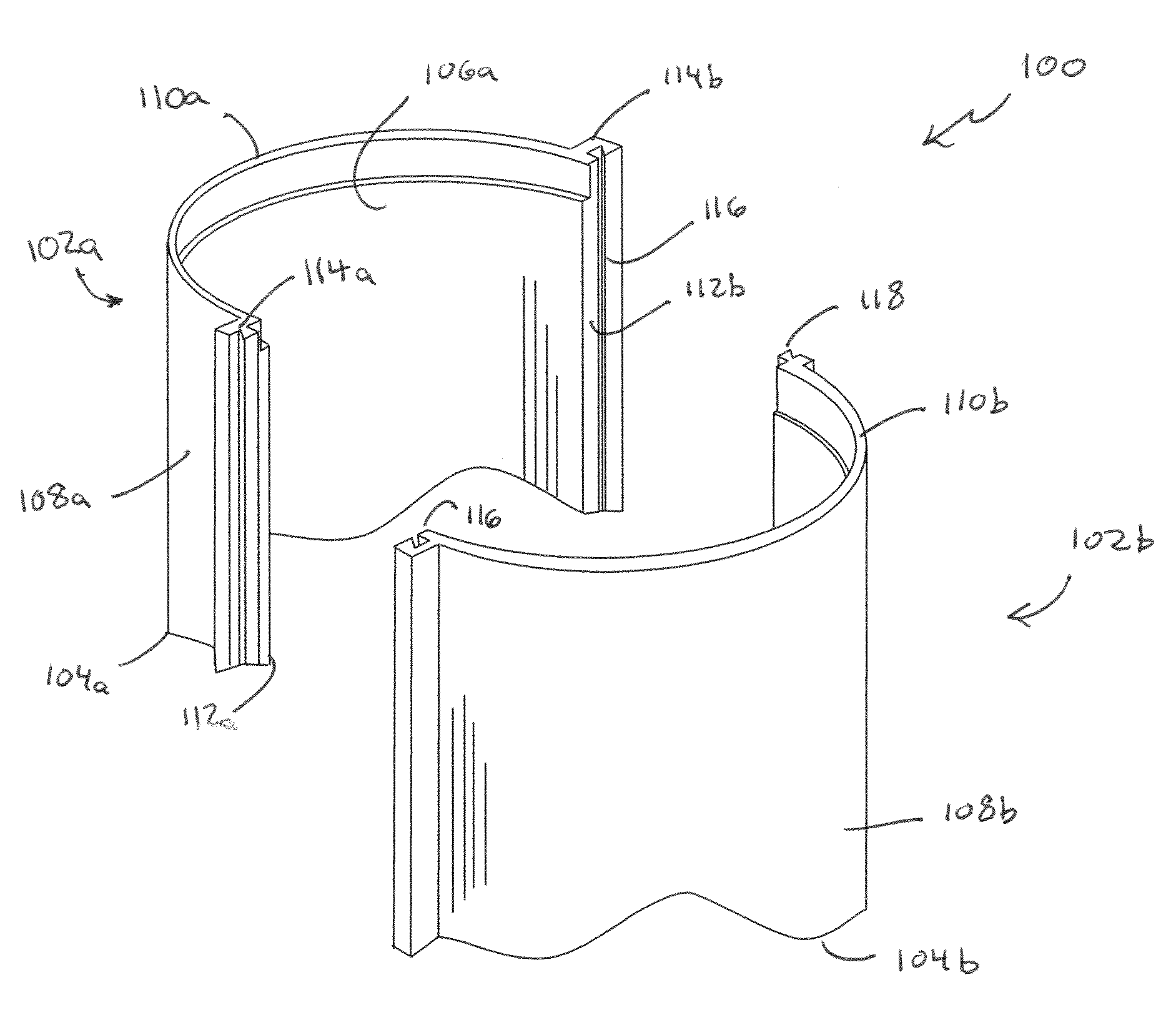

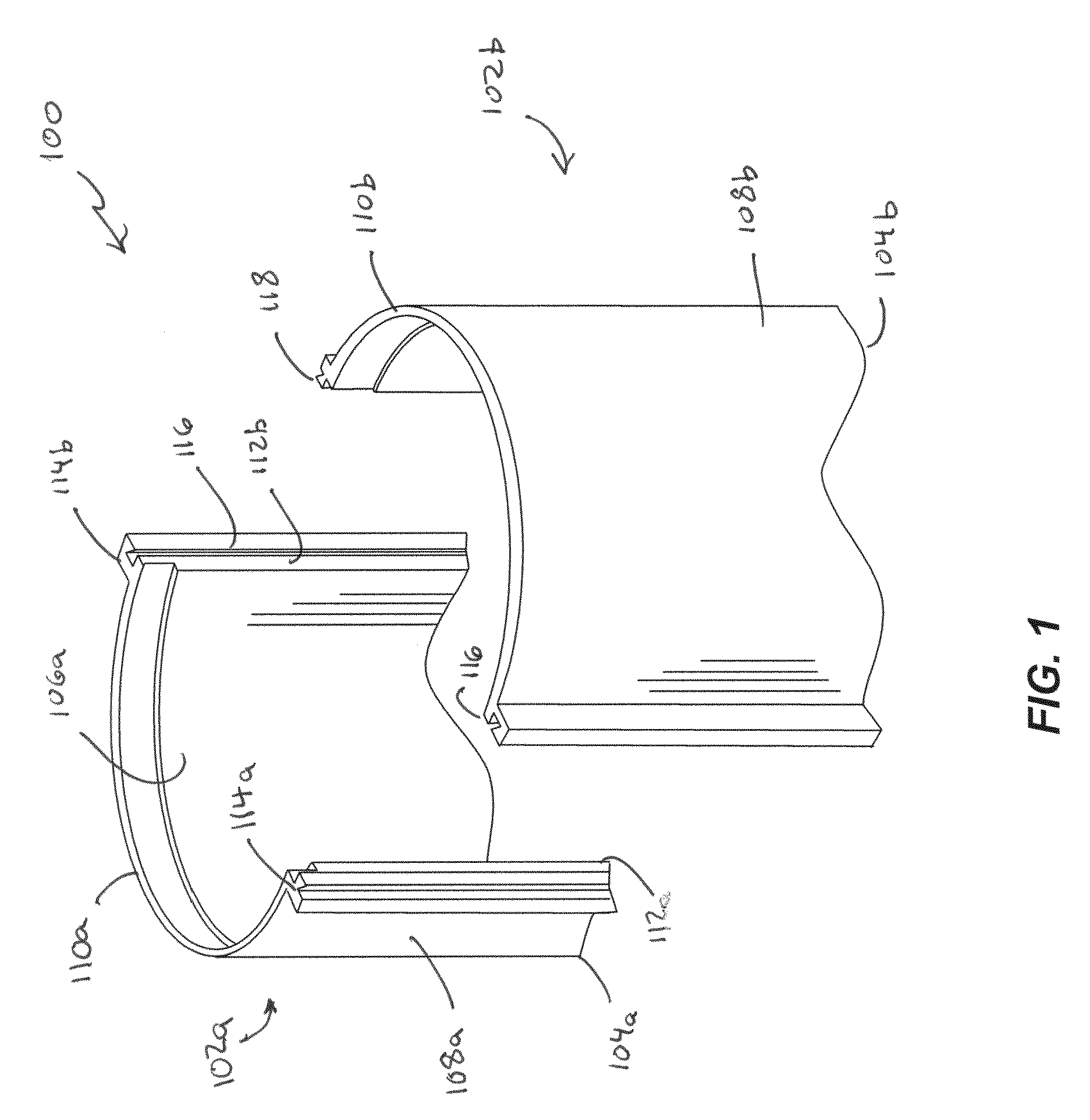

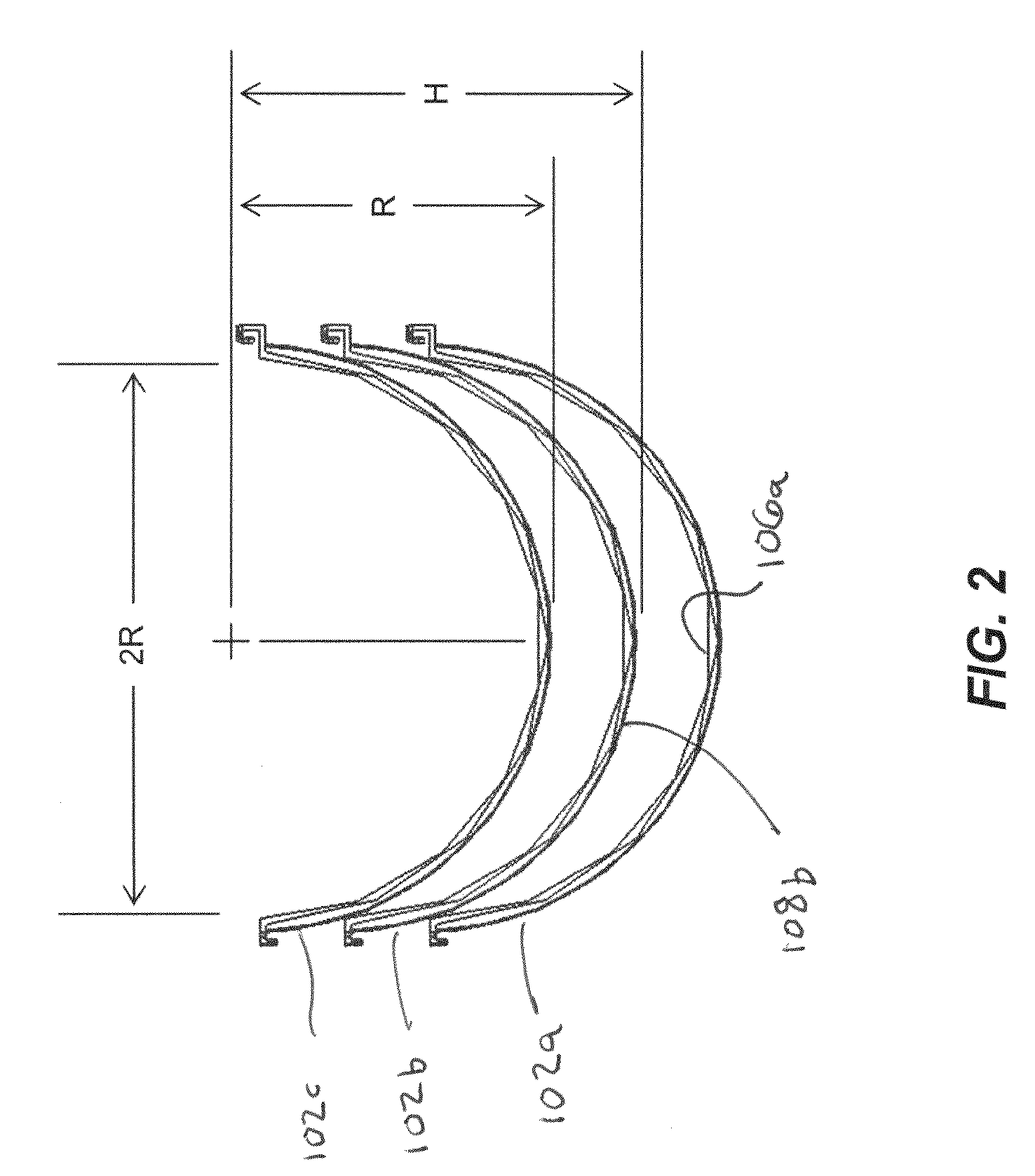

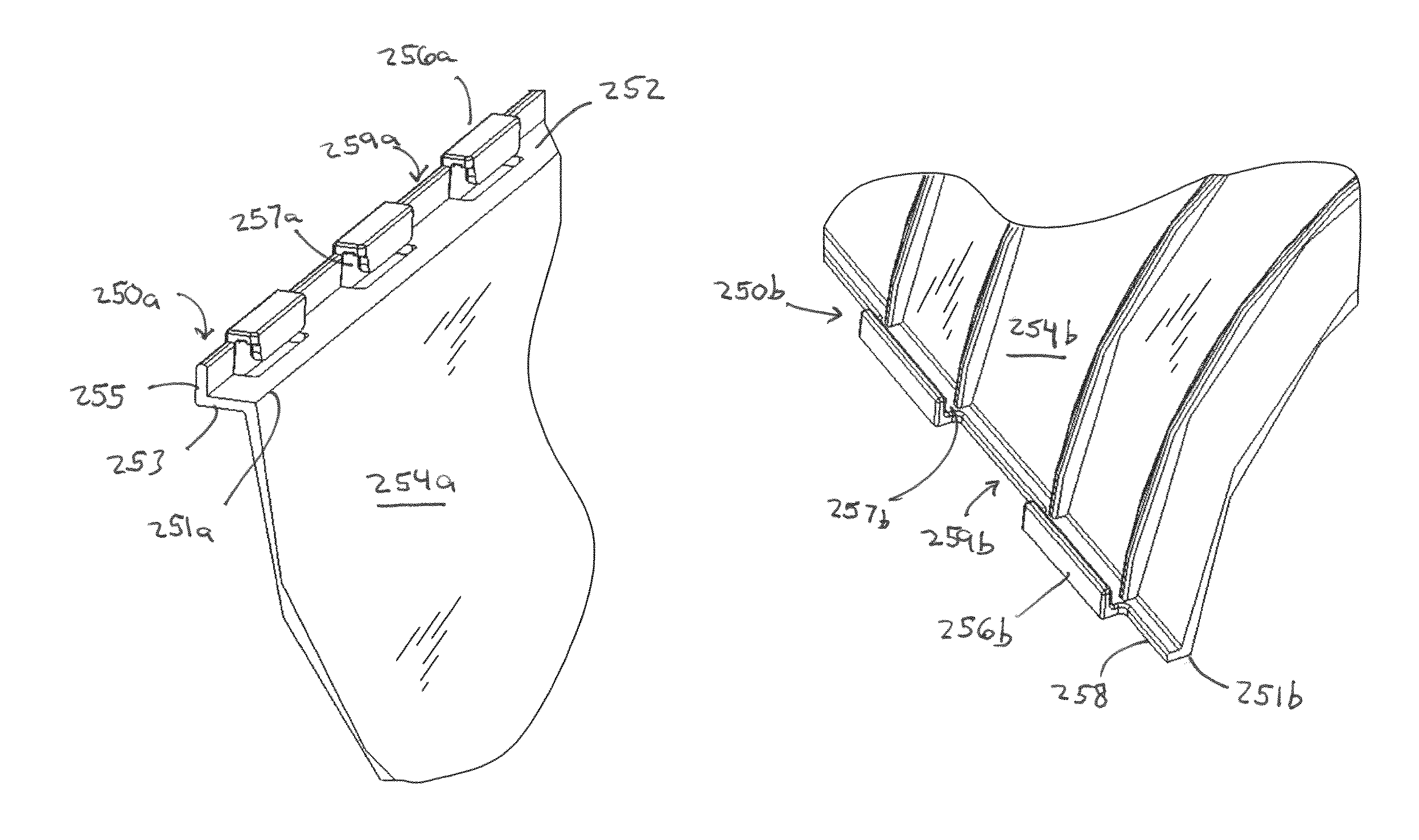

Concrete column forming assembly

Methods and apparatus providing a column forming assembly formable from multiple column forming sub-assemblies that are stackable providing a compact storage or transport configuration. A column forming structure is formed from multiple elongated wall sections configured for interlocking engagement with each other to form a hollow, open ended structure adapted to accept a settable substance, such as concrete or plaster. The multiple elongated wall sections are stackable and can be stored to shipped to a job site in a condensed or nested configuration. The nested configuration reduces empty or hollow spaces provided by assembled forms. In some embodiments, the forms can be disassembled after use for transport from the jobsite, storage, and later reuse. The column forming assembly can be combined with one or more column-end forms and with thin-walled column forming inserts.

Owner:SOUNDFOOTINGS

Fire retardant

InactiveUS6989113B1Good fire retarding ratingEffective and cost-efficient and aesthetically pleasingFireproof paintsAntifouling/underwater paintsFoaming agentNitrogen

Fire retardant composition includes an ammonium phosphate substance, which is in contact with a carbonific, for example, glucose, and a nitrogenous spumific, for example, urea. A polysaccharide and / or a nonionic alkylpolyglycoside surfactant may be present. The composition may be in the form of a clear, aqueous liquid.

