Projection screen, its manufacturing method and method for controlling light with the projection screen

A technology of projection screen and light, which is applied in the field of projection screen, can solve the problems of unusable and limited usage conditions of the projector, and achieve the effect of low cost, low price and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

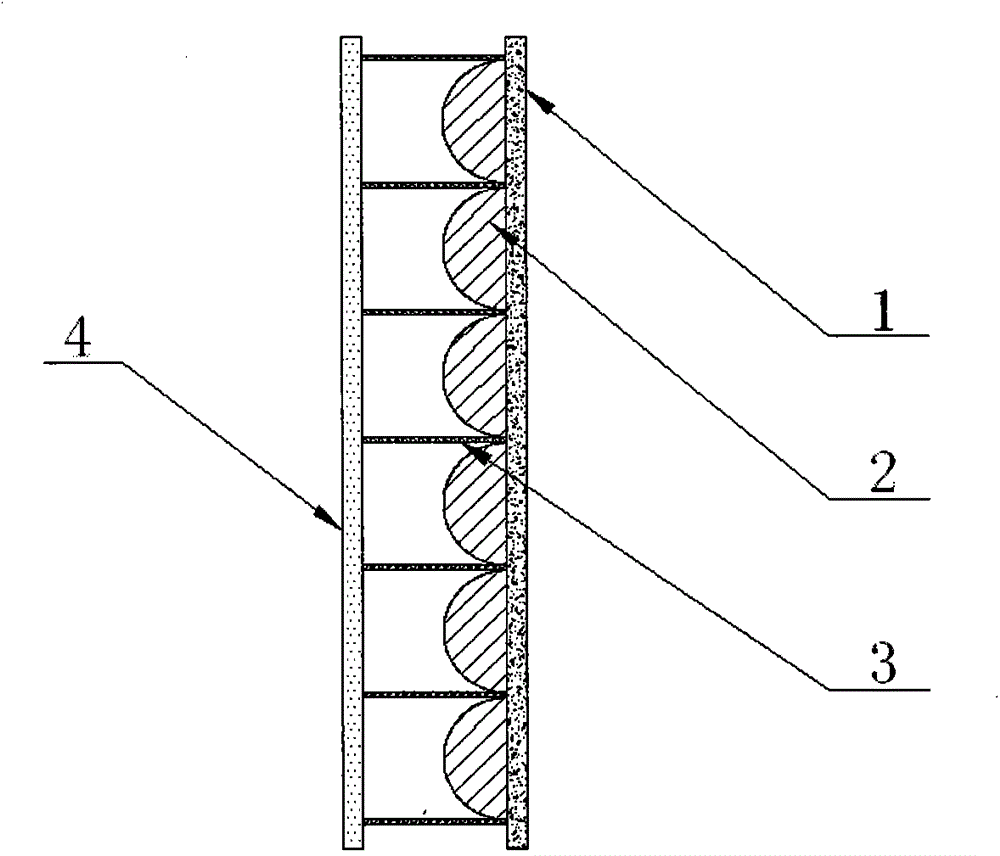

[0038] Such as figure 1 As shown, a projection screen includes a back film 1 arranged on the bottom surface, the upper surface of the back film 1 is covered with several convex mirrors 2 for reflecting light, and gaps are left between the sides of adjacent convex mirrors 2. The gap is filled with a light-blocking plate 3 that blocks light, and the light-blocking plate 3 extends outward perpendicular to the back film 1 to the light-transmitting film 4 . The light partition 3 blocks the light from around the projection screen and prevents the light from reaching the convex mirror 2. The light partition 3 is vertically attached to the film 1, and the projector is placed on the front of the projection screen. The light emitted by the projector It will pass smoothly through the gap between the light barriers 3 onto the convex mirror 2 without being blocked, and the light of the projector passes to the front of the projection screen through the reflection of the convex mirror 2; aga...

Embodiment 2

[0051] The projection screen described in this embodiment and the method for controlling light with the projection screen are the same as those in Embodiment 1, the difference lies in the manufacturing method of the projection screen. The manufacturing method of the present embodiment is as follows:

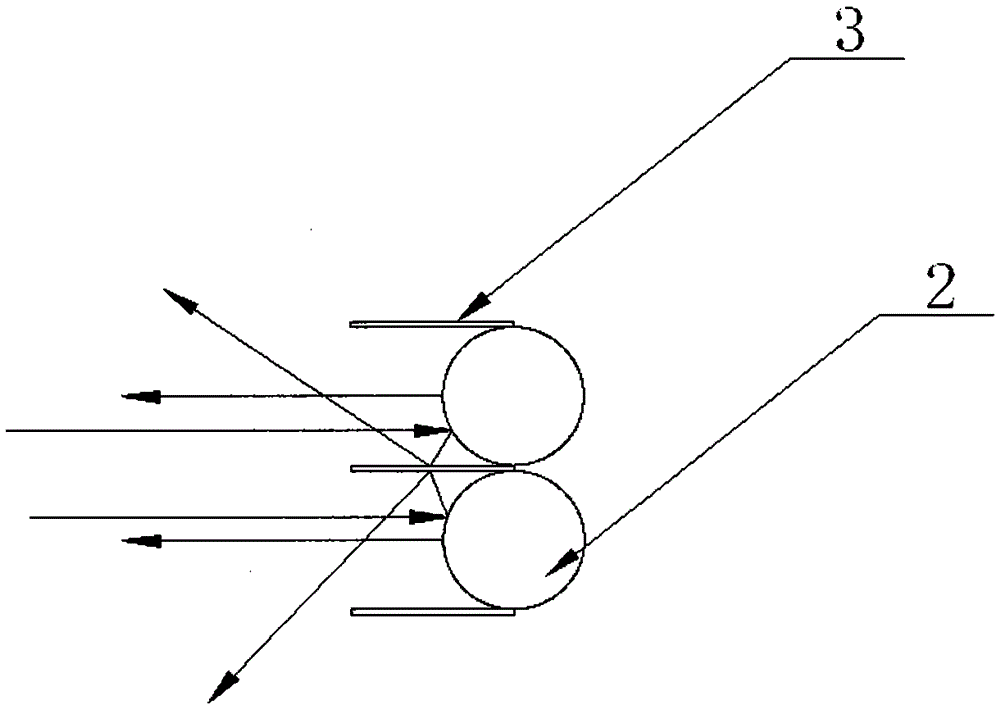

[0052] Rollers are used to press the back film 1 , the light barrier 3 and the convex mirror 2 ; and the pressed back film 1 , the light barrier 3 and the convex mirror 2 are fixedly connected. The manufacturing process is simple and the cost is low.

[0053] Using the synthetic production method, the honeycomb-shaped light-blocking plate 3 and the convex mirror 2 are respectively pressed and formed by corresponding rollers, and then the light-blocking plate 3 and the convex mirror 2 are respectively fixed on the back film 1, wherein: the light-blocking plate 3 The honeycomb holes are formed by a punching machine, and the convex mirror 2 is formed by an embossing machine to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com