Preparation method of regenerated cellulose fibers with high optical shielding property

A technology of regenerated cellulose and covering properties, applied in the direction of artificial filaments made of viscose, can solve the problems of increasing the number of light reflections, poor air permeability of fabrics, and high cost, achieving good results, high modification efficiency, The effect of mutual solubility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

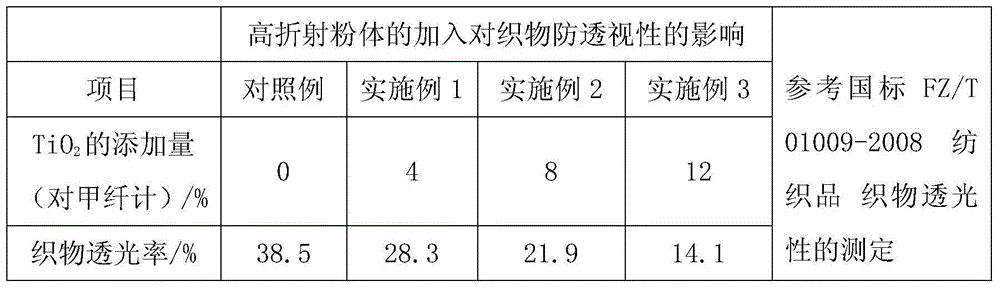

Examples

Embodiment 1

[0016] Embodiment 1: The preparation method of regenerated cellulose fiber with high optical shielding property

[0017] Preparation of viscose solution:

[0018] Cotton pulp with a degree of polymerization of 500 and a mass content of cellulose of 93.5% is used as a raw material, and it is prepared through processes such as dipping, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and degassing. In the viscose liquid that makes, methyl fiber mass content 8.7%, NaOH mass fraction 5.9%, viscosity (falling ball method) 45s, maturity (10%NH 4 Cl) 8.7 mL.

[0019] Preparation of high refractive powder dispersion system:

[0020] In the reactor, prepare 5wt% high refraction powder dispersion system with distilled water, add glyceryl tristearate dispersant accounting for 3% of the high refraction powder mass, and fully stir to obtain a relatively uniform moisture absorbent emulsion. Use a plate-and-frame filter to filter through double-layer fine cloth, a...

Embodiment 2

[0026] Embodiment 2: the preparation method of regenerated cellulose fiber of high optical shielding property

[0027] Preparation of viscose solution:

[0028] Cotton pulp with a degree of polymerization of 500 and a mass content of cellulose of 93.5% is used as a raw material, and it is prepared through processes such as dipping, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and degassing. In the viscose liquid that makes, methyl fiber mass content 8.9%, NaOH mass fraction 6.1%, viscosity (falling ball method) 45s, maturity (10%NH 4 Cl) 8.4ml.

[0029] Preparation of high refractive powder dispersion system:

[0030] In the reactor, use distilled water to prepare a 10wt% high-refraction powder dispersion system, add sodium hexametaphosphate dispersant accounting for 4% of the high-refraction powder mass, and stir well to obtain a relatively uniform high-refraction emulsion. Use a plate-and-frame filter to filter through double-layer fine cloth,...

Embodiment 3

[0036] Embodiment 3: the preparation method of regenerated cellulose fiber with high optical shielding property

[0037] Preparation of viscose solution:

[0038] Cotton pulp with a degree of polymerization of 500 and a mass content of cellulose of 93.5% is prepared through successive processes of dipping, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and deaeration. In the viscose liquid that makes, methyl fiber mass content 9.0%, NaOH mass fraction 6.3%, viscosity (falling ball method) 45s, maturity (10%NH 4 Cl) 8.5ml.

[0039] Preparation of high refractive powder dispersion system:

[0040] In the reaction kettle, a 15wt% high-refraction powder dispersion system was prepared with distilled water, and a relatively uniform high-refraction emulsion was obtained by adding tristearin dispersant accounting for 5% of the mass of the high-refraction powder and stirring thoroughly. Use a plate-and-frame filter to filter through double-layer fine cloth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com