Solar glass self-cleaning antireflection paint and production method thereof

A technology of solar glass and anti-reflection, which is applied in the direction of coating, etc., can solve the problems that the anti-reflection coating of solar glass cannot adapt to the working environment polluted in the field, the surface of solar anti-reflection glass is easily polluted, and electrostatic adsorption of dust is easy to achieve. Effect of treatment time, reduction of surface resistance, good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

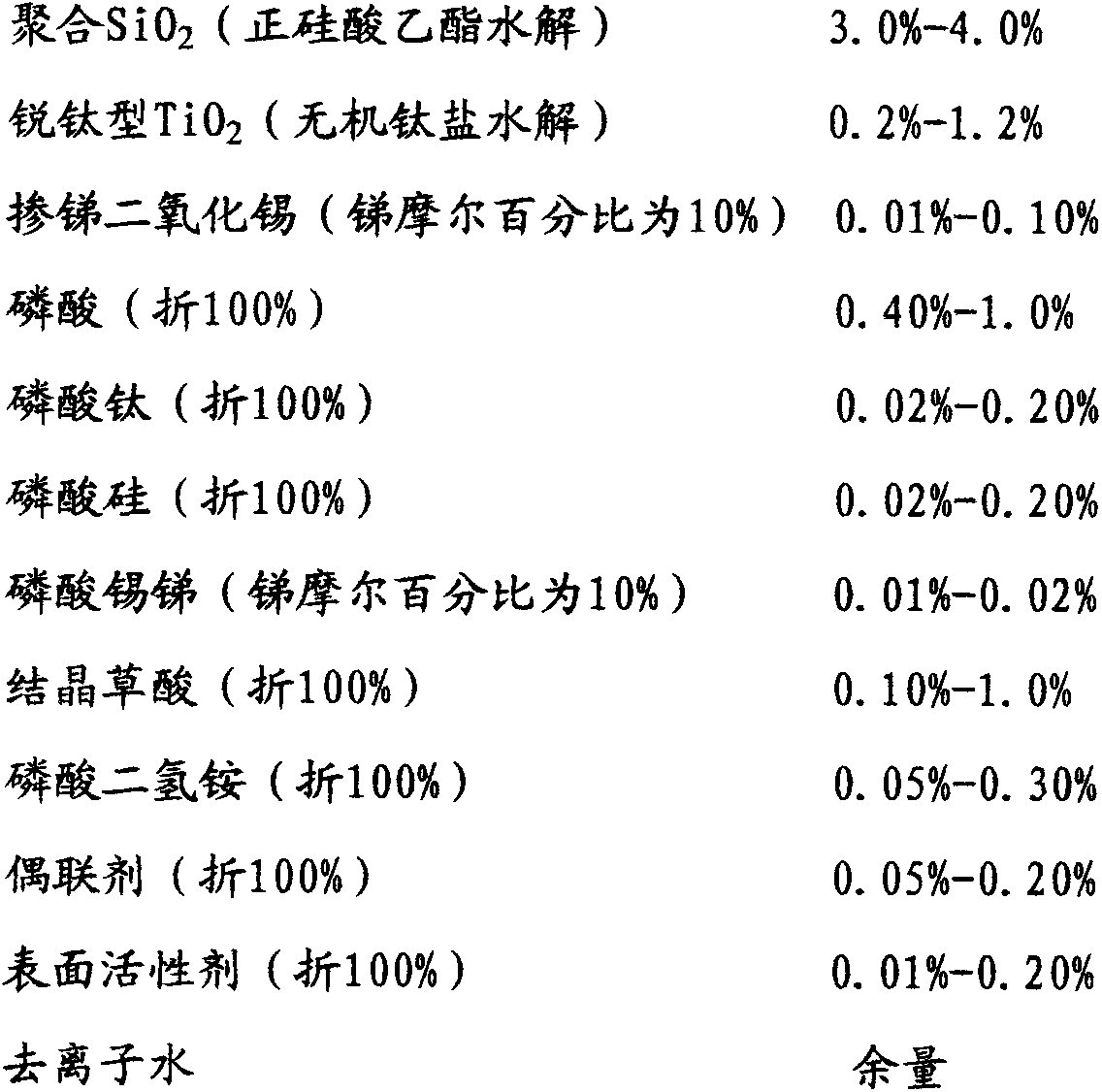

Method used

Image

Examples

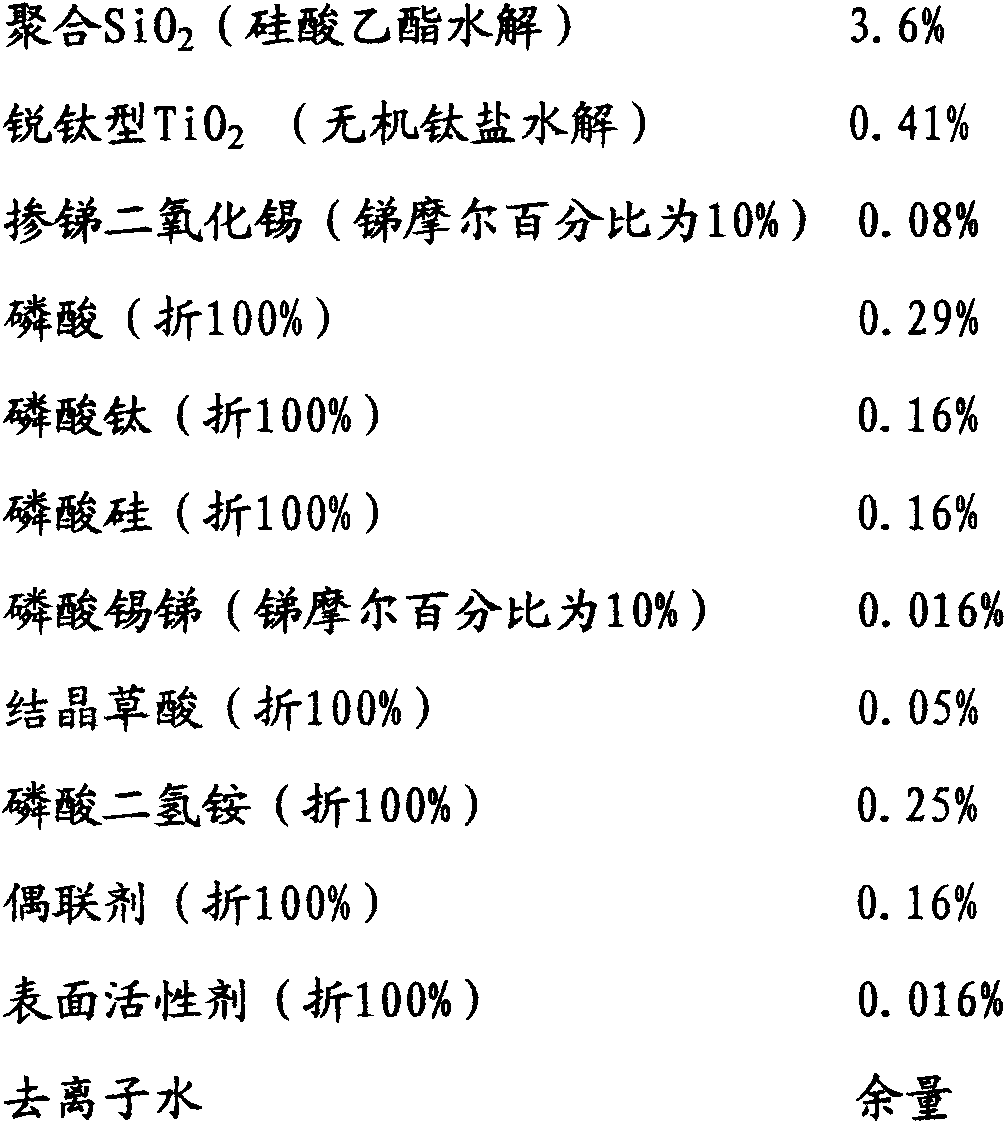

Embodiment 1

[0038] To a 2000mL four-port reactor equipped with a mechanical stirrer, a thermometer, a dropping funnel, and a condenser, successively add 700 g of ethanol with a mass percentage concentration of 95%, 2.0 g of ammonia water with a mass percentage concentration of 25%, and deionized water. 130g and 160g of ethyl silicate with a mass percentage concentration of 99%, stirred and reacted at 15-30°C for 4-6 hours, left to stand and aged for more than 12 hours to form transparent polymerized SiO 2 Ethanol sol A, the measured average particle size is about 10nm; add 700g of deionized water, and distill 700g of 95% ethanol aqueous solution at 70-75°C to obtain