Gas pretreatment device with alarm mechanism

A gas pretreatment and gas treatment technology, applied in the direction of sampling device, mining fluid, test sample preparation, etc., can solve the problems of not being able to warn in time, inconvenient maintenance and management, complicated equipment, etc., achieve significant technological progress, and be easy for industrial promotion , significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, in conjunction with the preferred embodiments, the detailed description of the specific embodiments, features and effects provided by the present invention is as follows; for the purpose of simplicity and clarity, the description of the well-known technologies is appropriately omitted below to avoid unnecessary details. Affect the description of this technical solution.

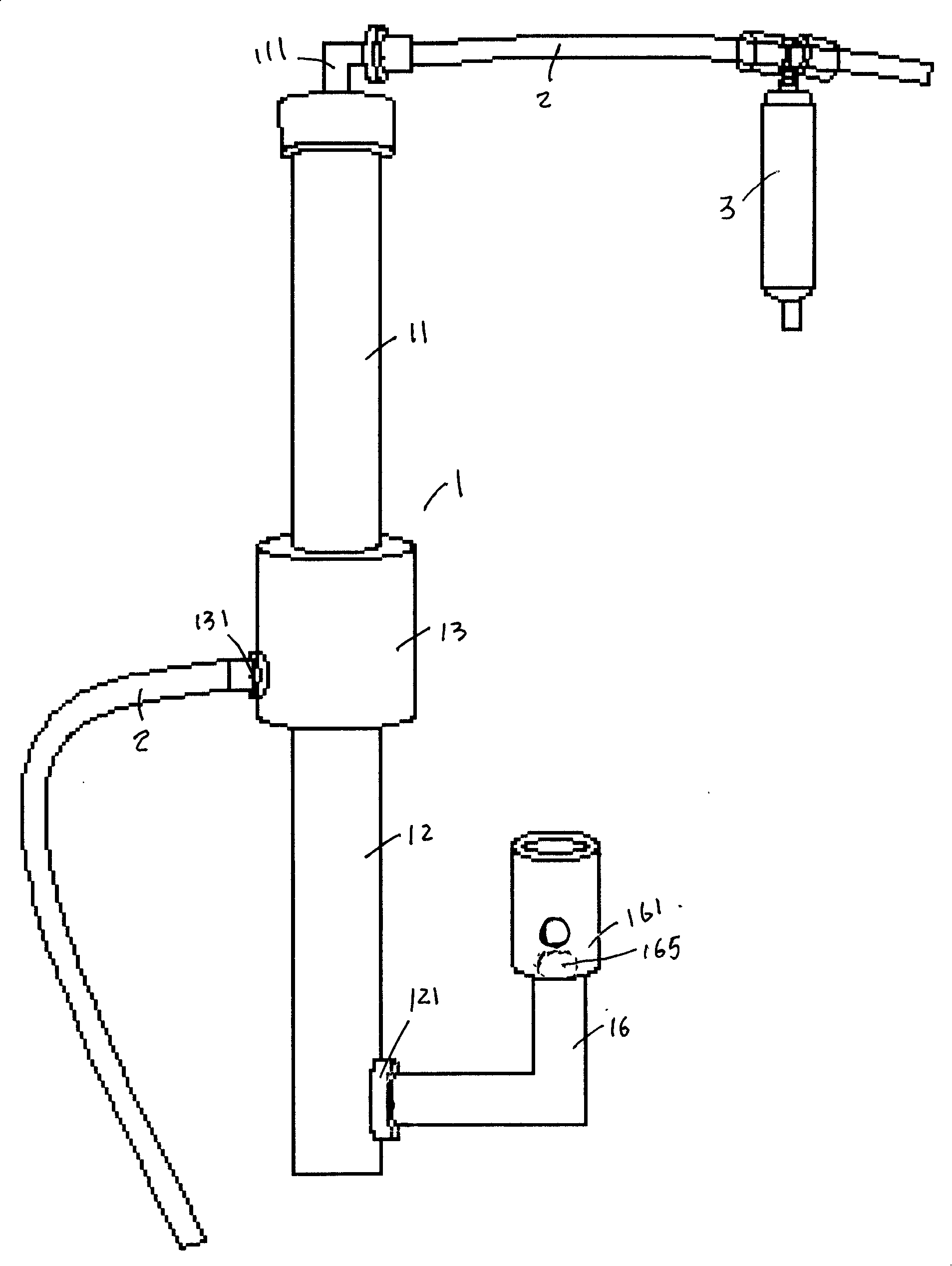

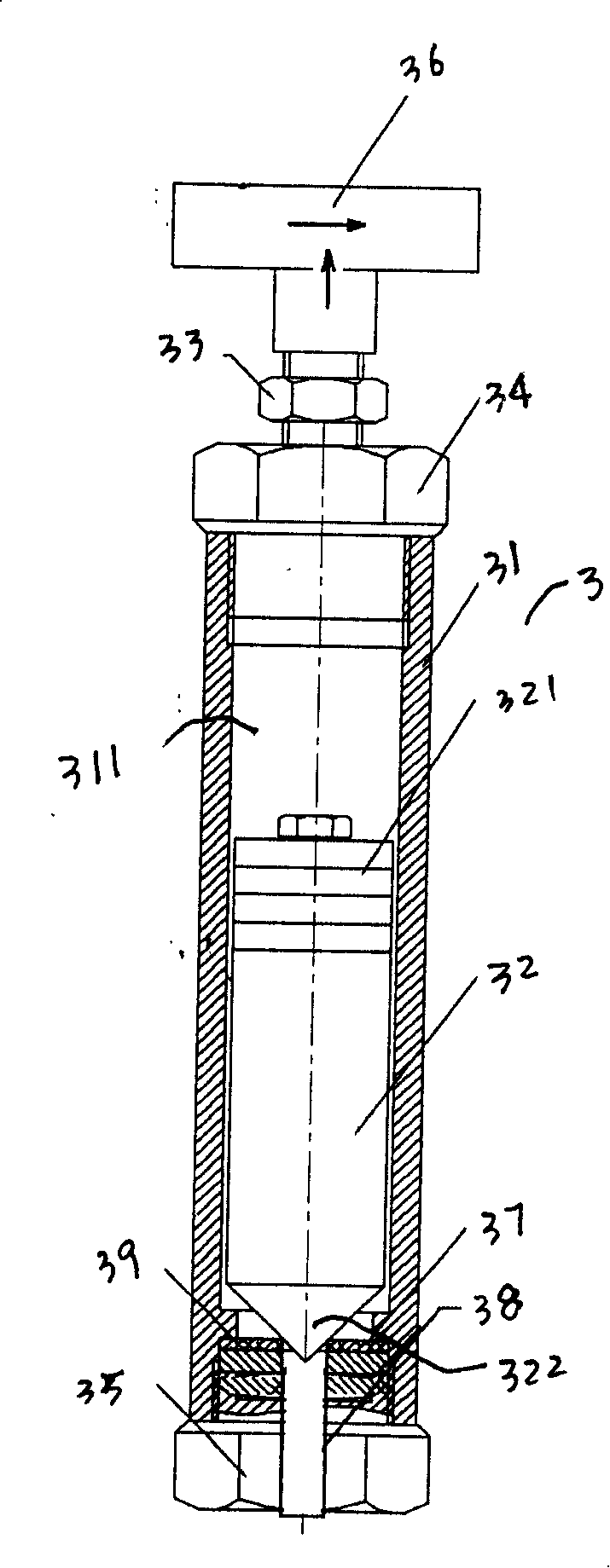

[0022] See Figure 1-2 , A gas pretreatment device with an alarm mechanism, wherein,

[0023] The gas pretreatment device 1 with an alarm mechanism includes a gas processing mechanism 1 with a liquid collecting pipe 12 and a dry gas collection pipe 11, wherein the gas processing mechanism is connected to a negative pressure valve through a gas pipeline 2 Structured negative pressure valve structure alarm 3; The gas processing mechanism is provided with a gas input port 131 connected to the degassing device through the gas pipeline 2;

[0024] The upper part of the gas processing mechanism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com