Patents

Literature

83results about How to "Less prone to error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

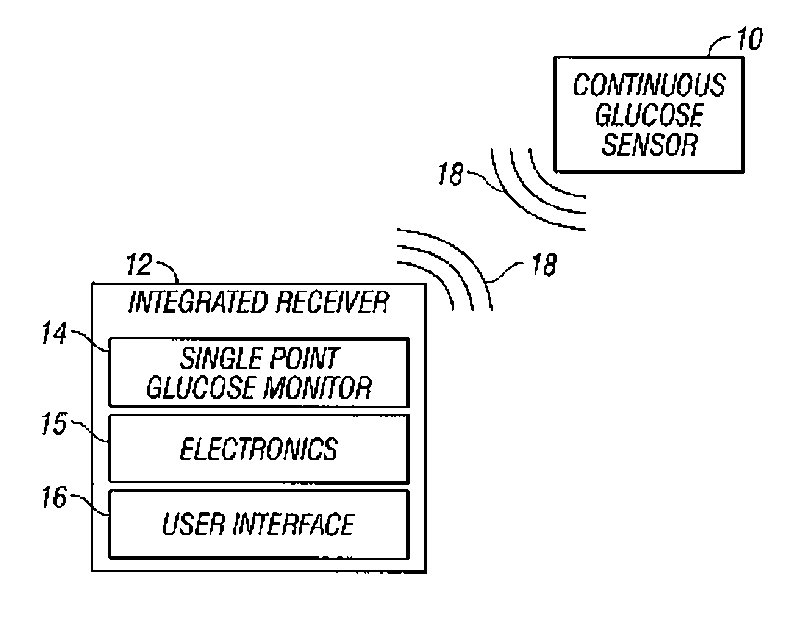

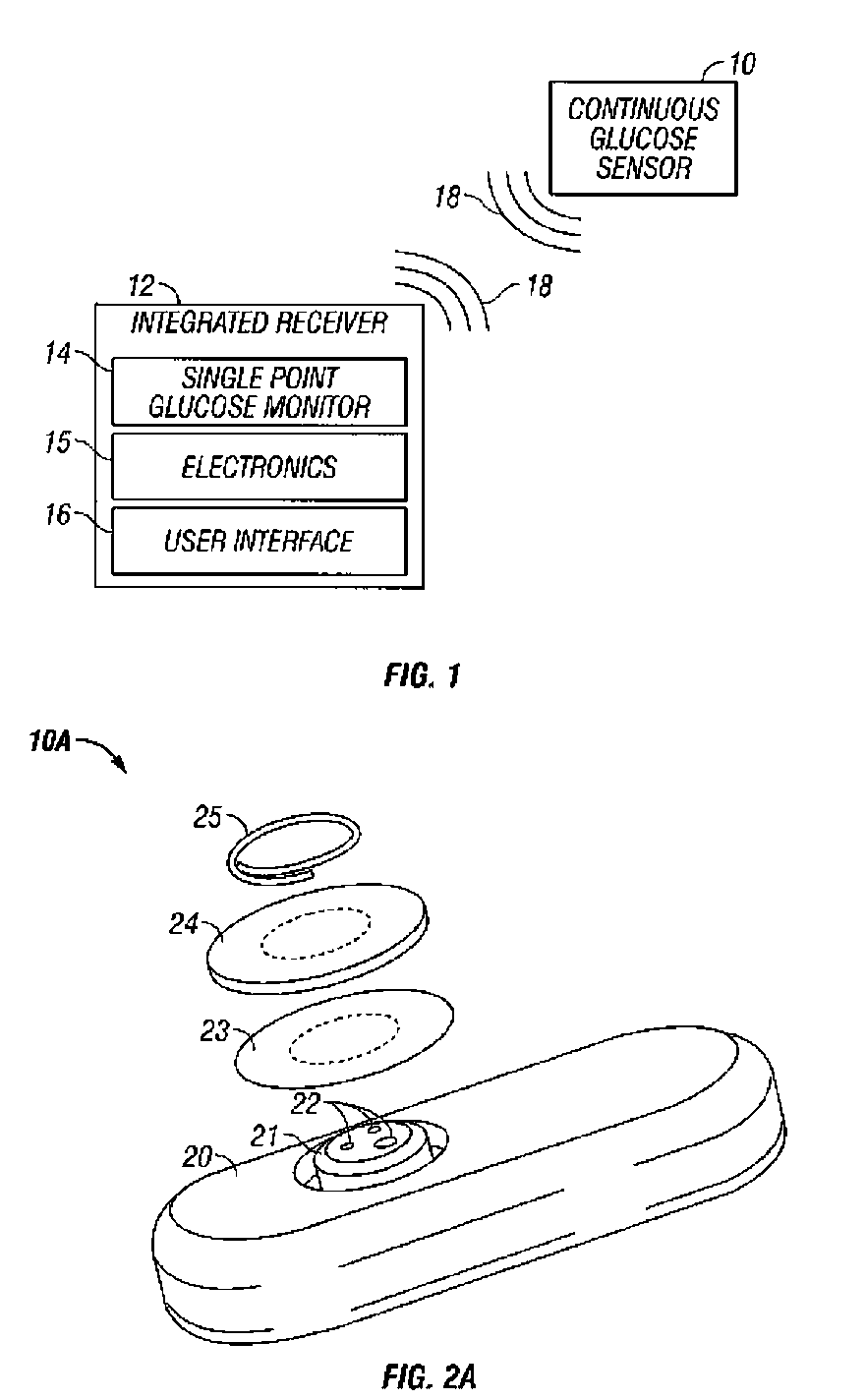

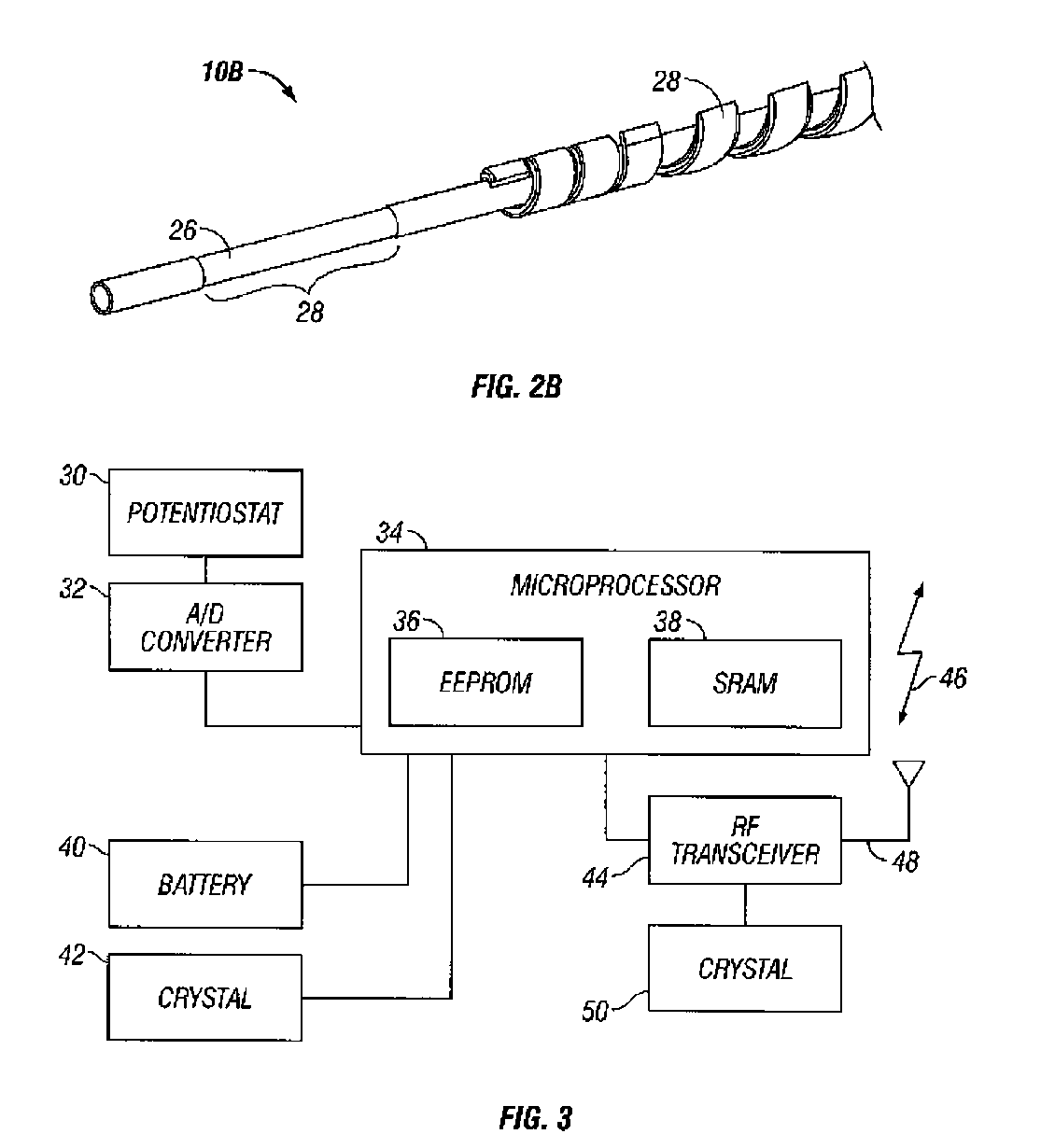

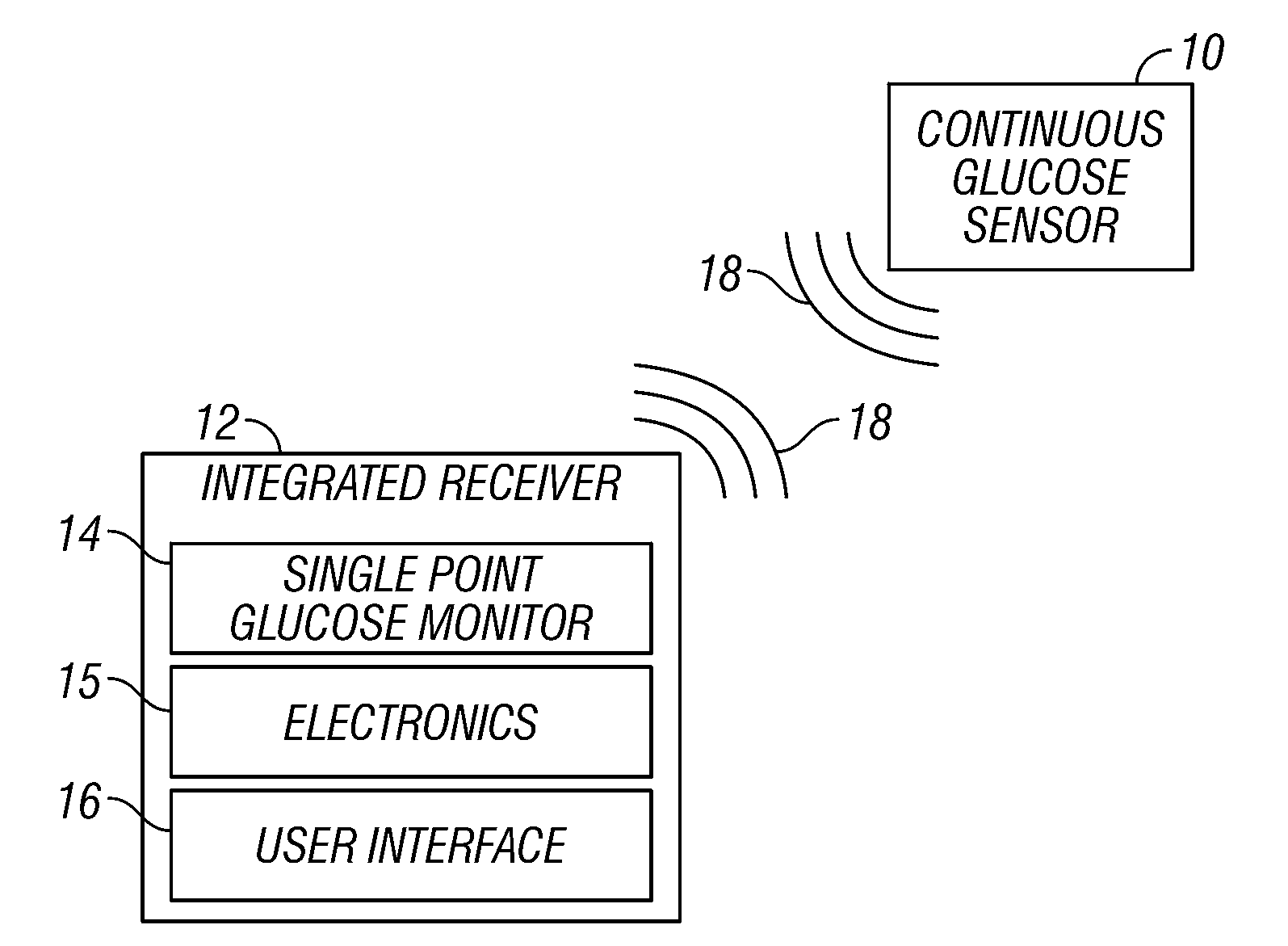

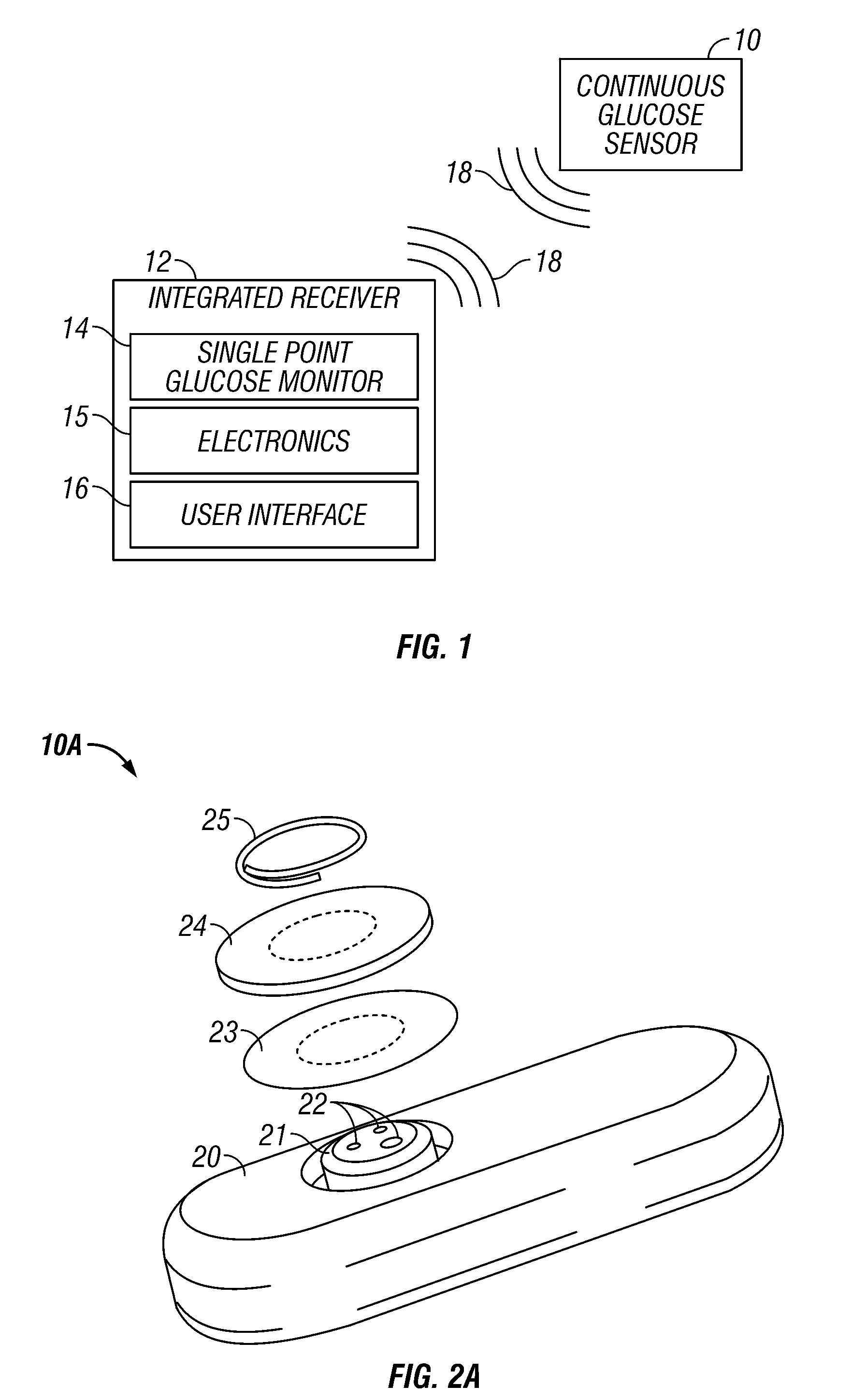

