Patents

Literature

107results about How to "Moisture absorption and quick drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of multifunctional textile lining

InactiveCN101280485AMoisture absorption and quick dryingUV resistantFilament/thread formingWoven fabricsPolyesterAnti bacterial

The invention discloses a textile technology, in particular to a textile technology of textile fabrics. In the invention, the quick-drying polyester yarns with moisture absorption, anti-ultraviolet polyester yarns, anti-bacterial polyester and nylon yarns, bamboo charcoal polyester, the coated yarns of spandex or Dow elastomer yarns, the coated yarns of conductive yarn and polyamide yarns, metal wires or the coated yarns of cotton and so on with specific properties are taken as the raw materials. Then the ingenious design and weaving are proceeded for the fabric structure. At last the fabric is dyed or in post preparation, and the modeling is also included. The invention has the advantages that the prepared fabric has moisture adsorption, quick-drying, anti-UV, anti-bacterial, anti-static, anti-radiation, flexibility and other functions. Therefore, the invention can be widely applied in many occasions, including the use as medicine or for decoration purpose.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing bamboo fiber from bamboo

InactiveCN1415790APromote growthWide variety of sourcesMechanical treatmentFibre treatment to obtain bast fibreFiberAcid washing

A process for preparing bamboo fibres from bamboo includes preparing raw material, softening, water washing, rolling, water washing, treating by urea and oxygen, water washing, boiling in alkali solution, water washing, bleaching by urea and oxygen, acid washing, dewatering, loosening and drying in air. The said bamboo fibres can be used to weave cold fabrics.

Owner:DONGHUA UNIV

Antibiotic moisture absorption function finishing technique for polyester/cotton blended fabric

The invention provides a relative functional finishing technology which not only can maintain characteristics of smooth feeling of polyester / cotton fabric, good crease resistance, excellent strength and dimensional stability, and easily washing and quickly drying, but also can overcome defects that polyester / cotton fabric has low moisture absorption, poor breathability and developed bacteria caused by sweat stains, thereby affecting the health of people. The invention adopts a special moisture adsorption and perspiration finishing agent SW and an antibacterial finishing agent SCJ-891, and the finishing technology is produced by processing the polyester / cotton fabric according to post finishing technological process of common fabric.

Owner:SHENGHONG GRP CO LTD

Polyester cotton moisture absorption and instant drying knitted fabric and preparation method thereof

ActiveCN103382616ABump effect is obviousIncrease surface areaWeft knittingBiochemical fibre treatmentPolyesterFiber

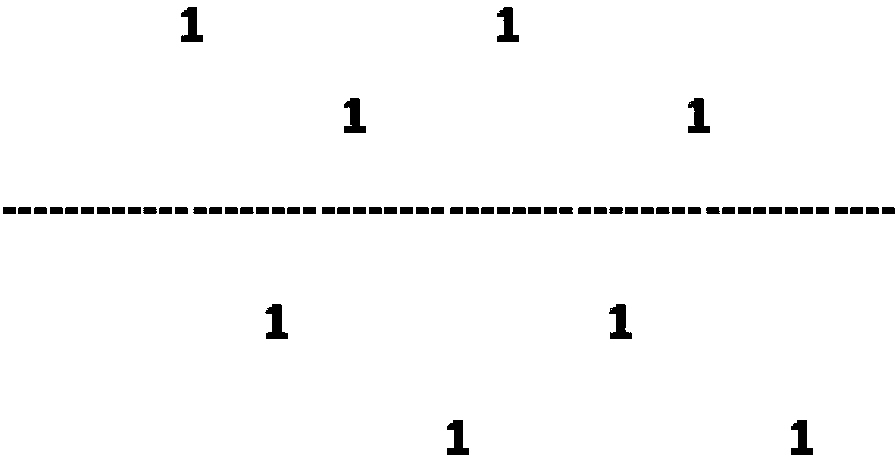

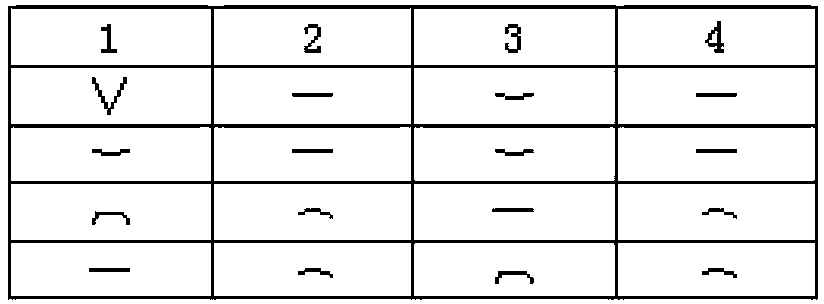

The invention relates to a polyester cotton moisture absorption and instant drying knitted fabric and a preparation method thereof. The polyester cotton moisture absorption and instant drying knitted fabric comprises an outer layer and an inner layer, wherein the outer layer is formed by knitting cotton fibers; the inner layer is formed by knitting anisotropic terylene; the outer layer and the inner layer are connected together via anisotropic terylene tucks on the surface; the outer layer knitted by the cotton fibers adopts a snakeskin tissue structure. The preparation method comprises the steps of raw material preparation, machine knitting, inspection, pre-forming, pre-treatment, dyeing, softness treatment, drying, scutching and shaping. According to the polyester cotton moisture absorption and instant drying knitted fabric, the area of the contact between sweat and air is greatly enlarged, and the sweat diffuses in the air, as a result, effects of moisture absorption and instant drying are obtained, and a microclimate between skin and the fabric keeps a comfortable state; the fabric is simple in preparation process and low in cost, and has good application prospects.

Owner:NINGBO DAQIAN TEXTILE

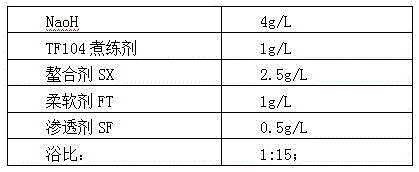

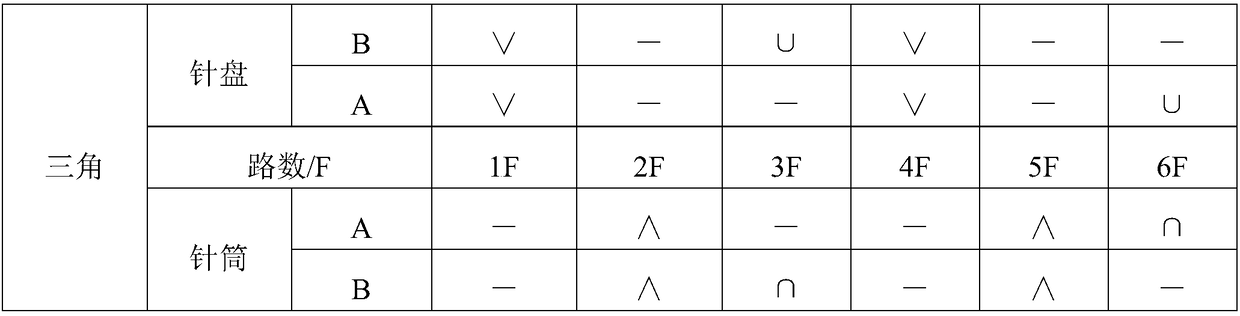

Production technology of medical stone fiber seamless knitted underwear with health-care function

The invention relates to the field of functional knitted product production, in particular to a production technology of medical stone fiber seamless knitted underwear with a health-care function. The production technology comprises the steps that a medical stone fiber blended yarn, a chinlon drawn textured yarn and a spandex core-spun yarn are subjected to once forming and seamless knitting to form the seamless knitted underwear, and the seamless knitted underwear is subjected to refining, bleaching, dyeing, softening finishing and shaping treatment, wherein the medical stone fiber blended yarn consists of 60wt% of medical stone fiber and 40wt% of combed cotton. The medical stone fiber seamless knitted underwear with the health-care function has the obvious characteristics of good functionality, comfortability and the like, can timely supplement microelements for a human body, and has a good adsorptive property, and a function of emitting a far-infrared ray and the like.

Owner:浙江芬雪琳针织服饰有限公司 +1

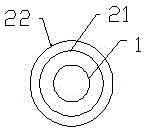

Sheath-core bicomponent fiber and functions thereof

InactiveCN102108565AMoisture absorption and quick dryingGuaranteed spinnabilityConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention discloses a sheath-core bicomponent fiber and functions thereof. The composition of the fiber is a polymer, and the composition of a sheath is the mixture of polymer and alkali soluble polyester, the compound ratio of a sheath core is 10 / 90-30 / 70, and alkali-soluble pet in the sheath composition accounts for 5-25wt% of the total weight of the fiber. After being made into textures, the sheath-core bicomponent fiber is subjected to weight reduction treatment and endowed with the performances of moisture absorption and fast drying, so that textiles with the performances of moisture absorption and fast drying can be produced; and the wicking height of the fiber is as high as 75-125mm, and the evaporation rate of water is 75-95%.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

