Air purification fanless radial flow electrostatic precipitator

An air purification, runoff technology, applied in the field of air purification, can solve problems such as dull noise, growth, filter plate blockage, etc., and achieve the effect of preventing dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] as attached figure 1 to attach Figure 9 Shown:

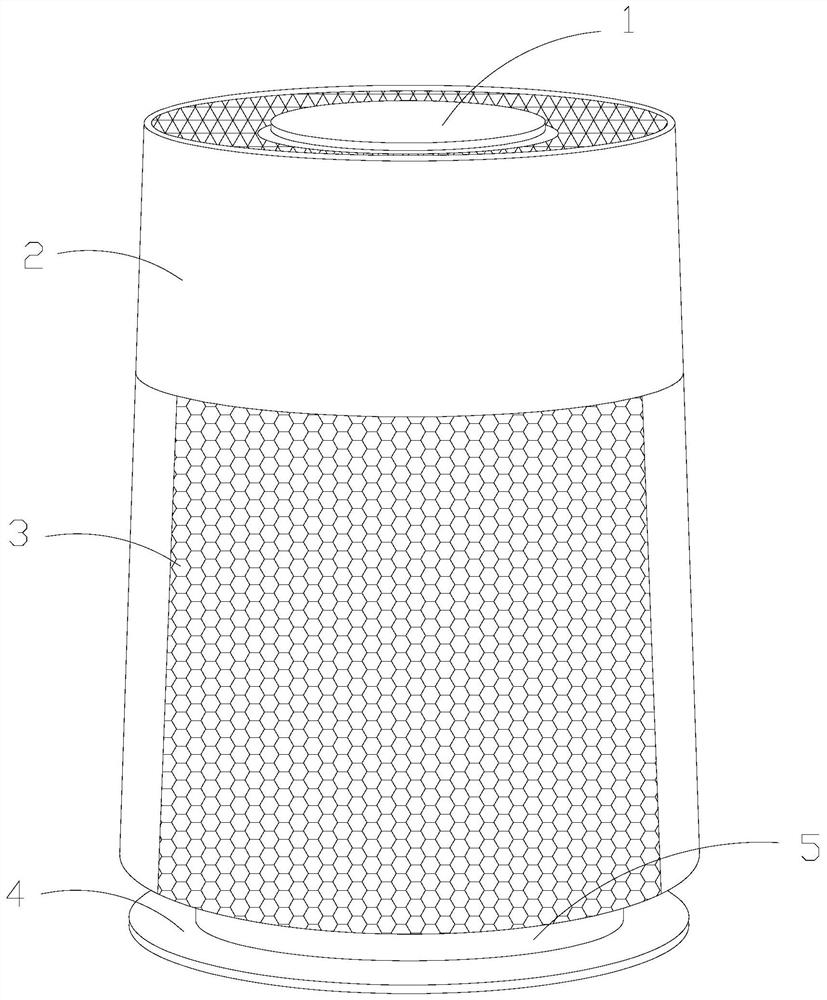

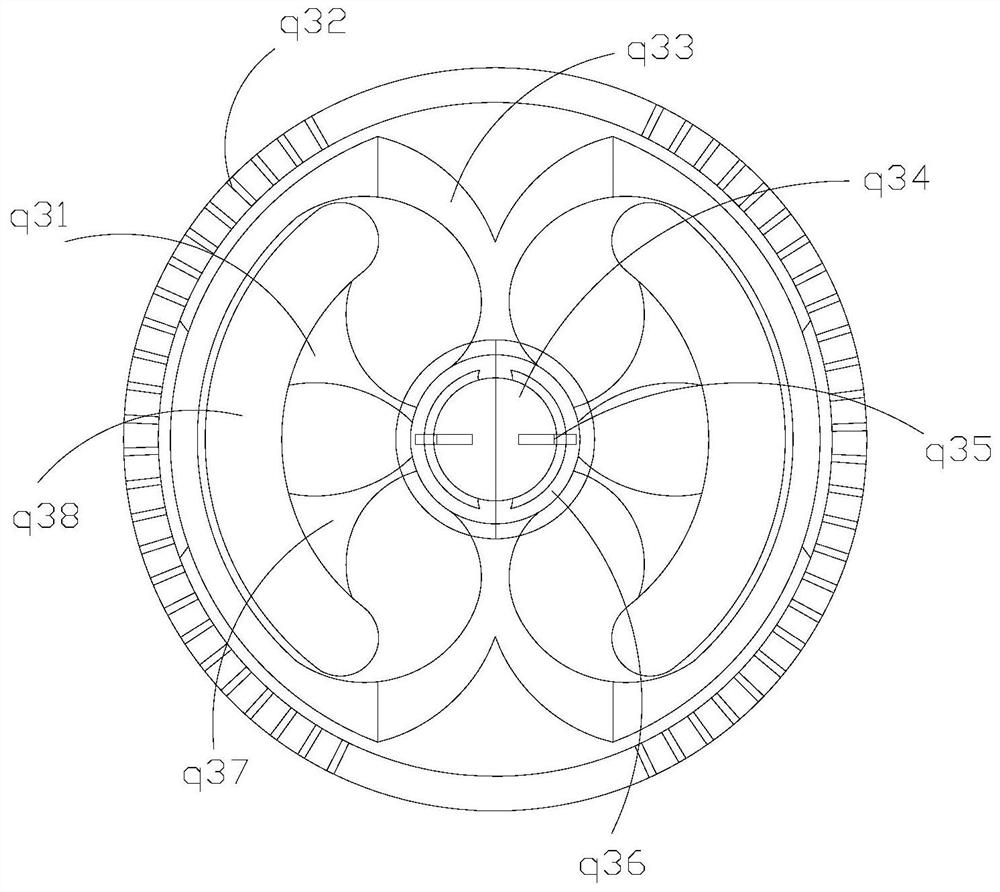

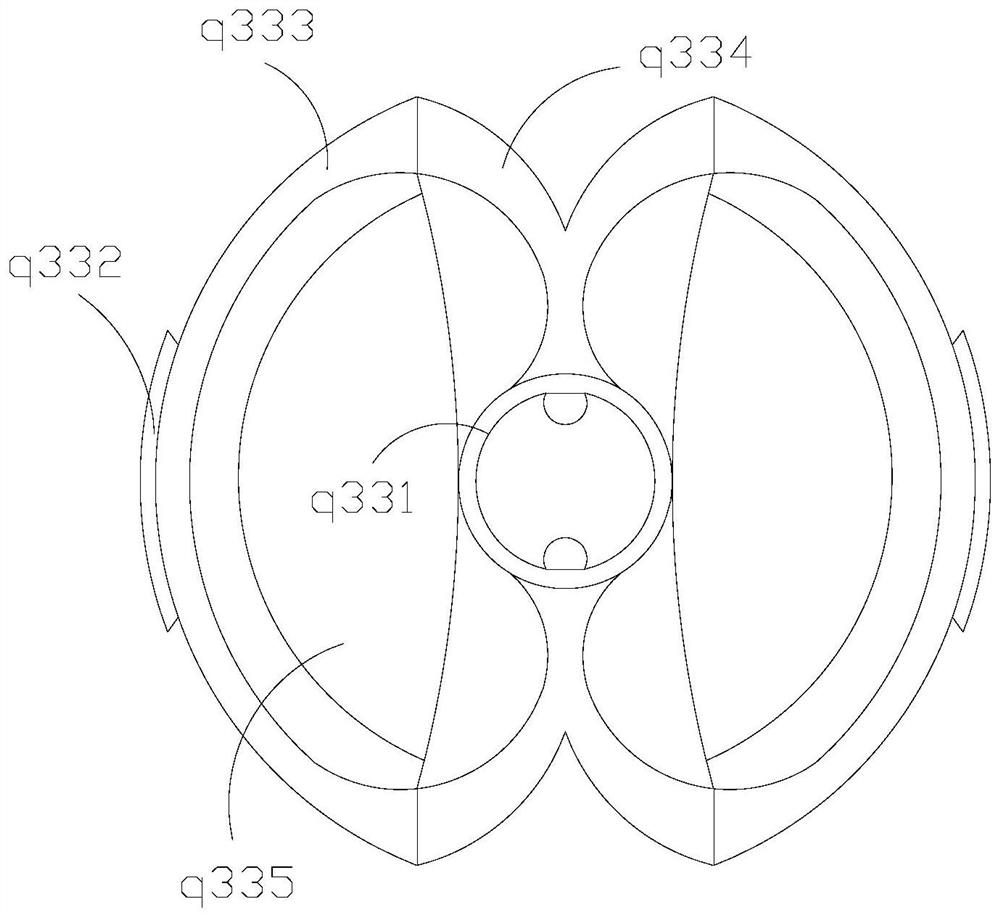

[0031] The present invention provides an air-purifying fanless radial-flow electrostatic precipitator, the structure of which includes a magnetic adsorption button 1, an outer row collar 2, a radial-flow electrostatic precipitator 3, a base 4, and a support ring 5. The bottom of the magnetic adsorption button 1 is The end is installed inside the bottom end of the outer row collar 2 by embedding, the bottom end of the outer row collar 2 is fixedly connected with the radial flow electrostatic precipitator 3, and the top end of the base 4 is fixedly connected to the support ring by electric welding 5 bottom end, the radial flow electrostatic precipitator 3 includes a positive connection bar q31, an outer spacer q32, a recovery mechanism q33, a conduit q34, a magazine clip q35, a resistance piece q36, a negative connection bar q37, and a runoff dust suction mechanism q38. The positive joint q31 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com