Owner:NO BURN INVESTMENTS

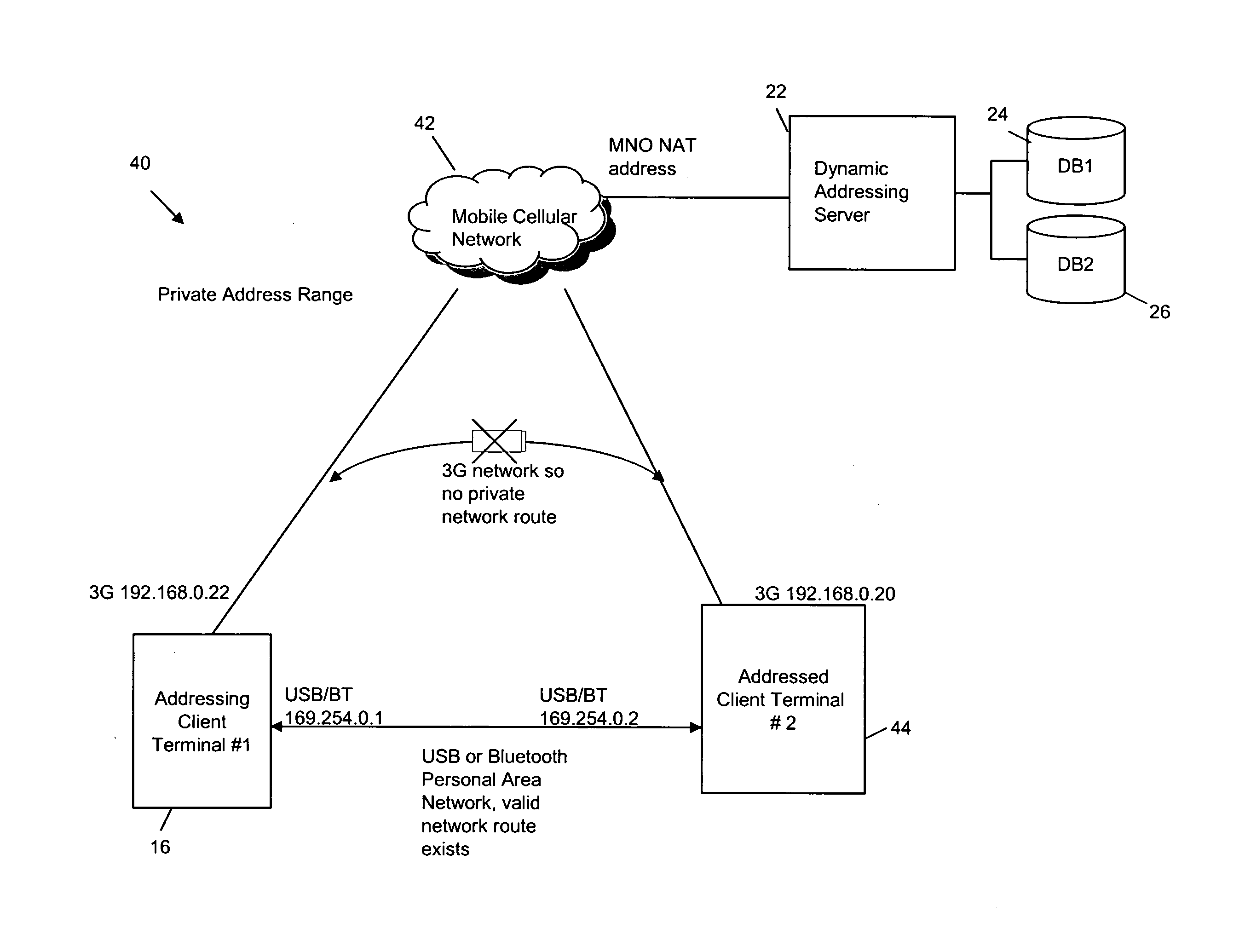

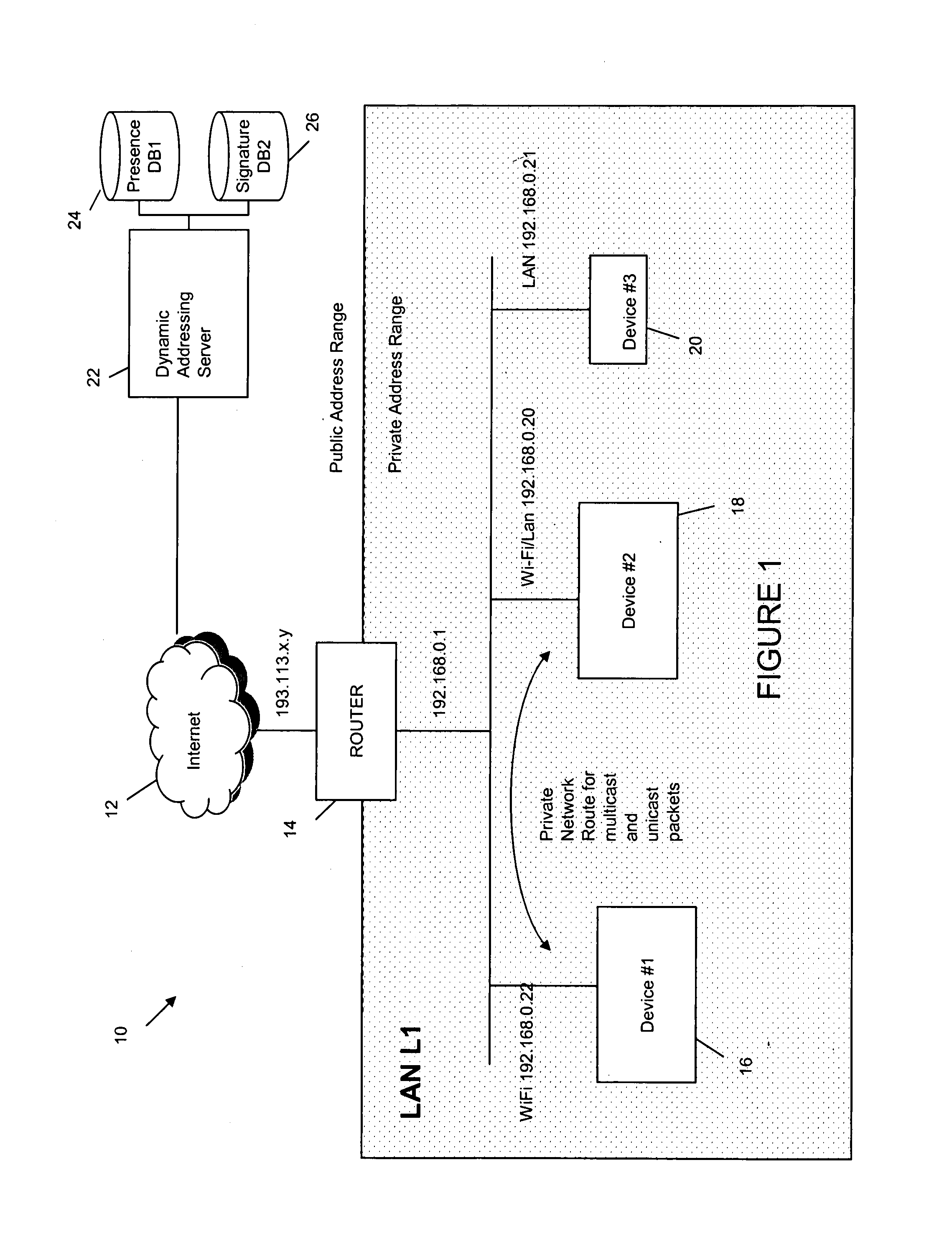

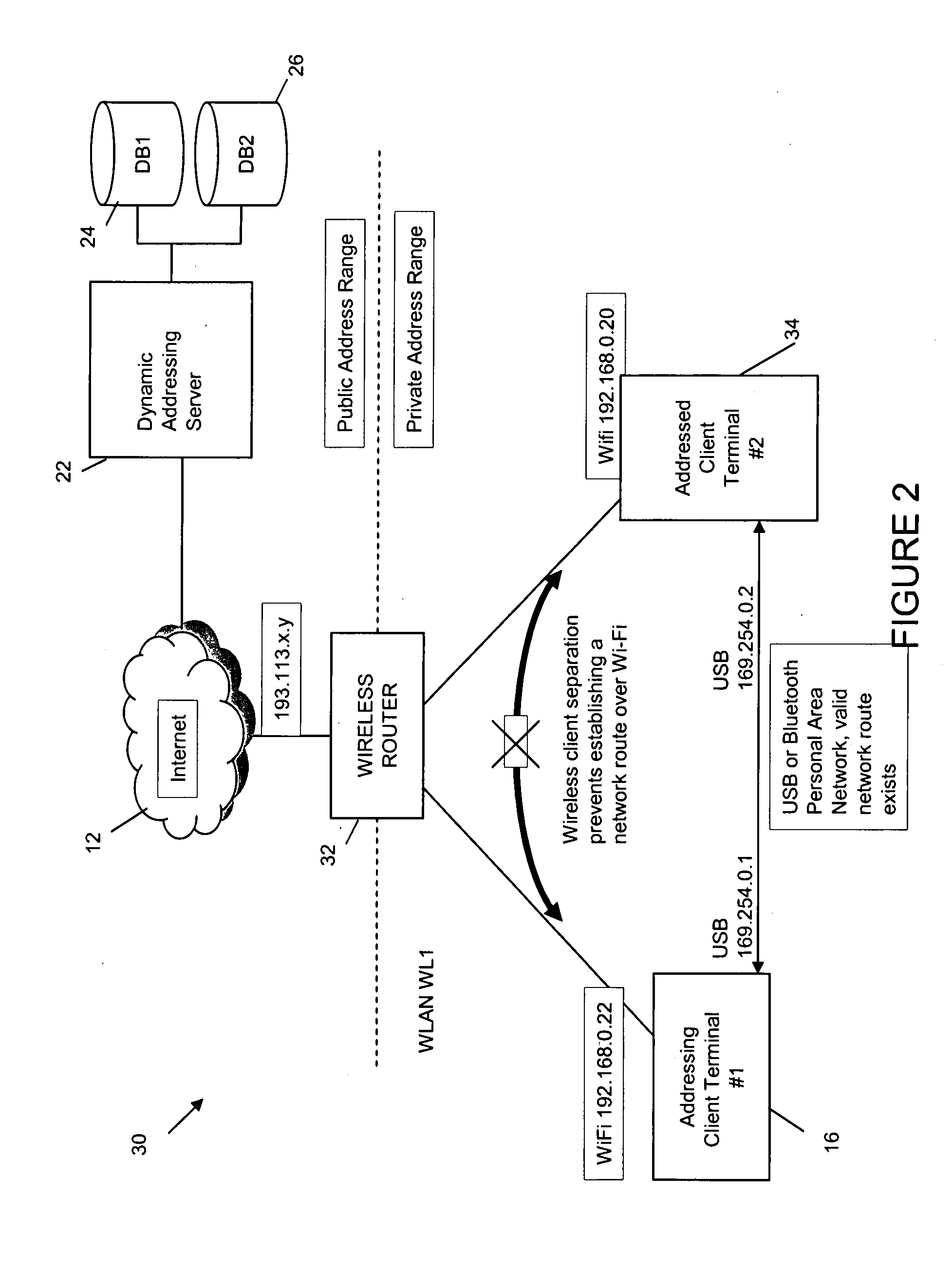

Addressing scheme

An addressing scheme enables mobile web-service providing devices located within private address domains to be contacted by other devices located on the same LAN segment regardless of whether or not the two devices are located in the same private IP address domain, providing a working network path can be identified directly or indirectly between the two devices. In this way, if a device-label (such as a telephone number which is associable with an addressed device) is provided by an addressing device to an addressing server, the server is able to resolve the device-label to a private address via which the addressing device can contacted. The private address is utilized by the web-browser application to seamlessly and transparently obtain a requested web-service from the addressed device using any suitable communications channel, e.g. WiFI, Bluetooth, etc, that provides a working path between the two devices.

Owner:BRITISH TELECOMM PLC

Concrete column forming assembly

ActiveUS8485493B2Many problemLight weightStrutsForms/shuttering/falseworksMechanical engineeringHollow core

Owner:SOUNDFOOTINGS

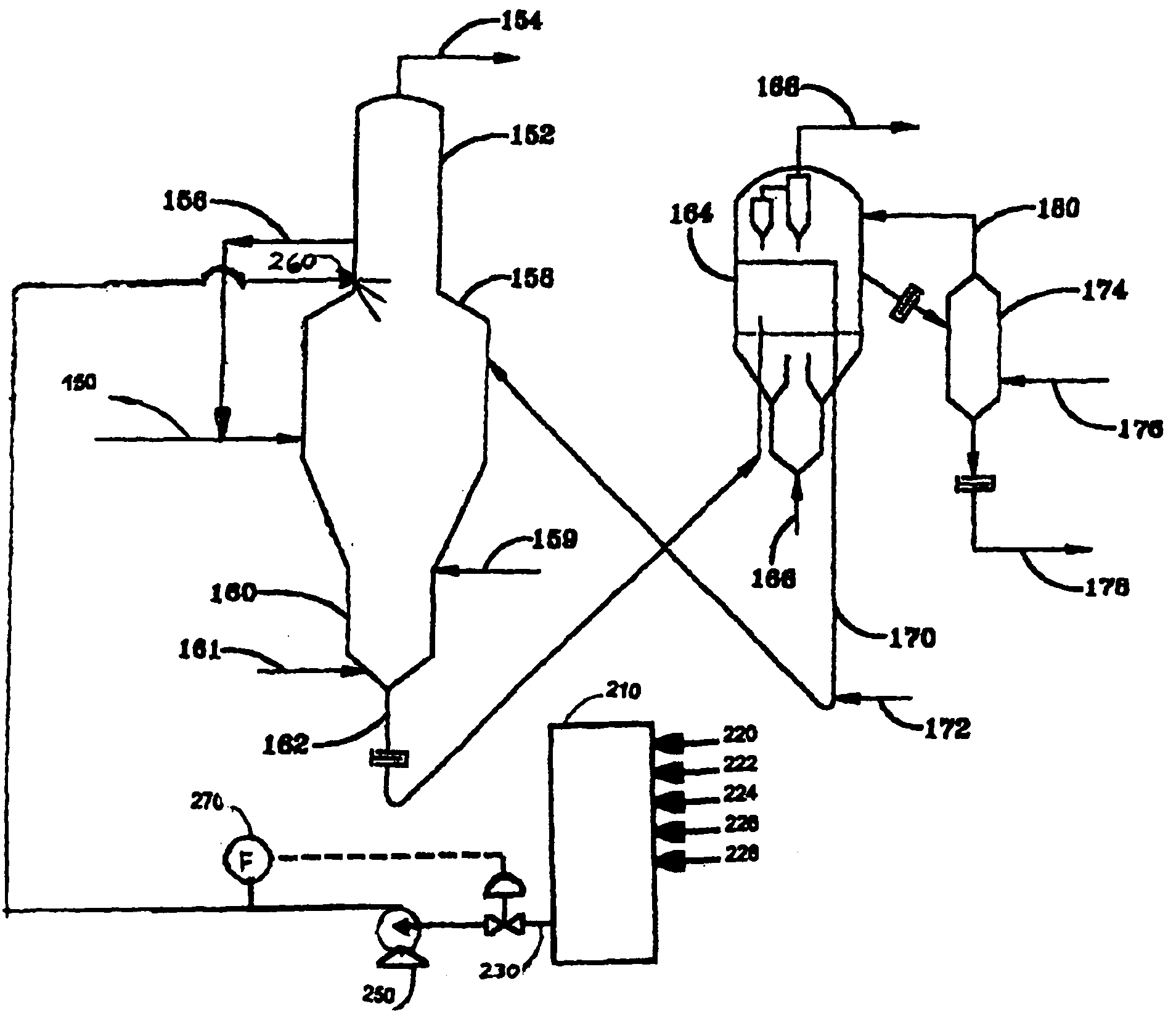

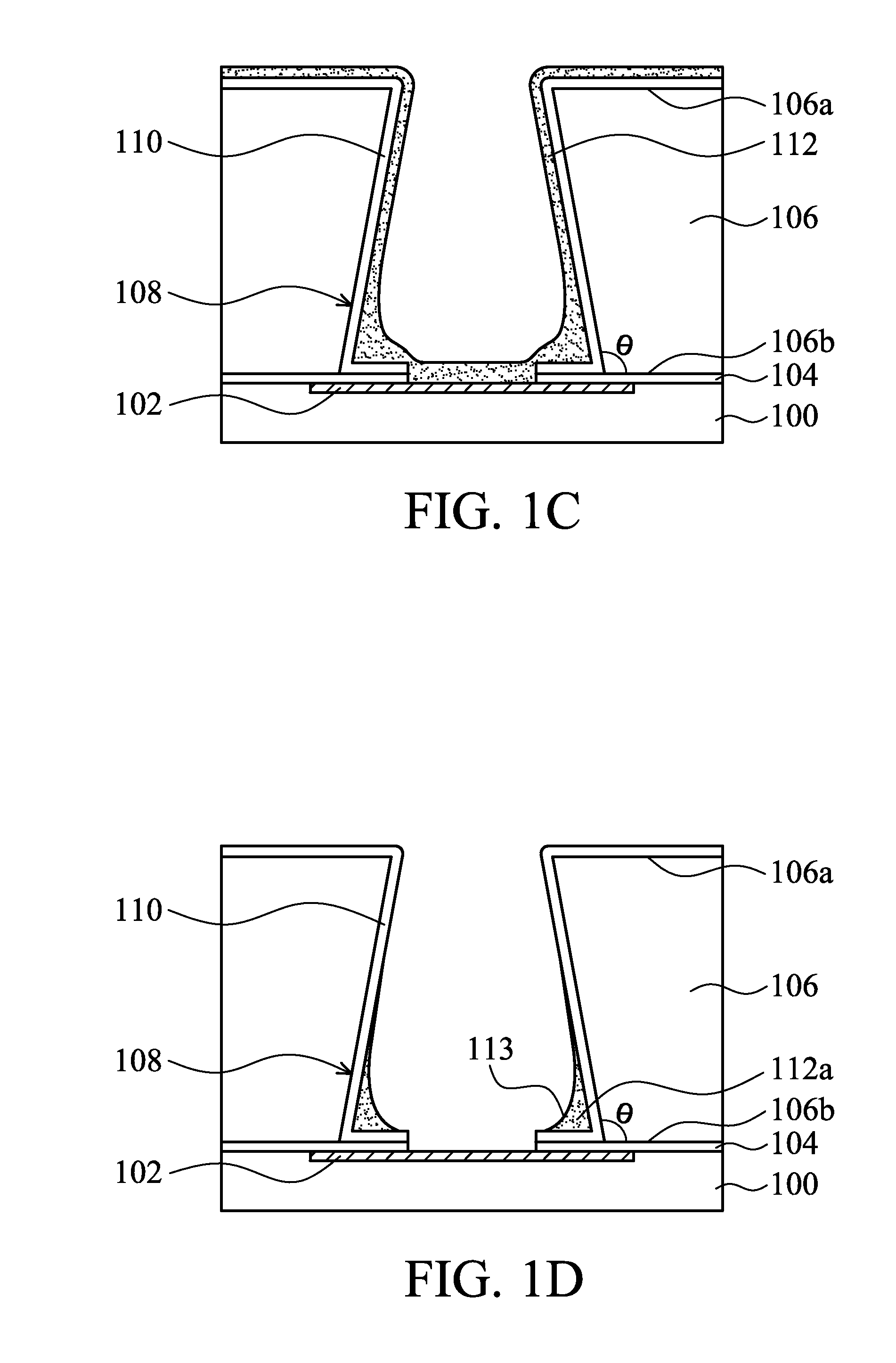

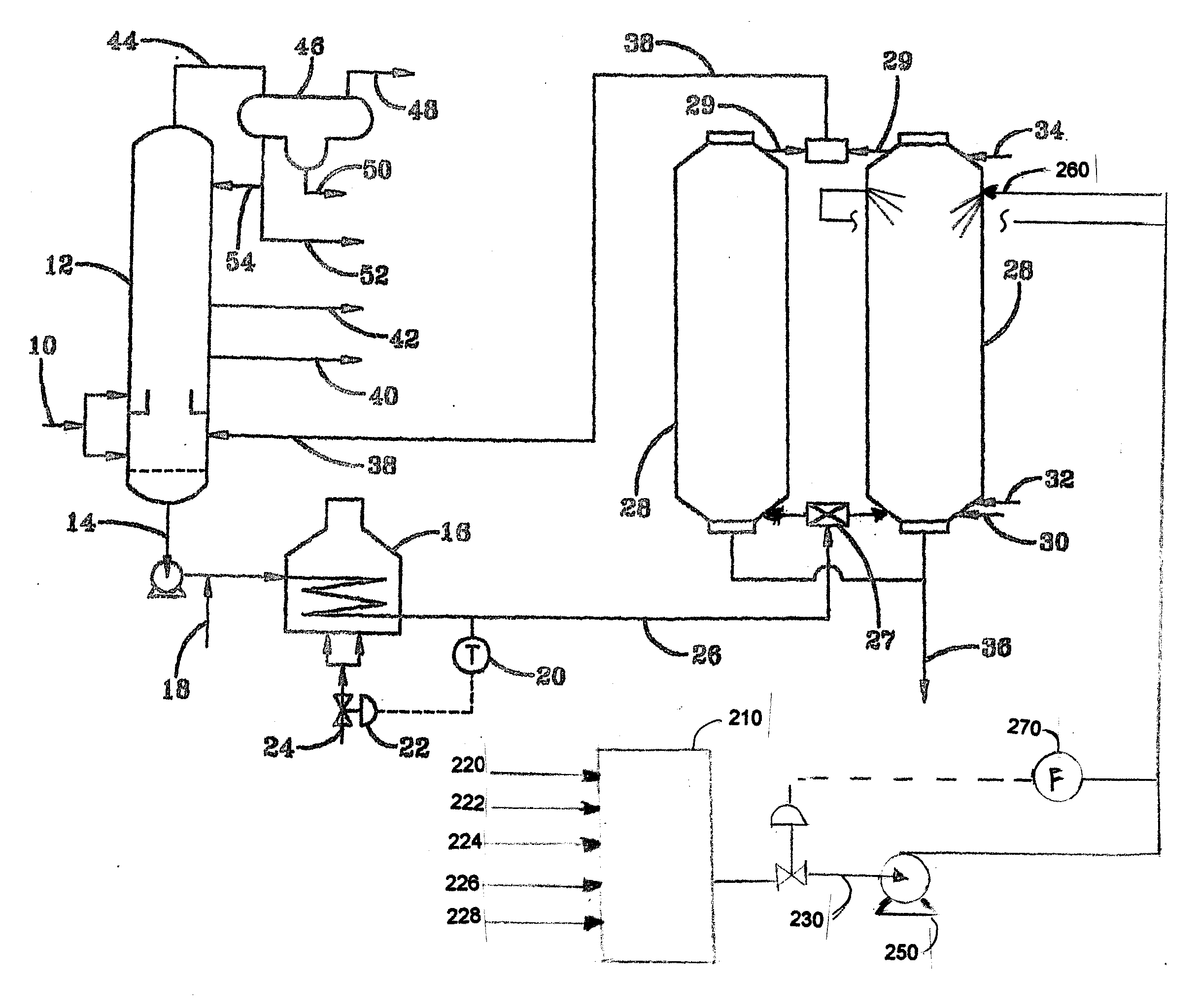

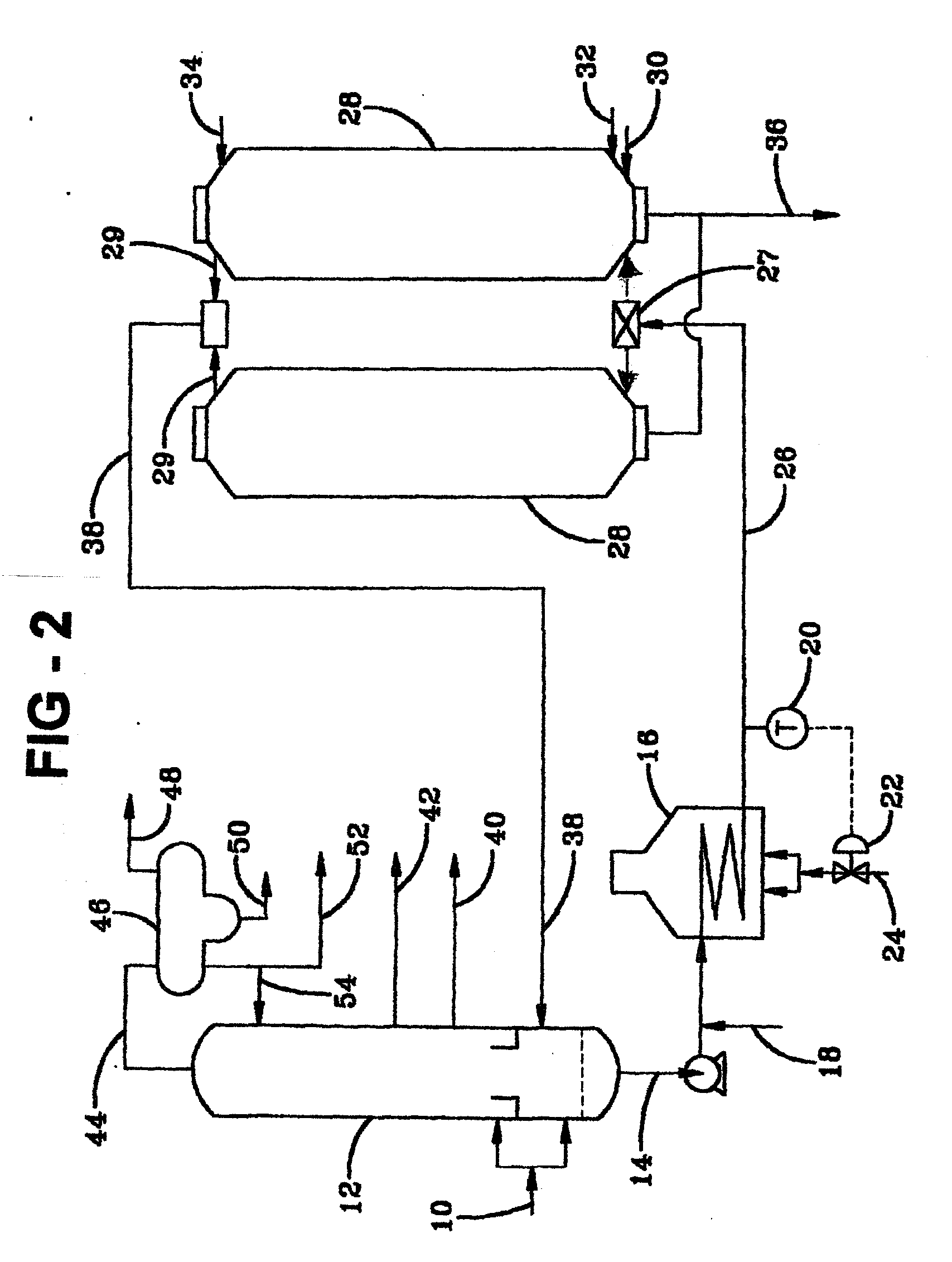

System and Method for Introducing an Additive into a Coking Process to Improve Quality and Yields of Coker Products

InactiveUS20090152165A1Promotes cokingImprove cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointTar

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. The quenching effect of the additive can be effectively used to condense the highest boiling point compounds onto the catalyst(s), thereby focusing the catalyst exposure to these target reactants. With a catalyst to crack these highest boiling point materials, this mechanism can effectively increase the catalyst's selectivity, thereby increasing its efficiency and reducing catalyst requirements and costs. Selective, catalytic conversion of the highest boiling point materials in the coking process product vapors (coker recycle and / or ‘heavy tail’ of the heavy coker gas oil) may be accomplished with an exemplary embodiment of the present invention in varying degrees. Exemplary embodiments of the present invention can also provide methods to control the (1) coke crystalline structure and (2) the quantity and quality of volatile combustible materials (VCMs) in the resulting coke. Pet coke from this process may have unique characteristics with substantial utility.

Owner:ETTER ROGER G

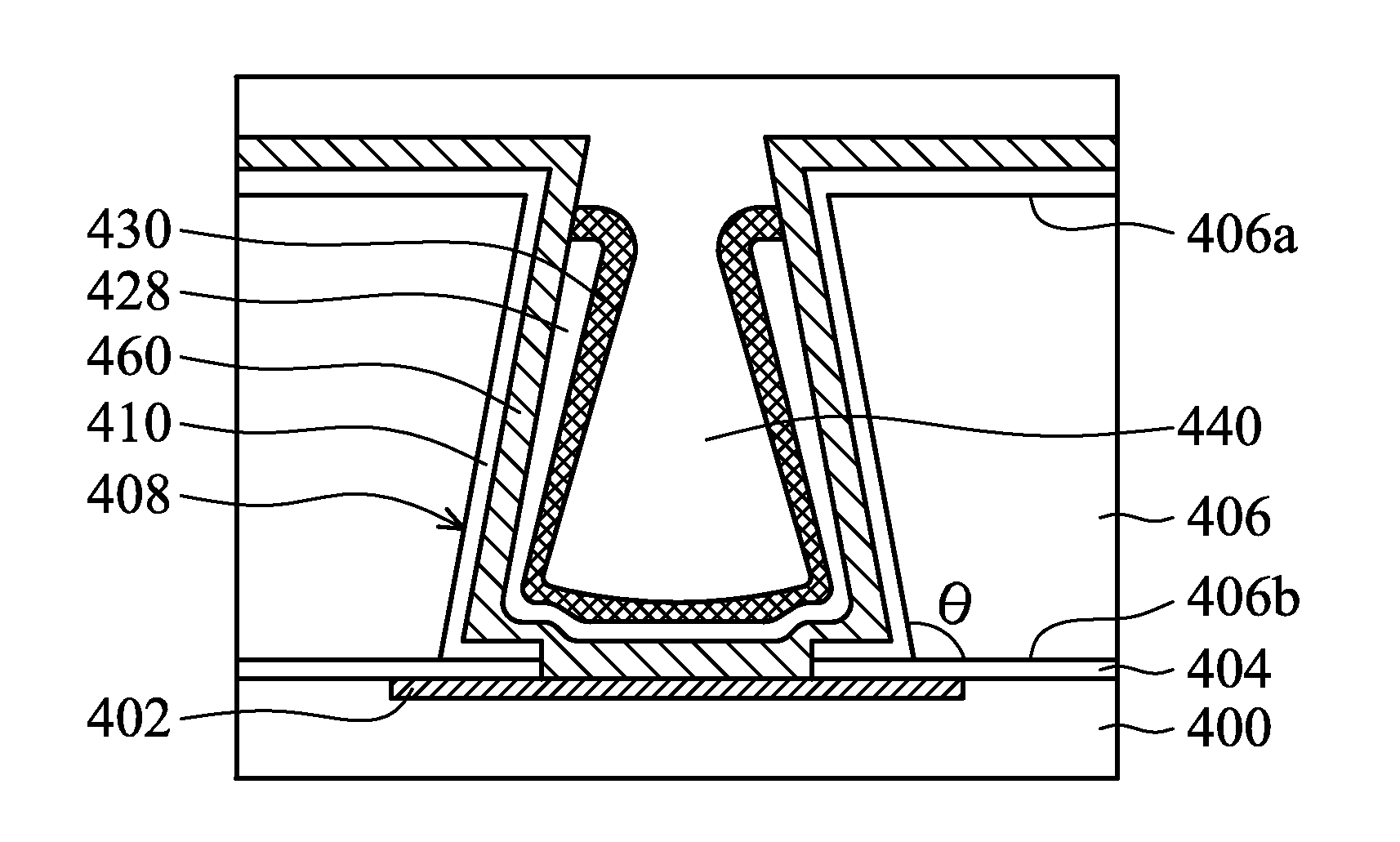

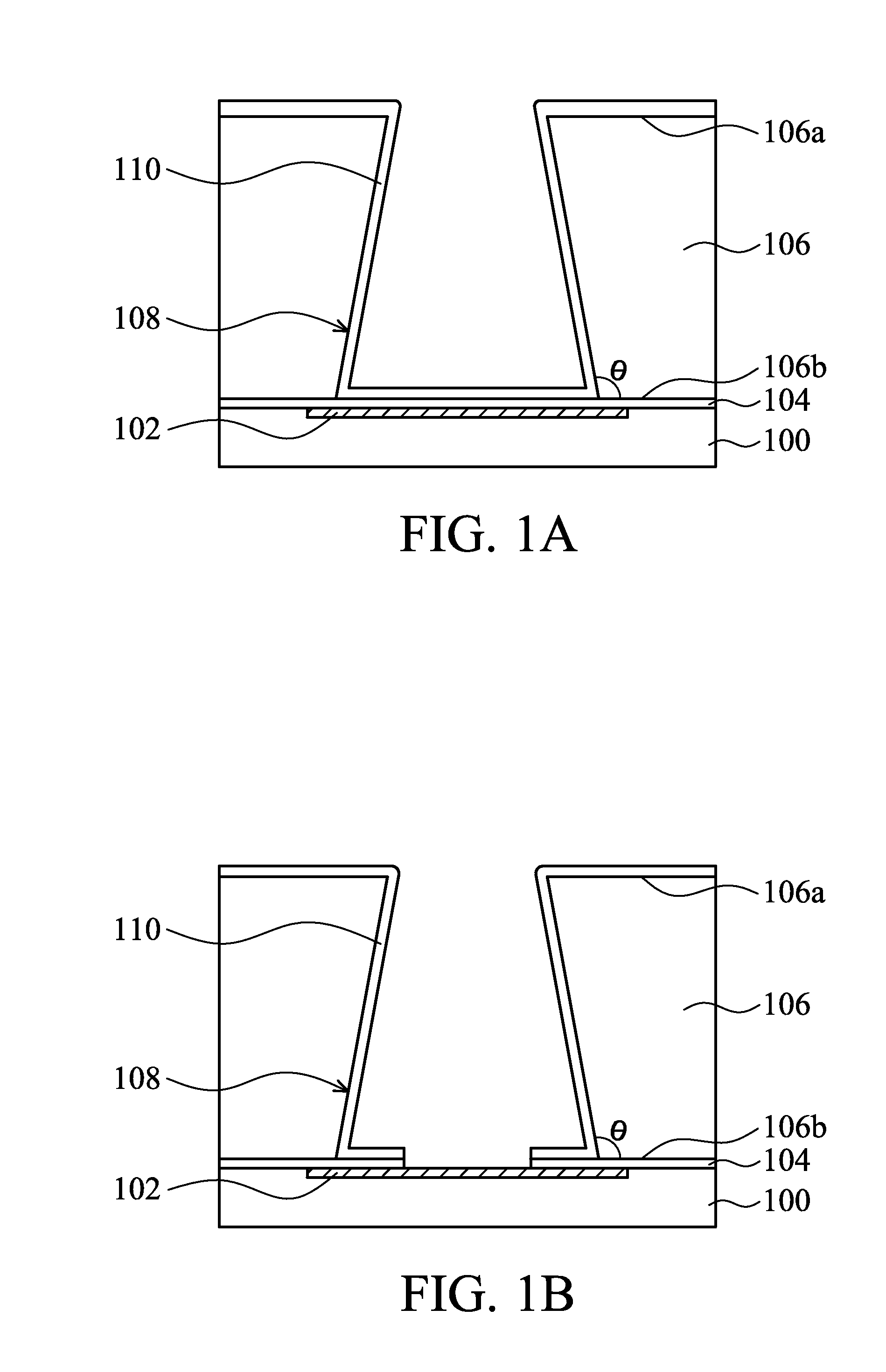

Chip package and method for forming the same

ActiveUS20110193241A1Reduce thicknessImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPhysics

