Patents

Literature

61results about How to "Wide range of products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing paraffin-embedded tissue cell specimen

InactiveCN103940658AAccurate chemical localizationShorten visit timePreparing sample for investigationMicrowave ovenParaffin embedded tissue

The invention provides a method for manufacturing a paraffin-embedded tissue cell specimen. The method is characterized by comprising the following steps: precipitating and performing centrifugal treatment on a tissue cell specimen, subsequently extracting the tissue cell specimen, adding an environmental-friendly biologic synthesis agent, synchronously fixing, dehydrating, transparentizing and performing paraffin dipping treatment on the tissue cell specimen by an ultrasonic tissue treatment instrument or a medical microwave oven, slicing the paraffin-embedded tissue, and dyeing and sealing the paraffin-embedded tissue slice. The method has the advantages that the operation is rapid, no pollution is caused, the operation is simple and convenient, a dyeing process can be performed together with daily work, a molecular pathological examination can be also performed, and the result is stable. The positive detection rate and the accuracy in pathological diagnosis are improved.

Owner:QINGDAO MUNICIPAL HOSPITAL

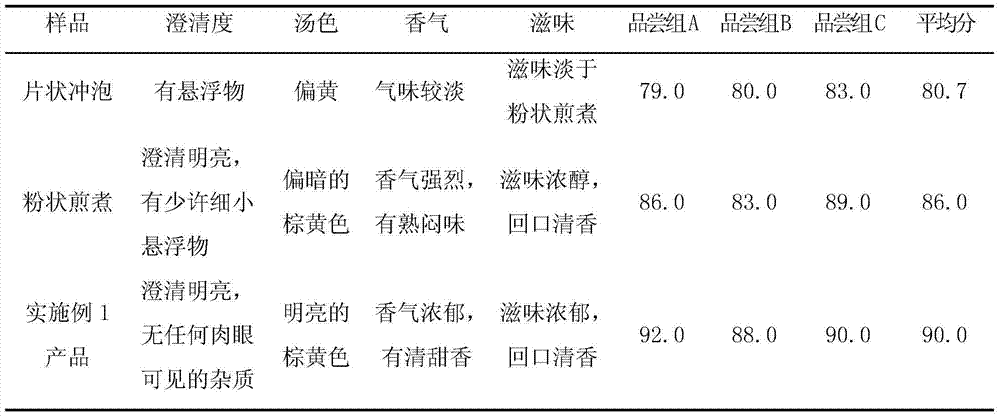

Diaphragma juglandis instant product and preparation method thereof

ActiveCN103875854AHigh extraction rateReasonable process designTea substituesInlet temperaturePectinase

The invention discloses a diaphragma juglandis instant product and a preparation method thereof. Diaphragma juglandis is taken as a raw material, and the method comprises the steps of cleaning the diaphragma juglandis, drying at 50-60 DEG C, grinding to 4-6 mm, carrying out enzymolysis, carrying out segmented decocting for a plurality of times, filtering, adding a thickening agent and drying, wherein enzymolysis is carried out by compounding cellulase and pectinase, decocting is carried out for three times at the temperature of 70-100 DEG C, and the drying conditions are as follows: the inlet temperature is 160-180 DEG C, the outlet temperature is 70-80 DEG C, and spray drying is carried out on 2.5-5 L of material per hour. The diaphragma juglandis instant product has the health care functions of tonifying kidney, arresting seminal emission, calming and helping sleep and the like, is low in cost of production raw materials, less in input of the preparation process, good in instant property, and clear and transparent in soup color; the diaphragma juglandis instant product has the original faint scent taste of diaphragma juglandis, and is excellent in quality, clean, sanitary, convenient to carry, stable in yield and wide in use. The product has great potential, and utilizes the rich diaphragma juglandis resource, so that the industry chain is prolonged, and the comprehensive benefit of the industry is improved.

Owner:新疆中科沙棘科技有限公司

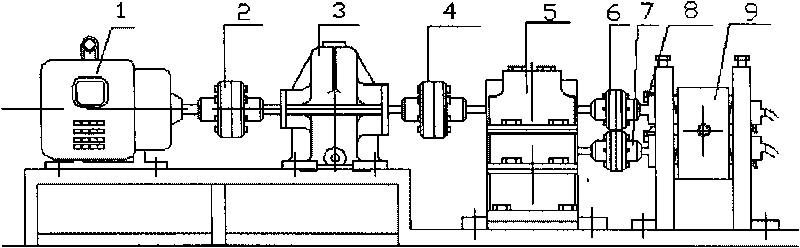

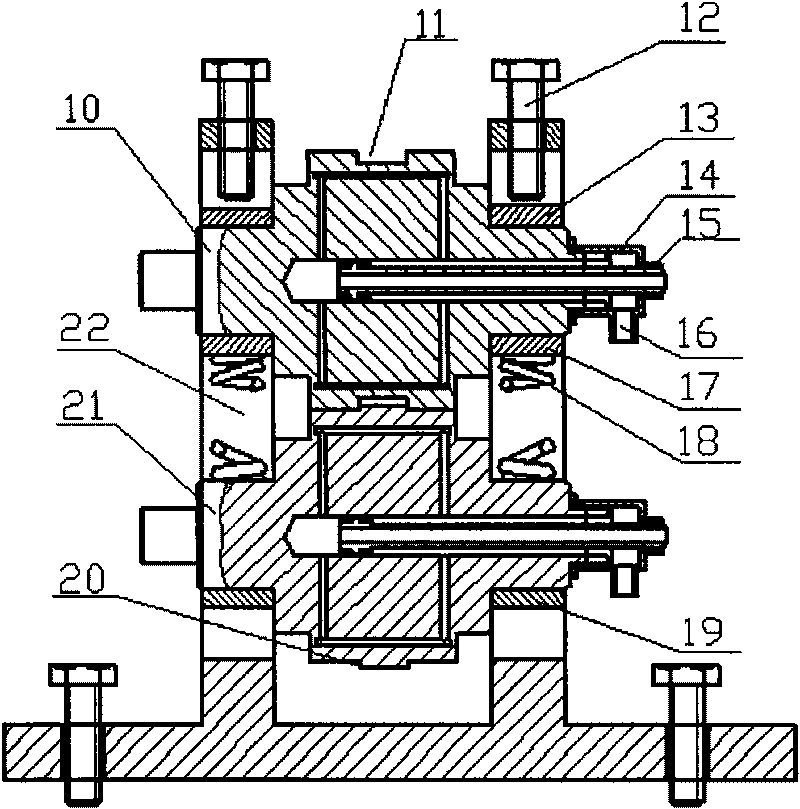

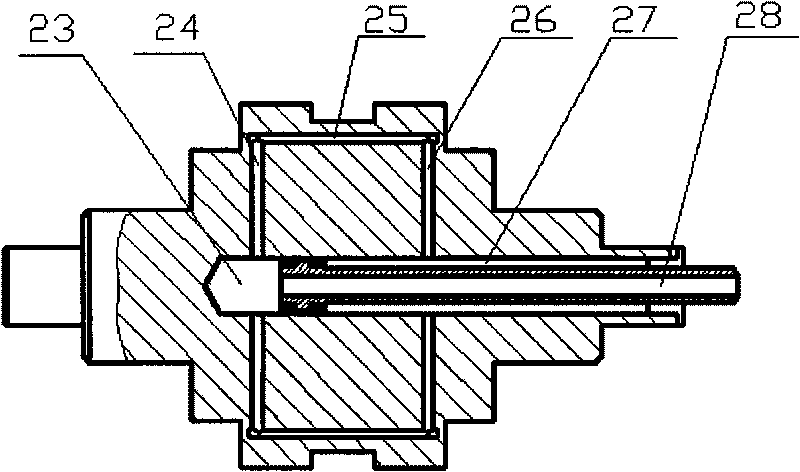

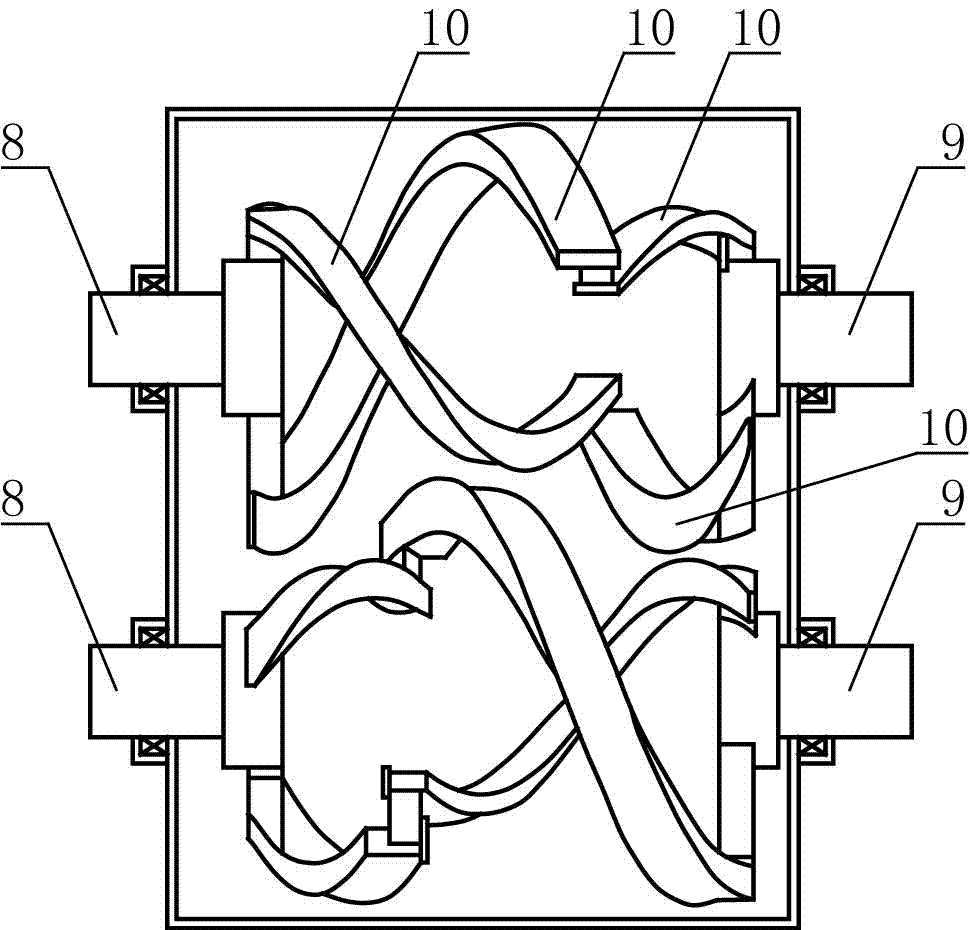

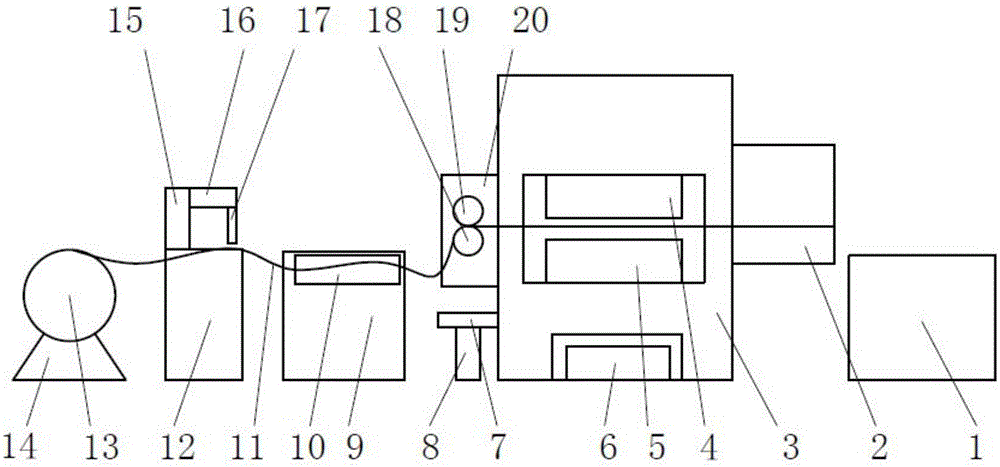

Multi-purpose double-roll continuous rheological forming device for liquid metal

InactiveCN101690941AIncrease productivitySolve low production efficiencyMetal rolling arrangementsLiquid stateCoupling

The invention discloses a multi-purpose double-roller continuous rheological forming device for liquid metal, which is mainly used for double-roller continuous rheological forming of plates, strips, pipes, profiles, wires, composite materials and wrapping materials. The device consists of a motor, a half coupling, a decelerator, a gear box, a main machine, a cooling water tank and a coiling machine, wherein the main machine consists of a stander, an upper working roller, a lower working roller, a feeding shoe, an extrusion shoe, a die in a cavity of the extrusion shoe, and rotating speed sensors at shaft heads of the upper working roller and the lower working roller of the main machine. An annular groove of the upper working roller is mutually matched with an annular lug boss of the lower working roller. The feeding shoe is arranged at the feeding end of the main machine, and the feeding shoe and the annular groove of the upper working roller form a feeding cavity. A metal material enters into a roller gap between the two working rollers through the feeding cavity. When producing pipes, profiles, wires and wrapping materials, the extrusion shoe is arranged at the discharging end of the main machine, and an extrusion forming die can be arranged in the cavity of the extrusion shoe. The device can realize quick continuous rheological forming of the liquid metal, and can also be used for direct forming of a semi-solid metal material.

