Patents

Literature

32results about How to "Reduce electrostatic adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibiotic moisture absorption function finishing technique for polyester/cotton blended fabric

The invention provides a relative functional finishing technology which not only can maintain characteristics of smooth feeling of polyester / cotton fabric, good crease resistance, excellent strength and dimensional stability, and easily washing and quickly drying, but also can overcome defects that polyester / cotton fabric has low moisture absorption, poor breathability and developed bacteria caused by sweat stains, thereby affecting the health of people. The invention adopts a special moisture adsorption and perspiration finishing agent SW and an antibacterial finishing agent SCJ-891, and the finishing technology is produced by processing the polyester / cotton fabric according to post finishing technological process of common fabric.

Owner:SHENGHONG GRP CO LTD

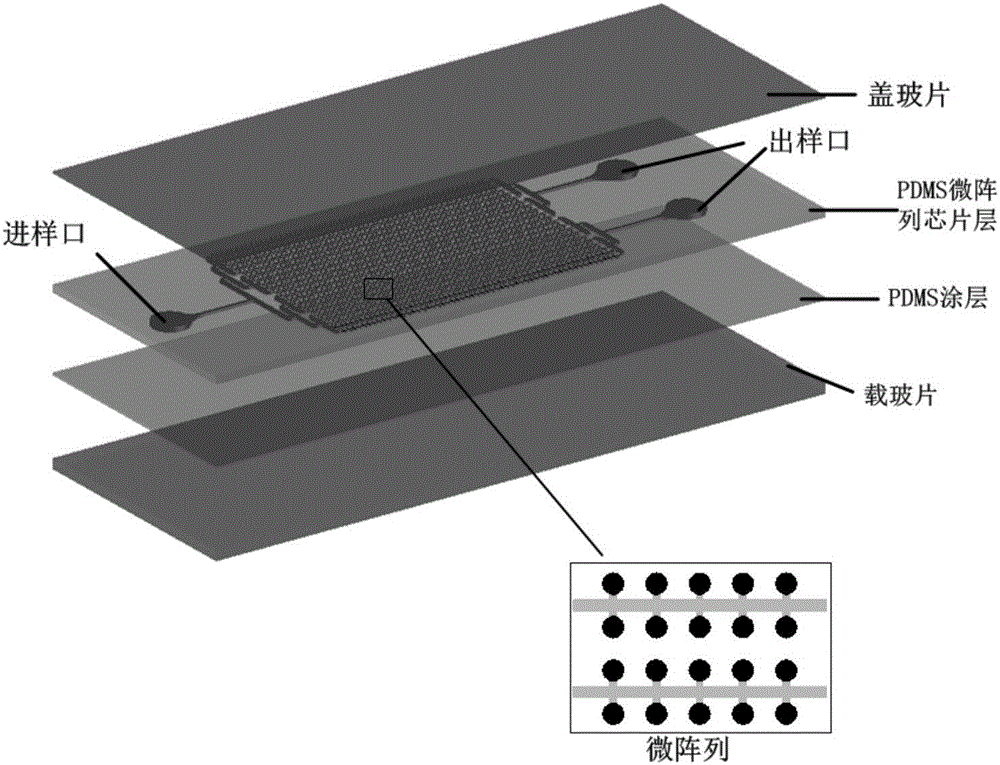

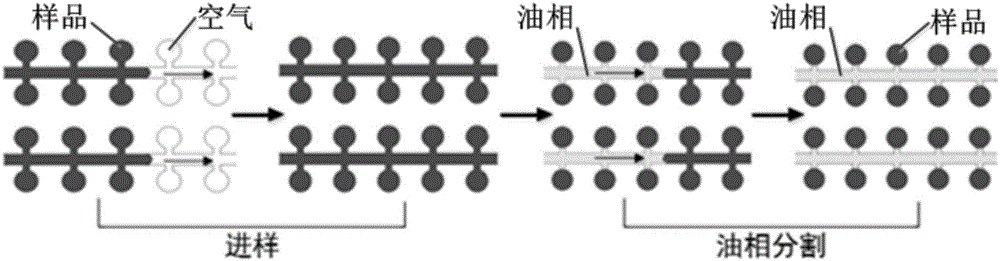

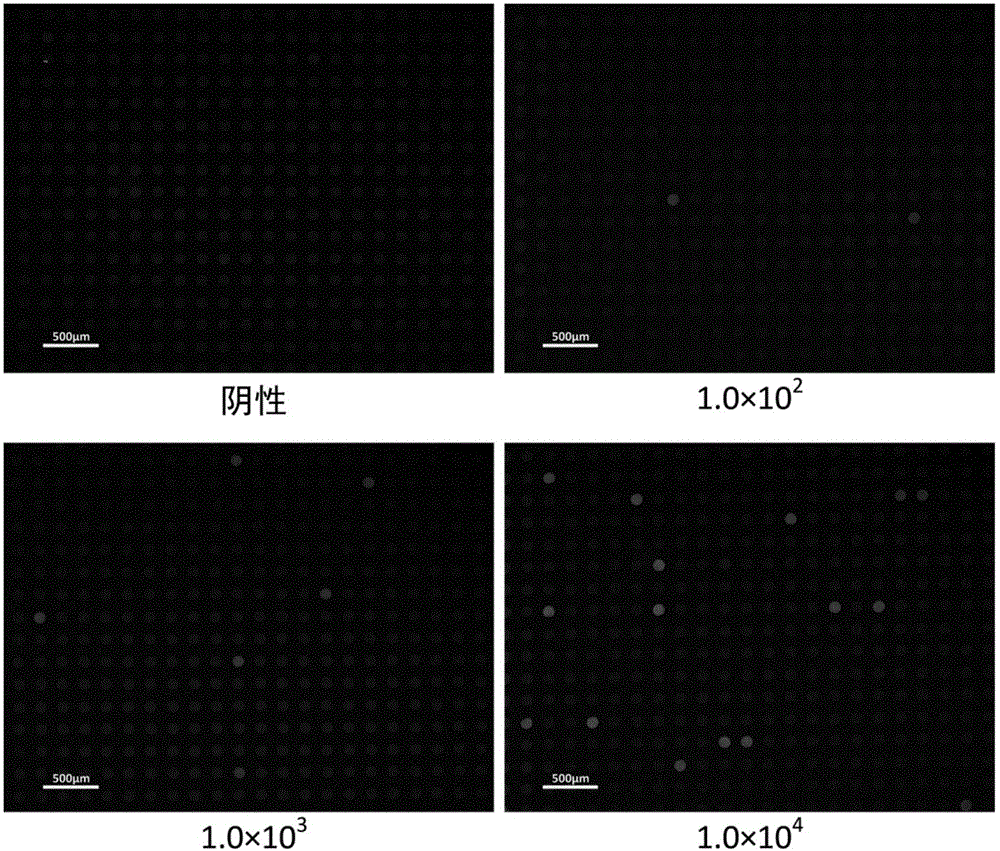

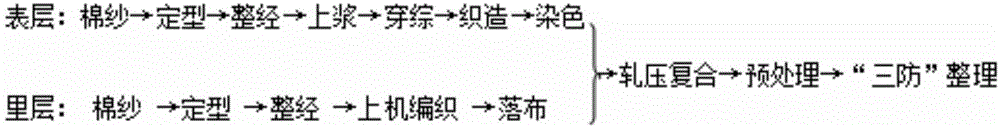

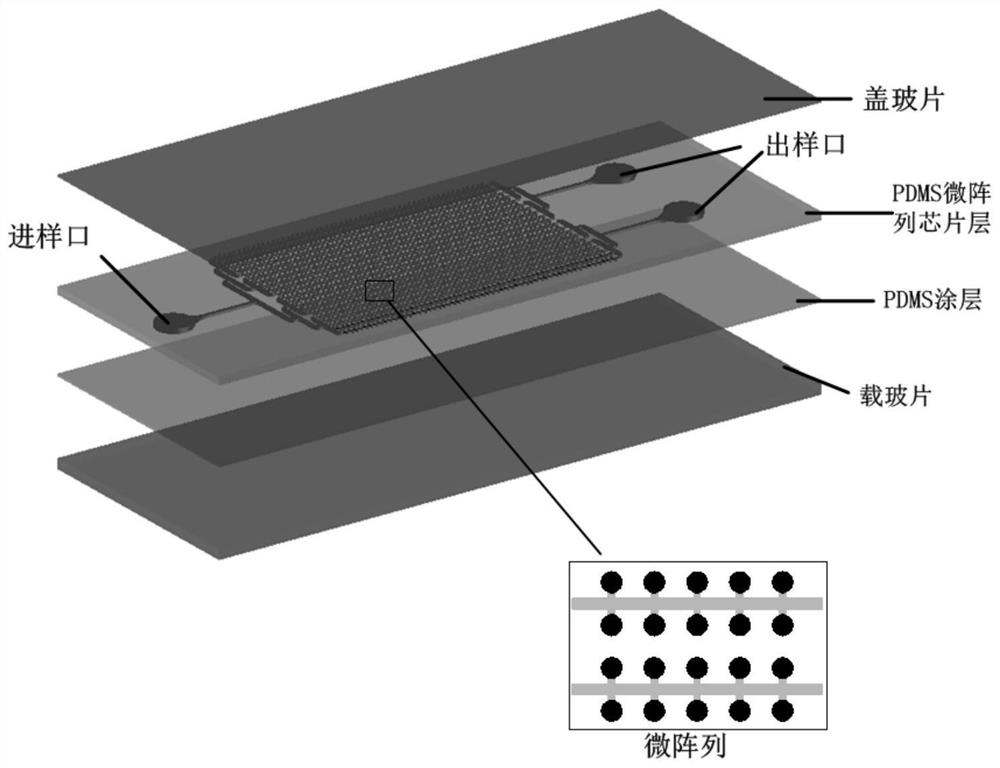

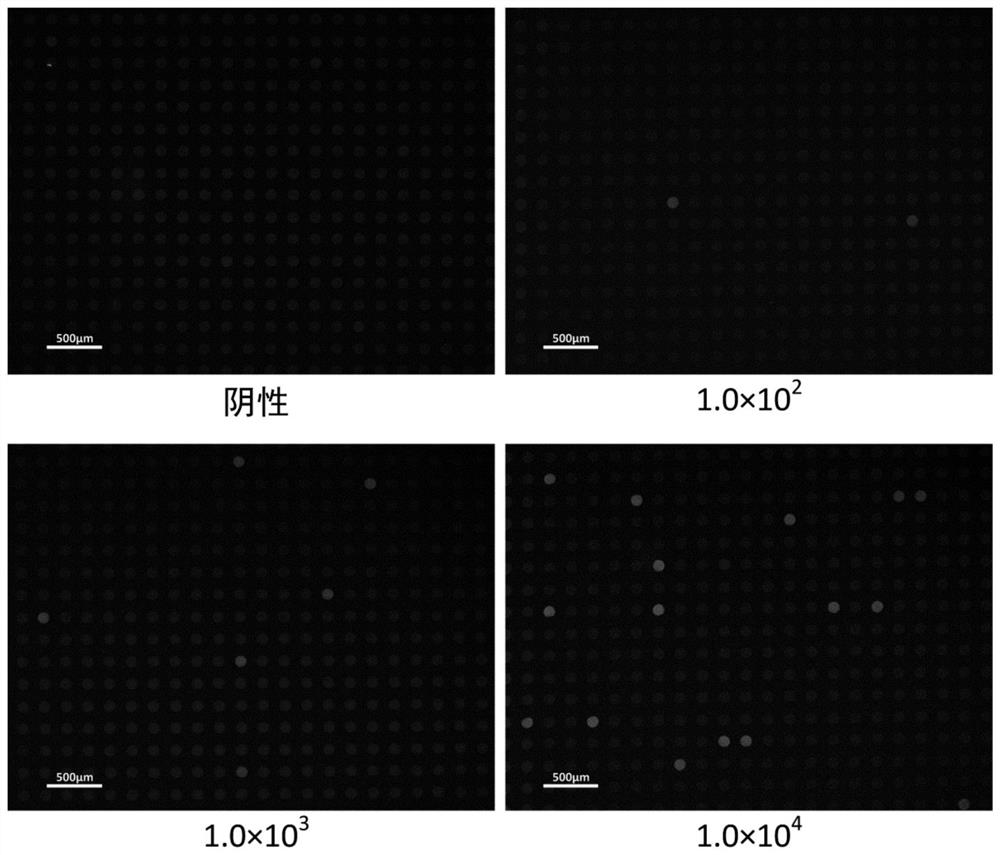

Digital PCR chip based on surfactant modified PDMS and method

ActiveCN106755420AChange surface propertiesReduce adsorptionMicrobiological testing/measurementPcr chipDissolution

The invention relates to a digital PCR chip based on surfactant modified PDMS, a preparation method and application. The digital PCR chip is characterized in that the digital PCR chip is a PDMS digital PCR array chip prepared by a PDMS material doped by a certain amount of a surfactant; sampling and distributing processes are realized by means of a high air dissolution characteristic of the pre-degassing thin type PDMS chip, and a sandwiched structure of glass-modified PDMS-glass is prepared to inhibit water volatilization. According to a design method of the chip, electrostatic adsorption of PDMS on biological molecules is reduced, and the stability and the volatility resistance of liquid drops are effectively improved, so that the amplification efficiency of PCR is improved. Moreover, compared with a reported digital PCR chip at present, the digital PCR chip is low in cost, simple to operate and quite wide in application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Nano self cleaning silk broadcloth and products

ActiveCN1277019CWith self-cleaning functionIncreased durabilityFibre treatmentChlorideSolid particle

This is a self-clean real silk cloth and its productive method. It features are: To treat the real silk cloth with the organic fluorine regulator it is nano-grade inorganic solid grain, use to soak, to coat or to spray on them, to make their surface have water-distant and oil-distant function. The organic fluorine regulator contains: the organic fluorine resin 10-70g / L, nano-grade inorganic solid grain water 5-30g / L. In the advanced organic fluorine regulator also contain the silicon alkanet, magnesium chloride, or isopropyl alcohol at least one of above compositions.

