Braking arrangement

A braking and cylinder technology, applied in safety devices, hydraulic brakes, engine components, etc., can solve problems such as machine damage, brake overtravel ejection, etc., and achieve the effects of simple structure, reliable operation, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

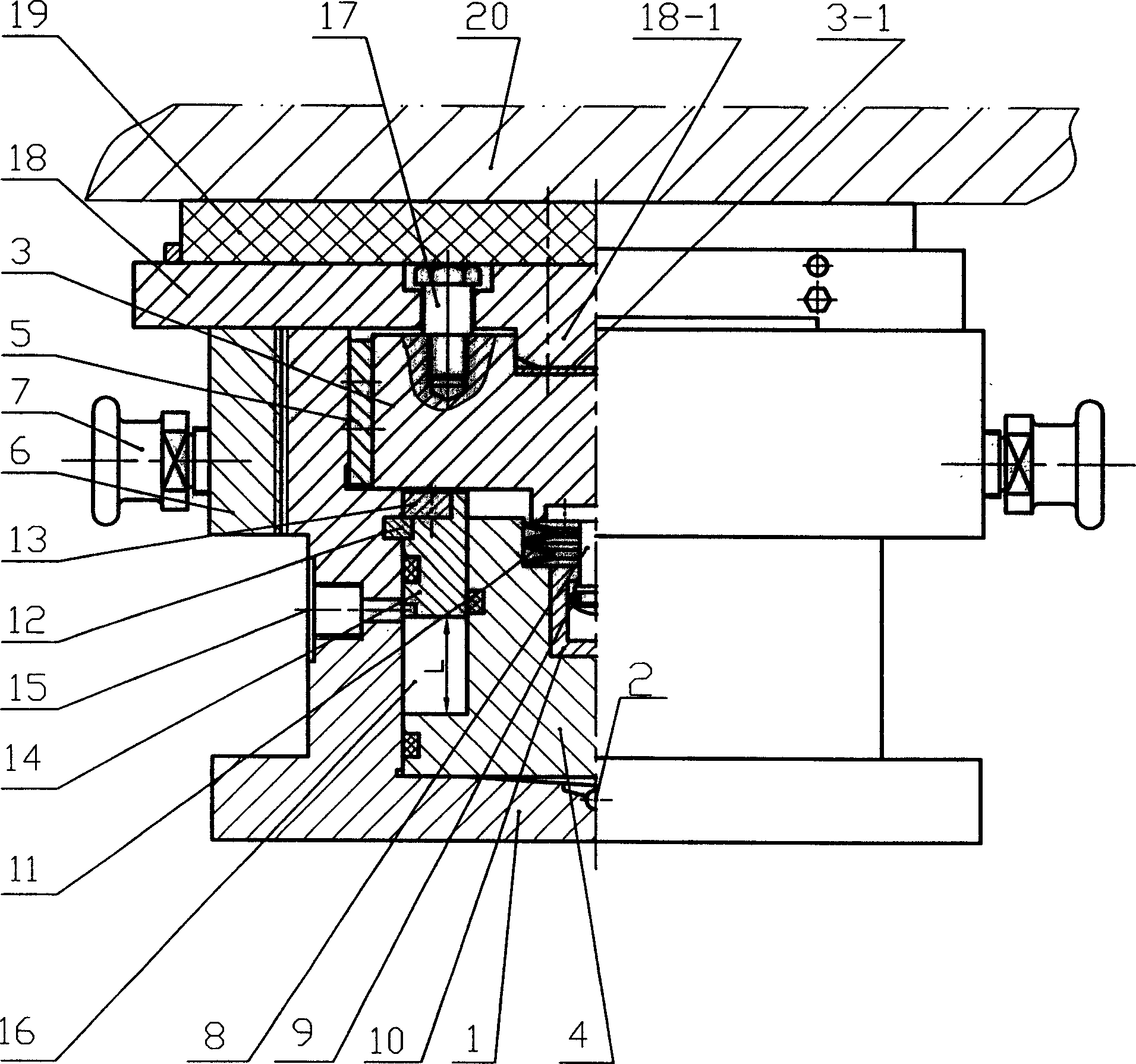

[0010] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0011] Such as figure 1 Shown, a kind of braking device that is used for hydroelectric generating set, it has cylinder body 1, is provided with oil inlet air inlet hole 2 on the cylinder body, upper piston 3, lower piston 4 are housed in the cylinder body, upper piston and A limit key 5 is installed between the inner wall of the cylinder, and a lock nut 6 and a handle 7 for adjusting and locking the upper piston are installed outside the cylinder body, and the top of the cylinder body 1 and the upper piston 3 is eccentrically fixed and connected with the brake supporting plate 18 and the brake by the positioning bolt 16. Brake shoe 19, the bottom end of its brake supporting plate 18 is shaped on a spherical convex head 18-1, which is installed in the groove 3-1 on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com