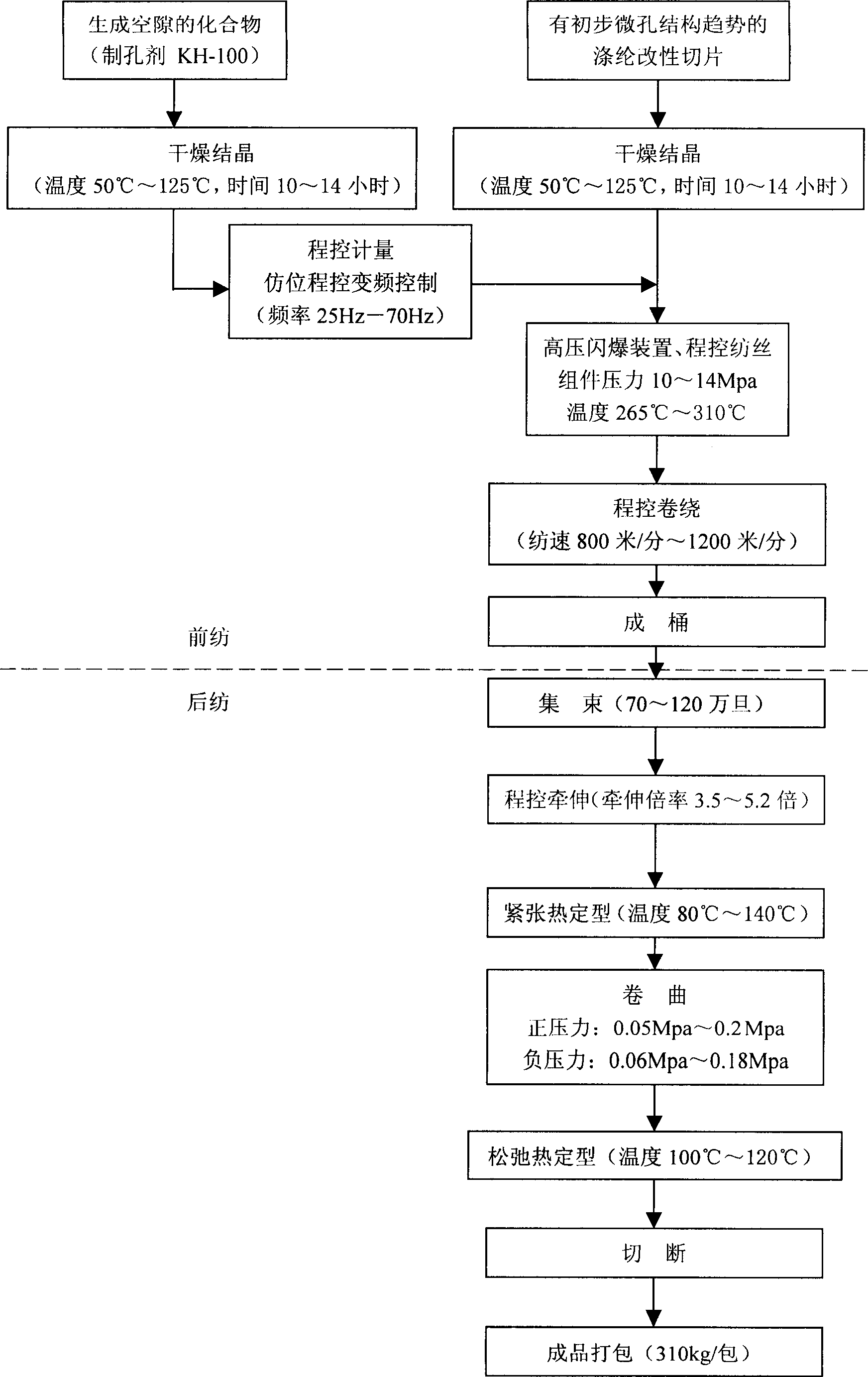

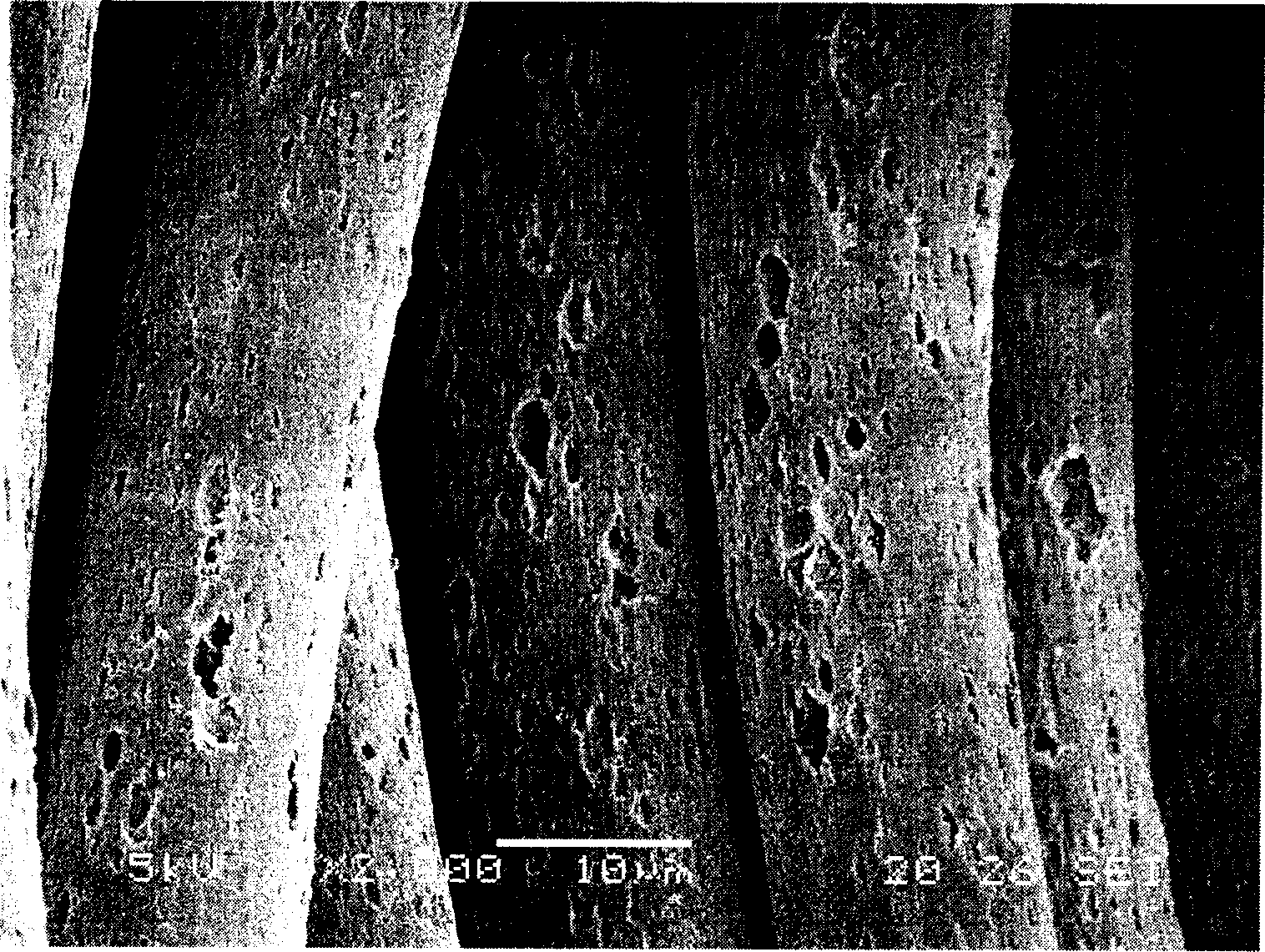

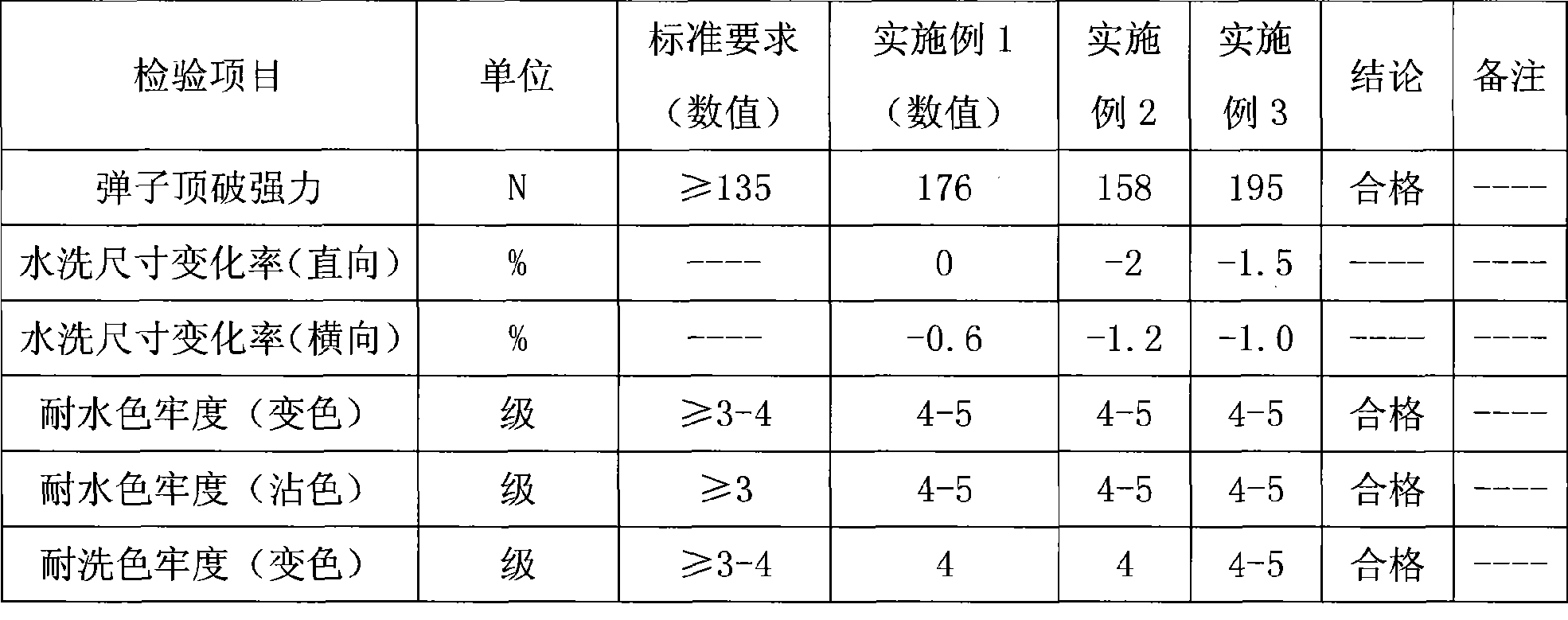

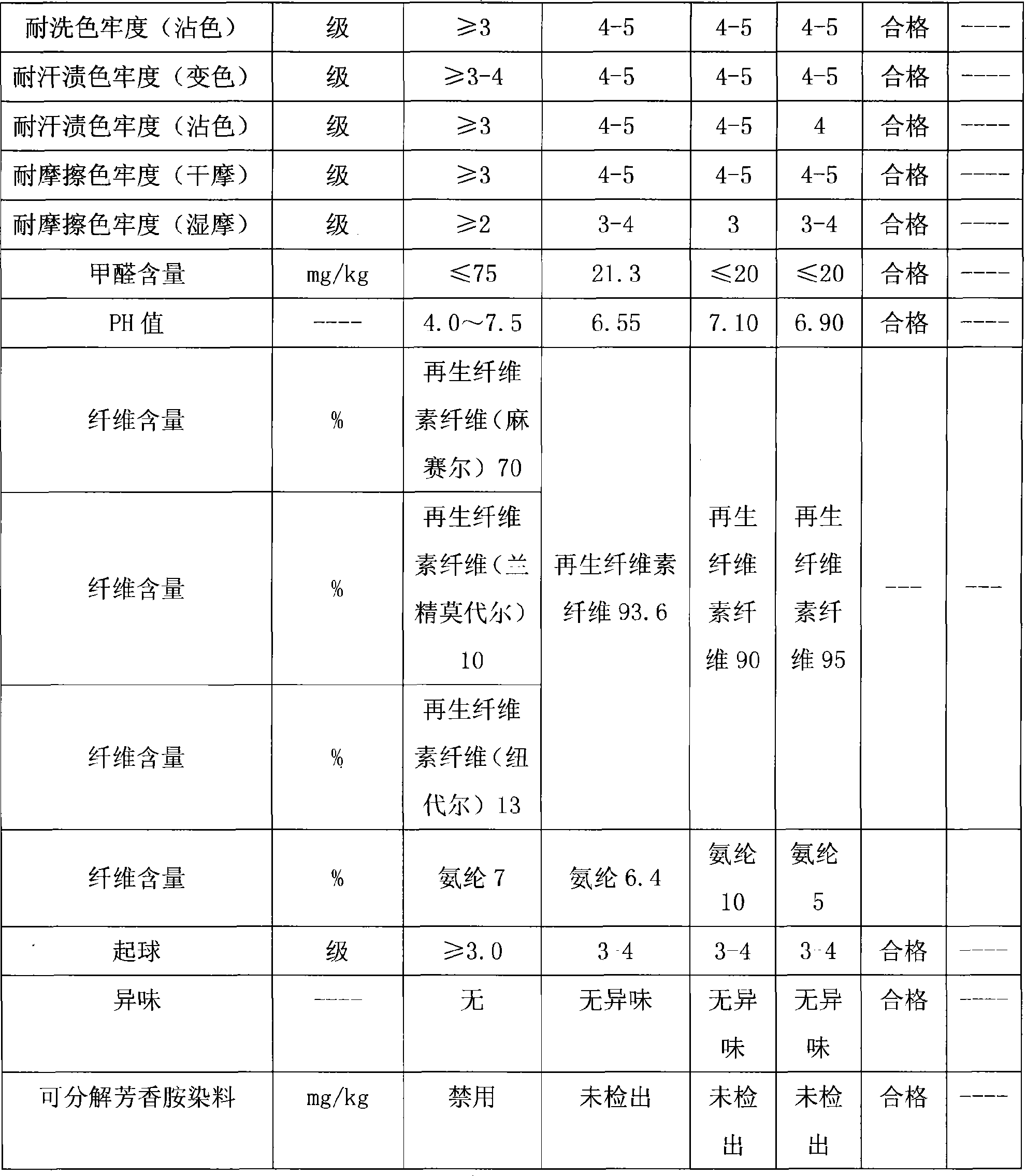

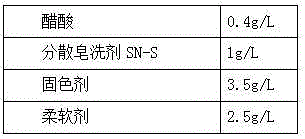

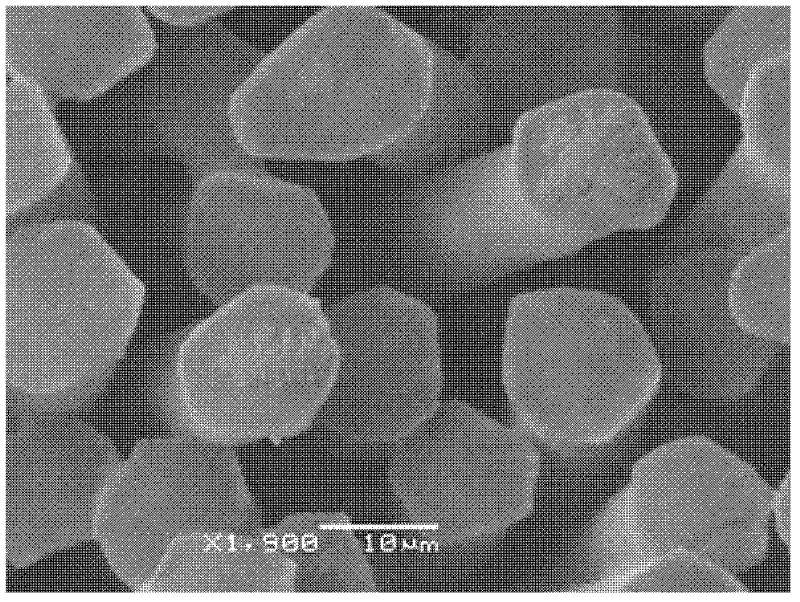

Novel honeycomb microporous structure functional polyester modified short fiber and its preparing method

InactiveCN1858310AGood flexibilityWidely usedStaple fibre formationMonocomponent polyesters artificial filamentPolyesterChemistry

The present invention relates to a new kind of modified functional polyester short fiber in honeycomb microporous structure and its preparation process. The modified functional polyester short fiber has surface and cross section honeycomb microporous structures. The modified functional polyester short fiber has high flexibility, less pilling tendency, high hygroscopicity, normal temperature and normal pressure cation dyeing power and other excellent performance, and is suitable for being blended with other short fibers to maintain the excellent performance.

Owner:谢建强

Jutecell underwear fabric and manufacture method thereof

The invention discloses a Jutecell underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The Jutecell underwear fabric is characterized by comprising the following components based on part by weight: 50 to 70 parts of Jutecell, 10 to 20 parts of Modal, 10 to 20 parts of Newdal, and 5 to 10 parts of polyurethane elastic fibers. The manufacture method comprises the following steps that: the Jutecell, the Modal and the Newdal are spun into compact spinning blended yarns; the compact spinning blended yarns are interwoven with the polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric is subjected to preshaping, dyeing, drying and shaping treatment. The fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also sufficiently reflects itching feel, bactericidal and antifungal activity, moisture absorption and fast dryness; and Modal has soft hand feeling, bright color, the Newdal is smooth and has good drapability, and the polyurethane elastic fiber has excellent performance of stretching and extending. The fabric adopts a unique textile structure to lead the appearance of the fabric to be more unique.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Blended yarn containing 11 different fibers and production method

The invention discloses a blended yarn containing 11 different fibers, belongs to the technical field of textile, and specifically relates to a technological method for producing the blended yarn. The weight percentage composition of the blended yarn comprises: 32 to 36% of Tencel Sun, 5 to 8% of silver ion antibacterial glue, 6 to 9% of aloe fiber, 2 to 6% of rose fiber, 2 to 6% of modal, 2 to 4% of viscose fiber, 2 to 6% of cotton fiber, 2 to 6% of Tencell A100, 5 to 8% of copper ammonia fiber, 8 to 11% of ramie fiber, and 8 to 11% of bamboo fiber. The textile technology used by the blended yarn containing 11 different fibers