Non-ironing triple-proof finishing method of ready-made garments

A non-iron finishing and three-proof finishing technology, which is applied in the field of textile printing and dyeing, can solve problems such as stuffiness, unsightly appearance, and single product functions, and achieve the effects of improving comfort, improving hydrophilicity, and high hydrophilicity and quick drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

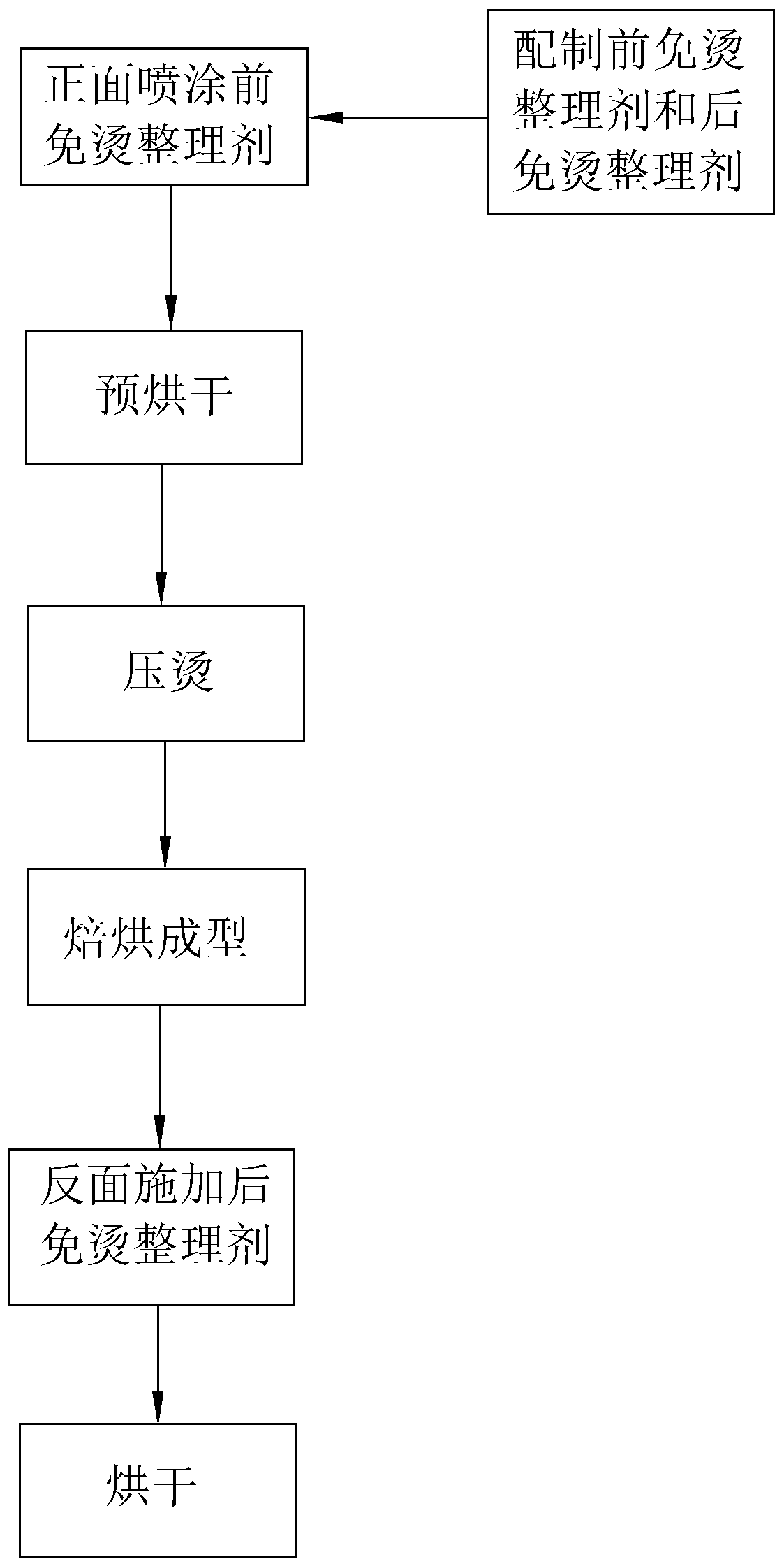

Method used

Image

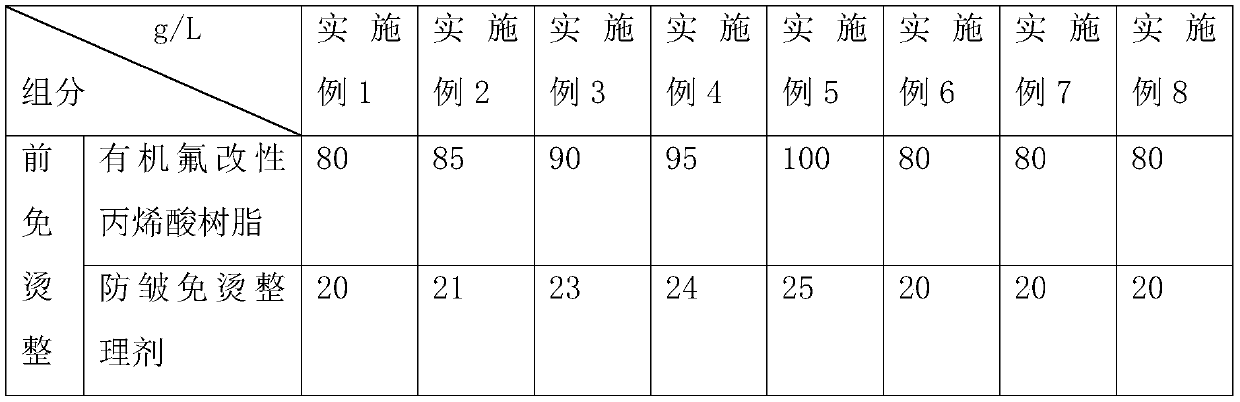

Examples

preparation example 1

[0037] Preparation Example 1: (1) 250 milliliters of polyvinyl alcohol with a concentration of 1% and a sodium chloride solution with a concentration of 3% are mixed and heated to 45° C., and 50 g of triallyl isocyanurate and 30 g of even Azodiisobutyrocyanide, stir well, heat up to 85°C, react for 4h, wash the product with hot water, cold water and ethanol respectively, and dry under vacuum at 80°C to obtain cross-linked polymethylacrylate, polyvinyl alcohol and sodium chloride solution quality The ratio is 1:1;

[0038] (2) Add cross-linked polymethyl acrylate to a mixed solution made of 15g divinylphenyl, 20g styrene and 15g benzoyl peroxide to fully swell the cross-linked polymethyl acrylate;

[0039] (3) 250 milliliters are heated up to 45 ℃ by mixing the mixed solution that 250 milliliters are made by the polyethylene of concentration 1% and the sodium chloride solution of 3% concentration, add swelling cross-linked polymethyl acrylate, heat up to 80 ℃, react 2h, heat u...

preparation example 2

[0042] Preparation example 2: Add 1kg of acrylic acid and 0.2kg of hexafluorobutyl acrylate into 3kg of acetone, raise the temperature to 200°C, add 0.5kg of benzoyl peroxide while stirring, and then add 0.5kg of benzoyl peroxide, The temperature is lowered and cooled to obtain an organic fluorine-modified acrylic resin.

preparation example 3

[0043] Preparation Example 3: Add 2kg of acrylic acid and 0.4kg of hexafluorobutyl acrylate into 4kg of acetone, raise the temperature to 230°C, add 0.8kg of benzoyl peroxide while stirring, and then add 0.8kg of benzoyl peroxide, The temperature is lowered and cooled to obtain an organic fluorine-modified acrylic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com