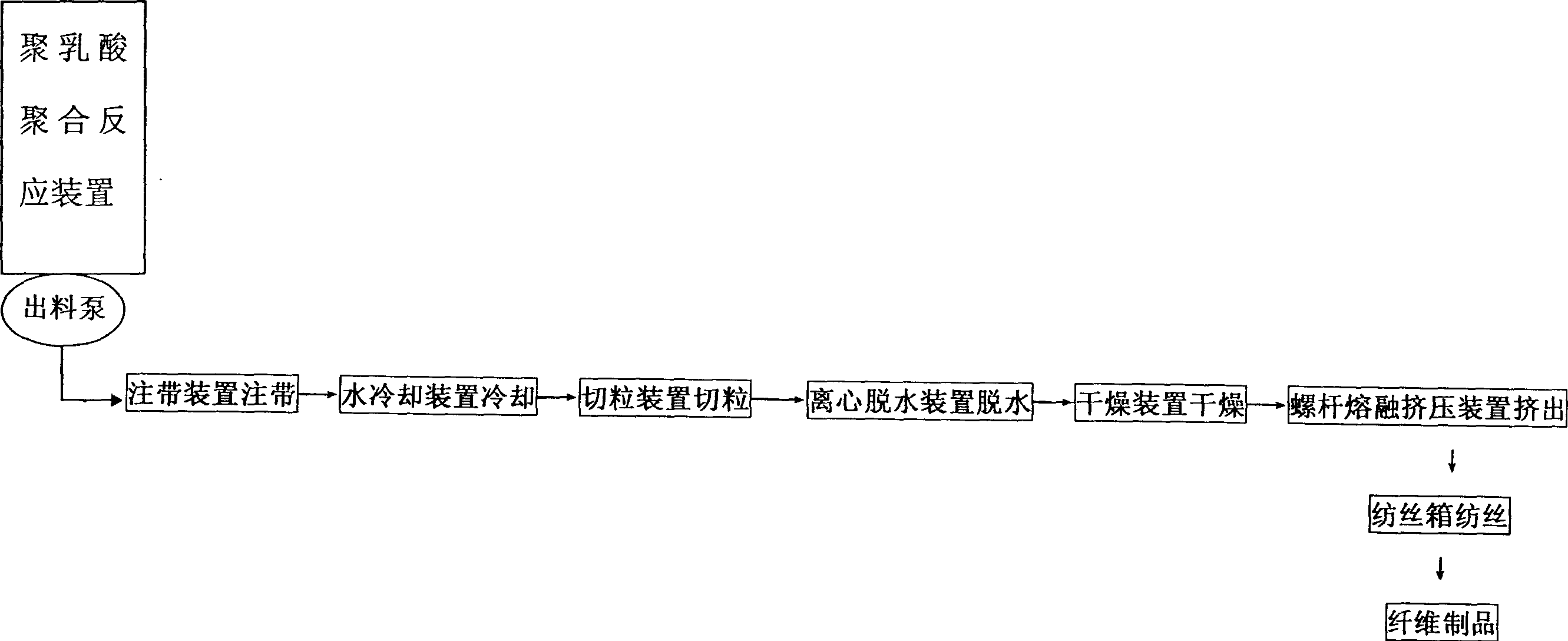

Method for directly preparing fiber product fron poly lactic acid polymerized smelting body

A technology of polylactic acid and melt, which is applied in the field of polymer materials, can solve the problems that restrict the industrialization process of fiber products, and achieve the effects of ensuring spinnability, less equipment investment, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