Owner:韦钧千

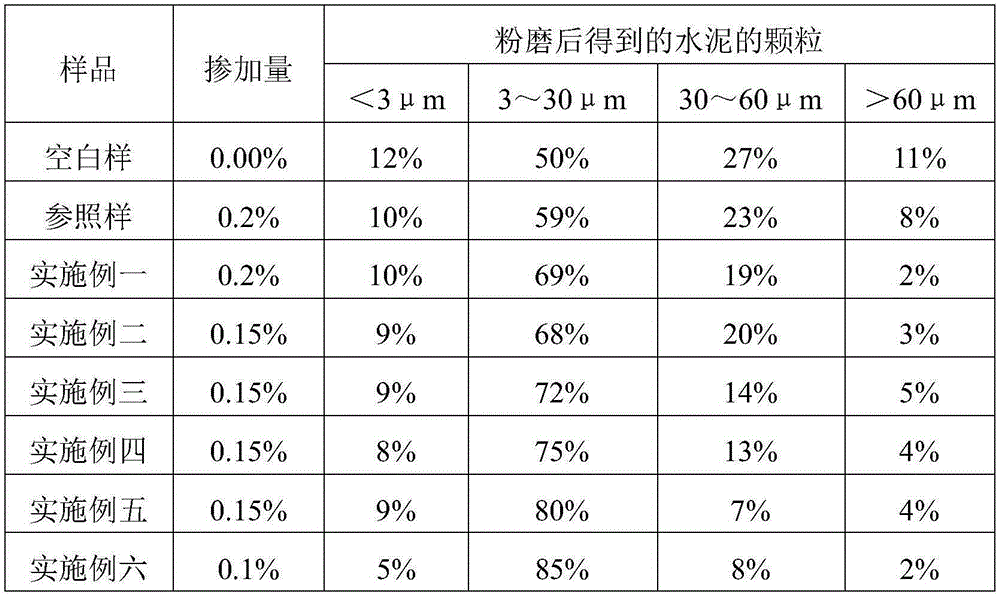

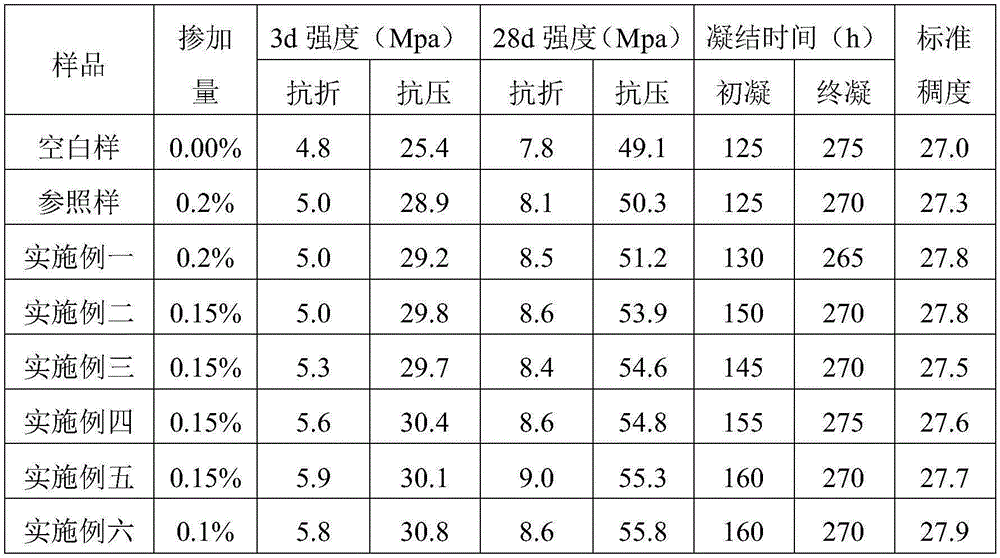

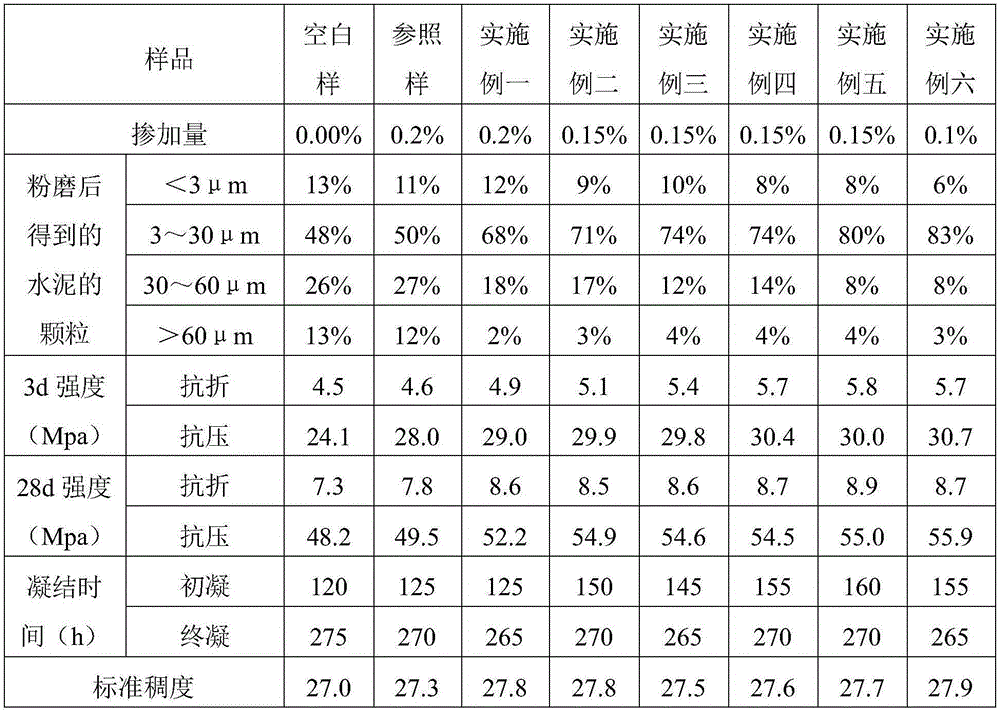

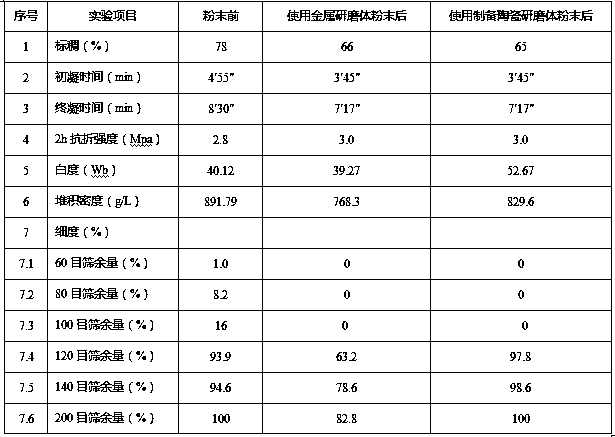

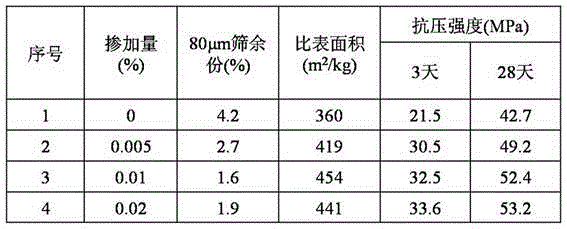

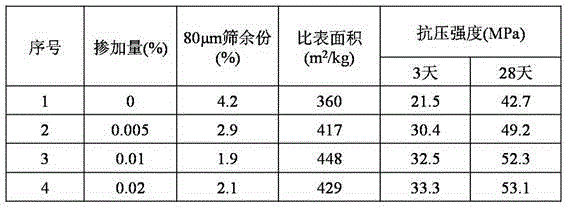

Cement grinding aid as well as preparation method and application method thereof

The invention discloses a cement grinding aid as well as a preparation method and an application method thereof. The cement grinding aid comprises the following raw materials in parts by weight: 5-15 parts of triethanolamine, 5-20 parts of honey, 1-5 parts of sodium gluconate, 1-5 parts of N-sulfo-glucosamine potassium salt, 5-10 parts of C1-C3 alcohol and 40-100 parts of water. The invention aims to provide the cement grinding aid that the grain composition of cement added with the cement grinding aid is reasonable after powdering, the fineness of cement is appropriately reduced, the strength of grinded cement can be improved, and the comprehensive effect is relatively good.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

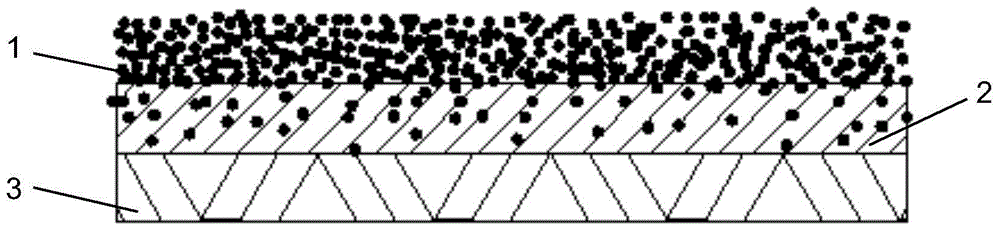

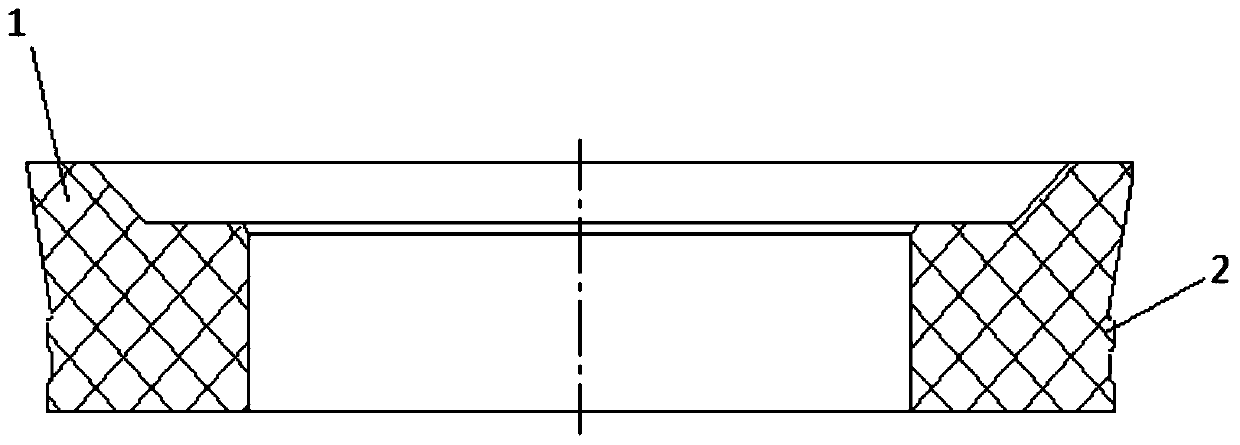

Fabric with waterproof and moisture-conductive functions

InactiveCN103112206AReduce electrostatic adsorptionReduce mechanical shrinkageLayered productsTwo or more solvent application treatmentFoaming agentEngineering

The invention discloses a fabric with waterproof and moisture-conductive functions. The fabric is constituted by a three-layer structure, a moisture absorbing and sweat releasing membrane layer is compounded in the textile fabric, and a waterproof layer is coated on the textile fabric; and the fabric is manufactured through the following steps of: adding 30-50g of a moisture absorbing and sweat releasing agent into each liter of water and reacting for 1-3 minutes; firstly padding and then shaping, wherein the shaping temperature is 170-180 DEG C, the vehicle speed is 30-60m / min and the reaction is performed for 24-48s; adding 80-100g of a waterproof agent, 1-3g of a foaming agent and 1-3g of a foam stabilizer into each liter of the water, adding into a foaming machine for making foam, and further uniformly coating the foaming agent on the other surface of moisture absorbing and sweat releasing cloth; shaping and drying; and inspecting and packaging. After the treatment through the special process, the moisture absorbing and sweat releasing membrane layer and the waterproof layer are arranged in the fabric, so that the fabric disclosed by the invention simultaneously has the waterproof and the moisture-conductive functions, has a wide range of applications, can reduce electrostatic adherence on ready-made clothes and mechanical shrinkage of knitted fabric, and is comfortable to wear and aesthetic in appearance.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