polymerized SiO 2 Aqueous sol B, the measured average particle size is about 10nm; add 30g of dilute phosphoric acid solution with a mass percentage concentration of 20% to adjust the sol to PH2-3 to obtain polymerized SiO 2 Hydrosol C; add anatase nano-TiO with a mass percentage concentration of 5% under stirring 2 100g of p...

Embodiment 2

[0042] To a 2000mL four-port reactor equipped with a mechanical stirrer, a thermometer, a dropping funnel, and a condenser, successively add 700 g of ethanol with a mass percentage concentration of 95%, 2.0 g of ammonia water with a mass percentage concentration of 25%, and deionized water. 130g and 160g of orthosilicate ethyl ester with a concentration of 99% by mass, stirred and reacted at 15-30°C for 4-6 hours, left to stand and aged for more than 12 hours to form transparent polymerized SiO 2 Ethanol sol A, the measured average particle size is about 10nm; add 700g of deionized water, and distill 700g of 95% ethanol aqueous solution at 70-75°C to obtain polymerized SiO 2 Aqueous sol B, the measured average particle size is about 10nm; add 30g of dilute phosphoric acid solution with a mass percentage concentration of 20% to adjust the sol to PH2-3 to obtain polymerized SiO 2 Hydrosol C; add anatase nano-TiO with a mass percentage concentration of 5% under stirring 2 50g of...