According to an embodiment of the invention, a chip package is provided, which includes: a substrate having an upper surface and a lower surface; a hole extending from the upper surface toward the lower surface; an insulating layer located overlying a sidewall of the hole; and a material layer located overlying the sidewall of the hole, wherein the material layer is separated from the upper surface of the substrate by a distance and a thickness of the material layer decreases along a direction toward the lower surface.

Owner:XINTEC INC

System and Method of Introducing an Additive with a Unique Catalyst to a Coking Process

InactiveUS20090209799A1High propensity to cokePromotes cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkyl transferNaphtha

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. Modifications of the catalysts in the additive improve performance for certain desired outcomes. One exemplary embodiment of the present invention uses the olefin production capabilities from newly developed catalysts to increase the production of light olefins (e.g. ethylene, propylenes, butylenes, pentenes) for alkylation process unit feed, the production of oxygenates, and petrochemical feedstocks, such as plastics manufacture. Another exemplary embodiment of the present invention is the use of the olefin production from newly developed catalysts to improve the coker naphtha quality. A third exemplary embodiment of the present invention uses the cracking characteristics of newly developed catalysts to optimize the production of light gas oils, naphtha, and gases from the coking process.

Owner:ETTER ROGER G +1

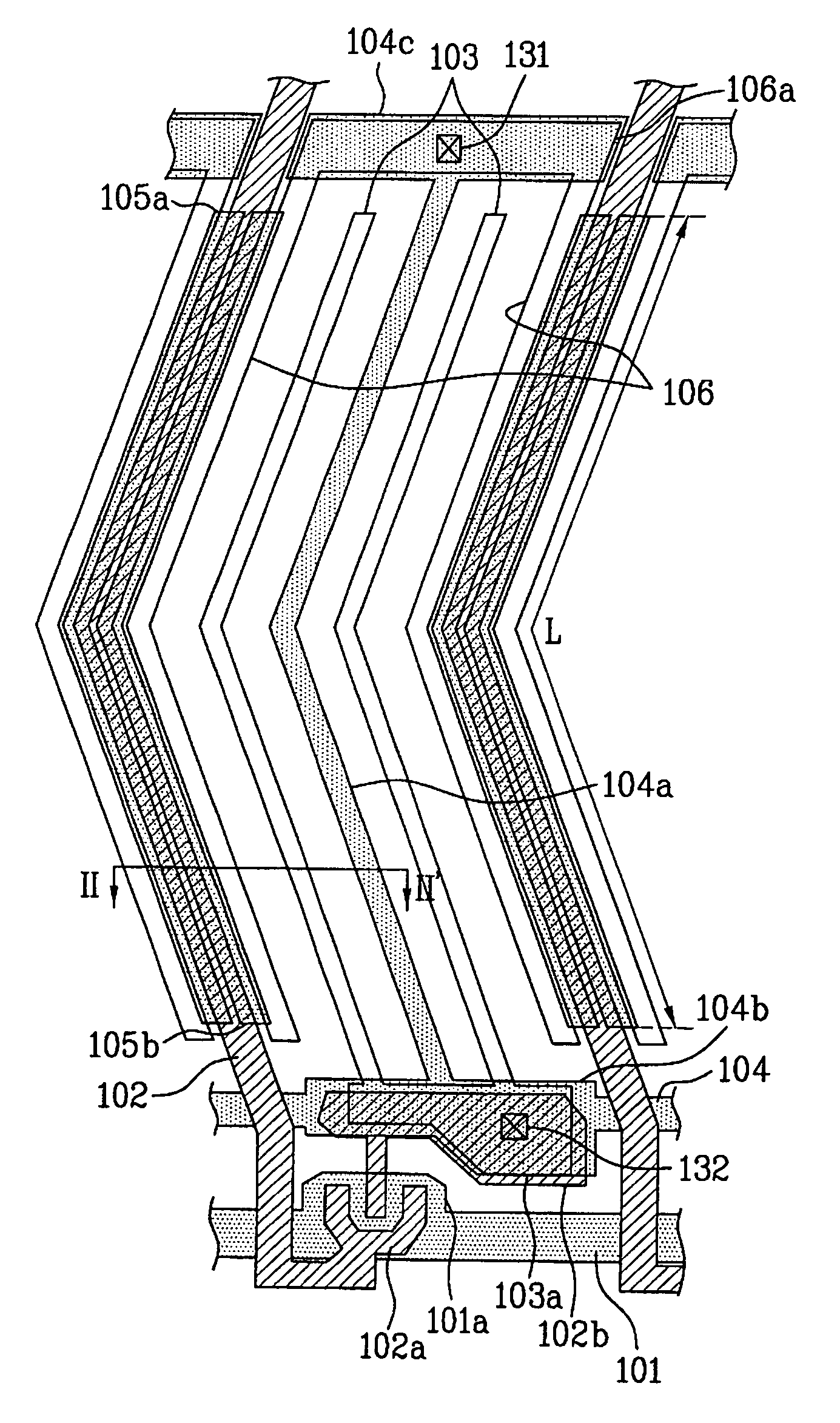

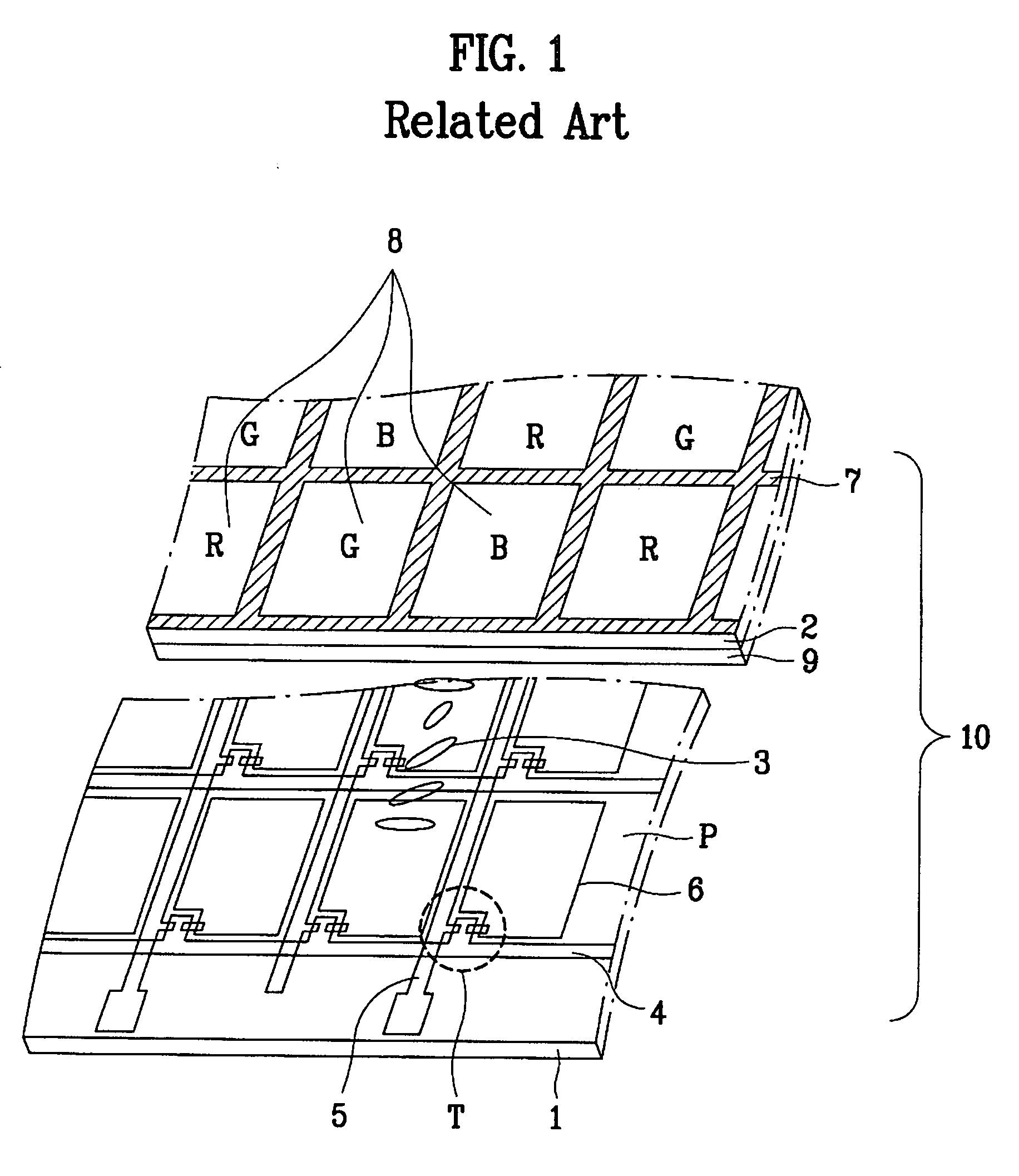

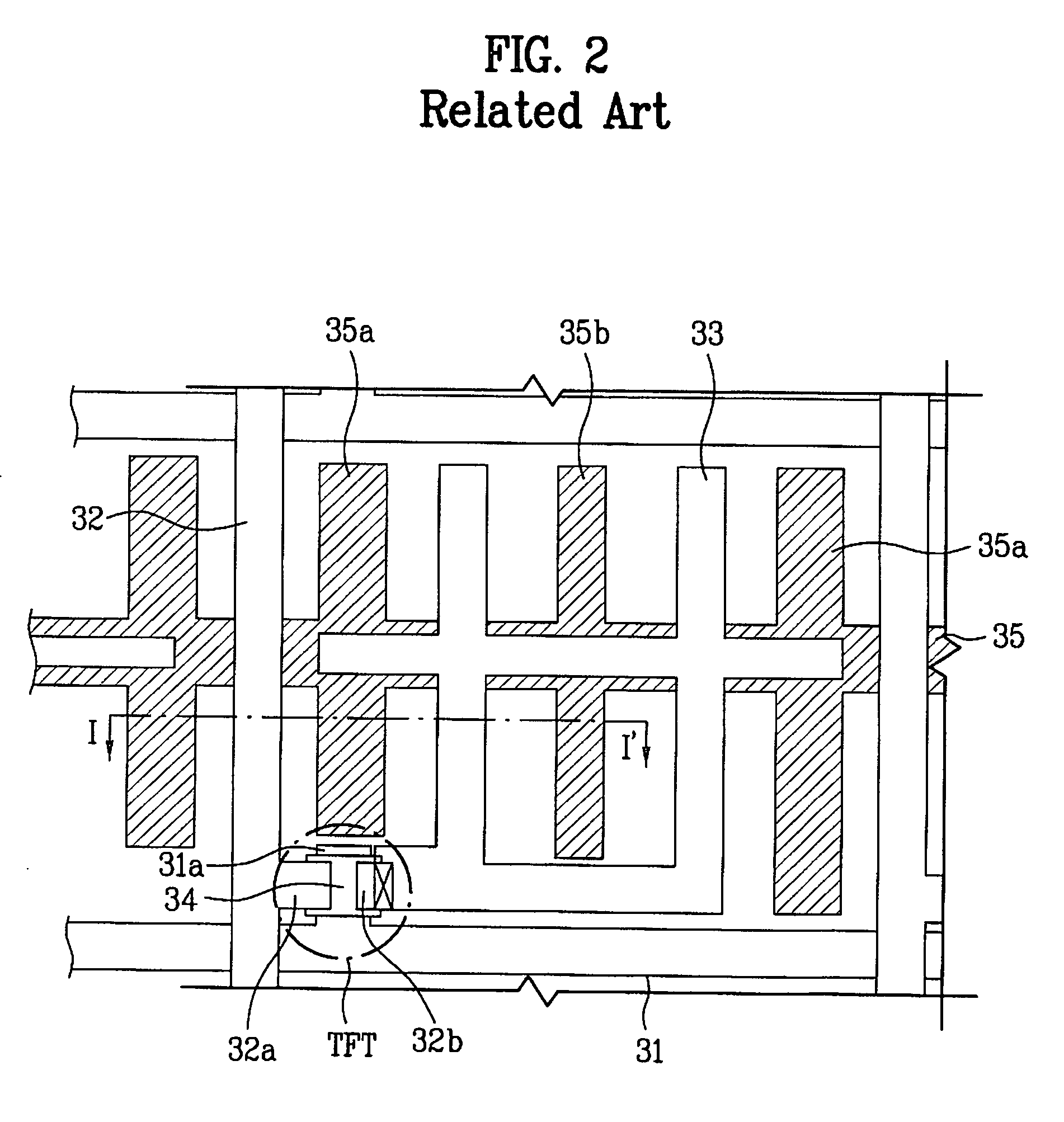

In-plane switching mode liquid crystal display device

ActiveUS20060227276A1High light transmittancePrevents viewing angle crosstalkNon-linear opticsIn planeLiquid-crystal display

An IPS mode LCD device includes first and second substrates facing each other, gate and data lines on the first substrate and crossing each other to define a plurality of unit pixel regions, first and second electrode patterns formed in an island shape at a pre-determined interval therebetween and overlapped with sides of the data line, a plurality of common electrodes formed in the unit pixel regions, each of the common electrodes having outermost common electrodes partially overlapped with the first and second electrode patterns, a pixel electrode alternately provided with the common electrodes within the pixel unit region, and a liquid crystal layer formed between the first and second substrates.

Owner:LG DISPLAY CO LTD

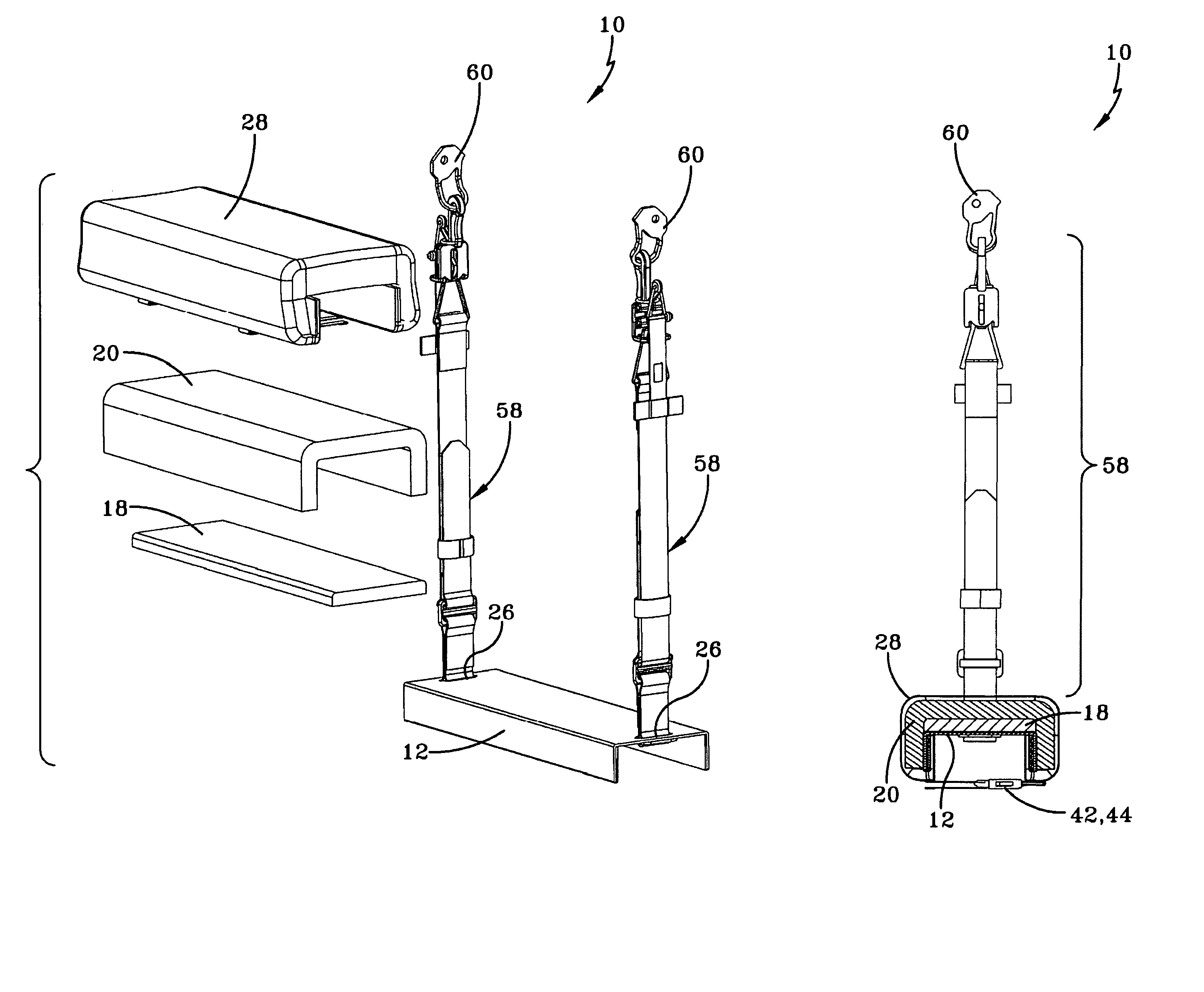

Drive for coverings for architectural openings

ActiveUS7886803B2Many problemEliminate needLight protection screensPackagingLinear motionEngineering

A cord drive mechanism to convert linear motion to circular motion for use in coverings for architectural openings. Various controls are used to provide a braking force on the cord. Some of the embodiments incorporate a capstan.

