PE shrink film

A shrink film and modification technology, which is applied in the field of PE shrink film, can solve the problems of poor shrinkage performance, low tensile strength, and high crystallinity, and achieve the effects of good shrinkage, high tensile strength, and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The PE shrink film is made of 2% PET and 98% modified PE, wherein the modified PE is modified by 0.1% crosslinking agent accounting for PE weight and 5% methyl methacrylate accounting for PE weight. into, the density of PE is 0.918g / cm 3 , the melt index is 1.0, and the weight of PE weighed is 500 parts.

[0026] The preparation method of modified PE is:

[0027] (1) Dissolving PE in toluene for 2-4 hours, the dissolution temperature is 75-85°C, specifically in this embodiment, the dissolution temperature is 80°C, and the dissolution time is 3h;

[0028] (2) Adding BPO and methyl methacrylate to react, the reaction temperature is 90-100° C., and the reaction time is 20-28 hours. Specifically, in this embodiment, the water bath is 95° C. for 24 hours;

[0029] (3) After the reaction is finished, the product is filtered clean with acetone.

Embodiment 2

[0031] The PE shrink film is made of 10% PET and 90% modified PE, wherein the modified PE consists of 0.5% crosslinking agent accounting for PE weight and 20% monomer (the weight of acrylonitrile in the monomer is 30%, the unit weight of methyl methacrylate is 70%) modified by PE, and the density of PE is 0.918g / cm 3 , the melt index is 1.0, and the weight of PE weighed is 500 parts.

[0032] Examples 2 to 7 except for the different components and proportions listed in Table 1, the rest of the formulation parameters and the preparation method of modified PE are the same as in Example 1. It should be noted that the compatibilizers in all examples are selected Maleic anhydride graft compatibilizer, specifically SEBS-g-MAH.

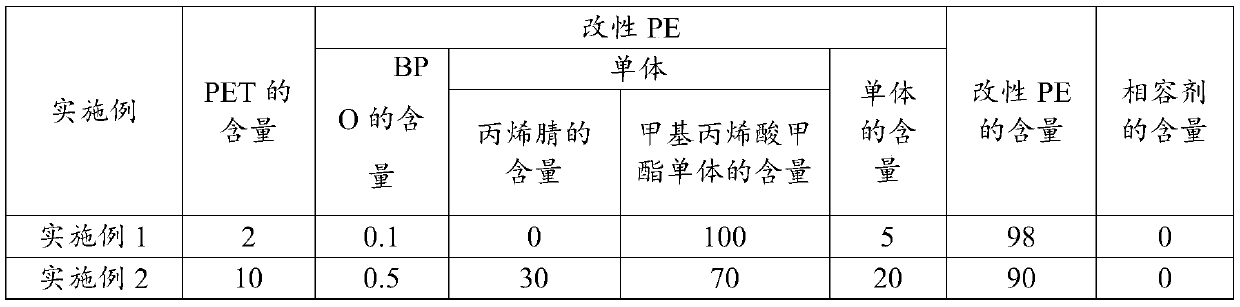

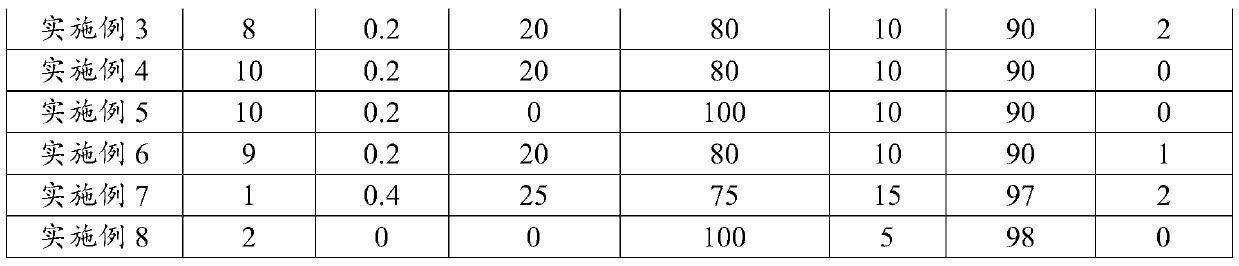

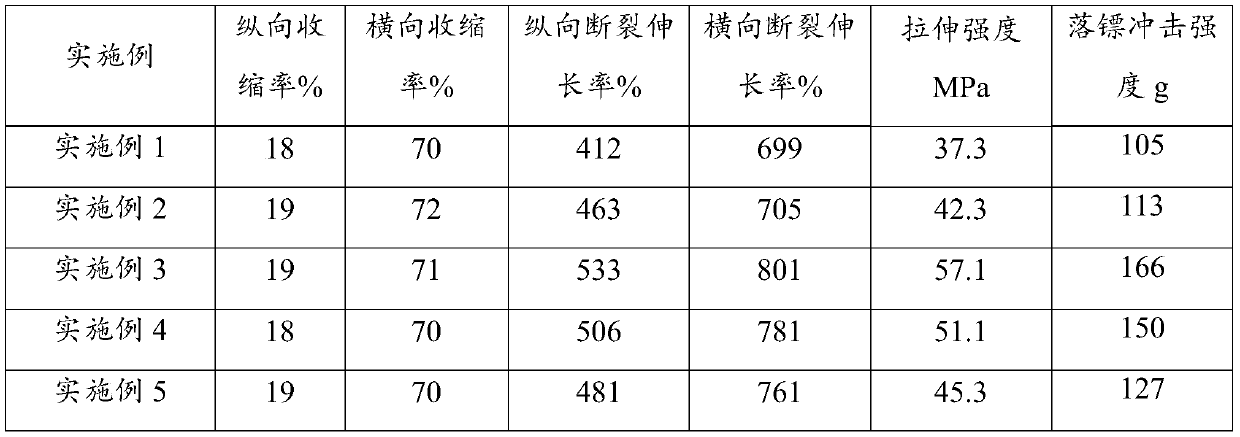

[0033] Table 1 each embodiment component and proportioning

[0034]

[0035]

Embodiment 3

[0050] Embodiment 3 is compared with embodiment 4, and the test result of embodiment 3 is better than embodiment 4, may be due to the reason of adding compatibilizer in embodiment 3, compatibilizer helps PET and modified PE better Compatibility, thereby improving the overall performance of PE shrink film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com