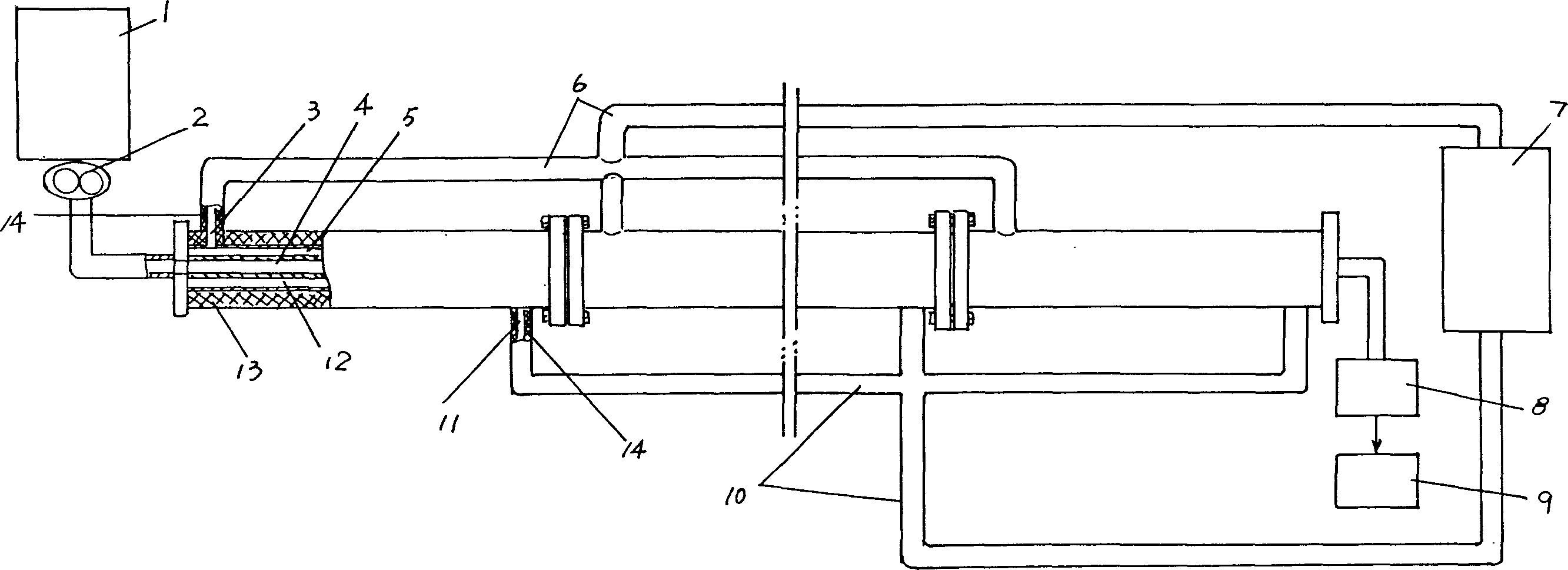

[0022] Please combine figure 2 , between the discharge port of the discharge pump 2 of the polylactic acid polymerization reaction device 1 and the feed port of the spinning box 8, a melt pipeline 4 that is placed in the jacket 5 and has a length of 180 meters in a straight line is connected. , the jacket 5 is connected with a medium introduction interface 3 for introducing the heat transfer medium, that is, the heat transfer oil, into the jacket cavity 12, and a medium outlet interface 11 for introducing the heat transfer medium, that is, the heat transfer oil, out of the jacket cavity 12. The interfaces 3 and 11 are respectively connected to the medium inlet and outlet pipes 6 and 10 , and the medium inlet and outlet pipes 6 and 10 are connected to the heat transfer oil furnace 7 . When the polylactic acid polymer melt obtained after the polymerization reaction of the polymerization reaction device 1 is completed by the discharge pump 2, and the temperature is in the range ...