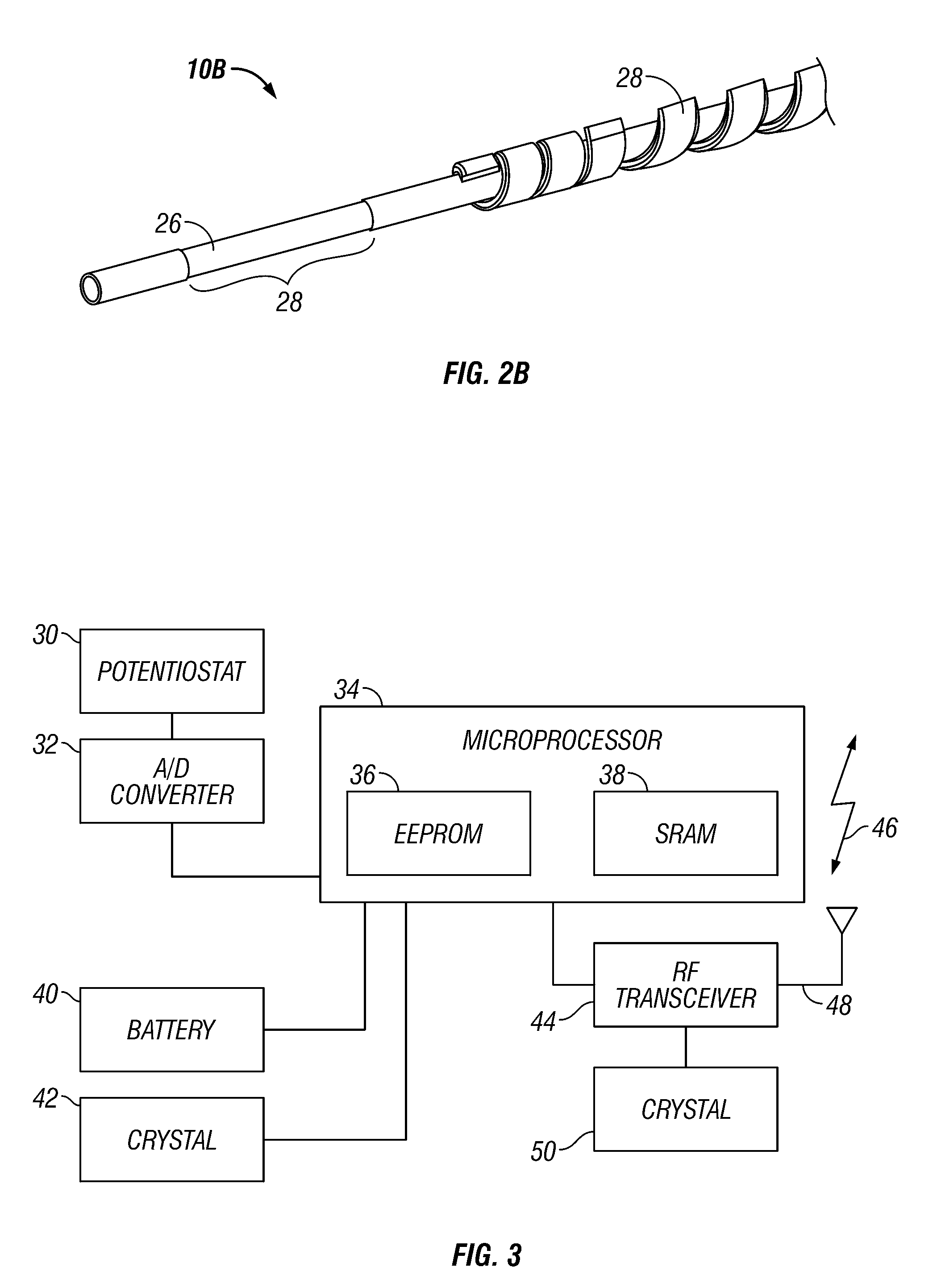

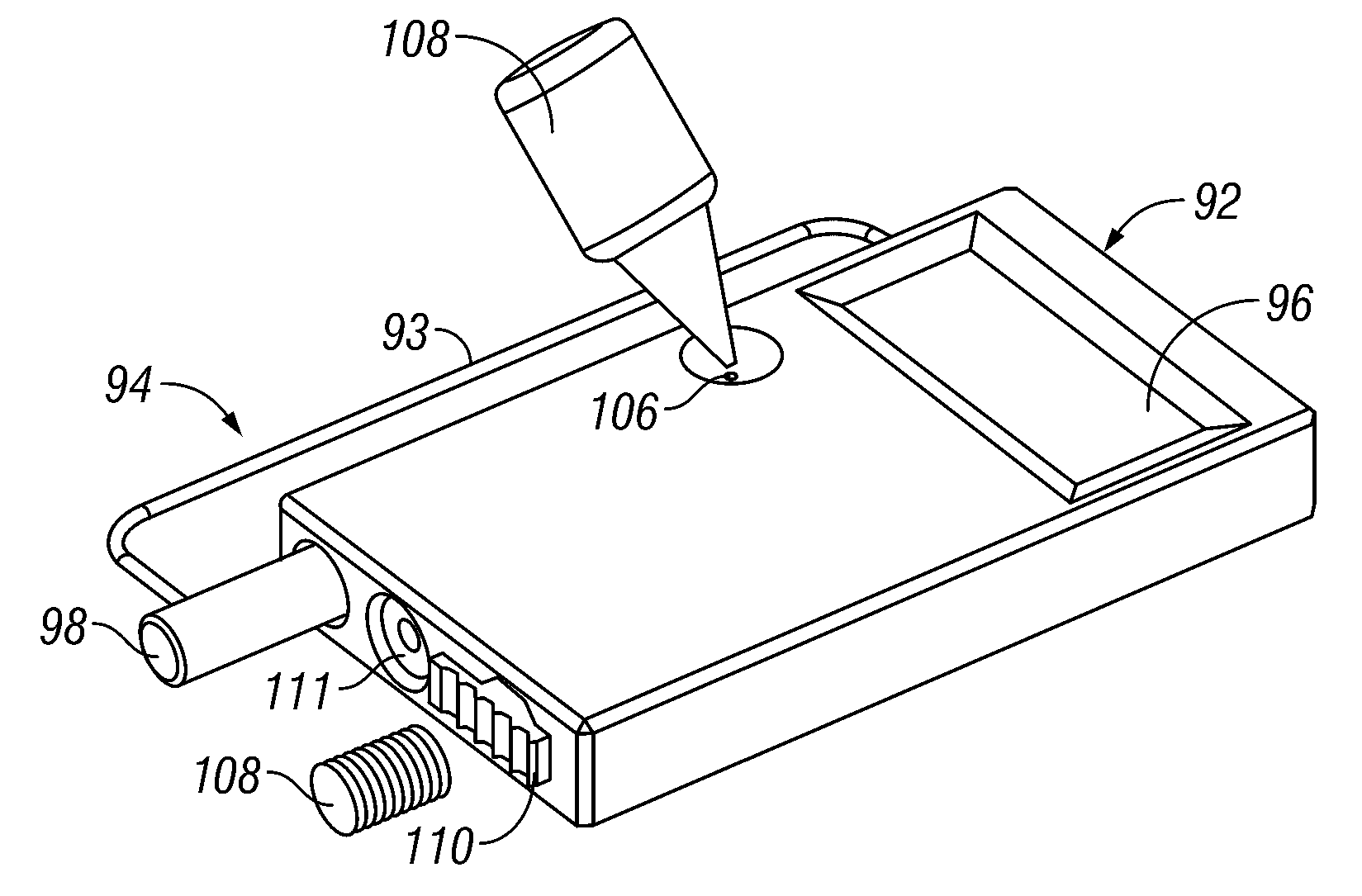

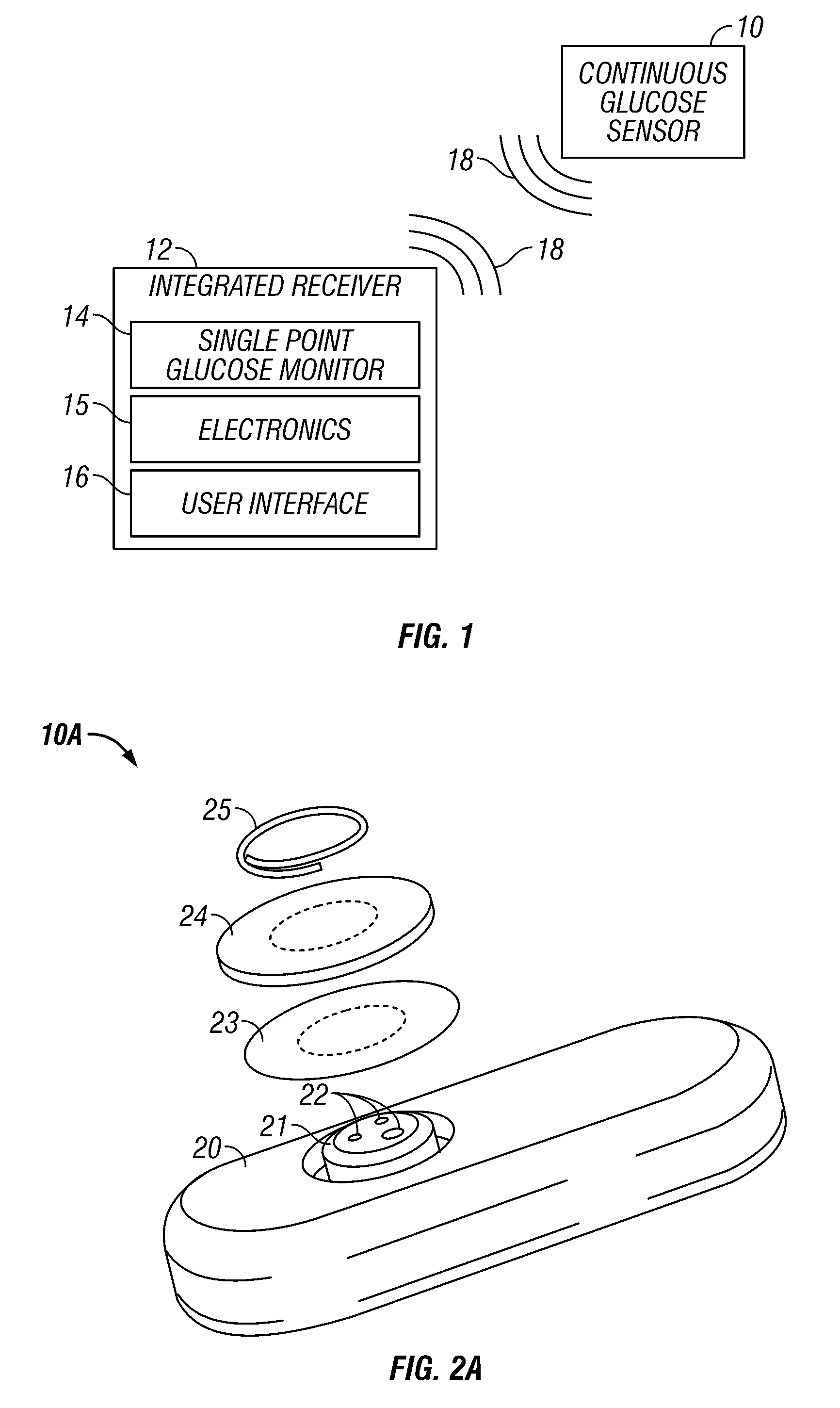

Integrated receiver for continuous analyte sensor

ActiveUS20050154271A1Reduce errorLess prone to human errorEndoradiosondesCatheterGlucose monitorsMonitoring glucose