Owner:HUNTER DOUGLAS INC

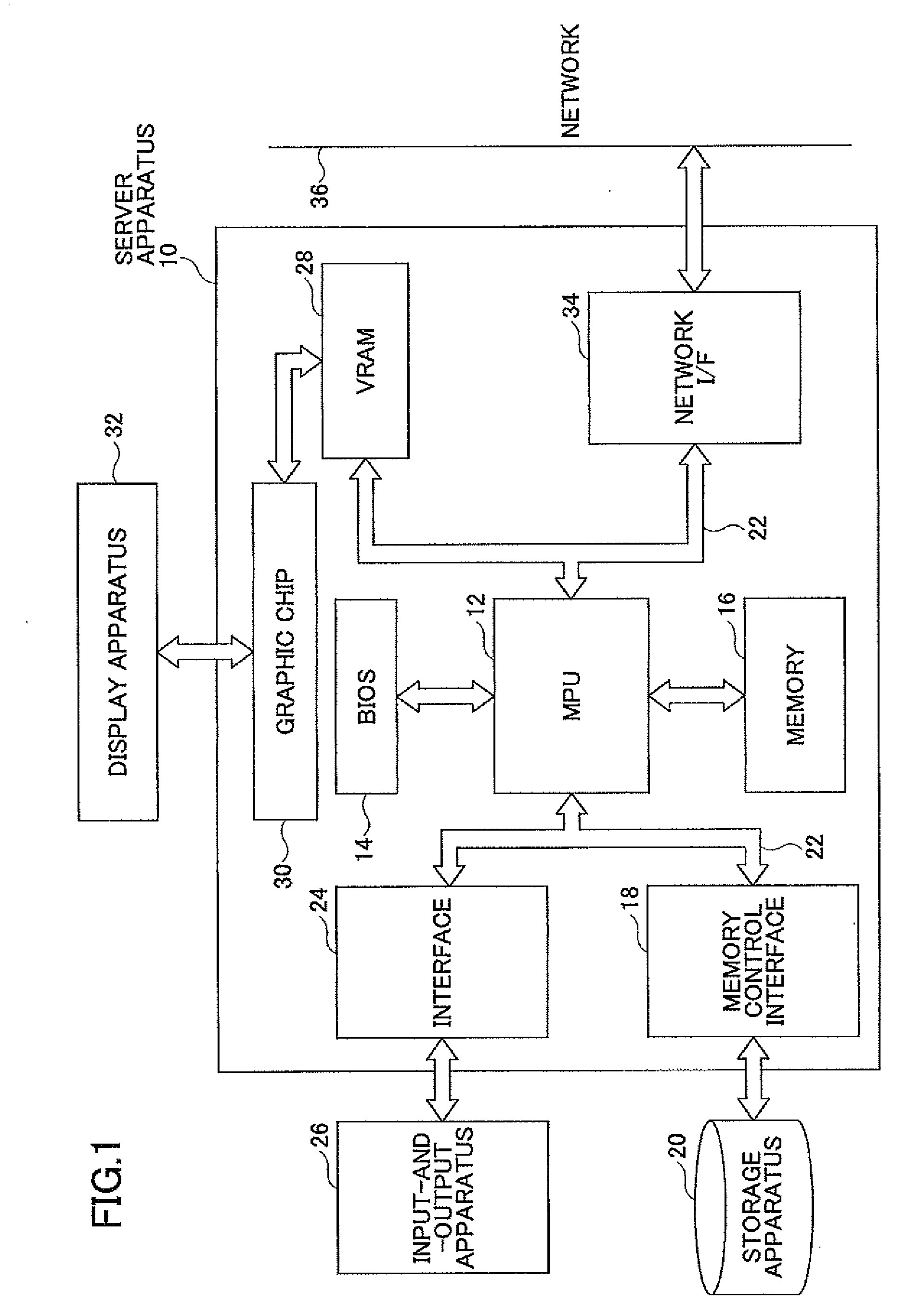

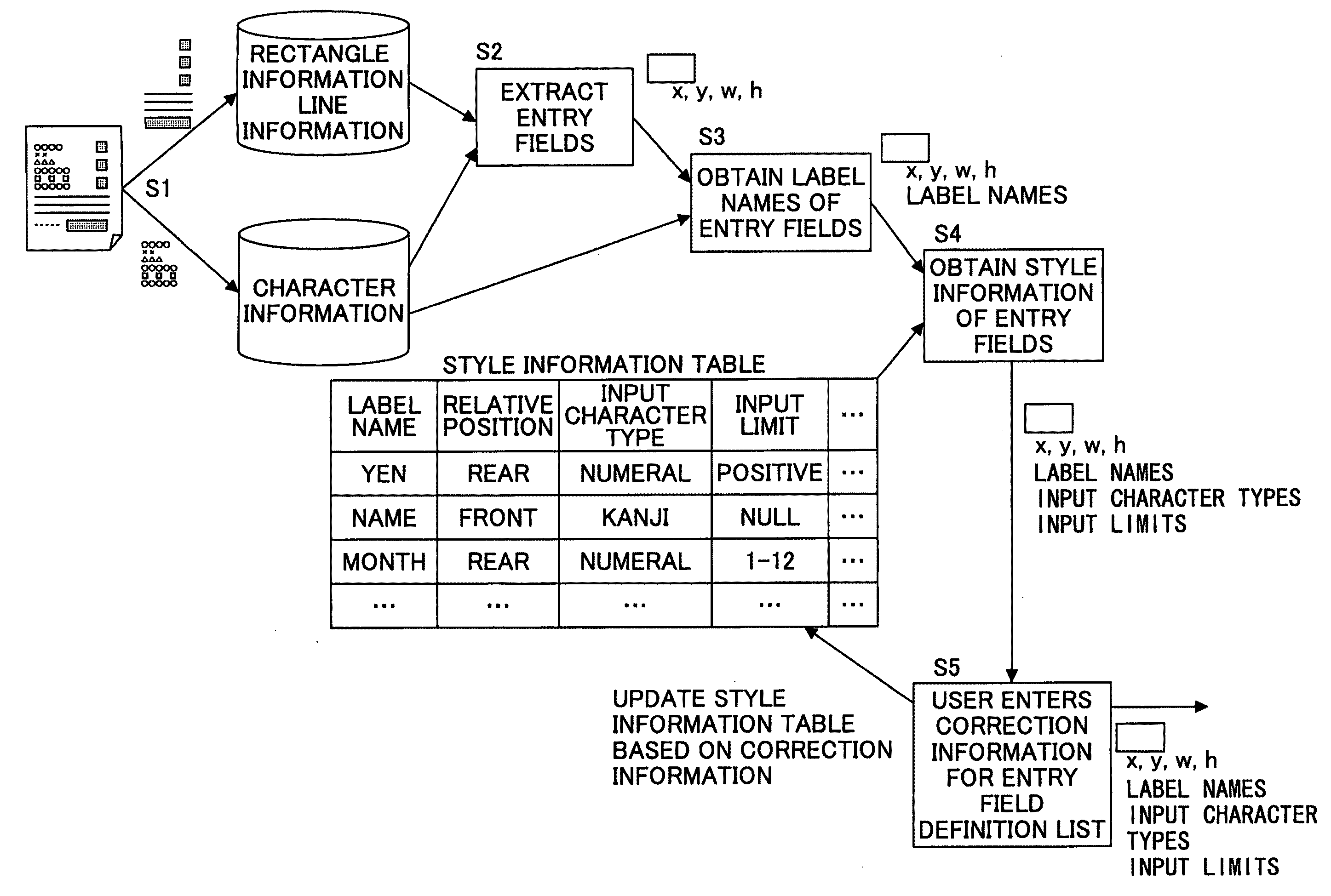

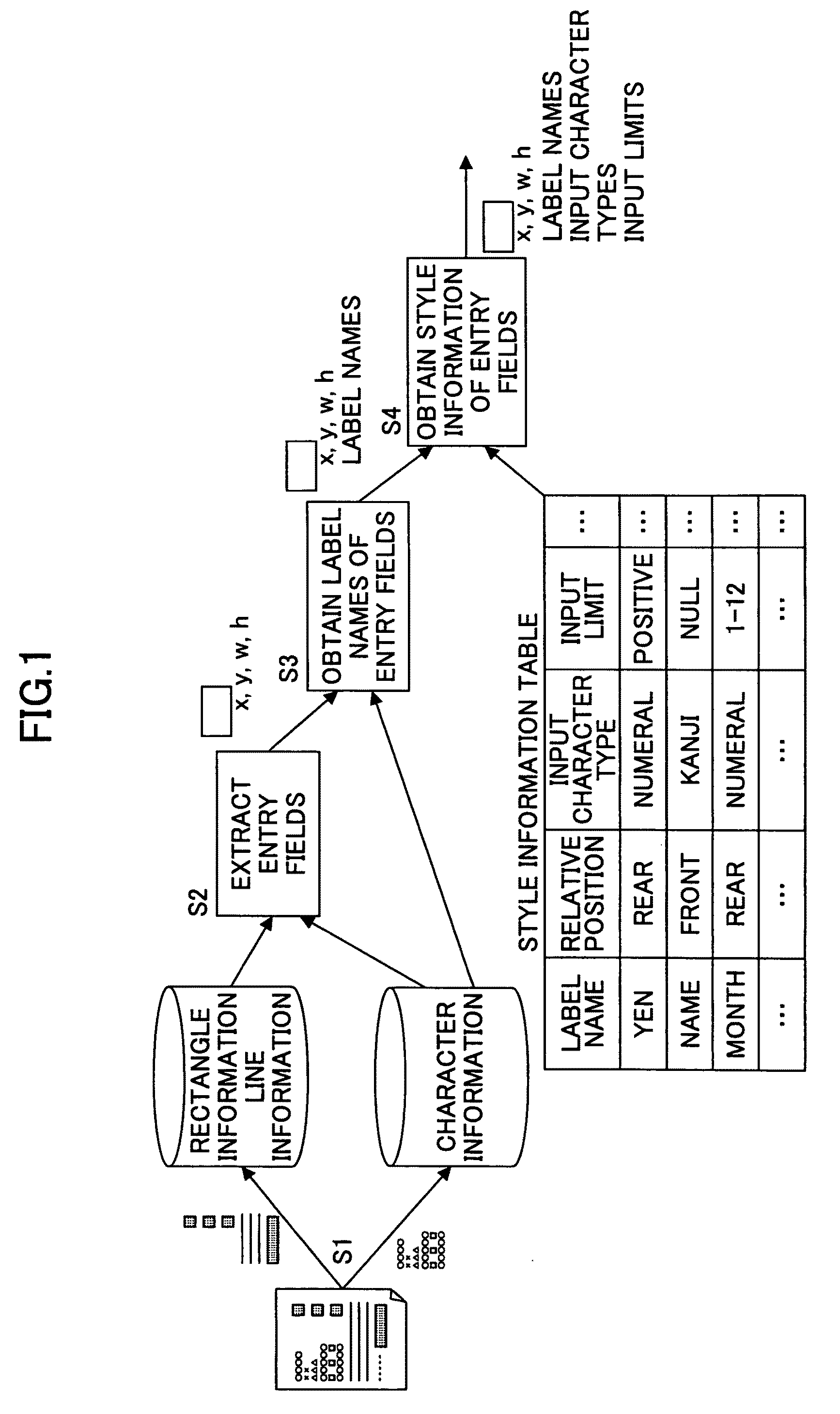

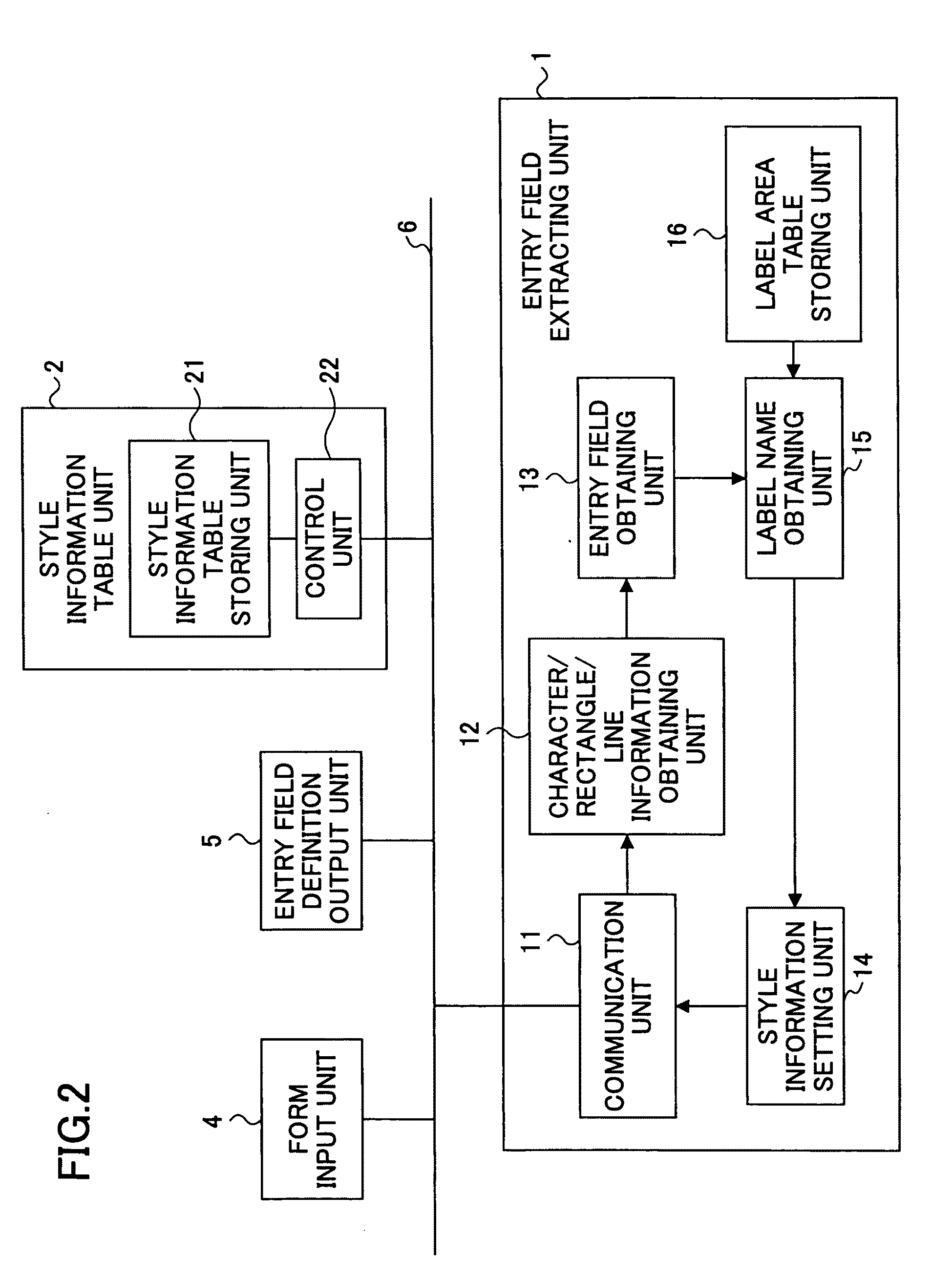

Information processing system, information processing apparatus, information processing method, and storage medium

InactiveUS20090226090A1Many problemCharacter recognitionInformation processingInformation handling system

A disclosed information processing system includes an input unit configured to input a file or an image of a form; an entry field obtaining unit configured to extract entry fields of the form from the input file or image; a label name obtaining unit configured to obtain label names of the extracted entry fields from characters or symbols in the form, the label names indicating information to be entered in the entry fields; a style information table storing unit configured to store a style information table that contains style information of the entry fields in association with the label names; a style information obtaining unit configured to search the style information table based on the obtained label names to obtain the style information of the entry fields; and an entry field definition output unit configured to output an entry field definition list including the entry fields, the label names, and the style information.

Owner:RICOH KK

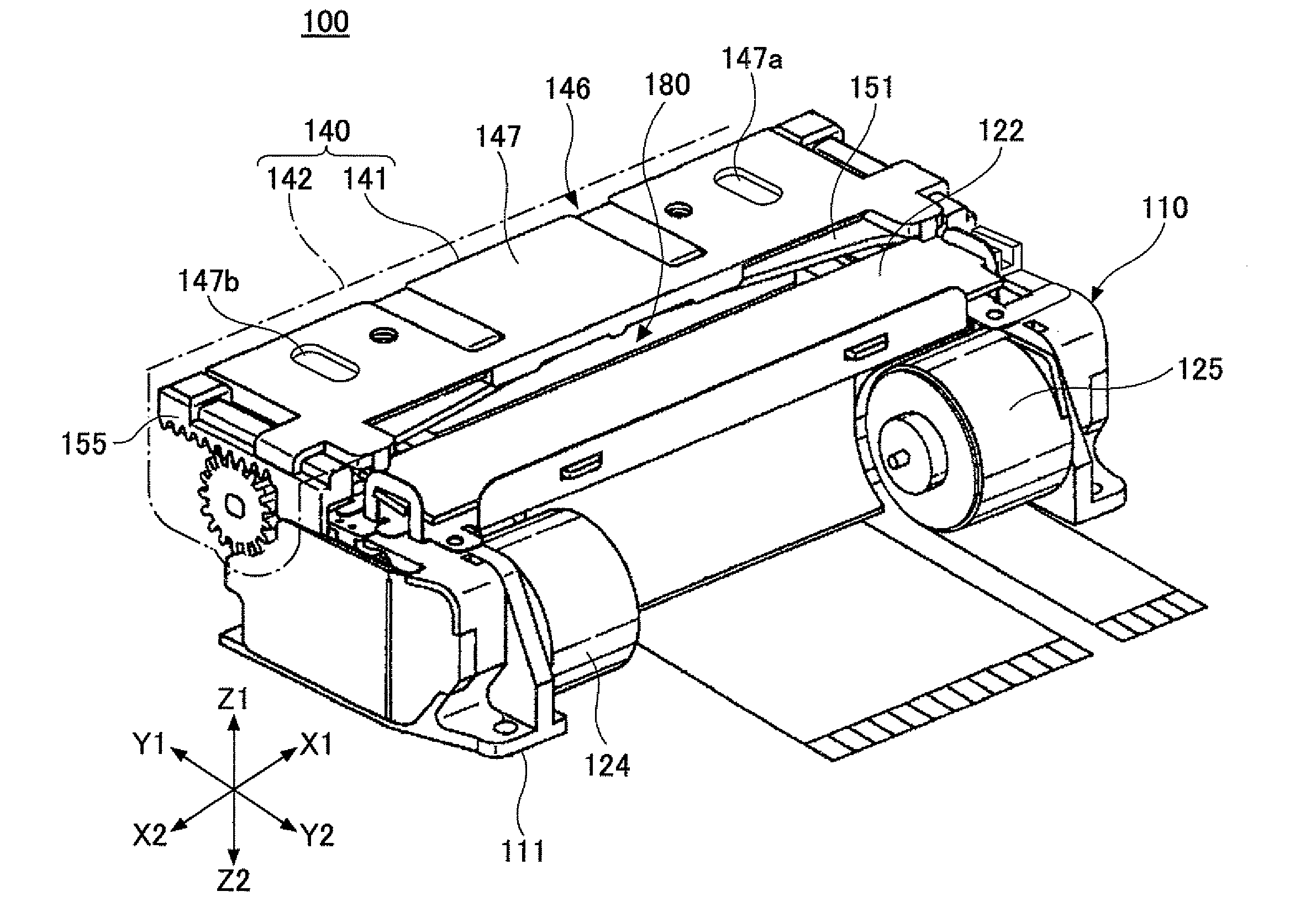

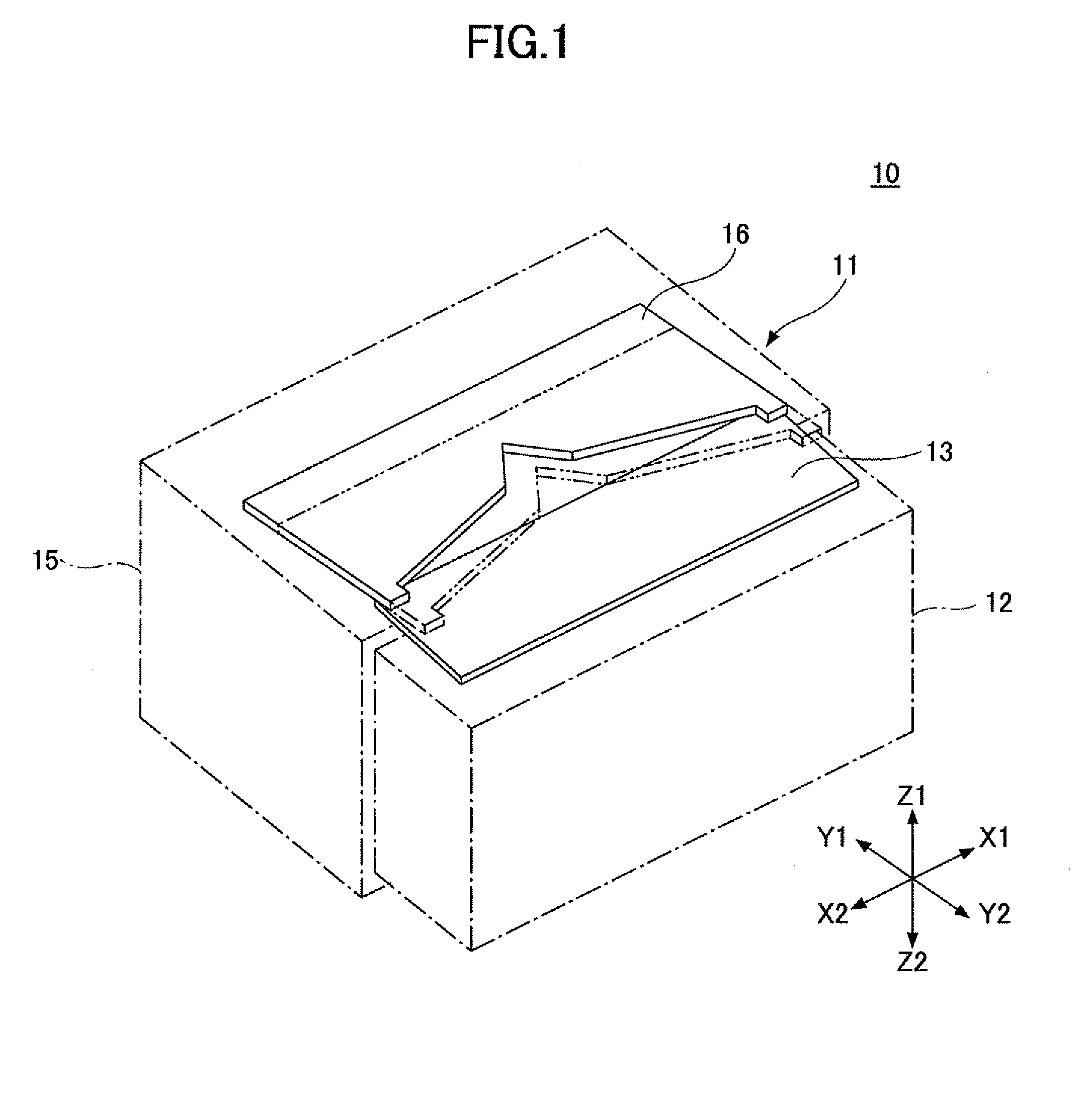

Printer module including movable blade module and fixed blade module

ActiveUS20100188470A1Improve reliabilityConvenient angleRecording apparatusDevelopersEngineeringKnife blades