Embodiment 2

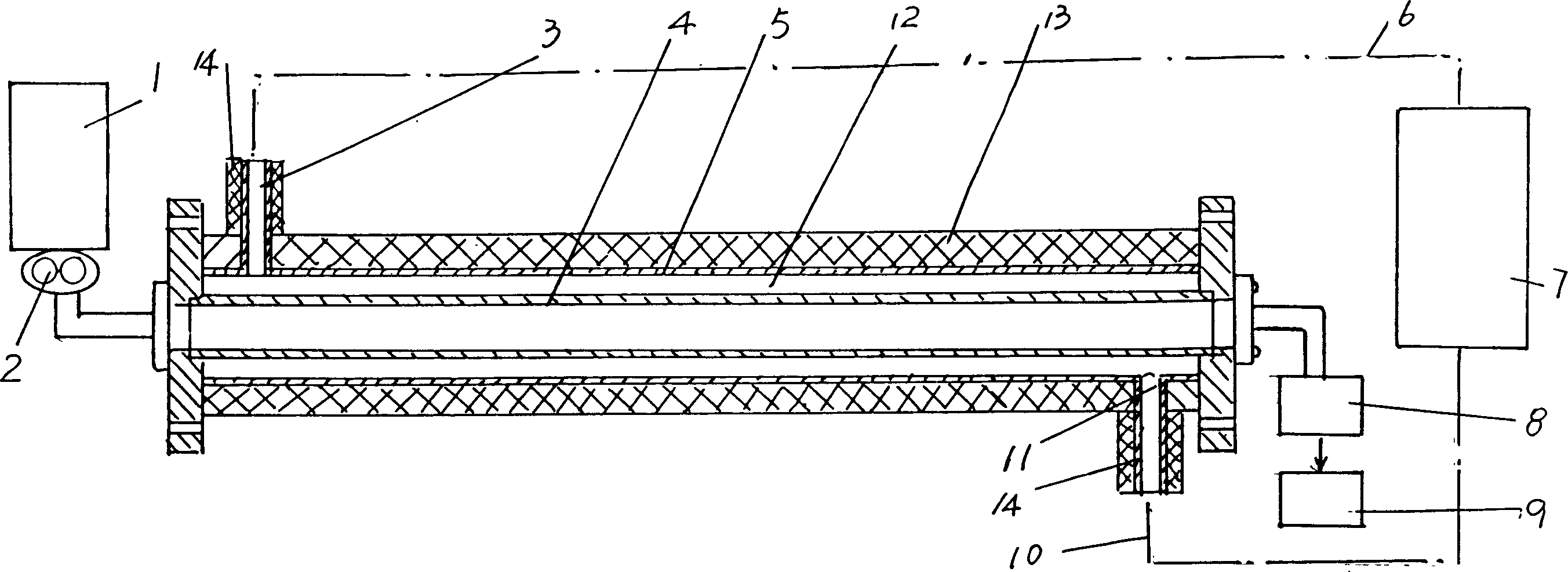

[0026] Please combine image 3 , the polylactic acid polymerized melt with a temperature of 175°C-185°C obtained after the polymerization reaction of the polymerization reaction device 1 is completed from the discharge pump 2 is directly sent to the spinning box 8 through the melt pipeline 4 with a linear distance of 20 meters, The temperature of the heat-conducting oil in the jacket 5 is the same as that of the polylactic acid polymer melt. After the fiber products spun from the spinning box 8, that is, the polylactic acid fiber products are oiled in the subsequent process, they are continuously drawn by the feeding roller to the drafting process. After the hot roller is drawn 3-6 times, it is continuously taken up on the bobbin of the coiling system to become FDY filament or BCF filament after air deformation treatment, which can be directly used in textile fabrics and fiber products of carpets. In this embodiment, since the linear distance from the discharge port of the dis...

Embodiment 3

[0028] The polylactic acid polymer melt obtained by the polymerization reaction of the polymerization reaction device 1 with a temperature of 185°C is directly sent to the spinning box 8 through the melt pipeline 4 with a linear distance of 100 meters by the discharge pump 2, and the heat conduction in the jacket 5 The temperature of the oil is 185°C. The obtained fiber product 9, that is, the polylactic acid fiber product, is bundled under the action of the godet roller of the subsequent process, and then drawn by multiple rollers, crimped, heat-set, cut, and unhaired. , Become short fiber. After the short fiber is spun, it is used for textile fabrics, and can also be directly used for the production of textile product fillers or short fiber non-woven fabrics, and the rest are the same as those described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com