Owner:NORTHEASTERN UNIV

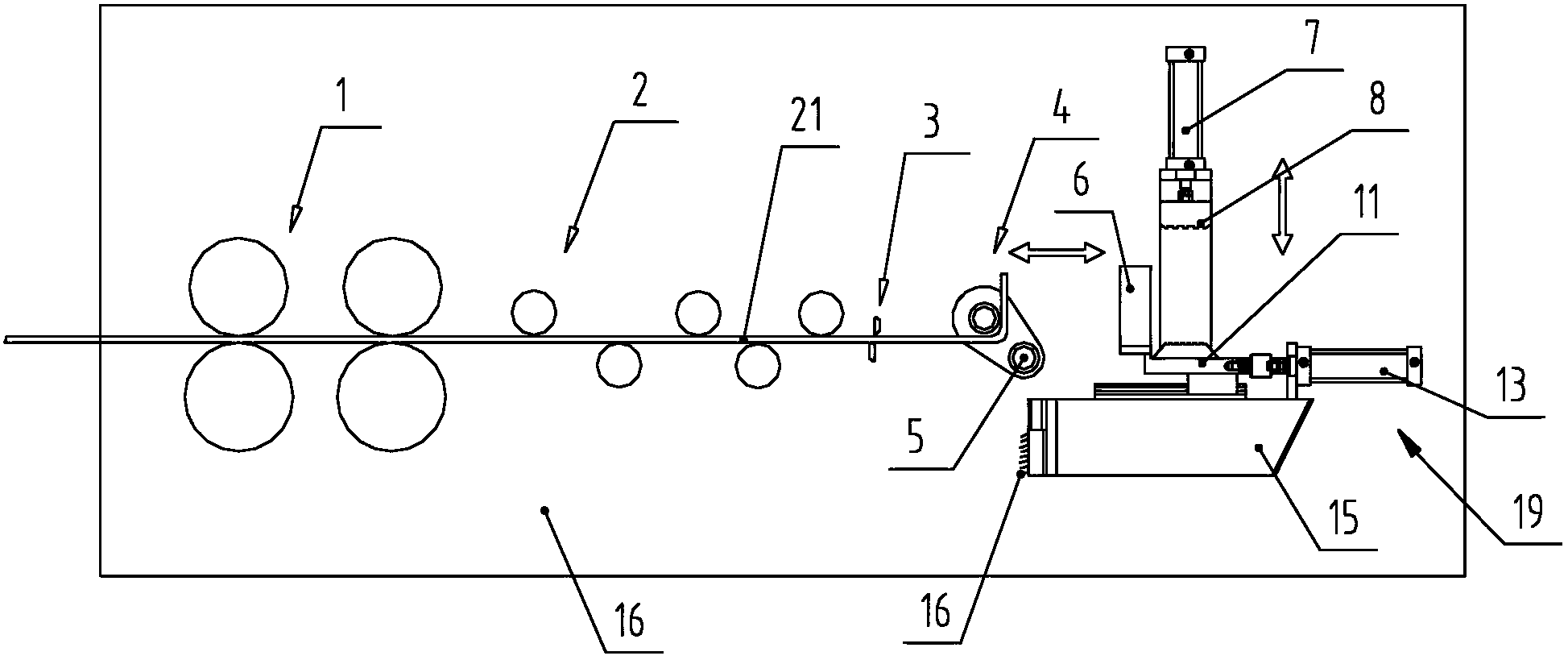

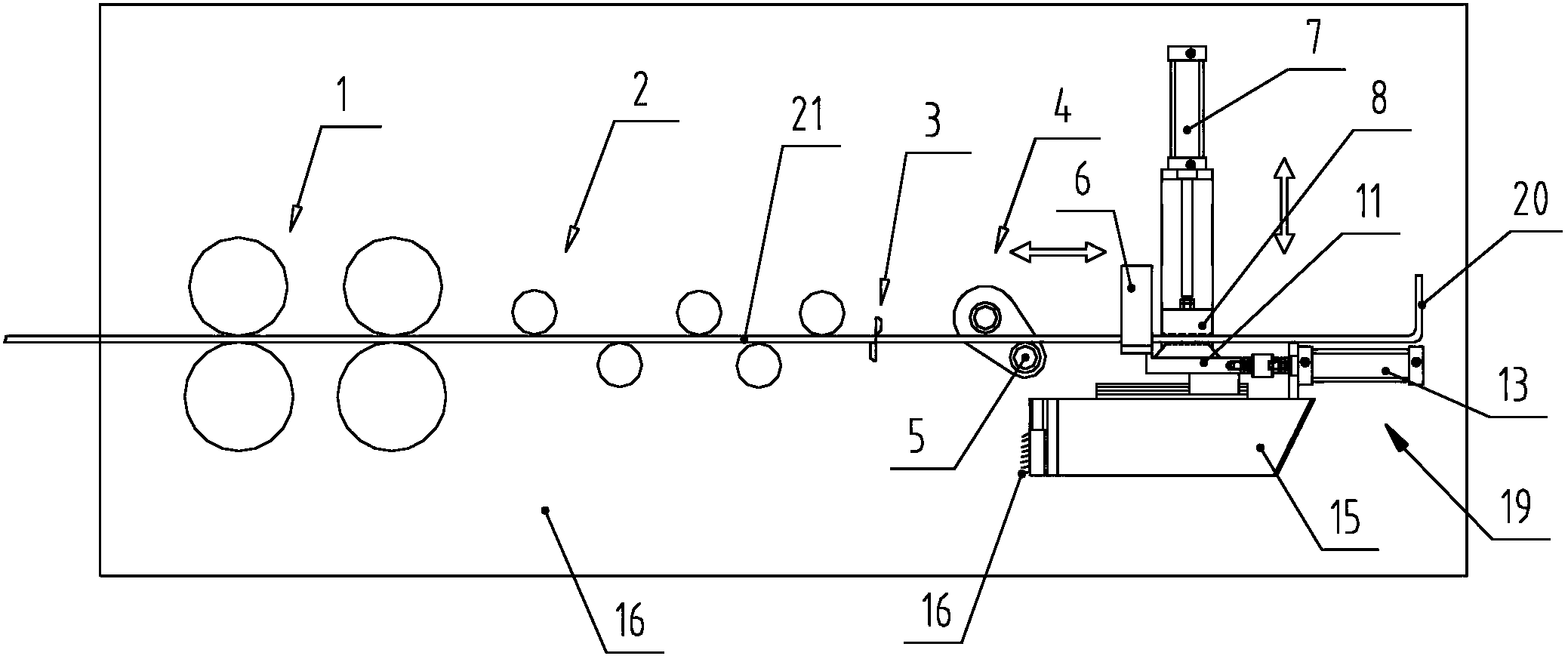

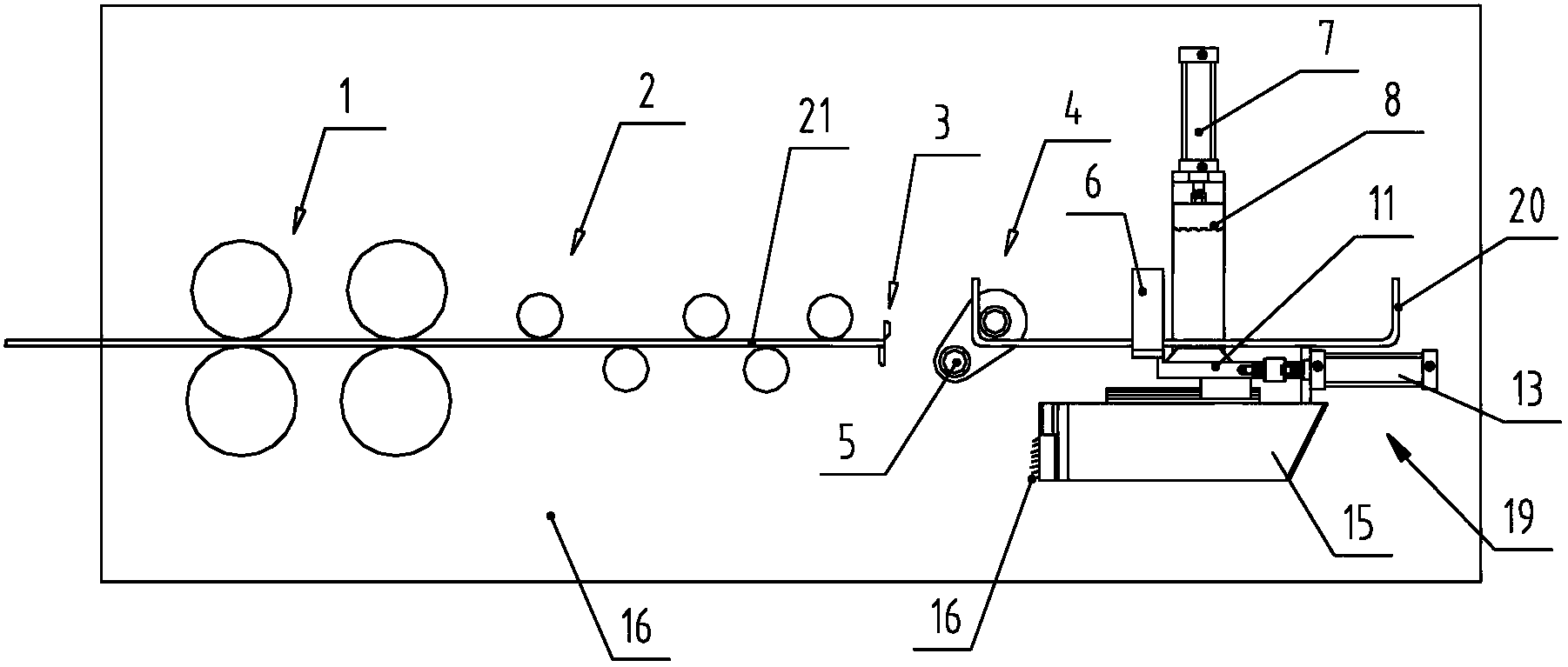

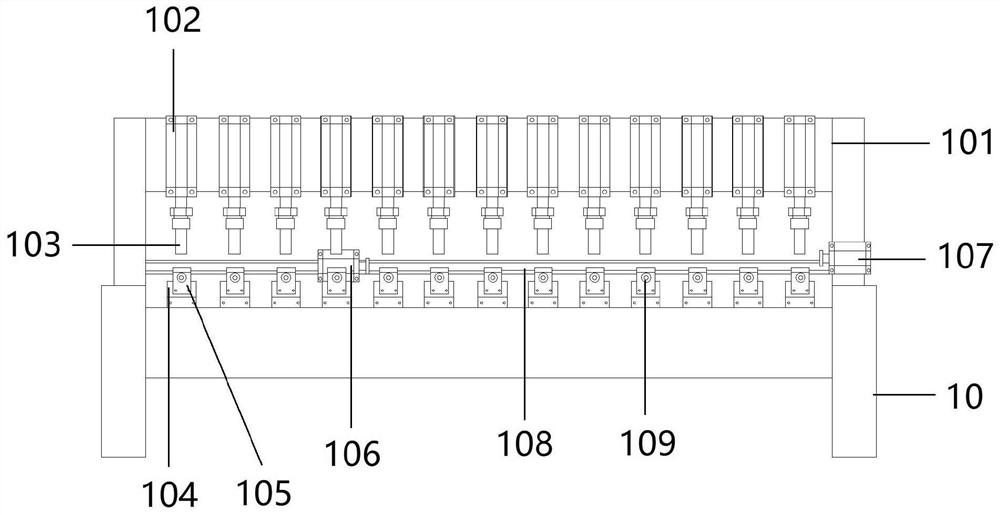

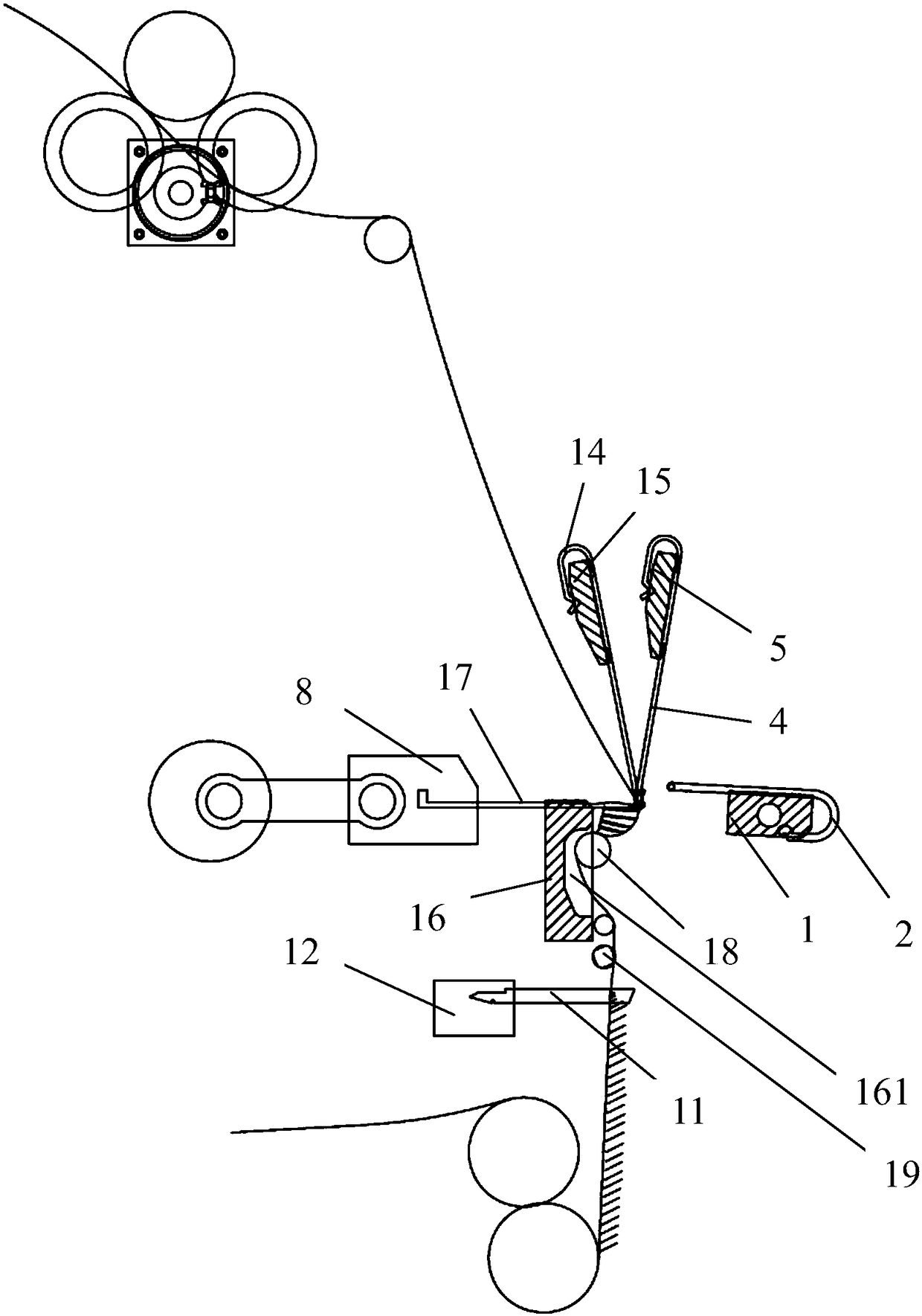

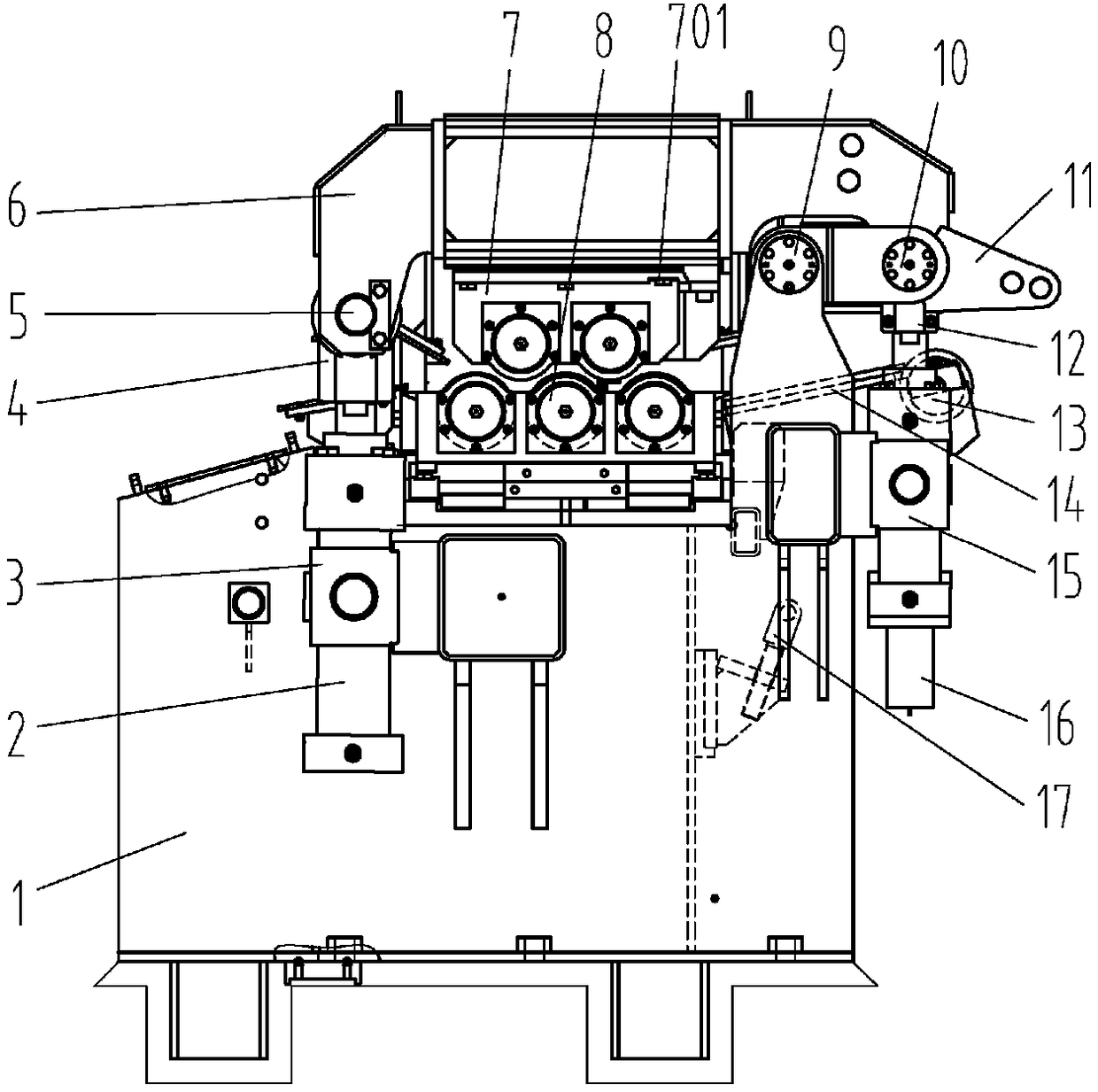

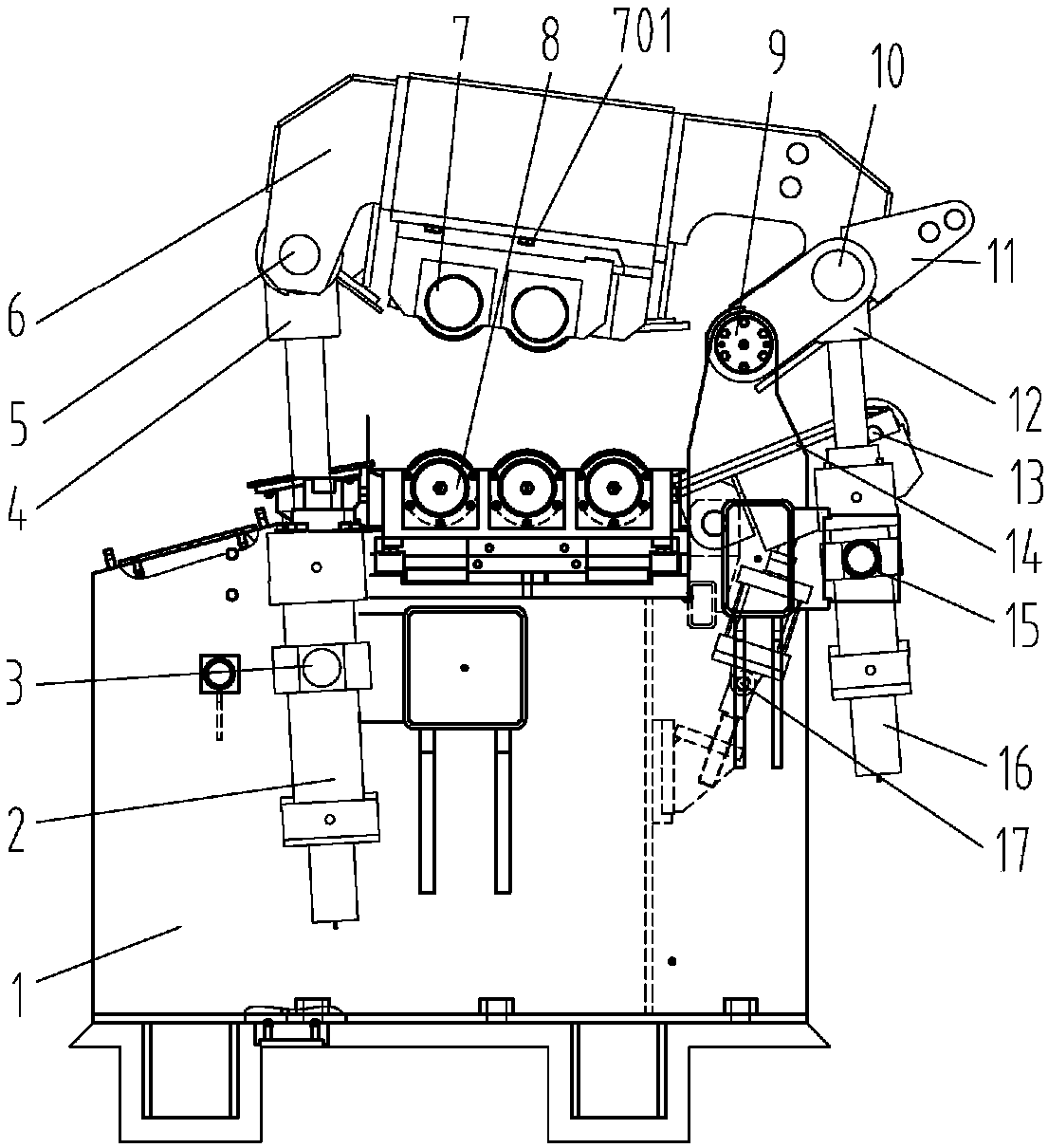

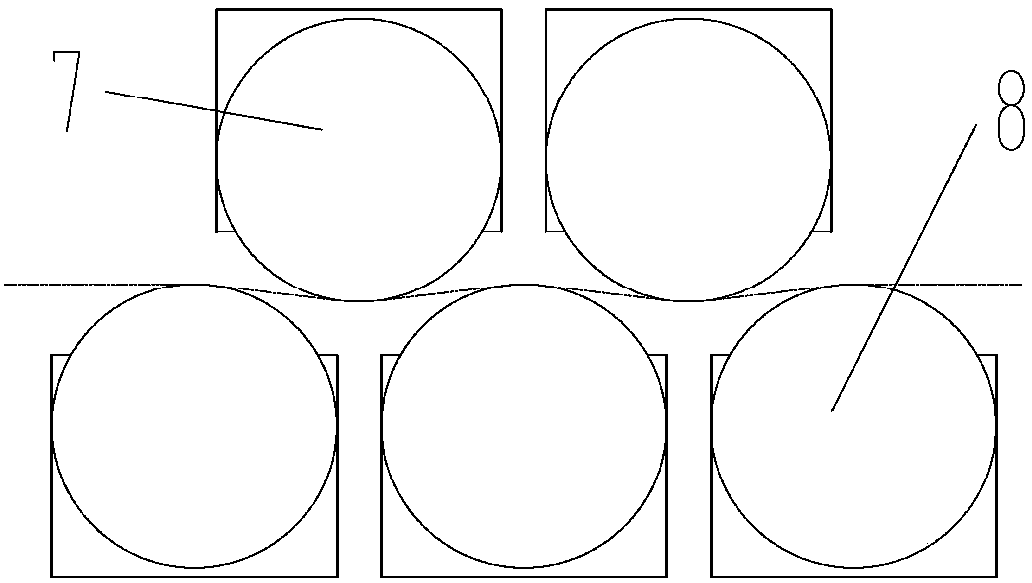

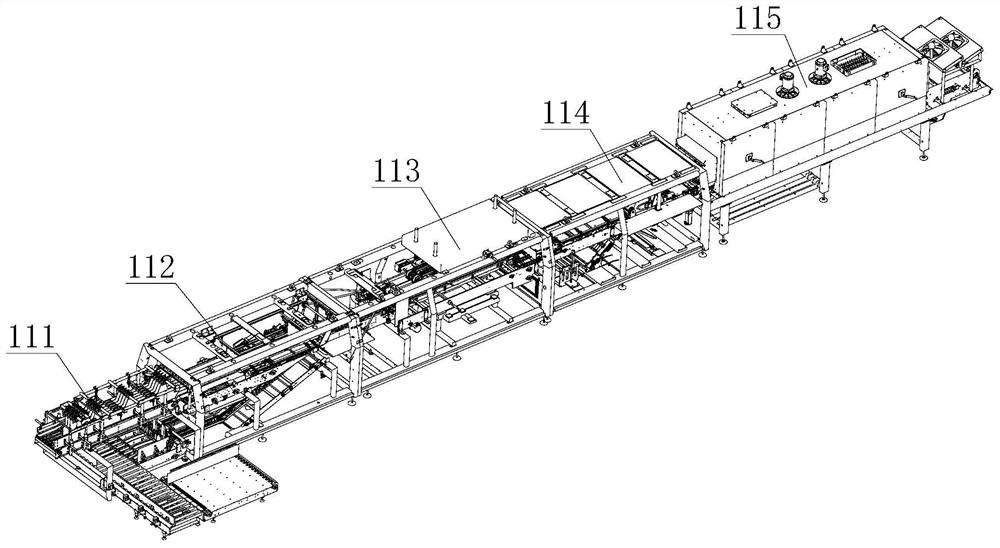

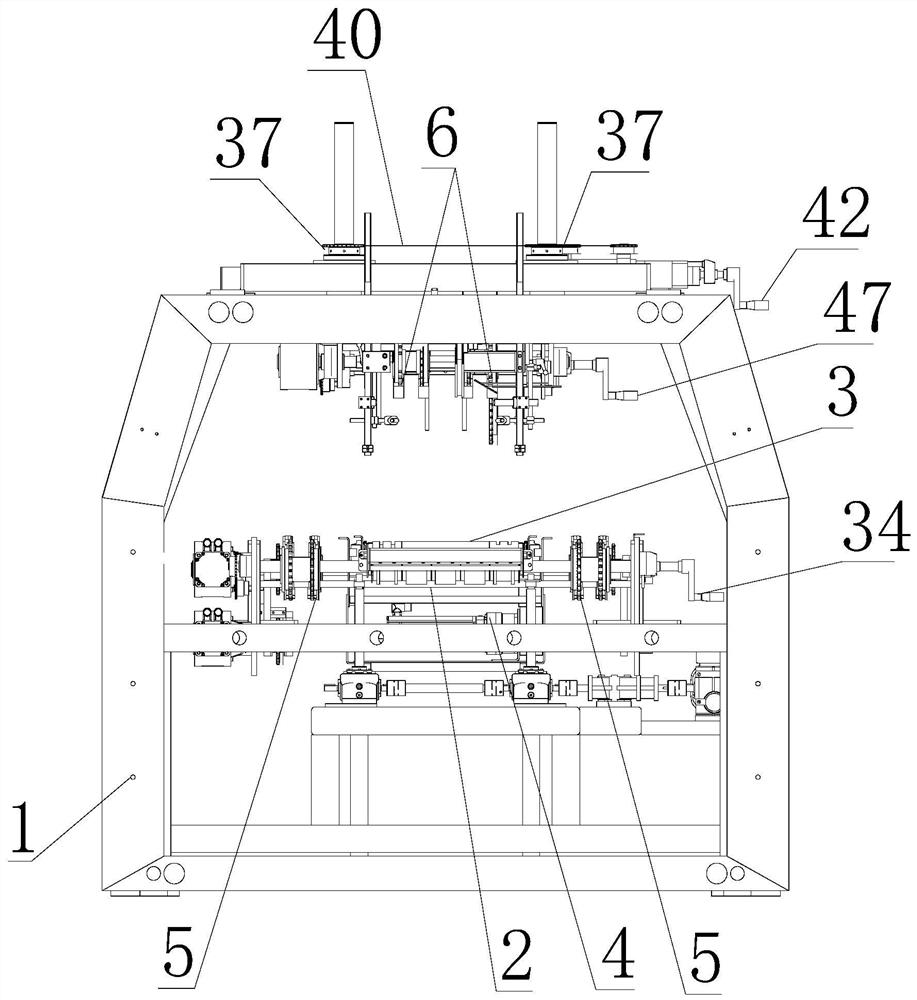

Multifunctional reinforcing steel bar automatic hoop-bending machine bending from two ends of reinforcing steel bar

The invention discloses a multifunctional reinforcing steel bar automatic hoop-bending machine bending from the two ends of a reinforcing steel bar. The multifunctional reinforcing steel bar automatic hoop-bending machine comprises a machine frame, wherein a traction mechanism, a straightening mechanism, a shearing mechanism and a bidirectional bending mechanism are axially arranged on the machine frame along the upstream of the reinforcing steel bar sequentially; a multifunctional mechanism is also arranged on the machine frame on the upstream of the bidirectional bending mechanism; the multifunctional mechanism comprises a compression moving mechanism, a material-pushing mechanism and an overall retraction mechanism; the material-pushing mechanism is used for pushing a hoop bar which is formed in a bending way; and the overall retraction mechanism is used for pulling the compression moving mechanism and the material-pushing mechanism into the inner side of a machine shell panel or pushing the compression moving mechanism and the material-pushing mechanism to a working position. The multifunctional reinforcing steel bar automatic hoop-bending machine has the beneficial effects that the other end of the reinforcing steel bar which is sheared by the shearing mechanism can be bent, long hoop bar products with hooks at the two ends can be bent rapidly and at one time, the requirement of production is met, and the production efficiency is high. The multifunctional reinforcing steel bar automatic hoop-bending machine is simple in structure, low in cost, high in adaptability, wide in production range, and has complete functions.