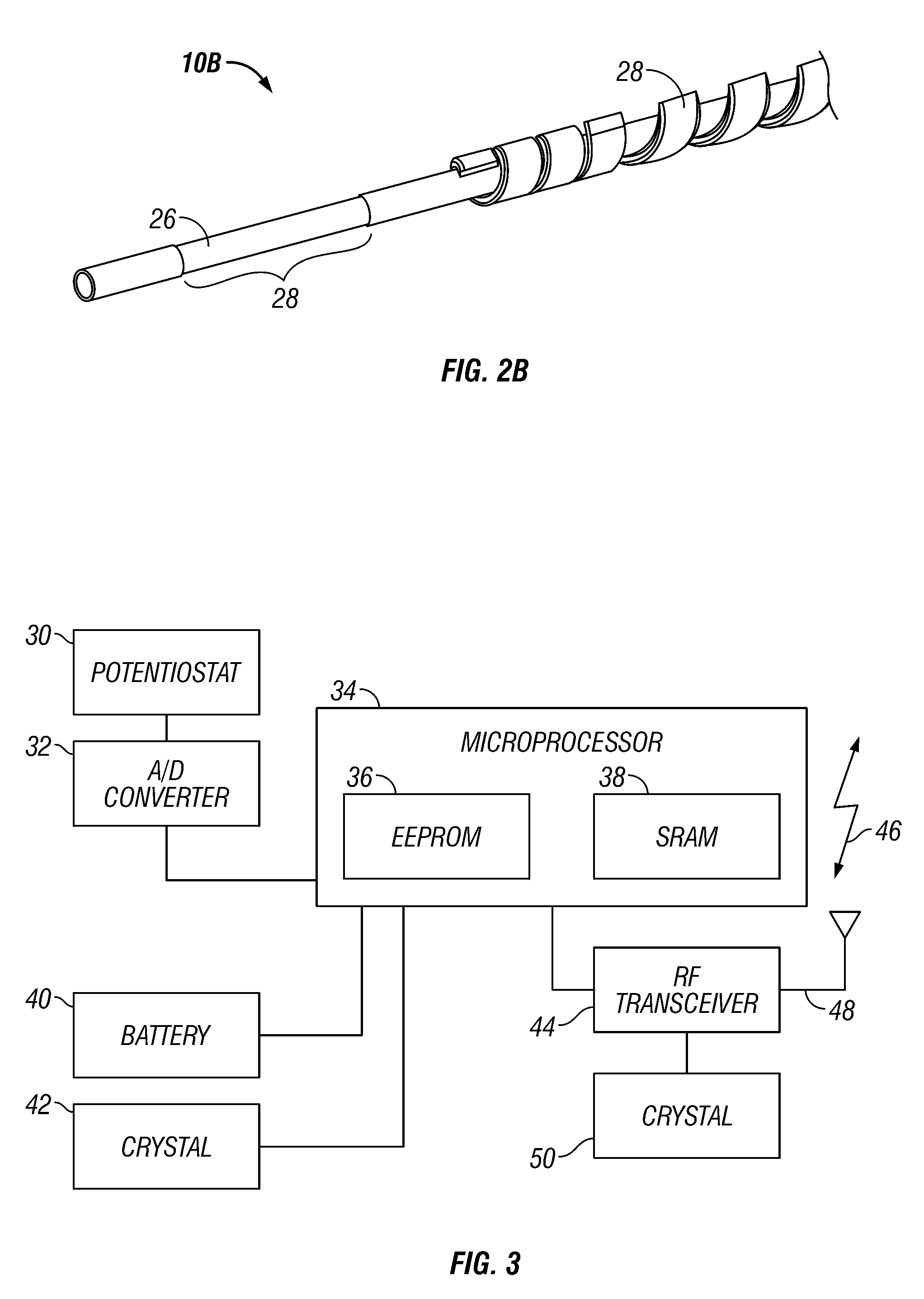

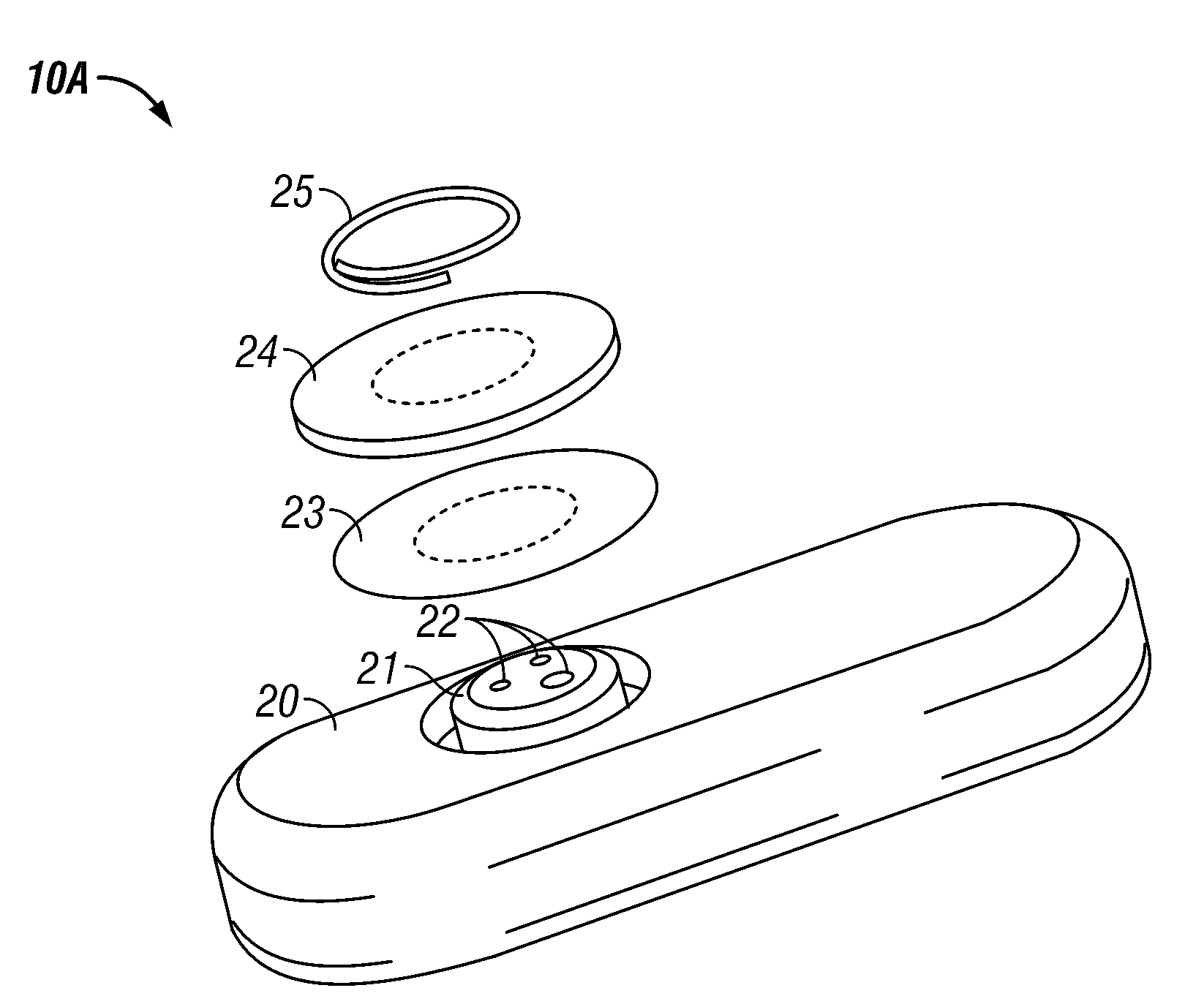

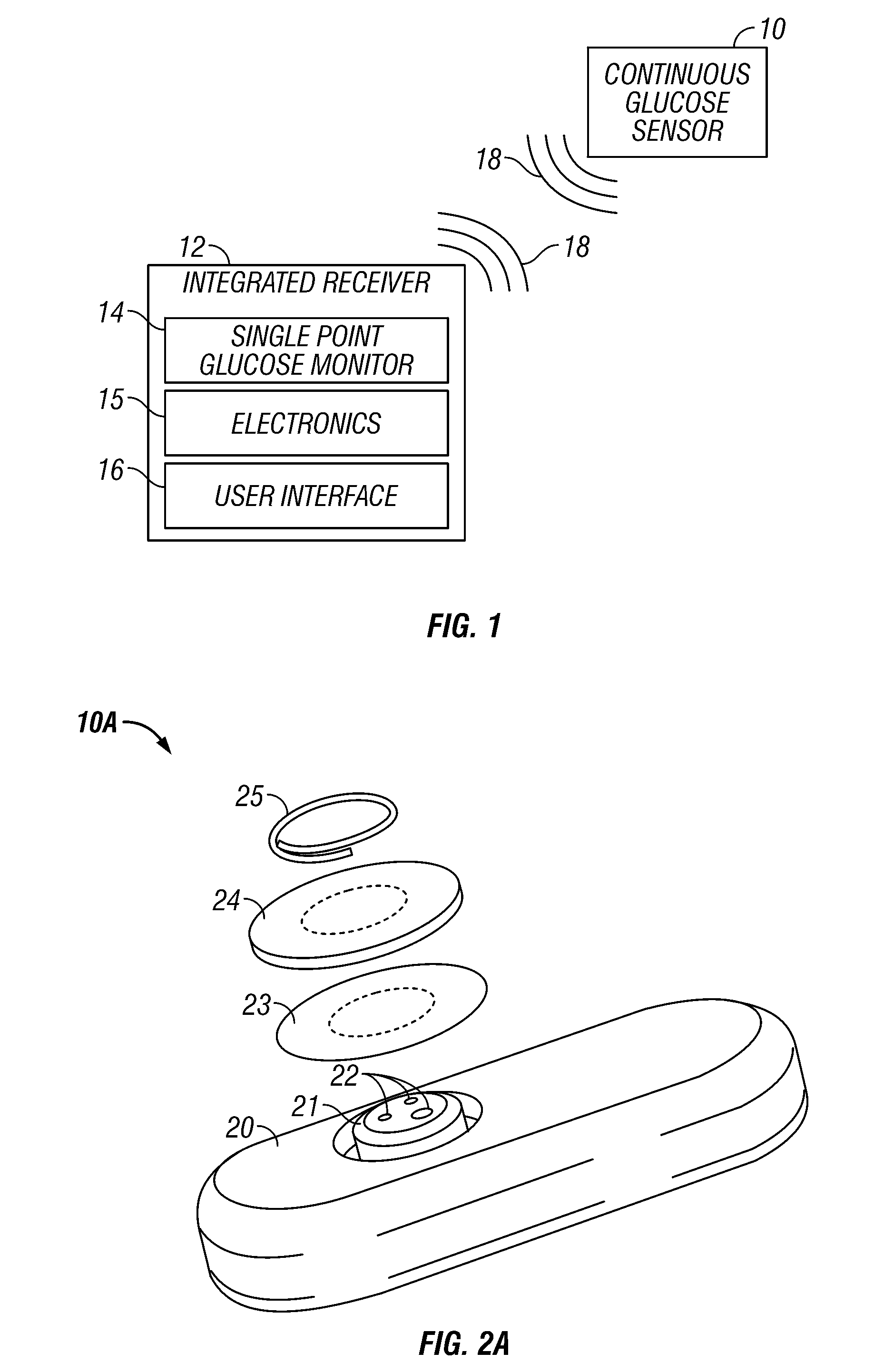

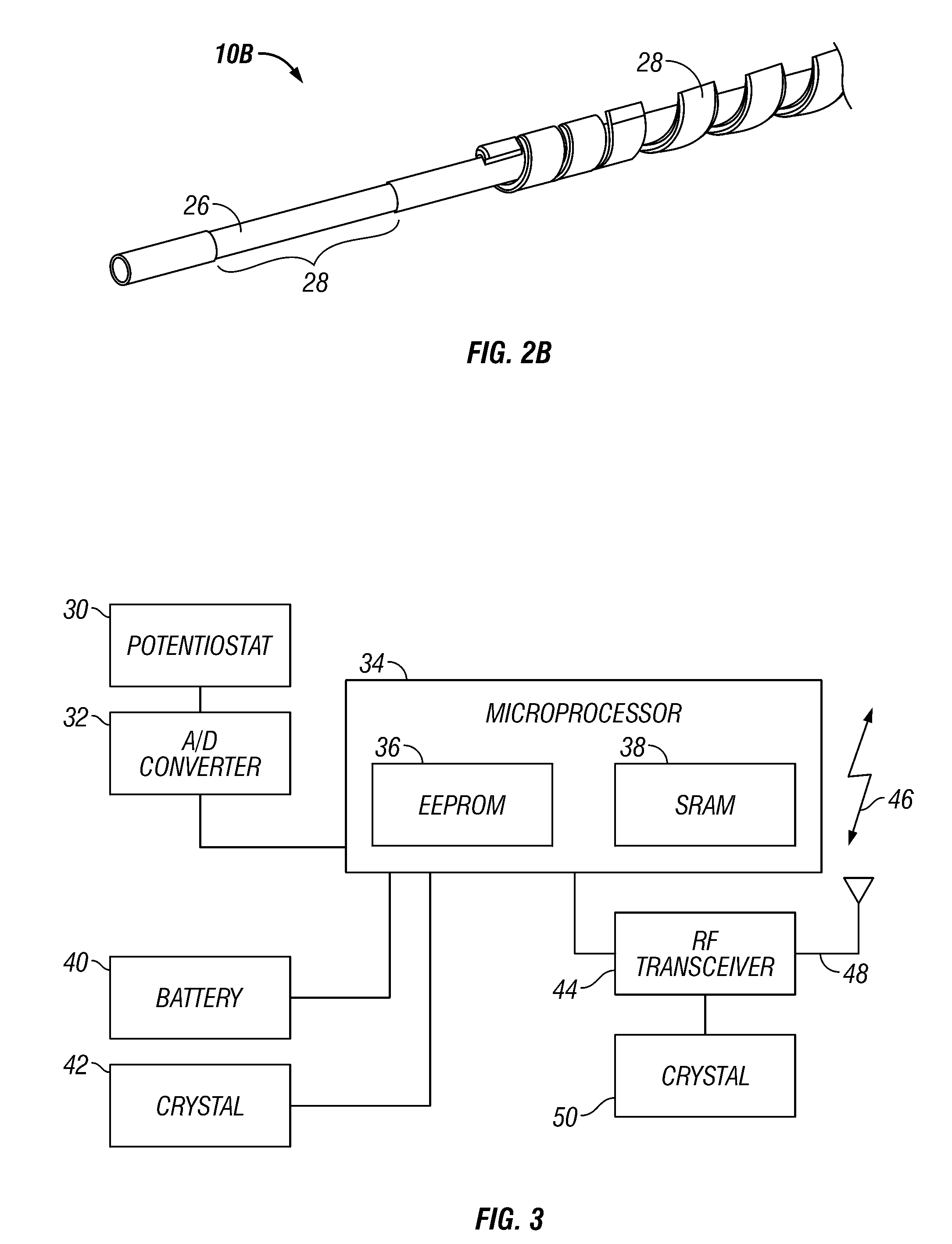

Abstract of the DisclosureA system is provided for monitoring glucose in a host, including a continuous glucose sensor that produces a data stream indicative of a host’s glucose concentration and an integrated receiver that receives the data stream from the continuous glucose sensor and calibrates the data stream using a single point glucose monitor that is integral with the integrated receiver. The integrated receiver obtains a glucose value from the single point glucose monitor, calibrates the sensor data stream received from the continuous glucose sensor, and displays one or both of the single point glucose measurement values and the calibrated continuous glucose sensor values on the user interface.

Owner:DEXCOM

Integrated receiver for continuous analyte sensor

InactiveUS20080287765A1Simpler and few componentReduce errorsEndoradiosondesCatheterGlucose sensorsData stream

A system is provided for monitoring glucose in a host, including a continuous glucose sensor that produces a data stream indicative of a host's glucose concentration and an integrated receiver that receives the data stream from the continuous glucose sensor and calibrates the data stream using a single point glucose monitor that is integral with the integrated receiver. The integrated receiver obtains a glucose value from the single point glucose monitor, calibrates the sensor data stream received from the continuous glucose sensor, and displays one or both of the single point glucose measurement values and the calibrated continuous glucose sensor values on the user interface.

Owner:DEXCOM INC

Integrated receiver for continuous analyte sensor

InactiveUS20080287764A1Simpler and few componentReduce errorsPharmaceutical delivery mechanismEndoradiosondesGlucose sensorsData stream

A system is provided for monitoring glucose in a host, including a continuous glucose sensor that produces a data stream indicative of a host's glucose concentration and an integrated receiver that receives the data stream from the continuous glucose sensor and calibrates the data stream using a single point glucose monitor that is integral with the integrated receiver. The integrated receiver obtains a glucose value from the single point glucose monitor, calibrates the sensor data stream received from the continuous glucose sensor, and displays one or both of the single point glucose measurement values and the calibrated continuous glucose sensor values on the user interface.

Owner:DEXCOM INC

Integrated receiver for continuous analyte sensor

ActiveUS20080287766A1Simpler and few componentReduce errorsEndoradiosondesCatheterGlucose sensorsData stream

A system is provided for monitoring glucose in a host, including a continuous glucose sensor that produces a data stream indicative of a host's glucose concentration and an integrated receiver that receives the data stream from the continuous glucose sensor and calibrates the data stream using a single point glucose monitor that is integral with the integrated receiver. The integrated receiver obtains a glucose value from the single point glucose monitor, calibrates the sensor data stream received from the continuous glucose sensor, and displays one or both of the single point glucose measurement values and the calibrated continuous glucose sensor values on the user interface.

