Multifunctional UV-curable coating

An ultraviolet light and multi-functional technology, applied in coatings, conductive coatings, polyester coatings, etc., can solve the problems of reduced adhesion between coatings and substrates, poor adhesion, insufficient durability, etc., to avoid Decreases coating adhesion, reduces surface resistance, and improves anti-fouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]In the multifunctional UV-curable coating according to the present invention, the preparation method of the nano-silica / hexafunctional urethane acrylate hybrid copolymer includes the steps: (1) at a temperature of 105-110°C and a vacuum degree of 0.08- Under the condition of 0.1MPa, after heating and drying dipentaerythritol for 3-4 hours, cool to 80-90° C. to obtain pretreated dipentaerythritol; (2) in molar parts, 100 parts of pretreated Put dipentaerythritol and 1-3 parts of catalyst into the reaction container together, after stirring evenly, add 600 parts of isophorone diisocyanate in molar parts in batches, keep stirring, and react 2- 3 hours, to obtain the pre-reaction base liquid; (3) in parts by mole, in the pre-reaction base liquid described in step (2), under the state of keeping stirring, add 10-20 parts of nano silicon dioxide, keep the temperature 80-90°C, react for 2-3 hours to obtain the grafting reaction base liquid; (4) in molar fractions, to the grafti...

Embodiment 1

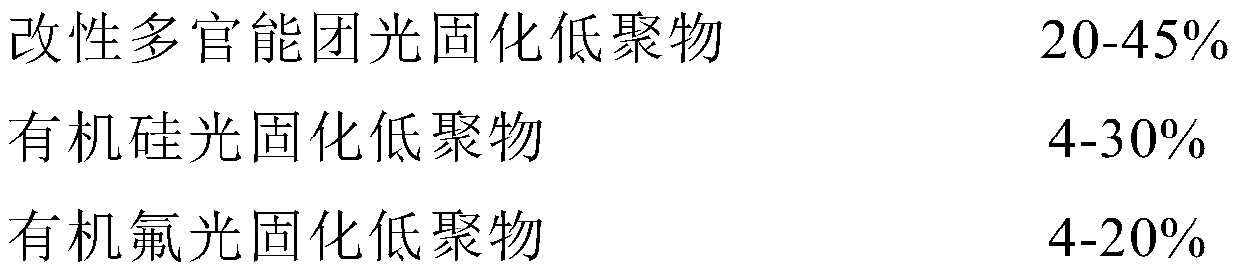

[0052] Multifunctional UV-curable coating, composed of the following raw materials in mass percentage:

[0053]

[0054] The preparation method of nano-silica / hexafunctional urethane acrylate hybrid copolymer comprises steps: (1) under the conditions of temperature 105°C and vacuum degree 0.08MPa, dipentaerythritol was heated and dried for 3 hours, then cooled to 80°C to obtain the prepared Treated dipentaerythritol; (2) in molar fractions, 100 parts of pretreated dipentaerythritol and 1 part of catalyst described in step (1) are put into the reaction vessel together, after stirring evenly, add 600 molar fractions in batches Parts of isophorone diisocyanate, stirring constantly, reacted for 2 hours at a temperature of 60°C to obtain a pre-reaction base liquid; (3) in parts by mole, to the pre-reaction base liquid described in step (2) , under the state of keeping stirring, add 10 parts of nano-silica, keep the temperature at 80° C., react for 2 hours, and obtain the graftin...

Embodiment 2

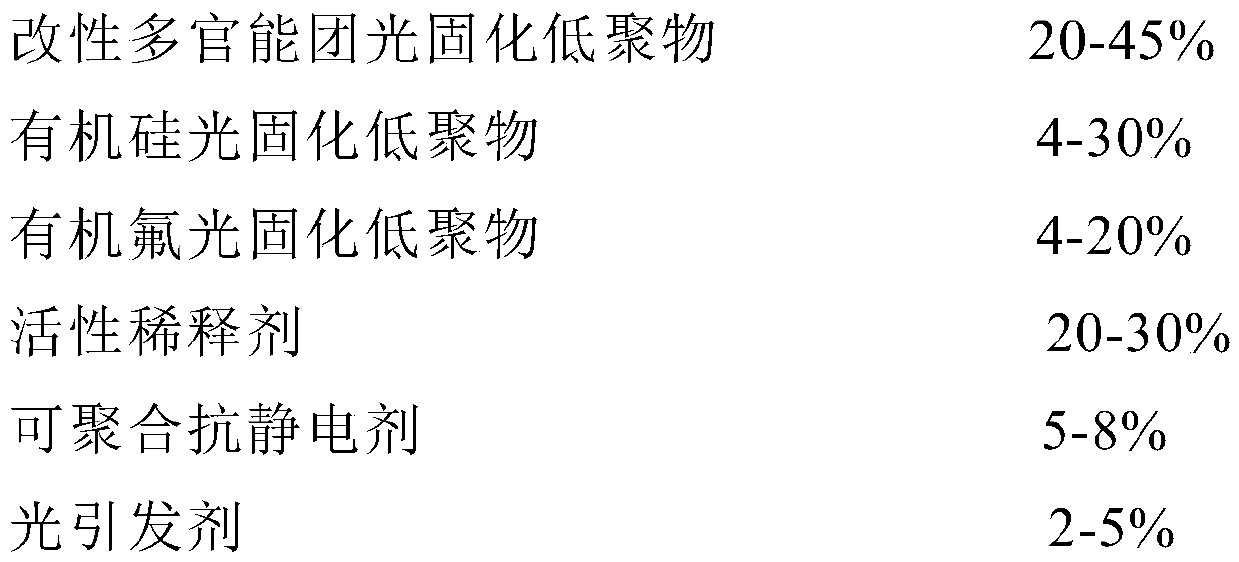

[0057] Multifunctional UV-curable coating, composed of the following raw materials in mass percentage:

[0058]

[0059]

[0060] The preparation method of nano-silica / hexafunctional urethane acrylate hybrid copolymer comprises the steps: (1) heating and drying dipentaerythritol for 4 hours at a temperature of 110° C. and a vacuum of 0.1 MPa, and then cooling to 90° C. to obtain the prepared Treated dipentaerythritol; (2) in molar fractions, 100 parts of pretreated dipentaerythritol and 3 parts of catalysts described in step (1) are put into the reaction vessel together, after stirring evenly, add 600 molar fractions in batches Parts of isophorone diisocyanate, stirring constantly, reacted for 3 hours at a temperature of 70°C to obtain a pre-reaction base liquid; (3) in parts by mole, to the pre-reaction base liquid described in step (2) , under the state of keeping stirring, add 20 parts of nano-silica, keep the temperature at 90° C., and react for 3 hours to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com