Antistatic protective film and manufacturing method thereof

A protective film, anti-static technology, applied in conductive adhesives, film/sheet adhesives, adhesives, etc., can solve the requirements that can not meet the anti-static performance of protective films, the curing difficulties of protective film products, platinum catalysts Poisoning and other problems, to achieve good electrostatic conduction performance, better adhesion, and less adhesion climb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

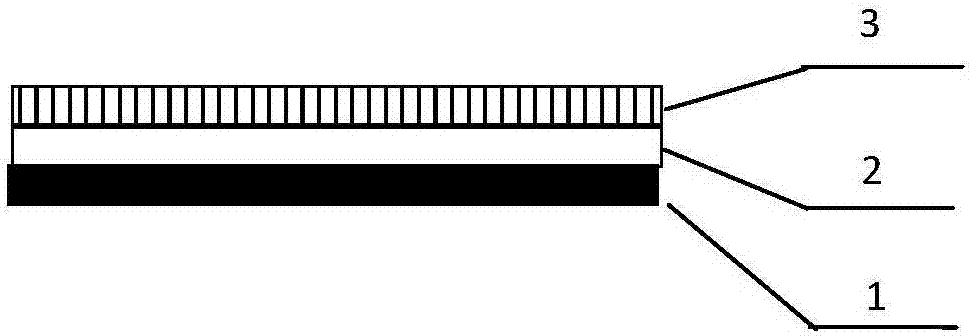

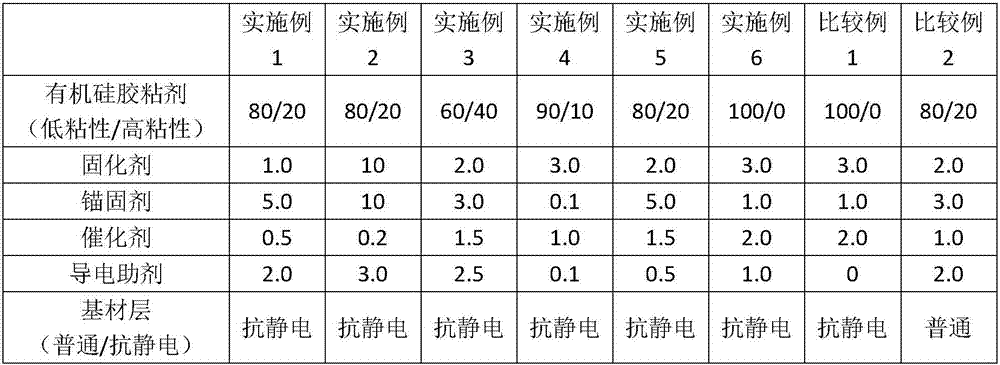

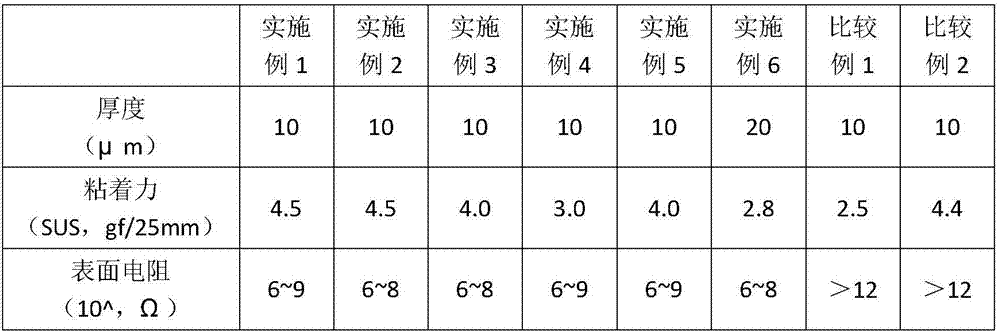

[0026] An antistatic protective film, comprising a release film layer 1, an adhesive layer 2, a substrate layer 3, such as figure 1 shown. The release film layer 1 is a non-silicon release film, the substrate layer 3 is a TPU film with an antistatic coating on one or both sides, and the raw materials for the preparation of the adhesive layer 2 include 80 parts by weight of low-viscosity silicone adhesive, 20 parts by weight of High-viscosity silicone adhesive, 1.0 parts by weight of curing agent, 5.0 parts by weight of anchoring agent, 0.5 parts by weight of catalyst, and 2.0 parts by weight of carbon black slurry conductive additive. Specifically, the adhesion of the above-mentioned high-viscosity silicone adhesive is ≥500g / 25mm, the adhesion of the low-viscosity silicone adhesive is ≤300g / 25mm, the curing agent is SYL-OFF(R)SL 7028CROSSLINKER from Dow Corning, the anchoring It is SYL-OFF (R) 297 ANCHORAGE ADDITIVE of Dow Corning Corporation of the United States, the catalys...

Embodiment 2

[0029] An antistatic protective film, comprising a release film layer 1, an adhesive layer 2, a substrate layer 3, such as figure 1 shown. The release film layer 1 is a polyethylene terephthalate film, the substrate layer 3 is a PET film with an antistatic coating on one or both sides, and the raw material for the preparation of the adhesive layer 2 includes 80 parts by weight of a low-viscosity silicone adhesive , 20 parts by weight of high-viscosity silicone adhesive, 10 parts by weight of curing agent, 10 parts by weight of anchoring agent, 0.2 parts by weight of catalyst, and 3.0 parts by weight of graphite slurry conductive additive. Specifically, the adhesion of the above-mentioned high-viscosity silicone adhesive is ≥500g / 25mm, the adhesion of the low-viscosity silicone adhesive is ≤300g / 25mm, and the curing agent is China National Bluestar Silicone Co., Ltd. Crosslinker 96A, the anchoring agent is from China National Bluestar Silicone Co., Ltd. ADD 208, catalyst fo...

Embodiment 3

[0032] An antistatic protective film, comprising a release film layer 1, an adhesive layer 2, a substrate layer 3, such as figure 1shown. The release film layer 1 is a fluorine release film, the substrate layer 3 is a PAR film with an antistatic coating on one or both sides, and the raw materials for the preparation of the adhesive layer 2 include 40 parts by weight of low-viscosity silicone adhesive, 60 parts by weight of High-viscosity silicone adhesive, 2.0 parts by weight of curing agent, 3.0 parts by weight of anchoring agent, 1.5 parts by weight of catalyst, and 2.5 parts by weight of graphene slurry conductive additive. Specifically, the adhesion of the above-mentioned high-viscosity silicone adhesive is ≥500g / 25mm, the adhesion of the low-viscosity silicone adhesive is ≤300g / 25mm, the curing agent is SYL-OFF(R)SL 7028CROSSLINKER from Dow Corning, the anchoring It is SYL-OFF (R) 297ANCHORAGE ADDITIVE of Dow Corning Corporation of the United States, the catalyst is SYL-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com