Owner:DEXCOM INC

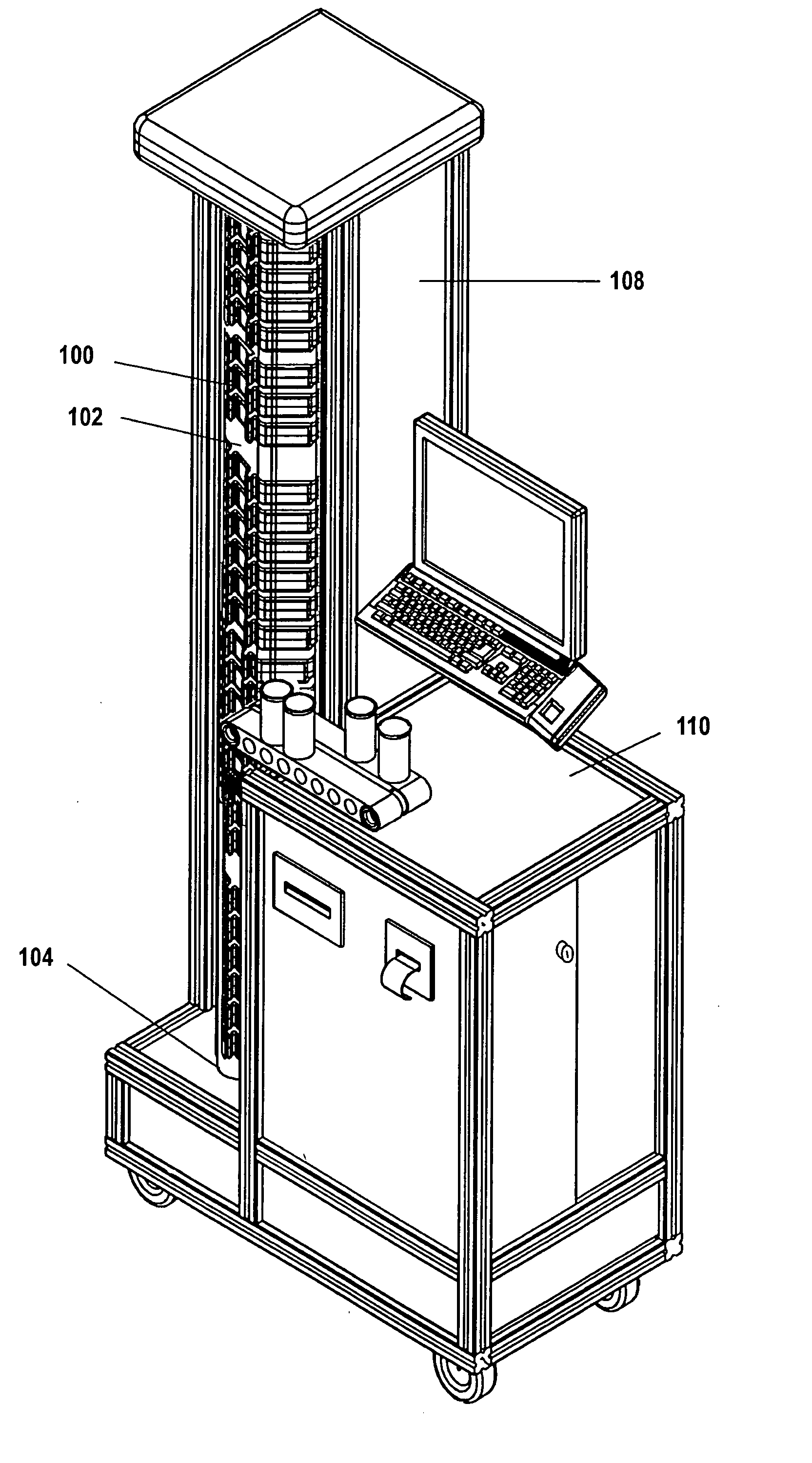

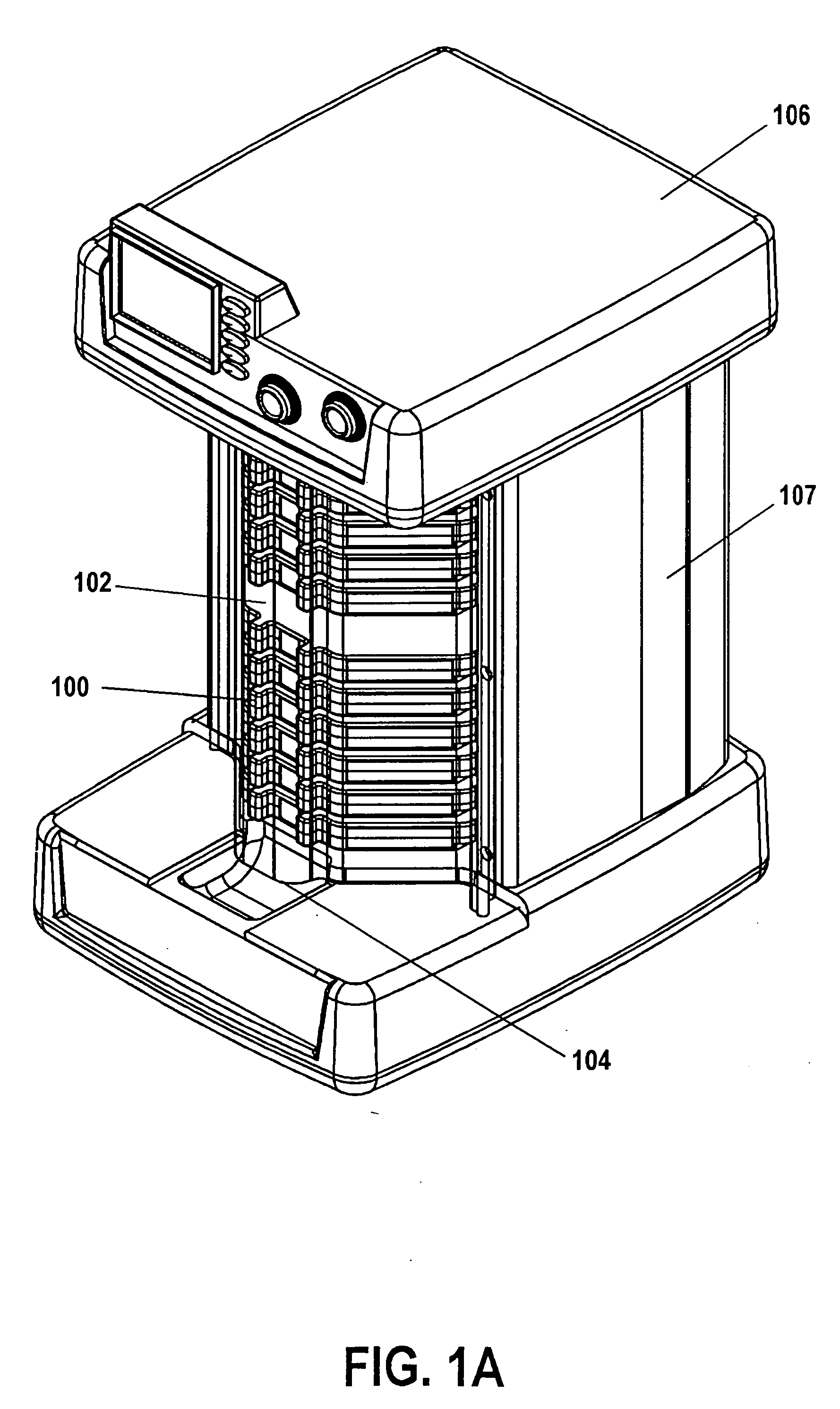

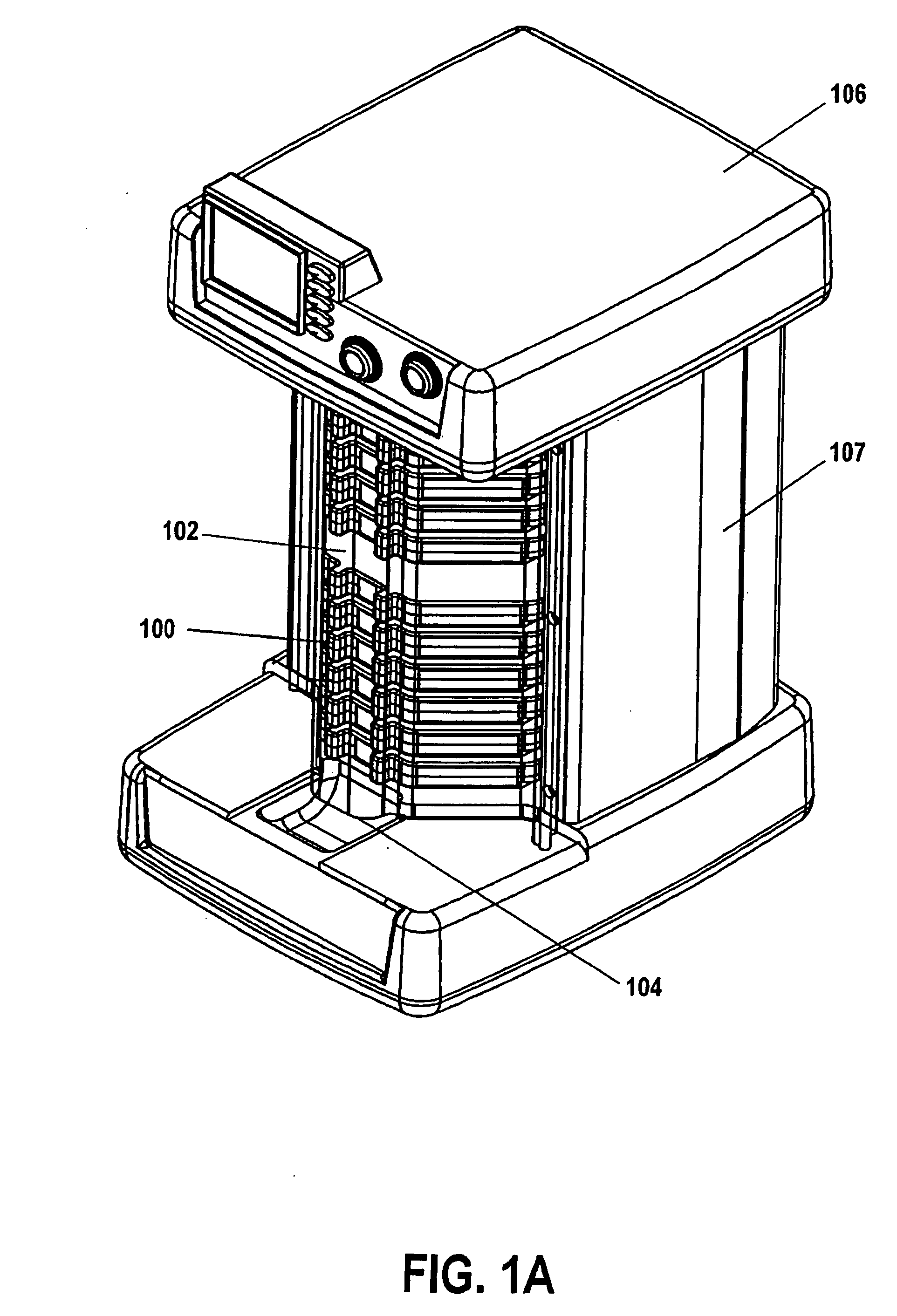

Smart tray for dispensing medicaments

ActiveUS20060058724A1Enhance shelf lifeLess prone to errorElectrotherapyDrug and medicationsBiomedical engineering

The invention relates to a method and system that utilizes one or more cassettes or trays, which hold one or more types of medicaments, the cassettes or trays being configured for secure and intelligent dispensing of the medicaments. In one embodiment, a smart tray for dispensing medicaments includes: a housing; a chamber within the housing to store the medicament units; an outlet defined in the housing to dispense the medicament units; and a rotatable disk within the housing and defining at least one radial groove configured to hold at least one medicament unit, the rotatable disk being positioned between the storage chamber and the outlet whereby when the rotatable disk rotates, the at least one radial groove carries the at least one medicament unit from the chamber to the outlet. In a further embodiment, the smart tray includes a memory device within the housing to store information pertaining to the medicament units stored in the tray and / or information pertaining to the status or operation of the tray.