is capable of adequately blending the different fibers, achieving the adequate blending between cell fibers, and solving the problem of inadequate blending of the blended yarn containing multiple compositions; and using the half-free end handing spinning technology of the air-jet vortex spinning, and wrapping and twisting the outer fibers under the reaction of the high-speed vortex in a nozzle chamber through the air twisting. The yarn is smoother and cleaner, straight, and rigid, and has the advantages of fluff and pilling resistance, absorption, quick dry and the like.

Owner:DEZHOU HUANYUAN ECOLOGICAL TECH

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

Hollow and fast-drying hydroscopic heat color-mixed spinning yarn and production thereof

The invention is about the color-mixture spinning with the function of the moisture absorption and the temperature keeping. The character of the spinning is: it contains the 40%-100% modified terylene fiber. The spinning thread has the wide color spectrum and bright color, also it has the good shaped firm and the sublimed firm but the fabric isn't limited by the color ratio. In the other, the spinning thread feels well to people all the time.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

China hemp cotton air vortex spinning product and preparing method thereof

InactiveCN103132208AGood moisture wicking effectMoisture absorption and quick dryingWoven fabricsYarnYarnCarding

The invention provides a China-hemp cotton vortex spun yarn product which has few feathers, is anti-pilling, has a soft and smooth yarn body and is good in hydroscopic and fast dry performance. Warps and wefts of the China-hemp cotton air vortex spinning product are China hemp fiber / cotton fiber vortex spun yarns, wherein the content of China hemp fibers occupies 60%, and the content of cotton fibers occupies 40%. The preparing method of the China-hemp cotton vortex spun yarn product comprises the following steps of a, preprocessing: the China hemp fibers are softened through emulgator before processing, the weight ratio of the emulgator, antistatic oiling agent and water satisfies the equation that ZY-06A:ZY-06B:water=1:0.5:5, and solution is prepared according to the ratio; the solution is evenly sprayed on the China hemp fibers according to 7% of the weight of the China hemp fibers; and the China hemp fibers are stored for 96 hours in the environment at the temperature of about 25 DEG C, and the China hemp fibers are turned over for a couple of times during storage; b, blending of the China hemp fibers and the cotton fibers: the China hemp fibers and the cotton fibers are mixed according to a portion inside a cotton box, and then blowing, carding, sliver lapping, combing and two combination processes are conducted; c, preceding spinning which comprises opening picking, cotton carding, combing and drawing; and d, vortex spinning: the temperature of a working workshop is 30 DEG C, and relative humidity is 65%.