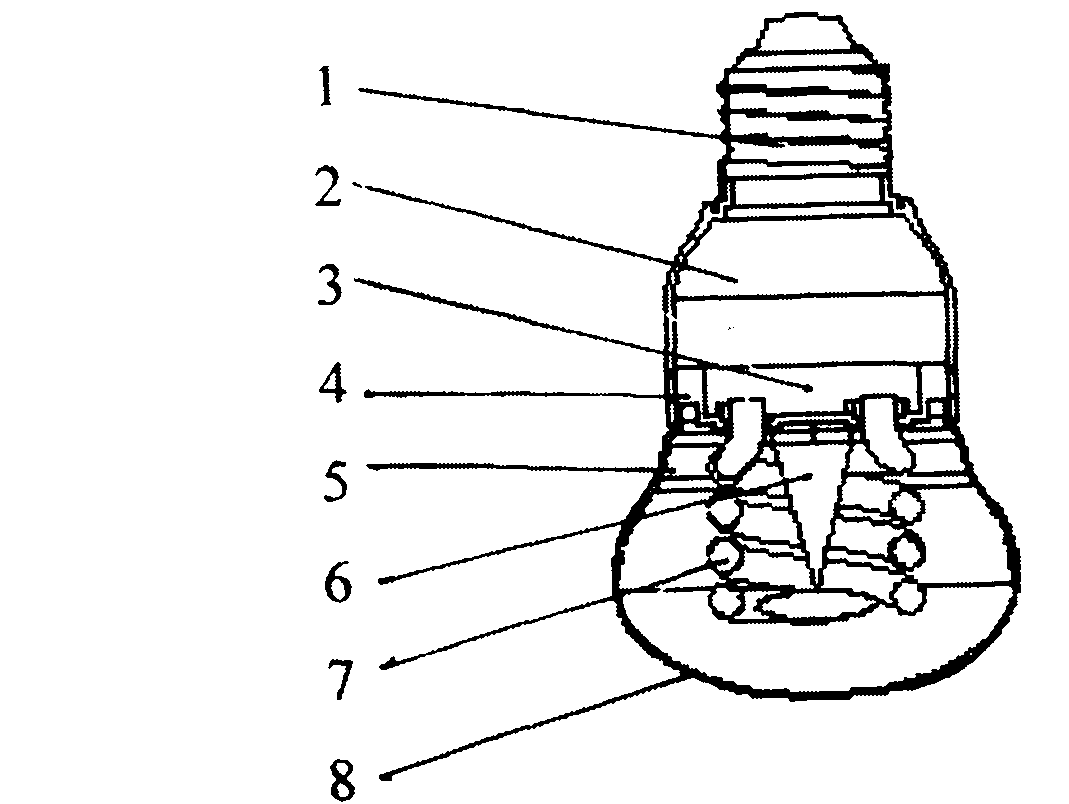

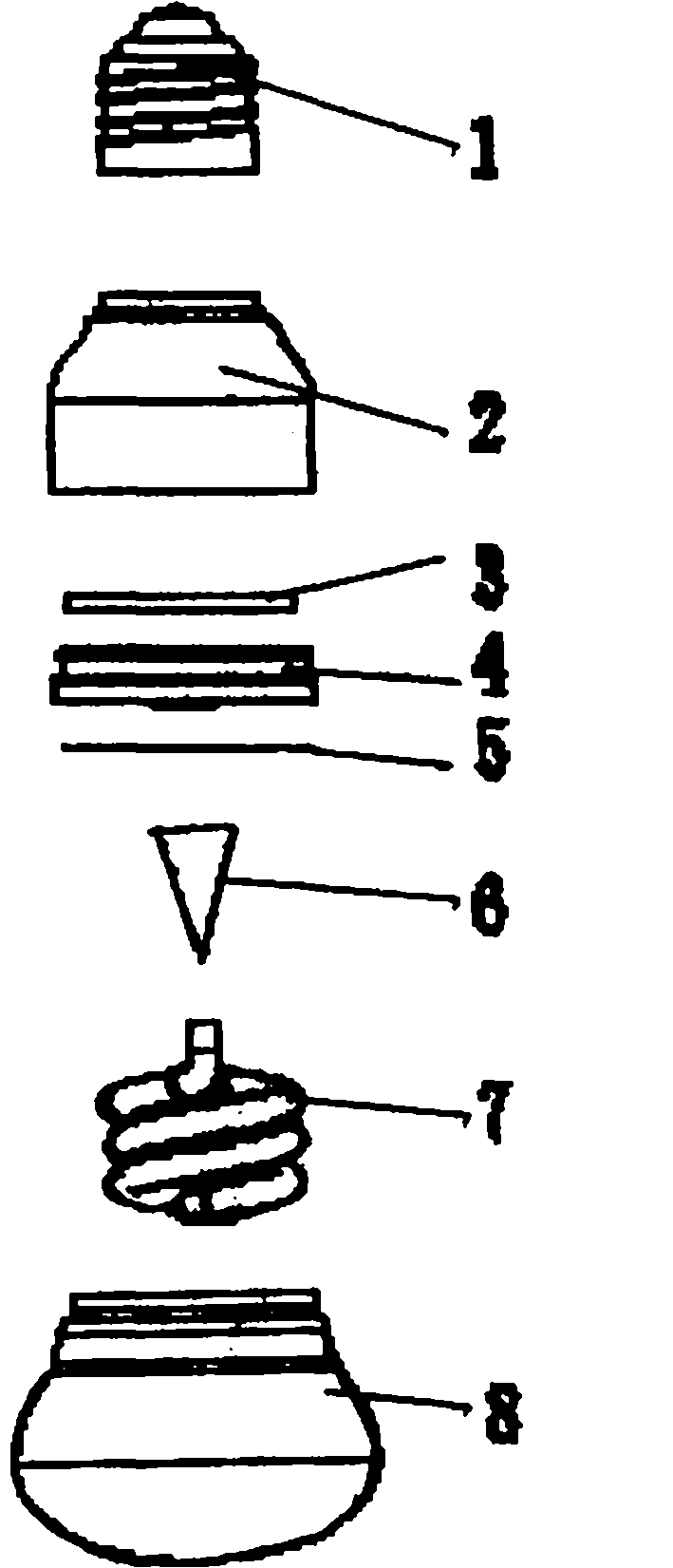

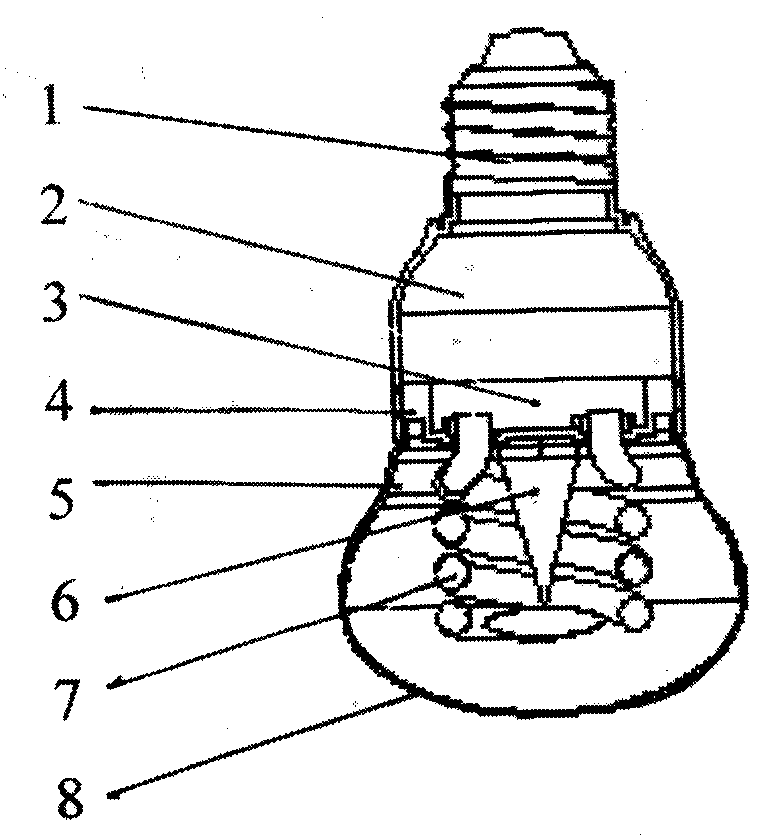

High-efficient reflecting condenser long-life-type electronic energy-saving spherical bubble

The invention discloses a high-efficient reflecting condenser long-life-type electronic energy-saving spherical bubble. The electronic energy-saving spherical bubble comprises an E27 lamp connector, an upper plastic shell, a switch electronic power panel, a lower plastic shell, a light source nanometer-coating reflector plate, a light source V-shaped nanometer-coating cone reflector, a U-shaped and spiral energy-saving lamp tube, and a glass nanometer-coating reflector, wherein the lamp connector inputs power to drive and light the lamp tube through the electronic power panel, the light generated by all power sources in the device is reflected, condensed and collected to be changed into effective light through the light source nanometer-coating reflector plate, the light source V-shaped nanometer-coating cone reflector and the glass nanometer-coating reflector, thus the lighting effect is improved; a concave-convex embedded type design is adopted between the glass nanometer-coating reflector and the lower plastic shell of the spiral energy-saving lamp tube, thereby realizing the simple and direct coordination and reducing the damage to the light source lamp part; and the light source lamp tube is subjected to dustproof protection, static easily-absorbed powder-dust protection and lighting effect homogenization, thus the service life of the lamp tube is prolonged by 3-5 times, and the life and lighting effect of the whole lamp are improved.

Owner:戴建国

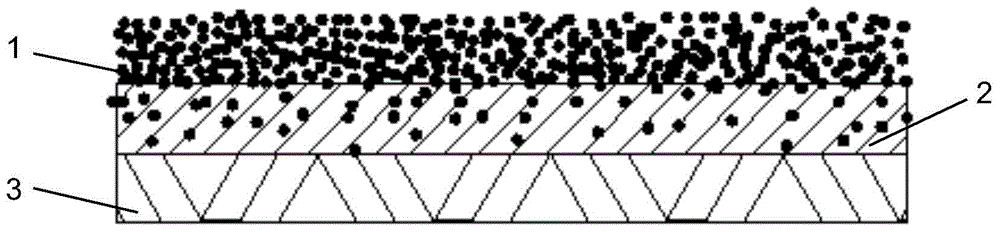

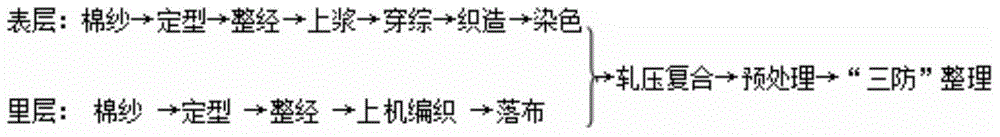

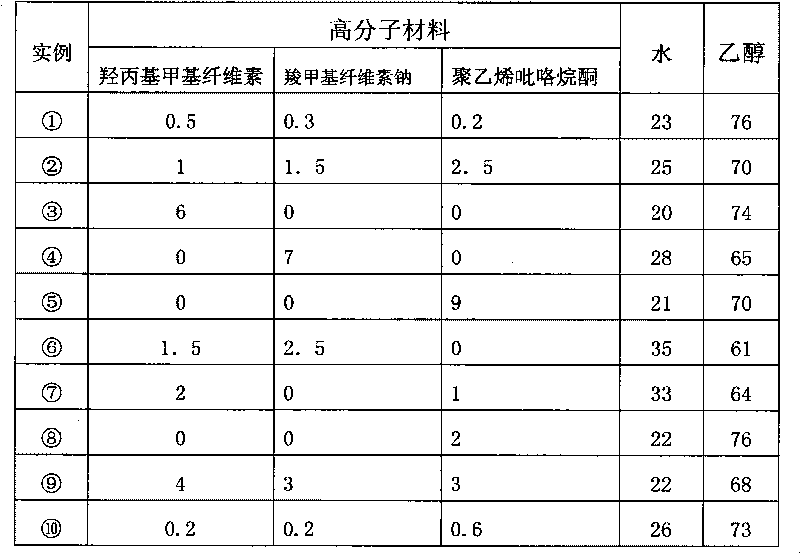

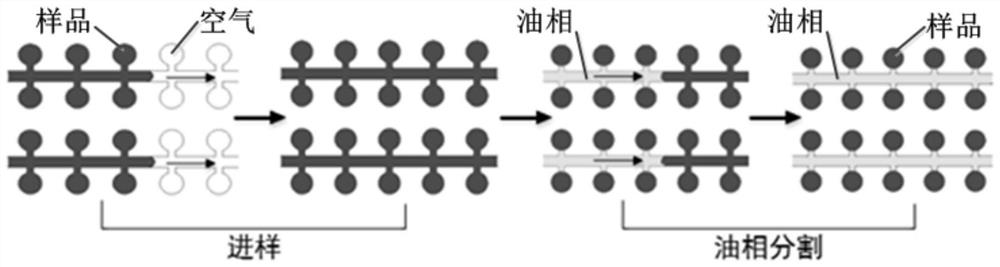

All-cotton composite functional fabric with all-cotton water-proof, oil-proof and antifouling properties

ActiveCN104404787AGood skin affinityGood dimensional stabilityStain/soil resistant fibresPhysical treatmentSurface layerGas phase

The invention discloses an all-cotton composite functional fabric with water-proof, oil-proof and antifouling properties; the all-cotton composite functional fabric includes a composite fabric having a surface layer and an inner layer, the surface layer is a machine-woven fabric layer, and the inner layer is a knitted fabric layer; the composite fabric is subjected to a pretreatment process by a cellulase and low-temperature oxygen plasma combination way; then a 'double-nano' finishing agent is applied to the fabric surface by using a physical vapor deposition method, a layer of thin film with 'three protection' function is formed on the fabric surface; the 'double-nano' finishing agent is a mixture of nano fluoride and ceramic powder nano particles. The composite functional fabric is pretreated by the cellulase and low-temperature oxygen plasma combination way, neps and impurities on the fabric surface are removed, the fabric softness is increased, and a final using effect is improved; and at the same time, with combination of the low-temperature plasma treatment process, and through the etching effect of plasma, the combination fastness of the finishing agent with the fabric surface is greatly improved, and the durability of functional finishing is improved.

Owner:SWOTO PROTECTION & TECH CO LTD

Textile fabric capable of preventing mosquito bites

InactiveCN104290385AImprove breathabilityAvoid bitesLayered productsOpen work fabricsSurface layerMosquito bite

The invention provides a textile fabric capable of preventing mosquito bites. The textile fabric comprises surface-layer screen cloth and inner-layer screen cloth, wherein the surface-layer screen cloth is provided with a plurality of first vent holes which are formed by interweaving of warp yarns and weft yarns; the size of each first vent hole is 80-120 meshes; the inner-layer screen cloth is attached on one face of the surface-layer screen cloth and is provided with a plurality of second vent holes which are formed by interweaving of warp yarns and weft yarns; the size of each second vent hole is 60-80 meshes; and the thickness of the warp yarns or the weft yarns of the inner-layer screen cloth is greater than the length of a lancet of a mosquito. According to the textile fabric, the first vent holes in the surface-layer screen cloth are used for preventing the mosquitoes from being in contact with skins, and in match with the thickness of the inner-layer screen cloth, the lancets of the mosquitoes are prevented from being stabbed into the skins, and therefore, the effect of preventing the mosquito bites can be realized. Moreover, each of the surface-layer screen cloth and the inner-layer screen cloth adopts a screen hole structure with vent holes, so that the ventilation performance of the fabric can be greatly improved and produced clothes have the ventilation and heat radiation effects when being worn.

