Method for blocking holes by using split bolts

A technology for tie bolts and hole plugging, which is applied in the field of tie bolt hole plugging and hole plugging, can solve problems such as affecting the apparent quality of wall concrete, leakage, and poor sealing, and achieves high promotion and application value and guarantees Appearance effect, the effect of ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

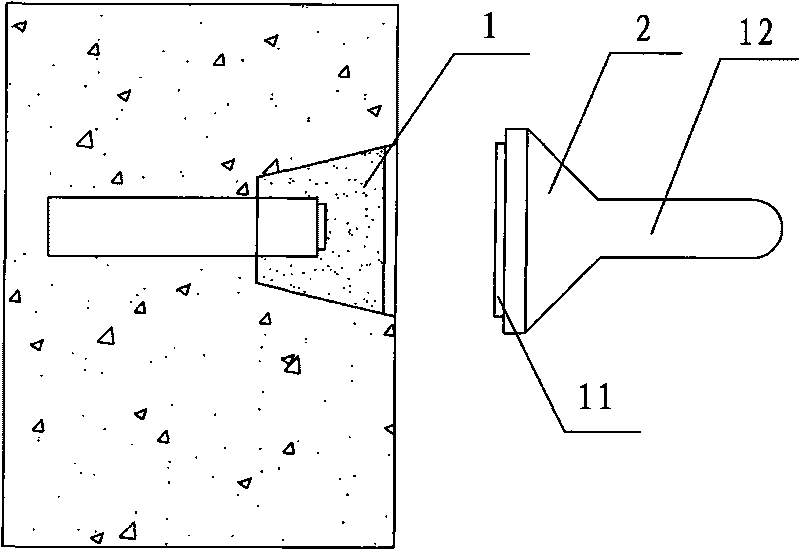

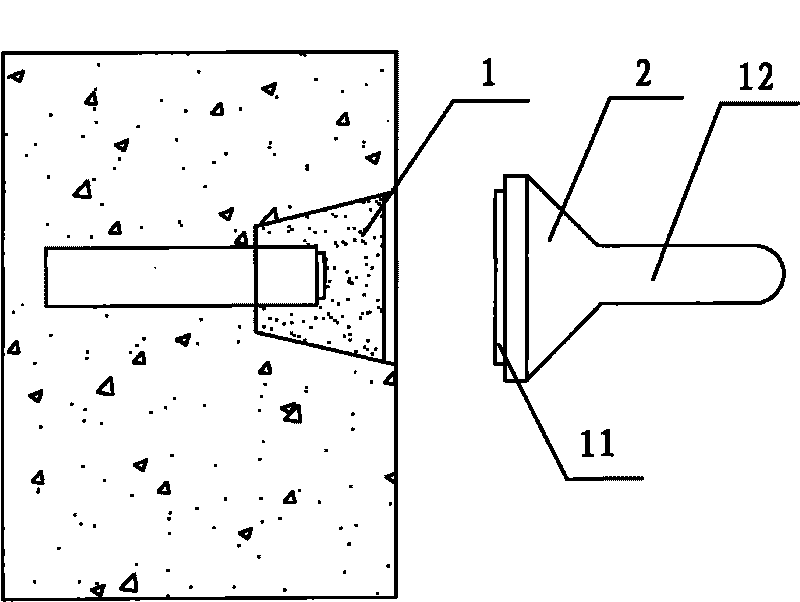

[0008] As shown in the figure, the present invention first uses cement mortar to apply layered smears to the pull bolt bolt holes 2 formed after the wall is poured and then compacts them, and then uses a sealing mold 1 to grind and seal the surface; the sealing mold 1 is a A special tool made of stainless steel, the front end is a disc-shaped boss 11 with a diameter of 45mm, which is the same as the outer diameter of the bolt hole 2 and can cooperate with each other; 12 handles, easy to use. After the cement mortar is used to seal and block the hole, the hole sealing mold 1 is used to align the position of the bolt hole for grinding and pressing to realize the final positioning of the bolt hole 2 to ensure the compactness of the plugging and the appearance of the concrete, and to improve the project quality.

[0009] Of course, the above description is not a limitation of the present invention, nor is the present invention limited to the above-mentioned operations, and all cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com