Owner:JIANGSU YDTEX GRP LTD

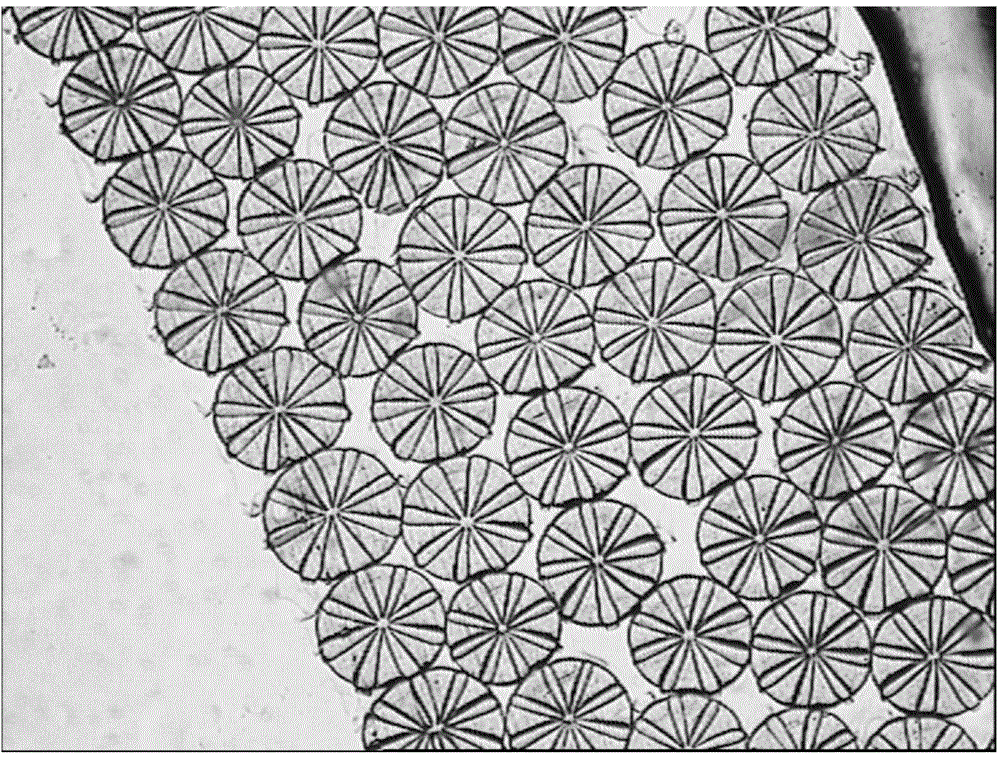

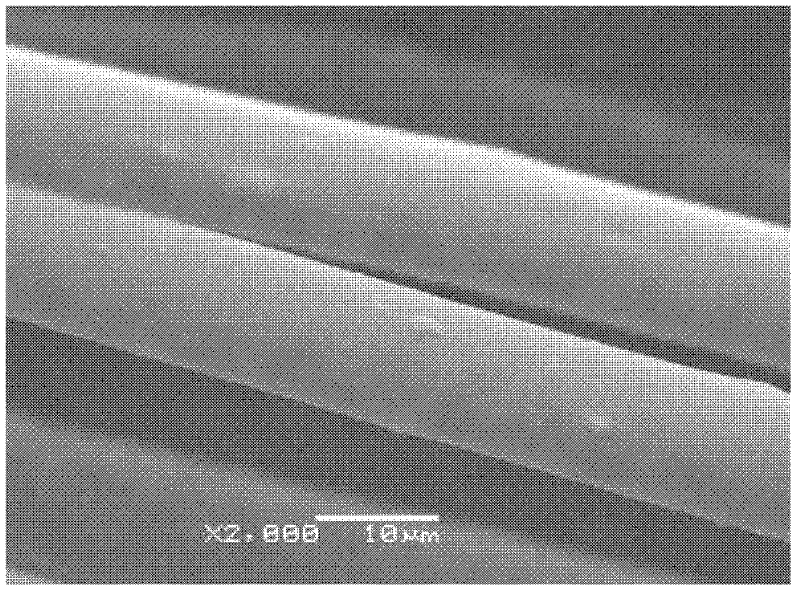

Split-lobe type high-contraction polyamide composite fully drawn yarn and preparation method thereof

InactiveCN104975360AImprove shrinkage performanceGood denier and elongation propertiesNew-spun product collectionArtificial filament heat treatmentPolyamideDyeing

The invention discloses a split-lobe type high-contraction polyamide composite fully drawn yarn and a preparation method thereof. The fully drawn yarn is made of two-component composite fibers combining high-contraction components and polyamide components. The cross section is in the shape of a split lobe. The weight percentage of the high-contraction components is 55%-65% while the polyamide components account for the left percentage. The fully drawn yarn is a novel elastic composite fiber which is highly elastic without spandex. Problems of a difficulty in dyeing, excessive elasticity, complex weaving, unstable size of fabrics and aging in the use process of the spandex are solved. The fully drawn yarn has higher contraction performance, fineness and extension performance.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Jutecell and coffee carbon fiber knitted fabric and manufacturing method thereof

The invention relates to jutecell and coffee carbon fiber knitted fabric and a manufacturing method thereof. The manufacturing method comprises the steps that 35-45wt% of natural cotton fiber, 25-35wt% of jutecell fiber and 25-35wt% of coffee carbon fiber are woven to form blended yarns, and 94-96wt% of blended yarns and 4-6wt% of spandex are woven by a double-sided loom, and subjected to soaping, fixation, mellowing and drying to from the jutecell and coffee carbon fiber knitted fabric. Compared with the prior art, the jutecell and coffee carbon fiber knitted fabric is better in skin friendliness, air permeability, heat preservation property, heat transfer coefficient, quick in drying, excellent in peculiar smell eliminating function, good in warmth preservation property, elasticity, color and luster, antibacterial, mildewproof and hygroscopic, and can rise the temperature for heating within a short time.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Functional finishing process of fabric

The invention provides a functional finishing process of a fabric, which can be used for maintaining the characteristics of smooth hand feeling, favorable wrinkle resistance, excellent strength and dimensional stability, easiness for washing and quick drying of polyester / cotton fabrics and overcoming the defect that the health of people is influenced due to bacteria breeding caused by low hydroscopic property, poor ventilation property and sweat stain of the polyester / cotton fabrics. According to the invention, the fabric is formed by finishing and processing the polyester / cotton fabrics by adopting a unique hygroscopic and sweat releasing finishing agent SW and an antibacterial finishing agent SCJ-891 according to a post-finishing process flow of general fabrics.

Owner:高莉萍

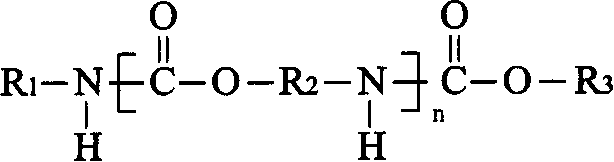

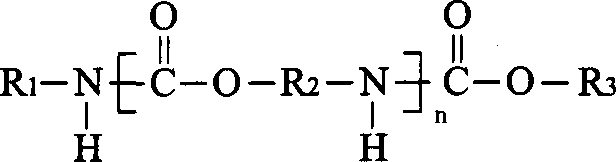

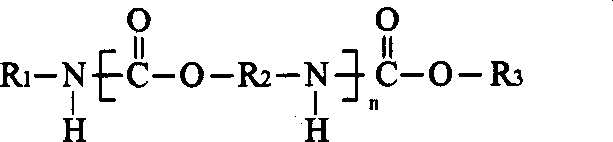

Polyurethane fibre/real silk crepe knit fabric and preparation process thereof

InactiveCN1793464AAddressing Exposed WeaknessesImprove comfortWeft knittingFibre treatmentYarnMoisture absorption

The invention relates to urethane elastic fiber / silk crape ground knitted fabric and its manufacturing method. It includes the following steps: using urethane elastic fiber as centre thread; covering its outer layer with silk composite yarn to form knitted fabric; putting in corrugating processing liquid formed by 0.5-5% hydrophilicity carbamates high molecule matter and 0.5-3% hydrophilicity polypeptide protein high molecule matter to gain cycle junction state urethane elastic fiber / silk crape ground knitted fabric. It utilizes the shrinking of the urethane elastic fiber heat yarn and the no shrinking of the silk yarn outer layer to make special loop crape ground structure to realize crape ground effect. The formed fabric has good resiliency, little washing deformity, good feel, moisture absorption, and quick drying effect. It overcomes the defect that the traditional silk crape clothes is easy to stick together caused by human body perspiring, and increases its comfortable.

Owner:SUZHOU UNIV +1

Process for producing dry and air-permeable colorful polyester cloth

InactiveCN109487577AThe effect of "meteor shower" is obviousIncrease the "disadvantages of different color absorption rates"Dyeing processAcetic acidPolyester

The invention discloses a process for producing dry and air-permeable colorful polyester fabric. The process comprises the following steps: weaving a cloth; removing oil from grey cloth in an open width manner; preshaping; dyeing; reducing and washing; and shaping and finishing, wherein the step of dispersing and dyeing is to add 0.6-4.0 percent by weight of dye, 0.2-0.8g / L of acetic acid and 0-0.3g / L of a levelling agent. The cloth is a knitted fabric which is stiff and smooth, has high-elastic restoring performance and meteor shower effect, has the dynamic aesthetic perception, has soft andsmooth hand feeling, damp absorption and quick drying, has the effect of meteor shower cloth to improve the appearance effect of clothes, has multiple functional clothing elements, and is popular.

Owner:ENPING KAM HING TEXTILE & DYEING

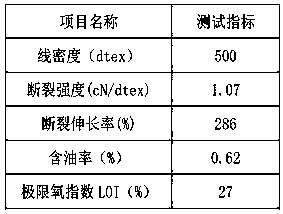

Preparation method of halogen-free flame retarding PETG composite fibers

InactiveCN108842203AImprove flame retardant performanceImprove heat resistanceFlame-proof filament manufactureArtificial thread manufacturing machinesFiberPolyester

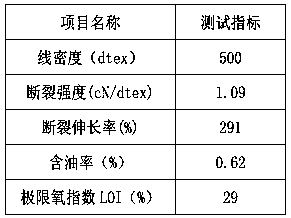

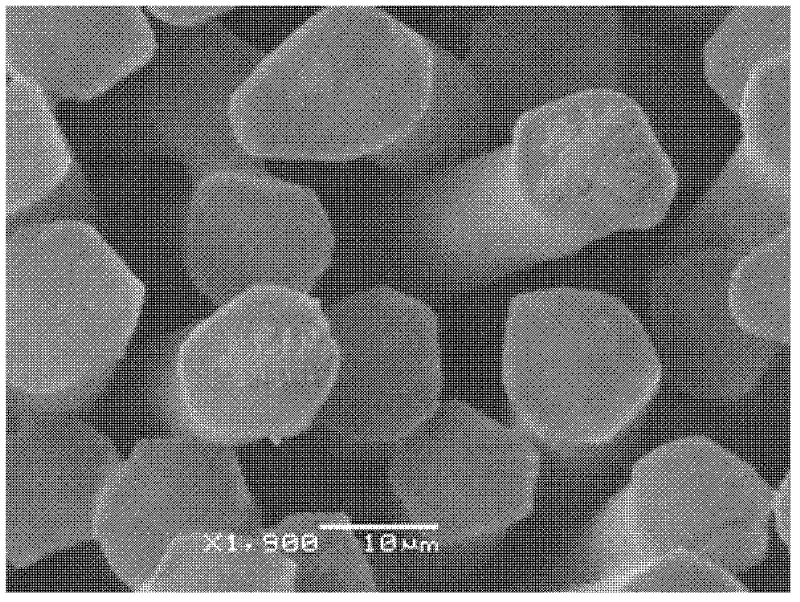

The invention relates to the technical field of production of polyester fibers, in particular to a preparation method of halogen-free flame retarding PETG composite fibers. The preparation method comprises the specific steps of (1) preparation of halogen-free flame retarding master batches, (2) preparation of halogen-free flame retarding nascent fibers with the Y-shaped sections, and (3) winding forming of the halogen-free flame retarding fibers. The obtained halogen-free flame retarding PETG composite fibers have significant effects in flame retardance and heat resistance, the limit oxygen index (LOI) of the halogen-free flame retarding PETG composite fibers can be 29, and the halogen-free, low-smoke and environment-friendly flame retarding requirements are met. In addition, the sectionsof the fibers are designed in a Y shape, so that the fibers can absorb, deliver, diffuse and volatilize water rapidly, and obtained products are soft and comfortable and have the moisture absorption and quick-drying effects.

