System and method for panelized, superinsulated building envelopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

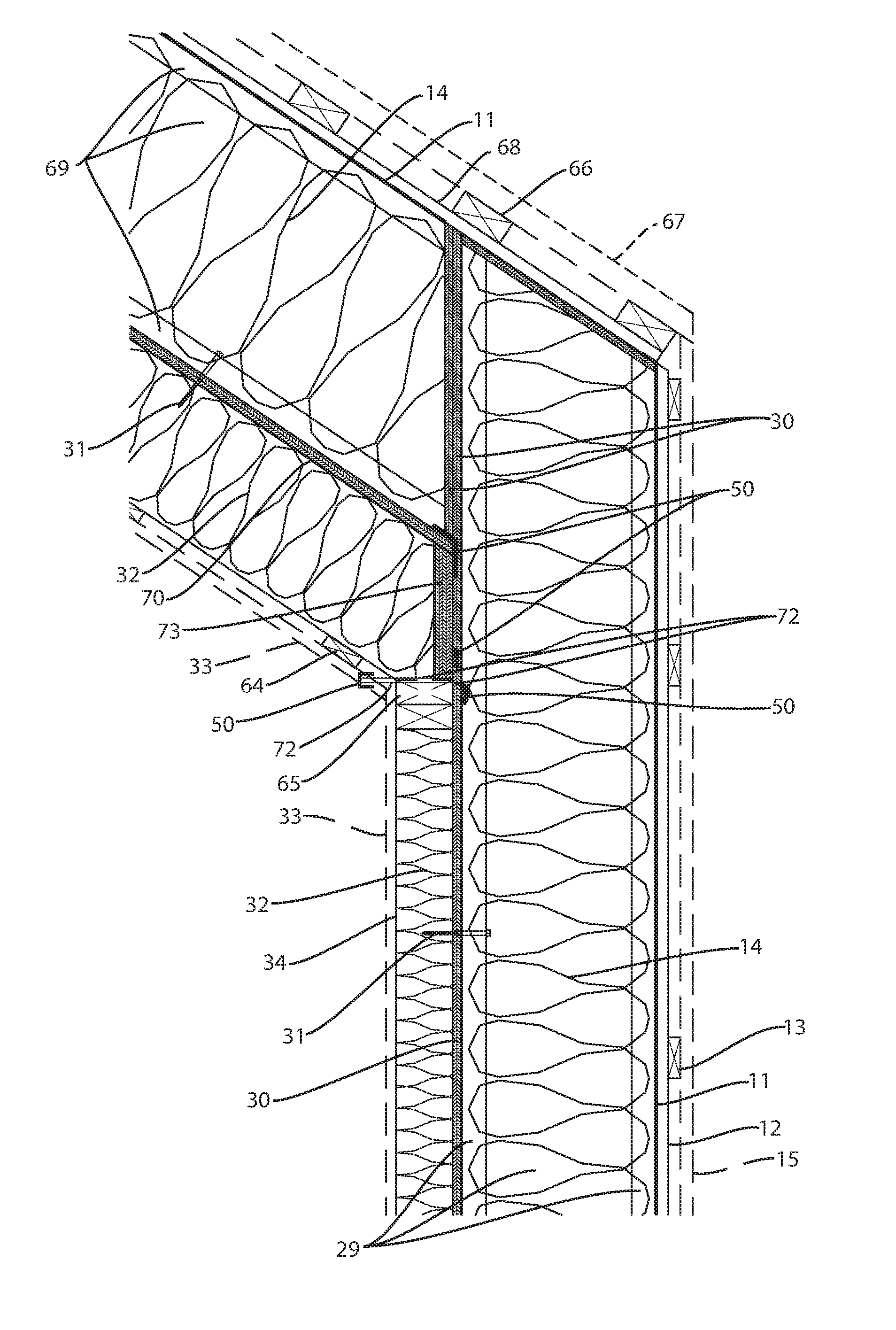

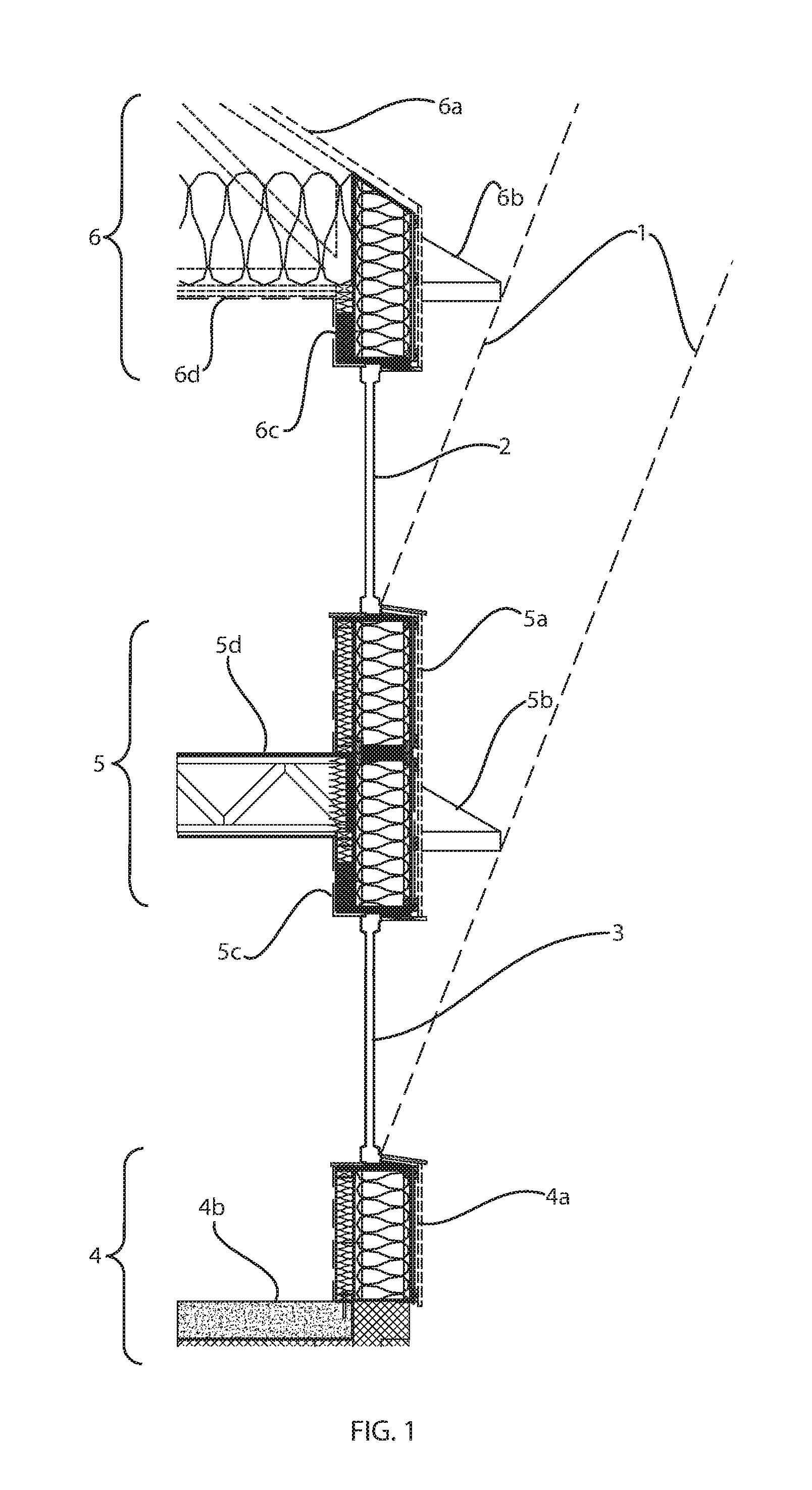

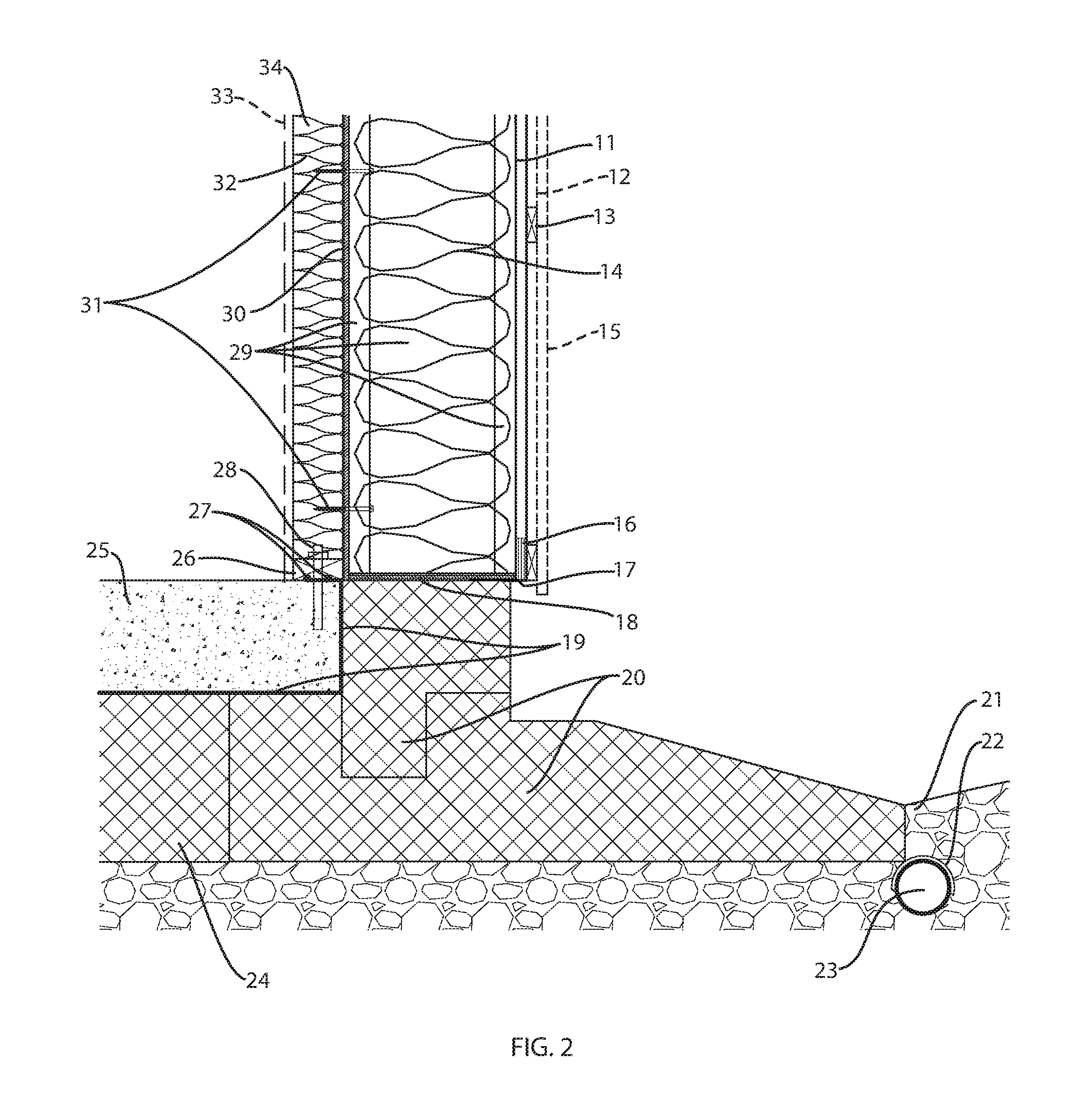

[0044]The present invention is a system and method which provides panelized, superinsulated building envelopes. In general, panel sections in accordance with the invention are shop-fabricated as completed assemblies or as partial assemblies and are installed as components on a building site. Assemblies in accordance with the present invention may include wall, roof, and floor assemblies. Such assemblies provide a new and useful alternative to standard SIPs such that the inventive assemblies are both thermal bridge free and foam free.

[0045]All assemblies in accordance with the present invention are designed and constructed to be highly energy efficient, resilient and durable, and to meet the voluntary International Passive House building energy standard and / or the Passive House Institute of the United States building energy standard. It should be understood that all parts of each building component or assembly are equally important to the overall inventive system and method in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com