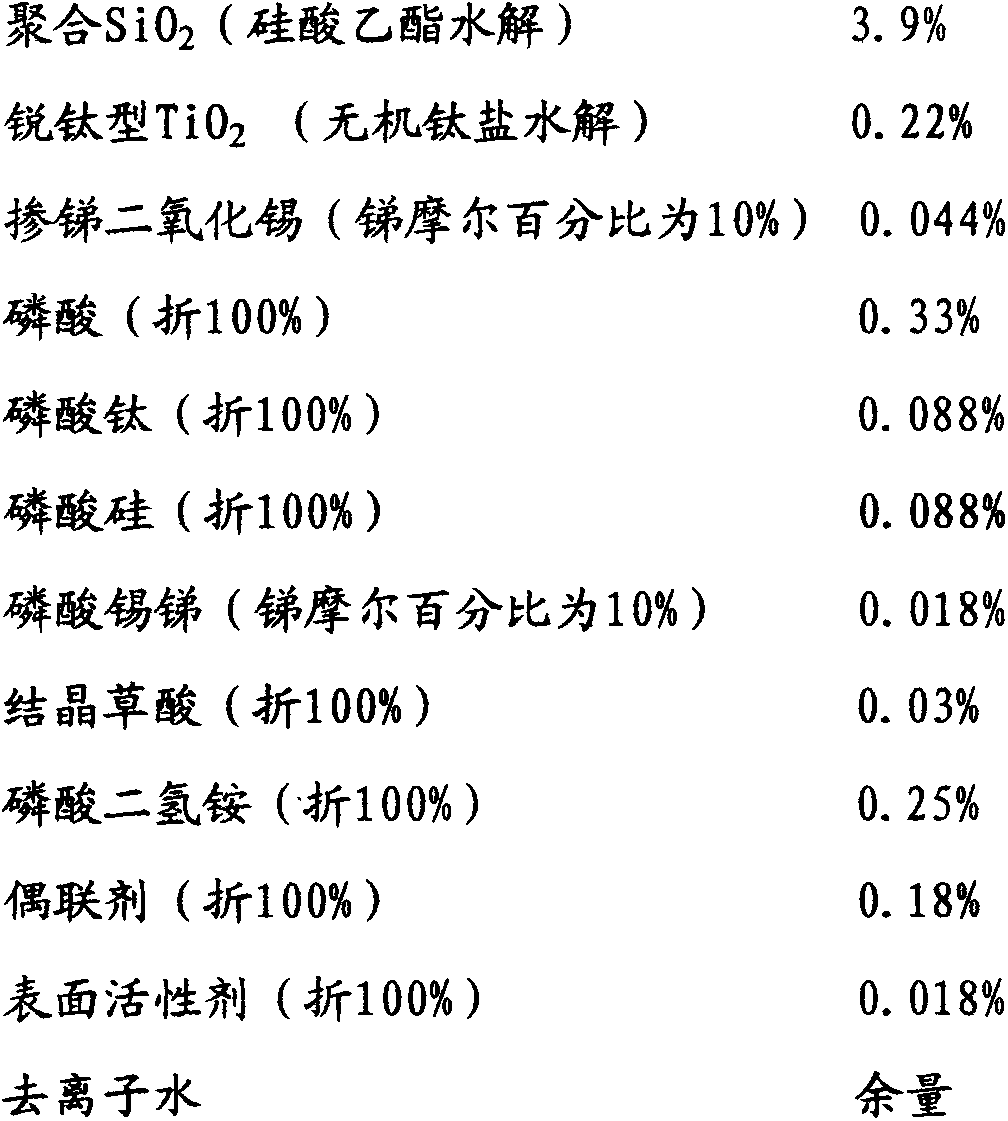

Embodiment 3

[0046] To a 2000mL four-port reactor equipped with a mechanical stirrer, a thermometer, a dropping funnel, and a condenser, successively add 700 g of ethanol with a mass percentage concentration of 95%, 2.0 g of ammonia water with a mass percentage concentration of 25%, and deionized water. 130g and 160g of orthosilicate ethyl ester with a concentration of 99% by mass, stirred and reacted at 15-30°C for 4-6 hours, left to stand and aged for more than 12 hours to form transparent polymerized SiO 2 Ethanol sol A, the measured average particle size is about 10nm; add 700g of deionized water, and distill 700g of 95% ethanol aqueous solution at 70-75°C to obtain polymerized SiO 2 Aqueous sol B, the measured average particle size is about 10nm; add 30g of dilute phosphoric acid solution with a mass percentage concentration of 20% to adjust the sol to PH2-3 to obtain polymerized SiO 2 Hydrosol C; add anatase nano-TiO with a mass percentage concentration of 5% under stirring 2 300g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com