Owner:新凤鸣集团股份有限公司

Composite fiber fabric and preparation method thereof

InactiveCN105671734AImprove performanceImprove tear resistanceWoven fabricsCarbon fibersTear resistance

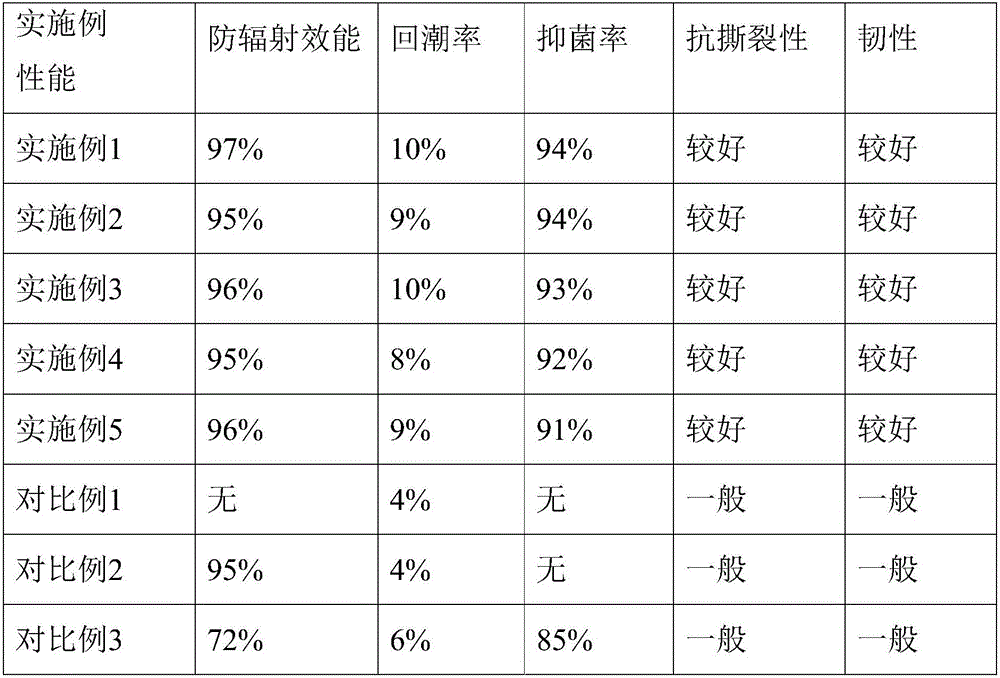

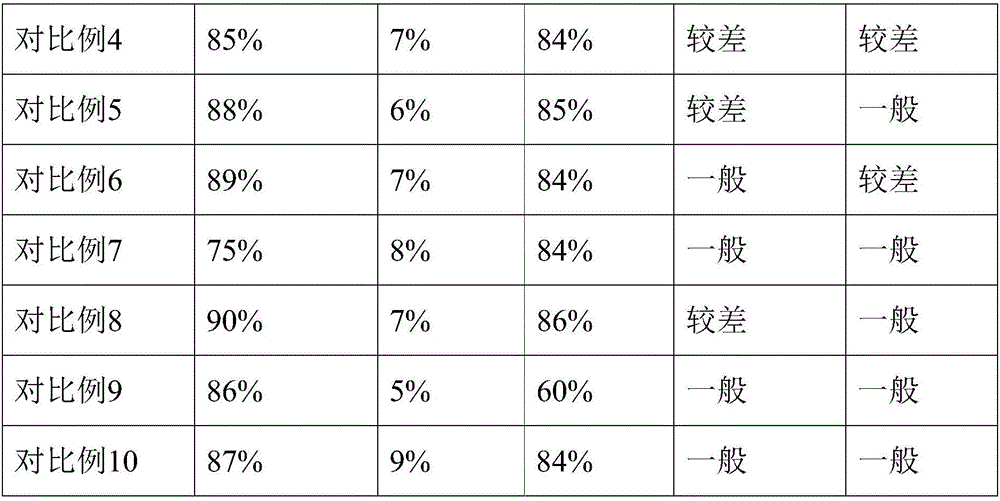

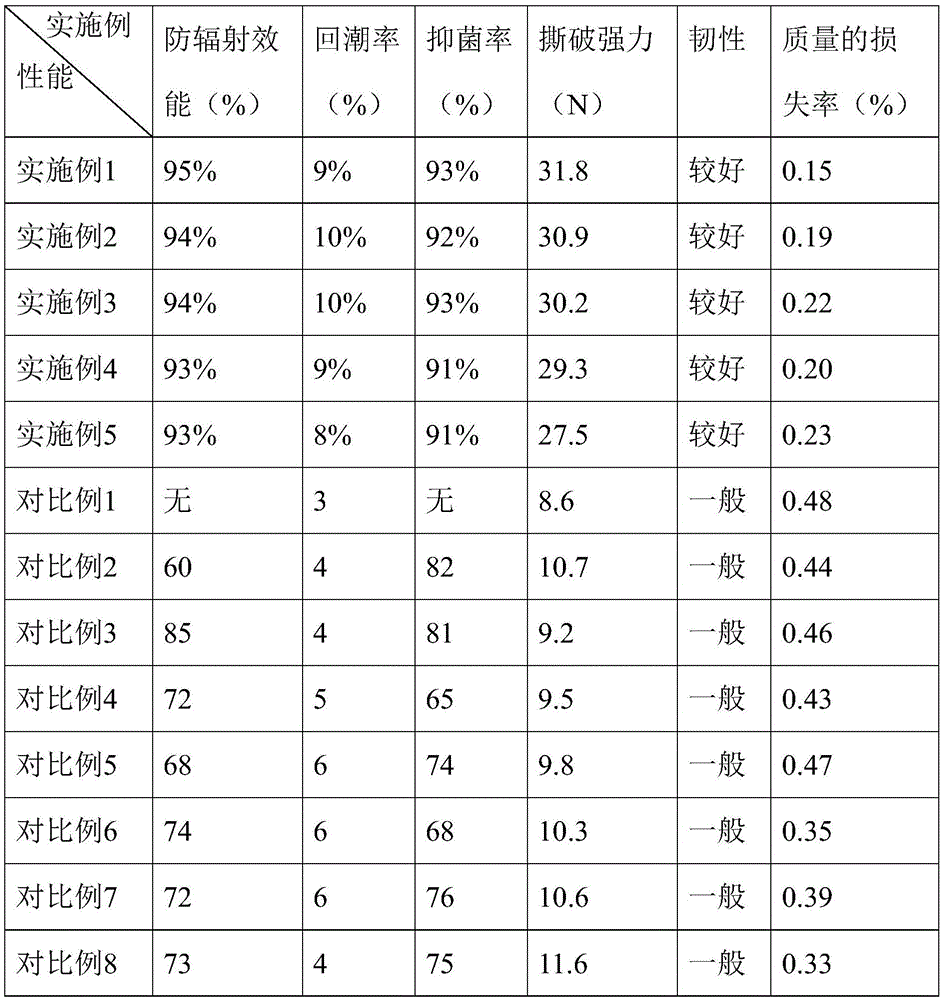

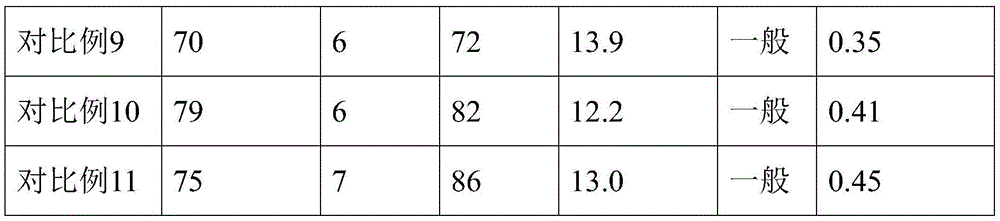

The invention relates to a composite fiber fabric and a preparation method thereof and belongs to the technical field of spinning engineering. Warp yarn of the composite fiber is blended yarn of stainless steel fibers, carbon fibers and cotton fibers, and weft yarn is blended yarn of stainless ramie and cotton fibers. In the blended yarn of the warp yarn, the content of the stainless steel fibers is 10-18%, the content of the carbon fibers is 2-5% and the content of the cotton fibers is 77-88%. In the blended yarn of the weft yarn, the content of the stainless steel fibers is 8-15%, the content of the ramie is 5-8% and the content of the cotton fibers is 77-87%. The fabric has the environmental protection performance and functionality in the aspects of bacteria resistance and bacteriostasis, moisture absorption, fast drying, biodegradation and the like of the ramie, has the strength of the carbon fibers so that the tear resistance of the fabric can be improved, and also has a good anti-radiation shielding effect of the stainless steel fibers, a cloth cover is level, soft and smooth, the anti-radiation effect is larger than or equal to 95%, and the moisture regain is 8-10%; the fiber bacteriostasis rate is larger than or equal to 90%.