Owner:TJK MACHINERY TIANJIN

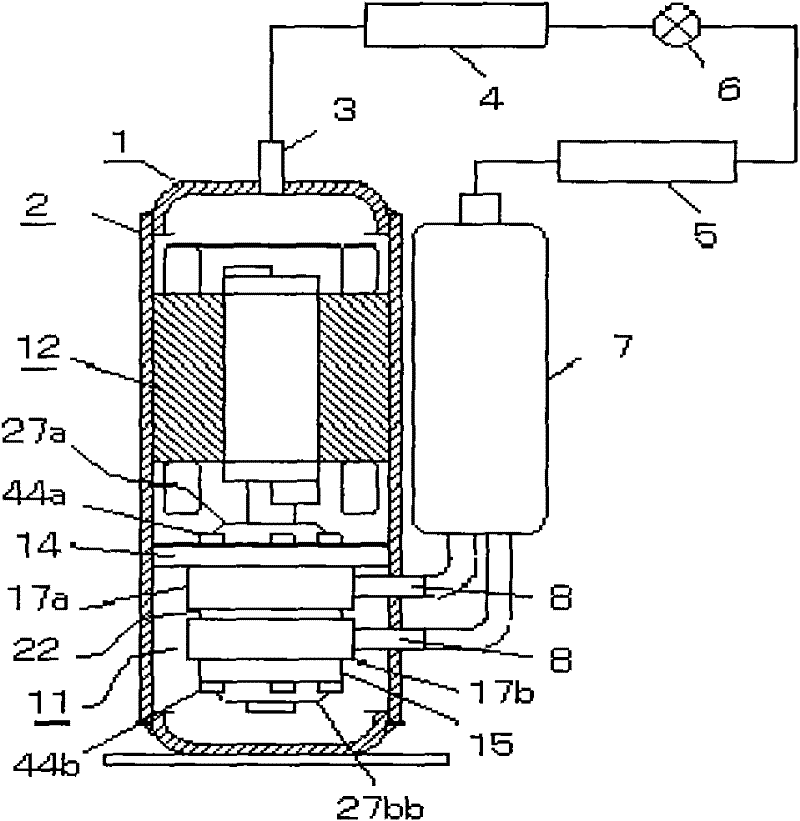

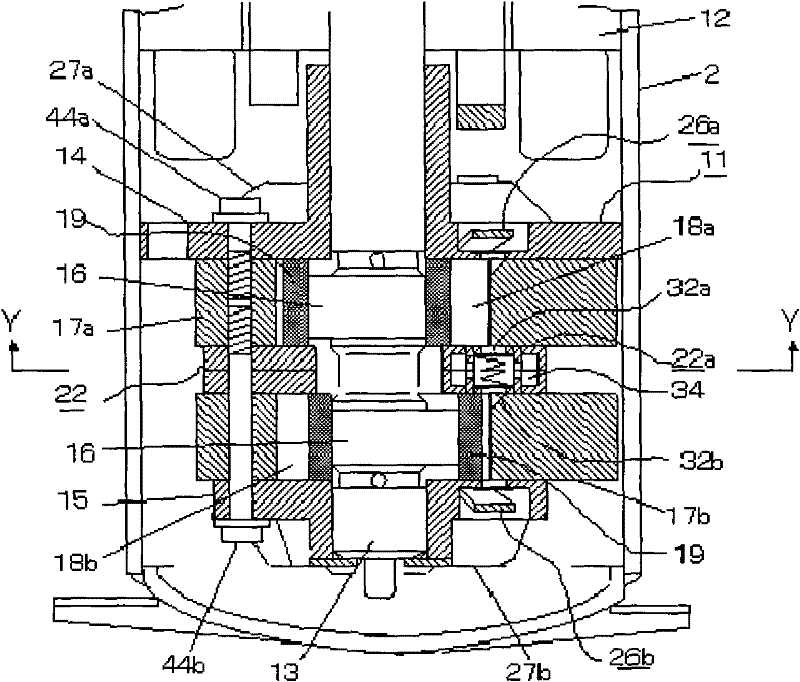

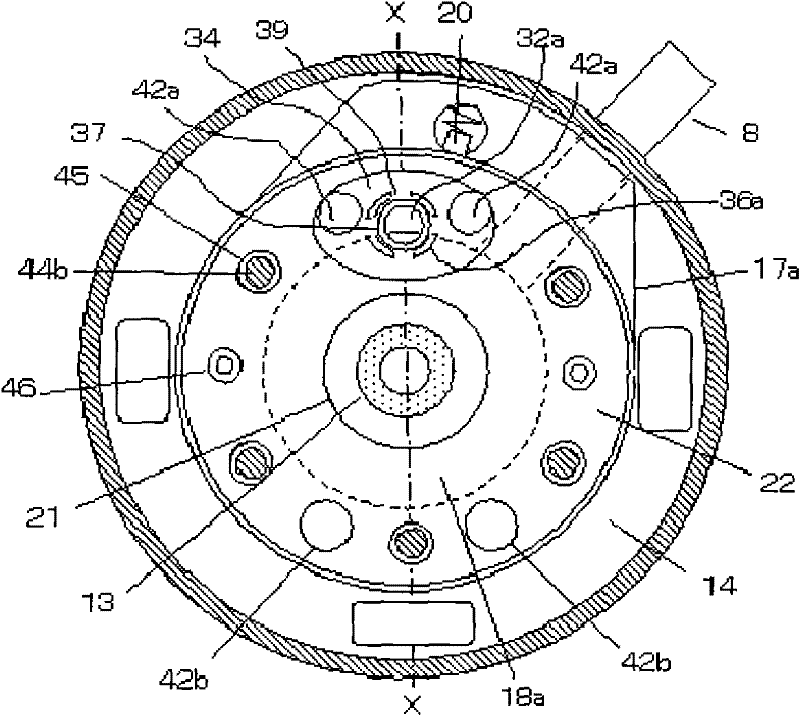

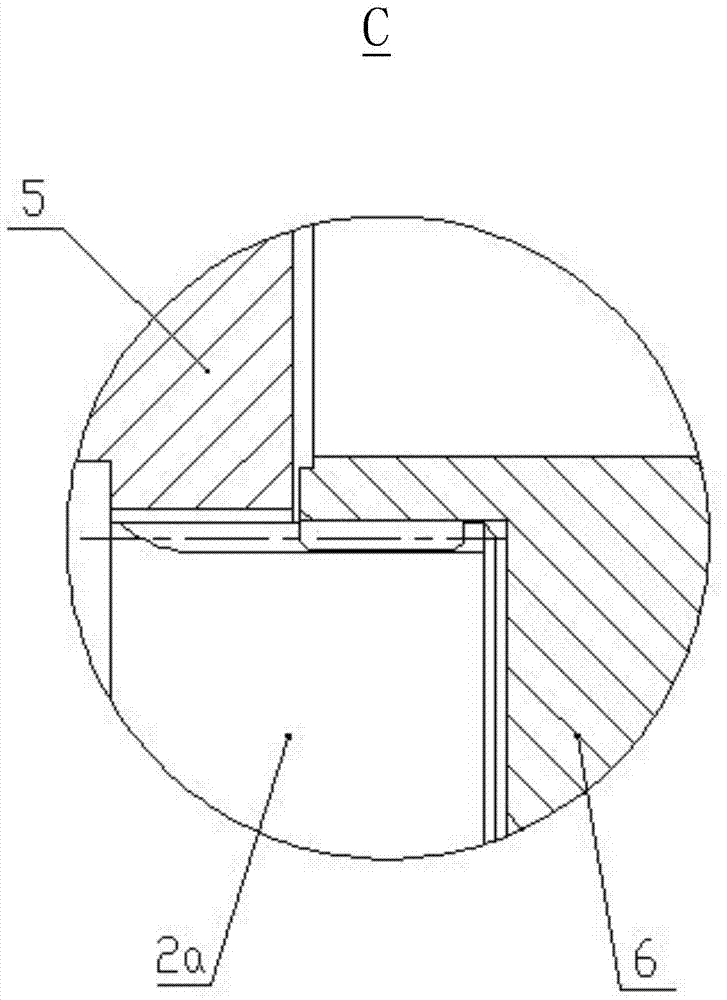

Double-cylinder rotary compressor

InactiveCN102235360AImprove rigidityReduce thicknessRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringCrankshaft

The invention relates to a double-cylinder rotary compressor. An electric engine section and a compressor section are arranged in a sealed housing. The compressor section comprises: a first cylinder, a second cylinder, a middle partitioning plate assembly arranged between the first cylinder and the second cylinder, a silencing cavity arranged on the middle partitioning plate, and a middle partitioning plate discharging apparatus arranged in the silencing cavity. The middle partitioning plate discharging apparatus comprises: two discharging ports arranged in the silencing cavity, wherein the discharging ports are respectively provided on the first cylinder compressing cavity and the second cylinder compressing cavity; two valve seats respectively arranged on the peripherals of the discharging ports; two discharging valves respectively arranged on the valve seats for opening and closing the discharging ports; a valve spring arranged between the two discharging valves for elastically adjusting the gap between the two discharging valves; cylinder walls or stop columns arranged on the outer sides of the two valve seats for limiting the scopes of the horizontal movements of the discharging valves. The double-cylinder rotary compressor provided by the invention is characterized in that: the rigidness of the middle partitioning plate assembly is high, the thickness of the middle partitioning plate assembly is small, crankshaft bending and middle partitioning plate deformation are not easy to occur, the product is easy to produce, and the application scope of the product is wide.

Owner:GUANGDONG MEIZHI COMPRESSOR

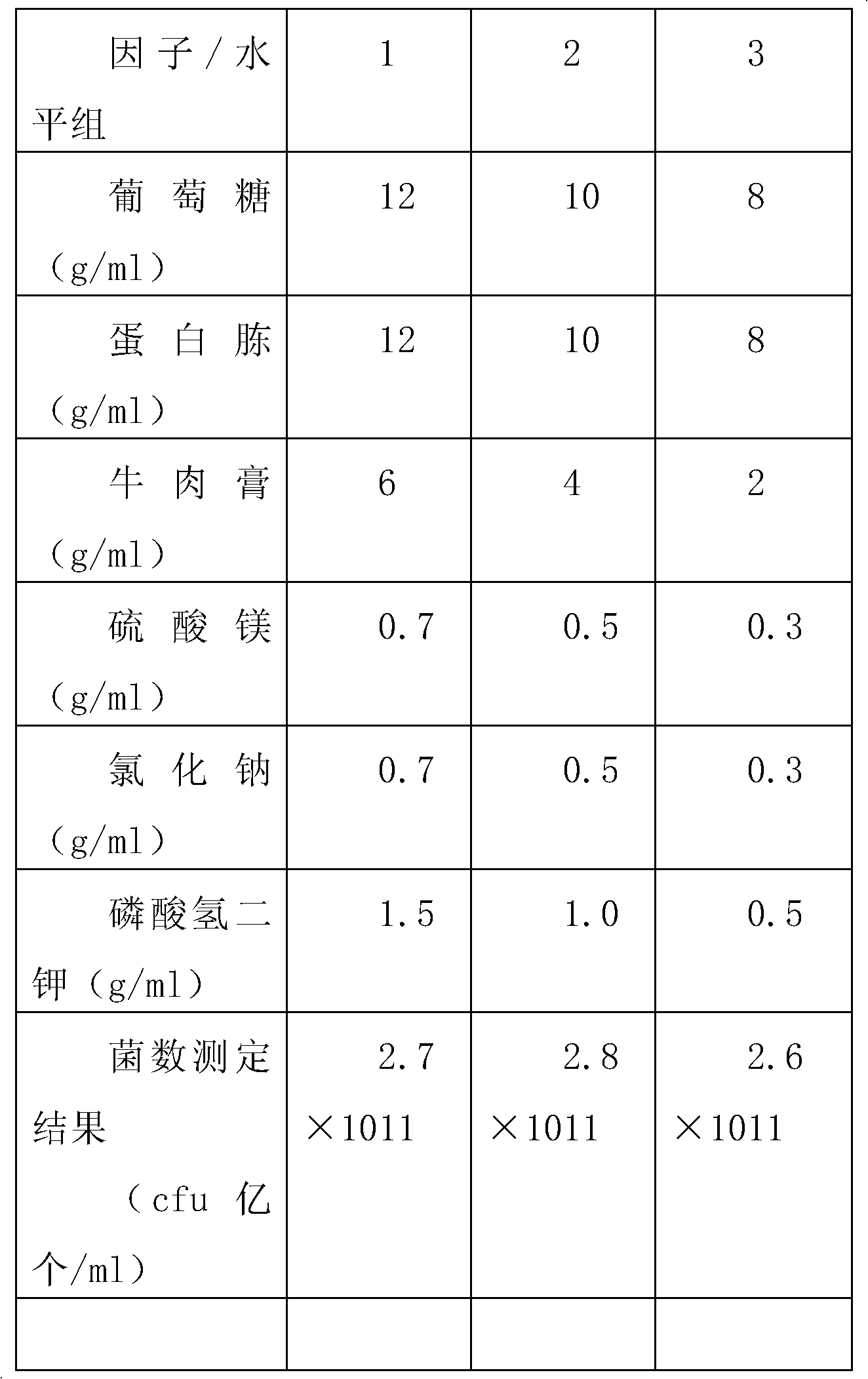

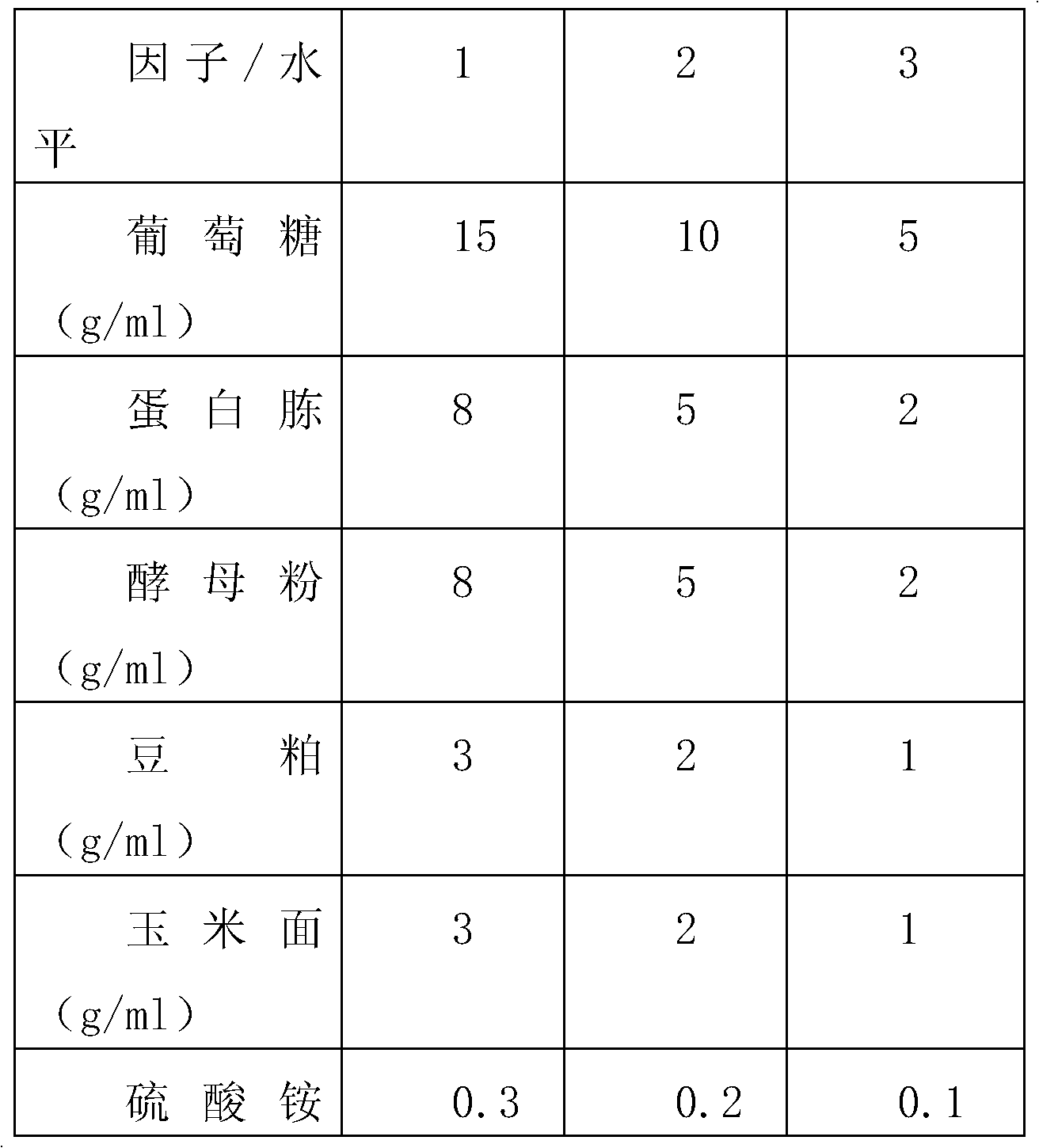

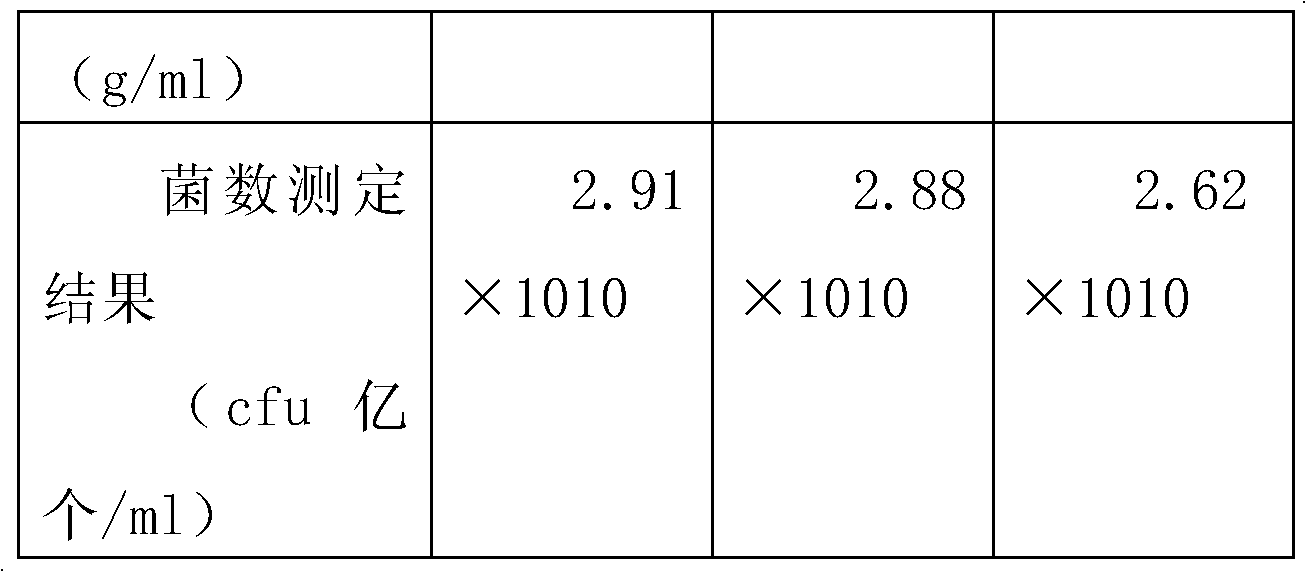

Production method of bacillus subtilis biological agent used for sodium humate-containing feed in medium

ActiveCN103184174AChoose appropriateNew technologyBacteriaAnimal feeding stuffBacterial strainFermentation

The invention relates to a microbe biological agent, and concretely relates to a production method of a bacillus subtilis biological agent used for a sodium humate-containing feed in a medium. The bacillus subtilis bacterial strain is subjected to first-stage solid seed culture and second-stage liquid seed fermentation culture to obtain a bacterial classification liquid. The bacterial classification liquid is inoculated in the medium which takes glucose, sodium humate, soybean meal, corn and wheat bran as raw materials for three-stage solid aerobic fermentation, the culture condition is adjusted to form spore, the spore can be treated, dried, and crushed to produce the bacillus subtilis biological agent. The biological agent contains more than or equal to 200 hundreds million / g of acillus subtilis, the pH value is 5.6-6.6, the moisture is less than or equal to 10%, and the granularity is greater than or equal to 100 meshes, the color presents special shallow grey or grey black, and the shelf life is 18 months. The biological agent can be taken as an additive application in aquatic product, and livestock and poultry culture, can increase the production performance and improve the culture environment.

