Knitted fabric containing volcanic ash microcrystal particles and preparation method thereof

A technology of knitted fabrics and volcanic ash, applied in the field of textile fabrics, can solve the problems of functional weakening and disappearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

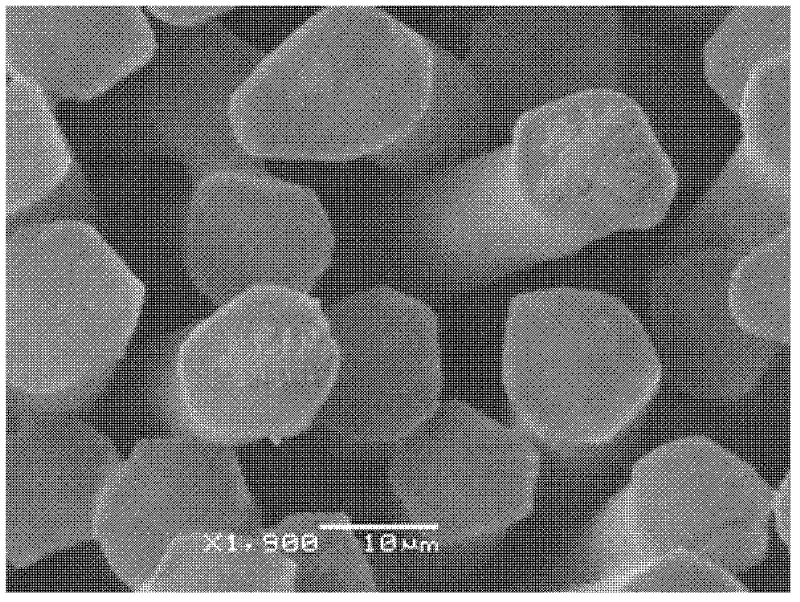

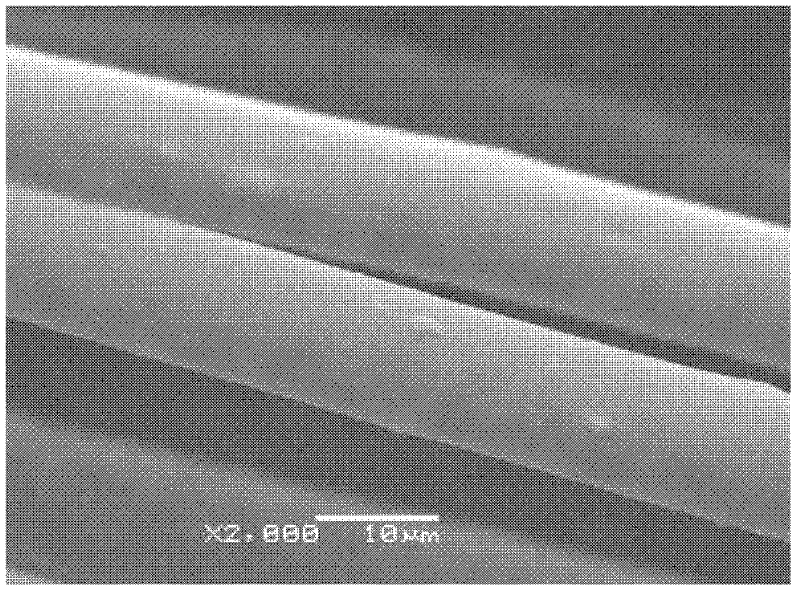

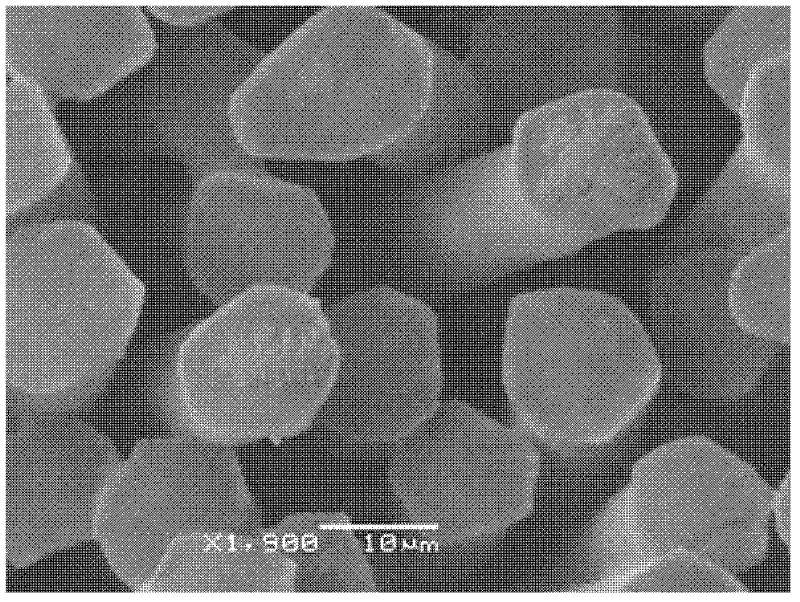

[0039] The volcanic ash fiber containing volcanic ash microcrystalline particles and 50% modal by weight percentage are spun into a yarn count of 40 by compact spinning technology s The blended yarn containing volcanic ash microcrystalline particles; the above-mentioned blended yarn containing volcanic ash microcrystalline particles is woven into a 1:1 rib knit fabric on a 20G rib machine, and the volcanic ash microcrystalline particles are formed after dyeing and finishing treatment. knitted fabric.

[0040] Dyeing and finishing process: capsule breaking treatment (put the fabric in a 130°C bath for 30 minutes)—cool down and put in soup—water washing—bleaching—light dehydration—drying—calendering.

[0041] Table 1 Test results of moisture absorption and quick drying, adsorption and antibacterial properties:

[0042] Test items unit judgement standard standard value measured value evaporation rate g / h GB / T 21655.1-2008 "Assessment of moisture absor...

Embodiment 2

[0044] 25% by weight of volcanic ash fiber containing volcanic ash microcrystalline particles and 75% cotton fiber are spun into a yarn count of 32 by vortex spinning technology s The blended yarn containing volcanic ash microcrystalline particles; the above-mentioned blended yarn containing volcanic ash microcrystalline particles is woven into a plain knit fabric on a 28G single-jersey machine, and after dyeing and finishing treatment, a volcanic ash microcrystalline particle is formed. knitted fabric.