Owner:福建泉州市健凯服饰有限公司

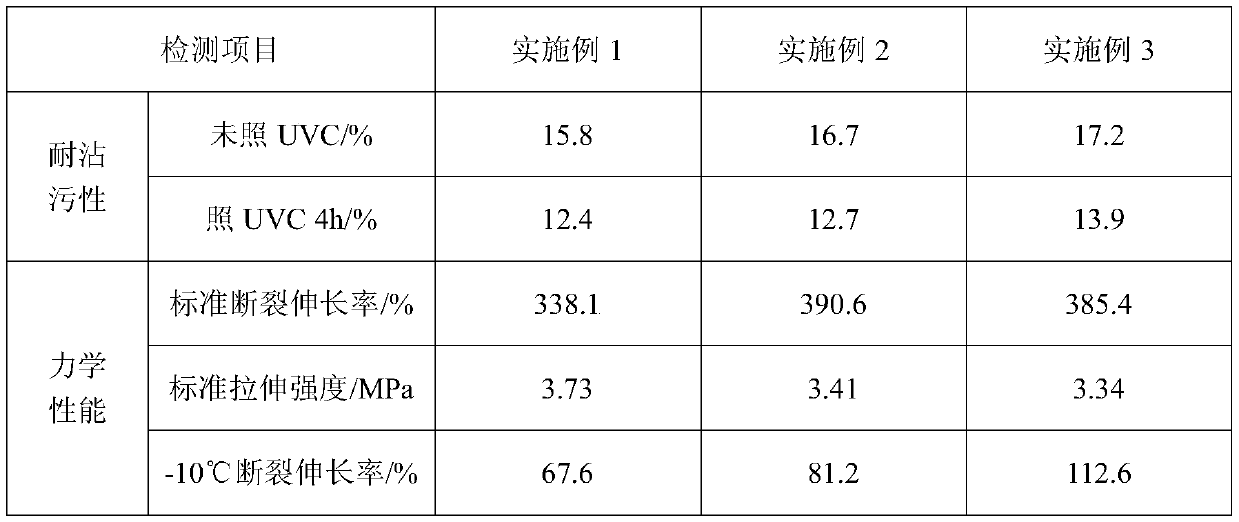

External wall elastic emulsion with antistatic effect and method for preparing external wall elastic emulsion

InactiveCN108148478AThe number of hydroxyl groups increasedImprove hydrophilicityAntifouling/underwater paintsPaints with biocidesIsooctyl acrylateFunctional monomer

The invention discloses external wall elastic emulsion with an antistatic effect and a method for preparing the external wall elastic emulsion. The external wall elastic emulsion comprises, by weight,90-120 parts of deionized water, 10-30 parts of iso-octyl acrylate, 60-80 parts of butyl acrylate, 20-35 parts of styrene, 5-15 parts of methyl methacrylate, 0.1-2 parts of acrylic acid, 0.1-1.5 parts of methacrylic acid, 0.1-1 part of acrylamide, 0-0.5 part of methacrylamide, 0-0.5 part of hydroxyethyl acrylate, 3-10 parts of acrylonitrile, 0.5-3 parts of acid anhydride functional monomers, 0.5-4 parts of diethanolamine, 0.1-3 parts of modified organophosphate high polymers, 1-8 parts of emulsifiers, 0.1-5 parts of initiators and 0.3-4.5 parts of ammonia water. The external wall elastic emulsion and the method have the advantages that the antistatic effect can be realized by the external wall elastic emulsion, the external wall elastic emulsion is excellent in stain resistance, and the excellent normal-temperature and low-temperature elasticity of the external wall elastic emulsion can be kept.

Owner:上海巴德富实业有限公司

Preparation method of insect-repellent textile fabric

InactiveCN104389070AWide range of applicationsReduce electrostatic adsorptionSynthetic fibresDyeing processPlain weaveChemistry

The invention discloses a preparation method of an insect-repellent textile fabric. The method comprises the following steps: a, preparing flax threads, bamboo charcoal fibers, an active dye and a nano-silver antibacterial solution; b, boiling a plurality of flax threads with soap, and soaking the boiled flax threads into the active dye to allow the flax threads to absorb slowly; c, boiling a plurality of bamboo charcoal fibers with soap, and soaking the bamboo charcoal fibers into the nano-silver antibacterial solution added with a PVP (Polyvinyl Pyrrolidone) dispersing agent and a PDA dispersing agent; d, weaving the insect-repellent textile fabric comprising surface layer screen cloth and inner layer screen cloth according to a double-layer plain weave method by operating a shuttle loom, wherein warps of the inner layer screen cloth are dip-dyed flax threads, and wefts are soaked bamboo charcoal fibers and a plurality of acrylic fibers; warps and wefts of the surface layer screen cloth are a plurality of machine sewing threads. After being treated in the nano-silver antibacterial solution through a soaking process, the bamboo charcoal fibers have the effect of disinfecting, resisting bacteria and repelling insects.

Owner:福建泉州市健凯服饰有限公司

Method for granulating medicament for treating osteoporosis

InactiveCN101708251AIncrease salesEasy to useSkeletal disorderPharmaceutical non-active ingredientsPrillSoft materials

The invention relates to a method for granulating a medicament for treating osteoporosis, which comprises the following steps of: firstly uniformly mixing the medicament and auxiliary materials; adding a polymer blend, and stirring the mixture to obtain a soft material; preparing wet granules from obtained soft material with a granulator; placing the prepared wet granules into a boiling drier to dry; discharging the granules after drying the granules; passing the granules through a 25-mesh screen; mixing the granules; and encapsulating 0.45g of granules into each number 1 capsule to obtain a capsule preparation. The polymer blend has the functions of adhesion and coating, and ensure that the medicament fine powder is tightly prepared into balls and each ball is coated with a layer of film coating, so that powder granule gaps are reduced, the requirements of encapsulating materials into the number 1 empty capsule is met, the medicament only encapsulated by a large number 0 empty capsule can be successfully encapsulated by the small number 1 empty capsule, the volume of the finished capsule is decreased which is convenient for administration, the compliance of medication is increased, sale and use of the medicament are promoted, and good benefits for society and enterprises can be created.

Owner:SICHUAN MEDCO PHARML

Macromolecular nano coating material composite slurry

The present invention relates to one kind of nanometer composite polymer paint slurry, which consists of water 30 wt%, dispersant 0.6 wt%, nanometer polymer assistants 1 wt%, sodium bentonite 2 wt%. heavy calcium carbonate 45 wt%, wollastonite 10 wt%, kaolin 10 wt% and titanium white powder 0-5 wt%, where, the nanometer polymer assistants includes aluminum sulfate 20 wt%, sodium silicate 50 wt%, pentaerythritol 20 wt%, hydroxypropyl methyl cellulose 2.5 wt% and sodium fluosilicate 7.5 wt%. The nanometer composite polymer paint slurry has the crystal structure of the components maintained and narrow size distribution, and can form coating with fire resistance, no smoke in fire, high adhesion to inorganic base material and other advantages.