Owner:SHENYANG BOSHAN YINGSHENG BIOLOGICAL TECH CO LTD

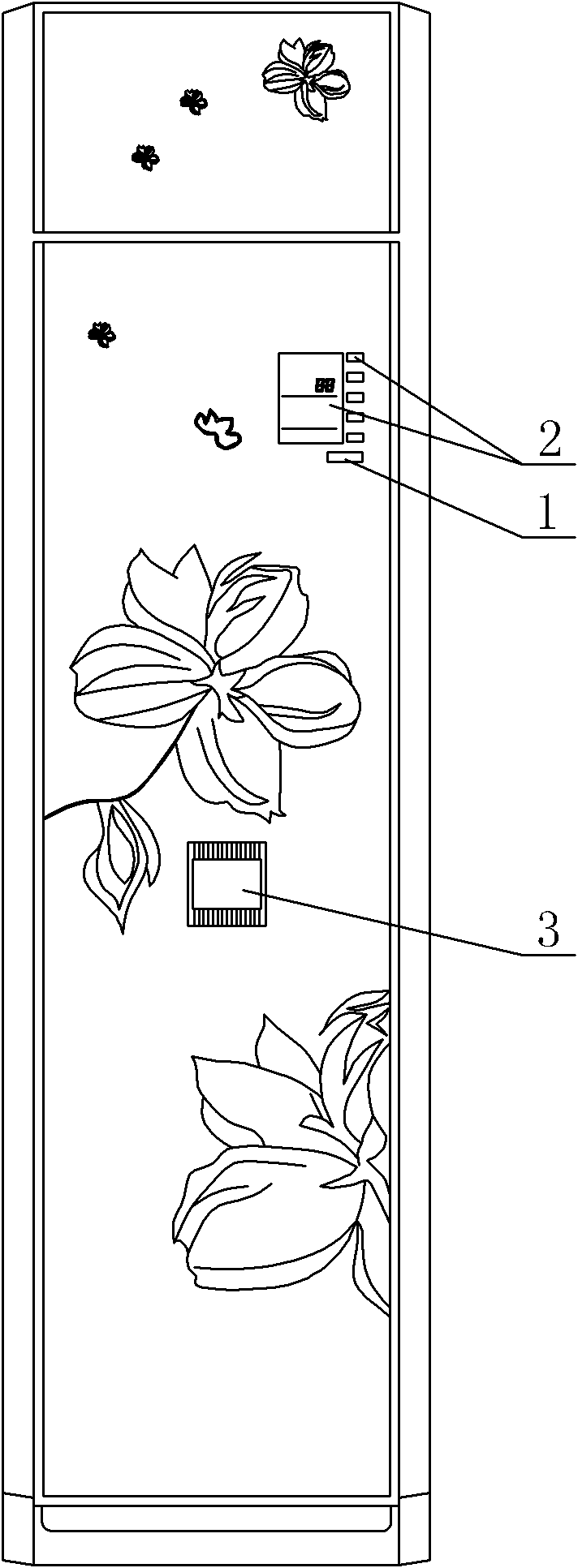

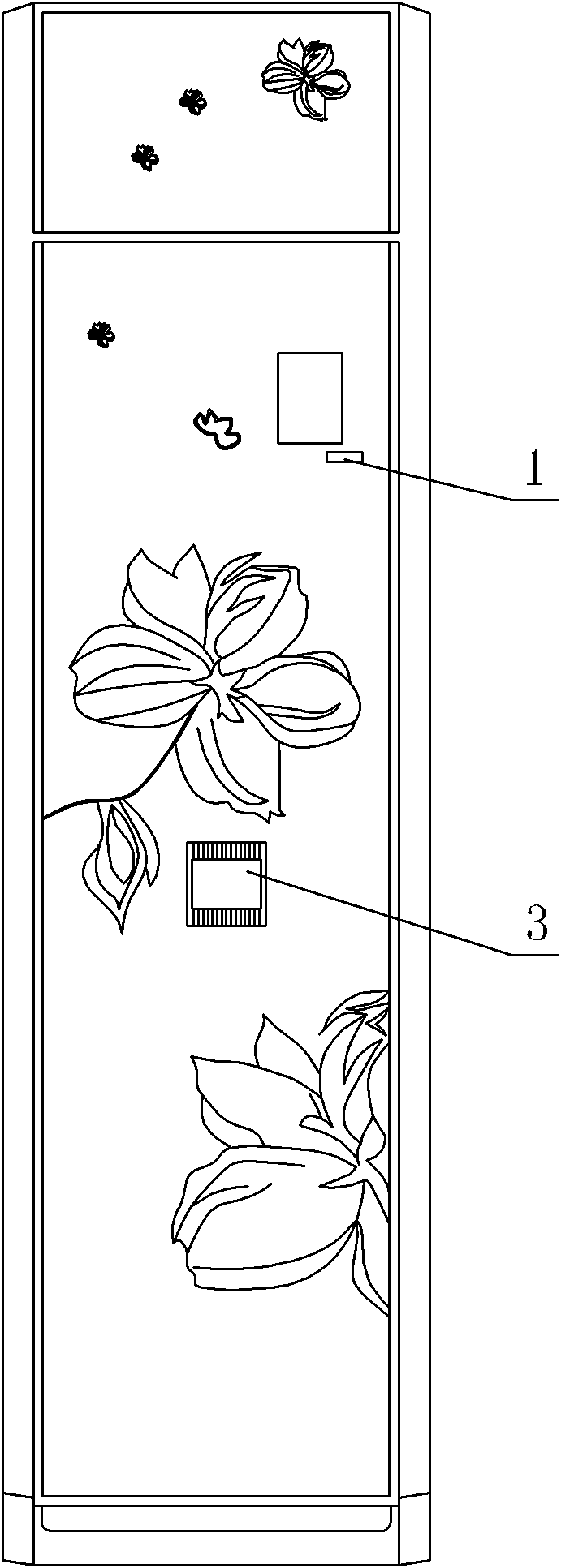

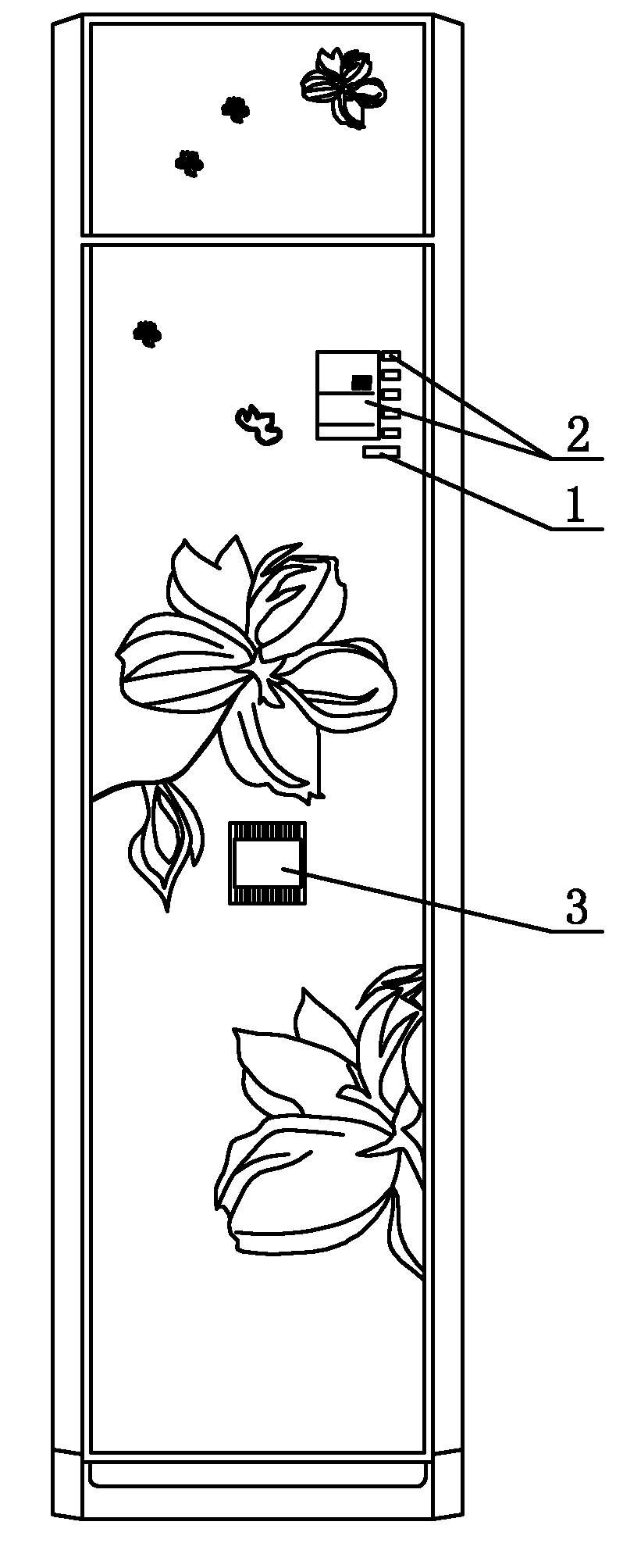

Floor type air conditioner and control method thereof

InactiveCN102192577AExtended service lifeSave energySpace heating and ventilation safety systemsLighting and heating apparatusInfraredEngineering

The invention relates to a floor type air conditioner comprising an air conditioner main body and a control assembly thereof. A human body induction control assembly is arranged on a panel of the air conditioner main body and is connected with a CPU (Central Processing Unit) within the air conditioner main body. The control method of the floor type air conditioner comprises the following steps: (1) infrared rays from a human body in front of the air conditioner are detected through an infrared sensor to judge whether any person exists in the room, and the quantity of the detected infrared rays is transmitted to the CPU; (2) according to changes of the quantity of the detected infrared rays, the CPU judges whether the indoor person needs to operate the air conditioner; (3) if the infrared sensor detects that any person exists indoors, the CPU sends instructions, an operation display interface enters a working mode; (4) if the infrared sensor detects that the person leaves the room, or no operation is carried out within the set period of time, the CPU sends instructions, the control assembly stops running, the operation display interface enters a dormant power-saving mode. The floor type air conditioner has the advantages of simple and reasonable structure, energy saving and environment friendliness and high reliability.

Owner:格兰仕(中山)家用电器有限公司

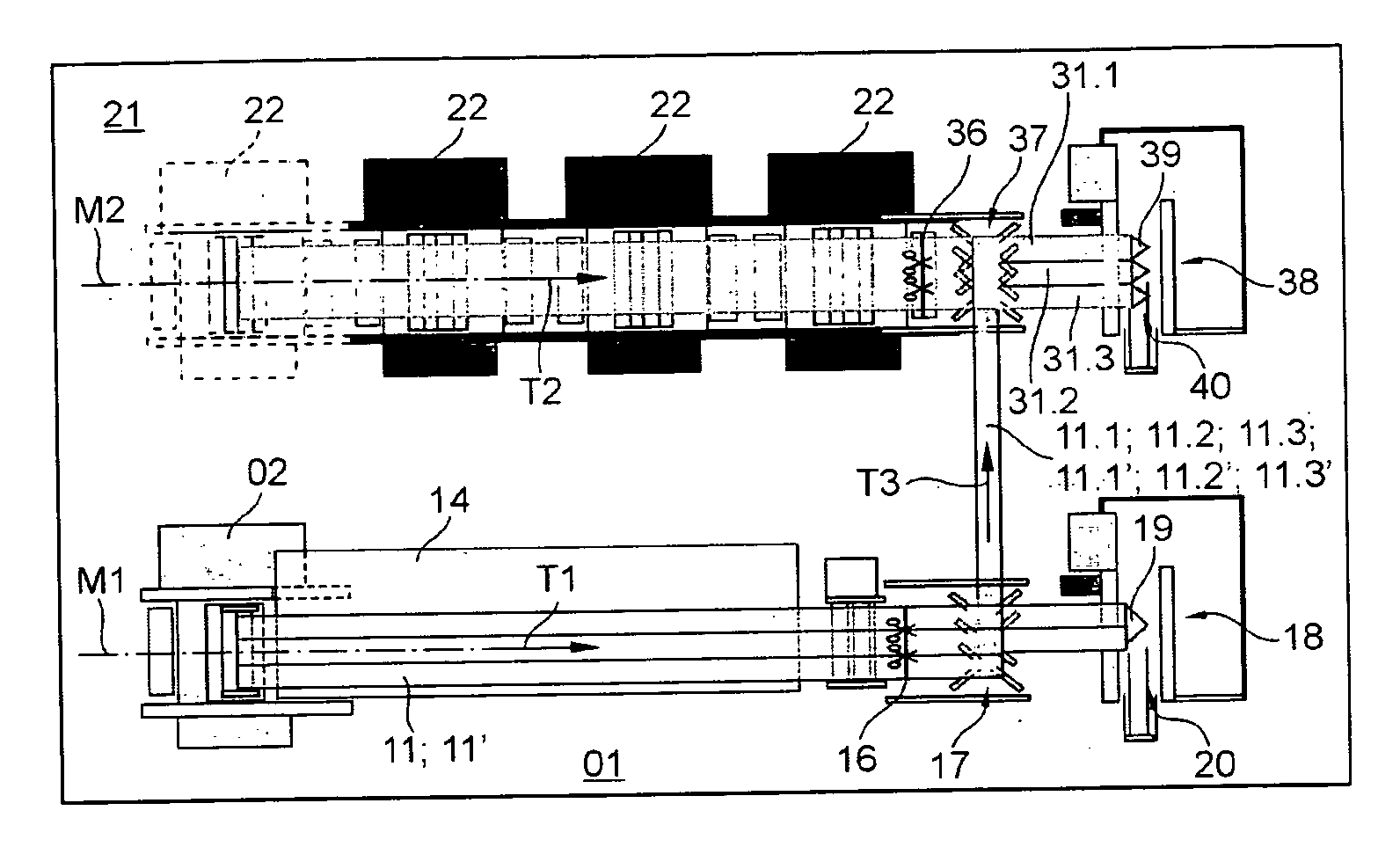

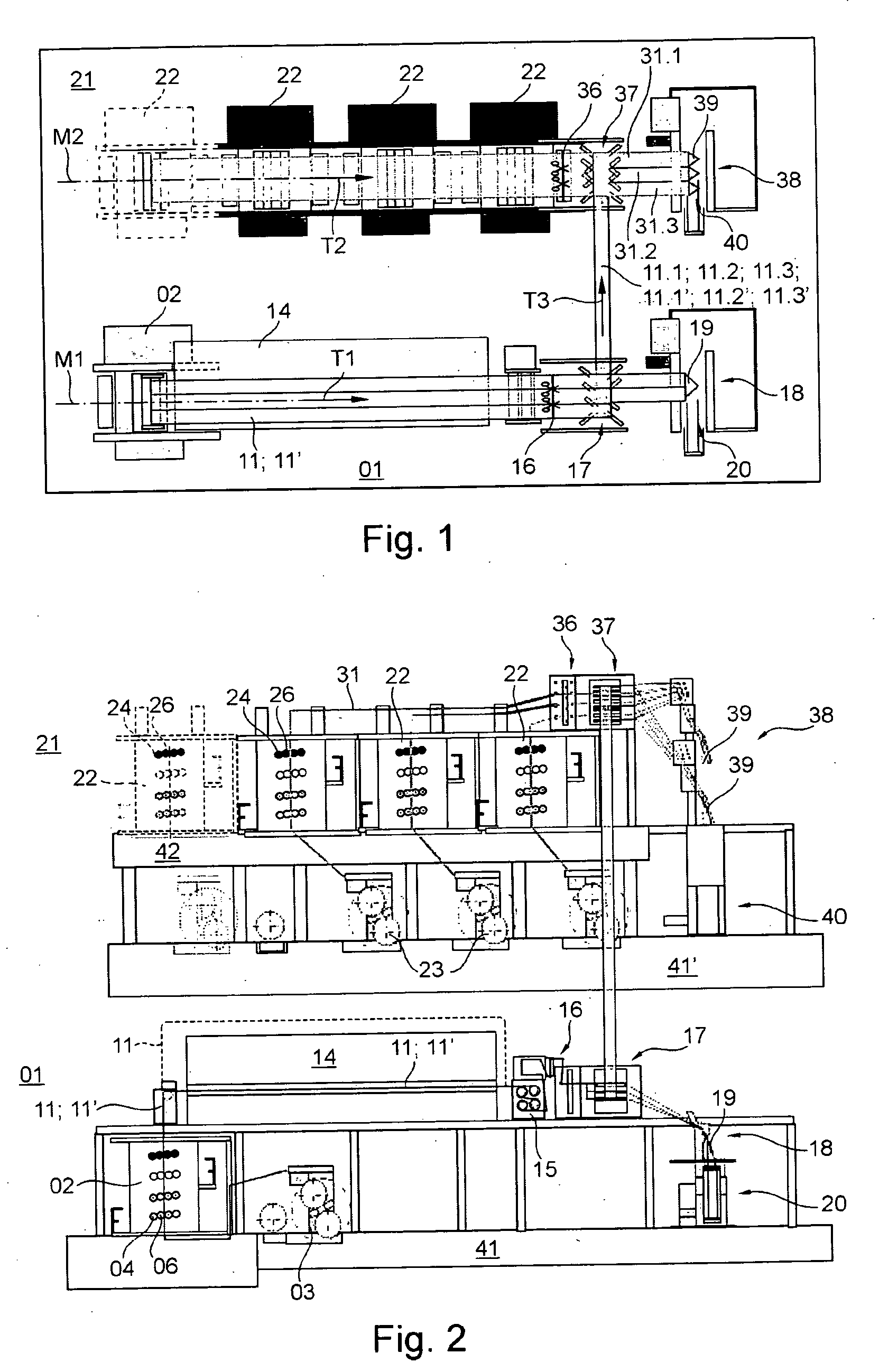

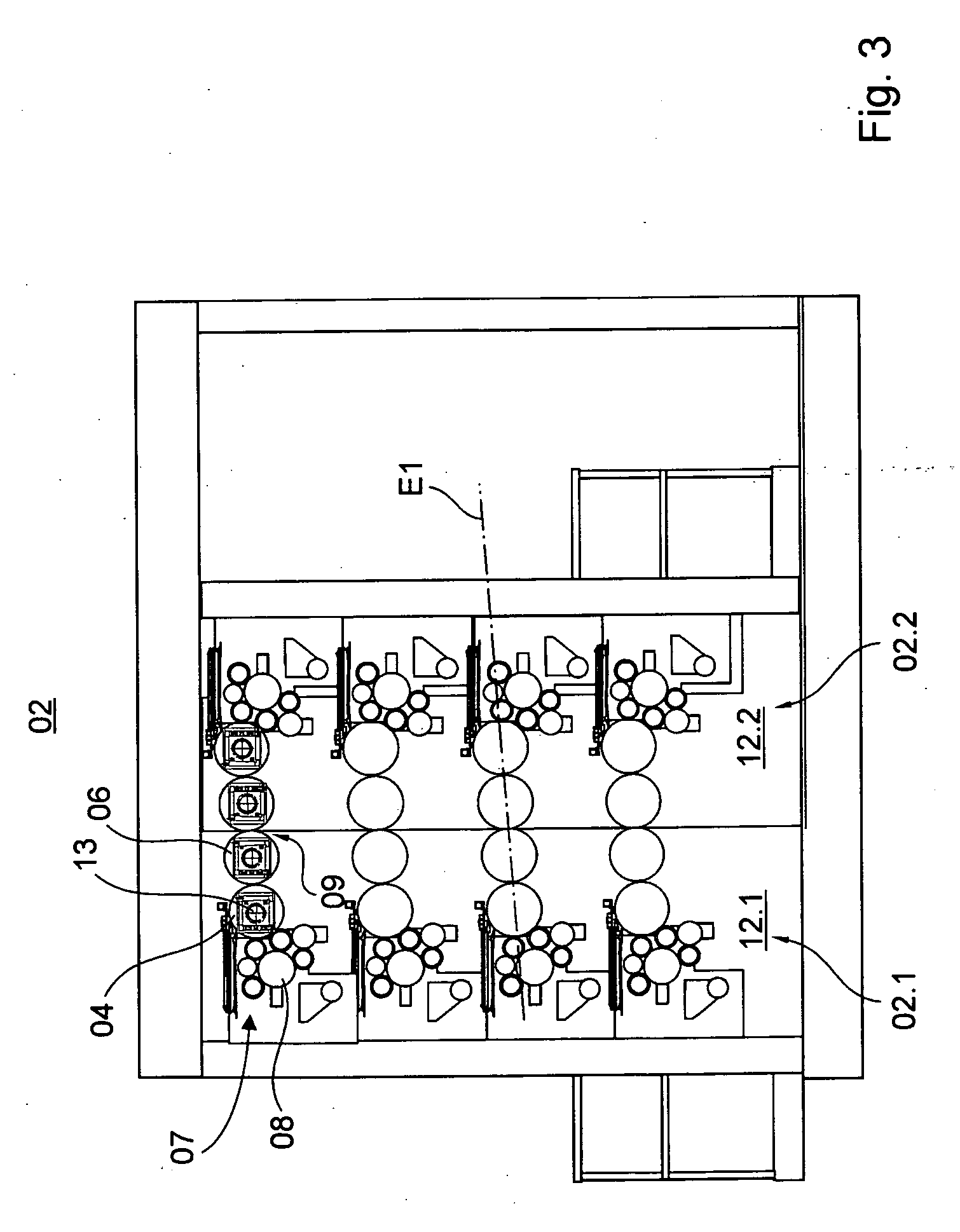

Printing press and method of operating a printing press, and printing press system and method of operating the printing press system

InactiveUS20090223393A1Easy to operateWide range of productsRotary letterpress machinesOffice printingPrinting pressElectrical and Electronics engineering

A printing press is comprised of at least one dry offset printing unit. At least two different webs can be fed through the dry offset printing unit. In a first production mode “C” of the printing press, a first web is fed through the dry offset printing unit without a subsequent drying process. In a second production mode “H” of the printing press, a second web is fed through the dry offset printing unit and through an active dryer. In both the first and second production modes “C”, “H”, an inking unit of the printing unit is filled with the same ink.

Owner:KOENIG & BAUER AG

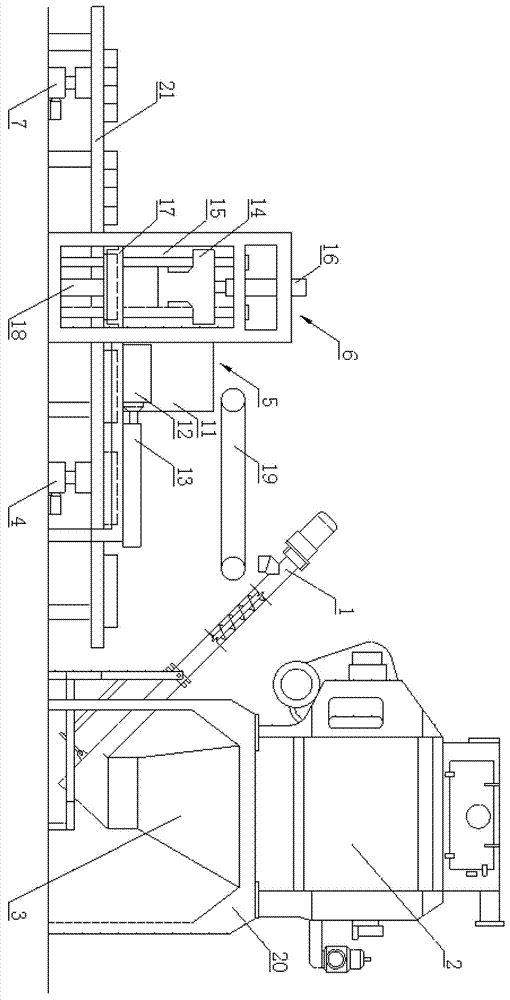

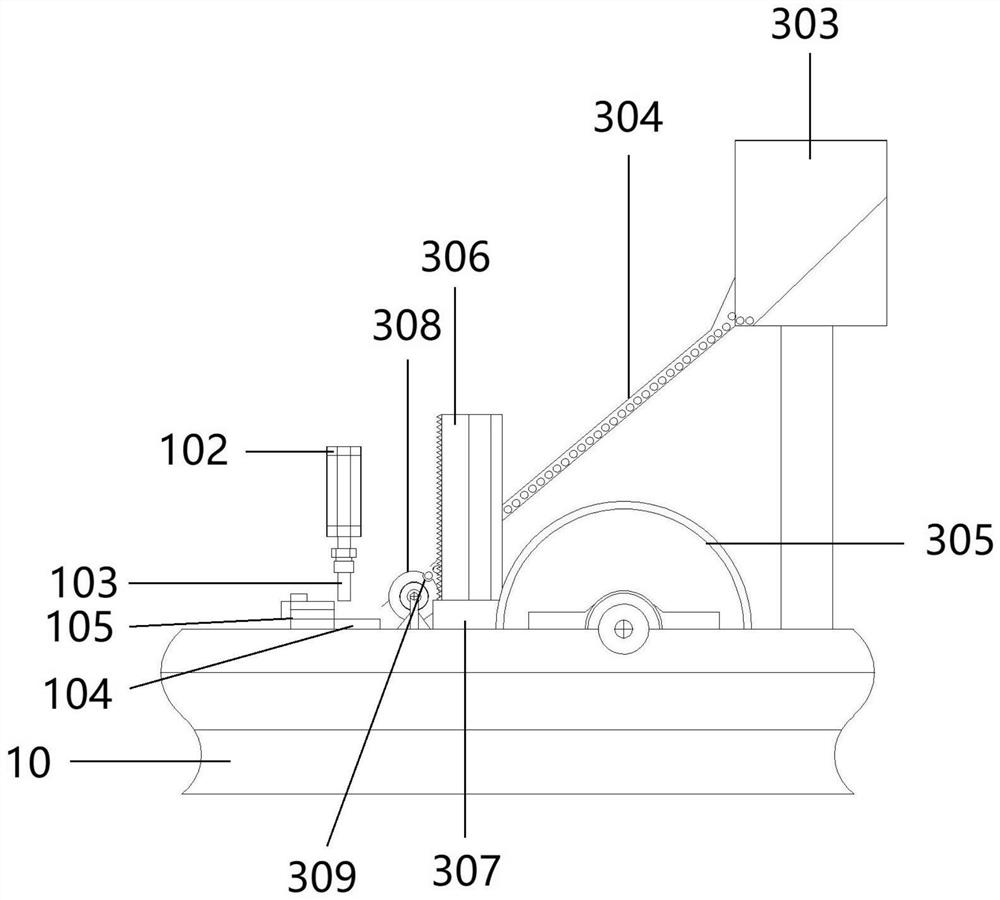

Continuous brick building block forming system

InactiveCN102825647ADouble the mixing efficiencyReduce energy consumptionCeramic shaping apparatusManufacturing technologyBrick

The invention relates to the technical field of manufacturing of brick block forming equipment, in particular to a continuous brick building block forming system which has the advantages of compact structure, short forming period, uniform distribution, good compaction effect of a product and reliability in operation. The continuous brick building block forming system comprises a stirring device, a spiral elevator (1) and a brick making building block device which are arranged in sequence, wherein the stirring device consists of a stirring machine (2) and a concrete storage hopper (3); the brick making building block device consists of an automatic plate feeder (4), an automatic distributor (5), a building block forming machine (6) and an automatic brick discharger (7); the concrete storage hopper (3) is hermetically arranged below the stirring machine (2); a discharge port of the concrete storage hopper (3) is hermetically connected with a feed end of the spiral elevator (1); the automatic distributor (5) is arranged below a discharge end of the spiral elevator (1); the automatic plate feeder (4) is connected below the automatic distributor (5), and the building block forming machine (6) is arranged on one side of the automatic plate feeder (4); and the automatic brick discharger (7) is arranged on the other side of the building block forming machine (6).

