Antibacterial mite-resistant cellulose viscose and its making method

A viscose fiber and manufacturing method technology, applied in the field of viscose fiber, can solve problems such as single function, single fiber component, and insufficient additional functions and value, so as to increase technical content, excellent washability, and enhance product added value. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

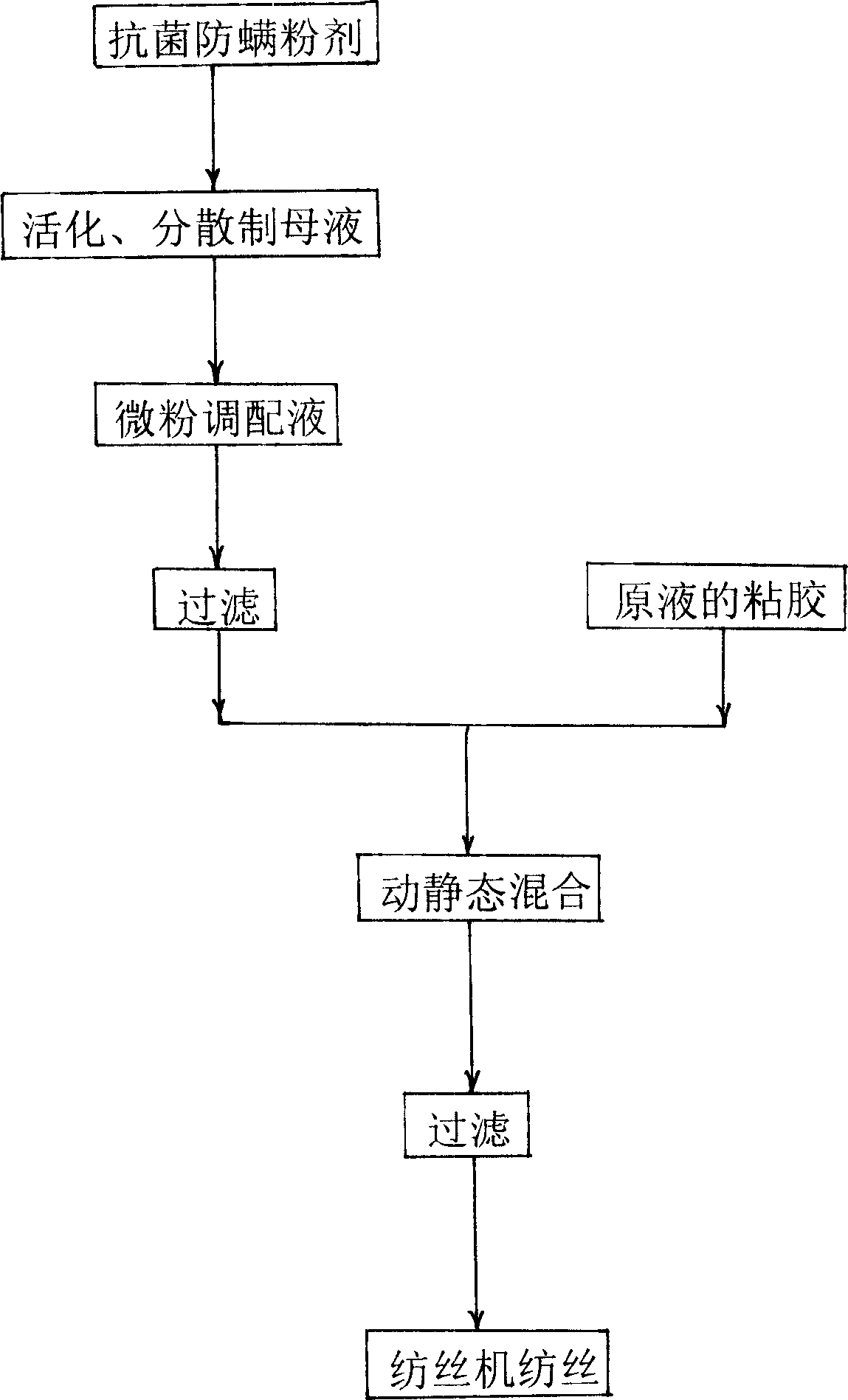

Method used

Image

Examples

Embodiment 1

[0034] Antibacterial and anti-mite viscose fiber, the antibacterial and anti-mite viscose fiber refers to the antibacterial and anti-mite solution mixed with the viscose solution at a ratio of 0.1% and then spun, the number of monofilaments obtained is 30, and the deviation of the number of monofilaments is 0% , the residual sulfur content is 6.3mg / 100g, the oil content is 0.4%, the dyeing uniformity is 3.5, and the anti-mite rate reaches 99.6%. Antibacterial and anti-mite viscose fiber products. The antibacterial and antimite solution is a solution formed by dispersing an antibacterial and antimite agent in deionized water. The antibacterial and anti-mite powder is a mixture of quaternary ammonium salt compound and specific pyrethrum extract. Contains quaternary ammonium salt benzalkonium bromide, benzalkonium chloride 20%, pyrethrin I, II 5%.

[0035] The manufacture method of antibacterial and anti-mite viscose fiber is realized according to the following steps:

[0036] ...

Embodiment 2

[0053] Antibacterial and anti-mite viscose fiber, the antibacterial and anti-mite viscose fiber refers to mixing the anti-bacterial and anti-mite solution to the viscose solution in a ratio of 2% before spinning, and the number of monofilaments obtained is 30, and the deviation of the number of monofilaments is 0%. , the residual sulfur content is 6.3mg / 100g, the oil content is 0.4%, the dyeing uniformity is 3.5, and the anti-mite rate reaches 99.6%. Antibacterial and anti-mite viscose fiber products. The antibacterial and antimite solution is a solution formed by dispersing an antibacterial and antimite agent in deionized water. The antibacterial and anti-mite powder is a mixture of quaternary ammonium salt compound and specific pyrethrum extract. Contains quaternary ammonium salt benzalkonium bromide, benzalkonium chloride 20%, pyrethrin I, II 5%.

[0054] The manufacture method of antibacterial and anti-mite viscose fiber is realized according to the following steps:

[0...

Embodiment 3

[0072] Antibacterial and anti-mite viscose fiber. The antibacterial and anti-mite viscose fiber refers to mixing the antibacterial and anti-mite solution with the viscose solution at a ratio of 1% before spinning. The number of monofilaments obtained is 30, and the deviation of the number of monofilaments is 0%. , the residual sulfur content is 6.3mg / 100g, the oil content is 0.4%, the dyeing uniformity is 3.5, and the anti-mite rate reaches 99.6%. Antibacterial and anti-mite viscose fiber products. The antibacterial and antimite solution is a solution formed by dispersing an antibacterial and antimite agent in deionized water. The antibacterial and anti-mite powder is a mixture of quaternary ammonium salt compound and specific pyrethrum extract. Contains quaternary ammonium salt benzalkonium bromide, benzalkonium chloride 20%, pyrethrin I, II 5%.

[0073] The manufacture method of antibacterial and anti-mite viscose fiber is realized according to the following steps:

[0074...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com