Split-lobe type high-contraction polyamide composite fully drawn yarn and preparation method thereof

A fully drawn yarn and high shrinkage technology, which is applied in the direction of conjugated synthetic polymer artificial filament, melt spinning, filament/thread forming, etc., can solve the problem of fabric hand feeling, difficulty in improving comfort, inability to use independently, polyester Ester fiber has no problems such as elasticity, and achieves the effect of smooth hand feeling, easy handling and easy elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

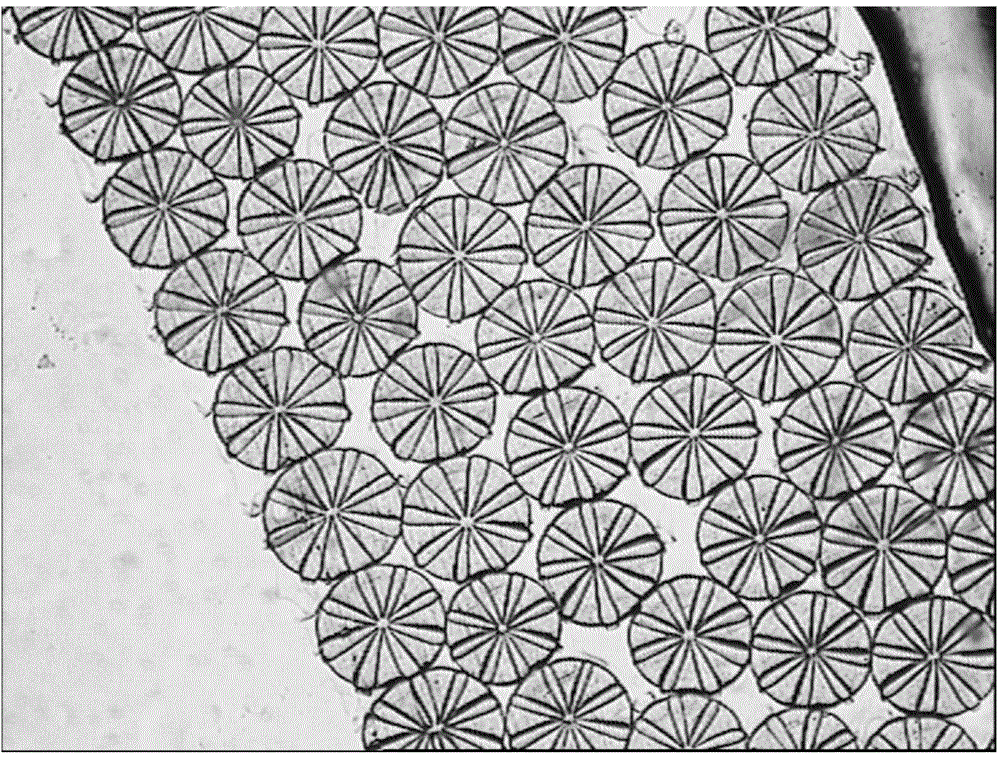

Image

Examples

Embodiment 1

[0025] A split-type high-shrinkage nylon composite full-drawn yarn, the split-type high-shrinkage nylon composite full-drawn yarn is a two-component composite fiber composed of a high-shrinkage component and a nylon component, and the cross-section is split. shape, the weight percentage of the high shrinkage component is 62.5%, and the nylon component is the balance.

[0026] The slice intrinsic viscosity of the high-shrinkage component is 0.7-1.0dl / g, the slice intrinsic viscosity of the nylon component is 0.4-0.6dl / g, and the viscosity difference between the high-shrinkage component and the nylon component is between 0.2-1.2.

[0027] A preparation method of split-valve high-shrinkage nylon composite fully drawn yarn, comprising the following steps:

[0028] (1) Take 150kg of high-shrinkage dry chips as the first raw material, enter the first material continuous drying tower, make high-shrinkage dry chips with a moisture content of <50ppm, and enter the melt extrusion of the...

Embodiment 2

[0037]A split-type high-shrinkage nylon composite full-drawn yarn, the split-type high-shrinkage nylon composite full-drawn yarn is a two-component composite fiber composed of a high-shrinkage component and a nylon component, and the cross-section is split. shape, the weight percentage of the high shrinkage component is 55%, and the nylon component is the balance.

[0038] The slice intrinsic viscosity of the high-shrinkage component is 0.7-1.0dl / g, the slice intrinsic viscosity of the nylon component is 0.4-0.6dl / g, and the viscosity difference between the high-shrinkage component and the nylon component is between 0.2-1.2.

[0039] A preparation method of split-valve high-shrinkage nylon composite fully drawn yarn, comprising the following steps:

[0040] (1) Take 110kg of high-shrinkage dry chips as the first raw material, enter the first material continuous drying tower, make high-shrinkage dry chips with a moisture content of <50ppm, and enter the melt extrusion of the fi...

Embodiment 3

[0049] A split-type high-shrinkage nylon composite full-drawn yarn, the split-type high-shrinkage nylon composite full-drawn yarn is a two-component composite fiber composed of a high-shrinkage component and a nylon component, and the cross-section is split. shape, the weight percentage of the high-shrinkage component is 65%, and the nylon component is the balance.

[0050] The slice intrinsic viscosity of the high-shrinkage component is 0.7-1.0dl / g, the slice intrinsic viscosity of the nylon component is 0.4-0.6dl / g, and the viscosity difference between the high-shrinkage component and the nylon component is between 0.2-1.2.

[0051] A preparation method of split-valve high-shrinkage nylon composite fully drawn yarn, comprising the following steps:

[0052] (1) Take 130kg of high-shrinkage dry chips as the first raw material, enter the first material continuous drying tower, make high-shrinkage dry chips with a moisture content of <50ppm, and enter the melt extrusion of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com