Owner:马倩

Preparation method of instant-soluble polygonatum kingianum powder

The invention provides a preparation method of instant-soluble polygonatum kingianum powder and relates to a production process of producing the instant-soluble polygonatum kingianum powder with leaves of polygonatum kingianum. The method solves the problem that the leaves of polygonatum kingianum are wasted and are not fully utilized at present and includes the following steps: collection and cutting, microwave de-enzyming, rolling and drying, hot-extraction, enzyme extraction, anti-oxidizing treatment, squeezing and filtration, vacuum concentration and drying, and vacuum packaging. The preparation method fully utilizes plant vegetables with the leaves of polygonatum kingianum as a raw material, is low in production cost, is high in extraction efficiency, is good in taste and high in quality, is rich in nutrition and has many applications.

Owner:ANHUI TIANPINTANG ECOLOGICAL TECH CO LTD

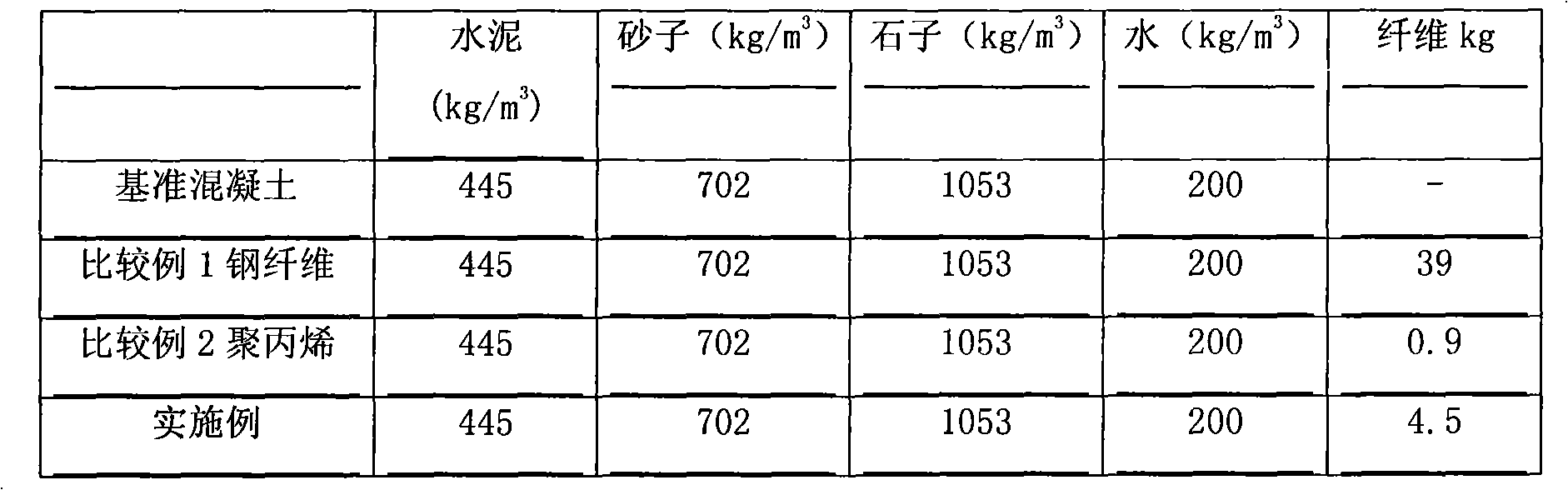

Structure enhanced synthetic fiber for concrete and preparation thereof

InactiveCN101348342AHigh compressive strengthHigh tensile strengthMelt spinning methodsSevering fibresRough surfacePolyamide

The invention relates to a structurally reinforced synthetic fiber for concrete. The synthetic fiber is prepared by processes of fusion, spinning, dispersion and fixing, and the synthetic fiber comprises the following components: 20 to 70 percent of polypropylene, 25 to 75 percent of polyethylene, 0 to 25 percent of polyamide, 0.05 to 0.5 percent of nucleating agent and 0.1 to 0.5 percent of antioxidant. The synthetic fiber of the invention has rough surface and clear contour, and has good dispersibility and cement basal body with excellent cementing property; the product has not only the functions of steel fibers, but also advantages of synthetic fibers, so that the synthetic fibers of the invention is mainly used to replace weld metal screens and steel fibers in the concrete panel structure for improving the bending resistant, shock resistant and fatigue resistant performance of concrete.

Owner:南京派尼尔科技实业有限公司

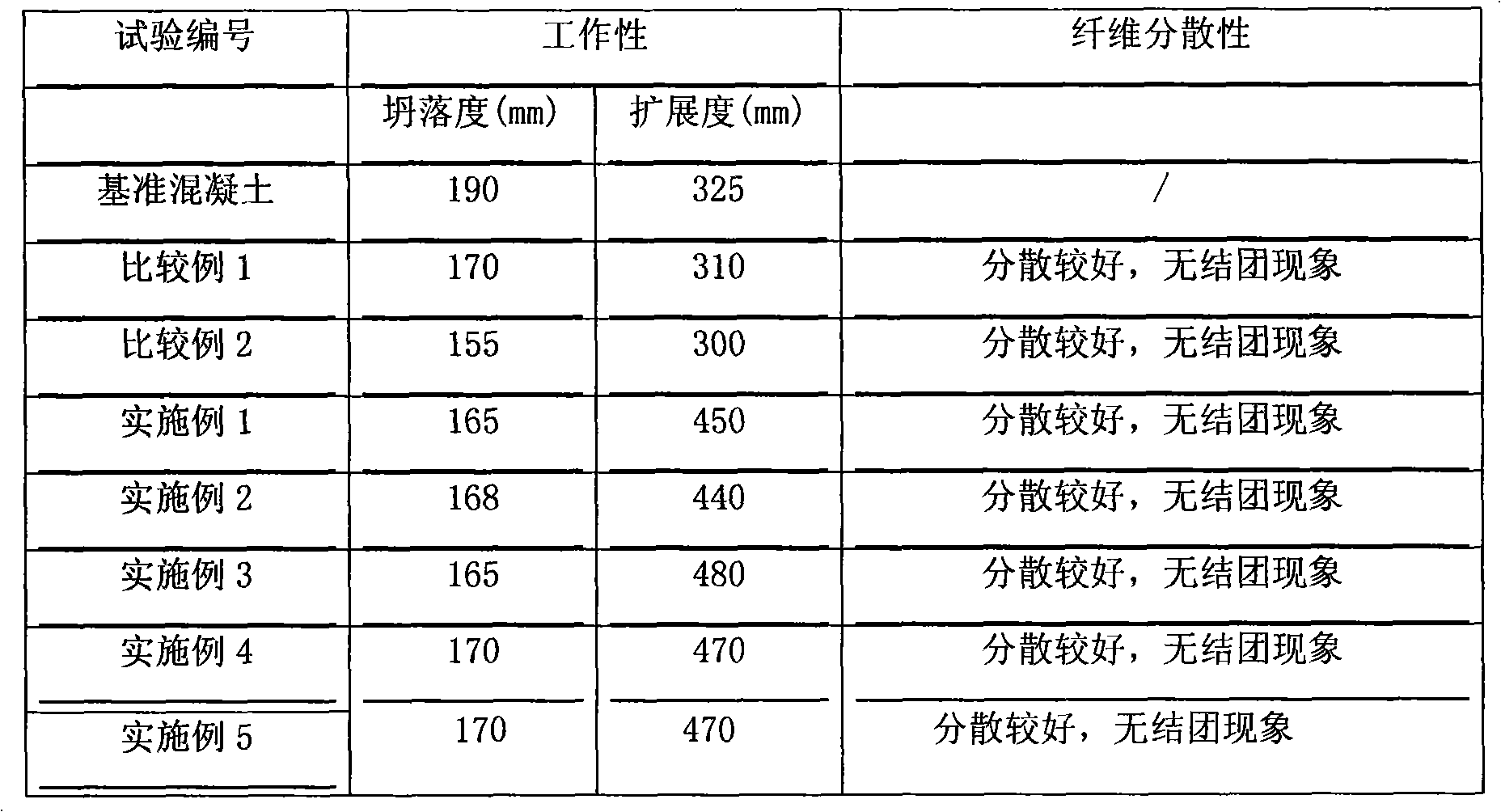

Method for producing paper tubes by waste paper pulp

InactiveCN102700174ALow costHigh speedEnvelopes/bags making machineryPaperboardPulp and paper industry

The invention relates to a method for producing paper tubes by waste paper pulp. The method is characterized in that the waste paper pulp used as a raw material is blended with glue and stone powder to produce the paper tubes by a squeezing method. Paper pulp is manufactured by steps including 1, uniformly grinding the waste paper pulp disposed during production of a paper mill by a grinder; 2, beating waste paperboards by a beater to obtain paper pulp; and 3, mixing the waste paper pulp and the paper pulp manufactured from the waste paperboards into mixed waste paper pulp. The glue is manufactured by steps including 1, boiling water and adding polyvinyl alcohol into the water to prepare glue; and 2, adding borax and caustic soda flakes into corn starch to prepare glue. The paper tubes made of the waste paper pulp have the advantages of low production cost, fast speed, good quality, simplicity in operation, wide production range and high applicability, and have an excellent commercial prospect, and the method is an ideal paper tube production method at present.

Owner:任立群

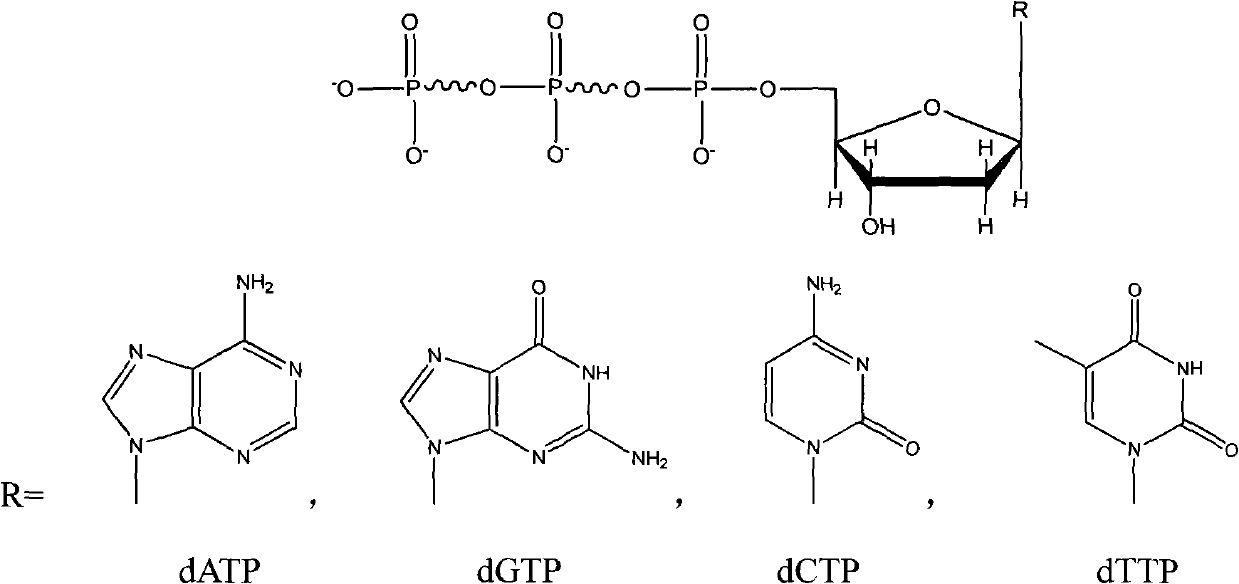

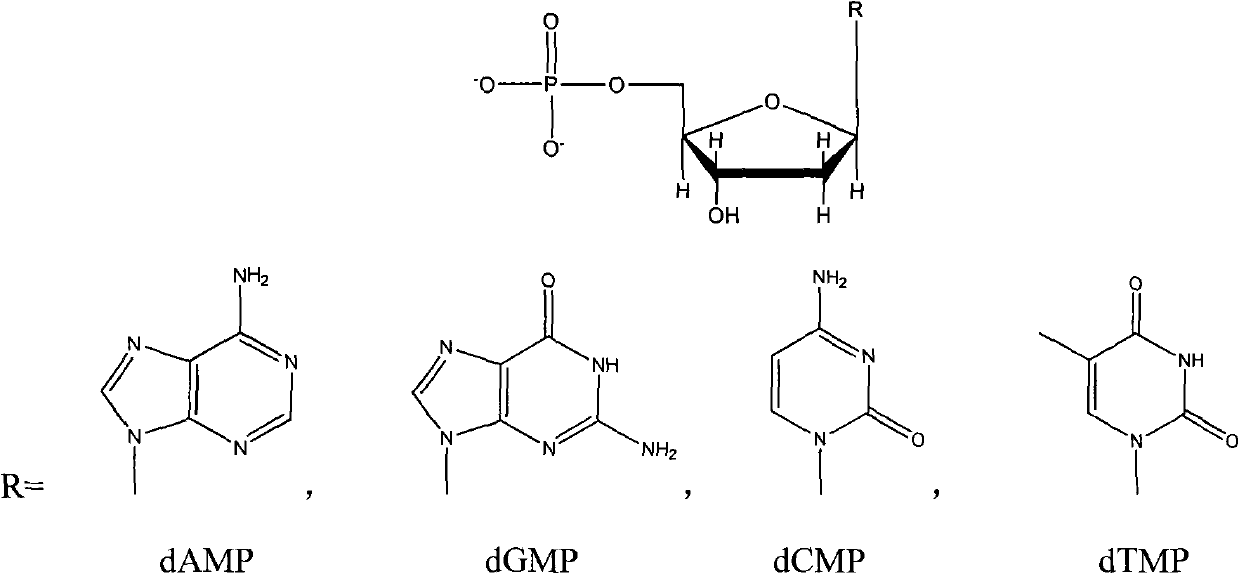

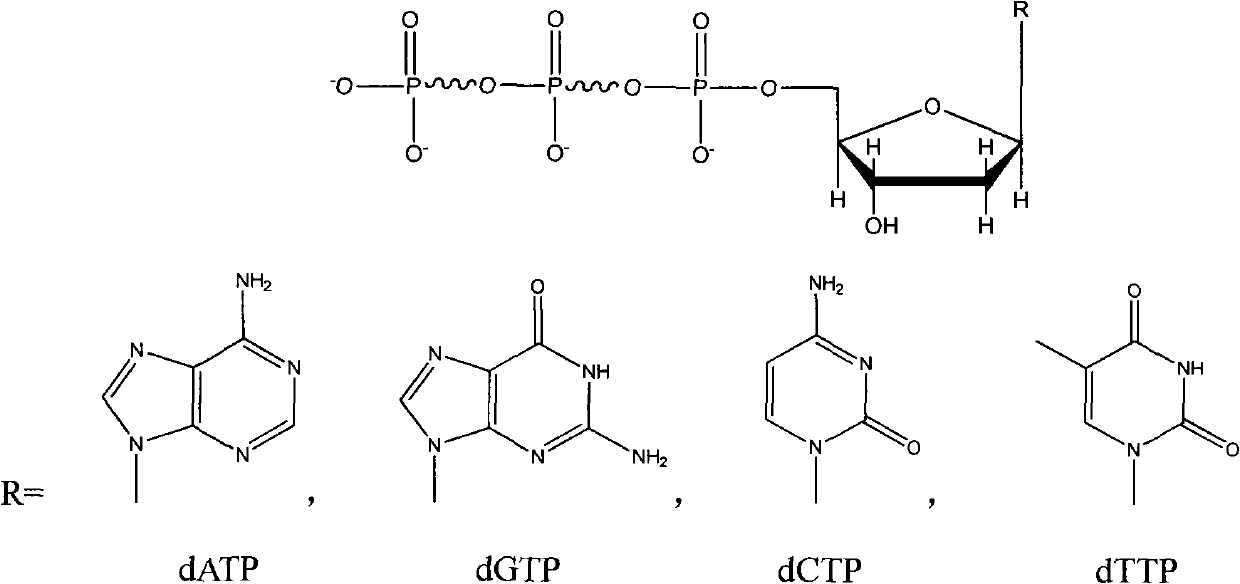

Novel technology for full cellular biosynthetic deoxyribonucleoside triphosphate

InactiveCN101768617ARich in enzymesWide range of productsMicroorganism based processesFermentationDeoxynucleoside triphosphateDeoxyribonucleoside triphosphate

The invention discloses novel technology for full cellular biosynthetic deoxyribonucleoside triphosphate, which takes deoxyribonucleoside monophosphate dNMP and phosphate anions as a substrate and saccharide as a power supplier, and uses permeable yeast cells for reaction in the presence of chemical effect substances to prepare the deoxyribonucleoside triphosphate. According to the technology, the theory of full cellular catalysis and metabolic engineering is used and the chemical effect substances are adopted to regulate and control a metabolic flow, so that a high effective power self-coupling and regeneration system is established, and high effective preparation of the deoxyribonucleoside triphosphate is finally realized. The novel technology for the full cellular biosynthetic deoxyribonucleoside triphosphate overcomes the disadvantages of the conventional production process of the deoxyribonucleoside triphosphate, and has the characteristics of simple process, high conversion, low cost and light pollution, and the like.