Owner:宁波弘邦信息咨询有限公司

Novel anti-ultraviolet baby fabric applicable to ordinary days and preparation method thereof

InactiveCN105239354AStrong absorptionImprove durabilityPhysical treatmentMulti-ply fabricsChemistryPolyester

The invention provides novel anti-ultraviolet baby fabric applicable to ordinary days and a preparation method thereof. The preparation method comprises the following specific steps: 1, mincing and adding buckwheat, red dates and eggplants to a hydrochloric acid anhydrous ethanol solution, conducting ultrasonic treatment for 20-30 minutes at the power of 200 W, conducting reflux extraction for 50-60 minutes at the temperature of 60-70 DEG C, and obtaining rutin extract; 2, nanometer attapulgite and citric acid to the rutin extract, stirring the mixture uniformly, conducting filtration for removing impurities, then adding honey and deionized water, conducting homogeneous stirring and defoaming, and obtaining an anti-ultraviolet treatment agent; 3, adopting exterior and interior knotting double layer weave as a fabric weave structure, treating spandex elastic covering yarn fibers and superfine polyester fibers as exterior warp and exterior weft respectively, treating cotton fibers and silk fibers as interior warp and interior weft respectively, and forming double layer fabric through weaving; 4, conducting plasma treatment on the double layer fabric, spraying the anti-ultraviolet treatment agent, conducting drying, repeating spraying and drying, conducting washing and drying, and finally obtaining the anti-ultraviolet baby fabric applicable to ordinary days.

Owner:HUZHOU SHENXIANG SILK

Knitted fabric containing volcanic ash microcrystal particles and preparation method thereof

ActiveCN102260954AMoisture absorption and quick dryingAntibacterial and antibacterialWeft knittingYarnYarnFiber

The invention discloses knitted fabric containing volcanic ash microcrystal particles and a preparation method thereof. The knitted fabric comprises blended yarns containing the volcanic ash microcrystal particles, wherein the blended yarns comprise 20 to 50 weight percent of volcanic ash fiber containing the volcanic ash microcrystal particles and 50 to 80 weight percent of other fiber. The knitted fabric has the functions of absorbing moisture, drying quickly, inhibiting and resisting bacteria and adsorbing peculiar smell strongly.

Owner:北京铜牛集团有限公司

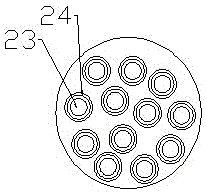

Light covered yarn with warmth-keeping and cooling functions and preparation method of yarn

InactiveCN105113084AStable temperatureKeep warmHollow filament manufactureMelt spinning methodsPolyesterYarn

The invention discloses light covered yarn with warmth-keeping and cooling functions. The yarn comprises core yarn and covering yarn covering the outer layer of the core yarn, wherein the covering yarn is made of two kinds of synthesized polyester yarn adopting different structures and having specially-shaped sections, one kind has round hollow sections, and the other kind has star-like hollow sections; the core yarn is spandex yarn. The invention further provides a preparation method for producing the covered yarn. The light covered yarn with the warmth-keeping and cooling functions is prepared with the method, yarn having the specially-shaped sections is synthesized, one kind has the hollow sections, the body temperature is kept relatively stable when the external environment is changed, warmth can be kept in cold winter, a user can have the cool feeling in hot summer, and the yarn has the characteristics of moisture absorption, quick dryness and lightness.

Owner:BANGYUAN SPIN JIANGSU

Novel biomass elastic short fiber blended sports knitted fabric

The invention relates to a novel biomass elastic short fiber blended sports knitted fabric. The knitted fabric comprises yarns which are formed by fibers and blended by biomass elastic short fibers (namely comfortable and elastic yarns) and bleached hemp fibers. The fabric structurally adopts weft-knitting interlock stitch. The novel blended sports knitted fabric is comfortable and elastic, is excellent in hand feeling and good in stretching resilience, can be still elastic, durable and stable after being stretched for multiple times, suffering from solarization and being subjected to after-treatment process, is not easy to wrinkle, is easy to manage and free in extension, can beautify stature and fit a wearer well, is free from compression and tension when being worn, is hydroscopic and fast-dry, has the functions and characteristics of preventing mold, bacteria, ultraviolet, static electricity and the like, and is a green, low-carbon and environment-friendly novel blended sports knitted fabric leading the trend of the times.

Owner:SHAOXING SHULILE TEXTILE PROD

Preparation method of superfine denier moisture absorption and sweat release ice cool antibacterial fiber

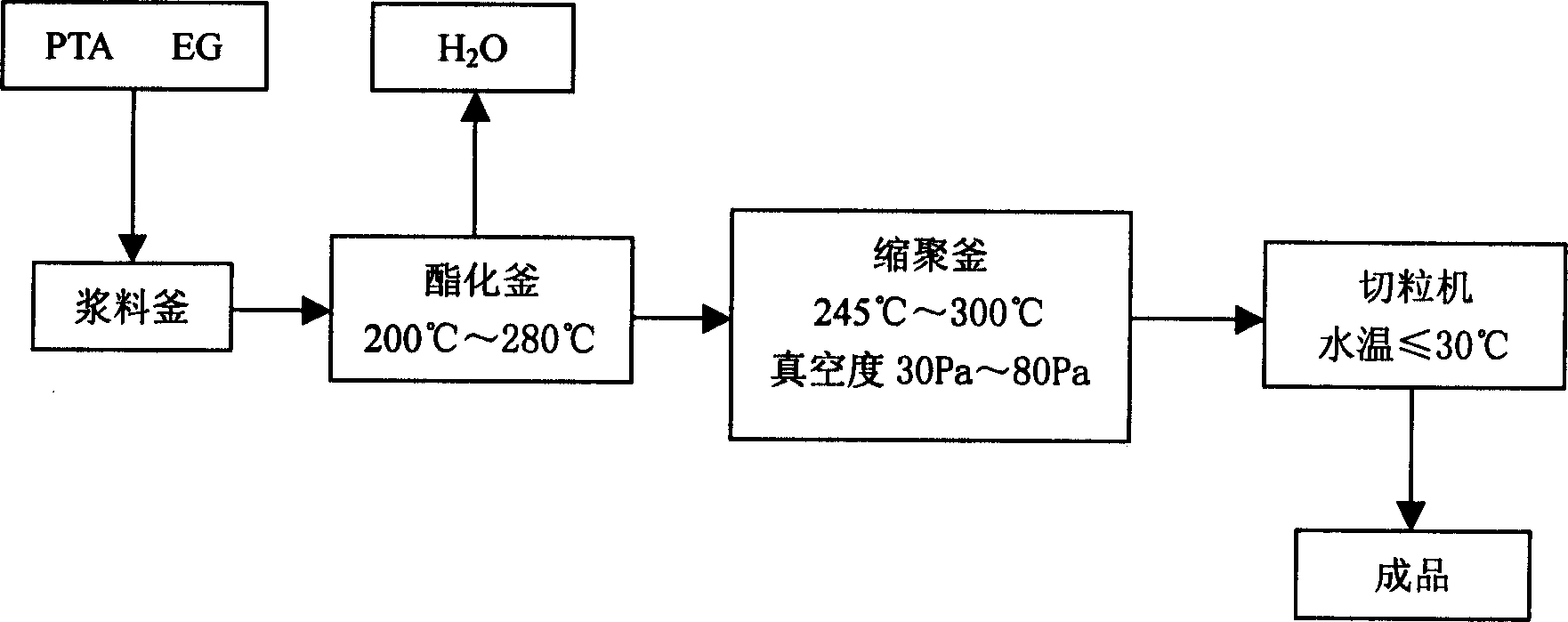

InactiveCN107761189ASimple production processShort stayArtificial filament supportMelt spinning methodsPolyesterChemistry

The invention relates to the technical field of production of polyester fibers, in particular to a preparation method of a superfine denier moisture absorption and sweat release ice cool antibacterialfiber. The preparation method comprises the following steps: (1) preparing a polyester melt; (2) preparing a nanometer ice cool jade powder mixed with trace amount of the polyester melt; (3) preparing a cross-shaped cross section polyester fiber; and (4) winding and forming the polyester fiber. According to the preparation method of the obtained superfine denier moisture absorption and sweat release ice cool antibacterial fiber, a certain amount of the nanometer ice cool jade powder is added, so that the fiber achieves the antibacterial effect while the heat conductivity coefficient of the fiber is improved, and the fiber is mixed together with the cross-shaped cross section abnormal fiber, so that the fiber achieves the effects of transporting moisture, releasing sweat, cooling, and being antibacterial and bacteriostatic. In addition, the nanometer ice cool jade powder and a fiber-forming polymer are tightly combined, last permanently, and do not fall off even after the fiber is washed and worn for a long period of time, in addition, the superfine denier moisture absorption and sweat release ice cool antibacterial fiber is in contact with the skin for long, and has the effects ofimproving blood microcirculation, promoting metabolism, preventing diseases and eliminating fatigue.

