Novel honeycomb microporous structure functional polyester modified short fiber and its preparing method

A microporous structure and polyester modification technology, applied in the field of spinning, can solve the problems of poor dyeability, low added value, no moisture absorption and quick drying, etc., and achieve good softness, high added value, and good versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

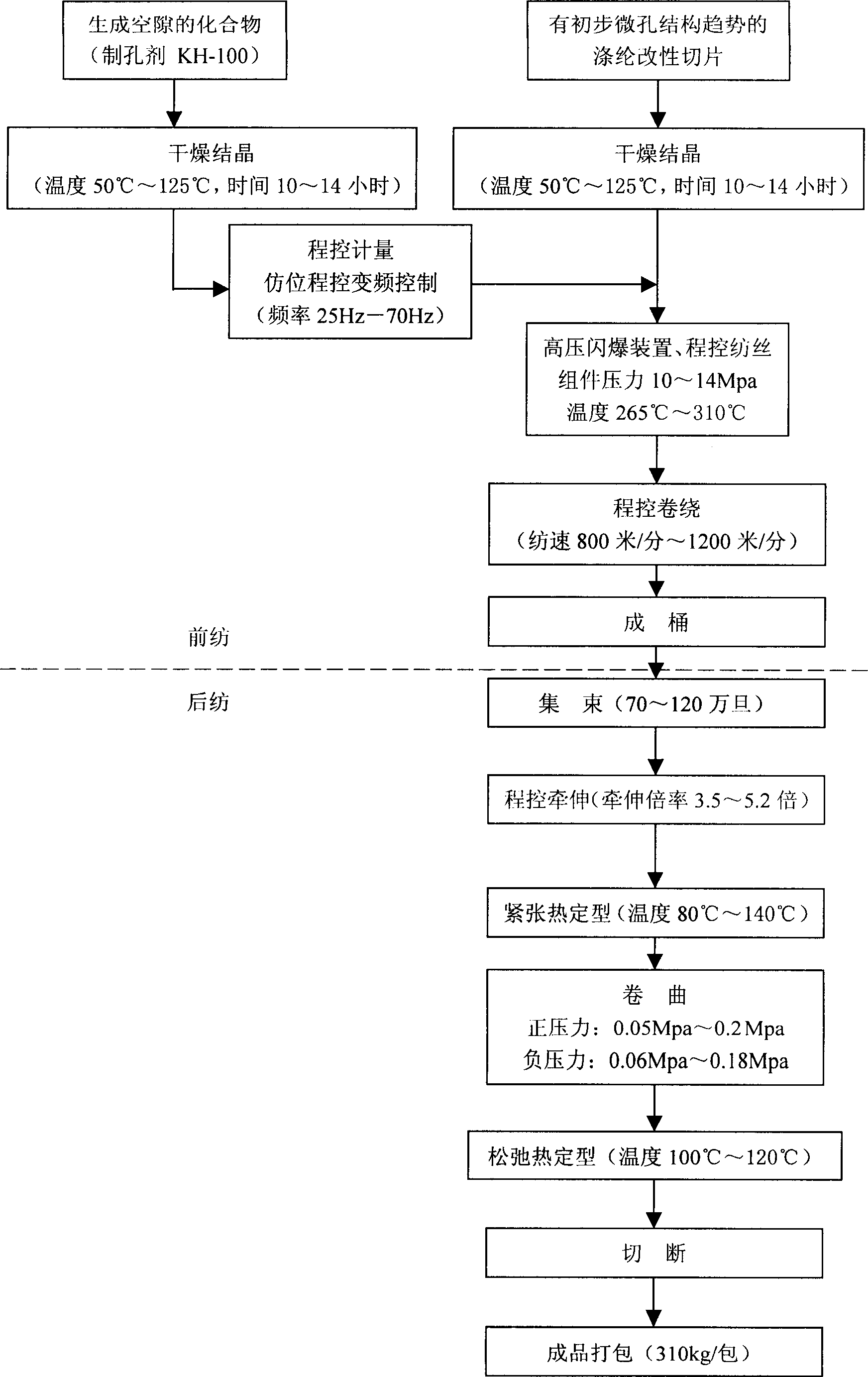

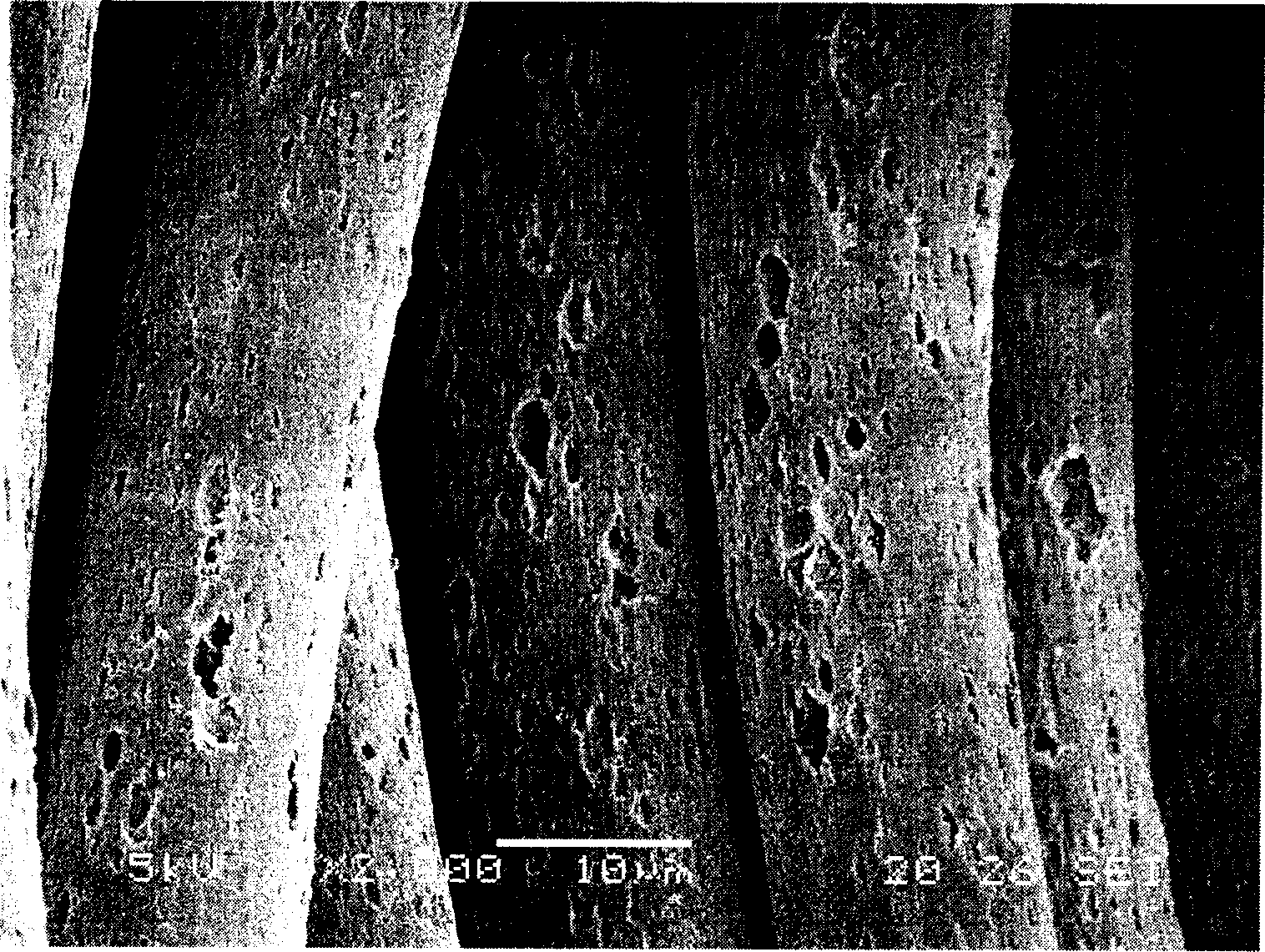

[0057] Embodiment 1: This novel honeycomb microporous structure functional polyester modified staple fiber has a honeycomb microporous structure. Because the fiber has a honeycomb microporous structure, it has efficient moisture absorption and quick drying according to the principle of capillary wicking.