Owner:NANJING UNIV OF TECH +1

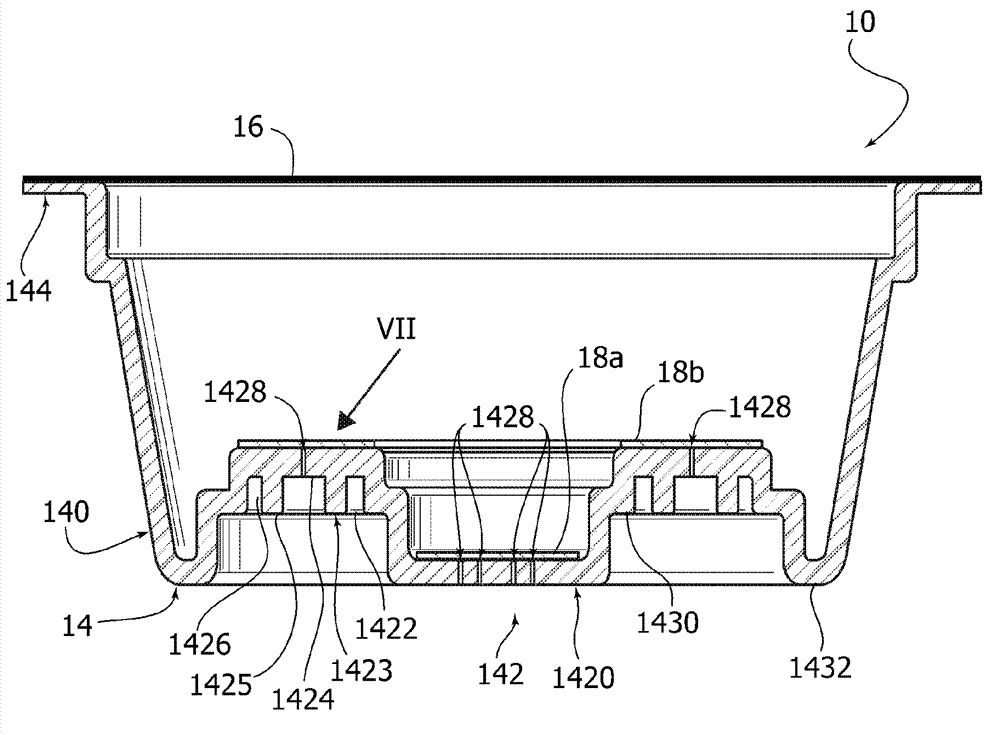

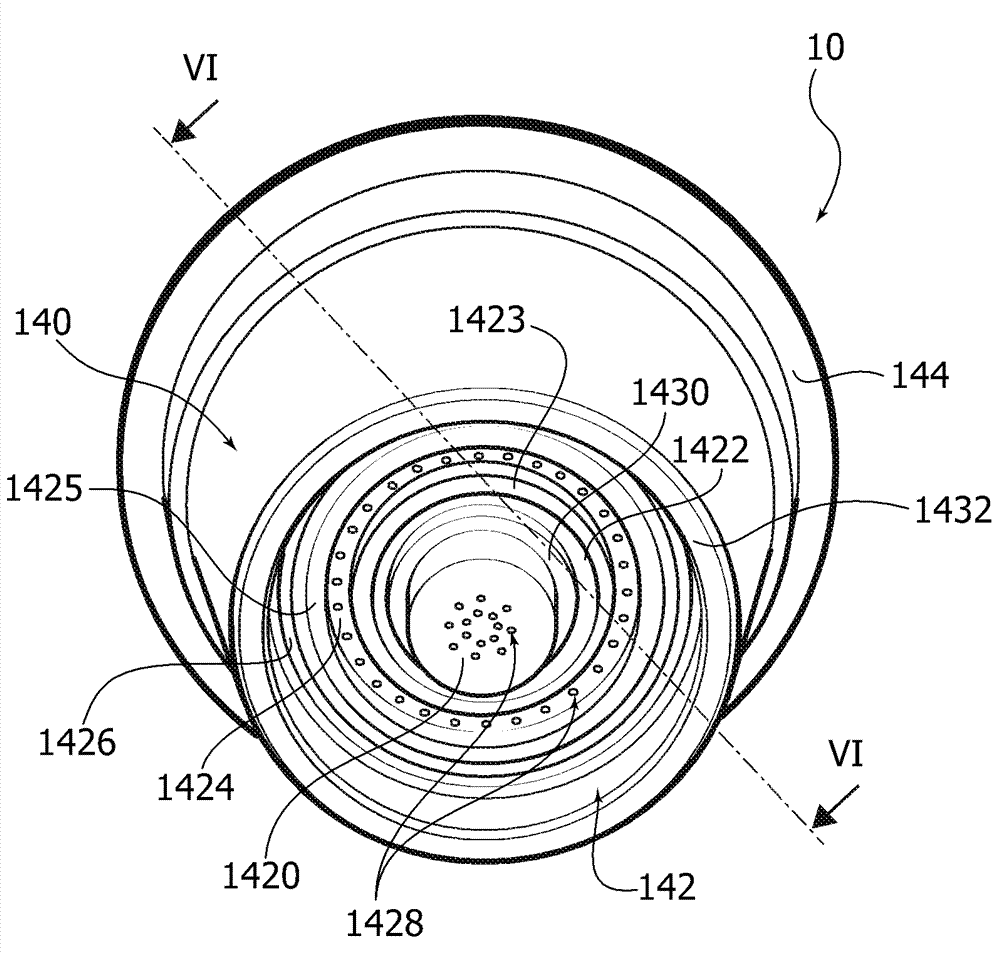

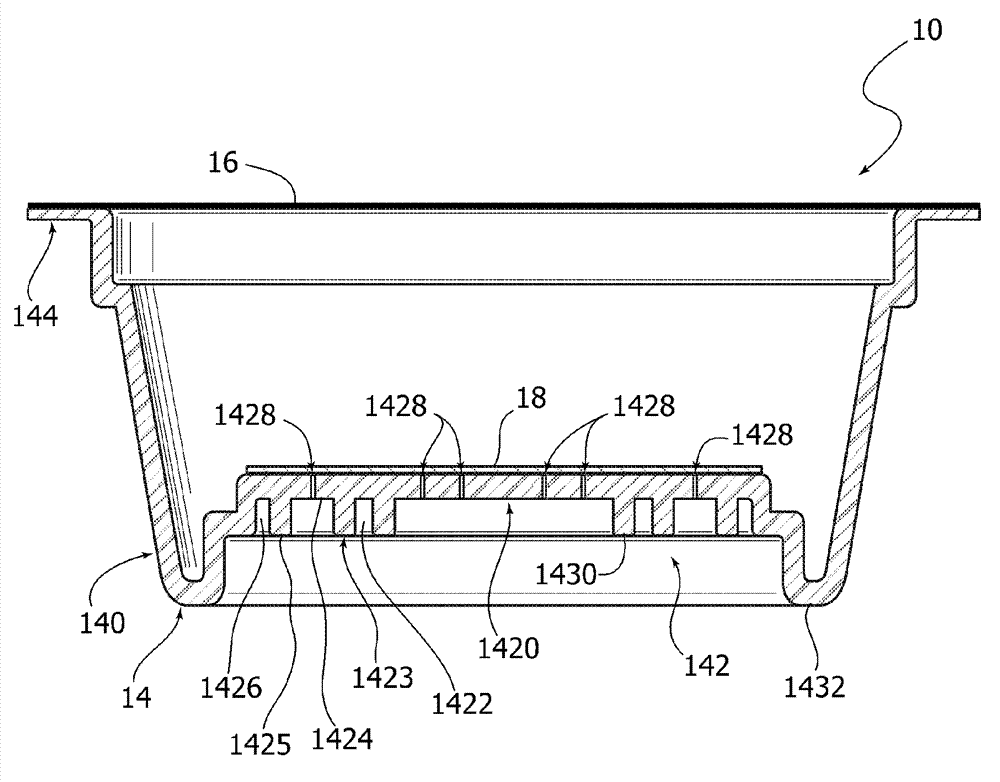

Cartridge for preparing a liquid product, and process for production thereof

ActiveCN104854001APrevent unwanted releaseIncrease flexibilityFlexible coversWrappersLiquid productSurgery

A cartridge (10) containing a dose (12) of at least one substance for preparing a liquid product, e.g., coffee, by means of liquid and / or vapour introduced into the cartridge (10). The cartridge comprises a casing (14) containing the aforesaid dose (12) with a bottom wall (142) through which the liquid product may flow out of the cartridge (10). The bottom wall (142) has, as viewed from outside the cartridge (10) : - a central portion (1420); - a first annular cavity (1422) that surrounds the central portion (1420); - an intermediate annular portion (1424) that surrounds the first annular cavity (1422) and is separated from the latter by a first annular rib (1423); and - a second annular cavity (1426) that surrounds the intermediate annular portion (1424) and is separated from the latter by a second annular rib (1425). The bottom wall (142) has openings (1428) for exit of the liquid product from the cartridge (10), which are localized, for example, in at least one from between, and preferably in both, the aforesaid central portion (1420) and the aforesaid intermediate portion (1424).

Owner:LAVAZZA

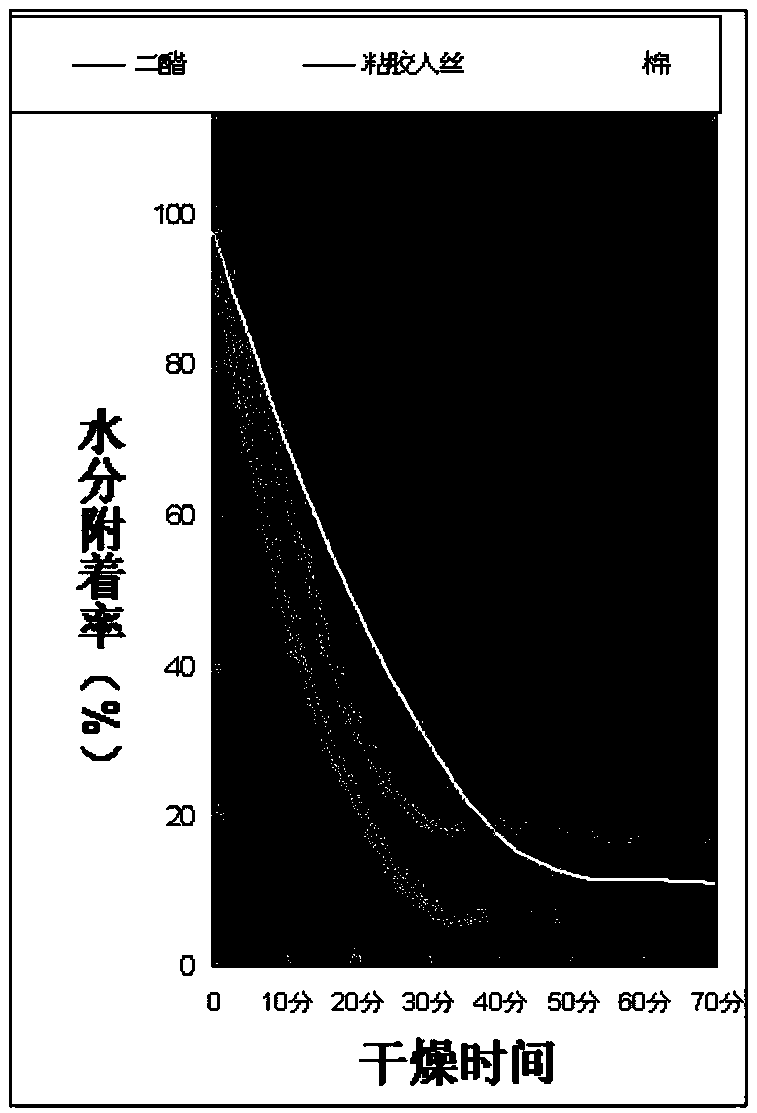

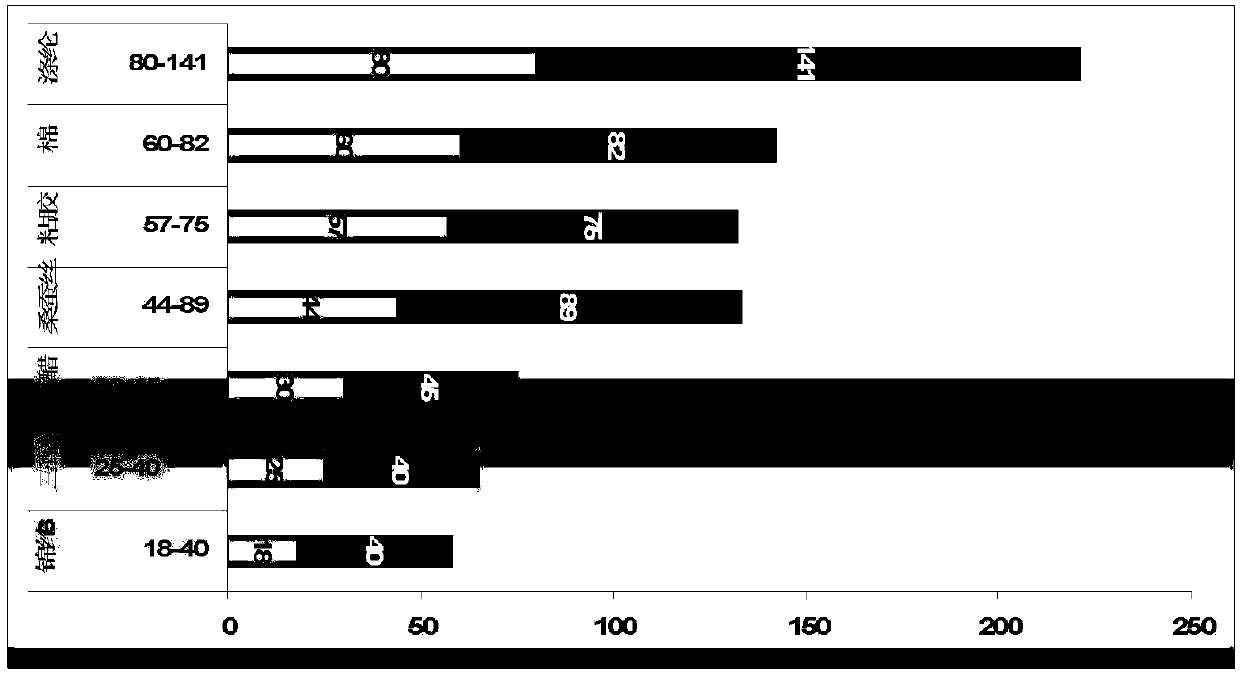

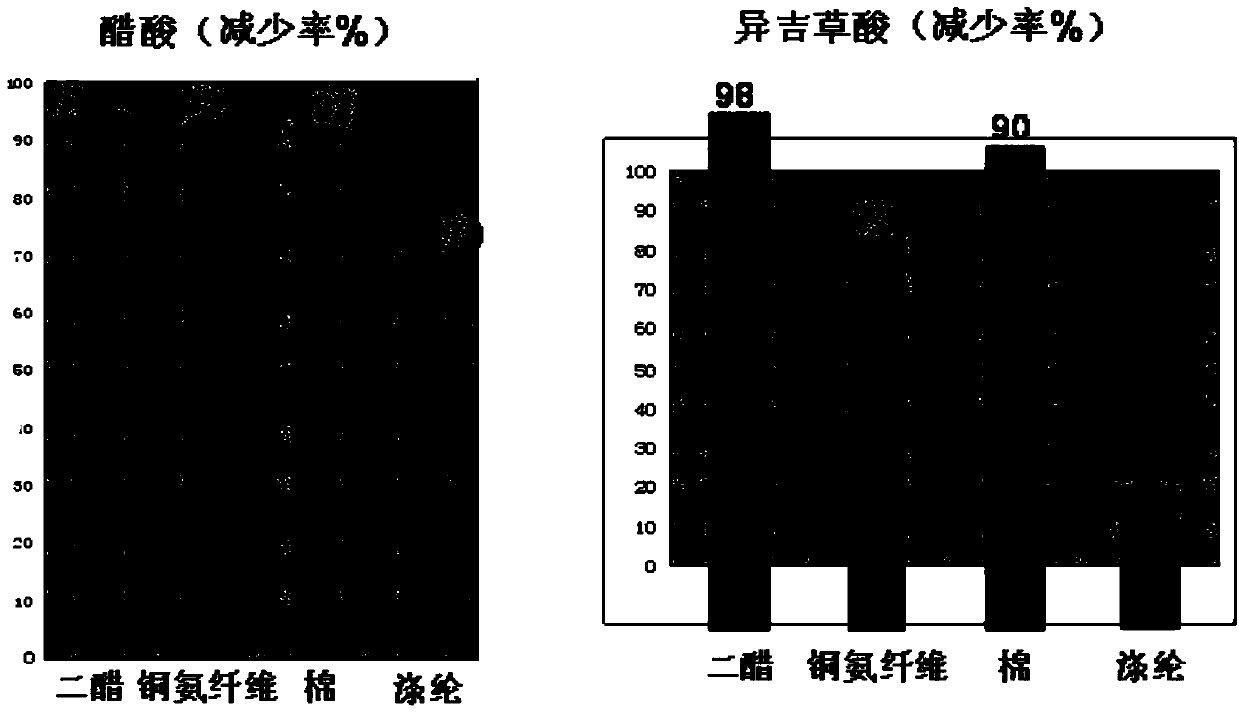

Tencel and diacetate interwoven fabric manufacturing method

InactiveCN107700034AImprove product qualityLow priceLiquid/gas/vapor open-width material treatmentDyeing processAir-jet loomEngineering

A tencel and diacetate interwoven fabric manufacturing method includes: adopting tencel as warp yarns, weaving diacetate filaments on an air-jet loom, and taking the diacetate filaments as weft yarns;performing a tencel fiber spinning step; performing a weaving step, an afterfinish scouring and dyeing step and the like. Defects of the diacetate filaments are overcome while appearance and handfeelof fabrics are guaranteed, and low cost is realized.

Owner:YUYUE HOME TEXTILE

Preparation process of indent silk printing glass

The invention relates to a preparation process of indent silk printing glass, which comprises the following steps of: 1, coating ink a on a screen printing plate, then printing on the surface of the glass, thoroughly drying; 2, fully printing ink b on the surface of the glass obtained from the step 1, thoroughly drying; and 3, spraying paint on the surface of the glass obtained from the step 2, and drying to obtain the indent silk printing glass. Compared with the prior art, the indent silk printing glass has the advantages of remarkable convex and concave effect, attractiveness and the like.

Owner:SHANGHAI YUNLANG KITCHEN EQUIP MFG

Automatic projection welding machine

The invention discloses an automatic projection welding machine. The automatic projection welding machine comprises a rack, a projection welding device, a warp wire inlet device, a weft wire inlet device, a discharging device and a discharging device, wherein the projection welding device, the warp wire inlet device, the weft wire inlet device, the discharging device and the discharging device areinstalled on the rack; warp steel bars wound around a warp steel bar disc penetrate into a rotary wire inlet pipe installed on the rack; wire inlet rolling shafts are distributed in an up-down staggered manner, and one end of each wire inlet rolling shaft is connected with a rolling shaft servo motor used for driving the corresponding wire inlet rolling shaft to rotate to drive wire inlet of thecorresponding warp steel bar; driven rolling wheels transfer weft steel bars to the warp steel bars between an upper electrode and a lower electrode for welding; an upward hook is arranged at the front end of a mechanical arm and used for hooking a net rack to move; a mechanical arm air cylinder controlling the mechanical arm to rotate up and down is arranged at the lower portion of the mechanicalarm; and a material cutting cutter for cutting off the net rack is arranged at the rear end of a discharging frame and used for cutting the net rack into finished net racks. According to the automatic projection welding machine, automatic feeding, cutting, welding and discharging of the warp steel bars and the weft steel bars are achieved, manpower is saved, the production efficiency is improved,unnecessary hurt to operators is avoided, and the quality of the net rack is better.

Owner:LAIWU IRON & STEEL GRP

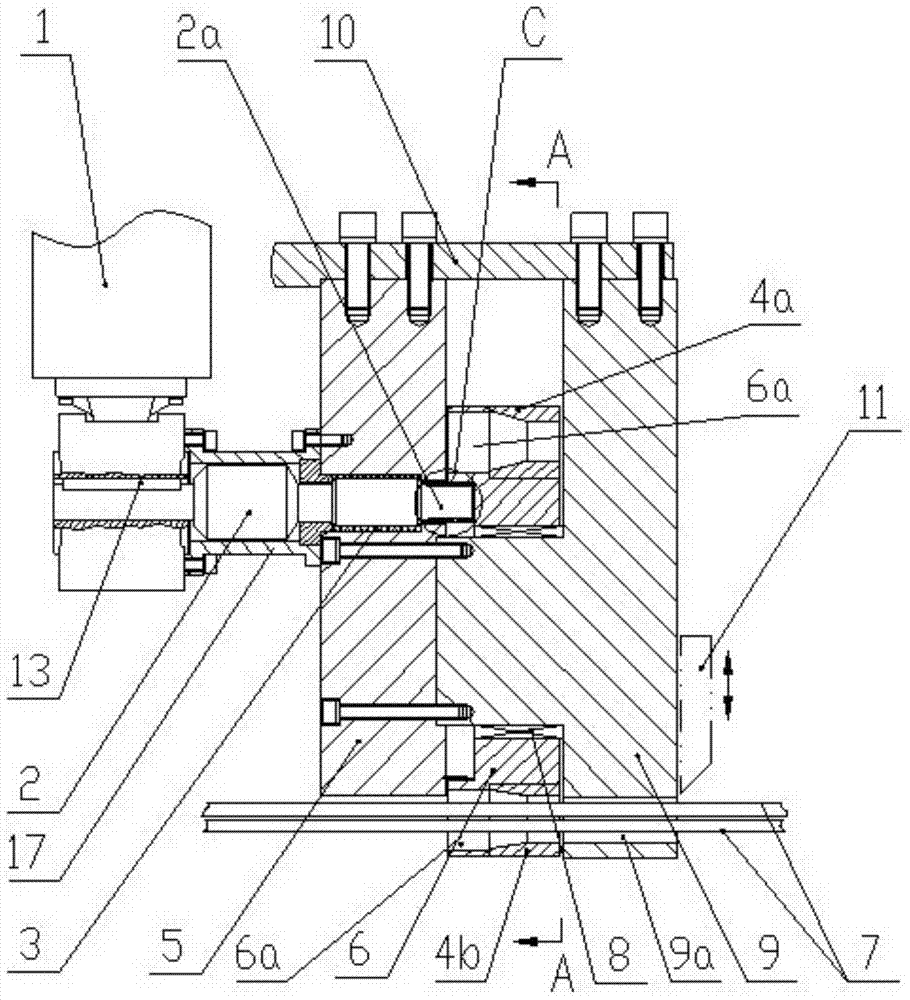

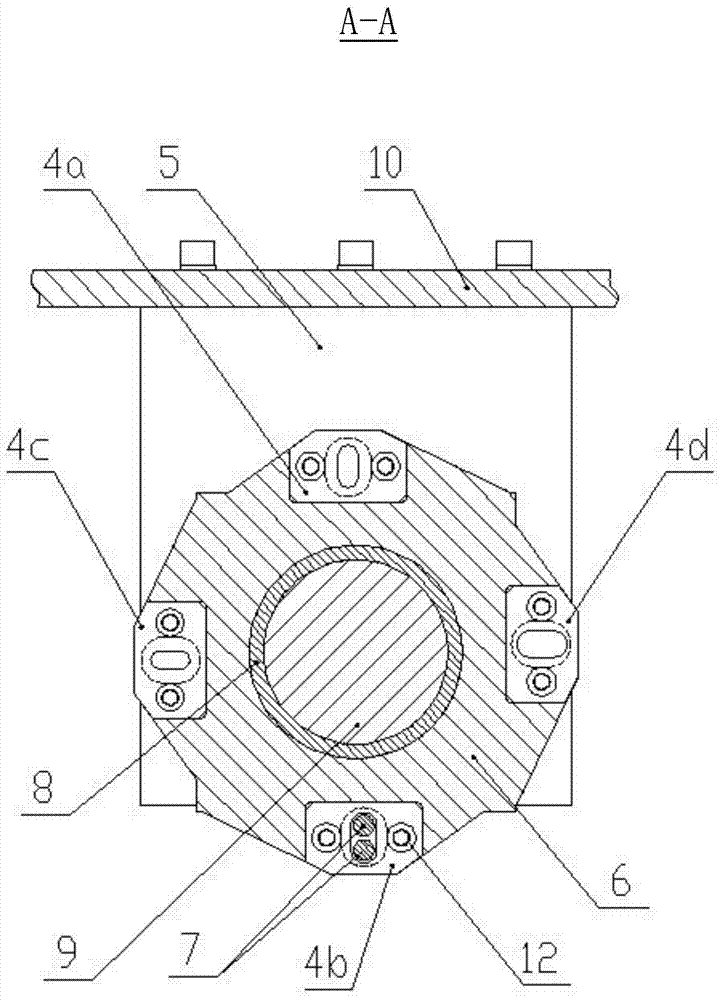

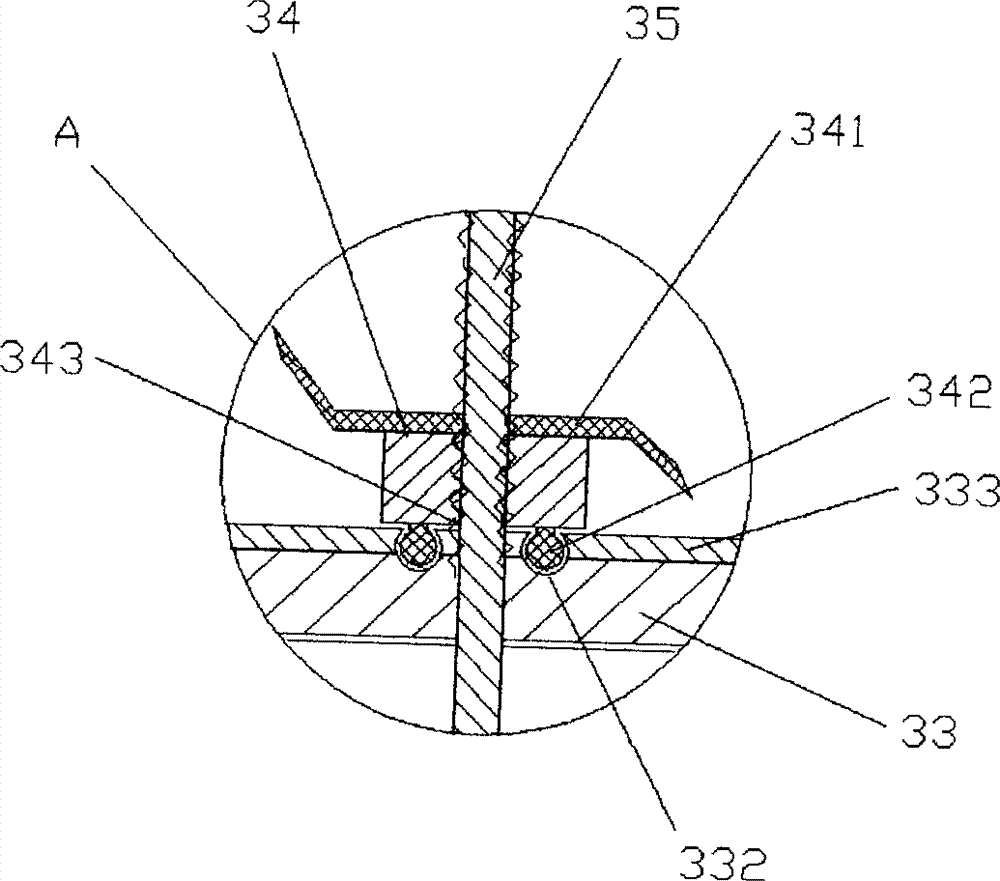

Automatic replacement fixed knife mechanism for steel bar automatic hoop bending machine

The invention discloses an automatic replacement fixed knife mechanism for a steel bar automatic hoop bending machine. According to the automatic replacement fixed knife mechanism, a rotating knife holder is hinged to a cutting fixing frame, and the lower portion of the cutting fixing frame is provided with steel bar cutting holes; a plurality of fixed knives are installed on one side of the rotating knife holder and correspond to the steel bar cutting holes, an inner gear is positioned on the other side of the rotating knife holder, a small gear meshed with the inner gear of the rotating knife holder is positioned at one end of a gear shaft, the other end of the gear shaft is connected with a motor reducer, and the motor reducer is supported on the fixing frame. The automatic replacement fixed knife mechanism has the advantages that the fixed knives of different specifications are installed on the rotating knife holder, the positions of the fixed knives are transformed rotatably through the rotating knife holder so as to process steel bars of different specifications, the steel bars of different specifications can be processed on the steel bar automatic hoop bending machine, and the automatic replacement fixed knife mechanism has the advantages of saving knife replacement time and being wide in production range and high in production efficiency. In addition, the fixed knives are installed on the rotating knife holder through fasteners, and new fixed knives can also be replaced extremely conveniently.