Owner:赵玉洪

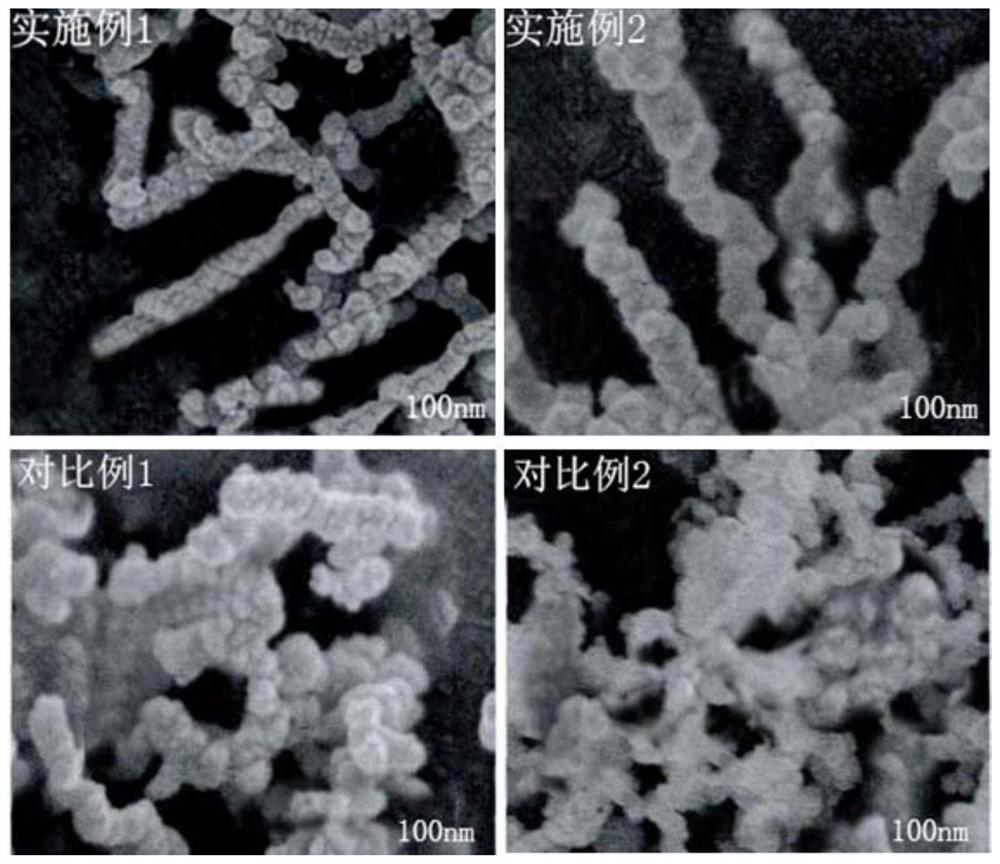

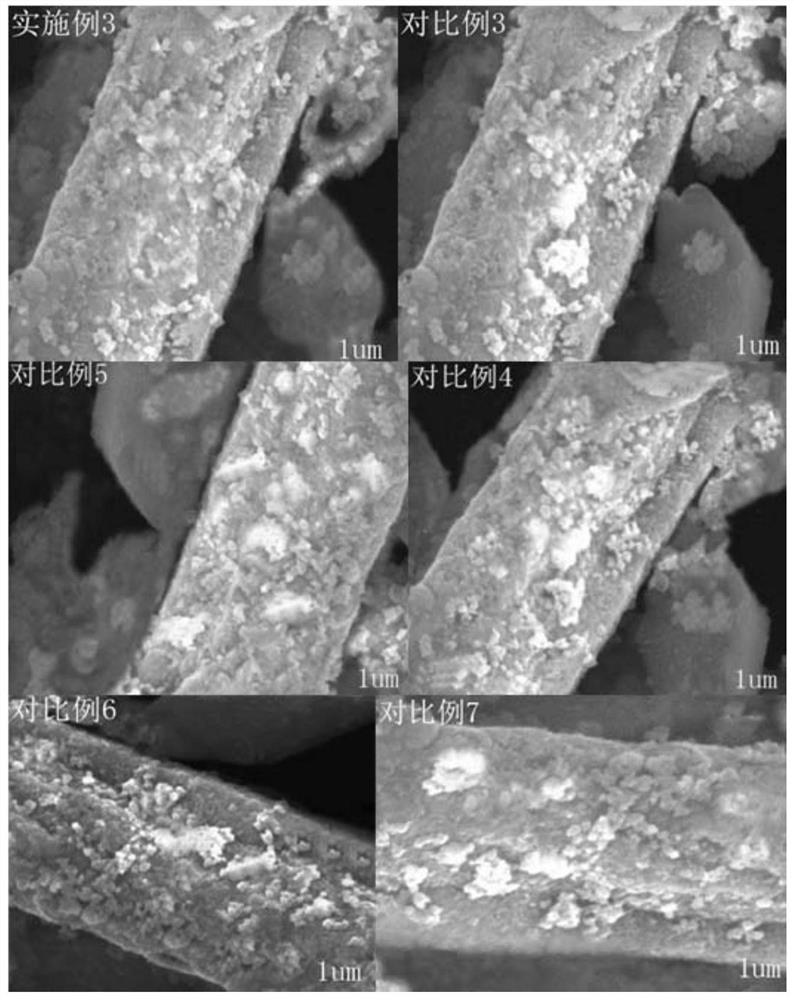

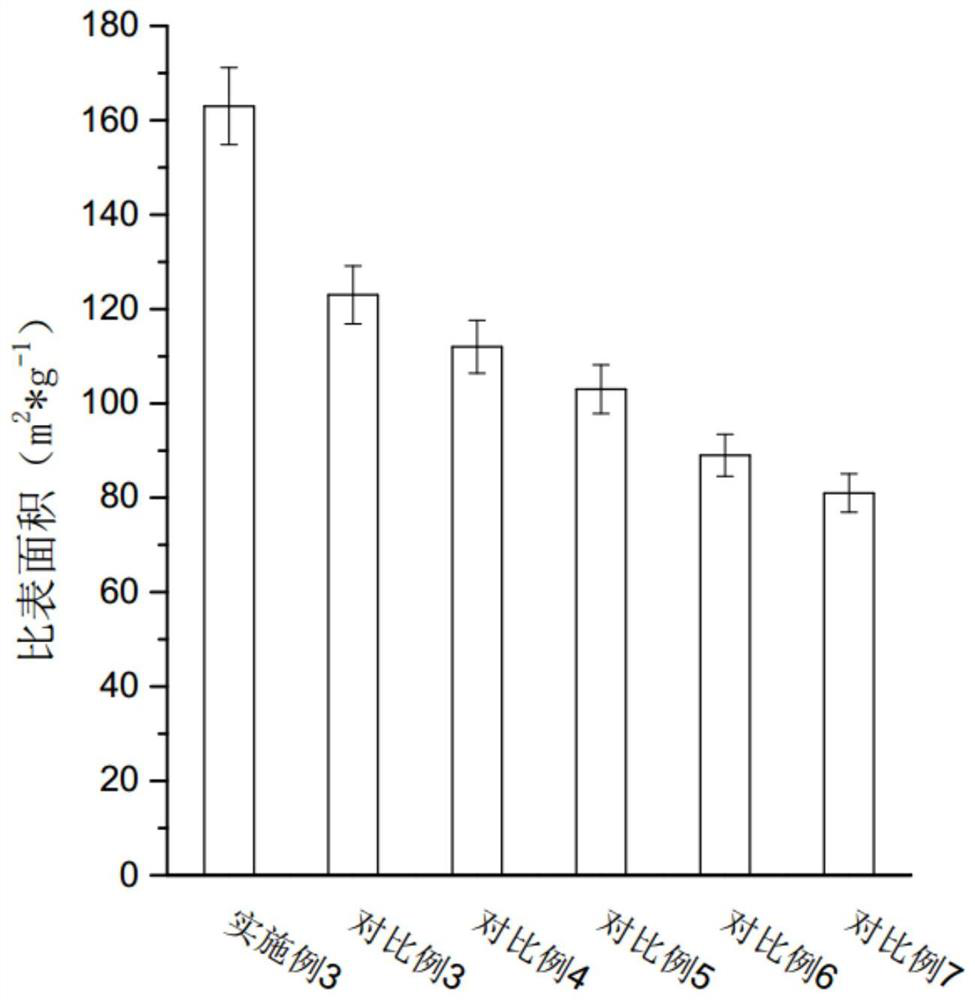

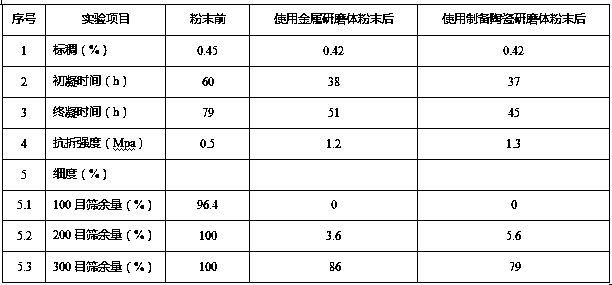

Preparation method of ceramic grinding body for gypsum grinding

The invention discloses a preparation method of a ceramic grinding body for gypsum grinding. The preparation method comprises the following steps of a, selecting the powder, using BaO (barium oxide),TiC (titanium carbide), Mo2C (molybdenum carbide), ZrO2 (zirconium dioxide), Cr2C3 (Chromium carbide) and TaC (tantalum carbide) as the raw materials, preparing acetic acid with concentration of 80% to 90% as a solvent, pouring into the raw materials, mixing with the raw materials, fully impregnating for 3 to 6h, mixing, and controlling the time within 0.5h, so as to obtain a grinding medium; b, drying the raw materials in step a, mixing with coke, selecting spheres, and fully grinding, wherein the ratio of spheres to material is 3:5, the rotation speed of sphere grinding is 300 to 450rpm, andthe duration of sphere grinding is 30 to 48h; c, screening the mixture after sphere grinding, wherein the sieve hole is 50 to 150 meshes; d, putting the screened mixture into a die, and pressing intothe blank at the pressure of 350 to 550MPa; e, heating the fetched blank, cooling the heated and formed blank, cutting after cooling, grinding and polishing. The prepared grinding body has higher hardness and longer service life.

Owner:FOSHAN HUAQIANG XIEXING CERAMIC CO LTD

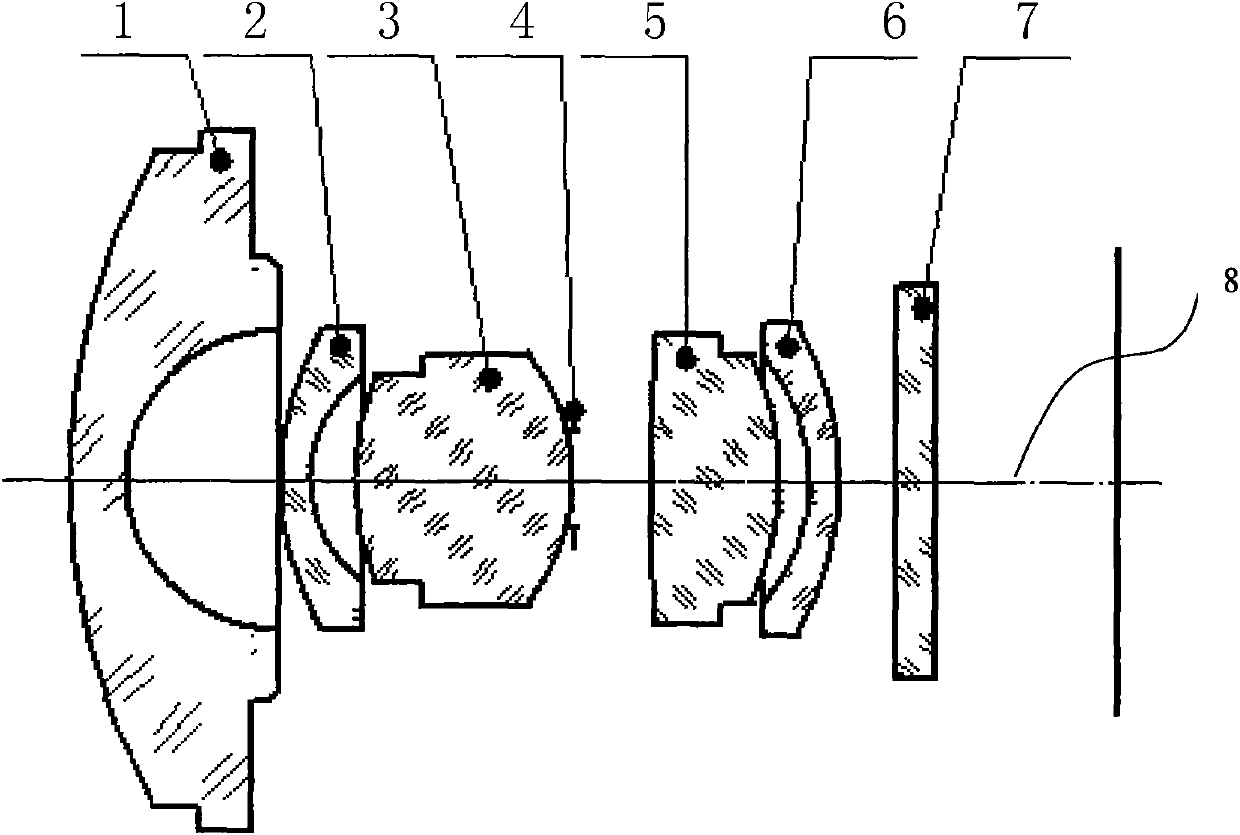

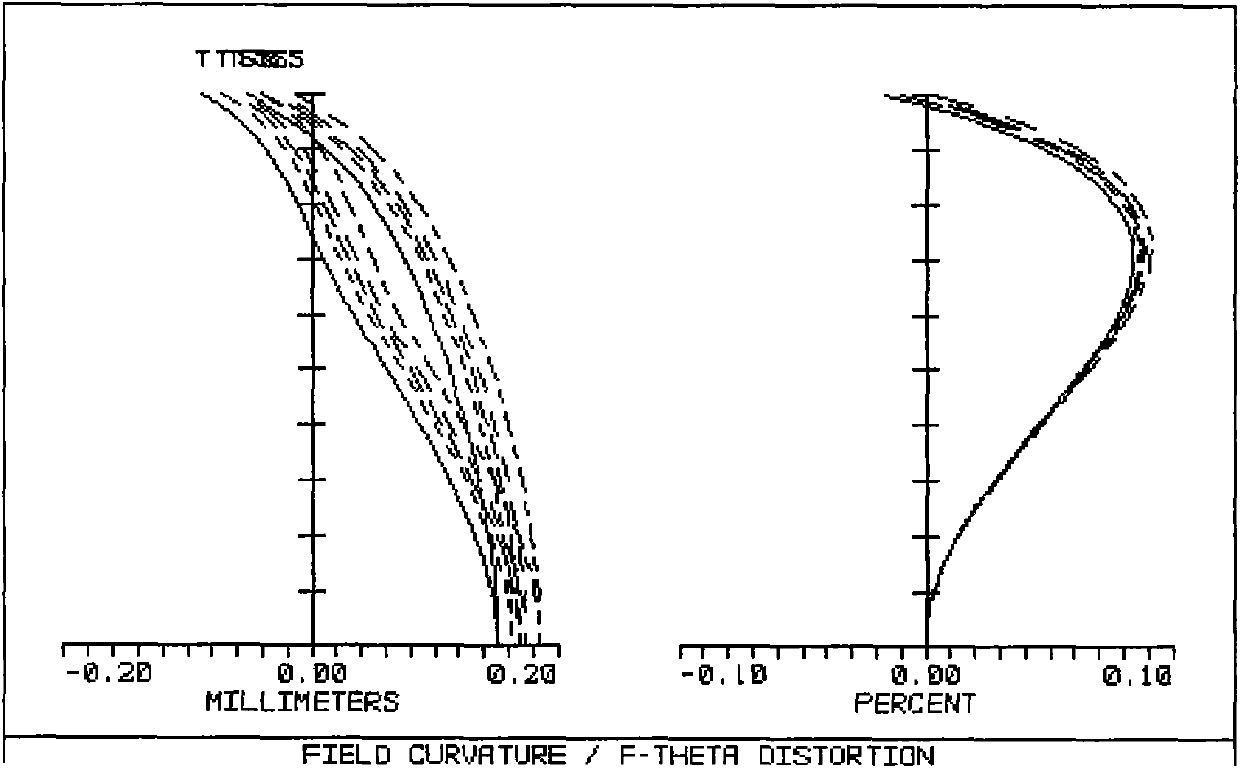

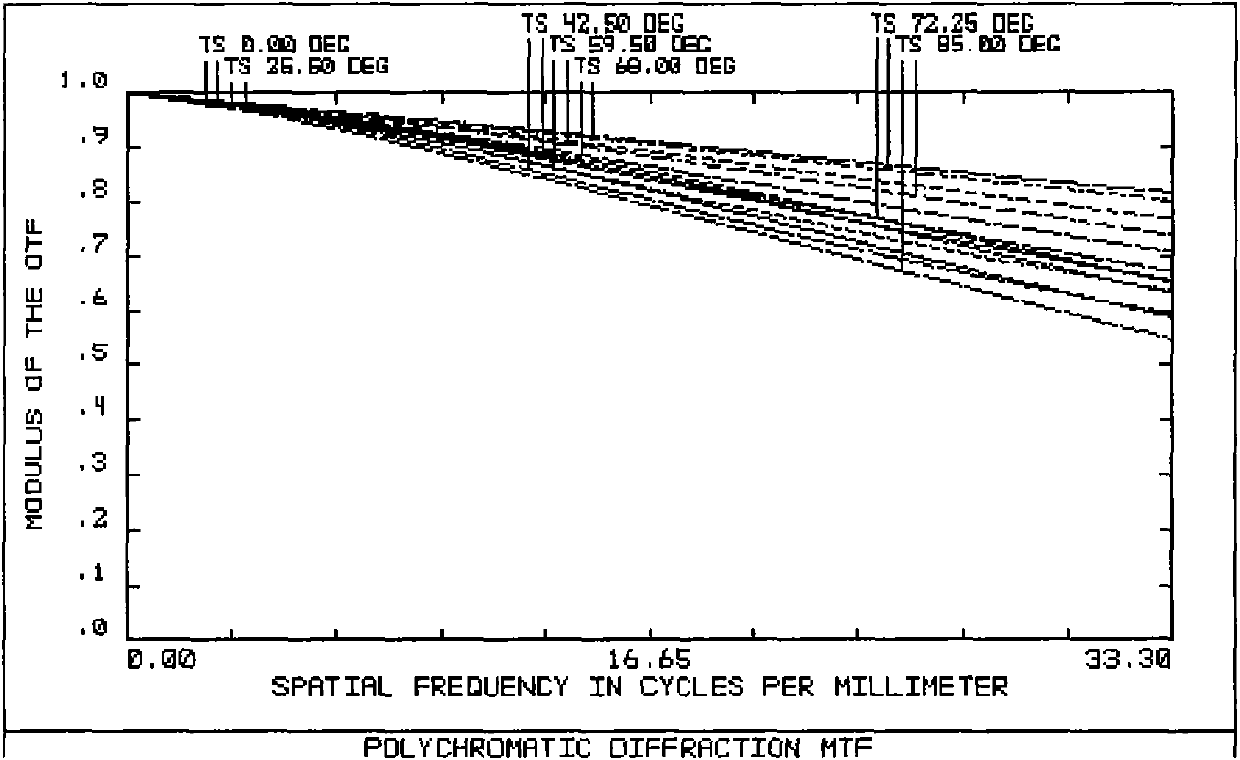

Ultralow distortion nearly-hemispherical viewing field antistatic adsorption optical system

The invention relates to an ultralow distortion nearly-hemispherical viewing field antistatic adsorption optical system. The optical system comprises a first negative lens, a second negative lens, a first positive lens, a diaphragm, a second positive lens and a third negative lens which are arranged on the same optical path sequentially. The ultralow distortion nearly-hemispherical viewing field antistatic adsorption optical system has a wide adaptation range and a nearly-hemispherical viewing field, is favorable for correcting system aberration, has lower f-theta distortion and more uniform illuminance of an image plane, can effectively reduce static adsorption dust and does not have vignetting.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Ceramic Grinding Body for Gypsum Grinding

The invention provides a ceramic grinding body for gypsum, which is mainly prepared from the following raw material components, Al2O3: 62%~83%, SiO2: 5%~8%, Cr2O3: 0.5%~1.8%, TiO2: 1%~ 1.45%, MnO: 1.51%~1.75%, ZrO2: 1.6%~3.4%, BaO: 1%~3%, Solitaire: 4.6%~7%, ZnO: 2%~2.8%, nano colloidal silicon: 0.5%~1.1%, co-solvent 2%~6%. The ceramic grinding body for gypsum milling of the present invention has light weight and low wear rate, can greatly reduce grinding energy consumption, prolong the service life of the grinding body, and reduce costs; there is no impurity metal iron ion doping in the grinding process, and the quality of building gypsum powder is not affected. Whiteness and strength; ceramic grinding body can also reduce electrostatic adsorption, which is beneficial to improve grinding efficiency.