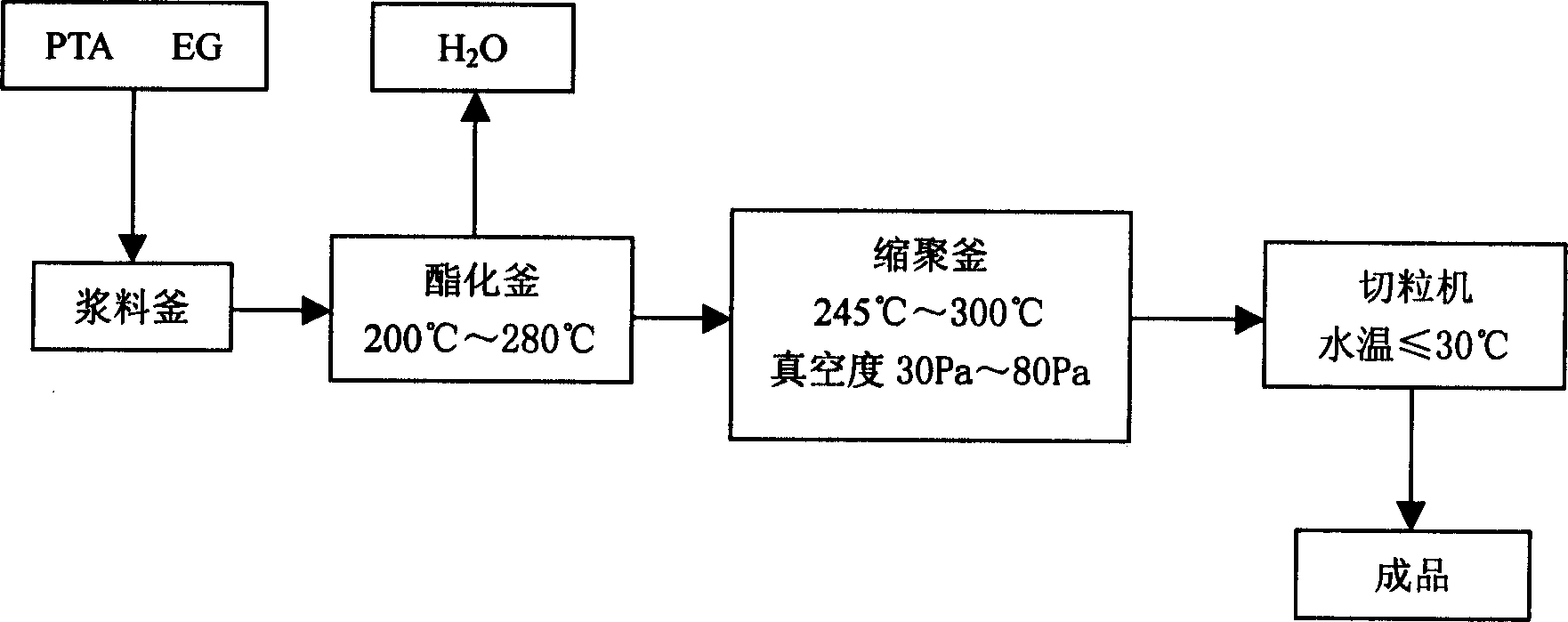

[0058] refer to figure 1 : the production method of this polyester modified chip, comprises the following steps:

[0059] 1) First, mix terephthalic acid, ethylene glycol, dimethyl isophthalate-5-sodium sulfonate, polyethylene glycol ether, ethylene glycol antimony and triphenyl phosphate in a slurry kettle in proportion Adequate mixing and pulping;

[0060] 2) Next, the slurry is introduced into an esterification kettle for esterification, the temperature is controlled at 200°C to 280°C, and the following esterification reaction occurs, and the reaction equation is as follows:

[0061]

[0062] 3) Again, in the polycondensation kettle, polyethylene glycol ether and dime...

Embodiment 2

[0116] Embodiment 2: The difference from Example 1 is that this novel honeycomb microporous structure functional polyester modified short fiber contains bamboo charcoal particles of 1.0 μm to 1.2 μm, and the bamboo charcoal particles account for 1.5% to 1.5% of the fiber weight. 2.3%. During preparation, polyester modified slices with microporous structure tendency are used, and bamboo charcoal masterbatch made of subnano-scale bamboo charcoal particles are added in the spinning process (bamboo charcoal masterbatch and modified polyester with preliminary microporous structure tendency Slices enter the screw extruder together for melt spinning), and finally make honeycomb microporous bamboo charcoal fibers. The surface and cross section of the fiber are of honeycomb microporous structure, and the bamboo charcoal particles are evenly distributed on the surface, surface layer and inner layer of the fiber, which can give full play to the function of bamboo charcoal. Normal temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com