Production method of yakwool hollow yarn

A production method, the technology of yak cashmere, is applied in yarn, textiles and papermaking, etc. It can solve the problems of high price of water-soluble vinylon filament, easy bonding and hardening of vinylon staple fiber, difficulty in spinning spun yarn, etc., and achieves a large market value , Improve heat retention and reduce the effect of spinning triangle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims in this application.

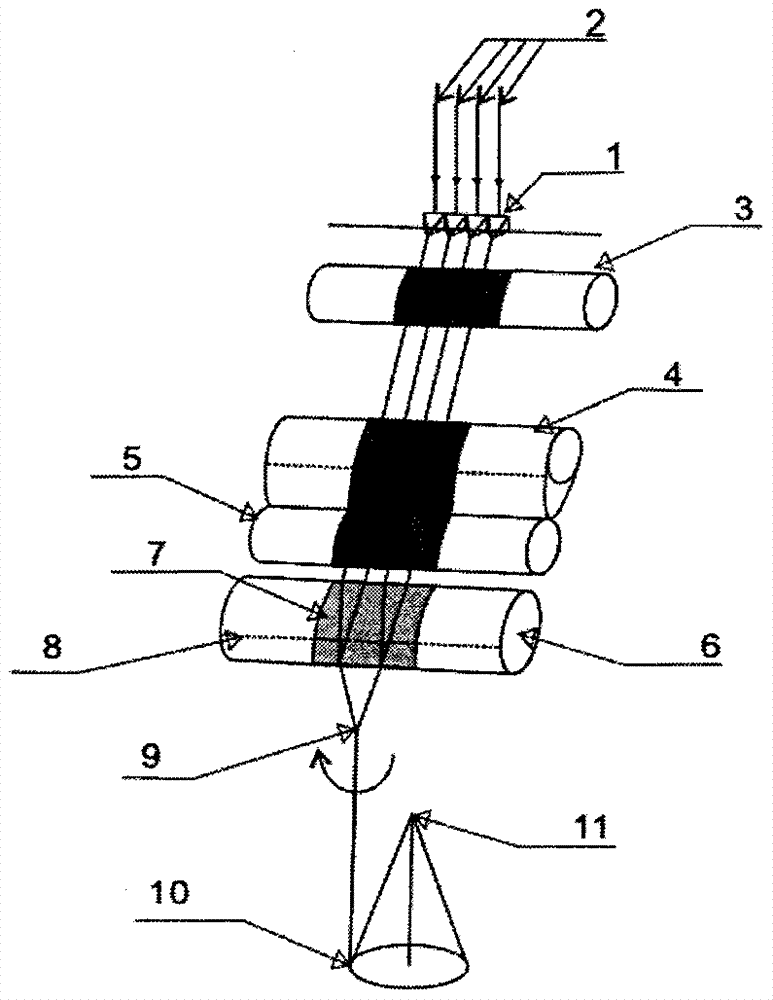

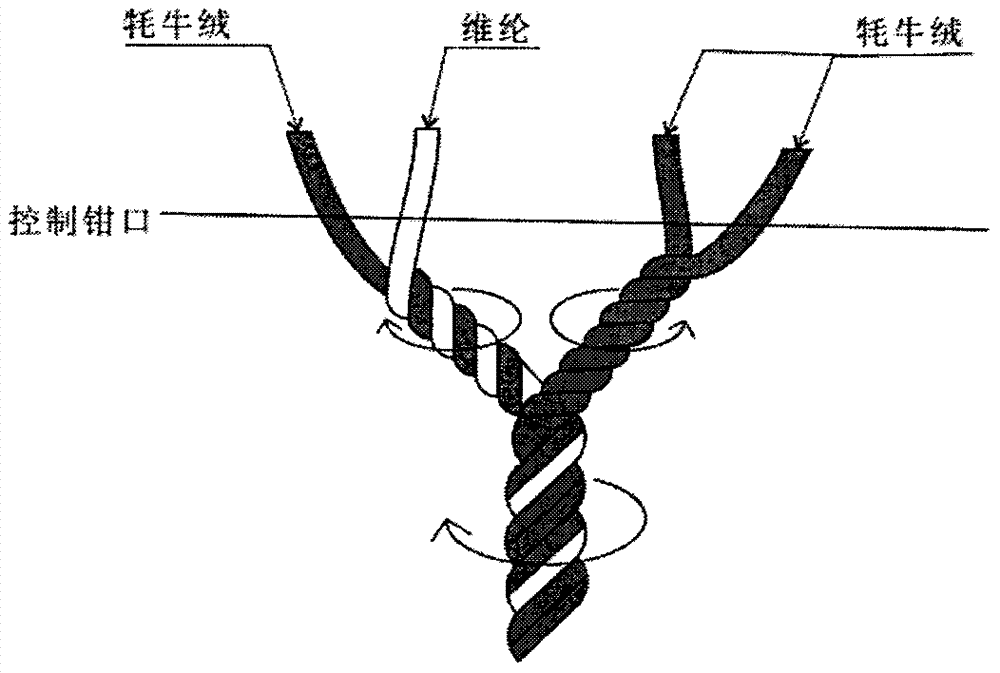

[0037] In the same way as compact siro spinning, four rovings are simultaneously fed into the ring spinning frame in parallel to spin 45tex yak cashmere core-spun yarn, and then the spun core-spun yarn is woven into double-ribbed knitted fabric with a computerized flat knitting machine. After the finished knitted fabric is dedimensionalized, after the final product is dedimensionalized, a knitted fabric with low fiber arrangement density, high yarn bulkiness and hollow yarn structure is formed.

[0038] The manufacturing process is as follows:

[0039] In the first step, the water-soluble vinylon staple fiber is opened with a wool machine, and then carded to obtain a raw sliver, which is drawn through the first and second draws, and finally spun ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com