Owner:FUJITSU COMPONENENT LTD

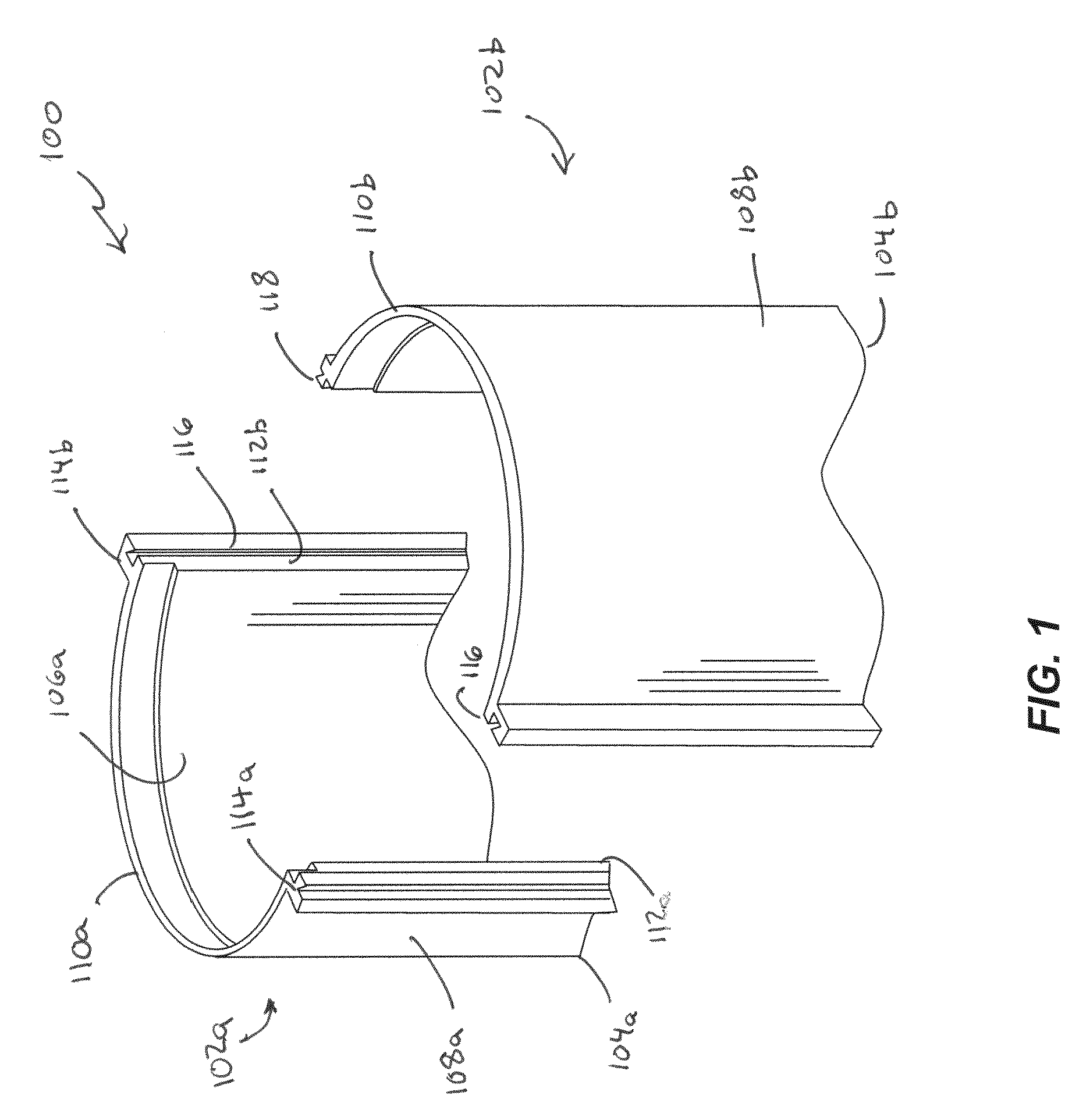

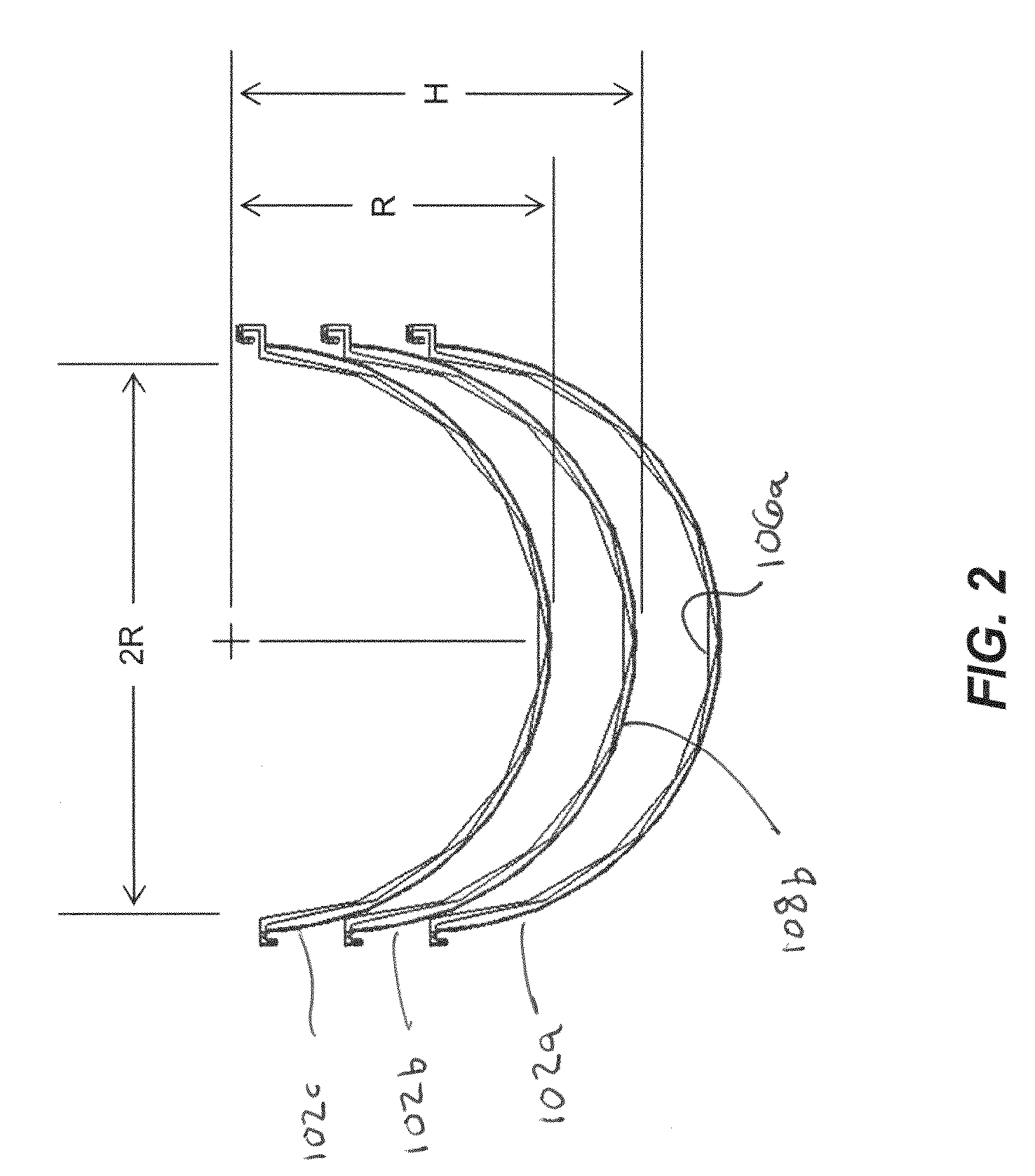

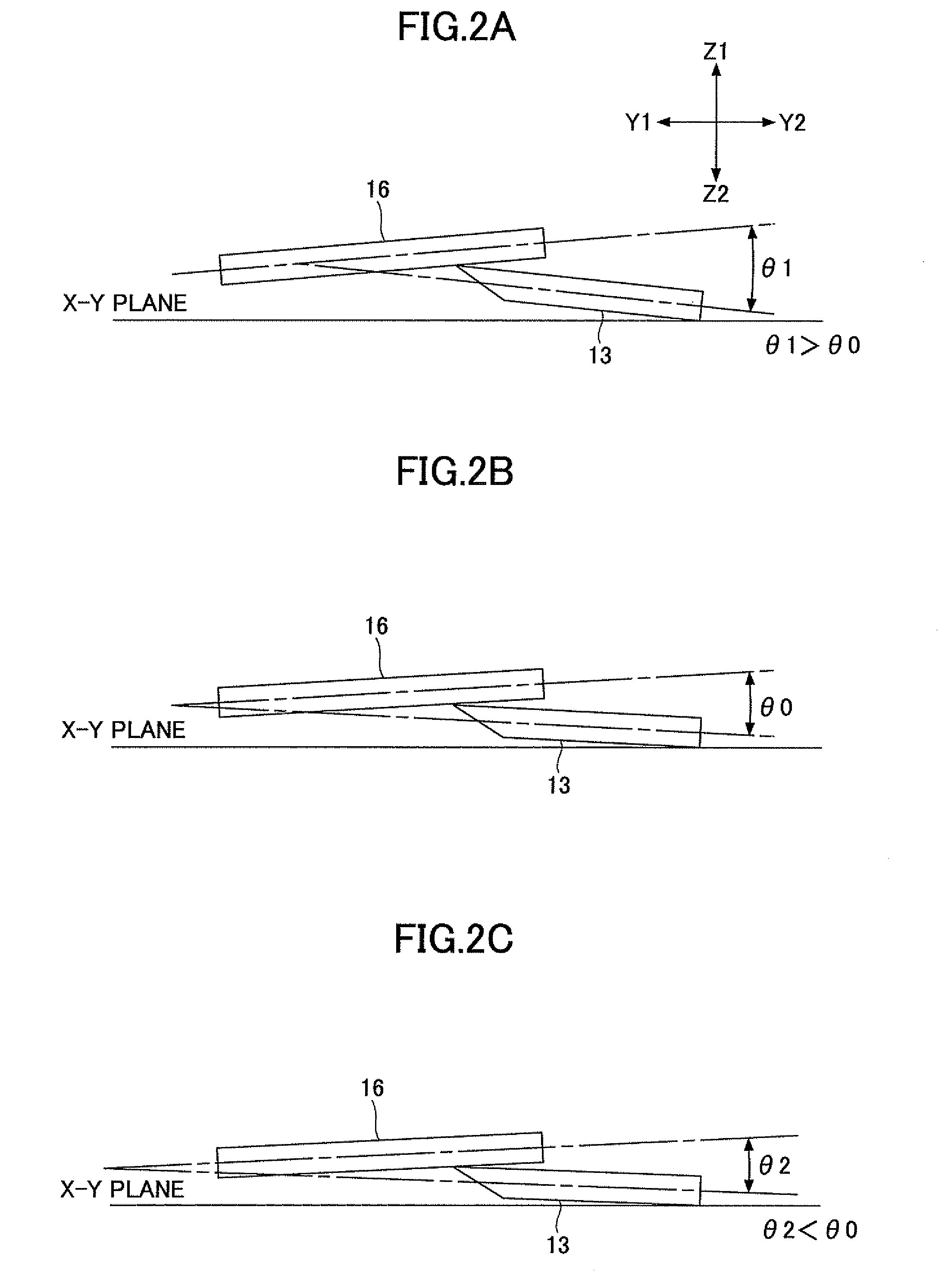

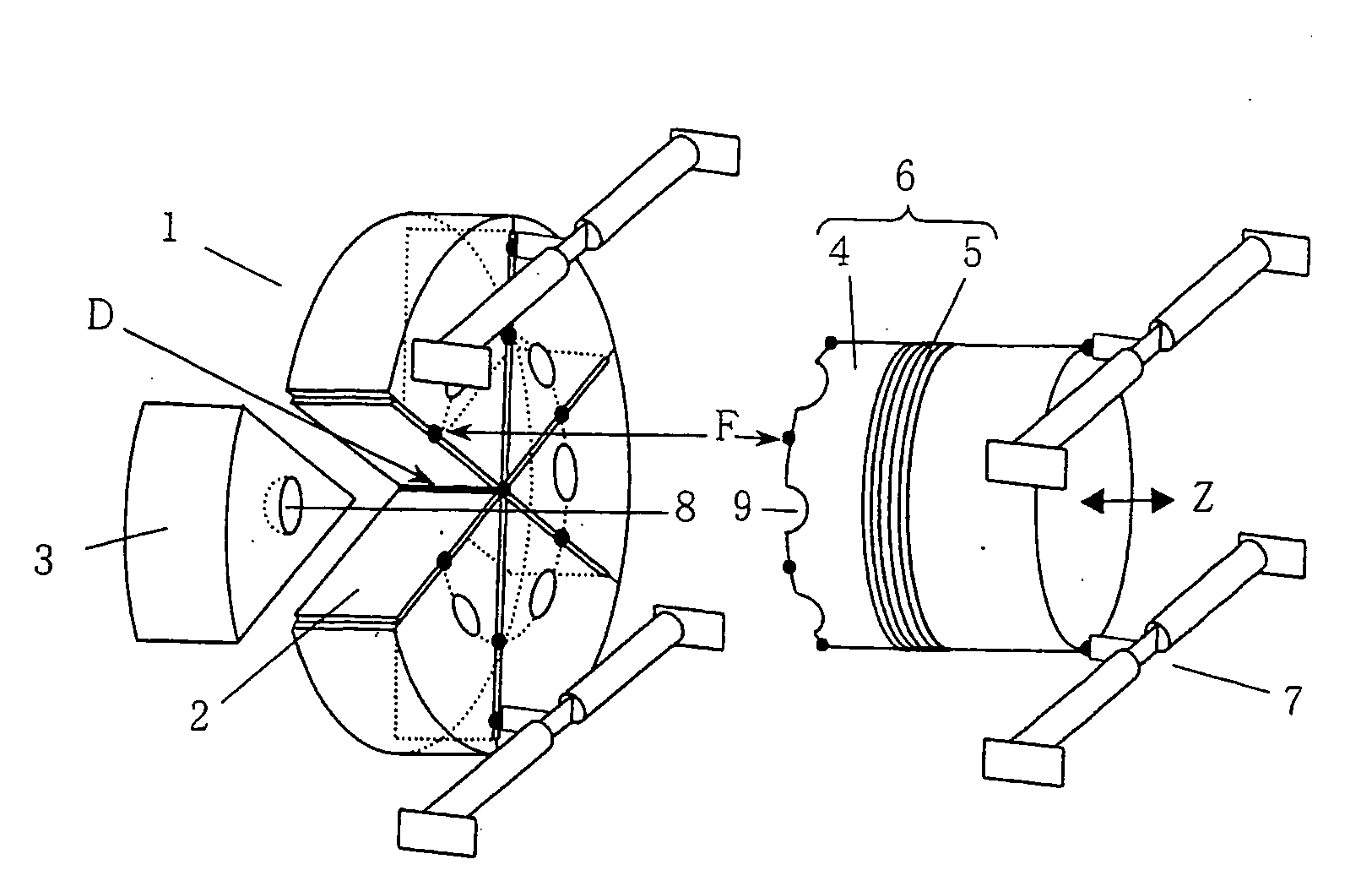

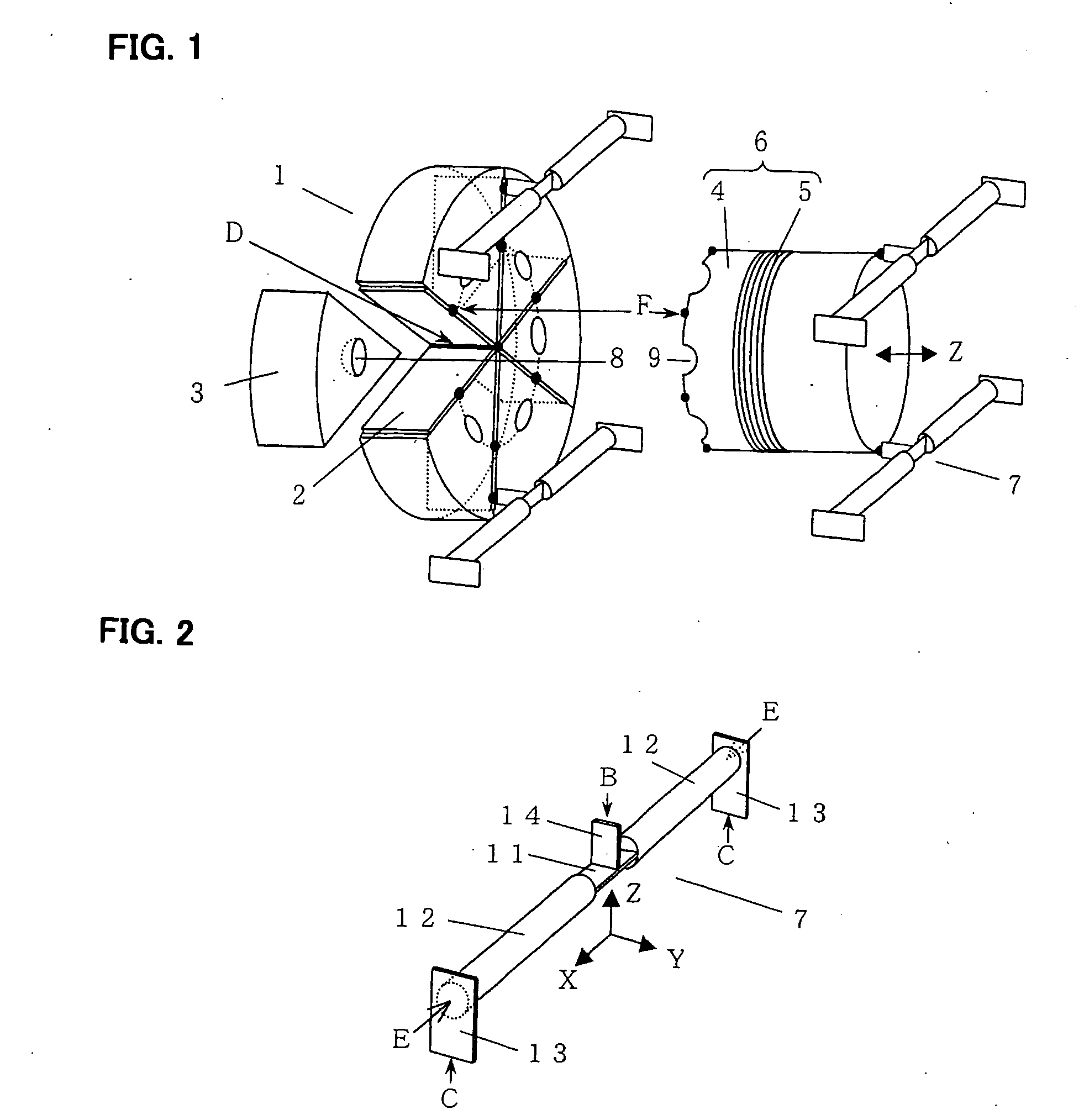

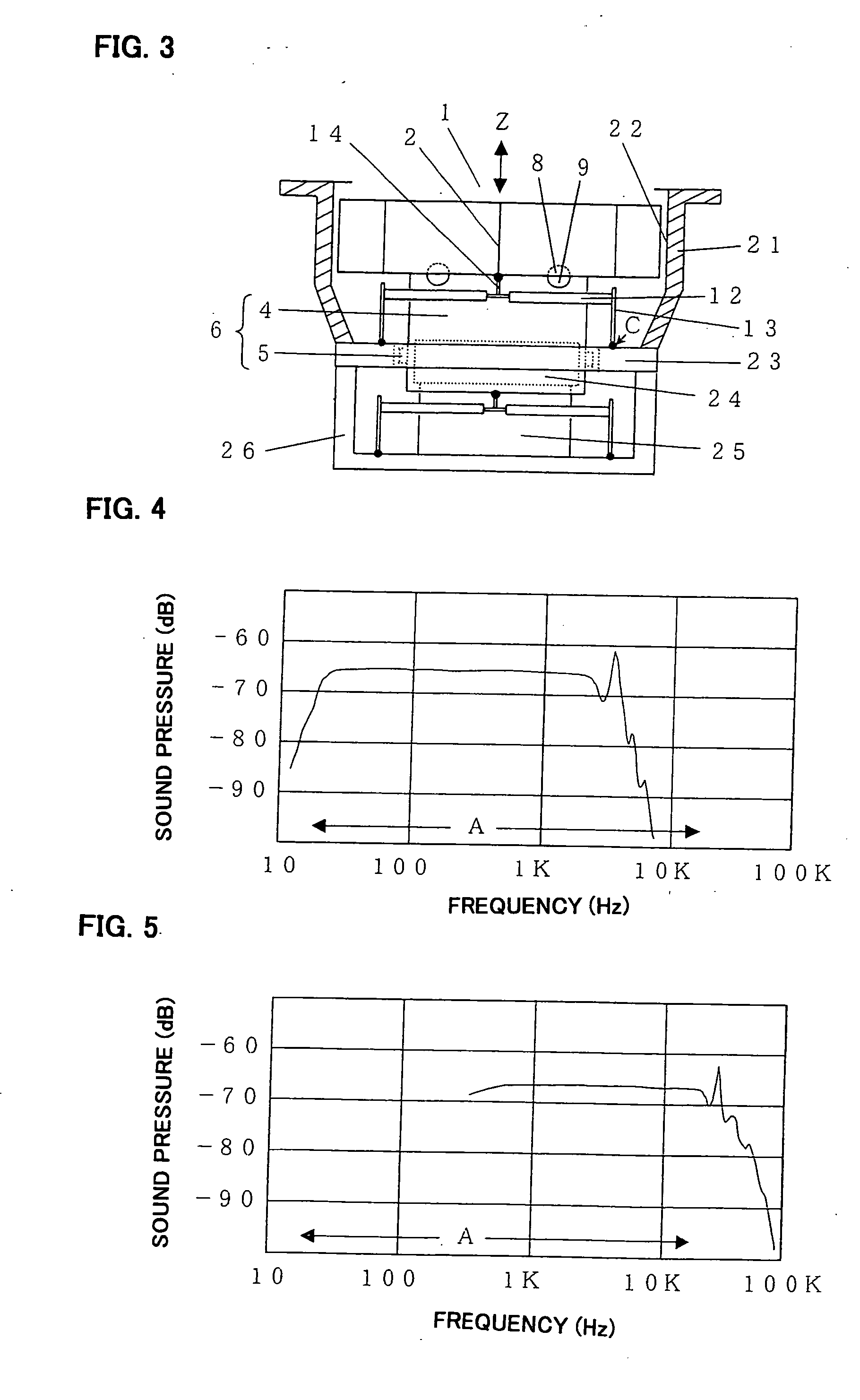

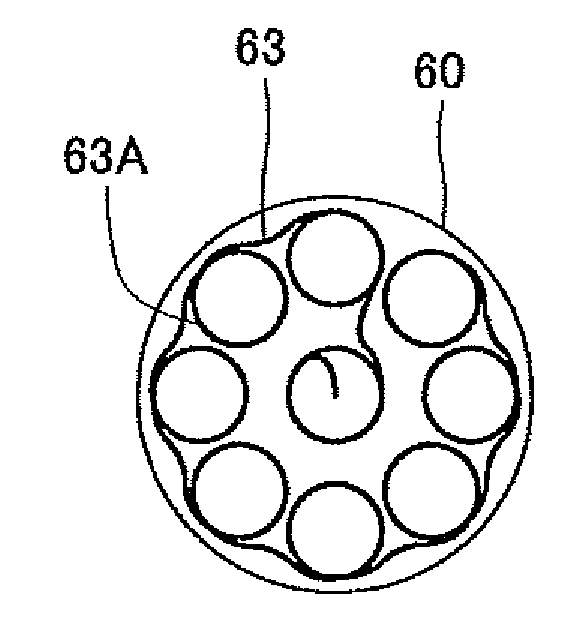

Loudspeaker, Speaker Diaphragm, and Suspension

InactiveUS20090226028A1Difficult to bendHigh stiffnessFibre diaphragmsMetallic diaphragmsLoudspeakerEngineering

The present invention relates to a hi-fi speaker. The diaphragm (1) is comprised of a frame member (2) and filler members (3) filled in the frame member (2). The frame member is comprised of flat plates all of which are arranged in parallel to the vibration direction and radially from the center of the diaphragm (1) toward the outer circumference, are fastened together at the radial center, and are fastened to the drive part (6). This frame member (2) has a high rigidity. The filler members (3) are comprised of foamed material etc. This diaphragm (1) does not have any skins, therefore also does not have any problem with resonance. The sound is emitted from the filler members (3). In the suspension (7), rod-like members (12) are fastened in a line at the both ends of the first leaf spring (11), second leaf springs (13) are fastened to the both ends of the rod-like members perpendicular to the rod-like members, and the both ends of the second leaf springs are fastened to unmovable parts of the speaker. The characteristic resonance occurring inside this suspension is slight and there is little displacement in directions other than the vibration direction. It is possible to use the present invention to form an edgeless plane diaphragm speaker system free of the effects of characteristic resonance and reproducing sound with a high fidelity.