Owner:HANDFIELD MICHAEL +1

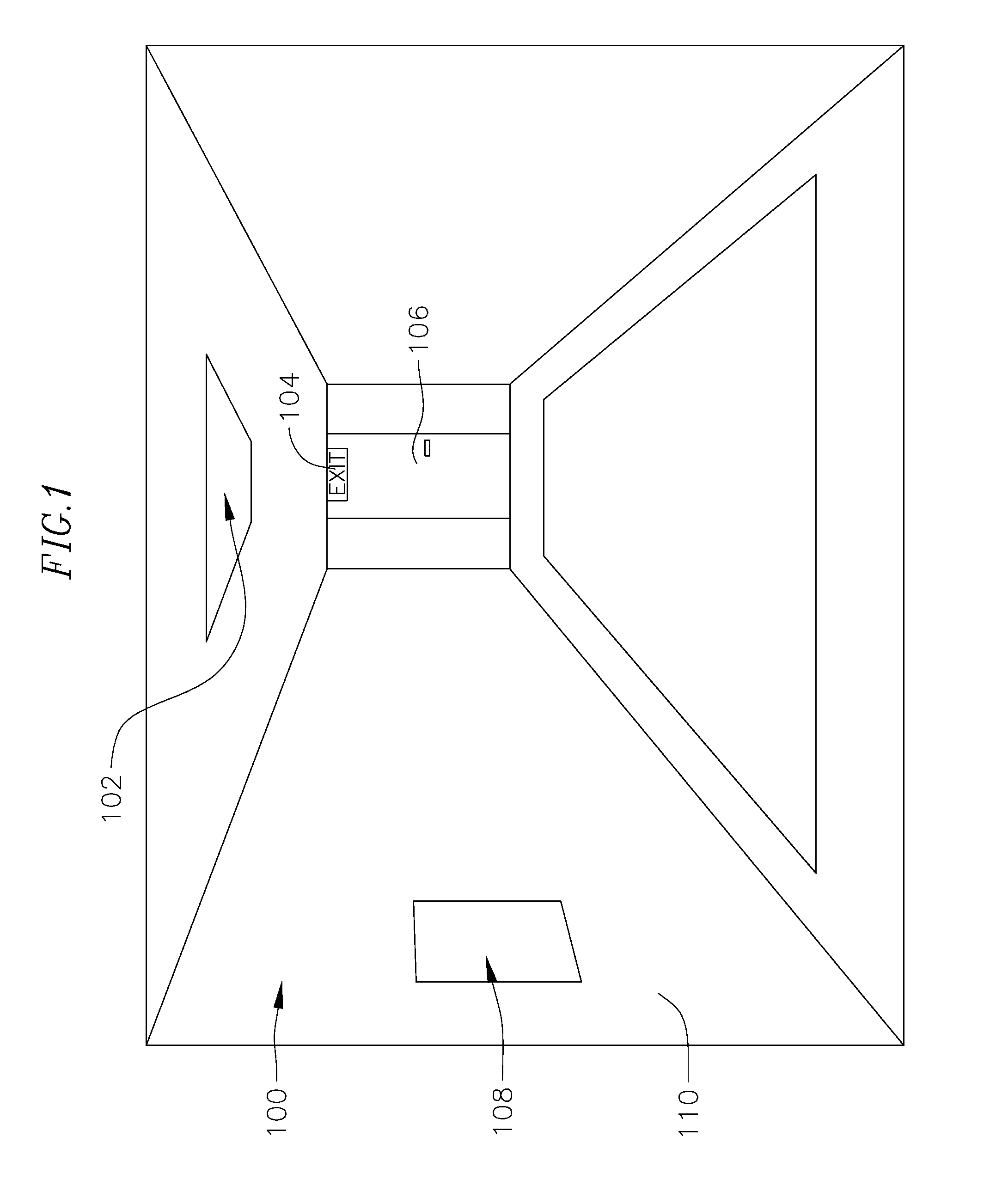

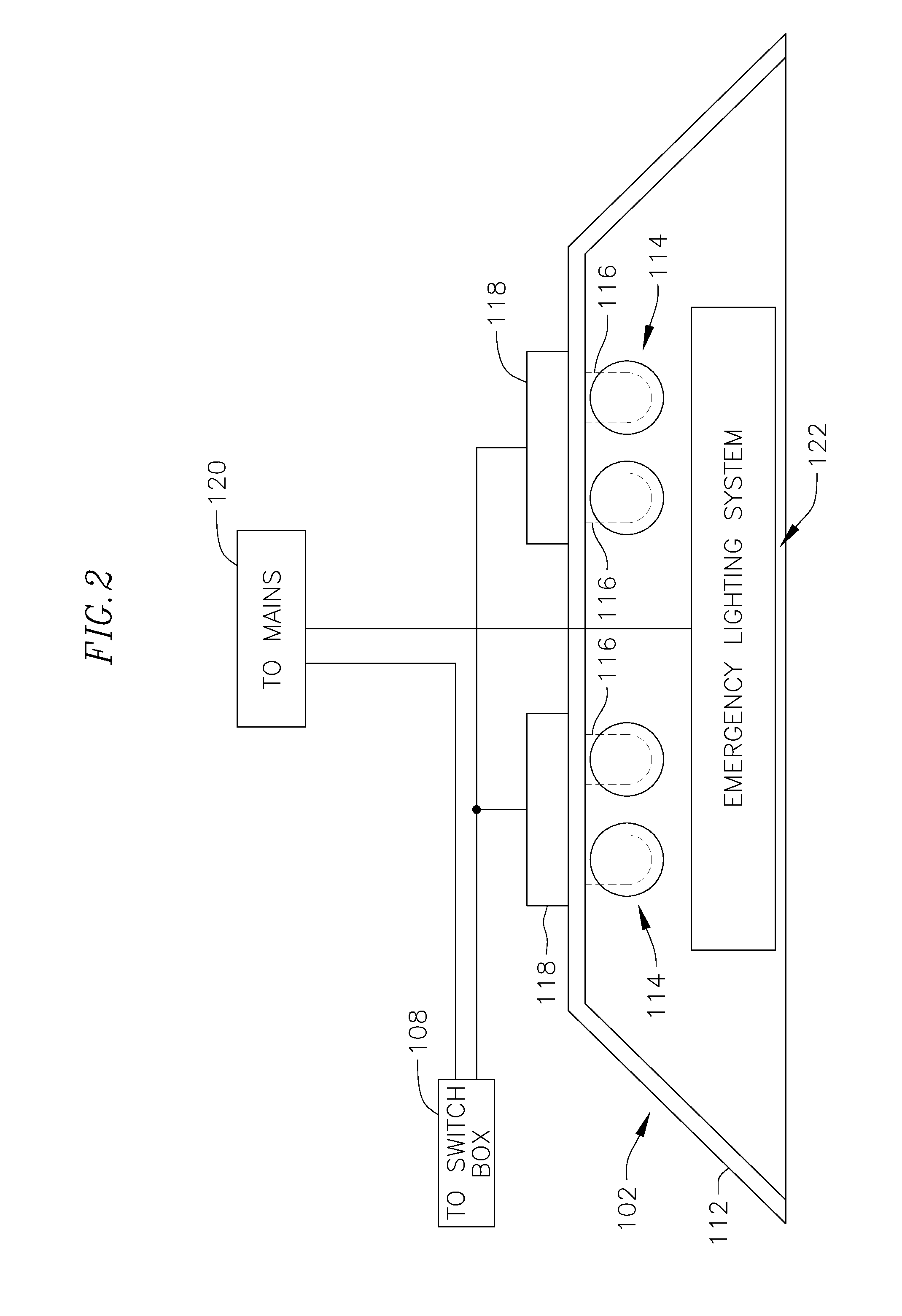

Supplemental, backup or emergency lighting systems and methods

InactiveUS20140240966A1Easy to installLess-prone to errorPlanar light sourcesBatteries circuit arrangementsElectrical batteryLighting system

A supplemental lighting system includes a charging circuit having a reference voltage for the charging circuit set through changes to reference resistances, and / or having an output voltage, current or power set through a connector configuration. In one example, a battery storage connector can be used to select a particular resistance for setting the reference voltage. Additionally, a supplemental lighting system may have a rechargeable battery coupled to a low-voltage part of the circuit, for example protected by an isolation circuit. Furthermore, a lithium ion or similar rechargeable battery supply can include a circuit for allowing it to be used with a circuit designed for a NiCad powered system or with a circuit designed for a lithium ion powered system.

Owner:FULHAM CO LTD

Method for manufacturing paraffin-embedded tissue cell specimen

InactiveCN103940658AAccurate chemical localizationShorten visit timePreparing sample for investigationMicrowave ovenParaffin embedded tissue

The invention provides a method for manufacturing a paraffin-embedded tissue cell specimen. The method is characterized by comprising the following steps: precipitating and performing centrifugal treatment on a tissue cell specimen, subsequently extracting the tissue cell specimen, adding an environmental-friendly biologic synthesis agent, synchronously fixing, dehydrating, transparentizing and performing paraffin dipping treatment on the tissue cell specimen by an ultrasonic tissue treatment instrument or a medical microwave oven, slicing the paraffin-embedded tissue, and dyeing and sealing the paraffin-embedded tissue slice. The method has the advantages that the operation is rapid, no pollution is caused, the operation is simple and convenient, a dyeing process can be performed together with daily work, a molecular pathological examination can be also performed, and the result is stable. The positive detection rate and the accuracy in pathological diagnosis are improved.

Owner:QINGDAO MUNICIPAL HOSPITAL

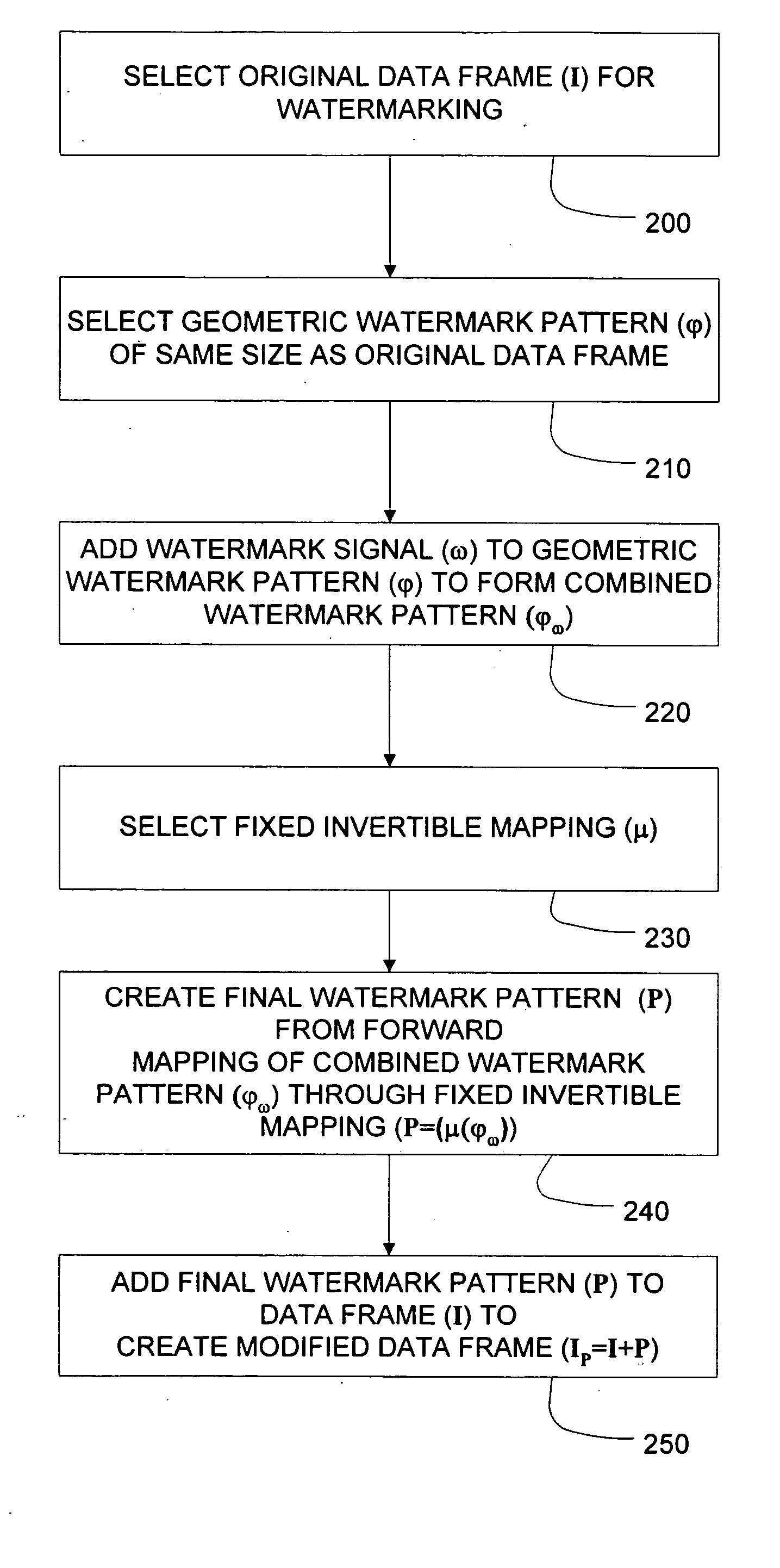

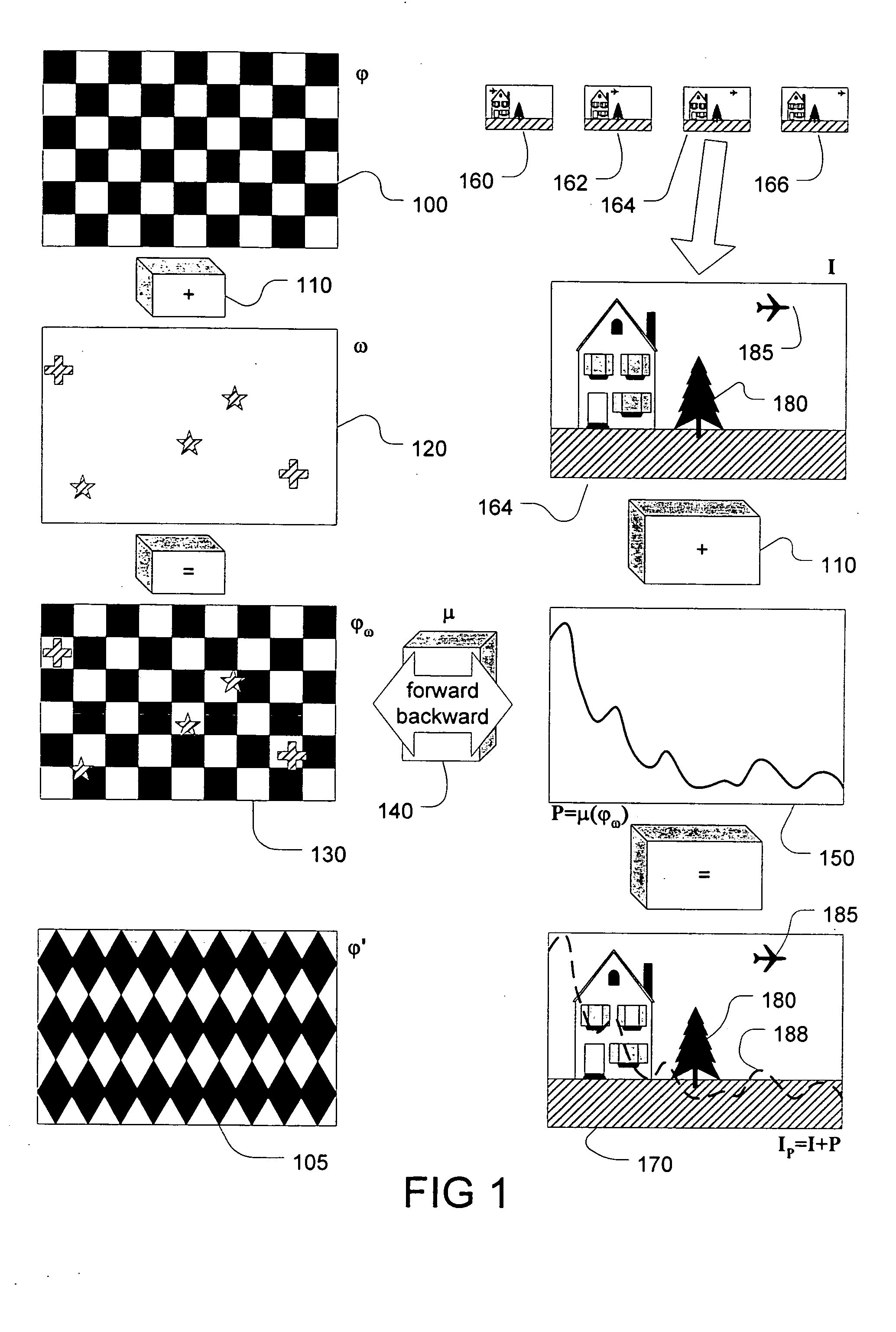

Method to make wavelet watermarks resistant to affine transformations

InactiveUS20050123169A1Not easy to make mistakesReduce calculationCharacter and pattern recognitionVisual presentationGeometric patternWavelet

A method and / or apparatus for embedding and detecting watermarks in a set of data frames, where a secondary domain is used for combining the data frame, watermark, and a geometric pattern for holding the watermark, and that secondary domain is used for post-combination filtering of the modified data frame. The secondary domain is preferably a wavelet domain or sub-band domain. The geometric pattern for holding the watermark is reversibly mapable between a complex pattern in the original domain of the data frame and a simple pattern in the secondary domain where combination and filtering takes place.

