Polyester cotton moisture absorption and instant drying knitted fabric and preparation method thereof

A technology of moisture-absorbing and quick-drying, knitted fabrics, applied in the directions of knitting, weft knitting, fabric surface trimming, etc., can solve the problems of poor moisture release, difficult sweat conduction, poor moisture absorption and quick-drying, etc., and achieves low cost and good application prospects. , the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as figure 1 As shown, this embodiment provides a polyester-cotton hygroscopic and quick-drying knitted fabric, comprising an outer layer and an inner layer, the outer layer is formed of cotton fibers, the inner layer is woven from heterosexual polyester, the outer layer and The inner layer is connected together through the tucking of heterosexual polyester on the surface, and the cotton fiber of the outer layer has a snakeskin structure.

[0025] 1) Raw material preparation: 14.8tex (40S) long-staple cotton, 8.3tex (75D / 72F) TOPCOOL (polyester yarn). At a temperature of 23°C and a humidity of 57%, pre-conditioning for 24 hours.

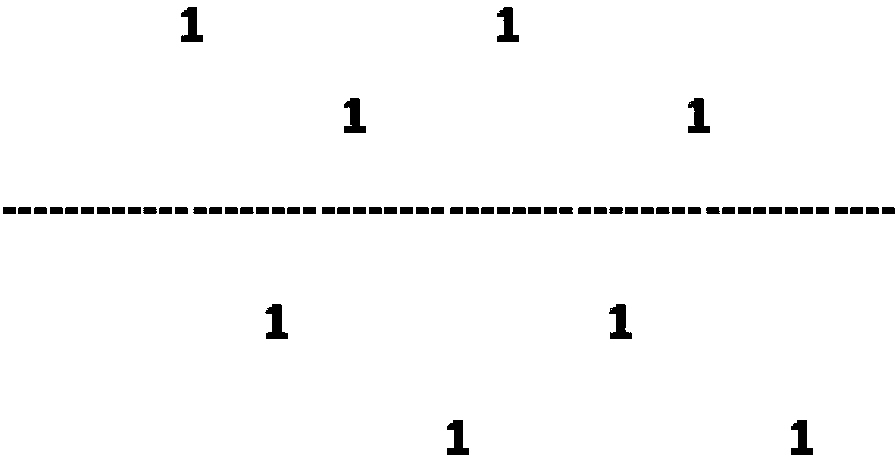

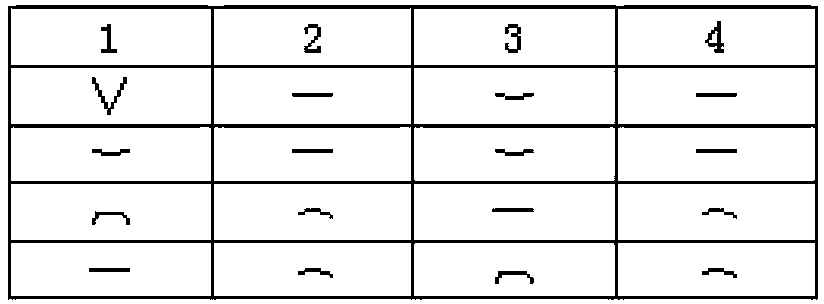

[0026] 2) Weaving on the machine: the selected model: Delo circular knitting machine, the machine number is 24G; the arrangement of the knitting needles in the knitting process (see attached figure 2 ), the triangular arrangement (see attached image 3 ), the 1st and 2nd roads cycle 3 times, the 3rd and 4th roads cycle 3 times; the 1s...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment provides a polyester-cotton hygroscopic and quick-drying knitted fabric, comprising an outer layer and an inner layer, the outer layer is formed of cotton fibers, the inner layer is woven from heterosexual polyester, the outer layer and The inner layer is connected together through the tucking of heterosexual polyester on the surface, and the cotton fiber of the outer layer has a snakeskin structure.

[0034] 1) Raw material preparation: 14.8tex (40S) long-staple cotton, 8.3tex (75D / 72F) TOPCOOL (polyester yarn). At a temperature of 25°C and a humidity of 63%, pre-conditioning for 24 hours.

[0035] 2) Weaving on the machine: the selected model: Delo circular knitting machine, the machine number is 24G; the arrangement of the knitting needles in the knitting process (see attached figure 2 ), the triangular arrangement (see attached image 3 ), the 1st and 2nd roads cycle 3 times, the 3rd and 4th roads cycle 3 times; the 1s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com