Owner:UNIV OF JINAN

Medicament composition containing paracetamol and pseudoephedrine hydrochloride and preparation method thereof

InactiveCN101467988BImprove liquidityGood compressibilityOrganic active ingredientsAntiviralsPseudoephedrine HydrochlorideCompressibility

The invention discloses a stable pharmaceutical composition and method for preparing same. The composition contains acetaminophen, pseudoephedrine hydrochloride and pharmaceutically acceptable accessories capable of improving disadvantages such as bad fluidity and compressibility, and electrostatic absorption during the production of acetaminophen which is suitable for industrialized production.

Owner:北京德众万全医药科技有限公司

A modified nanomaterial and its application in antimony-containing wastewater treatment

ActiveCN110813251BAdd carboxyl groupIncrease electrostatic adsorptionOther chemical processesWater contaminantsSorbentPolyethylene glycol

The invention provides a modified nano-material and its application in the treatment of antimony-containing wastewater, belonging to the technical field of environmental protection. The modified nano-material includes nano-zero-valent iron and a stabilizer; wherein, the stabilizer is selected from starch, polyethylene One of the diols, the stabilizer is modified with EDTA or EDTA and malic acid. The nanomaterial can reduce CO 3 2‑ with PO 4 3‑ OH produced by hydrolysis in aqueous solution ‑ with Sb(OH) on the adsorbent surface 6‑ Produce competitive adsorption and improve the removal effect on Sb(V). The present invention also provides a method for preparing iron-based nanomaterials, which can increase the specific surface area of the loaded material, increase the -COOH or -OH on the surface of the loaded material, increase the adsorption sites of the loaded material to antimony, and is green and environmentally friendly , The characteristics of cost reduction.

Owner:YIYANG SHENGLI CHEM IND

Ceramic grinding body for gypsum mill

The invention provides a ceramic grinding body for a gypsum mill. The ceramic grinding body for the gypsum mill is mainly prepared from 62%-83% of Al2O3, 5%-8% of SiO2, 0.5%-1.8% of Cr2O3, 1%-1.45% of TiO2, 1.51%-1.75% of MnO, 1.6%-3.4% of ZrO2, 1%-3% of BaO, 4.6%-7% of datolite, 2%-2.8% of ZnO, 0.5%-1.1% of nano-colloidal silica and 2%-6% of cosolvent. The ceramic grinding body for the gypsum mill is small in self-weight, low in wear rate and capable of substantially reducing grinding energy consumption and reducing cost, and the service life of the grinding body can be prolonged; no impurity metal iron ion is doped in the grinding process, and thus no influence is caused to the whiteness or strength of building gypsum powder; the ceramic grinding body is also capable of reducing electrostatic adsorption, and thus grinding efficiency is easily improved.

Owner:UNIV OF JINAN

A kind of preparation method of ceramic grinding body for gypsum mill

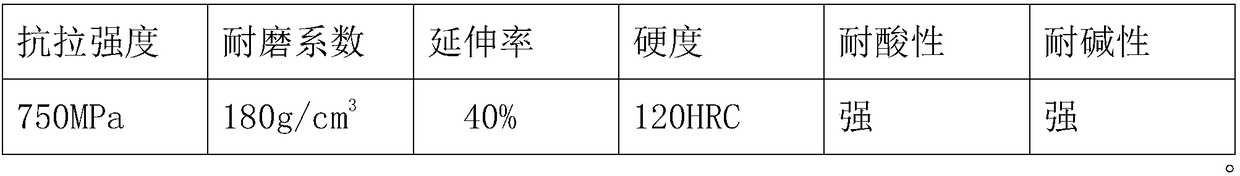

InactiveCN105669168BReduce electrostatic adsorptionExtended service lifeUltimate tensile strengthEnergy consumption

