Quick disassembly and assembly structure for liquid storage bottle of intelligent closestool

A technology of intelligent toilet and liquid storage bottle, which is applied in water supply installations, buildings, sanitary equipment for toilets, etc., can solve the problems of troublesome disassembly and assembly process, affecting the connectivity of pipelines, and disassembling pipelines by mistake, and achieves simple sealing, The effect of avoiding pipeline blockage and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

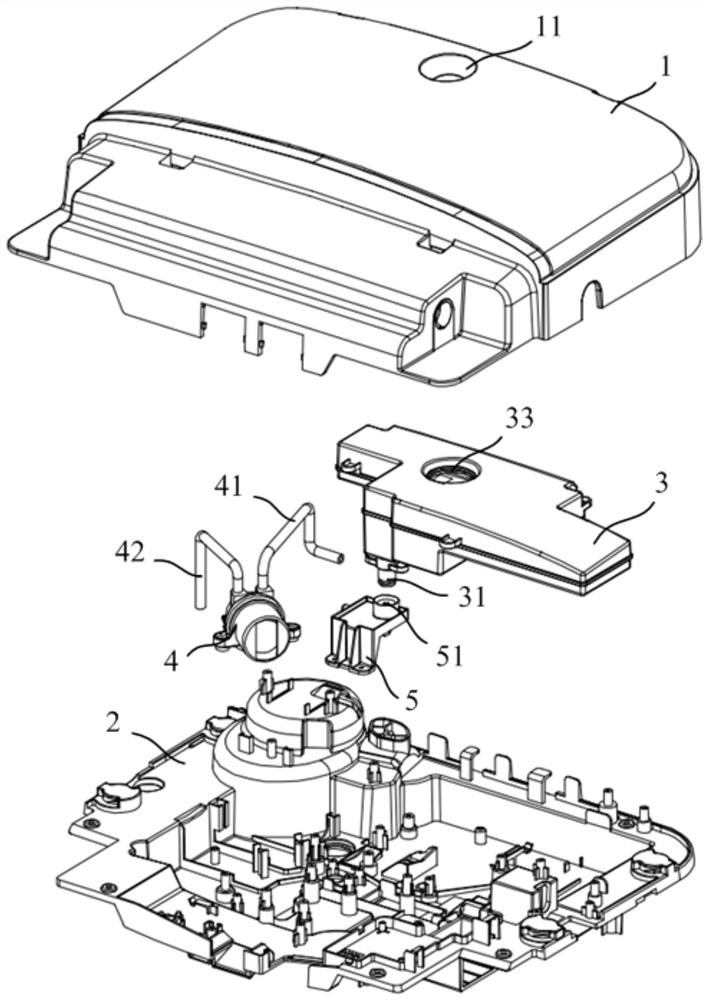

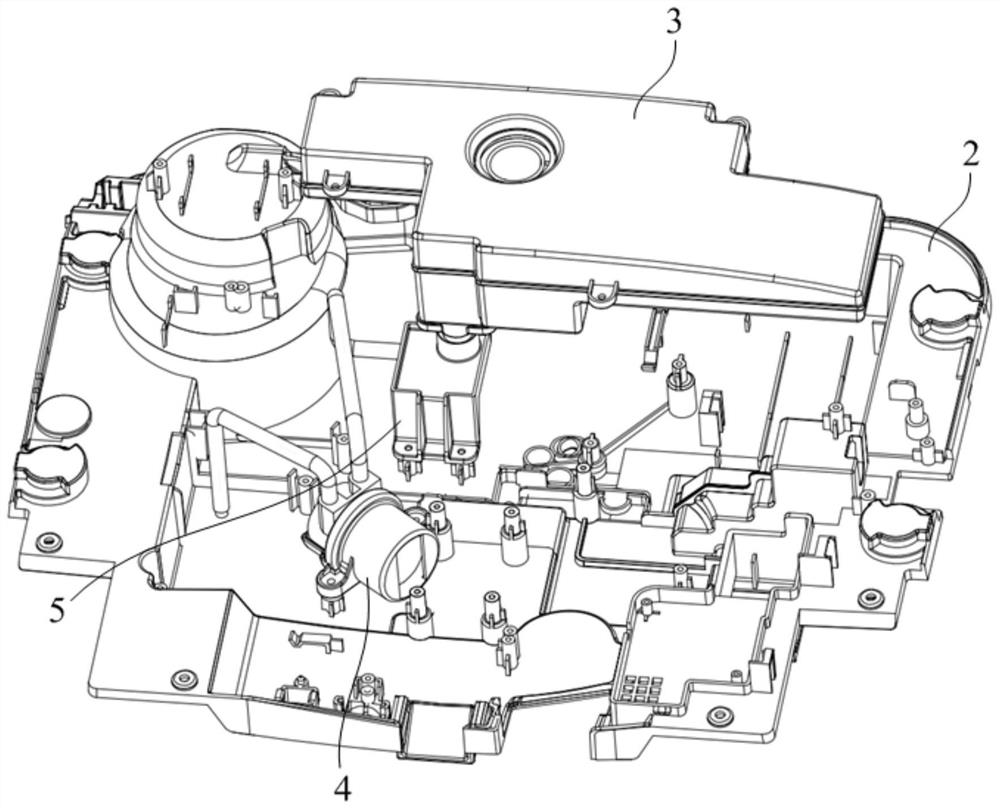

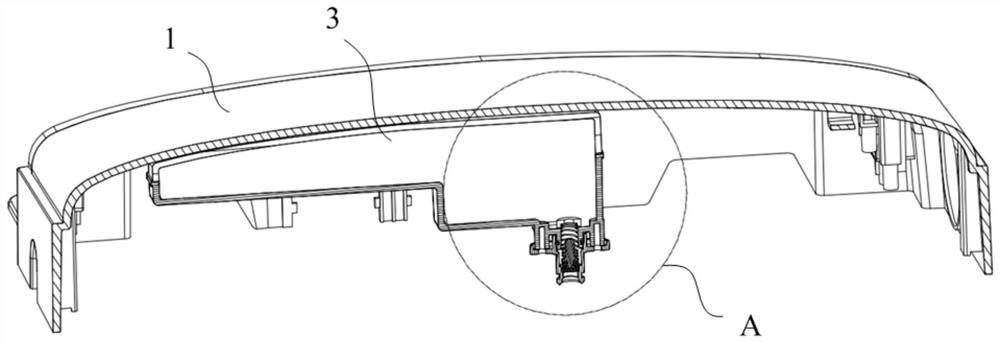

[0036] Such as Figure 1 to Figure 6 As shown, the present invention provides an embodiment of a quick disassembly and assembly structure of a smart toilet liquid storage bottle, including an upper shell 1 and a base 2, the upper shell 1 and the base 2 cooperate to form a chamber, and the chamber is provided with A liquid storage bottle 3, the bottom of the liquid storage bottle 3 is provided with a liquid outlet joint 31, the liquid outlet joint 31 is provided with a liquid outlet 311, and the liquid outlet joint 31 is provided with an elastic member 32a and a sealing plug 32b, One end of the elastic member 32a abuts against the sealing plug 32b, so that the sealing plug 32b blocks the liquid outlet 311; the base 2 is provided with an adapter seat 5, and the adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com