Owner:TJK MACHINERY TIANJIN

High-quality anti-damage long wool yarn crochet machine

The invention discloses a high-quality anti-damage long wool yarn crochet machine. A yarn outlet groove is an arc-shaped groove, an arc-shaped surface matching with the arc-shaped groove is formed inone side of a pressing plate, a diving lead screw is arranged on a machine frame, a circular groove matching with warps is formed in the outer surface of the dividing lead screw, the dividing lead screw is located above a cutter, and a weft unreeling device comprises a stepping motor. The machine has the advantage that the yield and quality of long wool yarns are improved by matching with a slip stitching mechanism under the condition that the length of a needle bed is not extended.

Owner:JIANGSU JIACHENG TECH

Processing method for raw frozen instant atrina peclinala linneaus

A disclosed processing method for raw frozen instant atrina peclinala linneaus comprises: selecting complete unbroken atrina peclinala linneaus, opening by rotating atrina peclinala linneaus by a right angle of 90 DEG, cleaning, trimming, grading, cleaning with running water, cleaning with brine with a concentration of 3% for 10 min for 3 times, immersing in icy water for 5 min, draining out water, marking with different-color spacers according to different specifications, rapidly freezing, plating atrina peclinala linneaus with an icy casing in icy water with a temperature of 2-3 DEG C, performing vacuum packaging, putting in a refrigeration house and storing for 4-5 days, detecting whether there is leakage phenomenon, putting in boxes, cartonning and regrigerating.

Owner:LIANYUNGANG ANNY FOOD

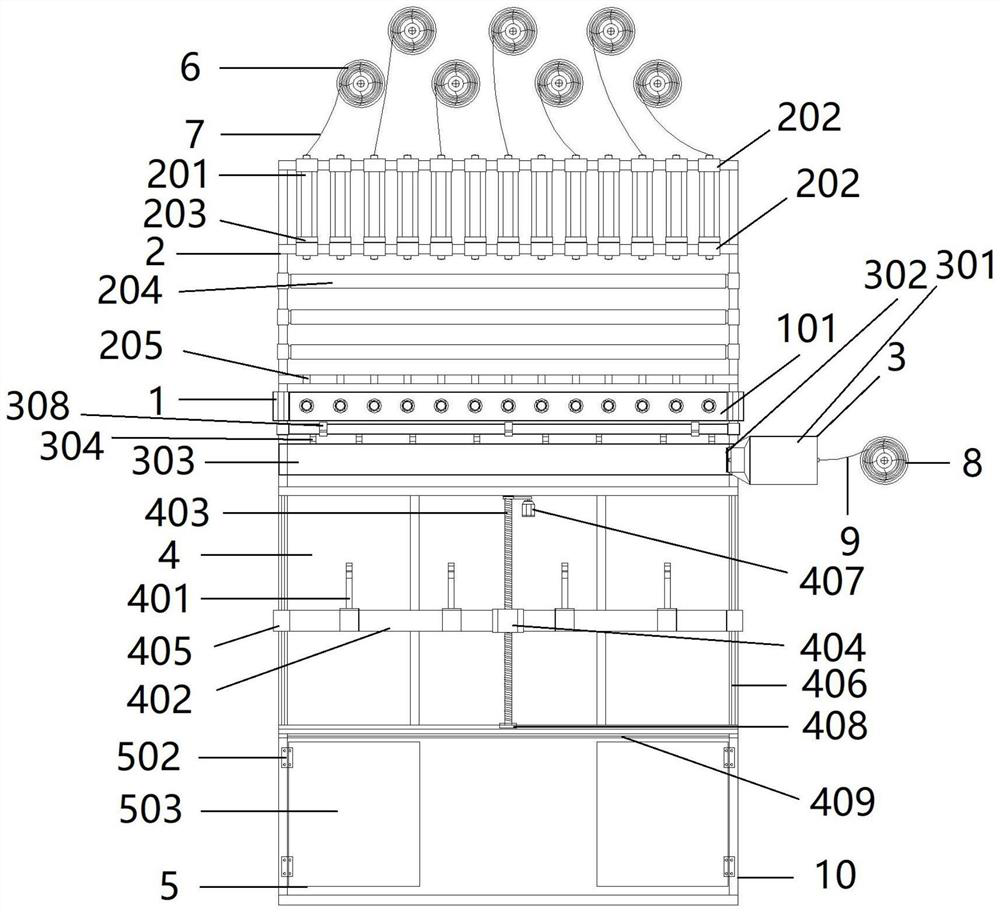

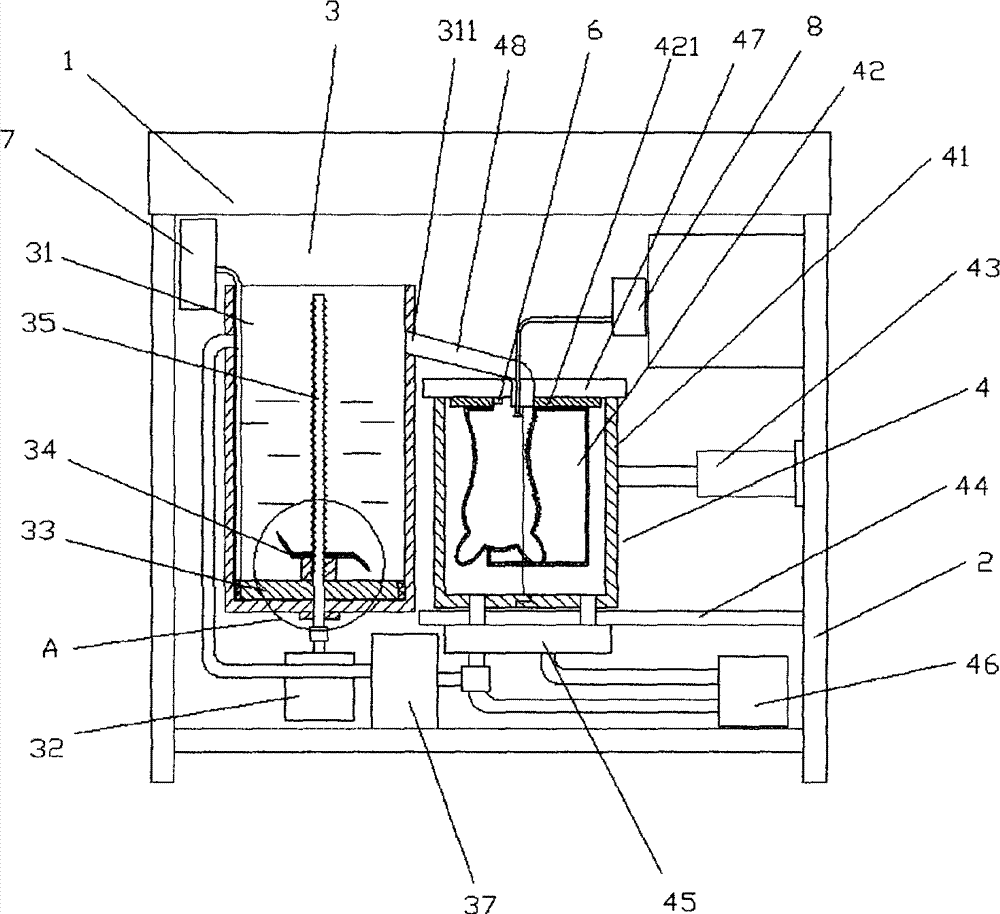

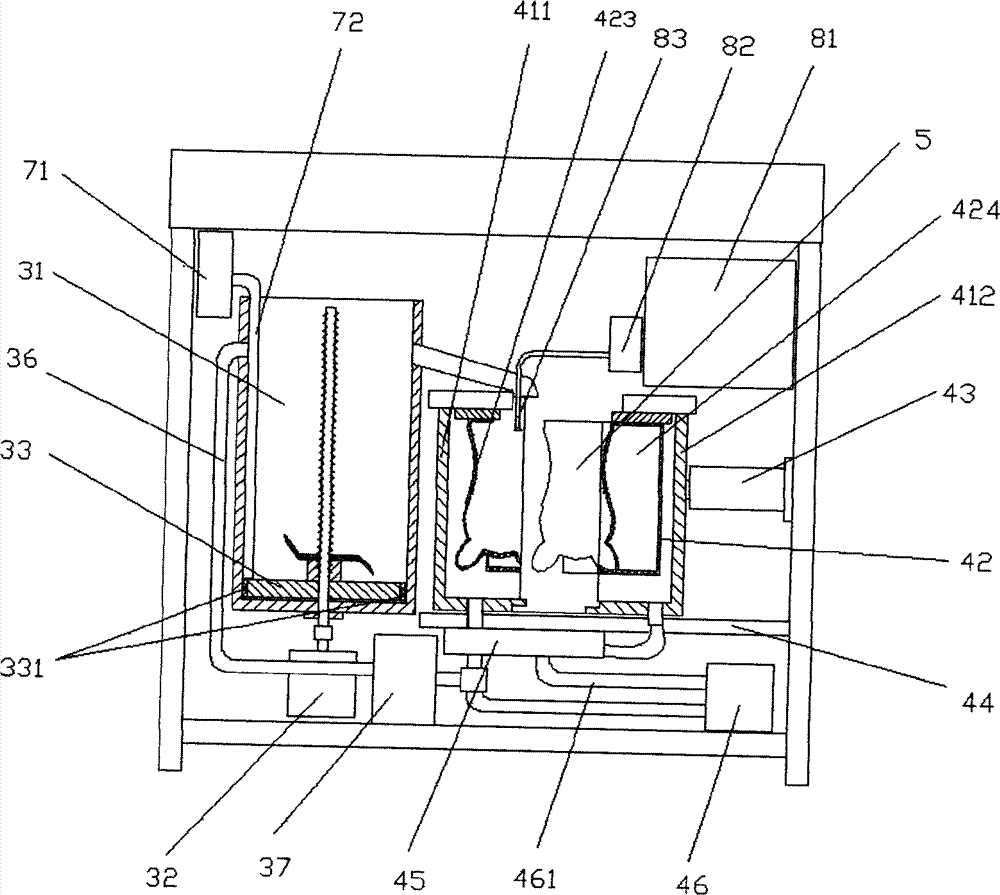

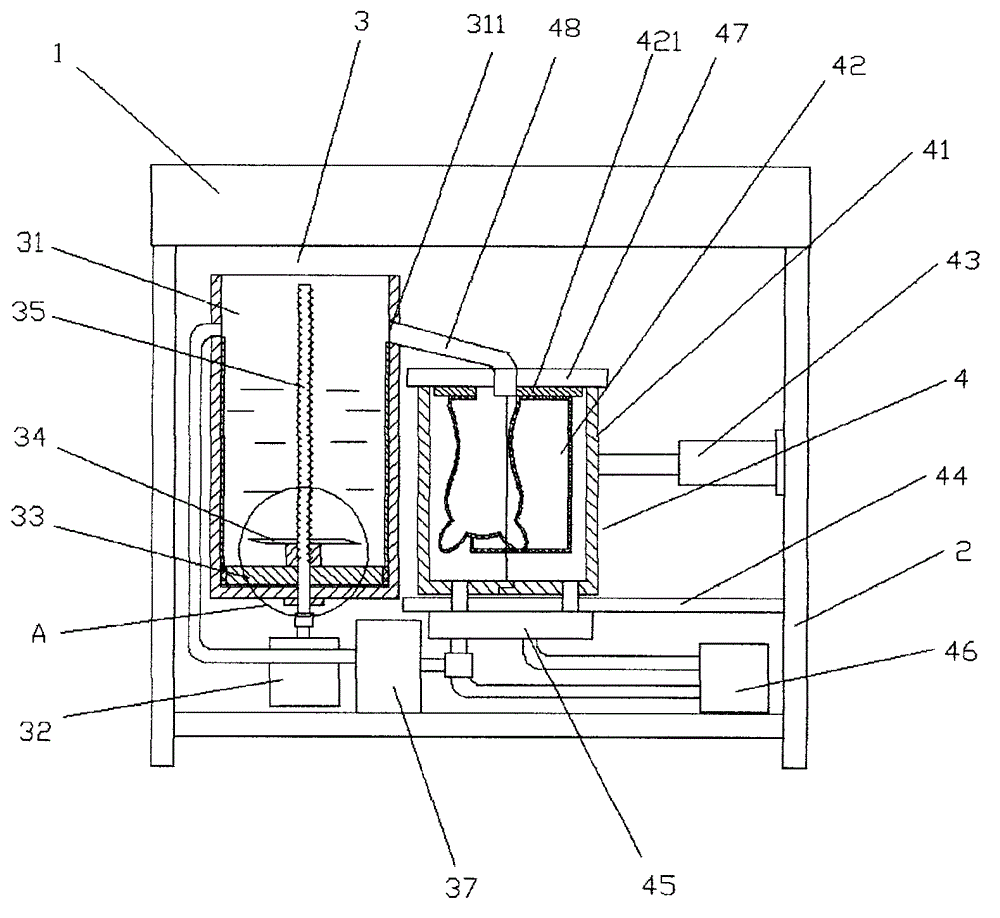

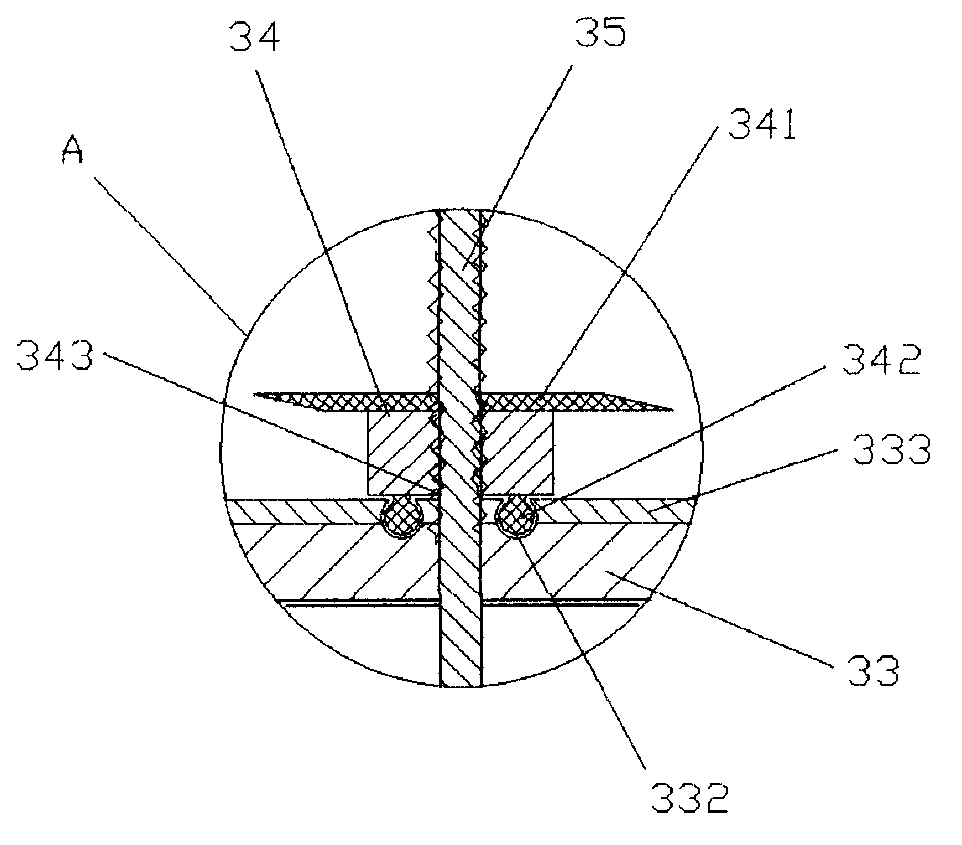

Integrated structure of crude fiber regenerative intelligent barrel-manufacturing machine

Provided is an integrated structure of a crude fiber regenerative intelligent barrel-manufacturing machine. The integrated structure includes an upper cover body, a lower machine body, a waste beating device, a moulding forming mechanism, a disinfection device and a plastification device. A beating barrel inner cavity of the waste beating device is provided with a lifting tray which is connected with a screw hole of a beating cutter in a concentric mode. A threaded rod penetrates through the beating cutter, the lifting tray, and the bottom portion of the beating barrel in sequence and is connected with a rotating shaft of a motor. The beating barrel is connected with a filtering mould of the moulding forming mechanism through a slurry-out through-pipe. A moulding net mould is arranged inside an inner cavity of the filtering mould. An electromagnetic heater is arranged above the moulding net mould. A separator, a vacuum pump and a water pump are arranged below the filtering mould and are connected through pipelines. An ozonator of the disinfection device is connected with an air exit pipe of the inner cavity of the beating barrel, a slurry-in opening of the moulding net mould is provided with a liquid-spraying head of the plastification device. The integrated structure of the crude fiber regenerative intelligent barrel-making machine recycles waste paper and rubbish with crude fiber, has the advantages of being energy-saving and environment-friendly, secure and healthy.

Owner:胡佳威

Coil opener

The invention discloses a coil opener. The coil opener comprises an upper rack and a lower rack, and further comprises a main controller, a first execute component arranged at an incoming inlet end ofthe lower rack, a second execute component and incoming conveying mechanism arranged at an incoming outlet end of the lower rack, a lower roll box arranged on the lower rack, an upper roll box arranged on the upper rack, and a third execute component arranged at the lower rack used for adjusting the incoming conveying mechanism, wherein the output end of the first execute component is connected to one side of the upper rack, the output end of the second execute component is connected to the other side of the upper rack, the lower roll box and the upper roll box are arranged between the firstexecute component and the second execute component, the upper roller box and the lower roller box cooperate with each other to straighten an incoming material; and the first execute component, the second execute component and the third execute component are coordinated by the overall controller. The coil opener has various working states, can adapt to wider ranges of products and requirements, hasa good straight effect, and can improve the production efficiency and work efficiency of a production line.

Owner:TAIYUAN HEAVY IND

Stamping equipment for hardware of plastic-steel door and window

InactiveCN105127759AAvoid wastingSimple structureOther manufacturing equipments/toolsStrip steelMechanical equipment

The invention belongs to the field of mechanical equipment, and particularly relates to stamping equipment for hardware of a plastic-steel door and window. The stamping equipment comprises a hardware collecting box, a material throwing device, a stamping box, an upper mold, a lower mold, a magnetic conveying belt, a control table, a power distribution cabinet, a straightening machine, a straightening tank, strip steel, a welding machine, an uncoiler, an uncoiler base, a welding support, a welding arm, a welding head, a lower roller, an upper roller and a feeder. The strip steel is arranged on the uncoiler. The welding support is arranged on the welding machine. One end of the welding arm is connected with the welding support, and the other end of the welding arm is connected with the welding head. The straightening machine is provided with the straightening tank. The upper mold and the lower mold are arranged in the stamping box. The magnetic conveying belt is arranged at the lower portion of the stamping box. The control table is arranged outside the stamping box. The feeder is arranged on one side of the stamping box, and the material throwing device is arranged on the other side of the stamping box. The uncoiler is arranged on the uncoiler base.

