Modifier for high-water-content clay filler and roadbed filling construction method

A technology with high moisture content and construction method, applied in soil protection, soil conditioning materials, infrastructure engineering and other directions, can solve the problems of difficult packing, low strength, large deformation of roadbed, etc., to improve the strength performance of roadbed, improve Dry shrinkage performance, good effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

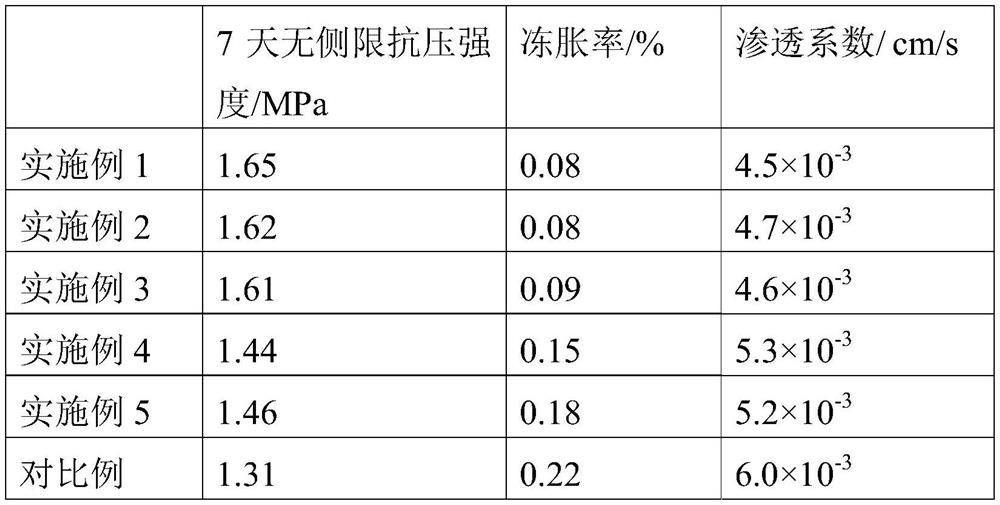

Examples

Embodiment 1

[0050] The composite improver for high moisture content clay filler described in this example is composed of cement and improver mixed in a mass ratio of 100:3.

[0051] Wherein, according to the calculation in parts by mass, the modifier consists of the following components:

[0052] 10 parts of sodium nitrate, 70 parts of sodium carbonate, 60 parts of sodium sulfate, 120 parts of calcium oxide, 45 parts of silicon fume, 40 parts of magnesium oxide, 100 parts of fine sand, 60 parts of cement; among them, the cement is ordinary Portland cement, the strength No grade lower than 42.5.

[0053] A high moisture content clay filler subgrade filling construction method, comprising the following steps:

[0054] S1. The preparation of composite improver, specifically:

[0055] S101. Mix sodium nitrate, sodium carbonate, sodium sulfate, calcium oxide, silica fume, magnesium oxide, fine sand, and cement according to the above-mentioned selected parts by mass, and stir evenly to obtain...

Embodiment 2

[0070] The composite improver for high moisture content clay filler described in this example is composed of cement and improver mixed in a mass ratio of 100:5.

[0071] Wherein, according to the calculation in parts by mass, the modifier consists of the following components:

[0072] 30 parts of sodium nitrate, 60 parts of sodium carbonate, 70 parts of sodium sulfate, 110 parts of calcium oxide, 40 parts of silicon fume, 50 parts of magnesium oxide, 120 parts of fine sand, and 50 parts of cement.

[0073] The construction method of filling the roadbed with high moisture content clay filler described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0075] The composite improver for high moisture content clay filler described in this example is composed of cement and improver mixed in a mass ratio of 100:1.

[0076] Wherein, according to the calculation in parts by mass, the modifier consists of the following components:

[0077] 20 parts of sodium nitrate, 80 parts of sodium carbonate, 80 parts of sodium sulfate, 100 parts of calcium oxide, 50 parts of silicon fume, 30 parts of magnesium oxide, 110 parts of fine sand, and 55 parts of cement.

[0078] The construction method of filling the roadbed with high moisture content clay filler described in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com