Owner:SONY CORP +1

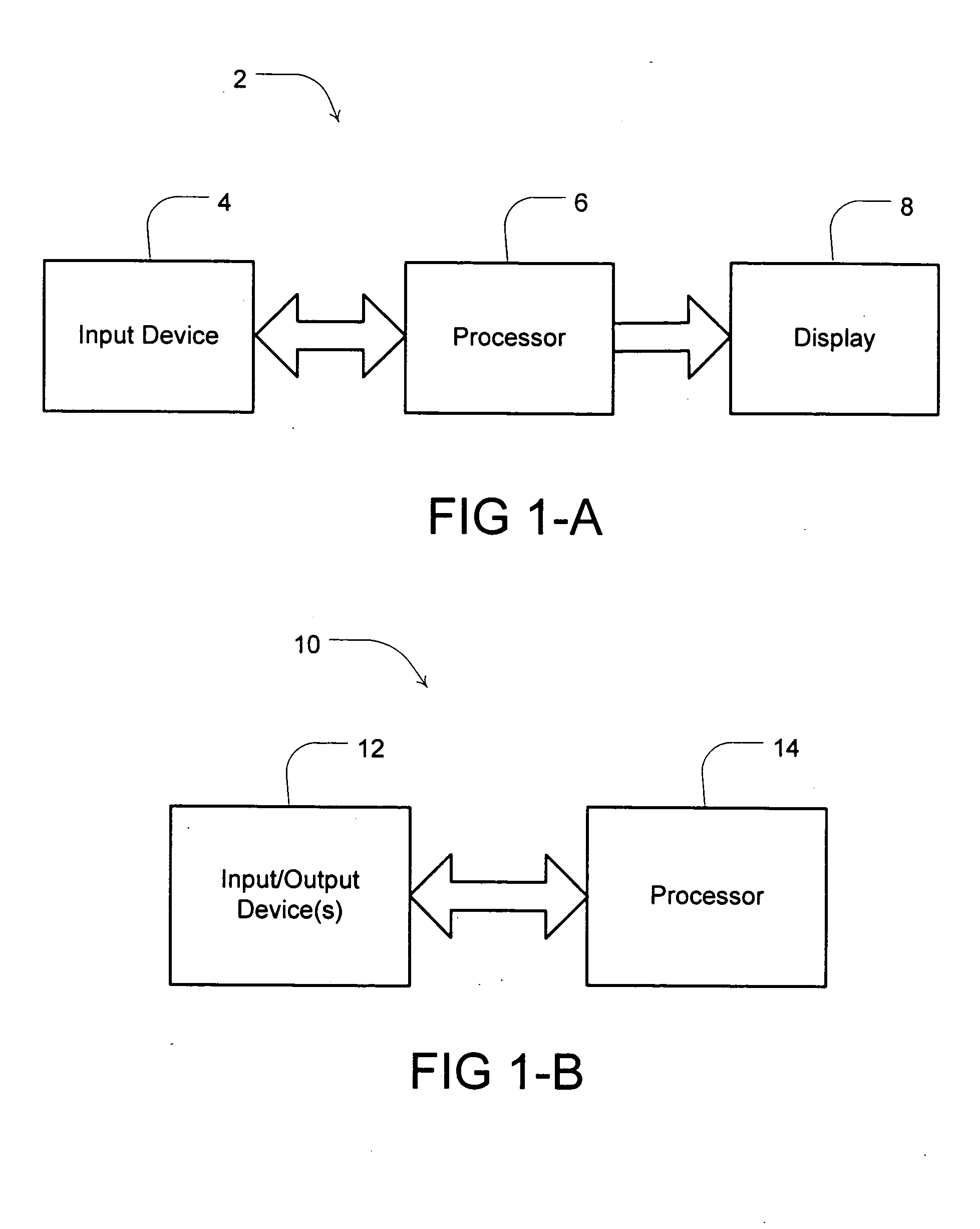

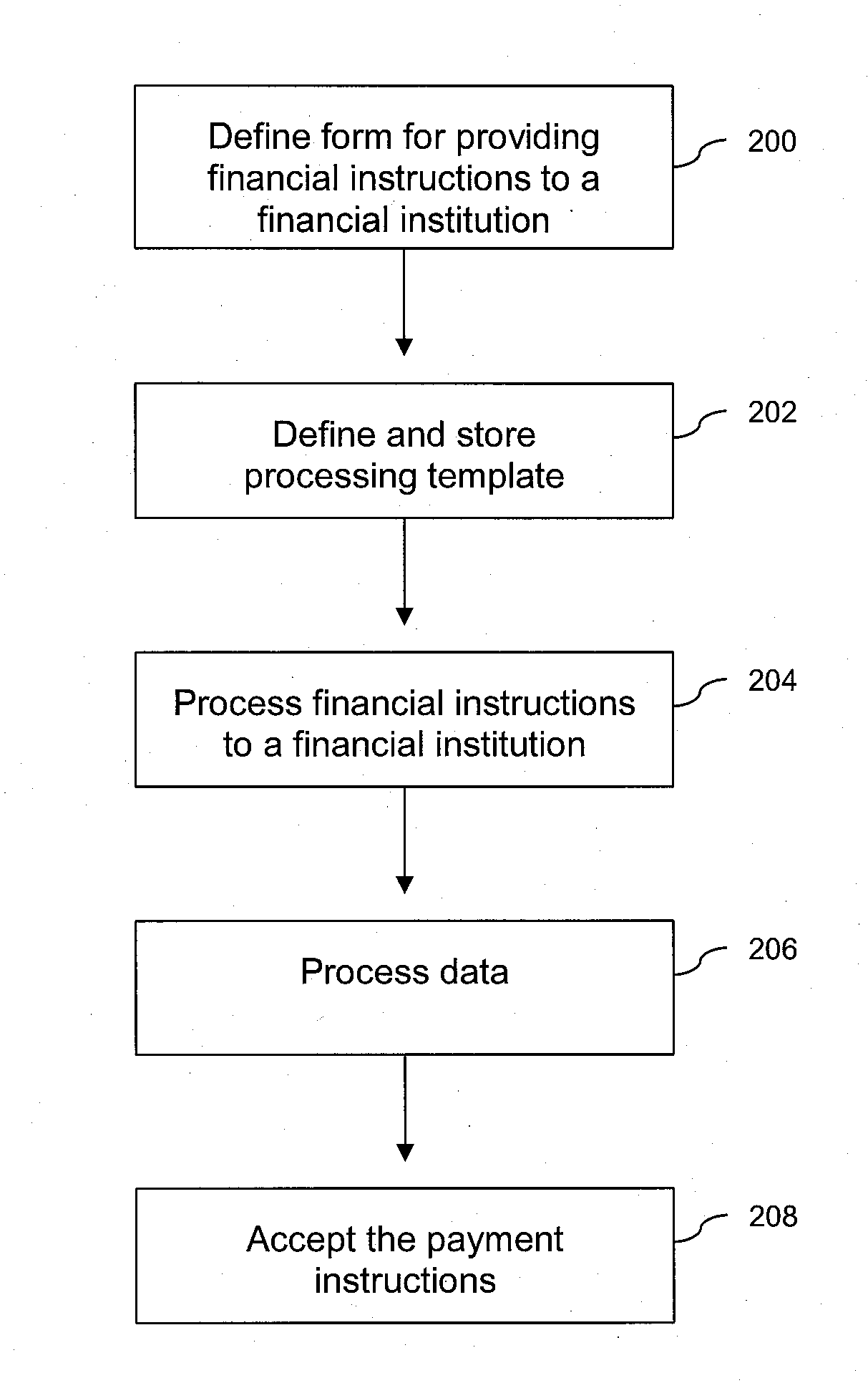

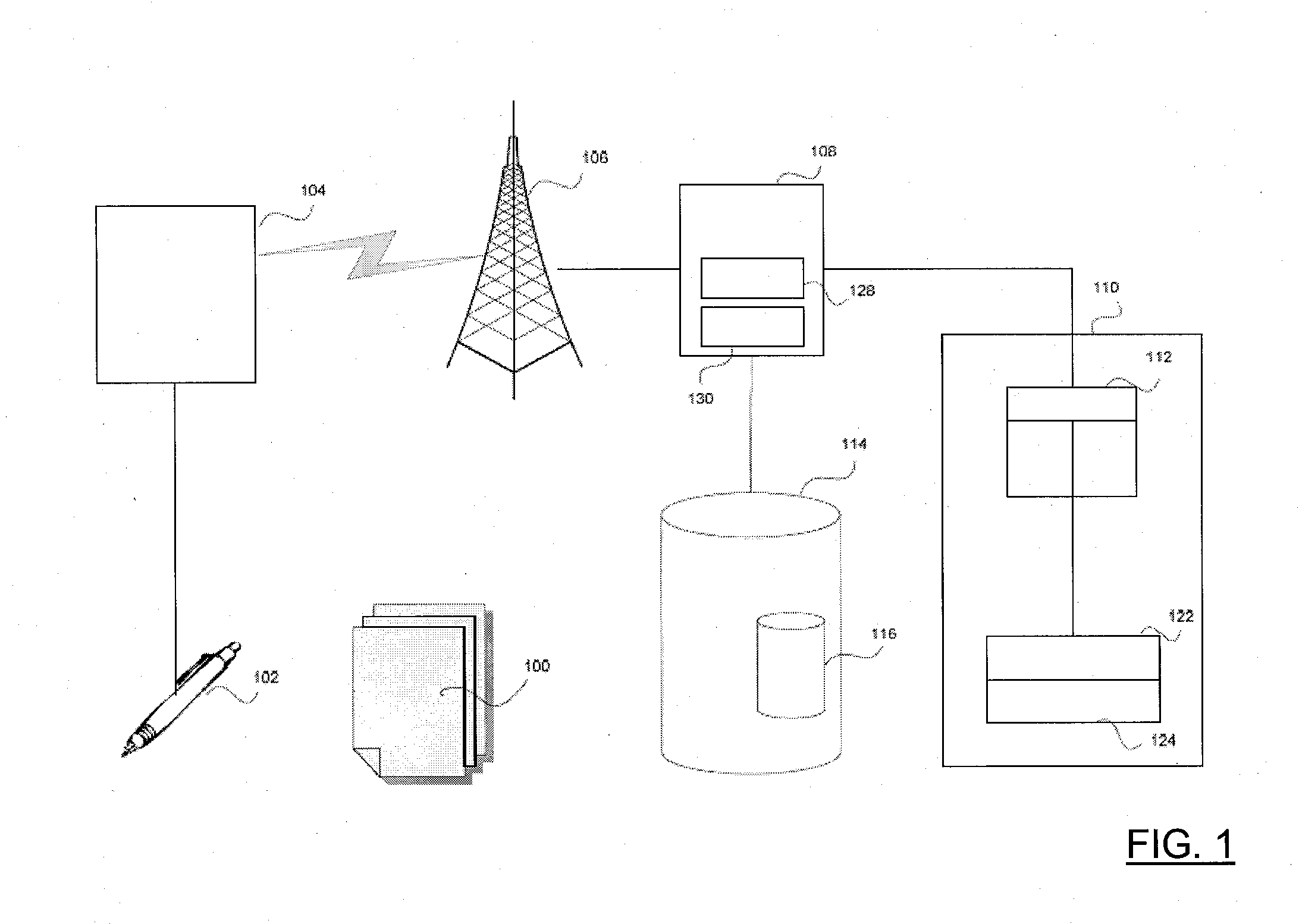

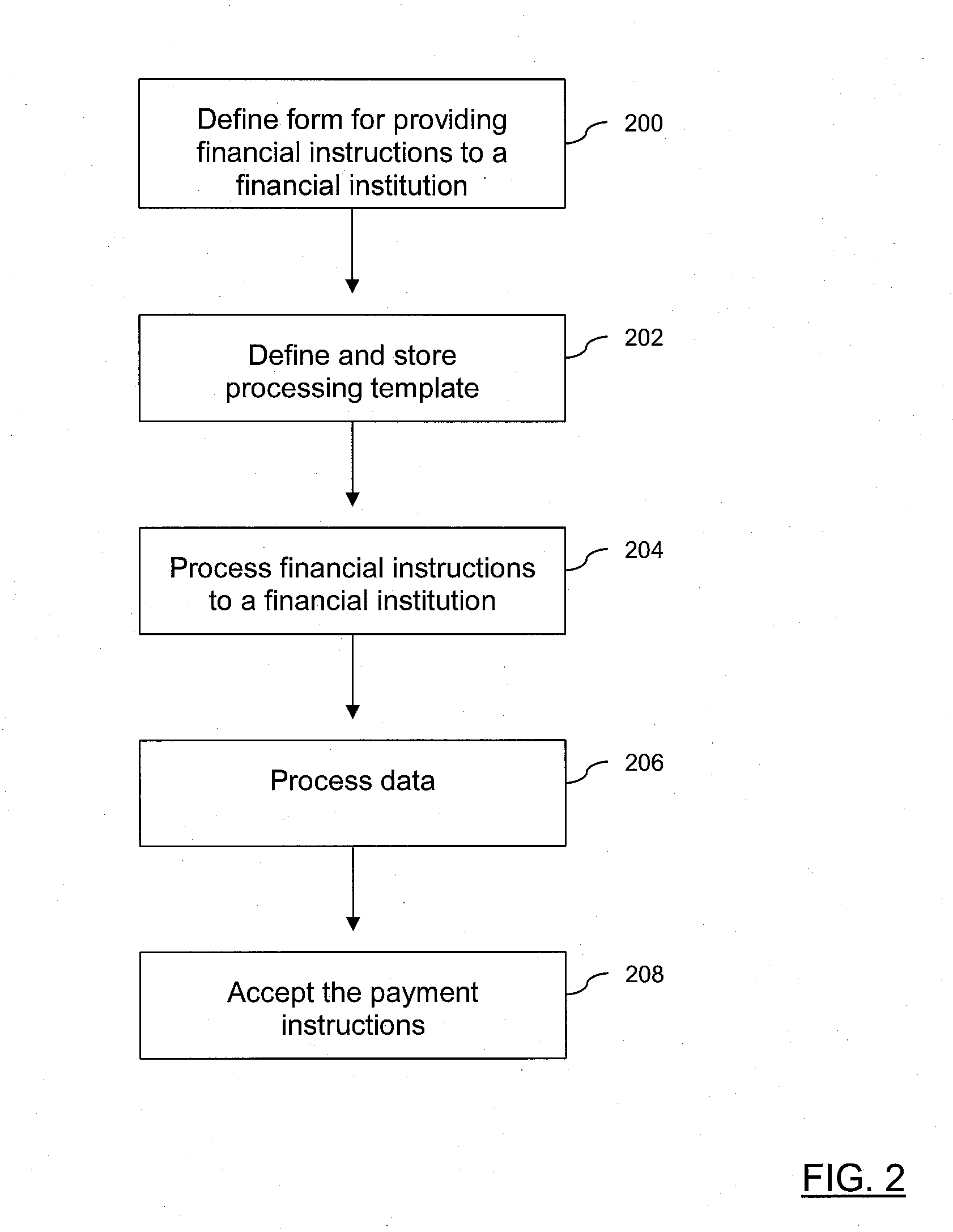

Method, system and computer program for generating financial transaction instructions

InactiveUS20090076951A1Easy accessLess prone to errorFinancePayment architectureComputer programServer

A method, system and computer program is provided for enabling on-line generation of financial instructions by a financial institution account holder and / or a signatory authorized to access his / her financial institution account. Hand written data provided by a user on a medium is digitized, such medium optionally including a digital pattern, by operation of a digital pen. The data is provided at communication device, and then to a server computer associated with the financial institution, the server computer being operable to interpret the data as financial instructions. The financial institution processes the financial instructions, and optionally generates feedback, which is made available to the communication device. The server computer enables the processing one or more financial transactions based on the financial instructions.

