Continuous training method and continuous training device for shape memory alloy wire

A technology of memory alloy wire and training device, which is applied in the field of material processing, can solve the problems that there is no industrialized promotion training method for shape memory alloys, so as to avoid excessive or too small training stress, avoid insufficient or excessive training, and facilitate industrialization. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

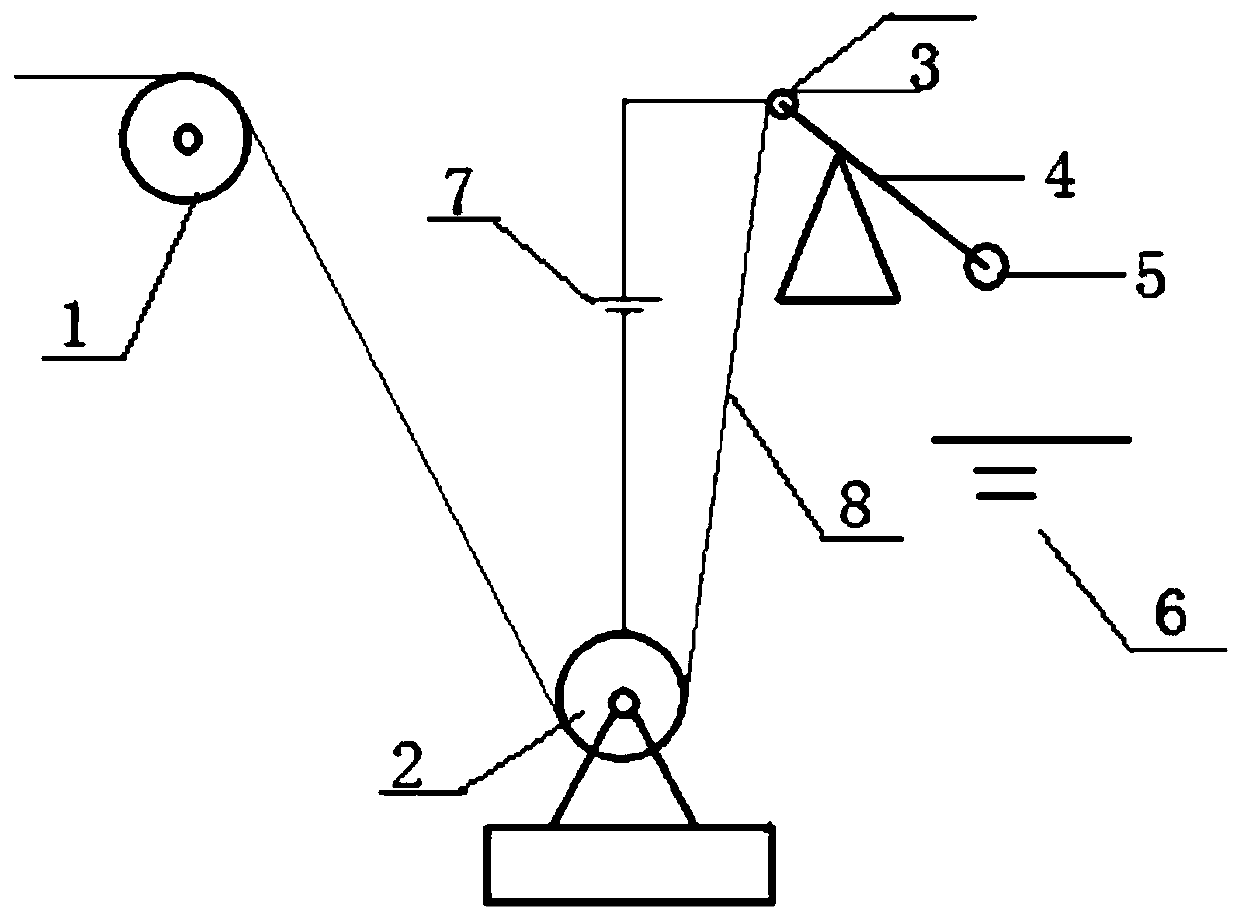

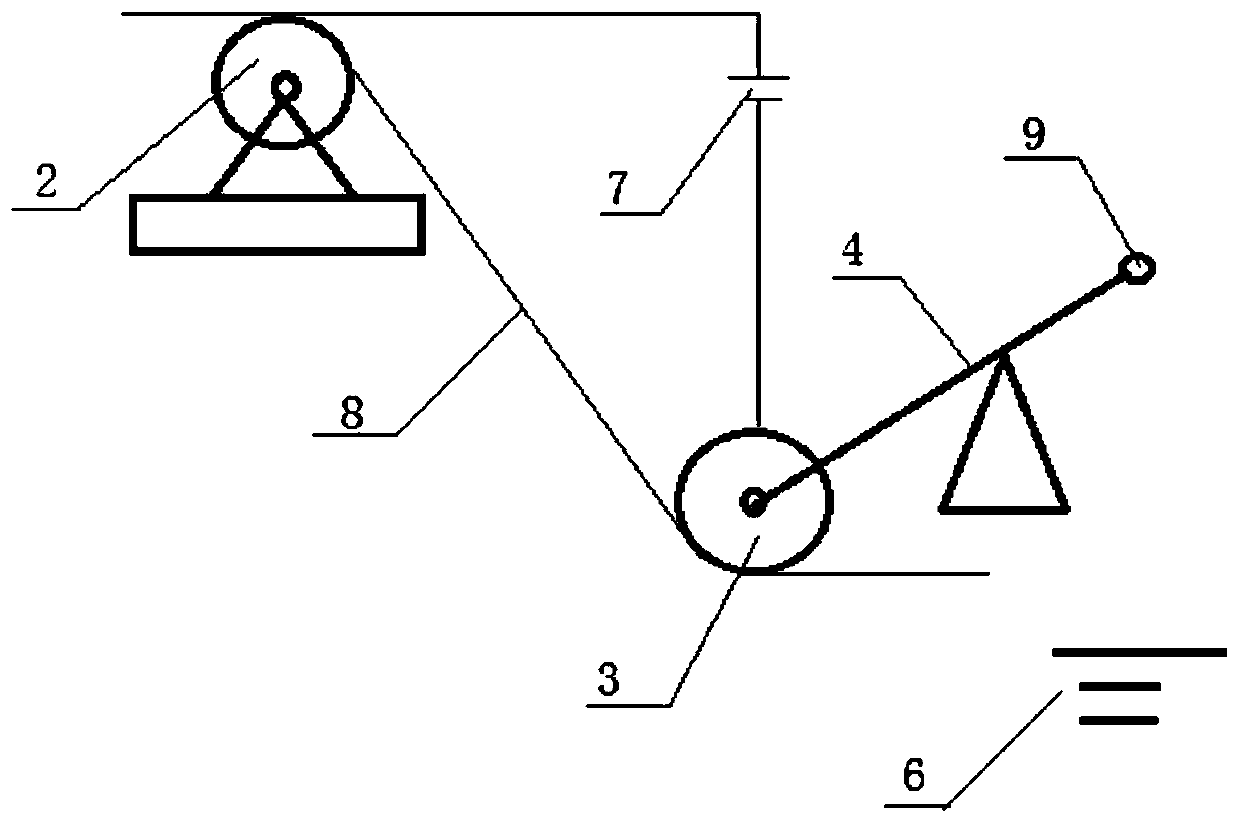

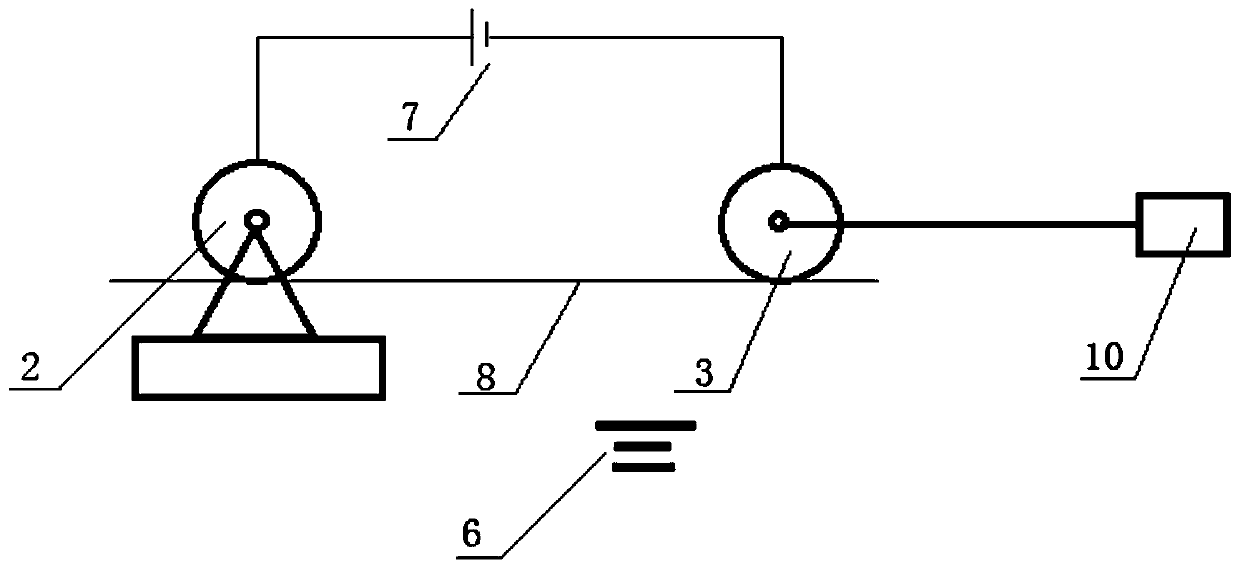

[0047] In specific implementation, such as figure 1 As shown, the present application first provides a continuous training device for shape memory alloy wire, including a fixed pulley 2 and a wire output system; the wire output system includes a wire output pulley 3, a counterweight tension rod 4 and an infrared displacement monitoring Device 6; the height of the wire outlet pulley 3 is higher than the height of the fixed pulley 2, the fixed pulley 2 is used to introduce the shape memory alloy wire, and the wire outlet pulley 3 is used to export the shape memory alloy wire, forming a A device that allows