Diaphragma juglandis instant product and preparation method thereof

A technology of distracting wood and products, which is applied in the field of food, can solve the problems that biologically active ingredients cannot be effectively dissolved, collected and preserved, the taste and taste of distracting wood are single, and it is difficult to achieve the desired effect, so as to achieve good enzyme killing effect and preparation The process is simple and convenient, the effect of improving the grade and adding value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

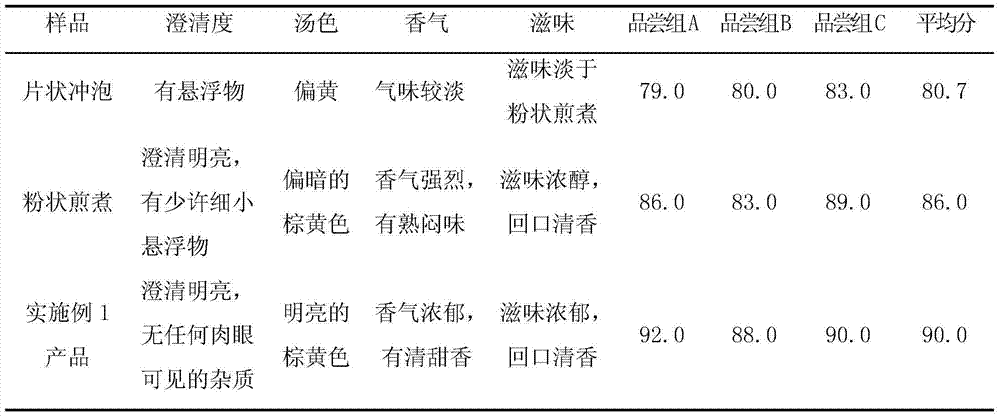

Examples

Embodiment 1

[0045] The parts by weight of the instant product of Fenxinmu are as follows: 22 parts of Fenxinmu, 13 parts of maltodextrin, and 2 parts of β-cyclodextrin.

[0046] The split wood instant product is prepared by the following method: use split wood as raw material, wash, dry at 60°C, and pulverize to a particle size of 4 mm, then add cellulase and pectinase with a mass fraction of 0.1% each, Enzymolysis at a solid-liquid ratio of 1:10 at a temperature of 45°C for 40 minutes, adding 7 times the amount of distilled water, decocting at 100°C for 10 minutes, and filtering to obtain the first extract; 15 times the amount of distilled water, decoct at 70-80°C for 25 minutes, filter to obtain the second extract, take the filter residue and add 12 times the amount of distilled water, decoct at 80-90°C for 15 minutes, and obtain the third extract after filtering Extraction solution; combine three extraction solutions, add maltodextrin and β-cyclodextrin, mix well, under the conditions ...

Embodiment 2

[0048] Described distracting wood instant product is formed with embodiment 1;

[0049]The split wood instant product is prepared by the following method: use split wood as raw material, wash, dry at 55°C, and pulverize to a particle size of 5 mm, then add cellulase and pectinase with a mass fraction of 0.12% each, Enzymolysis at a solid-liquid ratio of 1:12 at a temperature of 50°C for 35 minutes, adding 5 times the amount of distilled water, decocting at 100°C for 10 minutes, and filtering to obtain the first extract; 15 times the amount of distilled water, decoct at 70-80°C for 25 minutes, filter to obtain the second extract, take the filter residue and add 12 times the amount of distilled water, decoct at 80-90°C for 15 minutes, and obtain the third extract after filtering Extraction liquid: combine the three extraction liquids, add maltodextrin and β-cyclodextrin, mix well, under the conditions of inlet temperature of 180°C, outlet temperature of 78°C, and feed rate of 2....

Embodiment 3

[0051] Described distracting wood instant product is formed with embodiment 1;

[0052] The split wood instant product is prepared by the following method: use split wood as raw material, wash, dry at 50°C, and pulverize to a particle size of 6 mm, then add cellulase and pectinase with a mass fraction of 0.08% each, Enzymolysis at a solid-liquid ratio of 1:12 at a temperature of 55°C for 32 minutes, then adding 8 times the amount of distilled water, decocting at 100°C for 12 minutes, and filtering to obtain the first extract; 14 times the amount of distilled water, decoct at 70-80°C for 24 minutes, filter to obtain the second extraction solution, take the filter residue and add 10 times the amount of distilled water, decoct at 80-90°C for 12 minutes, and obtain the third extract after filtering Extraction liquid: combine three extraction liquids, add maltodextrin and β-cyclodextrin, mix well, under the conditions of inlet temperature of 180°C, outlet temperature of 76°C, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com