Preparation method of lenticular glass grating

A glass grating and lenticular technology, applied in the production field of lenticular glass grating, can solve the problems of poor quality stability of lenticular grating, low 3D image resolution, low work efficiency, etc., and achieve wide application range and simple manufacturing process , the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

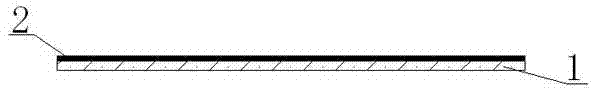

[0037] Such as figure 1 As shown, the UV-curable adhesive 2 is evenly coated on a 3mm thick ultra-clear glass substrate 1 (produced by Shandong Jinjing Glass Co., Ltd.) and cured by ultraviolet light;

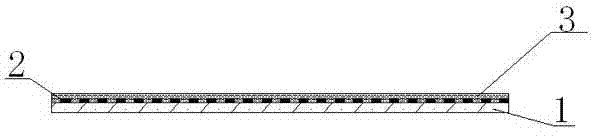

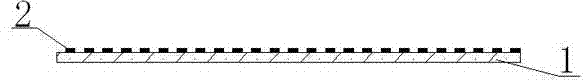

[0038] Such as figure 2 with image 3 As shown, the temperature of the cured glass substrate is heated to 95°C, and then the processed 21.5-inch high-precision mold 3 (silicon dioxide) is used to cover the surface of the UV-curable adhesive 2, and the pressure and temperature are maintained for 30 minutes , the UV-curable adhesive 2 fills the gap of the mold 3, then lowers the temperature to below the glass transition temperature, removes the mold, and the UV-curable adhesive 2 forms a columnar rectangular array on the surface of the glass substrate;

[0039] Such as Figure 4 As shown, the glass substrate is placed in a constant temperature box, and the temperature is raised to 210°C and maintained for 30 minutes. Due to the surface tension of the molten UV-curable adhesi...

Embodiment 2

[0043] Such as figure 1 As shown, the UV-curable adhesive 2 is evenly coated on a 5mm thick ultra-clear glass substrate 1 (produced by Shandong Jinjing Glass Co., Ltd.) and cured by ultraviolet light;

[0044] Such as figure 2 with image 3 As shown, the temperature of the cured glass substrate is heated to 95°C, and then the processed 46-inch high-precision mold 3 (silicon carbide) is used to cover the surface of the UV-curable adhesive 2, and the pressure and temperature are maintained for 30 minutes. The UV-curable glue fills the mold gap, then lowers the temperature below the glass transition temperature, removes the mold, and the UV-curable glue forms a columnar rectangular array on the surface of the glass substrate;

[0045] Such as Figure 4 As shown, the glass substrate is placed in a constant temperature box, and the temperature is raised to 210°C and maintained for 30 minutes. Due to the surface tension of the molten curable adhesive, the UV curable adhesive 2 ...

Embodiment 3

[0049] Such as figure 1 As shown, the UV-curable adhesive 2 is evenly coated on a 6mm thick ultra-clear glass substrate 1 (produced by Shandong Jinjing Glass Co., Ltd.) and cured by ultraviolet light;

[0050] Such as figure 2 with image 3 As shown, the temperature of the cured glass substrate is heated to 95°C, and then the processed 55-inch high-precision mold 3 is covered on the surface of the UV glue, and the pressure and temperature are maintained for 30 minutes, and the UV-curable glue fills the mold gap , then lower the temperature to below the glass transition temperature, remove the mold, and form a columnar rectangular array on the surface of the glass substrate with the UV-curable glue;

[0051] Such as Figure 4 As shown, the glass substrate is placed in a constant temperature box, and the temperature is raised to 210°C and kept for 30 minutes. Due to the surface tension of the molten UV-curable adhesive, the UV-curable adhesive becomes a columnar arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com