Glass fiber reinforced plastic tubular product pultrusion glue-injection device and glue-injection unit

A glue injection device and fiberglass technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve problems affecting product quality, the working environment of the glue is not environmentally friendly, and the viscosity stability of the glue is difficult to guarantee. Promote and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

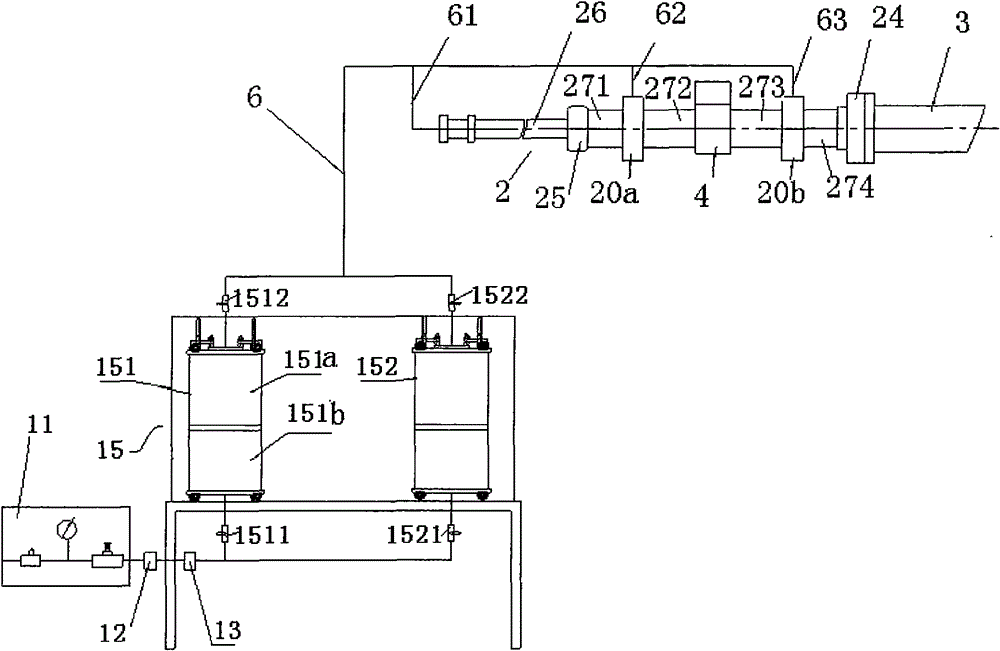

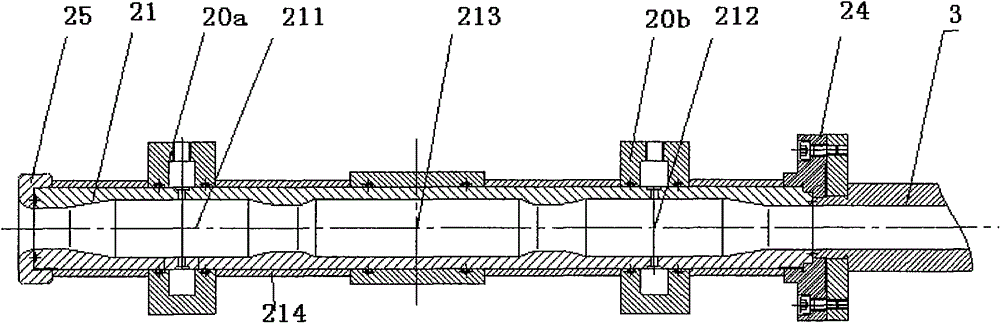

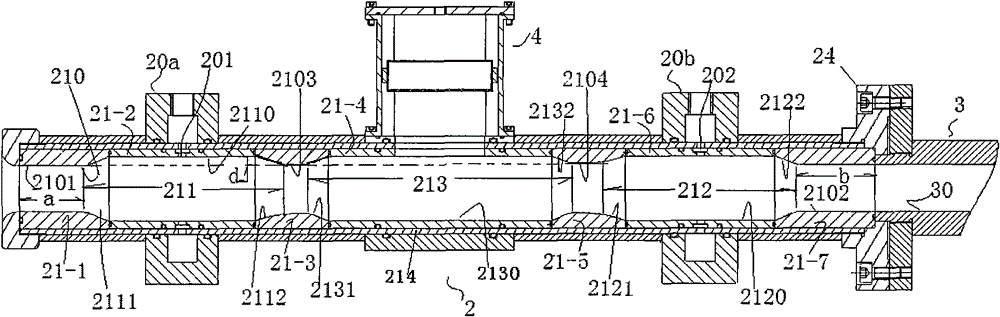

[0033] see Figure 1-4 As shown, a glass fiber reinforced plastic pipe pultrusion glue injection device and its glue injection unit, the glue injection device includes a glue supply unit 1, wherein the glue supply unit 1 and the glue injection unit 2 pass through the glue delivery pipeline 6 to be able to The glue injection unit is connected by injecting preset pressure; the glue injection unit 2 is fixedly connected with the pultrusion mold 3 through the flange 24, and the glue injection unit 2 and the pultrusion mold 3 are on the same traction axis;

[0034] The glue injection unit 2 has a glue injection mold 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com