Owner:BEAM TECH KULERU HACHIOJI 1109

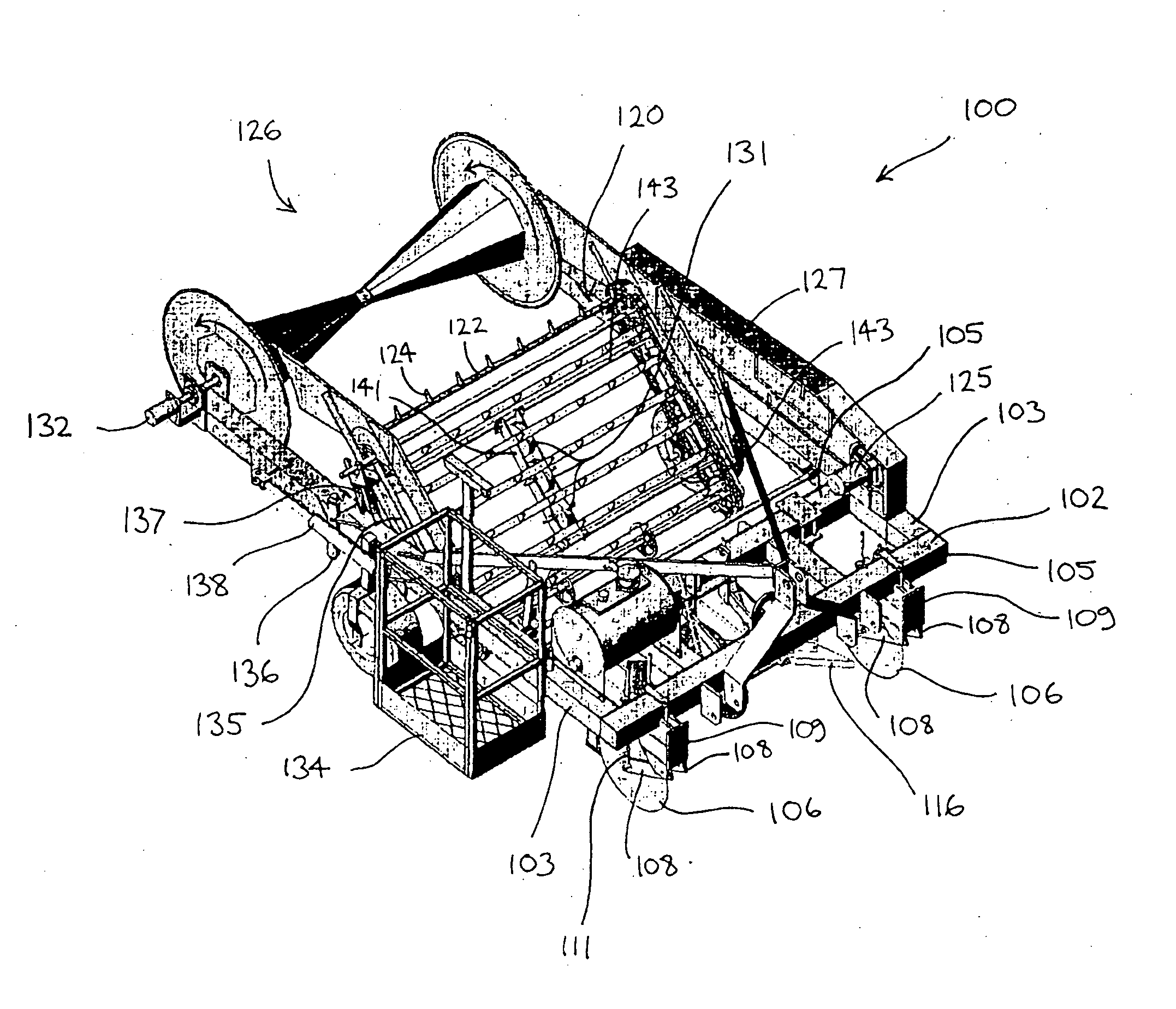

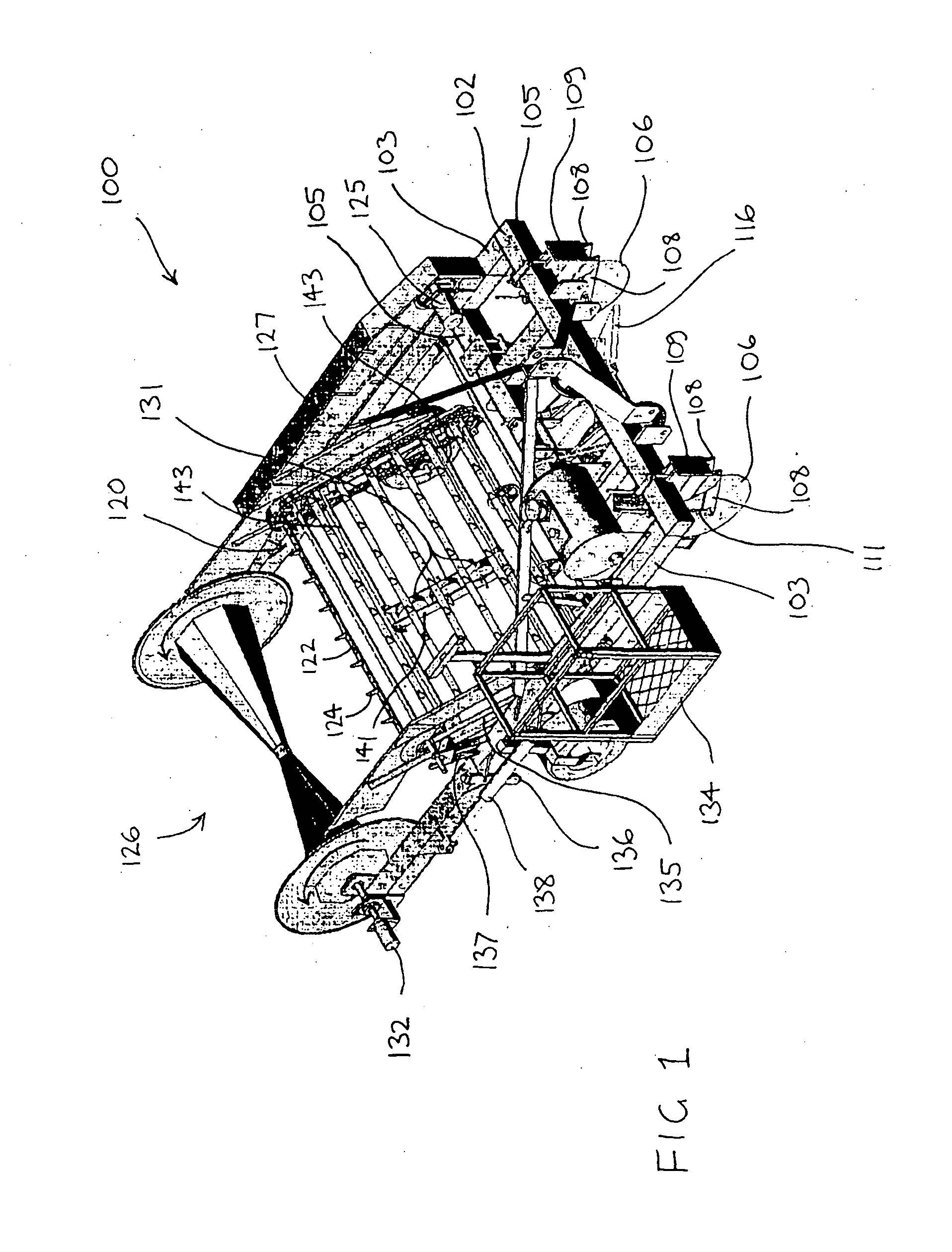

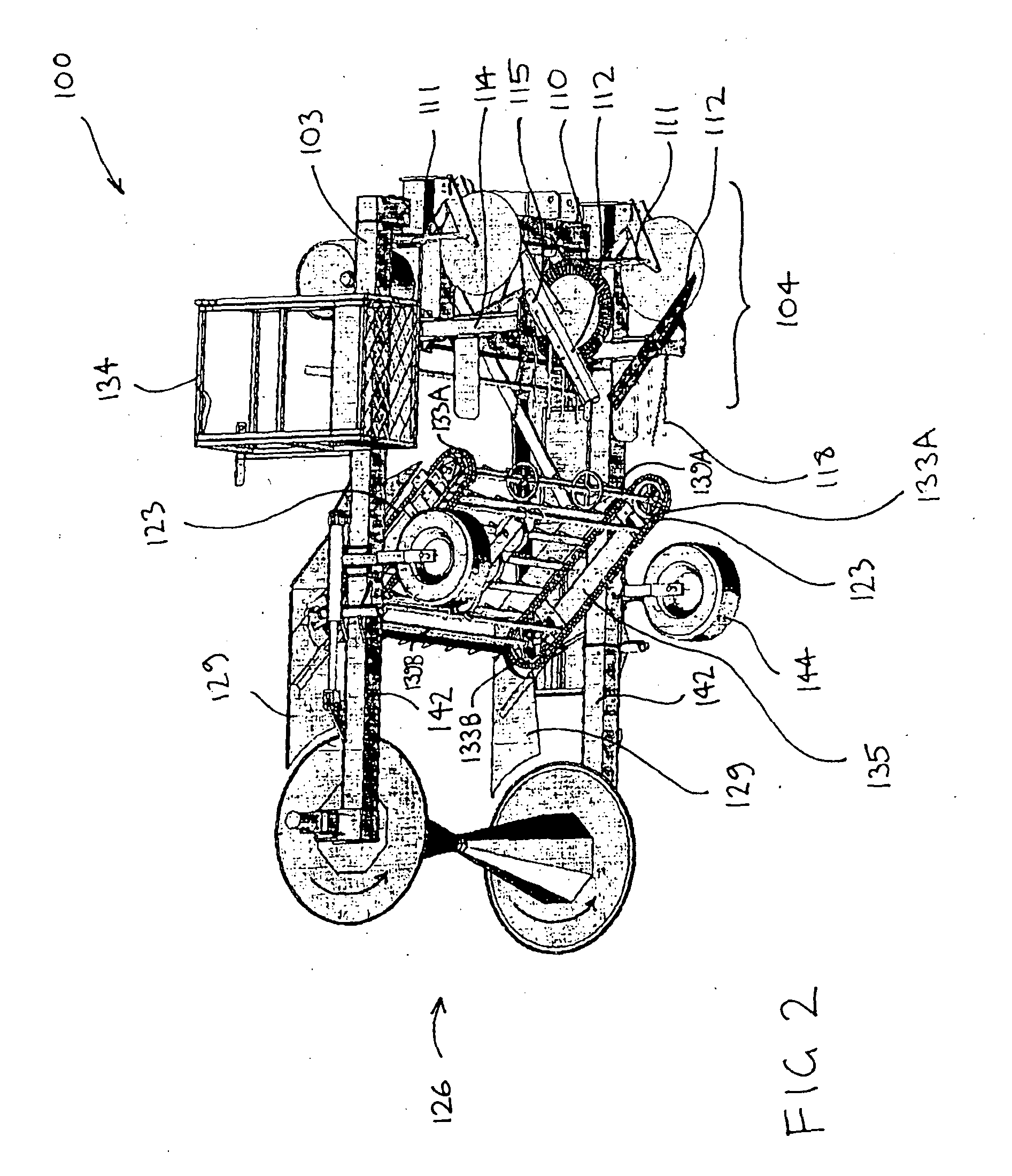

Plastic mulch retriever

InactiveUS20110000687A1Many problemMaximising removal of dirtSoil lifting machinesLiftersPlastic mulchEngineering

A plastic mulch retriever is disclosed comprising a body and at least one cutting or digging element mounted to the body to loosen plastic mulch embedded in the ground. A conveyor is mounted to the body rearward of the at least one cutting or digging elements to engage the loosened plastic mulch and remove at least some of the ground material attached to the extracted plastic mulch. At least one storage device is mounted to the body rearward of the conveyor to store the retrieved plastic mulch.

Owner:ROCCA MFG

Seat for combat vehicle

A seat for a combat vehicle includes a generally rectangular rigid base including front and rear ribs disposed on opposite, longer sides of the base, the base including a pair of slot openings disposed adjacent opposite, shorter sides of the base; a generally rectangular inner cushion disposed on a top surface of the base; a generally U-shaped outer cushion disposed on a top surface of the inner cushion and along outer surfaces of the front and rear ribs; a cover disposed over the outer cushion; and a pair of support assemblies for supporting the seat in the vehicle.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

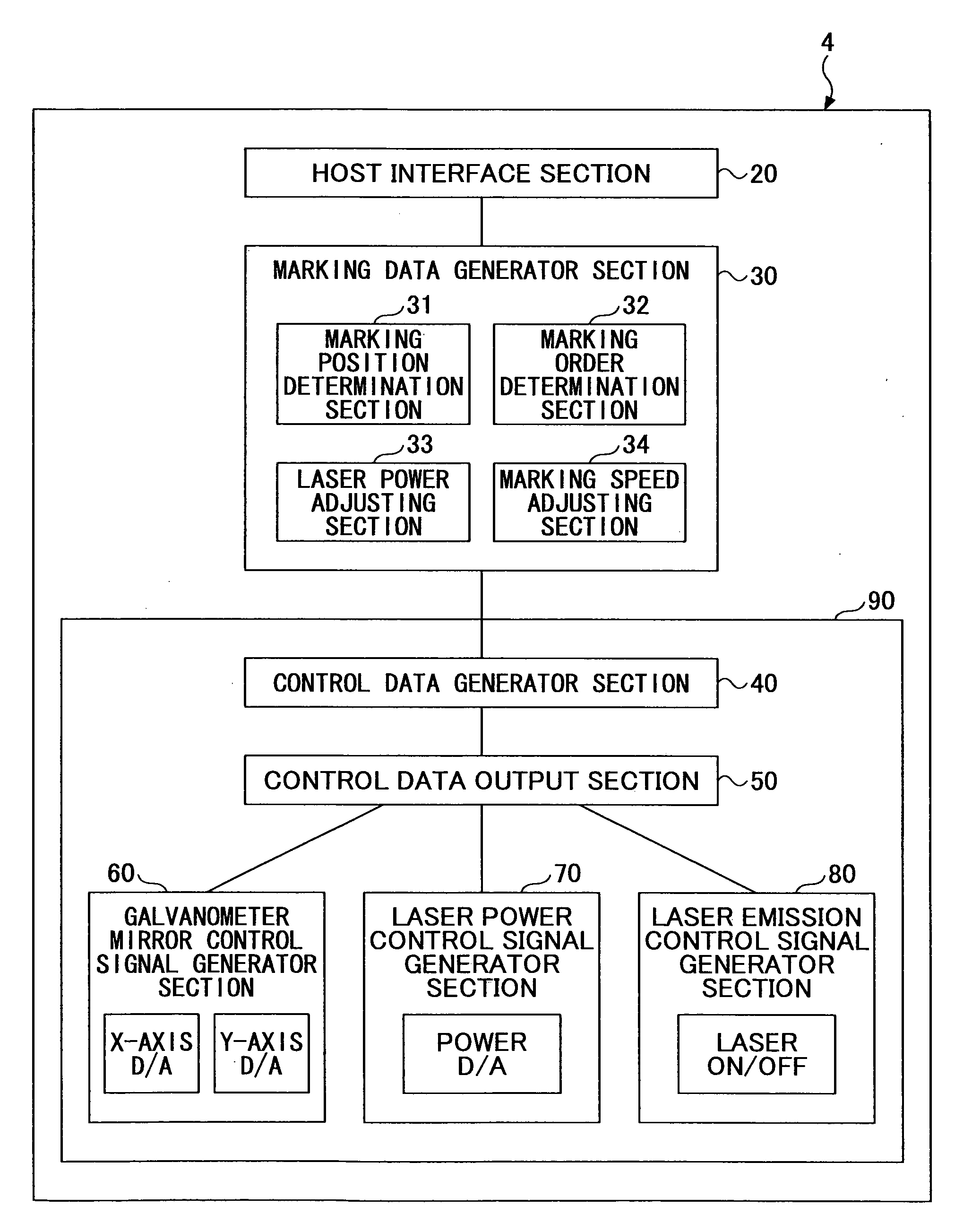

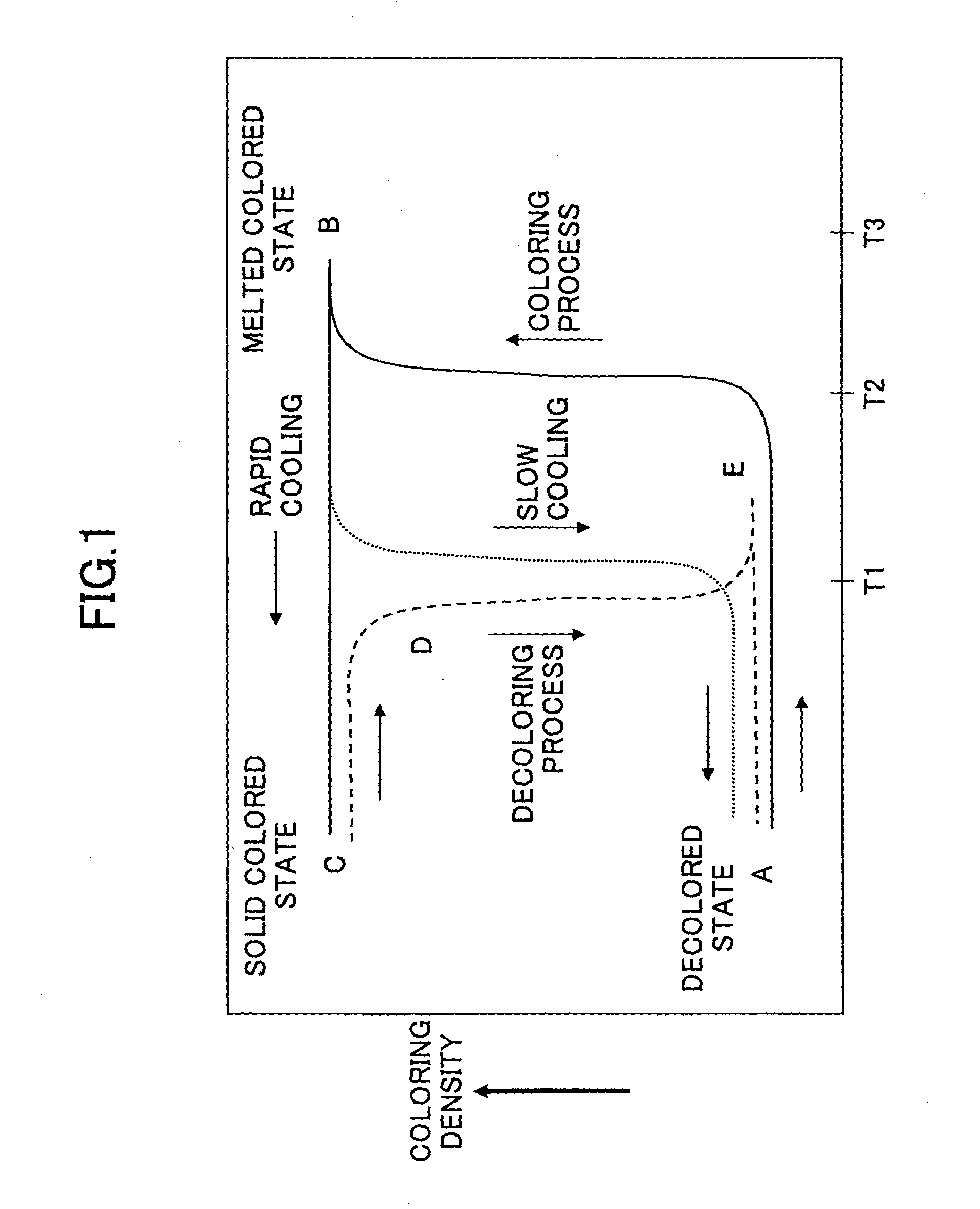

Marking control device, laser application device, marking control method, and computer-readable recording medium having marking control program

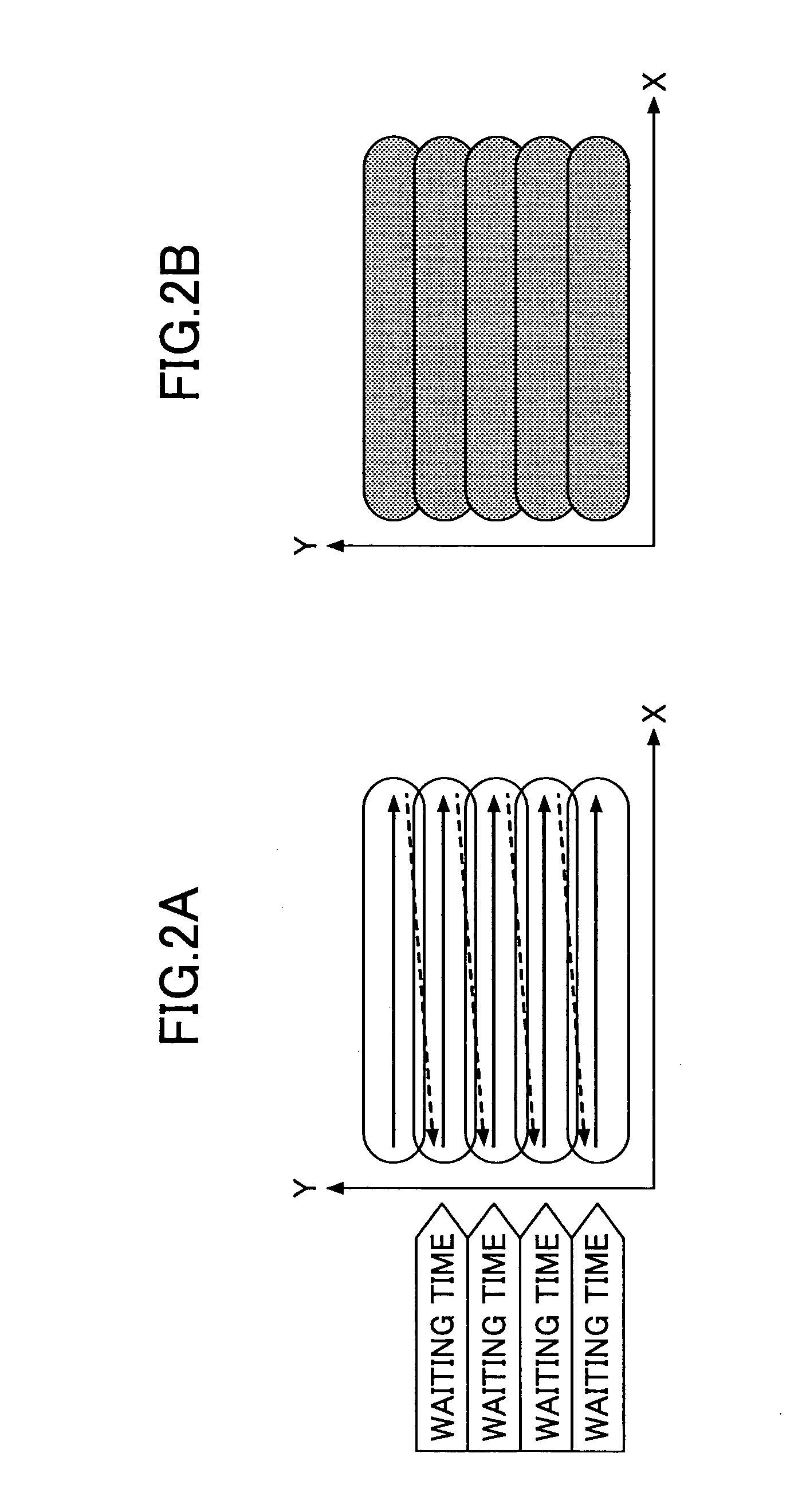

InactiveUS20120212564A1Quality improvementWide image erasable energy widthRecording apparatusVisual representation by thermal printersEngineeringLaser beams

A disclosed marking control device controls a marking device to mark a target image on a thermoreversible recording medium by applying a laser beam includes a marking position determination unit dividing the image into plural marking lines, and determining their marking positions; a marking order determination unit determining a marking order to mark the marking lines in mutually opposite directions; an adjusting unit adjusting a distance between a first ending point and a second starting point to be longer than a distance between a first starting point and a second ending point, or adjusting laser power applied to a second starting point side of the second marking line to be lower than the laser power applied to a second ending point side of the second marking line; and a marking instruction generator unit generating marking instructions including the marking positions of the marking lines and the marking order thereof.