Owner:新凤鸣集团股份有限公司

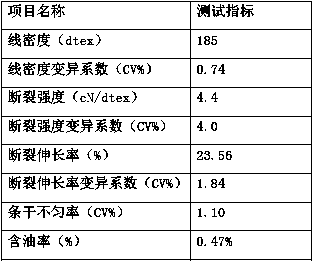

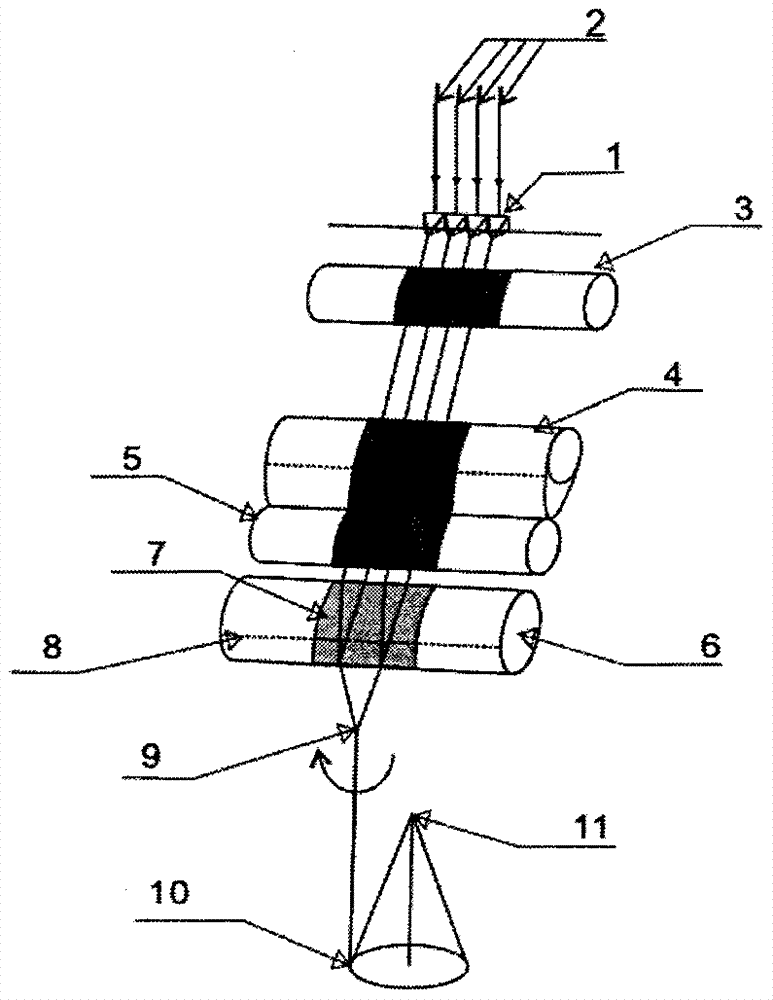

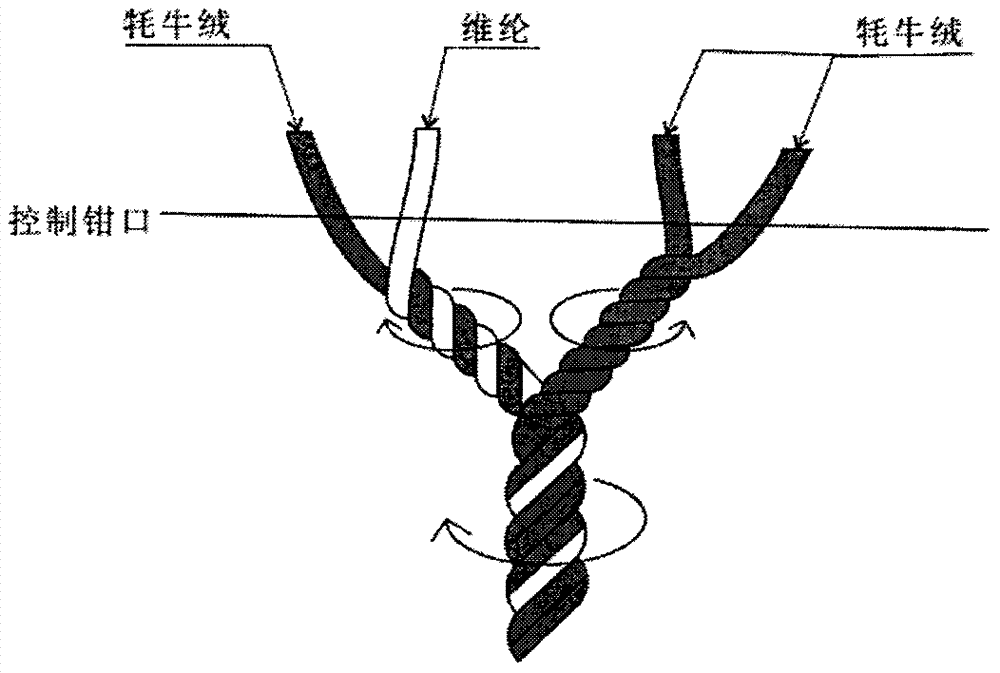

Production method of yakwool hollow yarn

The invention discloses a production method of yakwool hollow yarn. The production method comprises the following steps: taking vinylon as core yarn and yakwool as covering yarn, respectively spinning vinylon roving and yakwool roving by use of semi-worsted spinning, feeding four roving into a ring spinning frame in parallel at the same time by following compact siro spinning, wherein the yakwool roving is three, and the vinylon yarn is one; feeding the vinylon roving from the left second hole of a four-hole horn mouth so that the vinylon roving is centered; therefore, the effect of covering the yakwool on the vinylon can be well realized. By use of the yarn method disclosed by the invention, the process of spinning the core yarn as the spun yarn is omitted, the process flow is shortened, and the effect of being similar to core spun yarn is achieved. And meanwhile, the yakwool only needs to be processed as roving, the procedure that the yakwool is hard to be processed as the spun yarn due to short and thick characteristics is avoided. Finally, a hollow yarn structure is formed by the yarns in the fabric after the dissolution by use of the fabric dissolution method, the air is trapped, the warm keeping coefficient is increased, and the formed fabric has the features of being light and thin, soft, and moisture-absorbing and quick in drying.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of fabric capable of enhancing cool feeling

ActiveCN112501915ACool to touchMoisture absorption and quick dryingVegetal fibresPolymer scienceMoisture absorption

The invention discloses a preparation method of a fabric capable of enhancing cool feeling. The preparation method comprises the following steps of firstly, carrying out dipping finishing on a synthetic fiber knitted fabric by using a moisture absorption and sweat releasing composite finishing agent formed by blending a moisture absorption and sweat releasing agent and high-thermal-conductivity short fibers to prepare a moisture absorption and quick-drying fabric; and carrying out single-sided silk-screen finishing on the moisture absorption and quick-drying fabric by using mixed glue slurry of cool feeling microcapsules and phase-change microcapsules to obtain the fabric capable of enhancing the cool feeling. The fabric capable of enhancing the cool feeling prepared by the invention can achieve the effect of obviously enhancing the cool feeling by endowing the fabric with the functions of instant cool feeling, continuous cool feeling, moisture absorption, quick drying and the like, brings comfortable experience to a human body, and can be used for sportswear, protective clothing, home textiles and the like.

Owner:武汉中科先进材料科技有限公司

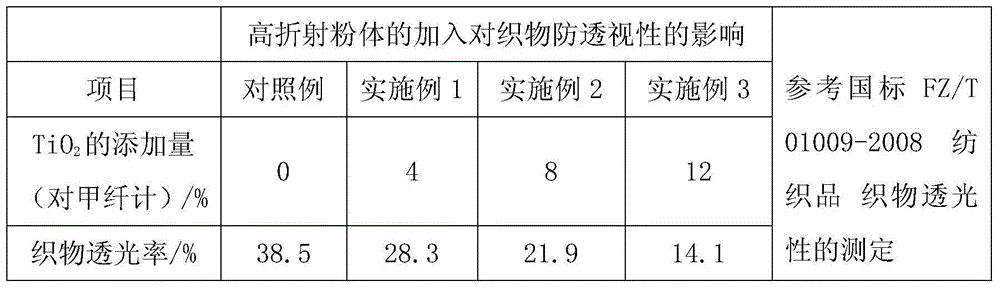

Preparation method of regenerated cellulose fibers with high optical shielding property

ActiveCN104928784AMoisture absorption and quick dryingReduce penetrationArtificial filaments from viscoseRefractive indexDiffuse reflection

The invention relates to a preparation method of regenerated cellulose fibers with high optical shielding property. The preparation method comprises the following steps: mixing high-refractivity powder and regenerated cellulose fibers before spinning; adding a dispersant to enable the high-refractivity powder to be uniformly dispersed among the fibers to prepare the regenerated cellulose fibers with high optical shielding property. When passing through a fiber fabric and propagating in the fabric, light can be reflected, the refraction and diffuse reflection frequencies are increased, and the permeability of light in the fabric is greatly reduced to achieve the anti-perspective effect.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Blended yarn multifunctional fabric and making method thereof

The invention relates to a blended yarn multifunctional fabric and a making method thereof, and belongs to the technical field of spinning engineering. Warp of the fabric is blended yarn spun by adopting spandex silk as a yarn core and wrapping the yarn core by stainless steel fibers, copper fibers and carbon fibers. Weft of the fabric is blended yarn spun by adopting spandex silk as a yarn core and wrapping the yarn core by stainless steel fibers, natural bamboo fibers and ramie. The content of the stainless steel fibers in the warp ranges from 5% to 10%, the content of the copper fibers in the warp ranges from 2% to 5%, the content of the carbon fibers in the warp ranges from 2% to 5%, and the content of the spandex silk in the warp ranges from 80% to 91%. The content of the stainless steel fibers in the weft ranges from 3% to 10%, the content of the natural bamboo fibers in the weft ranges from 3% to 8%, the content of the ramie in the weft ranges from 3% to 8%, and the content of the spandex silk in the weft ranges from 74% to 91%. The fabric has the environmental protection property and functionality on the aspects of bacteria resistance and bacteriostasis, moisture absorption and quick drying, biodegradation and the like, and has good strength, elasticity, tear resistance and tenacity, and a good radiation protection and shielding effect is further achieved. The cloth face is flat, soft and smooth, the radiation protection efficiency reaches 92% or above, the moisture regain ranges from 8% to 10%, and the fiber bacteriostasis rate is larger than or equal to 91%.