Owner:UNIV OF JINAN

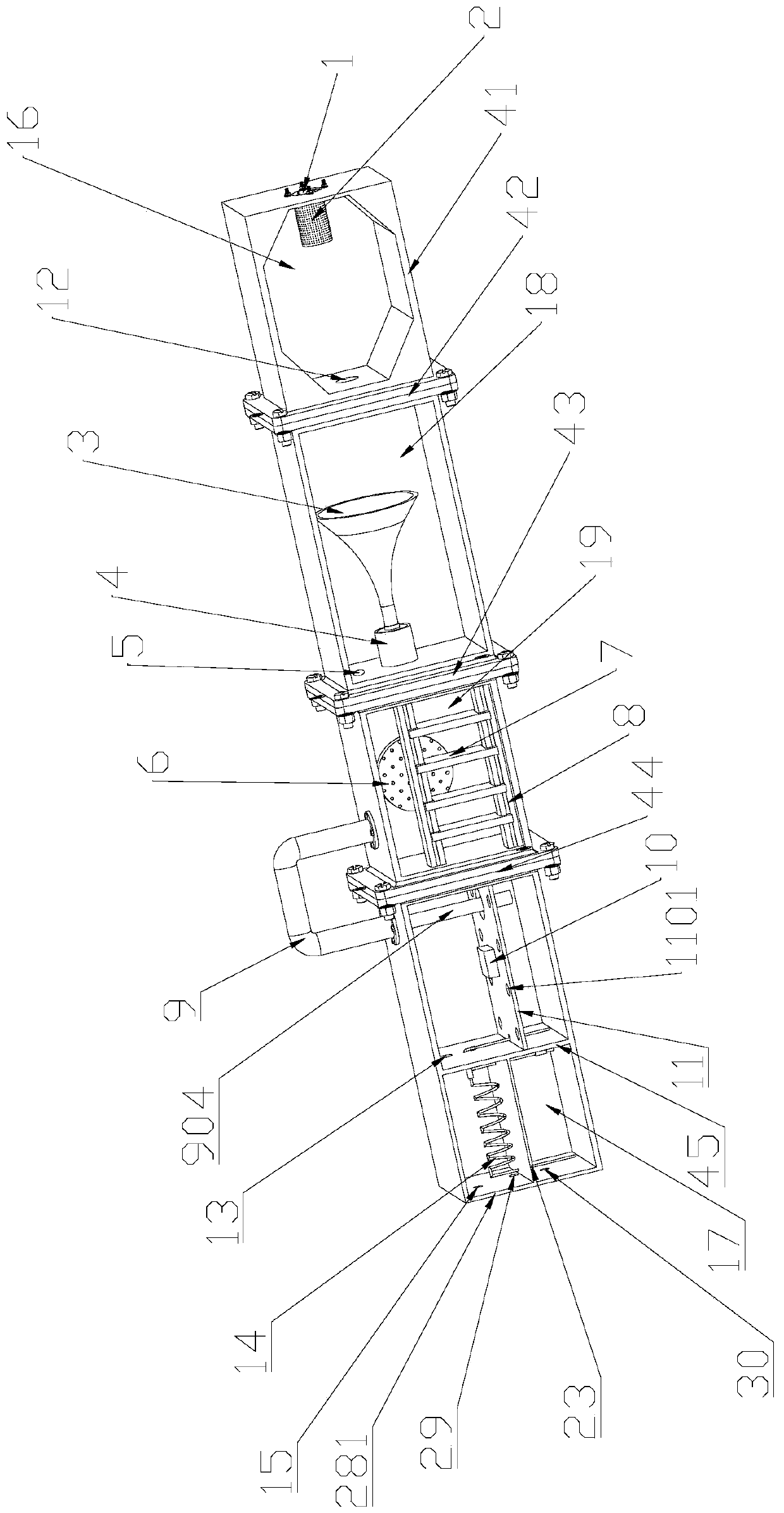

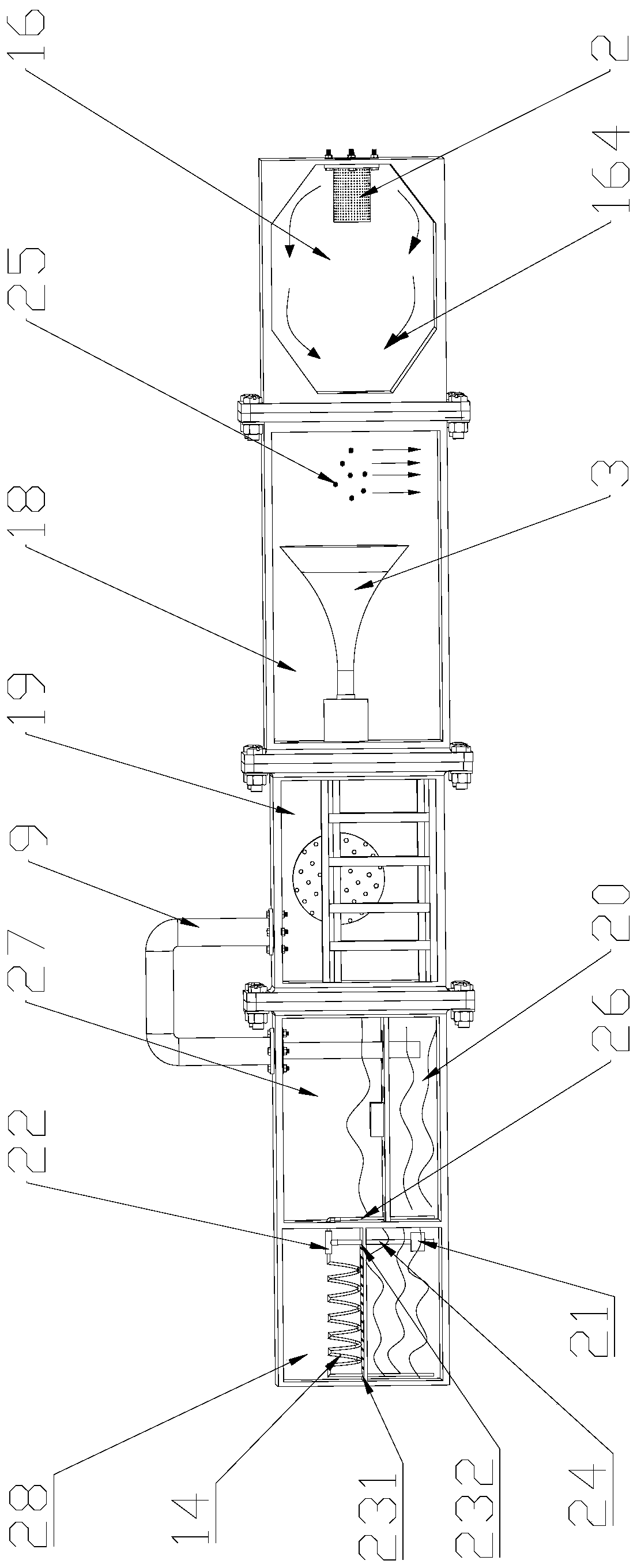

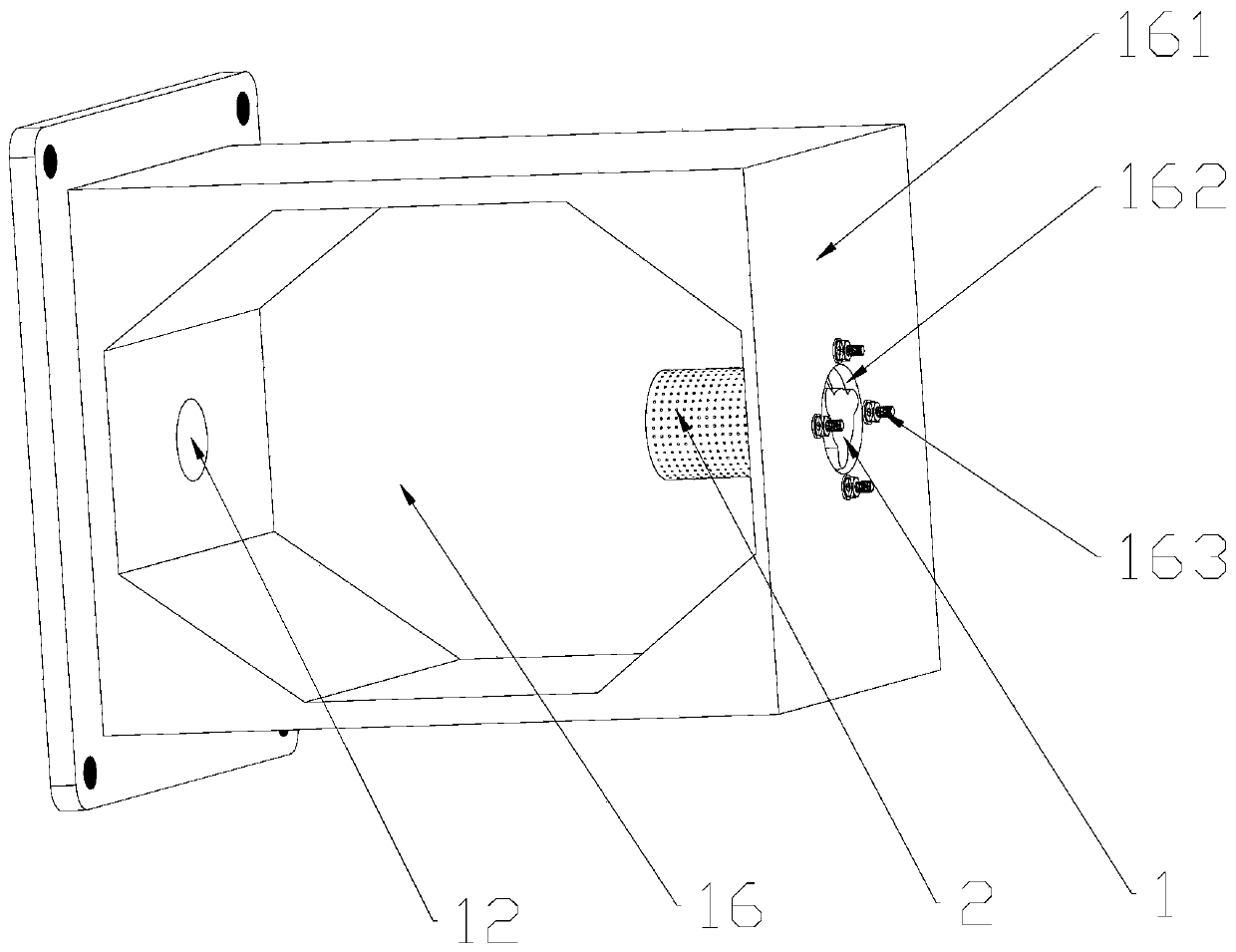

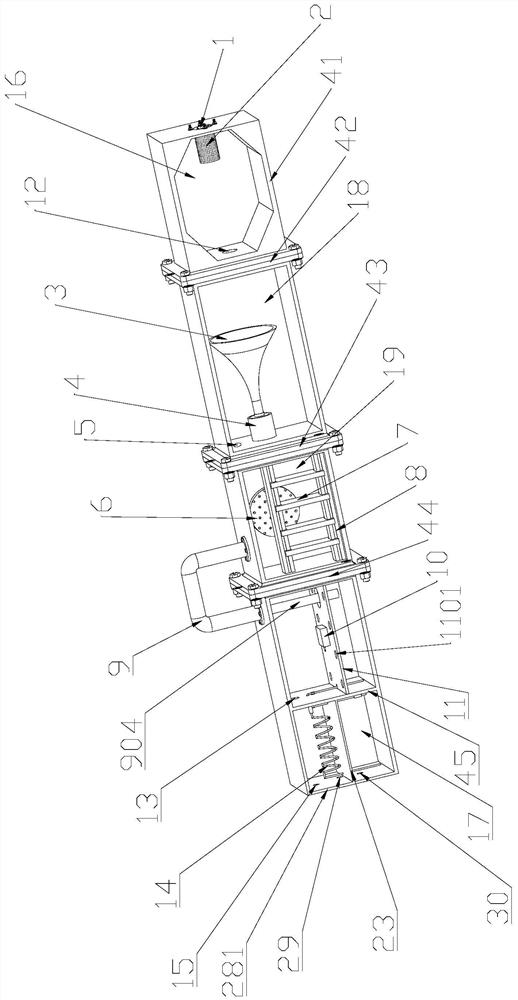

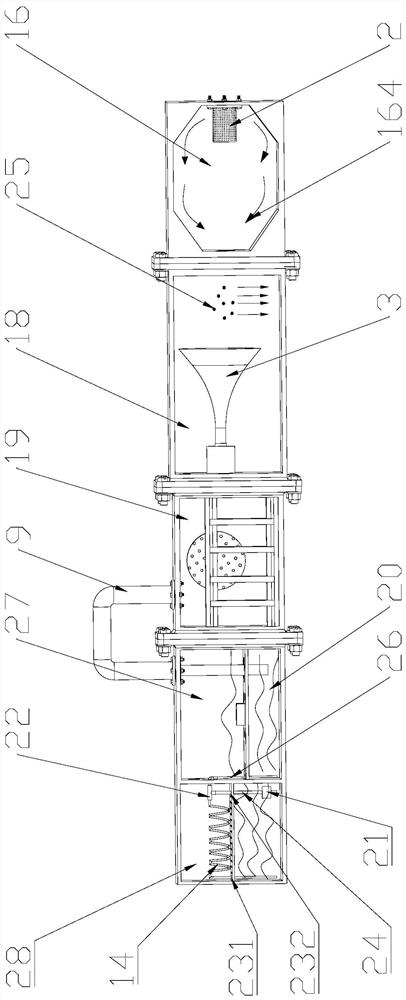

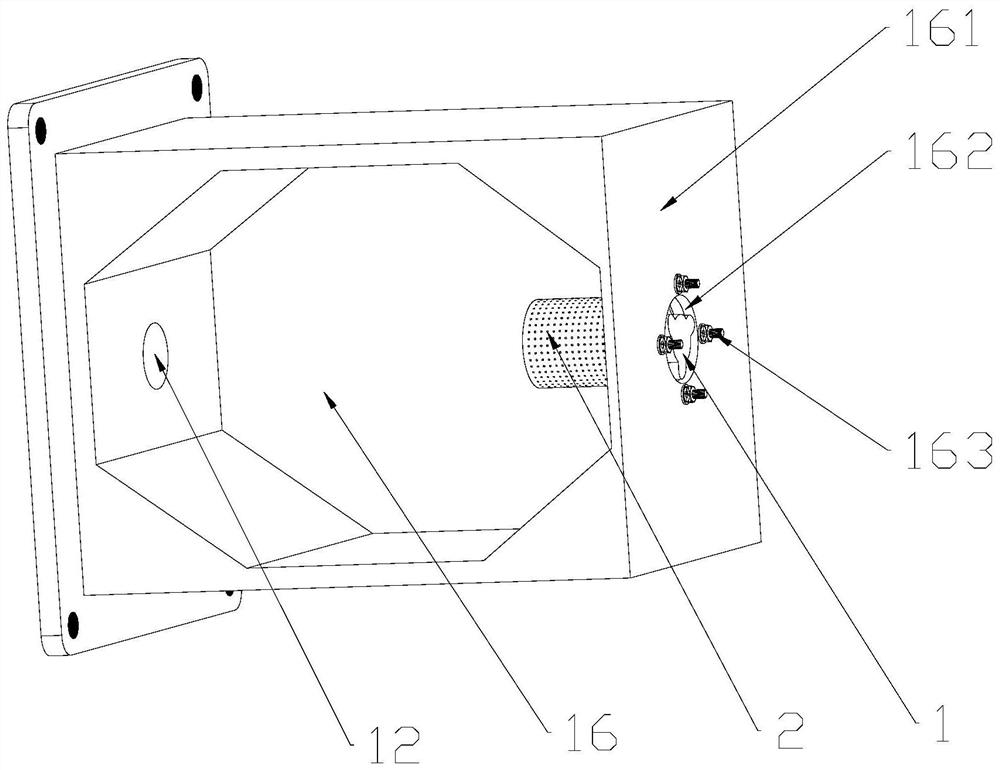

Dust removal method based on agglomeration, static electricity and ultrasonic atomization technologies

ActiveCN111195469AImprove implementation efficiencyEasy to operateCombination devicesEngineeringSound wave

The invention relates to the technical field of air dust removal and purification, and provides a dust removal method based on agglomeration, static electricity and ultrasonic atomization technologies, which uses an agglomeration, static electricity and ultrasonic atomization dust removal device, removes large-particle and small-particle impurities in air through acoustic agglomeration, static electricity dust removal and ultrasonic atomization technologies, and has the characteristics of high implementation efficiency and simple operation. The agglomeration, static electricity and ultrasonicatomization dust removal device is used; large-particle impurities in the air are agglomerated into agglomerated particles to form dust fall by at least utilizing sound waves generated by a whistle; the corona ball discharges to form an electrostatic field, so that fine impurities in the air are negatively charged and are adsorbed by the positively charged dust collection polar plate to remove dust, the air is washed by water to remove water-soluble fine impurities in the air, and fine particles which cannot be seen by naked eyes are condensed by fine water drops formed by ultrasonic atomization to remove dust.

Owner:NANJING FORESTRY UNIV

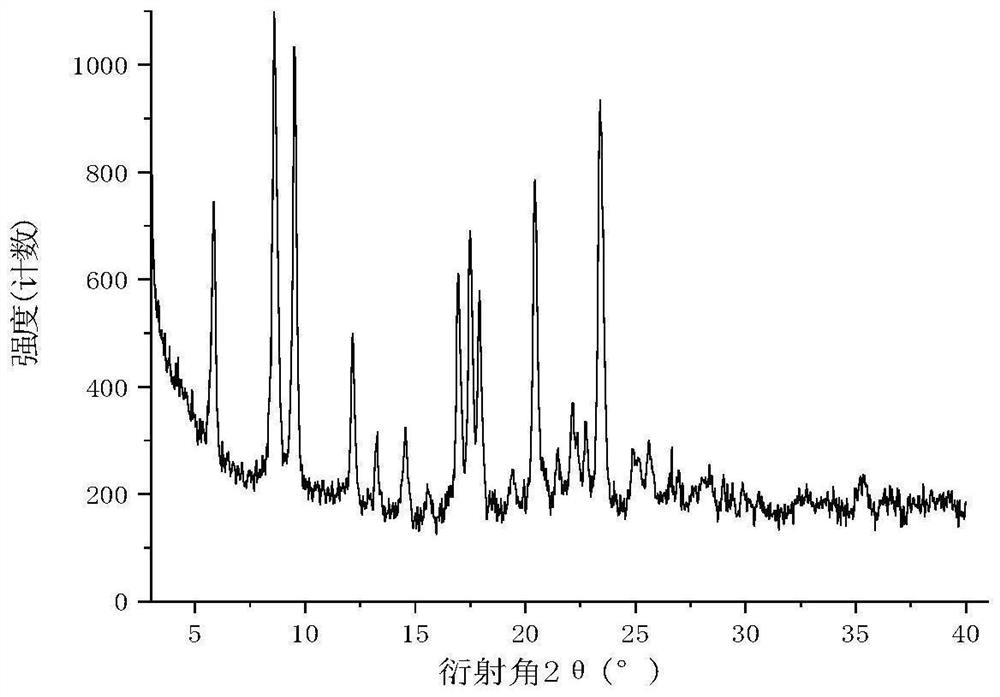

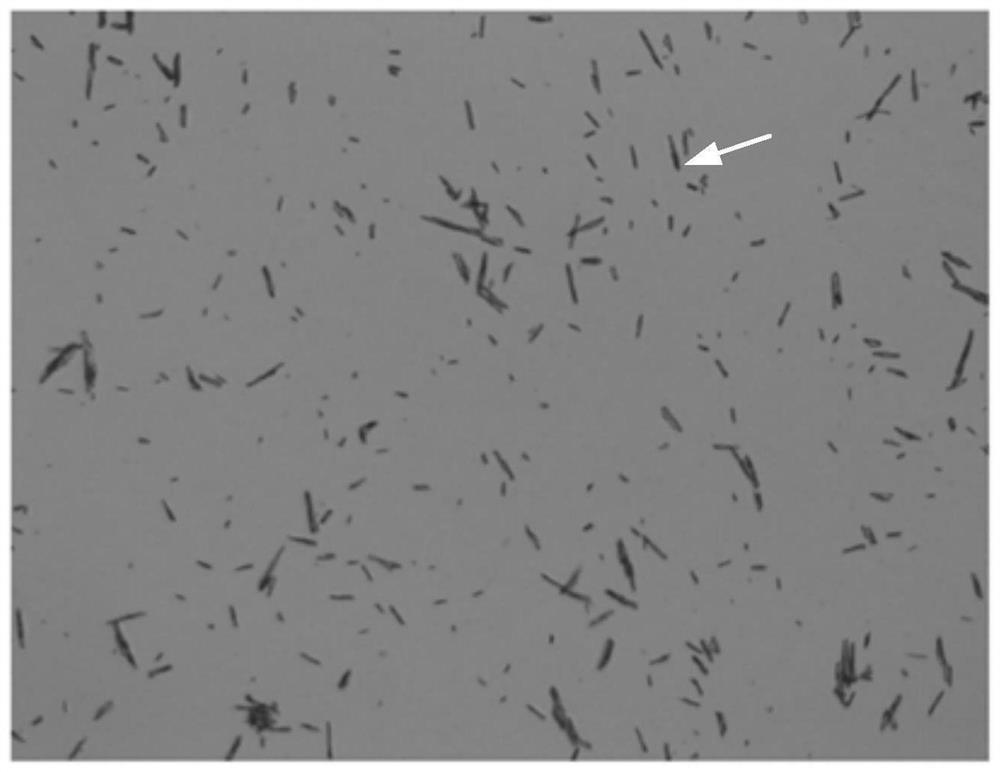

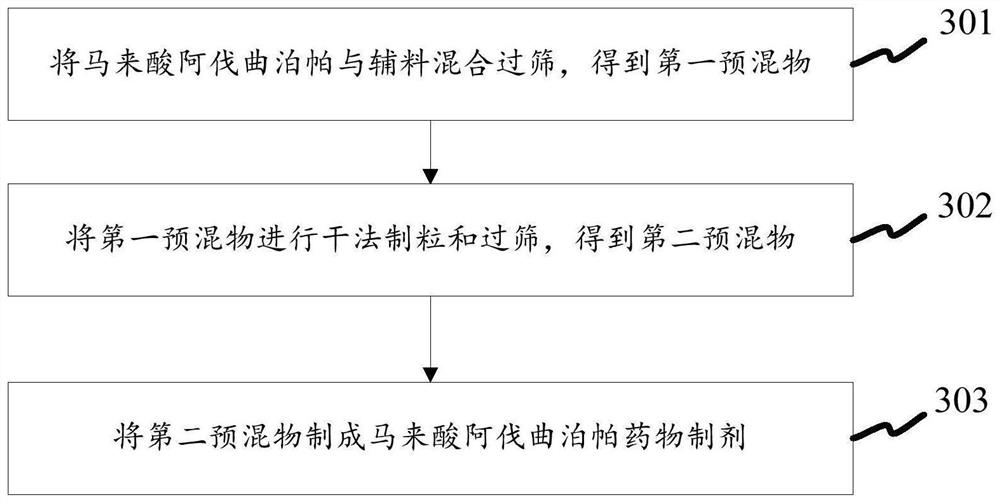

Avantrombopag maleate pharmaceutical preparation as well as preparation method and application thereof

PendingCN114712359AImprove solubility and stabilityExcellent Oral AbsorptionOrganic active ingredientsPowder deliveryComposite materialDrugs preparations

The invention discloses an atavalopag maleate pharmaceutical preparation as well as a preparation method and application thereof, relates to the technical field of medicines, and aims to solve the problems that the atavalopag maleate is poor in dissolution rate and is not suitable for large-scale production of pharmaceutical preparations. The crystal form of the acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike acicular or rodlike The preparation method is used for preparing an atavalopag maleate pharmaceutical preparation. The acavalopag maleate pharmaceutical preparation as well as the preparation method and the application thereof provided by the invention are used for producing an acavalopag maleate solid preparation.