Owner:RICOH KK

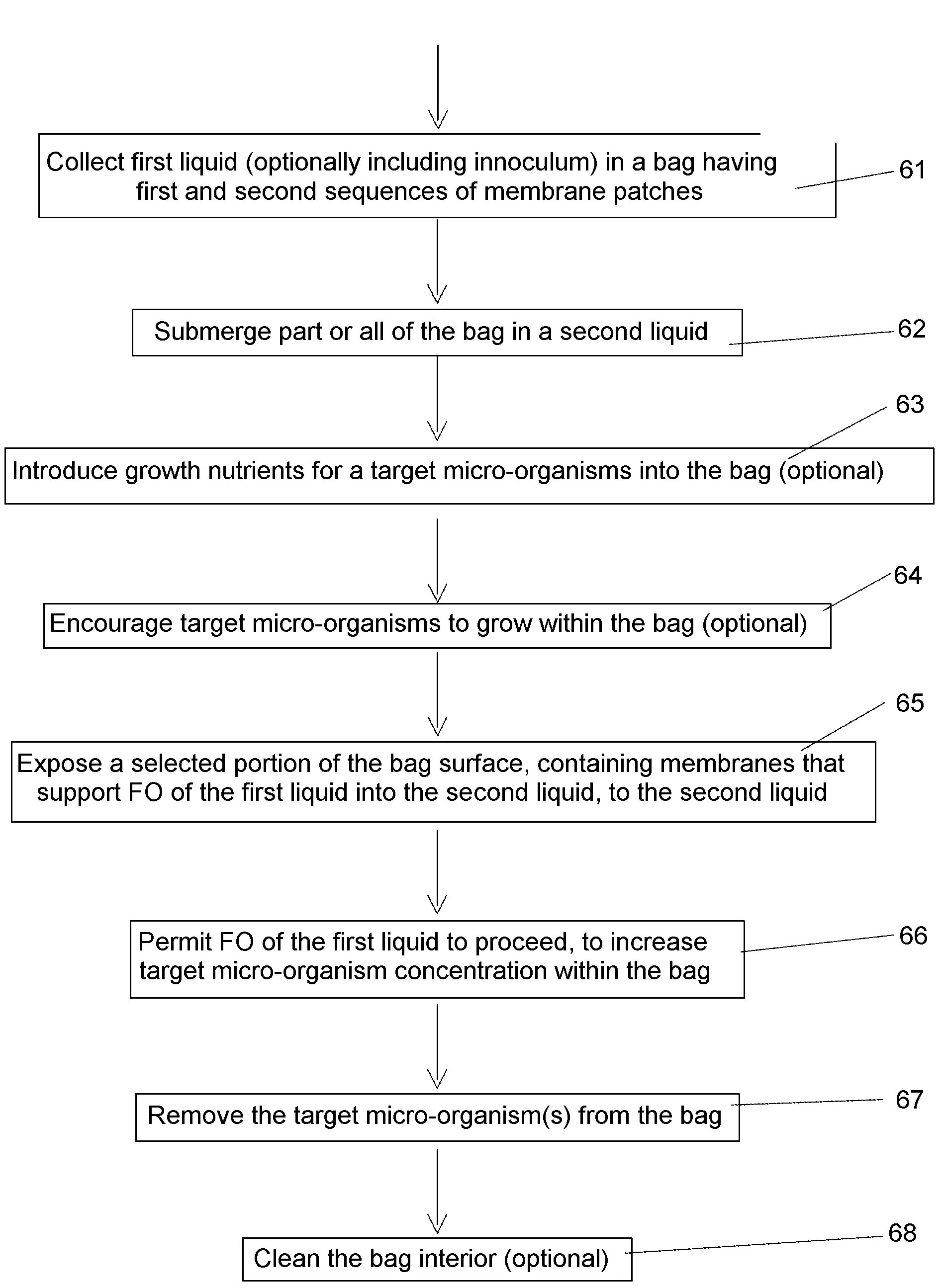

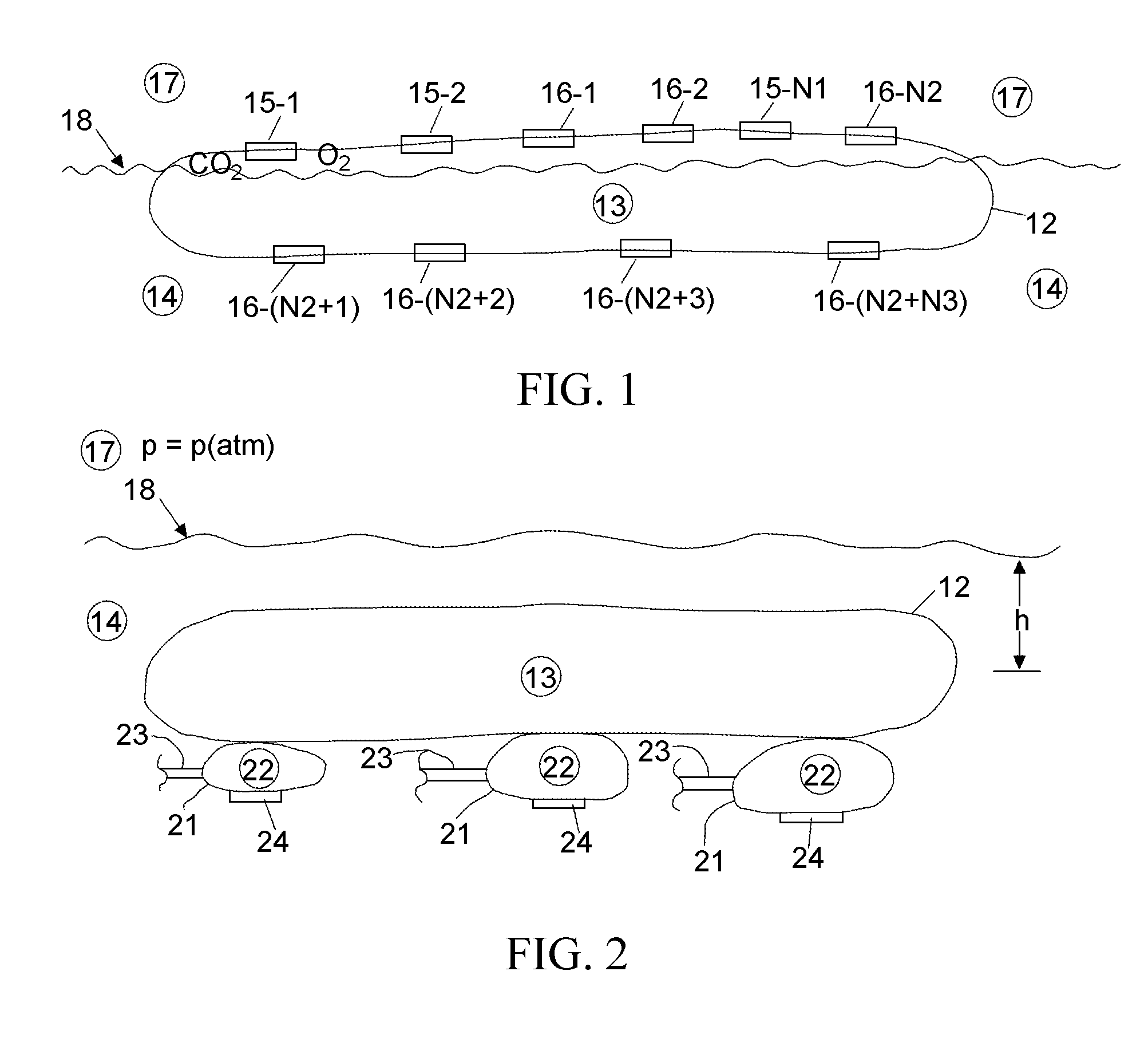

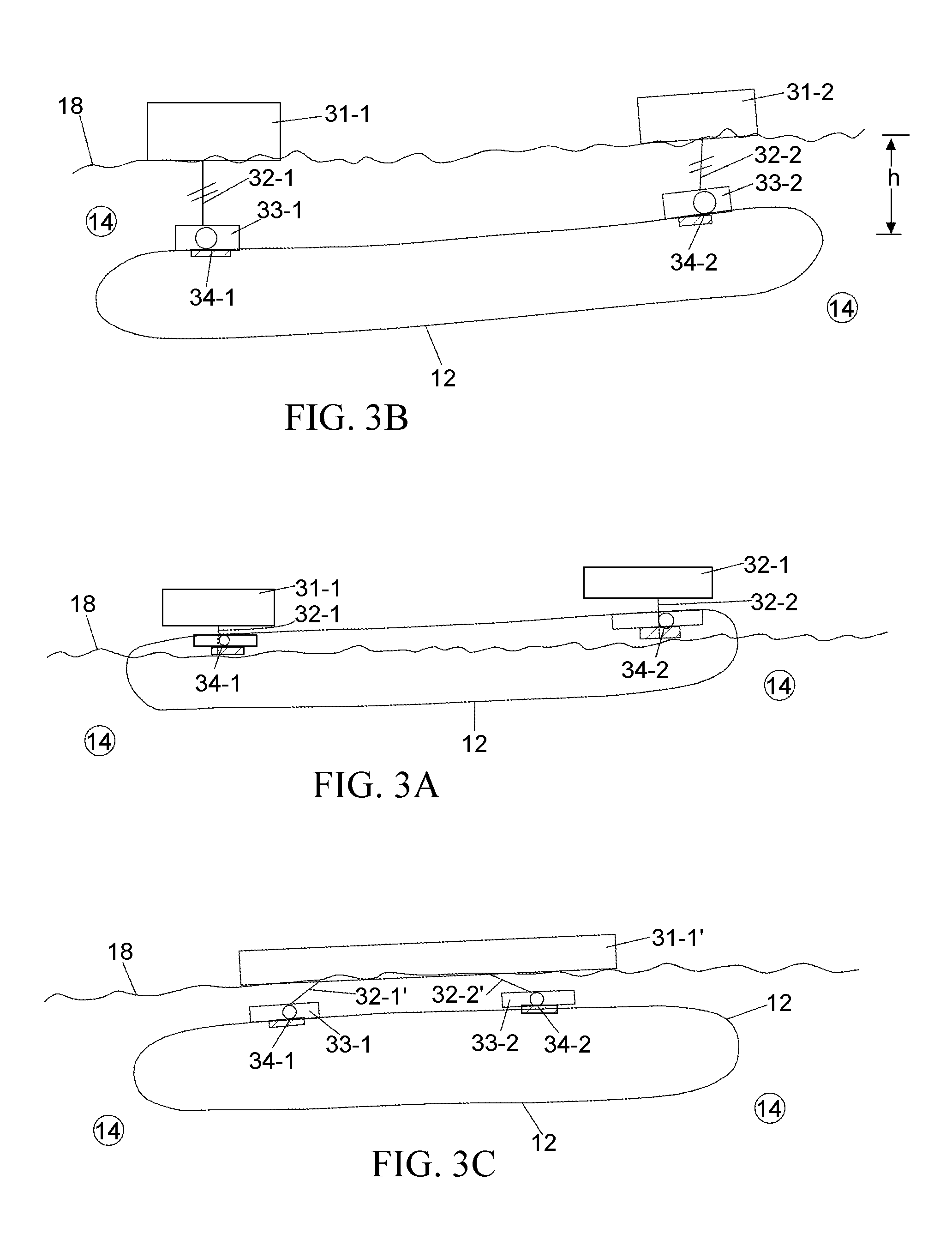

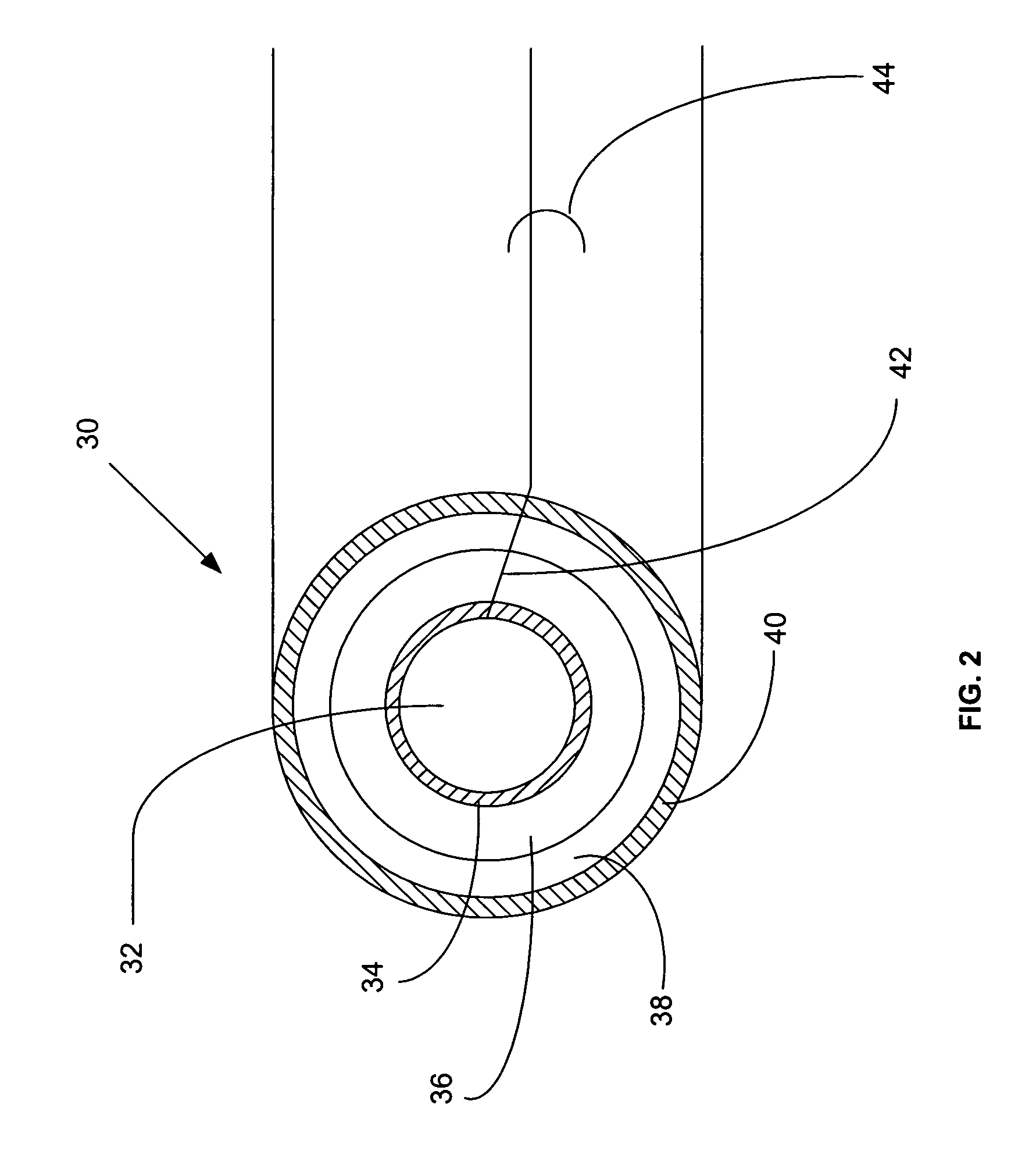

Algae bioreactor using submerged enclosures with semi-permeable membranes

ActiveUS20100216203A1Avoid problemsMitigate contribution carbon dioxide is making to global warmingBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismHydrocotyle bowlesioides

Methods for producing hydrocarbons, including oil, by processing algae and / or other micro-organisms in an aquatic environment. Flexible bags (e.g., plastic) with CO2 / O2 exchange membranes, suspended at a controllable depth in a first liquid (e.g., seawater), receive a second liquid (e.g., liquid effluent from a “dead zone”) containing seeds for algae growth. The algae are cultivated and harvested in the bags, after most of the second liquid is removed by forward osmosis through liquid exchange membranes. The algae are removed and processed, and the bags are cleaned and reused.

Owner:NASA +1

Thermal blanket including a radiation layer

InactiveUS20050208851A1Reduce performanceIncrease thermal resistivityThermal insulationSynthetic resin layered productsThermal radiationThermal management system

A thermal management system utilizing a composite thermal radiation barrier comprising alternating layers of a carbon cloth insulating layer and a silica-based organic cloth to reduce the temperatures experienced by the insulating layer.

Owner:HALE NICHOLAS

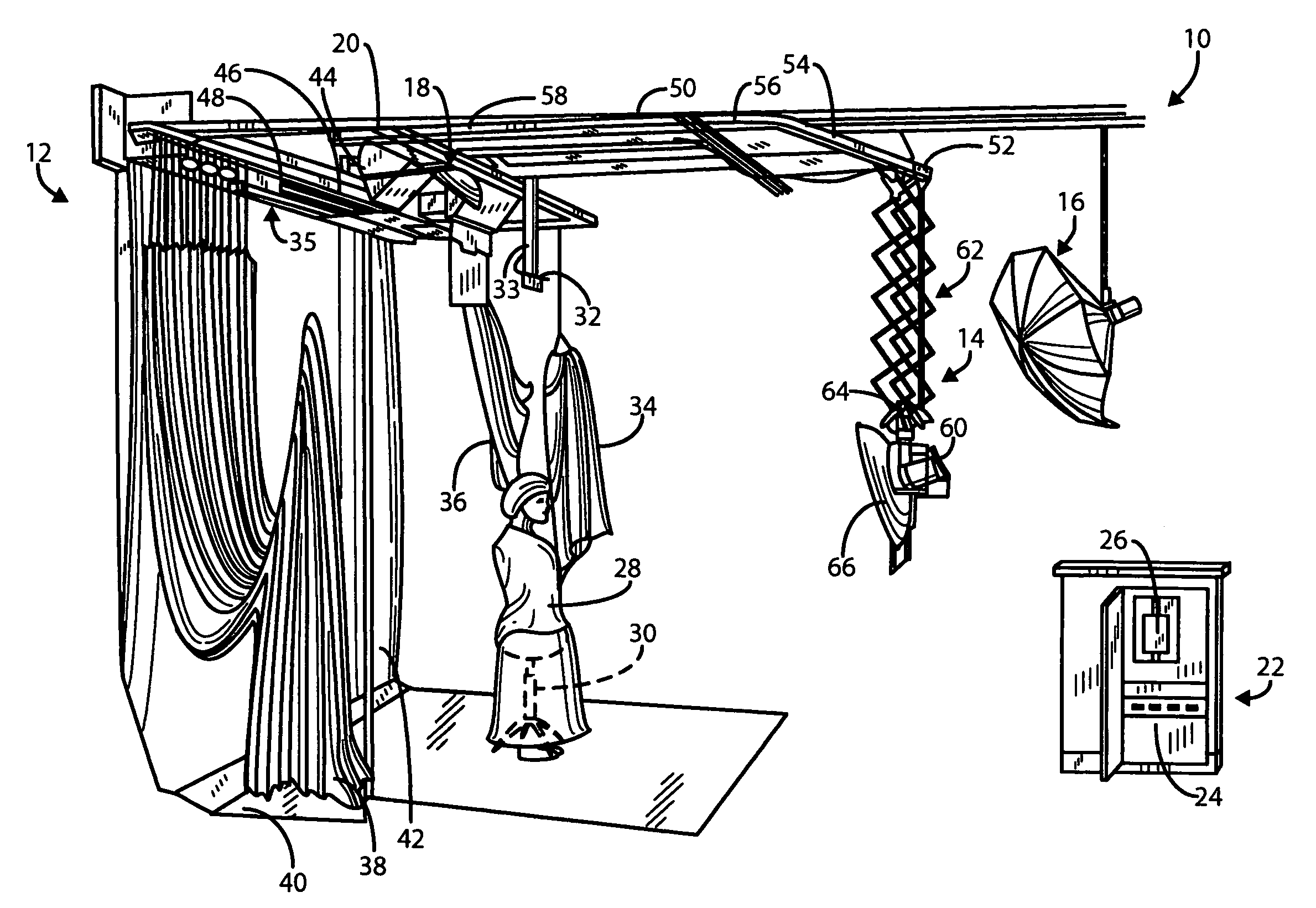

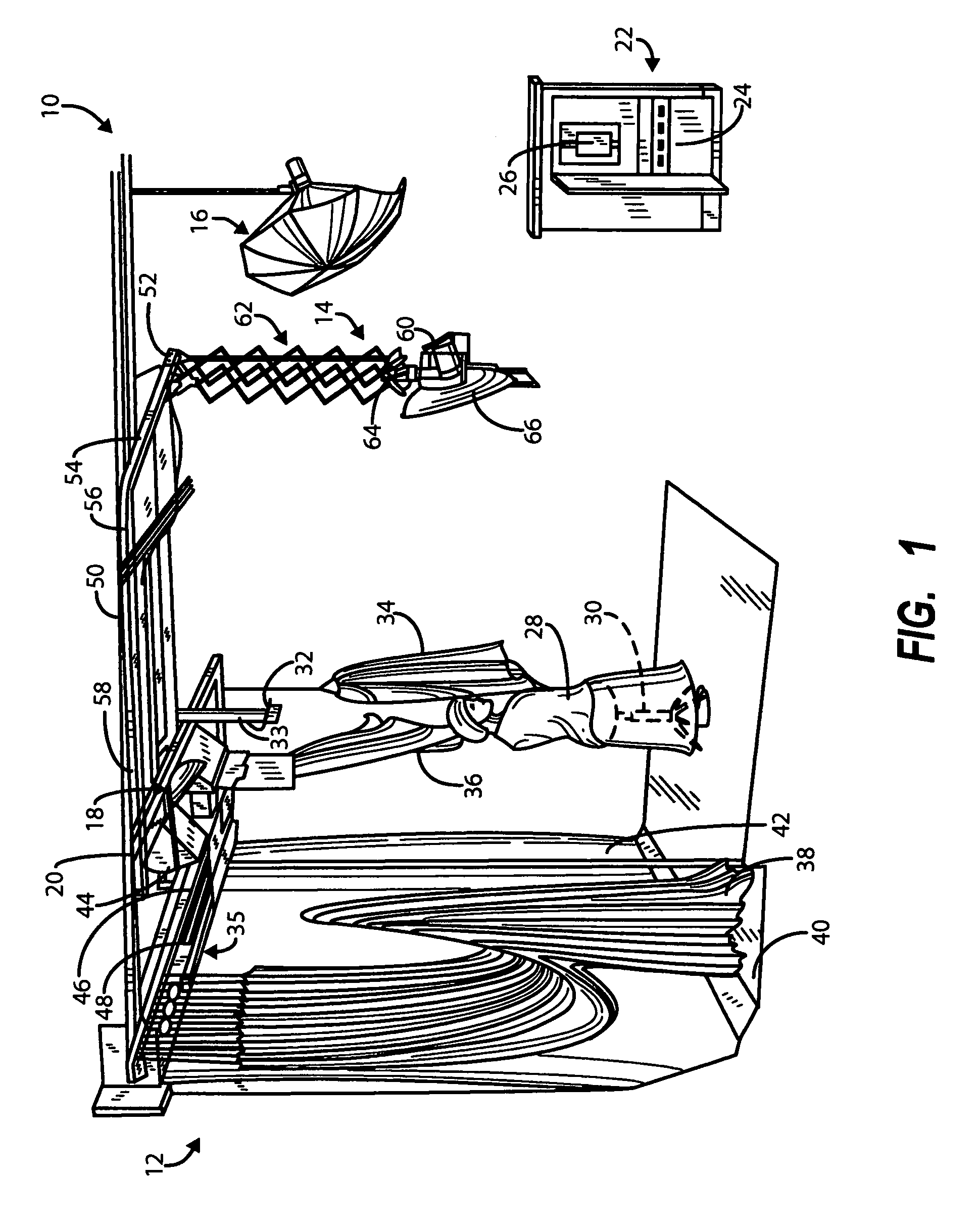

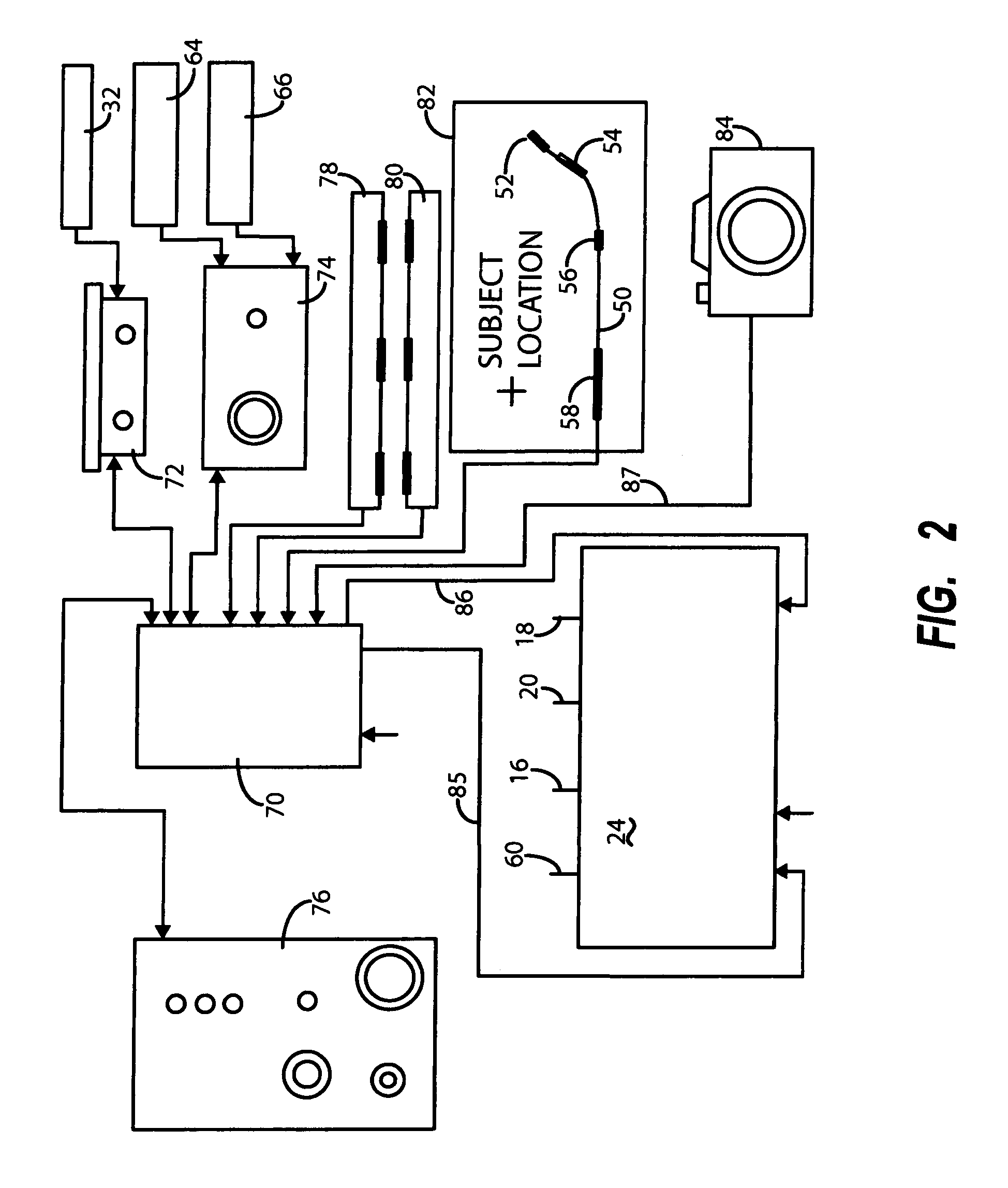

Automated portrait studio

ActiveUS7177537B1Many problemSimplifies variableCamera body detailsPhotographyVerification systemLighting system

An automated studio and control system for taking photographs is disclosed that alleviates many exposure problems and simplifies variables with which the photographer must deal in order to achieve consistent high quality photographs. The studio includes a multi-light portrait lighting system, a subject location verification system and a system for varying backgrounds, all of which are tied to an integrated control system and synchronized to a camera.