Owner:NINGBO MH IND CO LTD

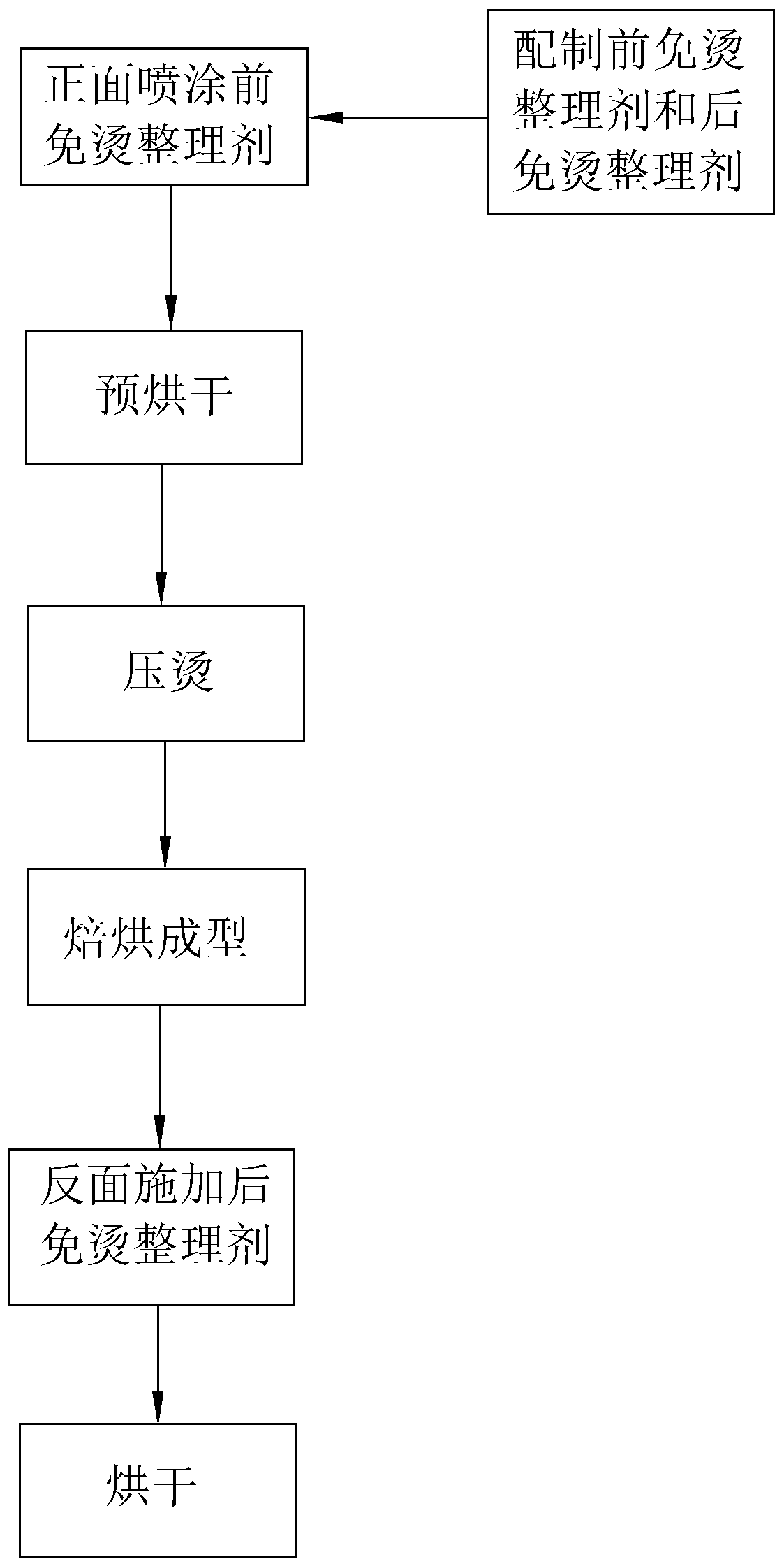

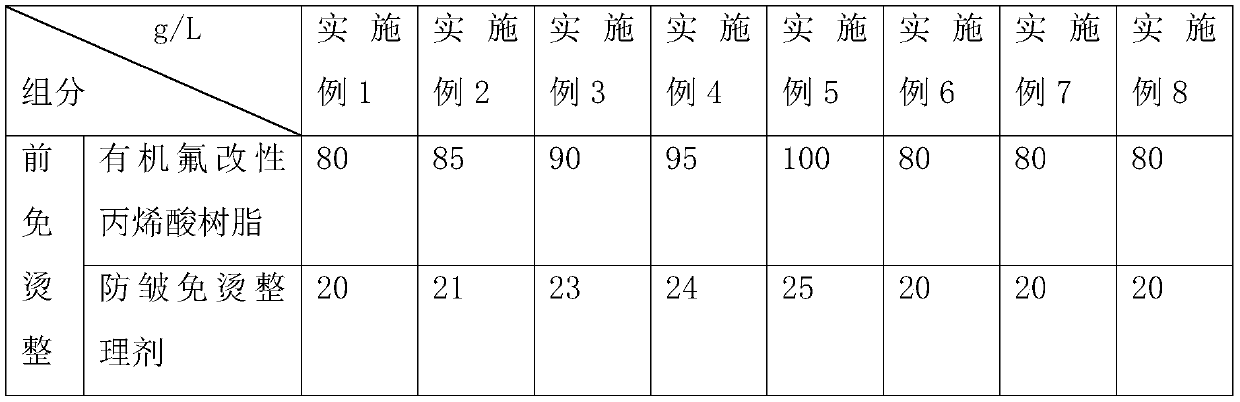

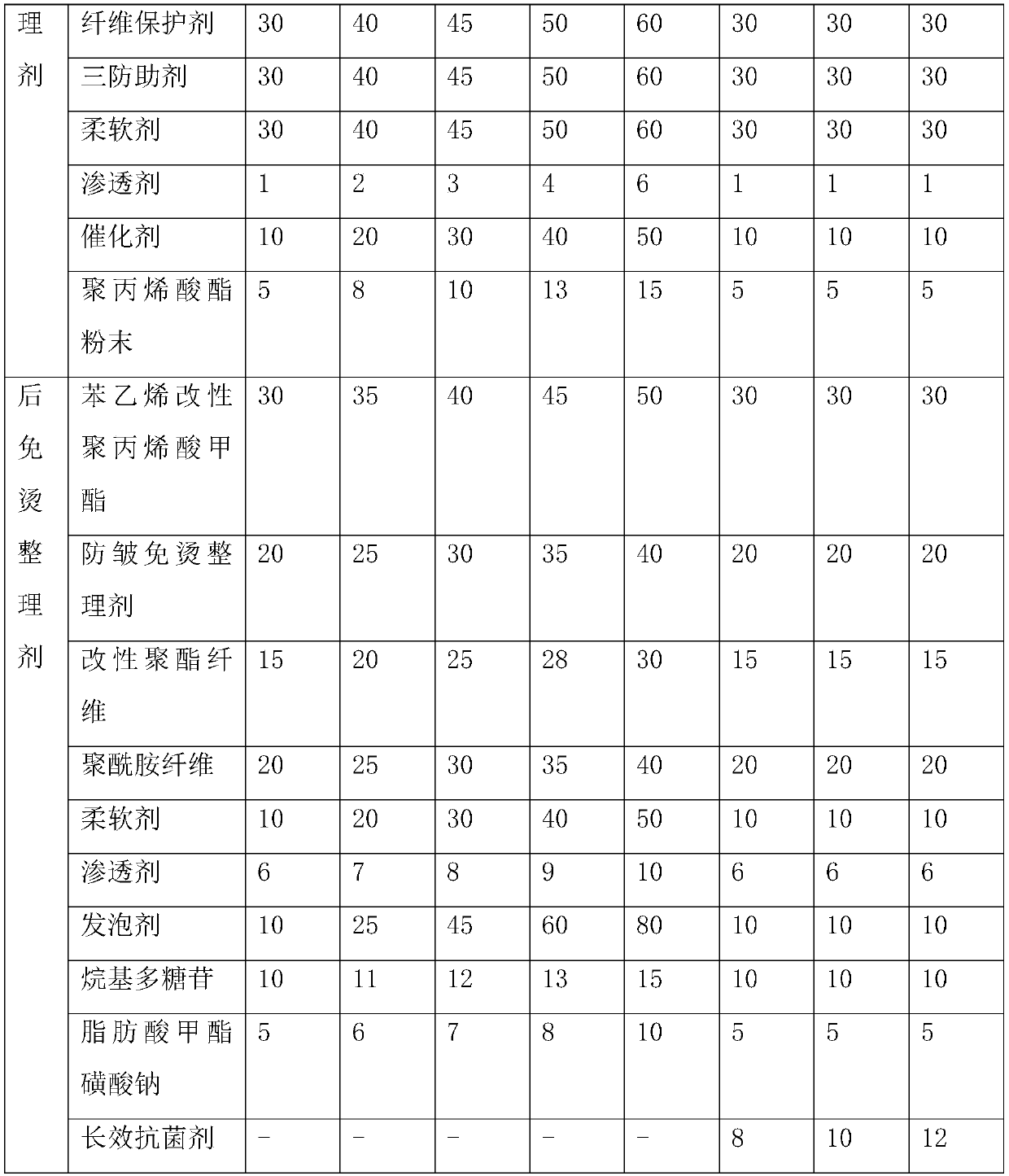

Non-ironing triple-proof finishing method of ready-made garments

InactiveCN110424160AMoisture absorption and quick dryingDry and comfortableStain/soil resistant fibresBiochemical fibre treatmentSulfonateFoaming agent

The invention discloses a non-ironing triple-proof finishing method of ready-made garments, which comprises the steps of S1, preparing a non-ironing pre-finishing agent and a non-ironing post-finishing agent, and foaming the non-ironing post-finishing agent; S2, spraying the non-ironing pre-finishing agent evenly to the front; S3, pre-drying; S4, carrying out pressure ironing; S5, carrying out baking setting; S6, applying foam of the non-ironing post-finishing agent to the back; and S7, drying. The non-ironing pre-finishing agent is made with organic fluorine-modified acrylic resin, an anti-wrinkle non-ironing finishing agent, a fiber protectant, a triple-proof aid, a softener, a penetrant, a catalyst and polyacrylate powder; the non-ironing post-finishing agent is made with styrene-modified polymethyl acrylate, an anti-wrinkle non-ironing finishing agent, modified polyester fibers, polyamide fibers, a softener, a penetrant, a foaming agent, alkyl polyglucoside, and fatty acid methyl ester sulfonate. The non-ironing triple-proof finishing method herein has the advantages that non-ironing finishing can be provided for ready-made garments, and the ready-made garments can wick moisture and dry fast, can repel water and oil, can prevent pollution and can inhibit bacteria for long time.

Owner:北京金添仕制衣有限公司 +1

Matt eight-leaf polyester fibers and production method thereof

ActiveCN103233293AWith mattingMoisture absorption and quick dryingFilament forming substance formingArtificial thread manufacturing machinesFiberPolyester

The invention relates to the technical field of differential fibers and productions thereof. In order to solve problems of surface reflection and shining of polyester, the present invention provides matte eight-leaf polyester fibers and a production method thereof, wherein a crystallization accelerator is added during polyester condensation polymerization production, and a spinning plate with a eight-leaf-shaped spinning hole cross section is adopted to spin to obtain the matte eight-leaf polyester fibers. According to the present invention, the produced fibers have good matt property without addition of titanium dioxide, and further have characteristics of good moisture absorption and sweat discharging, good dyeability, good bionic property, wide application range, and high product added value.

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com