Owner:SZAMEL JOSEPH

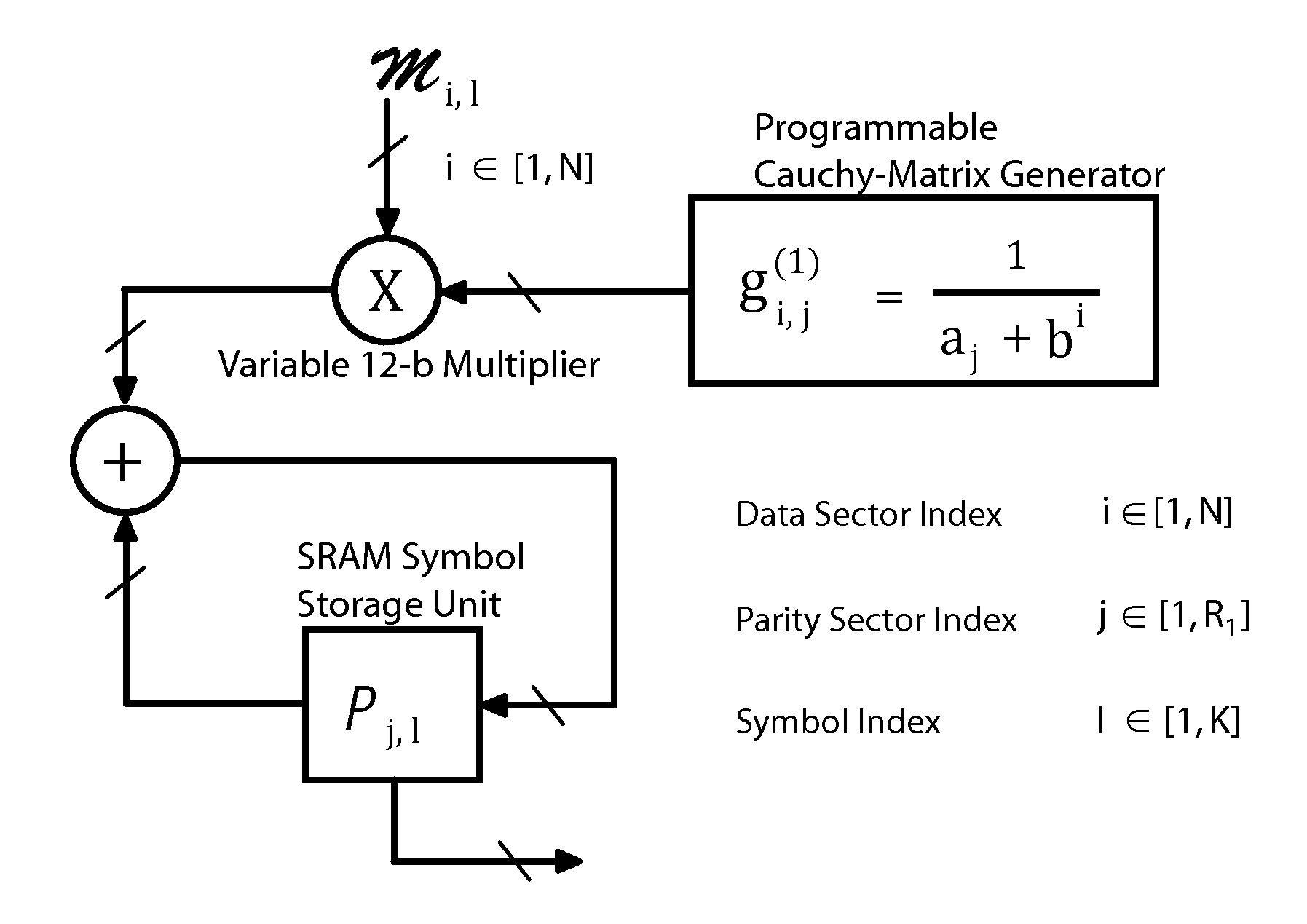

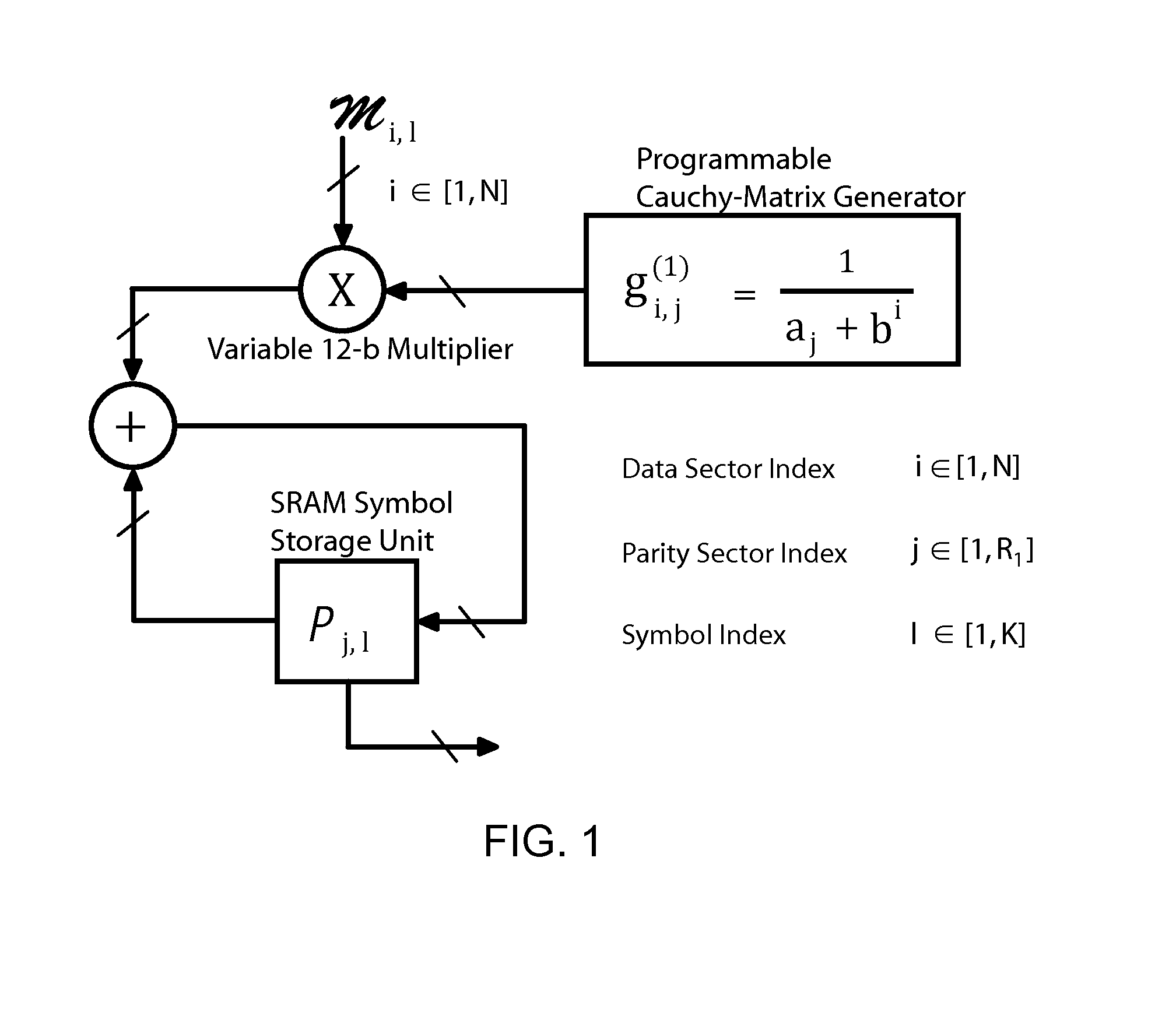

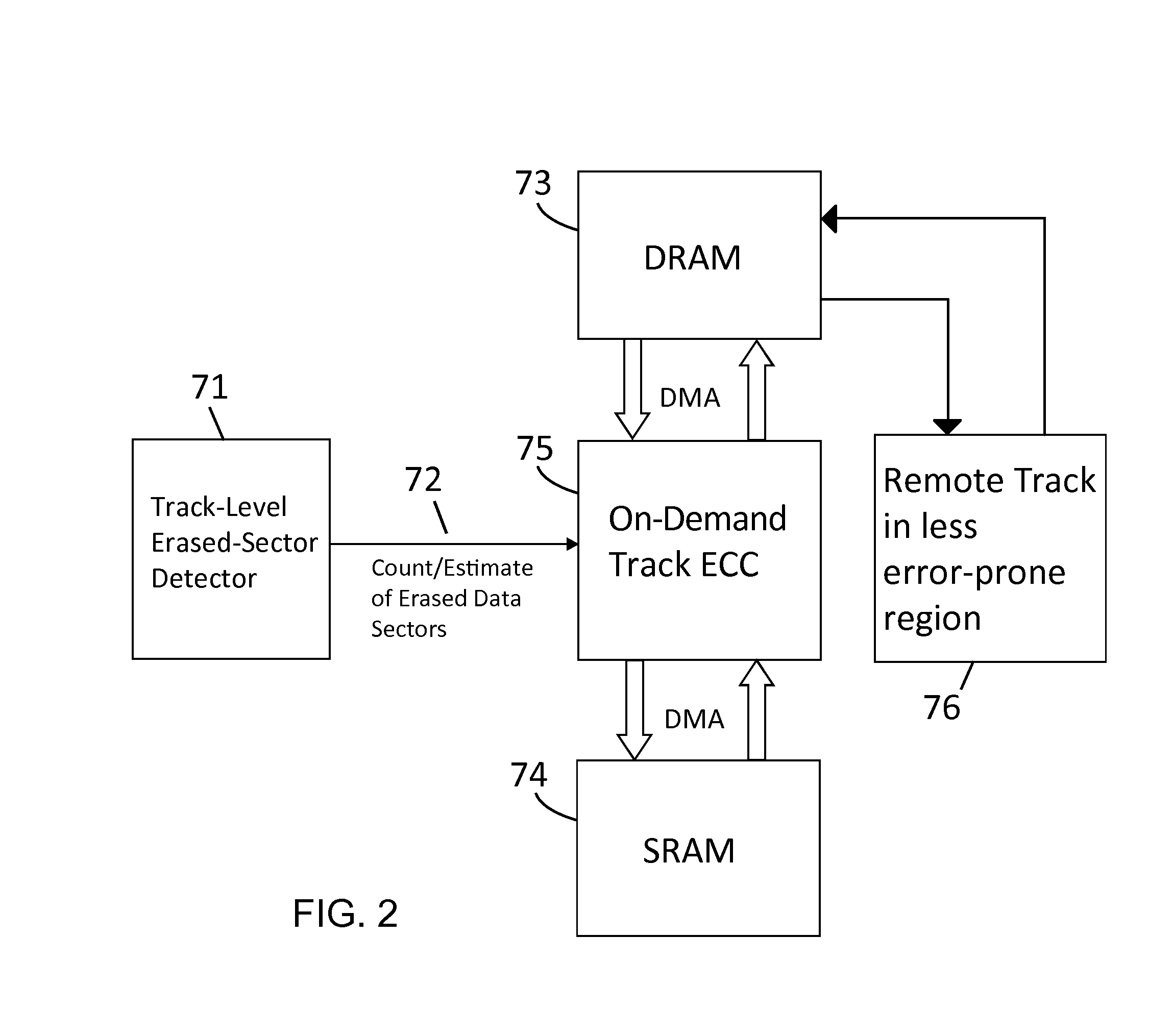

Error correction with on-demand parity sectors in magnetic data storage devices

ActiveUS20150254135A1Less prone to errorAvoid errorCode conversionRecord information storageData errorHead position

Data storage devices are described with an ECC system that generate additional on-demand ECC information for a previously written track to provide for correction of data errors in the track and thereby avoid having to rewrite the track. Embodiments of the invention address the squeeze-error problem that arises when writing the next (second) track in a sequence causes errors to be introduced in the adjacent previously written (first) track. In alternative embodiments the existence of the data errors in the first track can be detected by reading the track or by estimating the number of likely errors using head position data measured while writing the first and second tracks. The additional on-demand ECC information can be written on any track that is available.