Owner:SHUTTERFLY LLC

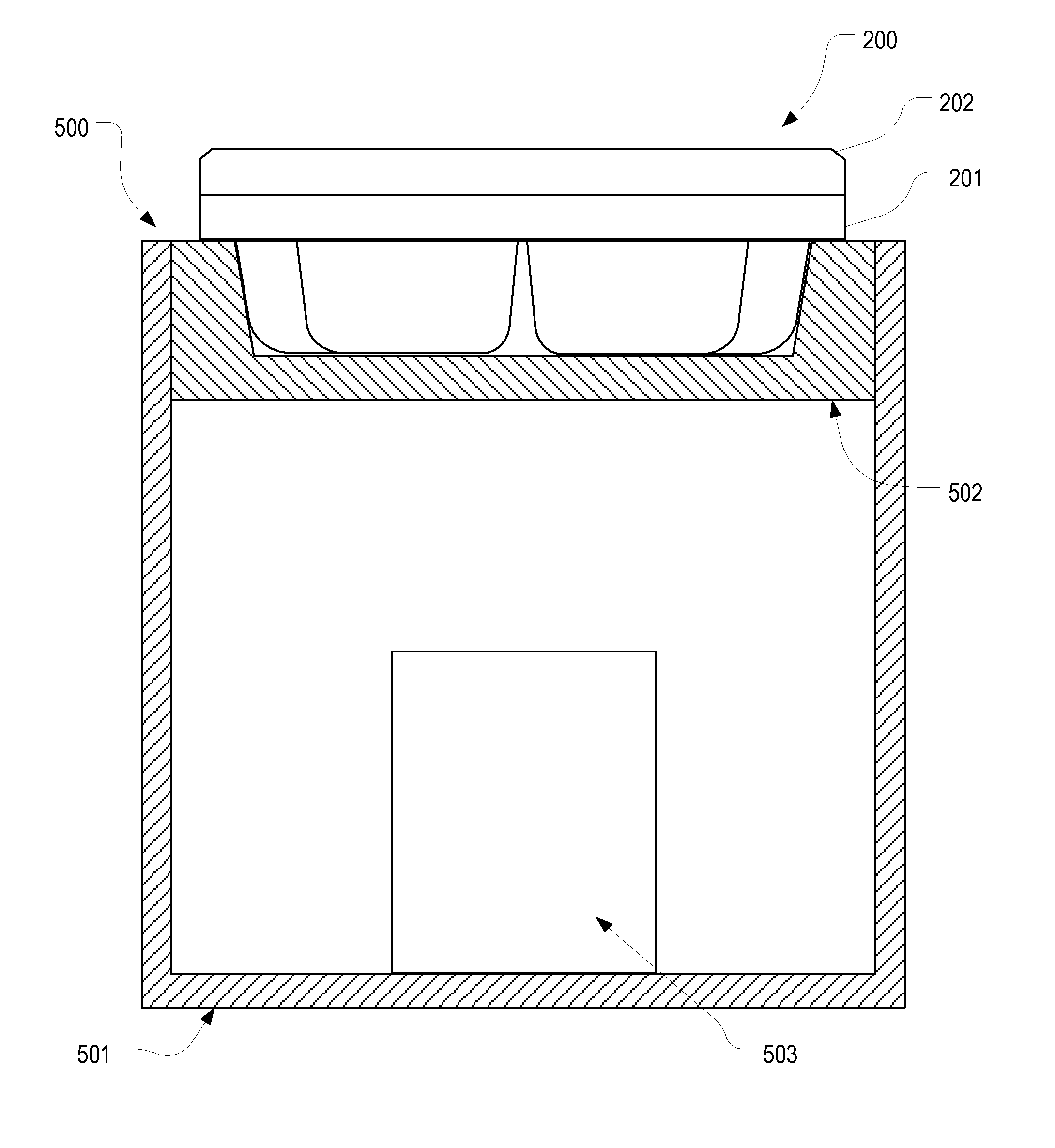

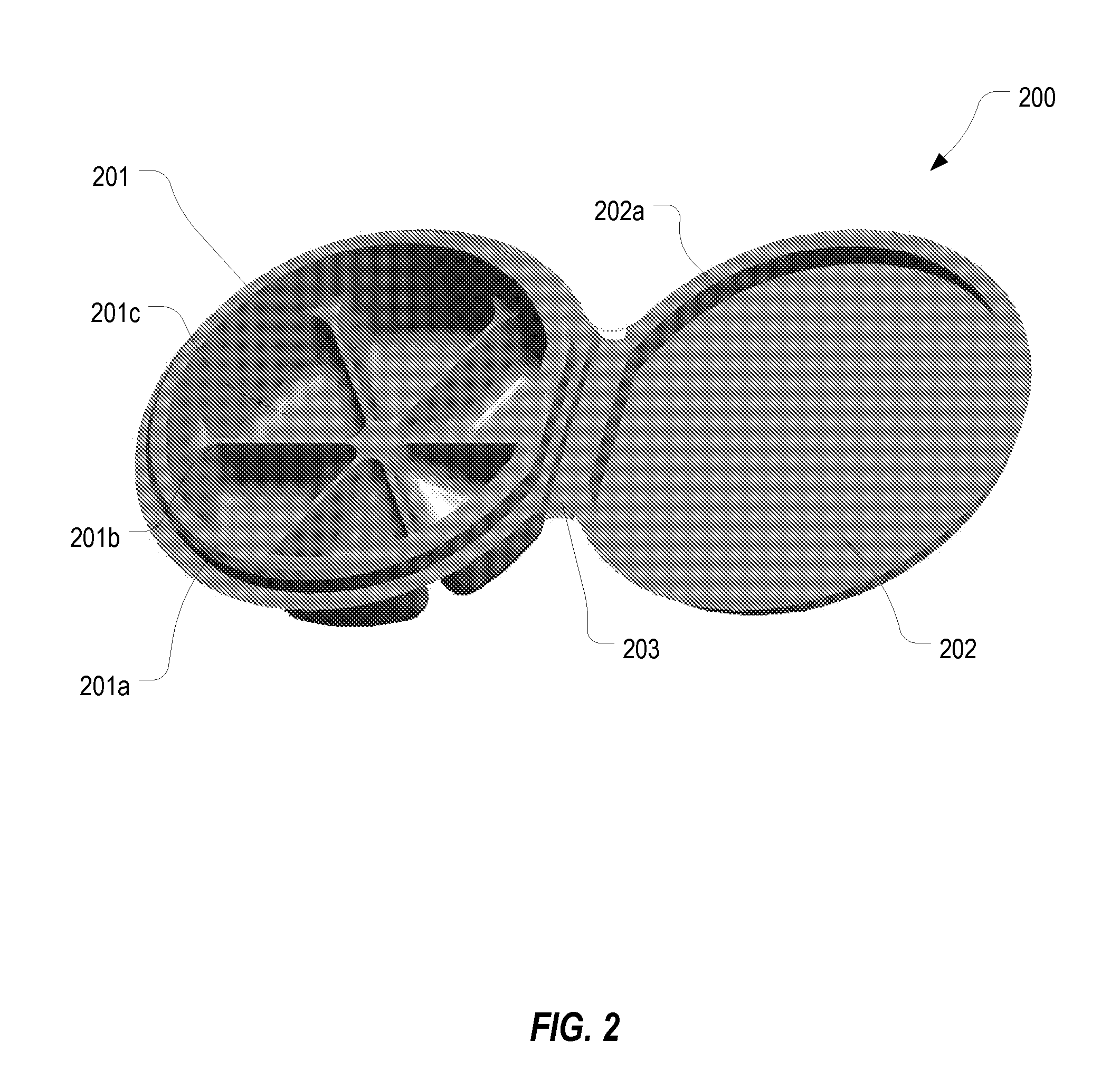

Clamshell packaging for scented wax that serves as a tray when warming the wax within a candle warmer

A clamshell packaging for scented wax can serve as a tray when warming the wax within a candle warmer. The clamshell packaging can be shaped and sized to fit within a dish of a candle warmer and can be made of a heat conducting material. In this way, the user can place the packaging directly in the dish of a candle warmer so that the wax is melted within the packaging rather than within the dish. After the wax has been used, the user can simply remove the packaging from the dish and throw it away. The clamshell packaging can include a lid with a number of vents to allow the wax within the base to be heated while the lid is secured over the base. These vents can be configured to control the rate at which the scent within the wax is emitted from the clamshell packaging.

Owner:RIMPORTS USA

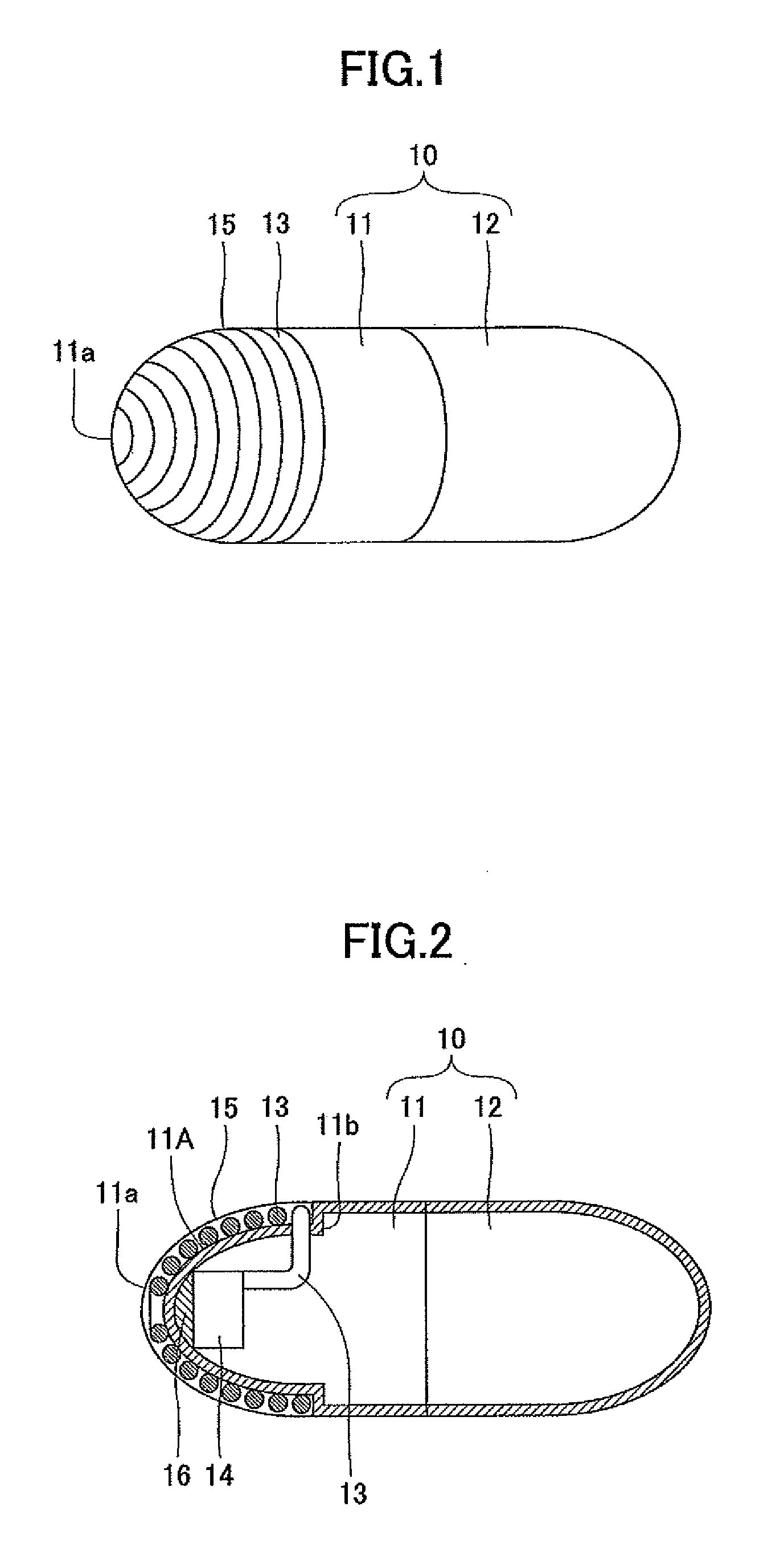

Capsule for medical use

InactiveUS20090234203A1Satisfactory communication conditionMany problemEndoscopesEndoradiosondesEngineeringAnimal body

A capsule for medical use which is to be passed through a tract of a human or animal body includes a capsule-shape case, a wire antenna placed in a wrapped or folded state on at least a portion of an outer surface of the case, and a fixing member configured to fix the wire antenna in the wrapped or folded state, wherein the fixing member is configured to release the antenna inside the tract.

Owner:FUJITSU COMPONENENT LTD

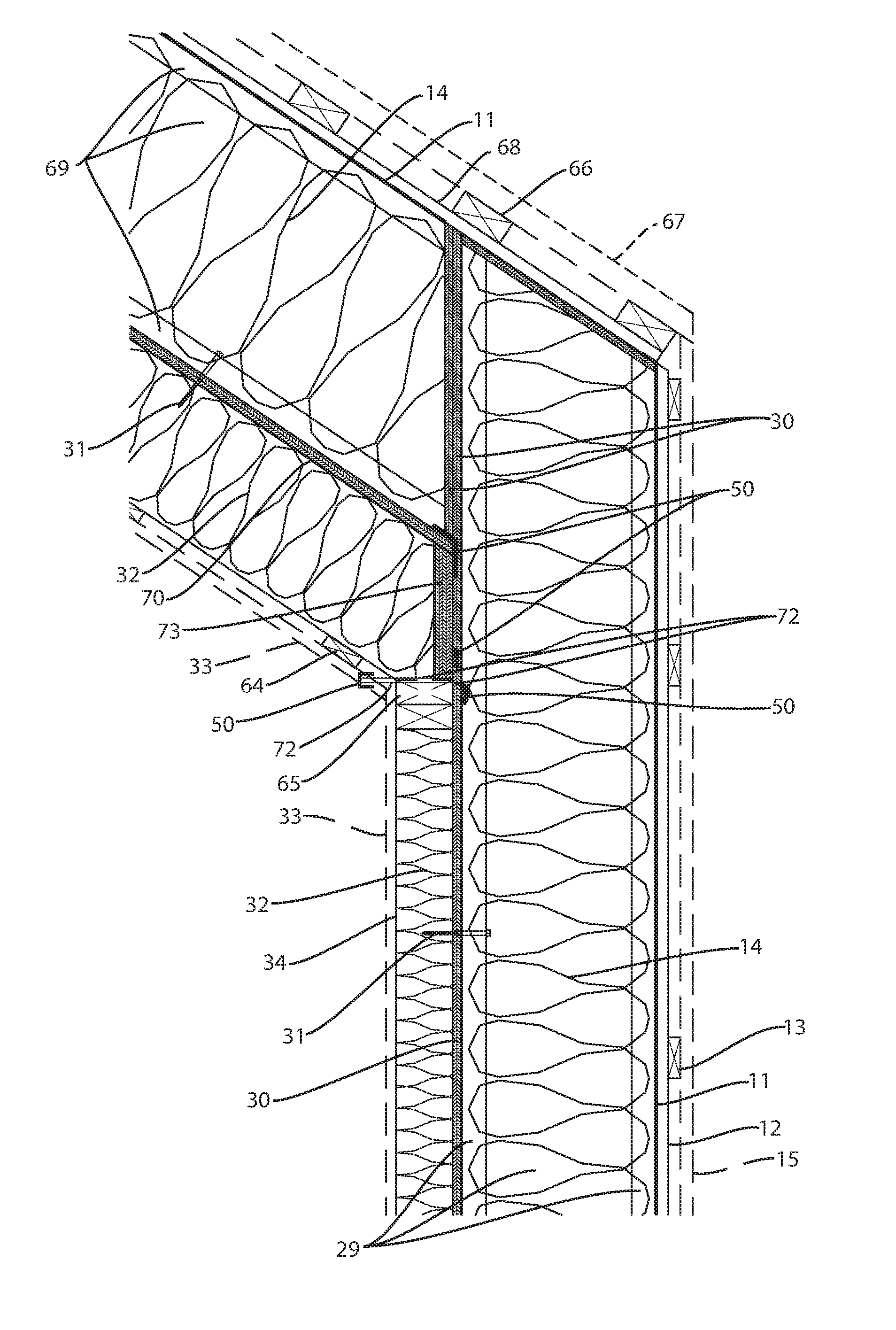

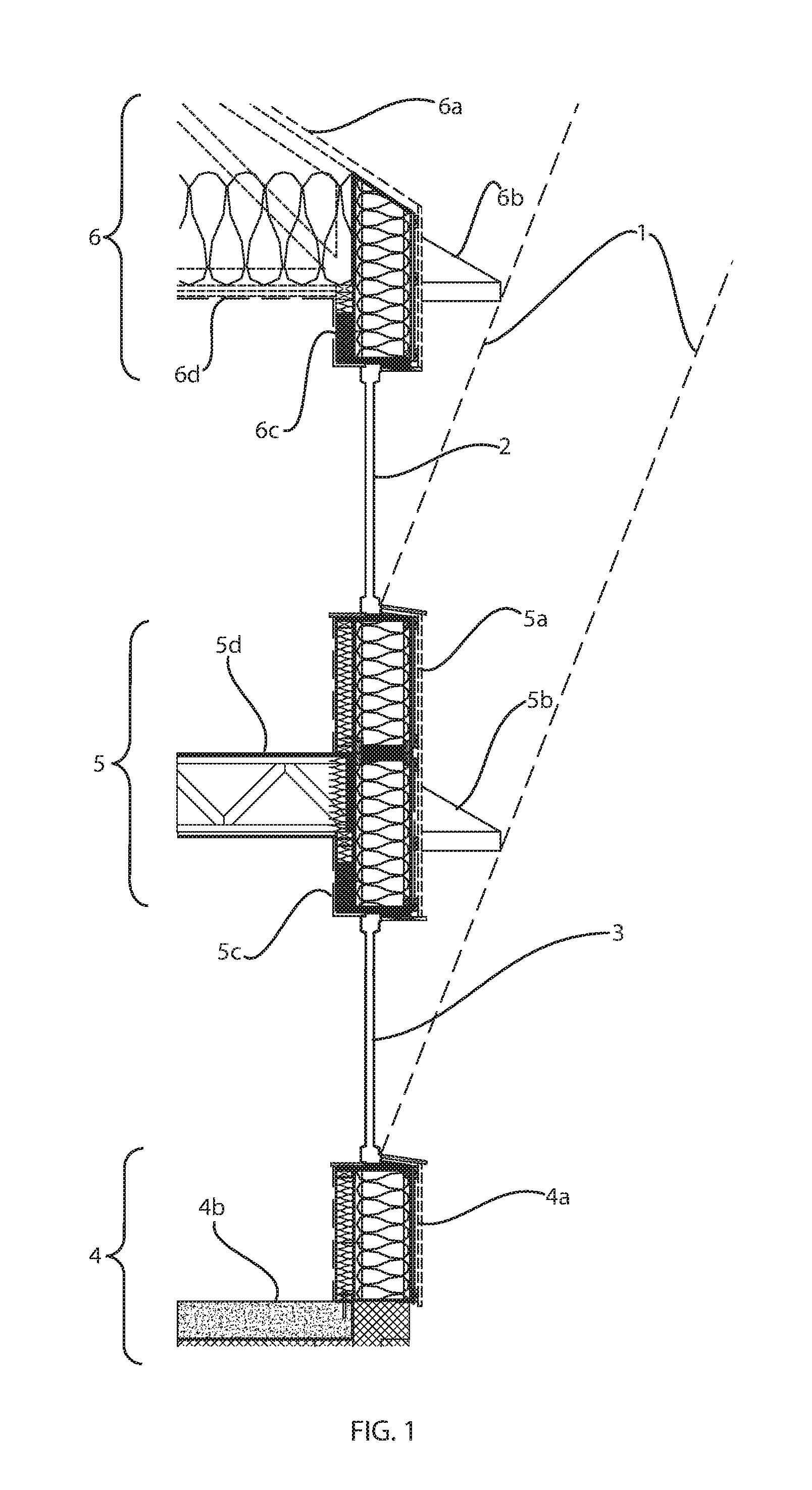

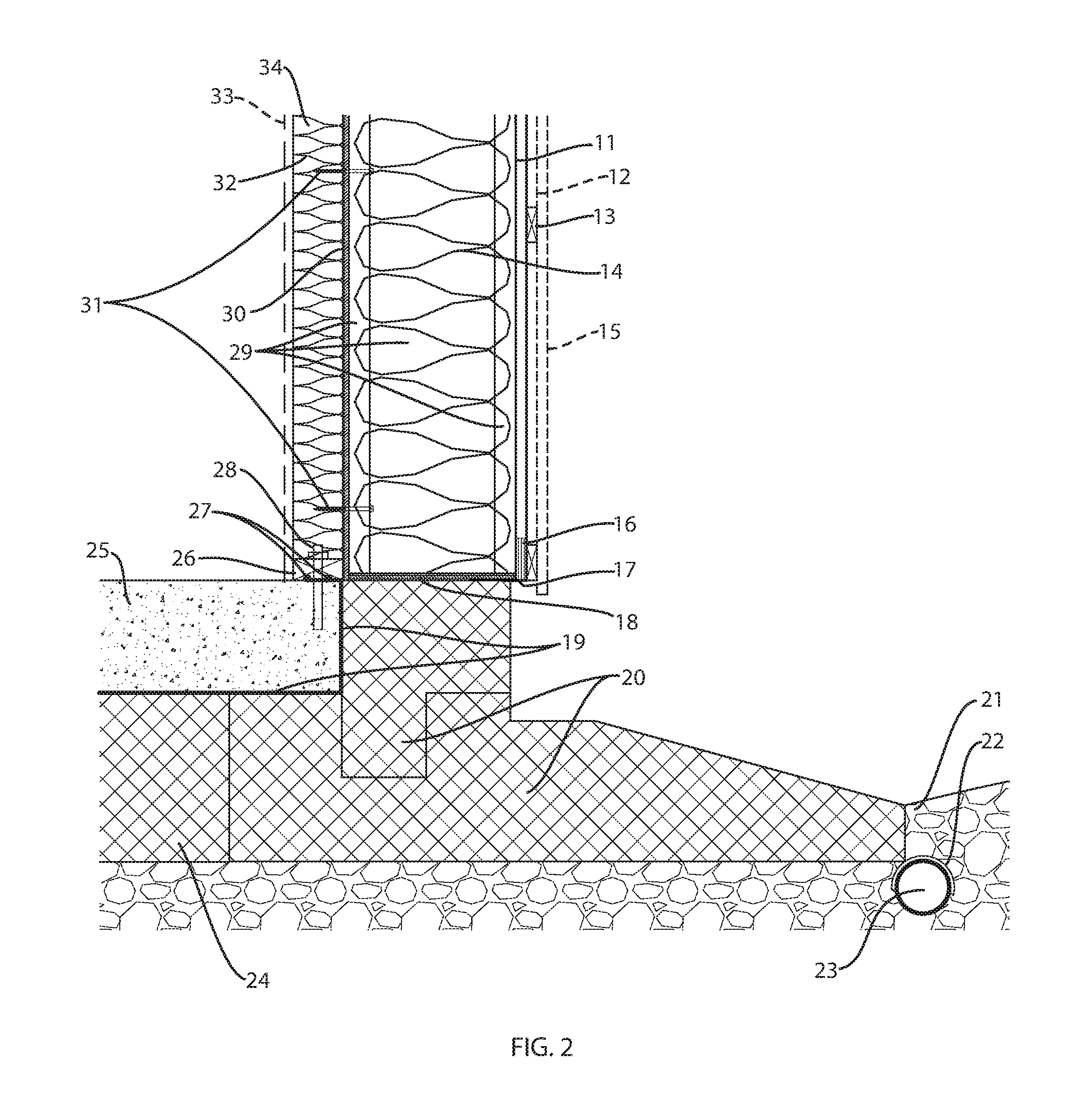

System and method for panelized, superinsulated building envelopes

Panelized wall and roof structures for constructing energy efficient buildings. The panelized structures have a structural layer with insulation, an airtight layer providing a primary air barrier and a vapor retarder exterior to the structural layer, a vapor open blanket layer including insulation and attached to the structural layer via structural screws, a weather resistant barrier provided exterior to the blanket layer and including an airtight, water-repelling, vapor-open fabric, and a rain screen provided exterior to the weather resistant barrier and including a drainage plane for channeling moisture away from the weather resistant barrier.

Owner:CORSON CHRISTIAN PETER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com