the shape memory alloy wire to be continuously fed in and out; the fixed pulley 2 and the wire outlet pulley 3 are provided with a fixed structure, and the fixed structure is used to transfer the shape memory alloy between the fixed pulley 2 and the wire outlet pulley 3 The wire is fixed to ensure that the length of the shape memory alloy wire between the trained fixed pulley ...

Embodiment 2

[0053] In specific implementation, such as figure 1 As shown, adopt the continuous training device of the shape memory alloy wire material as described in embodiment 1, select the shape memory alloy wire material with a diameter of 25 microns, the nickel content composition is 54.5%, the rest is titanium, and the average grain size of the wire material is The particle size is 35 nanometers, and the shape memory alloy wire is sequentially bypassed into the wire pulley 1, the fixed pulley 2 and the wire outlet pulley 3 and straightened. The two ends of the shape memory alloy wire 8 are respectively fixed on the tangent points with the movable pulley and the wire outlet pulley 3. At this time, the length of the shape memory alloy wire 8 within the electric pulse range is L, which is the initial state. It is 650Mpa that the training load that the shape memory alloy wire material 8 is subjected to in the electric pulse range is adjusted by adjusting the weight of the first counterw...

Embodiment 3

[0056] In specific implementation, such as figure 1 As shown, adopt the continuous training device of the shape memory alloy wire material as described in embodiment 1, select the shape memory alloy wire material with a diameter of 30 microns, the nickel content composition is 54.7%, the rest is titanium, and the average grain size of the wire material is The particle size is 50 nanometers, and the shape memory alloy wire is sequentially bypassed into the wire pulley 1, the fixed pulley 2 and the wire outlet pulley 3 and straightened, through the fixed structure on the fixed pulley 2 and the wire outlet pulley 3. The two ends of the shape memory alloy wire 8 are respectively fixed on the tangent points with the movable pulley and the wire outlet pulley 3. At this time, the length of the shape memory alloy wire 8 within the electric pulse range is L, which is the initial state. By adjusting the weight of the first counterweight 5, the training load that the shape memory alloy w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com