Owner:成都佰世成科技有限公司

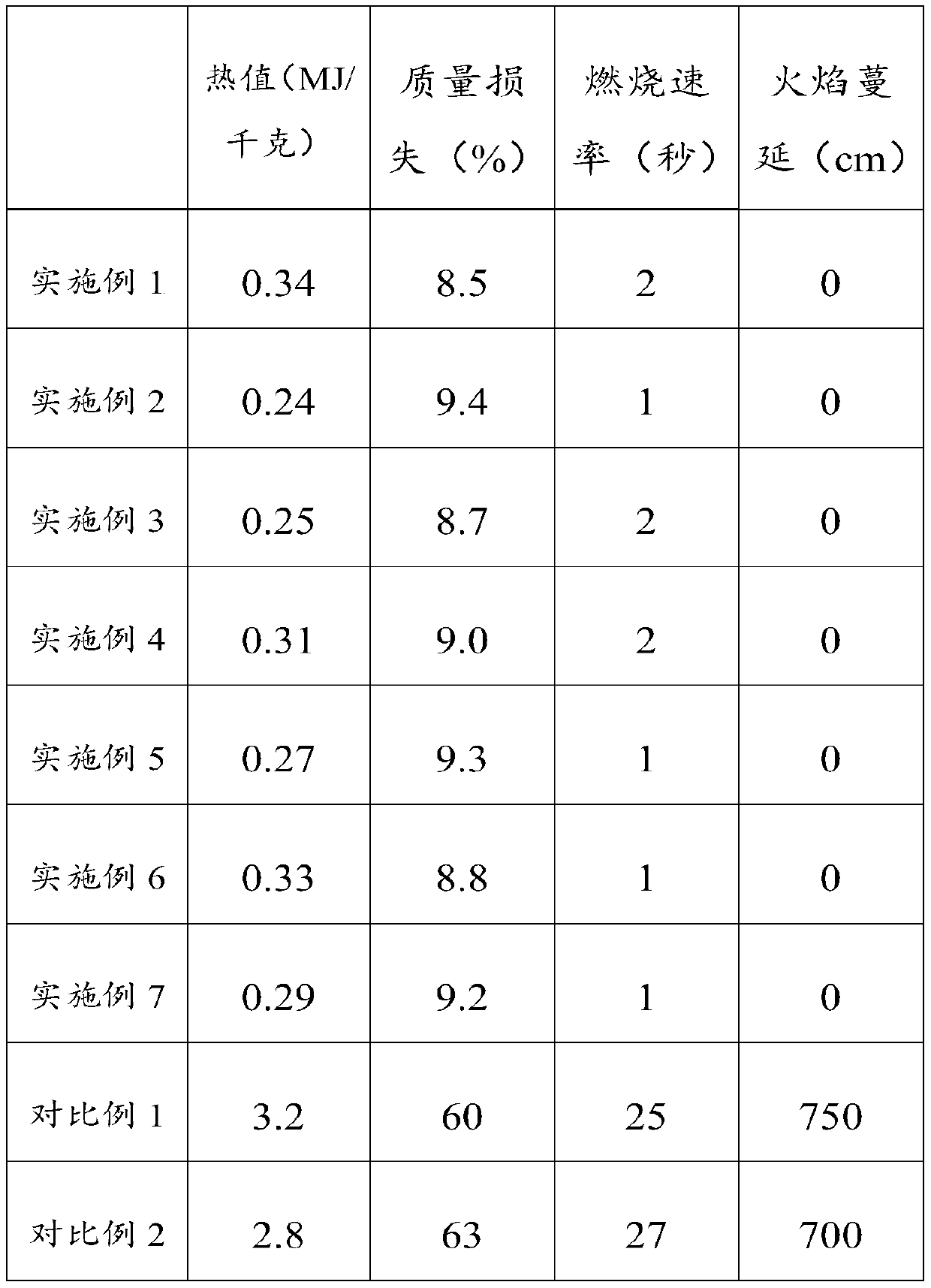

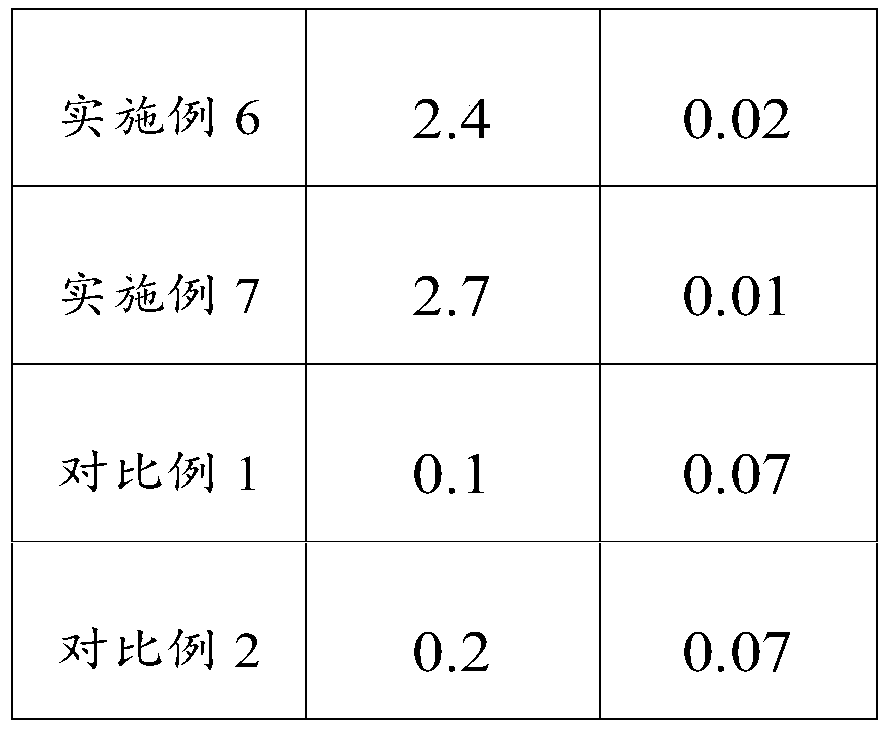

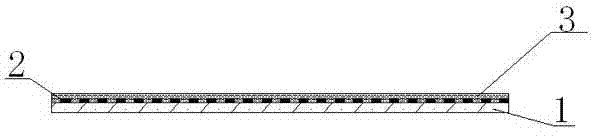

Graphene eps fireproof insulation board and preparation method thereof

The invention relates to the field of a fireproof heat-insulating material and especially relates to a graphene EPS fireproof heat-insulating plate and a preparation method thereof. The method for preparing the graphene EPS fireproof heat-insulating plate comprises the following steps: physically foaming a binding material and then mixing with graphene EPS, rolling and forming. The volume ratio of binding material to graphene EPS is 100:(65-85). The fireproof heat-insulating plate has excellent heat-insulating effect, excellent fireproof property and capability of promoting the safety of the heat-insulating plate.

Owner:河北泰晟利华节能材料有限公司

Preparation method of lenticular glass grating

InactiveCN104297827AThe production process is simpleShorten production timeDiffraction gratingsPhysicsChemistry

The invention discloses a preparation method of a lenticular glass grating, which comprises the steps that ultraviolet irradiation is cured after coating an ultraviolet light curing adhesive on a glass substrate; the processed glass substrate is heated to a temperature between the ultraviolet light curing adhesive glass transition temperature and the melting temperature, a mold is coated on the surface of the ultraviolet light curing adhesive, and the clearance of the mold is enabled to be filled with the ultraviolet light curing adhesive; then the temperature drops below the glass transition temperature, the mold is removed, and the ultraviolet light curing adhesive forms a cylindrical rectangular array on the surface of the glass substrate; and the glass substrate is placed in a constant-temperature device, the temperature rises above the ultraviolet light curing adhesive melting temperature and maintains for a period of time, the ultraviolet light curing adhesive is changed into a cylindrical circular-arc-shaped array, then the temperature drops below the glass transition temperature and maintains for a period of time, and the lenticular glass grating is acquired after the ultraviolet light curing adhesive is cured. The preparation method disclosed by the invention is simple to operate, low in production cost and wide in production application range. The lenticular glass grating is smooth in surface, high in precision and good in uniformity.

Owner:ZHENGZHOU HENGHAO GLASS TECH

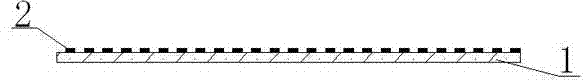

Multifunctional wrapping and film packaging all-in-one machine

PendingCN112357172AImprove moisture-proof and insect-proof effectAvoid enteringWrappers shrinkagePackaging bottlesGear wheelCarton

The invention discloses a multifunctional wrapping and film packaging all-in-one machine, the all-in-one machine comprises a container feeding unit, a wrapping machine unit, a carton set and bottle set transition conveying unit, a film packaging machine film packaging unit and a film packaging machine thermal shrinkage unit, based on the structure of the carton set and bottle set transition conveying unit, a stretching chain plate supporting bracket is arranged in a rack, a first lifting mechanism is arranged between the chain plate supporting bracket and the rack, a conveying chain plate is arranged outside the chain plate supporting bracket in a winding mode, a first driving motor is arranged at the position, below the conveying chain plate, of the rack, an output shaft of the first driving motor is sleeved with a first driving gear, two lower box clamping conveying belts are arranged on the rack at a transition conveying station, the two lower box clamping conveying belts can be driven by a first width adjusting mechanism to move horizontally, and two upper box clamping conveying belts are arranged at the position, above the transition conveying station, of the rack. The multifunctional wrapping and film packaging all-in-one machine has the advantage of being capable of producing products of various specifications.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

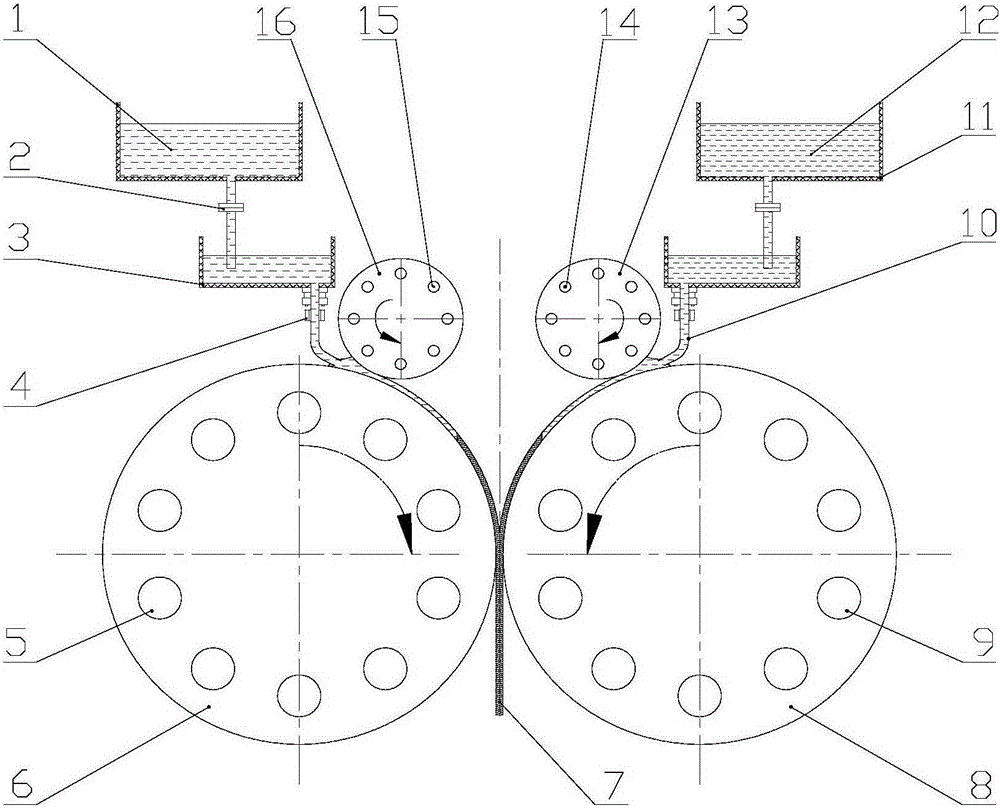

Equipment and method for continuous casting and rolling of bimetallic composite plate and strip using single machine and two streams

The invention discloses a device and method for thermometal composite board strip cast-rolling in a double flow and continuous mode through a single machine. According to the device, two main cast-rolling rollers of an ordinary stand type double-roller cast rolling machine are respectively and additionally provided with an auxiliary cast-rolling roller to form a cast-rolling-composite rolling union rolling mill provided with two monometallic composite strip blank cast-rolling units and a thermometal composite rolling area. The method mainly comprises the steps that cast-rolling forming of two different metal strips are independently and synchronously finished on the two monometallic composite strip blank cast-rolling units, and the different metal strips serve as blanks to be rolled and combined into thermometal board strips through the two main cast-rolling rollers. The device is simple and capable of greatly simplifying the technological procedures, and has the advantages of being capable of continuously working, high in yield and the like. The method is efficient and small in number of the procedures.

Owner:YANSHAN UNIV

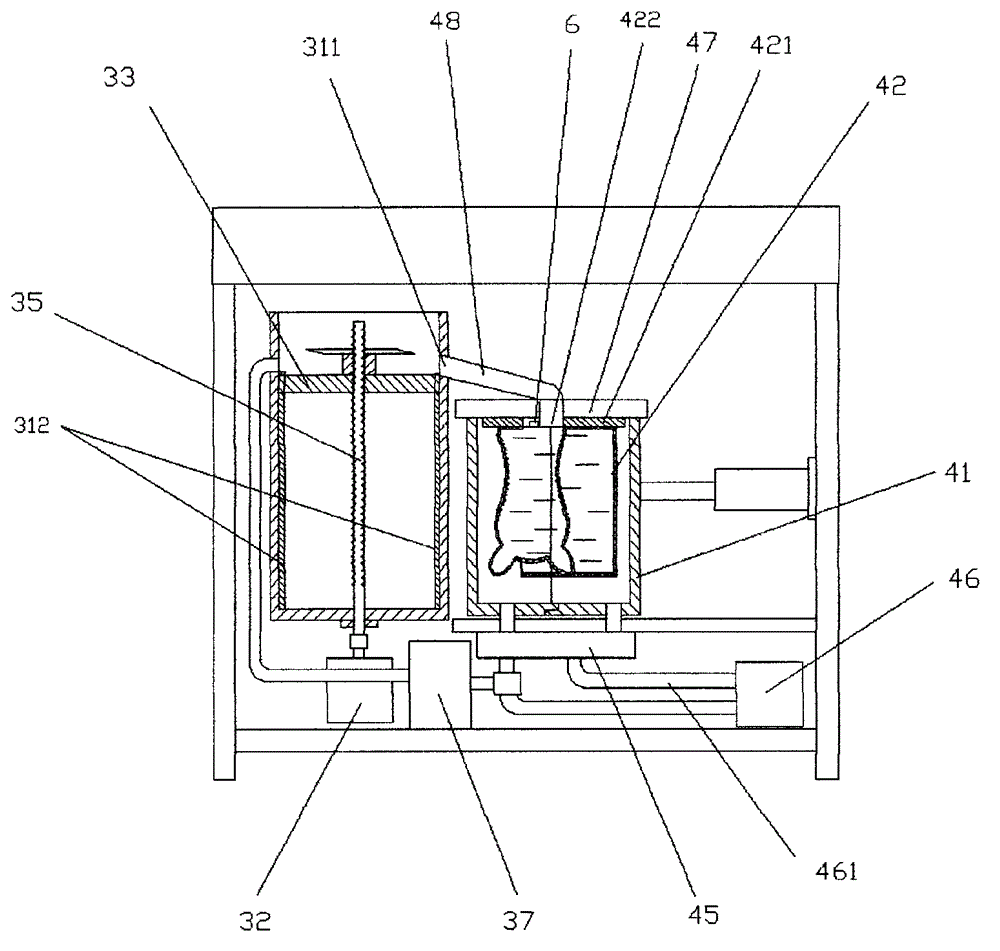

Crude fiber regeneration equipment for synchronous organization treatment and vacuum adsorption

InactiveCN103147335ALow costWide range of productionPaper recyclingWaste paper working-upFiberFiltration

The invention discloses crude fiber regeneration equipment for synchronous organization treatment and vacuum adsorption. The crude fiber regeneration equipment comprises an upper cover body, a lower machine body, a pulp processing device and a molding forming device, wherein a lifting plate which is attached to the wall of a pulping bucket in the radial direction and can move up and down is arranged inside an inner cavity of the pulping bucket of the pulp processing device; a pulping tool which is concentric with a screw hole is formed in the lifting plate; a screw rod orderly passes through the pulping tool, the lifting plate, the bottom part of the pulping bucket to be connected with a rotating shaft of a motor; a pulp outlet in the upper end of the pulping bucket is connected with a suction filtration die of the molding forming device via a pulp outlet pipe; a molding net die is arranged inside an inner cavity of the suction filtration die; an electromagnetic heater is arranged above the molding net die; and a separator, a vacuum pump and a water pump connected via a pipeline are arranged below the suction filtration die. Waste paper and garbage containing the crude fiber are recycled, so that the energy is saved and the environment is protected. The procedures from feeding to forming are automatically finished by one time; and the crude fiber regeneration equipment is fast in speed, high in efficiency and strong in applicability.

Owner:胡佳威

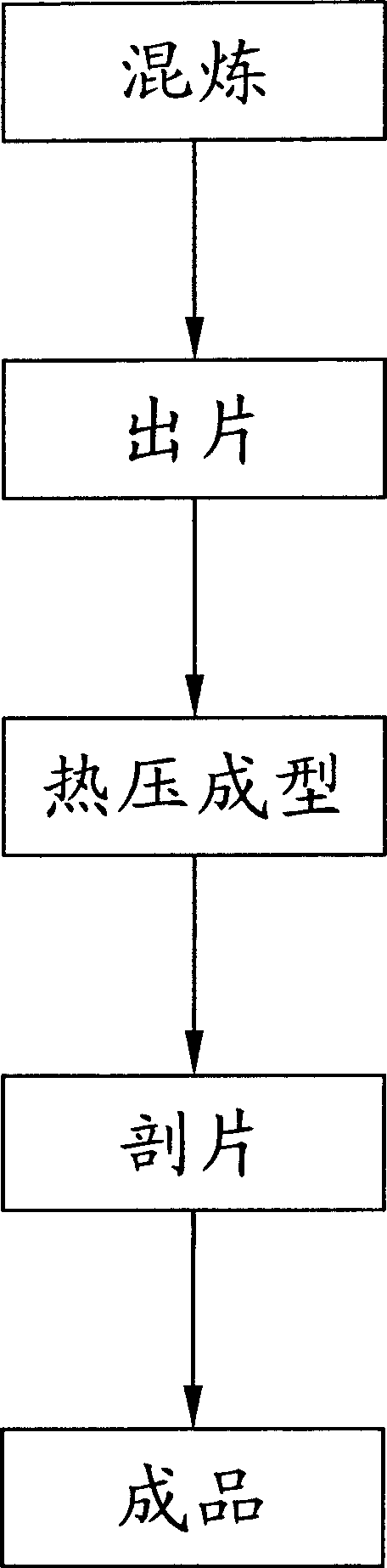

Production process of foamed polyolefin wool with high hygroscopicity and air permeability

The production process of foamed polyolefin wool with high hygroscopicity and air permeability features that polyethylene vinyl acetate as basic material, hollow aluminum silicate bead, wood powder and interfacial active agent in certain weight proportion are mixed while adding bridging agent and foaming agent to form the mixture, the mixture is cut, and the cut mixture is hot pressed and foamed inside mold to form the foamed wool product with excellent hygroscopicity and air permeability.

Owner:EVA GLORY INDAL

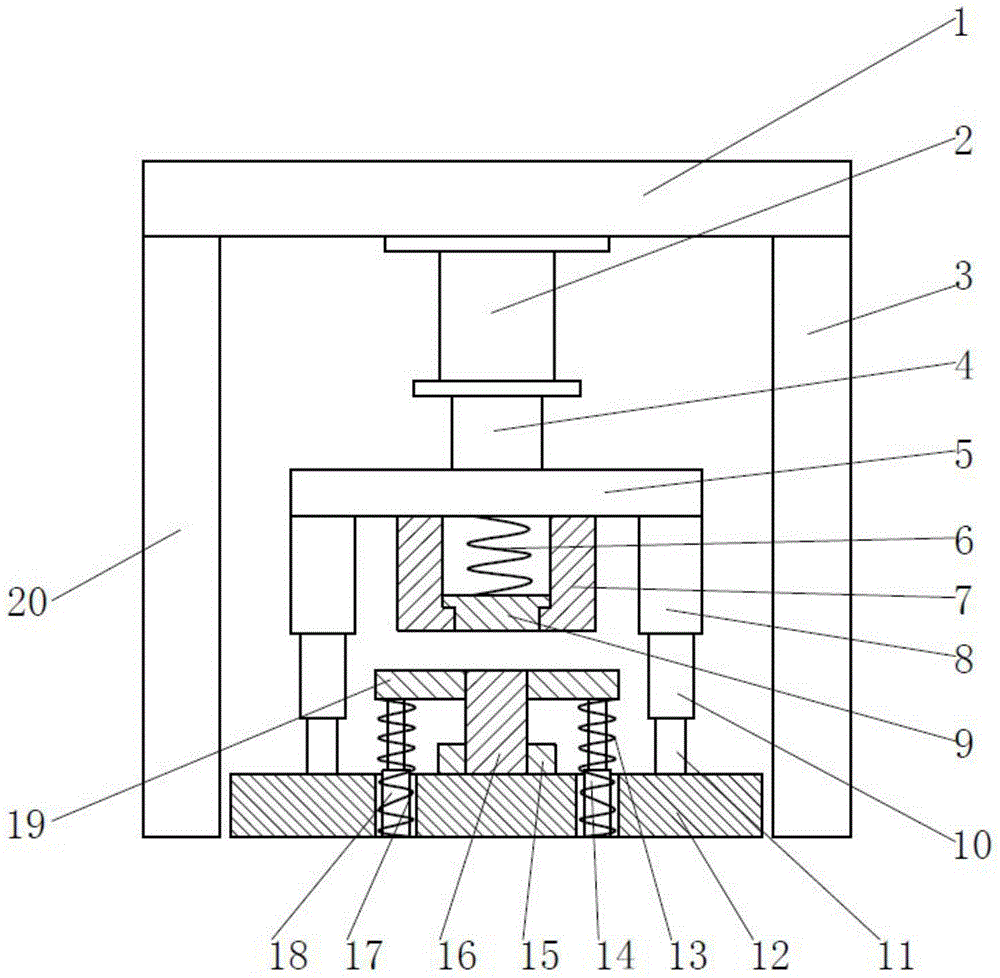

Hole enlarging device for motor end cover of wastewater treatment device

The invention belongs to the field of hole enlargement machining, and particularly relates to a hole enlarging device for a motor end cover of a wastewater treatment device. The hole enlarging device comprises a supporting cross beam, a main hydraulic cylinder, a left stand column support, a hydraulic cylinder push rod, a movable mold supporting plate, a spring, a movable mold outer support, supporting hydraulic cylinders, a movable mold, supporting hydraulic cylinder push rods, second-stage push rods, a machine tool base, a supporting platform left spring, a platform left supporting rod, a platform base plate, a hole enlarging column, a supporting platform right spring, a platform right supporting rod, a hole enlarging platform and a right stand column support, wherein the main hydraulic cylinder is arranged on the supporting cross beam; one end of the hydraulic cylinder push rod is arranged on the main hydraulic cylinder; the other end of the hydraulic cylinder push rod is arranged on the movable mold supporting plate; the two supporting hydraulic cylinders are arranged on the lower end of the movable mold supporting plate; the movable mold is arranged in the movable mold outer support; the hole enlarging column and the platform base plate are arranged on the machine tool base; and the platform left supporting rod and the platform right supporting rod are arranged on the lower end of the hole enlarging platform.

Owner:天津达新源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com