Owner:SHANGHAI FOSUN PHARMA DEV CO LTD

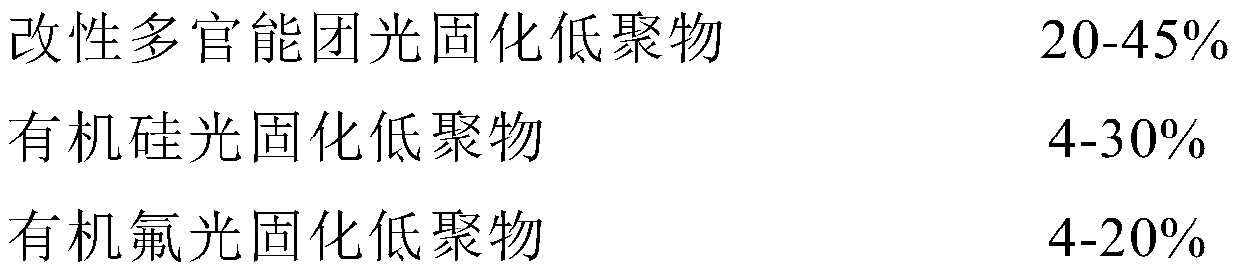

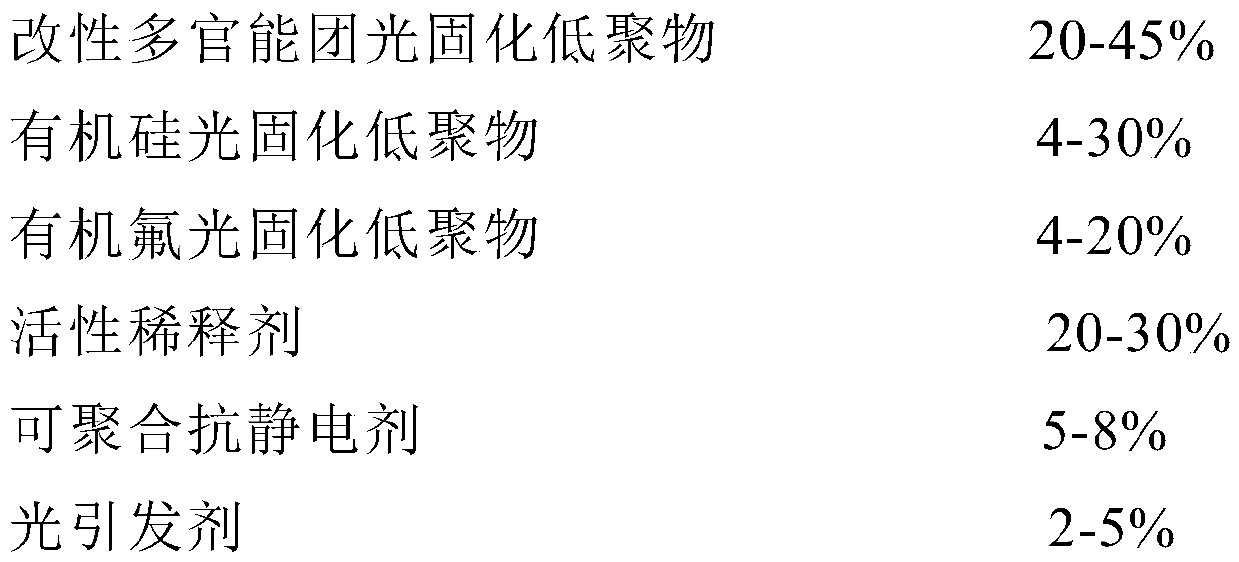

Multifunctional UV-curable coating

InactiveCN108977010BReduce surface resistanceImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceOligomer

The invention provides a multifunctional ultraviolet curing coating which is composed of the following raw materials in percentage by mass: 20 to 45% of modified multi-functional groups photocurable oligomer, 4 to 30% of organic silicone photocurable oligomer, 4 to 20% of organic fluorine photocurable oligomer, 20 to 30% of a reactive diluent, 5 to 8% of a polymerizable antistatic agent, and 2 to5% of a photoinitiator. The multifunctional ultraviolet curing coating of the invention has the advantages of long-lasting self-cleaning, anti-fouling, weather resistance, aging resistance, scratch resistance and the like, which prevents the existing ultraviolet curing coating from the deficiency adhesion to the substrate and easy peeling due to excessive additives.

Owner:BEIJING UNIV OF CHEM TECH

A dust removal method based on agglomeration, electrostatic and ultrasonic atomization technology

ActiveCN111195469BImprove implementation efficiencyEasy to operateCombination devicesSound waveUltrasonic atomization

The invention relates to the technical field of air dust removal and purification, and provides a dust removal method based on agglomeration, electrostatic and ultrasonic atomization technology, which uses agglomeration, electrostatic and ultrasonic atomization dust removal device, and clears the air through sound wave agglomeration, electrostatic dust removal and ultrasonic atomization technology Large and small particles of impurities in the air have the characteristics of high implementation efficiency and simple operation; it uses agglomeration, electrostatic and ultrasonic atomization dust removal device, at least uses the sound waves generated by the flute to reunite the larger particles of impurities in the air into agglomerated The particles form dust, and use the corona ball discharge to form an electrostatic field to make the fine impurities in the air negatively charged and be adsorbed by the positively charged dust collecting plate to remove dust, and use water to wash the dust to clean the air to remove soluble particles in the air. For the fine impurities in the water, the fine water droplets formed by ultrasonic atomization will condense the fine particles invisible to the naked eye to remove dust.

Owner:NANJING FORESTRY UNIV

An all-cotton composite functional fabric with waterproof, oil-repellent and anti-fouling properties

ActiveCN104404787BGood skin affinityGood dimensional stabilityStain/soil resistant fibresPhysical treatmentGas phaseEngineering

The invention discloses an all-cotton composite functional fabric with water-proof, oil-proof and antifouling properties; the all-cotton composite functional fabric includes a composite fabric having a surface layer and an inner layer, the surface layer is a machine-woven fabric layer, and the inner layer is a knitted fabric layer; the composite fabric is subjected to a pretreatment process by a cellulase and low-temperature oxygen plasma combination way; then a 'double-nano' finishing agent is applied to the fabric surface by using a physical vapor deposition method, a layer of thin film with 'three protection' function is formed on the fabric surface; the 'double-nano' finishing agent is a mixture of nano fluoride and ceramic powder nano particles. The composite functional fabric is pretreated by the cellulase and low-temperature oxygen plasma combination way, neps and impurities on the fabric surface are removed, the fabric softness is increased, and a final using effect is improved; and at the same time, with combination of the low-temperature plasma treatment process, and through the etching effect of plasma, the combination fastness of the finishing agent with the fabric surface is greatly improved, and the durability of functional finishing is improved.

Owner:SWOTO PROTECTION & TECH CO LTD

Digital PCR chip and method based on surfactant-modified PDMS

ActiveCN106755420BChange surface propertiesReduce adsorptionMicrobiological testing/measurementPcr chipBio molecules

The invention relates to a digital PCR chip based on surfactant modified PDMS, a preparation method and application. The digital PCR chip is characterized in that the digital PCR chip is a PDMS digital PCR array chip prepared by a PDMS material doped by a certain amount of a surfactant; sampling and distributing processes are realized by means of a high air dissolution characteristic of the pre-degassing thin type PDMS chip, and a sandwiched structure of glass-modified PDMS-glass is prepared to inhibit water volatilization. According to a design method of the chip, electrostatic adsorption of PDMS on biological molecules is reduced, and the stability and the volatility resistance of liquid drops are effectively improved, so that the amplification efficiency of PCR is improved. Moreover, compared with a reported digital PCR chip at present, the digital PCR chip is low in cost, simple to operate and quite wide in application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Photocatalytic long-acting stain-resistant elastic acrylate emulsion and preparation method thereof

InactiveCN111333772AReduce adverse effectsAvoid damageAntifouling/underwater paintsPaints with biocidesPhosphoric Acid EstersPolymer science

The invention discloses a photocatalytic long-acting stain-resistant elastic acrylate emulsion and a preparation method thereof. The photocatalytic long-acting stain-resistant elastic acrylate emulsion comprises the following raw materials: styrene, alkyl methacrylate, alkyl acrylate, a functional monomer, an initiator, an emulsifier, deionized water and ammonia water. The preparation method comprises the following steps: step a, preparing a backing material liquid; step b, preparing pre-emulsified liquid; step c, dropwise adding the pre-emulsified liquid to react; and step d, after finishingof the reaction, preserving heat, adjusting the pH value, and performing discharging. According to the invention, the reactive emulsifier is compounded with the phosphate salt, such that emulsifier migration and surface charges are reduced, and coating film adhesion resistance is improved. The compactness of a coating film can be effectively enhanced by reasonably matching the functional monomer and the photoinitiator, permanent damage caused by dust permeation is reduced, and the decorative service life of the coating film is prolonged.

Owner:广东巴德富新材料有限公司

Antistatic nano self-cleaning coating for glass and antistatic nano self-cleaning glass prepared therefrom

ActiveCN107057417BImprove hydrophilicitySuperhydrophilicElectrically-conductive paintsHydrothermal synthesisUltrasonic dispersion

The invention relates to a self-cleansing coating, in particular to a nanometer antistatic self-cleansing coating for glass and nanometer self-cleansing glass prepared from the nanometer antistatic self-cleansing coating for the glass, and belongs to the technical field of functional film manufacturing. A preparation method of the nanometer antistatic self-cleansing coating for the glass includes the steps of (1), preparing a nanometer titanium dioxide crystal sol water solution, namely mixing titanium dioxide sol with water to form titanium dioxide gel, subjecting the titanium dioxide gel to hydrothermal synthesis to obtain nanometer titanium dioxide crystal gel, and dispersing titanium dioxide crystals into the water so as to form the nanometer titanium dioxide crystal sol water solution; (2), preparing an ATO nanometer crystal sol water solution; (3), mixing the nanometer titanium dioxide crystal sol water solution with silicon dioxide sol prior to ultrasonic dispersion, and regulating a pH value of the system to 6-10 with an alkaline solution so as to obtain a self-cleansing coating precursor; (4), mixing the ATO nanometer crystal sol water solution with the self-cleansing coating precursor prior to ultrasonic dispersion, and stirring sufficiently to obtain the nanometer antistatic self-cleansing coating.

Owner:浙江鼎昇新材料科技股份有限公司

A kind of concrete piston and its raw material preparation method

InactiveCN104895780BExtended service lifeReduce electrostatic adsorptionPositive displacement pump componentsLiquid fuel engine componentsRubber materialFiber

The invention relates to a concrete piston and a method for preparing raw materials thereof. The rubber material for the concrete piston comprises the following components according to weight percentage: 100 parts of NBR, 5-8 parts of ZnO, 1 part of SA, 1-3 parts of anti-aging agent, Carbon black 30-40 parts, white carbon black 25-35 parts, fiber 2-4 parts, plasticizer 1.5 parts, tackifying resin 2-4 parts, adhesive RS 4-7 parts, adhesive A 1- 2 parts, sulfur 1-1.5 parts, accelerator 2.5-3.5 parts. It has good high temperature resistance, hydrolysis resistance, wear resistance and tear resistance, reduces the friction coefficient, increases the service life and improves the working efficiency of the equipment.

Owner:QINGDAO TKS SEALING IND

Macromolecular nano coating material composite slurry

InactiveCN101081947BHigh hiding powerShorten the production cycleCoatingsSodium BentoniteKaolin clay

The present invention relates to one kind of nanometer composite polymer paint slurry, which consists of water 30 wt%, dispersant 0.6 wt%, nanometer polymer assistants 1 wt%, sodium bentonite 2 wt%. heavy calcium carbonate 45 wt%, wollastonite 10 wt%, kaolin 10 wt% and titanium white powder 0-5 wt%, where, the nanometer polymer assistants includes aluminum sulfate 20 wt%, sodium silicate 50 wt%, pentaerythritol 20 wt%, hydroxypropyl methyl cellulose 2.5 wt% and sodium fluosilicate 7.5 wt%. The nanometer composite polymer paint slurry has the crystal structure of the components maintained and narrow size distribution, and can form coating with fire resistance, no smoke in fire, high adhesion to inorganic base material and other advantages.

Owner:赵玉洪

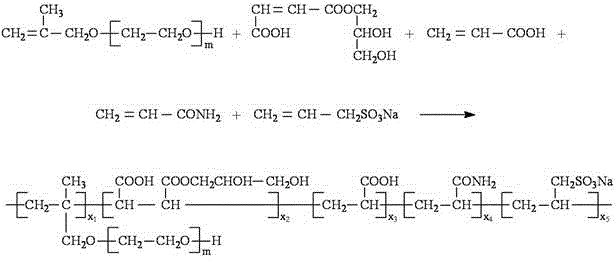

A kind of multiple copolymer cement grinding aid and preparation method thereof

ActiveCN103664040BChange physical propertiesImprove grinding effectPolymer chemistrySodium hydroxide

The invention discloses a multipolymer cement grinding agent and a preparation method, and belongs to the technical field of cement grinding agents. The cement grinding agent is prepared through the following steps: mono-esterification is performed on maleic anhydride and glycerin, then the maleic anhydride and the glycerin copolymerize with TPEG, crylic acid, sodium allylsulfonate and acrylamide under the effect of the molecular chain transfer agent isopropanol by using hydrogen peroxide and ammonium ferrous sulfate as initiators, the polymerization product is neutralized until the pH is 7.5 by using triisopropanolamine and sodium hydroxide respectively, the solid content of the product is ensured to be 57-63%, and the molecular weight of the product is 5,000-10,000. The multipolymer cement grinding agent is low in cost and good in stability, the grinding effect and cement quality are improved obviously, waste gas, waste water and waste residue are not discharged during the synthetic process, and the multipolymer cement grinding agent has a good market prospect and economic benefits.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com