Graphene eps fireproof insulation board and preparation method thereof

A technology of fireproof insulation board and graphene, which is applied in the field of fireproof insulation materials, can solve the problems of insufficient fireproof performance, easy anti-halogen and anti-alkali deformation, environmental protection and weather resistance, etc., and achieve good processability, good stability, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

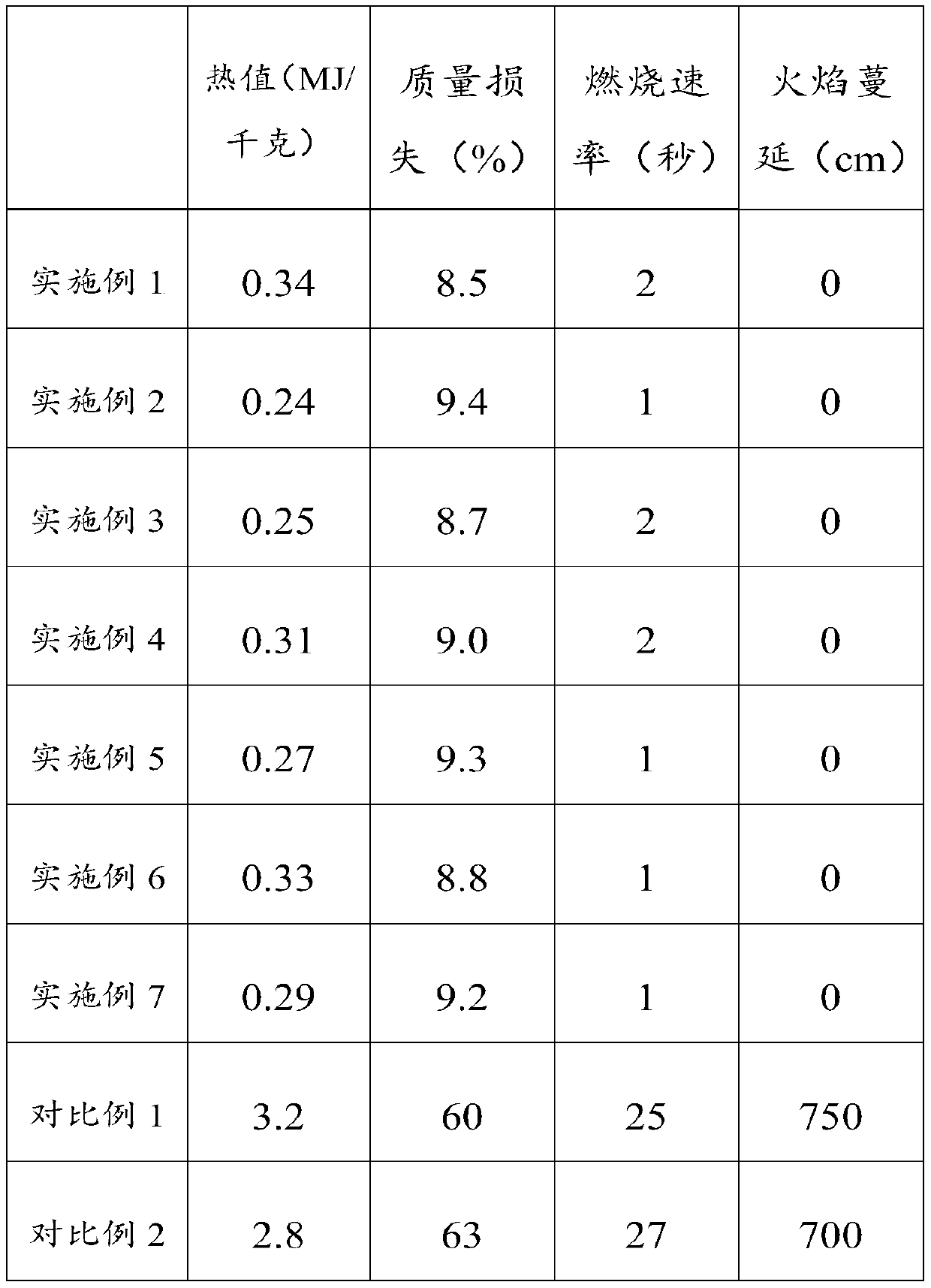

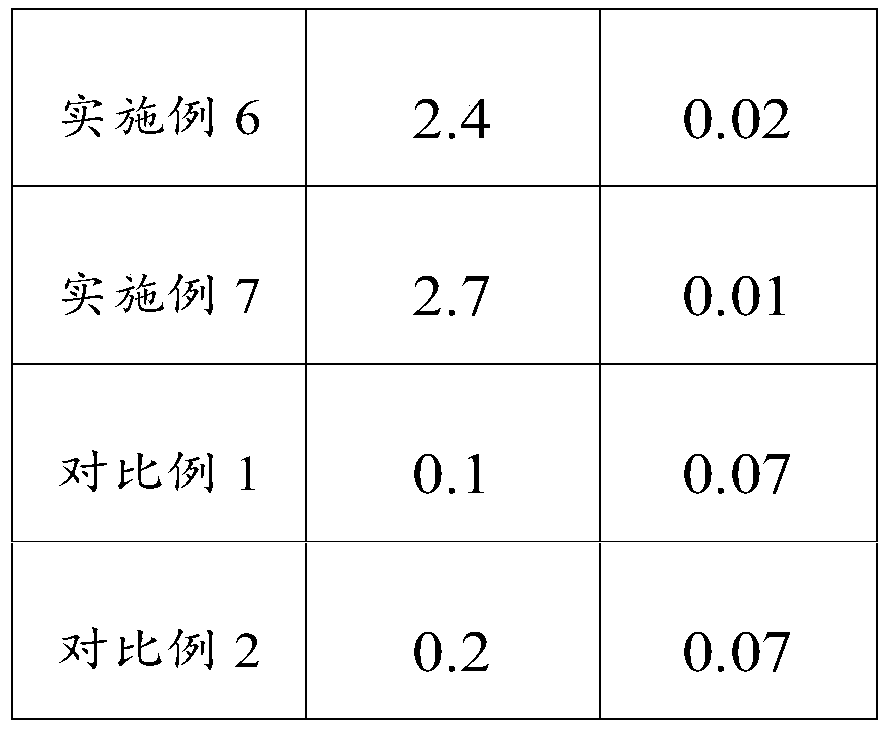

Examples

Embodiment 1

[0046] The present embodiment provides a kind of method for preparing graphene EPS fireproof insulation board:

[0047] S1, preparation of gelling material:

[0048] The gelling material is mainly made of 1g of magnesium sulfate solution, 0.8g of magnesium oxide, 0.005g of sulfuric acid with a mass concentration of 28%, 0.2g of filler, 0.018g of water-resistant agent and 0.02g of modifier. Among them, the fineness of the filler is 300 mesh, and the filler is fly ash; the modifier is phosphoric acid; the magnesium oxide is light-burned magnesia, and the mass ratio of magnesium in light-burned magnesia is 90%, and its activity is 60%. ; The anti-water agent is stearic acid; the Baume degree of the magnesium sulfate solution is 20 degrees.

[0049] Specifically, 1g of magnesium sulfate solution, 0.02g of modifier, 0.005g of sulfuric acid, 0.2g of filler, 0.8g of magnesium oxide and 0.018g of water-resistant agent were mixed sequentially, rolled into shape, and then maintained at...

Embodiment 2

[0056] The present embodiment provides a kind of method for preparing graphene EPS fireproof insulation board:

[0057] S1, preparation of gelling material:

[0058] The gelling material is mainly made of 1g of magnesium sulfate solution, 0.85g of magnesium oxide, 0.008g of sulfuric acid with a mass concentration of 30%, 0.4g of filler, 0.015g of water-resistant agent and 0.015g of modifier. Among them, the fineness of the filler is 400 mesh, and the filler is fly ash and stone powder; the modifier is citric acid and boric acid; the magnesia is light-burned magnesia, and the mass ratio of magnesium in the light-burned magnesia is 95%, and Its activity degree is 64; the anti-water agent is made by mixing stearic acid and calcium stearate; the Baume degree of the magnesium sulfate solution is 25 degrees.

[0059] Specifically, 1g of magnesium sulfate solution, 0.015g of modifier, 0.008g of sulfuric acid, 0.4g of filler, 0.85g of magnesium oxide and 0.015g of water-resistant age...

Embodiment 3

[0066] The present embodiment provides a kind of method for preparing graphene EPS fireproof insulation board:

[0067] S1, preparation of gelling material:

[0068] The gelling material is mainly made of 1g of magnesium sulfate solution, 0.9g of magnesium oxide, 0.006g of sulfuric acid with a mass concentration of 29%, 0.6g of filler, 0.02g of water-resistant agent and 0.013g of modifier. Among them, the fineness of the filler is 250 mesh, and the filler is a mixture of fly ash, mineral powder and stone powder; the modifier is triethanolamine; the magnesium oxide is light-burned magnesia, and the mass ratio of magnesium in the light-burned magnesia is 85%, and its activity is 65; the anti-water agent is zinc stearate; the Baume degree of the magnesium sulfate solution is 30 degrees.

[0069] Specifically, 1g of magnesium sulfate solution, 0.013g of modifier, 0.006g of sulfuric acid, 0.6g of filler, 0.9g of magnesium oxide and 0.02g of water-repellent agent were mixed sequent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com