[0045] Dyeing and finishing process: capsule breaking treatment (put the fabric in a bath liquid at 130°C for 30 minutes)—cool down and put in soup—washing—bleaching—light dehydration—setting.

[0046] Table 2 Test results of moisture absorption and quick drying, adsorption and antibacterial properties:

[0047] Test items unit judgement standard standard value measured value evaporation rate g / h GB / T 21655.1-2008 "Assessment of moisture absorptio...

Embodiment 3

[0049] 30% by weight of volcanic ash fibers containing volcanic ash microcrystalline particles and 70% of modal are spun into a yarn count of 40 by compact spinning technology s The blended yarn containing volcanic ash microcrystal particles; the above-mentioned blended yarn containing volcanic ash microcrystal particles and 20D spandex are woven into plain knitted fabrics on a 28G single-jersey machine, and the volcanic ash microcrystalline particles are formed after dyeing and finishing. Body grain knitted fabric.

[0050] Dyeing and finishing process: pre-setting - capsule breaking treatment (put the fabric in a 130°C bath for 30 minutes) - cooling down and putting in soup - washing - bleaching and dyeing - light dehydration - finalizing.

[0051] Table 3 Test results of moisture absorption and quick drying, adsorption and antibacterial properties:

[0052] Test items unit judgement standard standard value measured value evaporation rate g / h GB / T ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com