Owner:WESTERN DIGITAL TECH INC

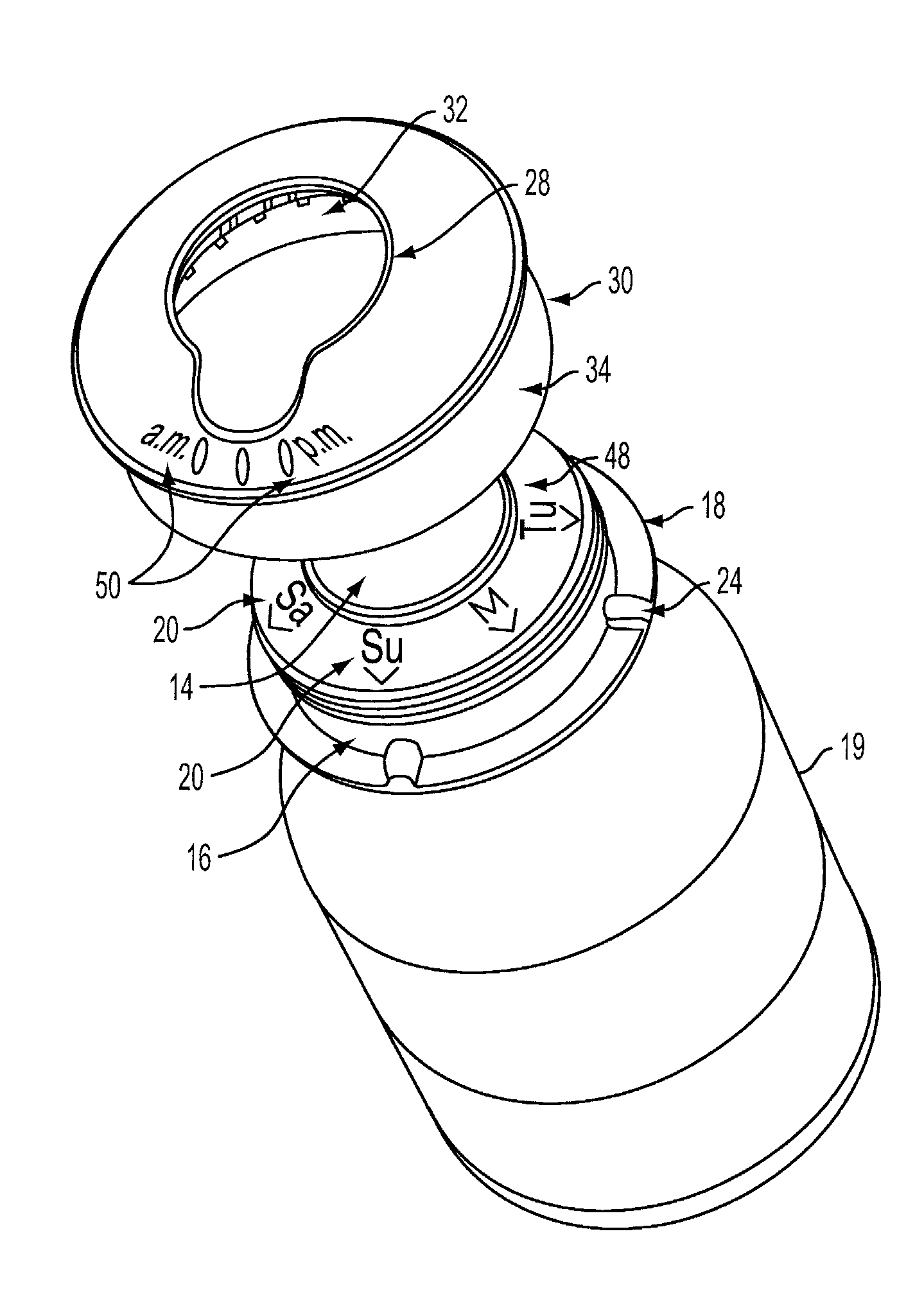

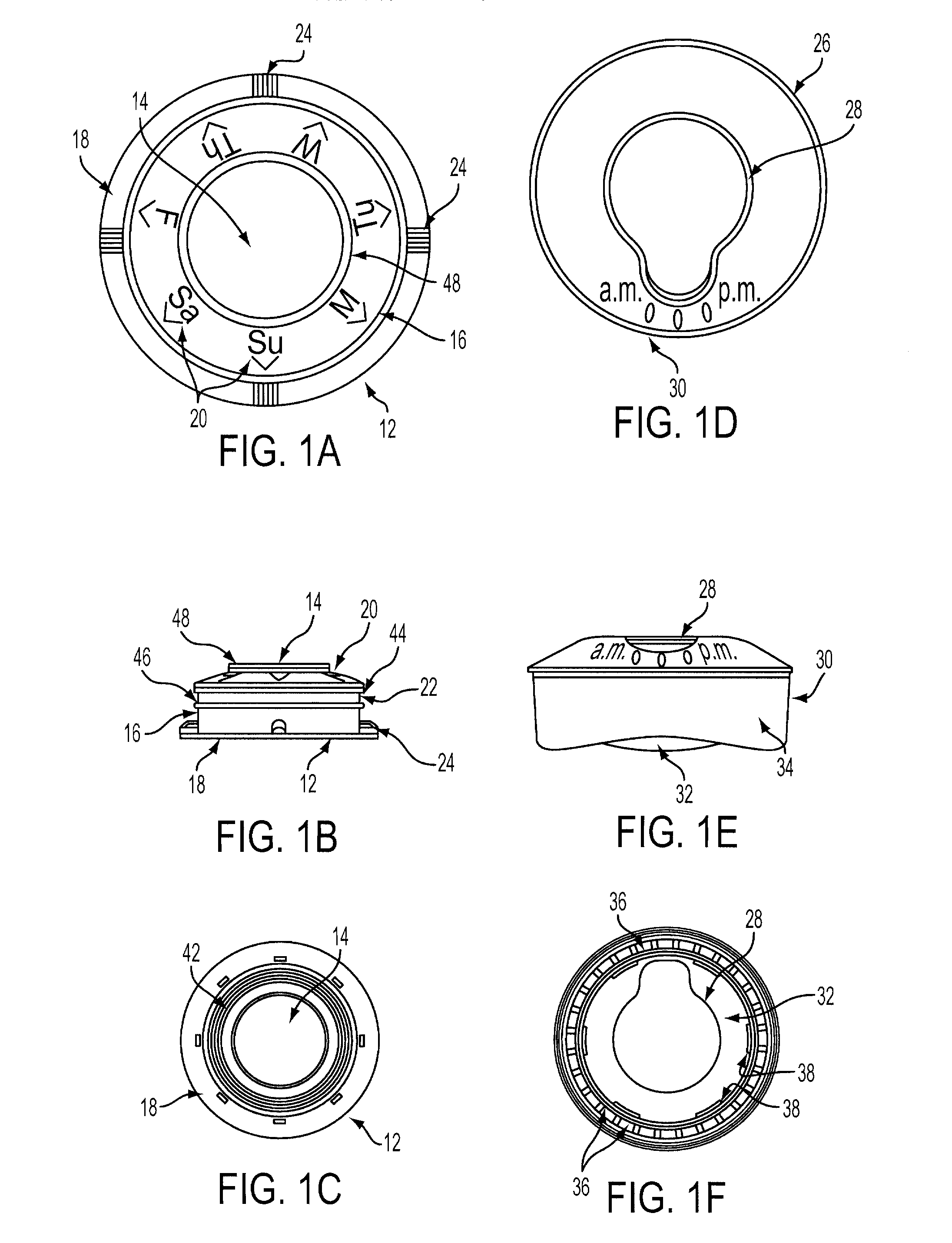

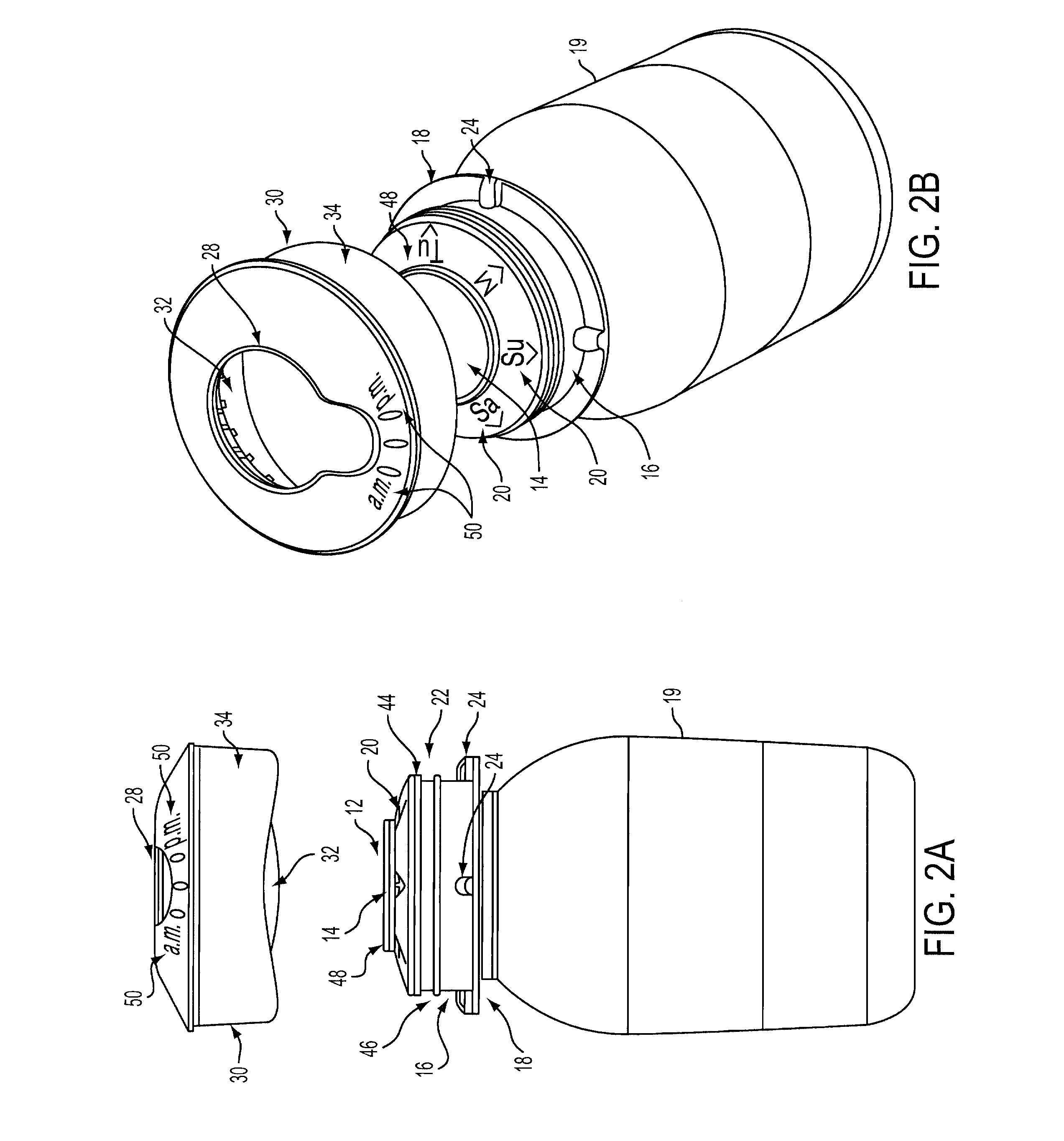

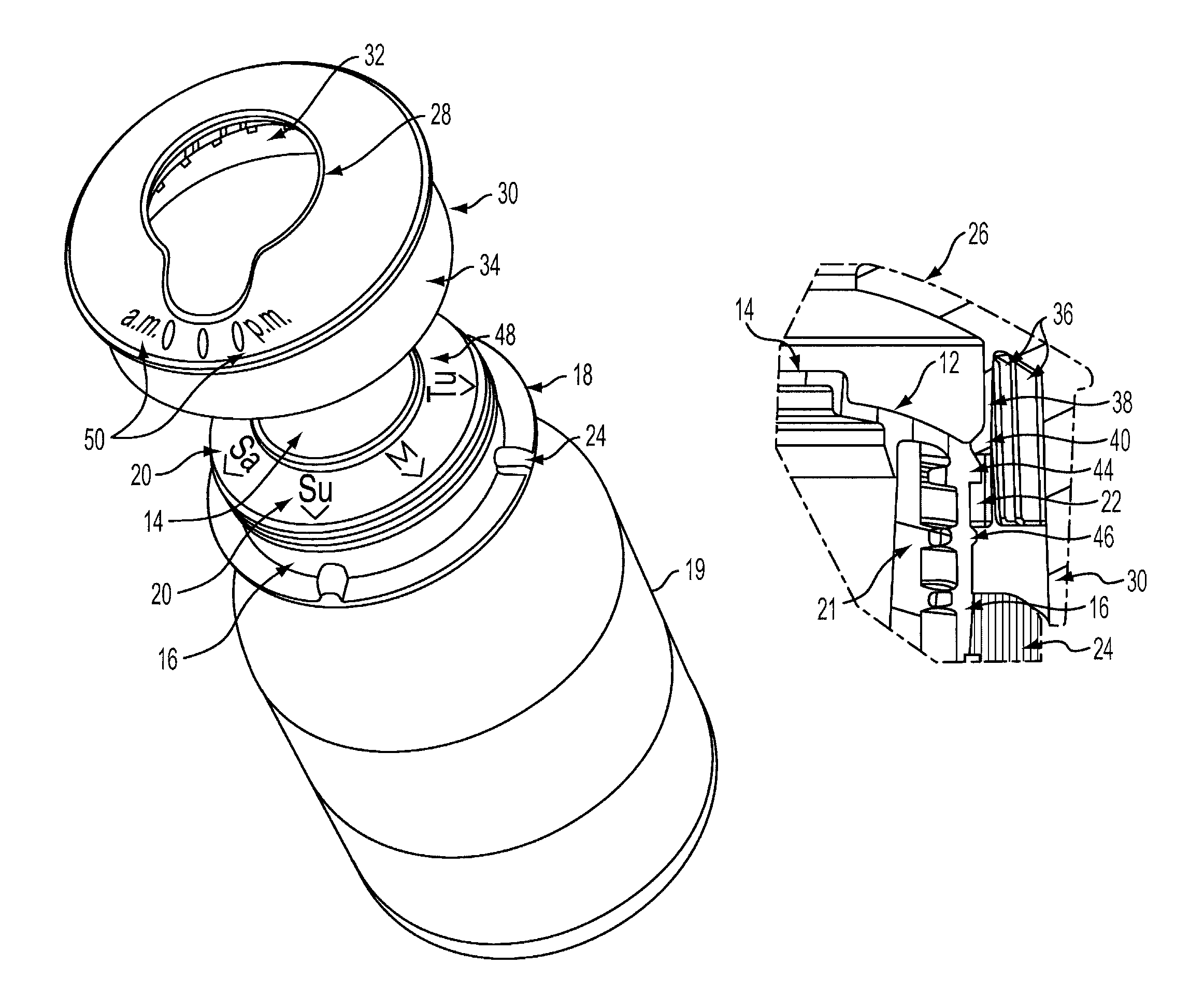

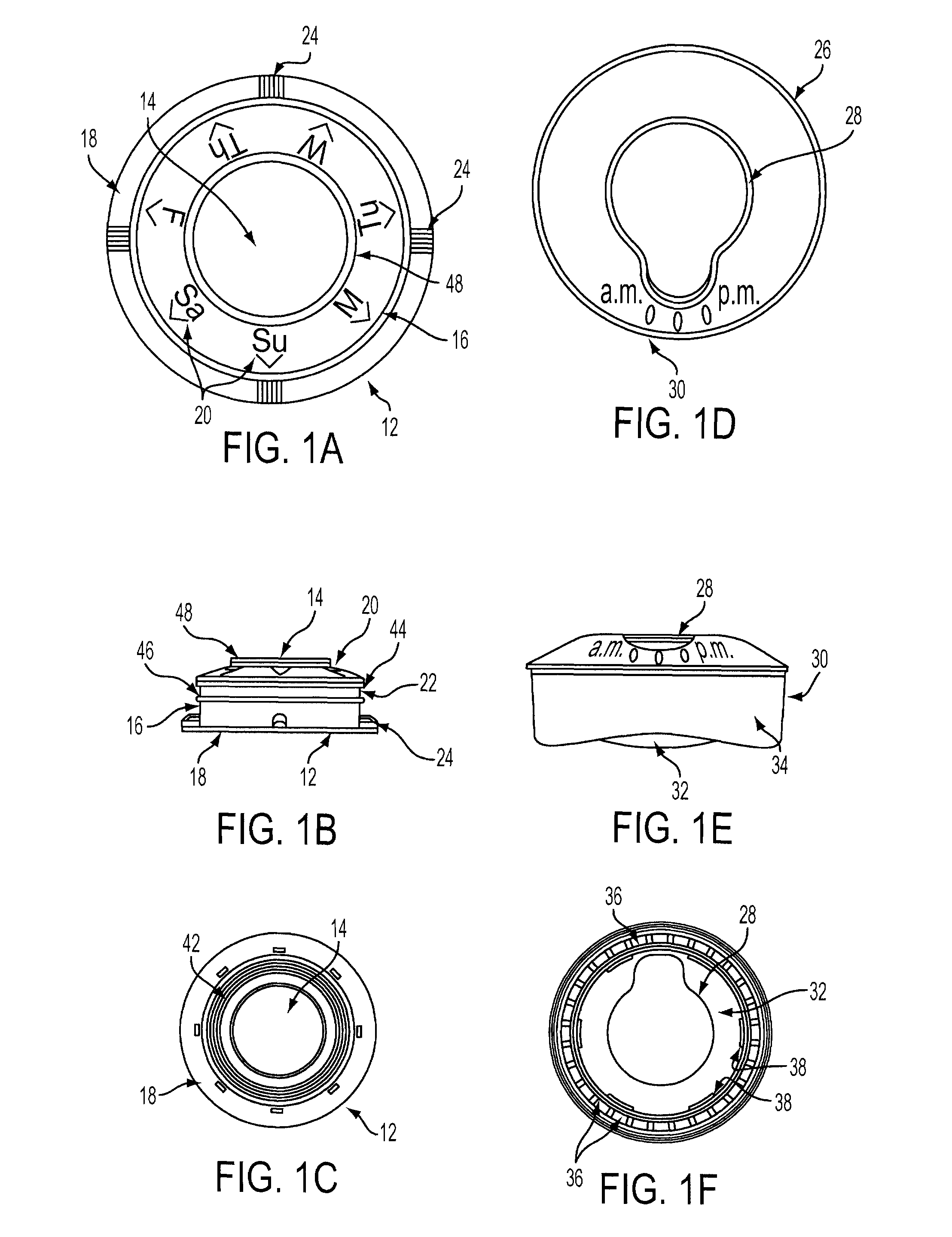

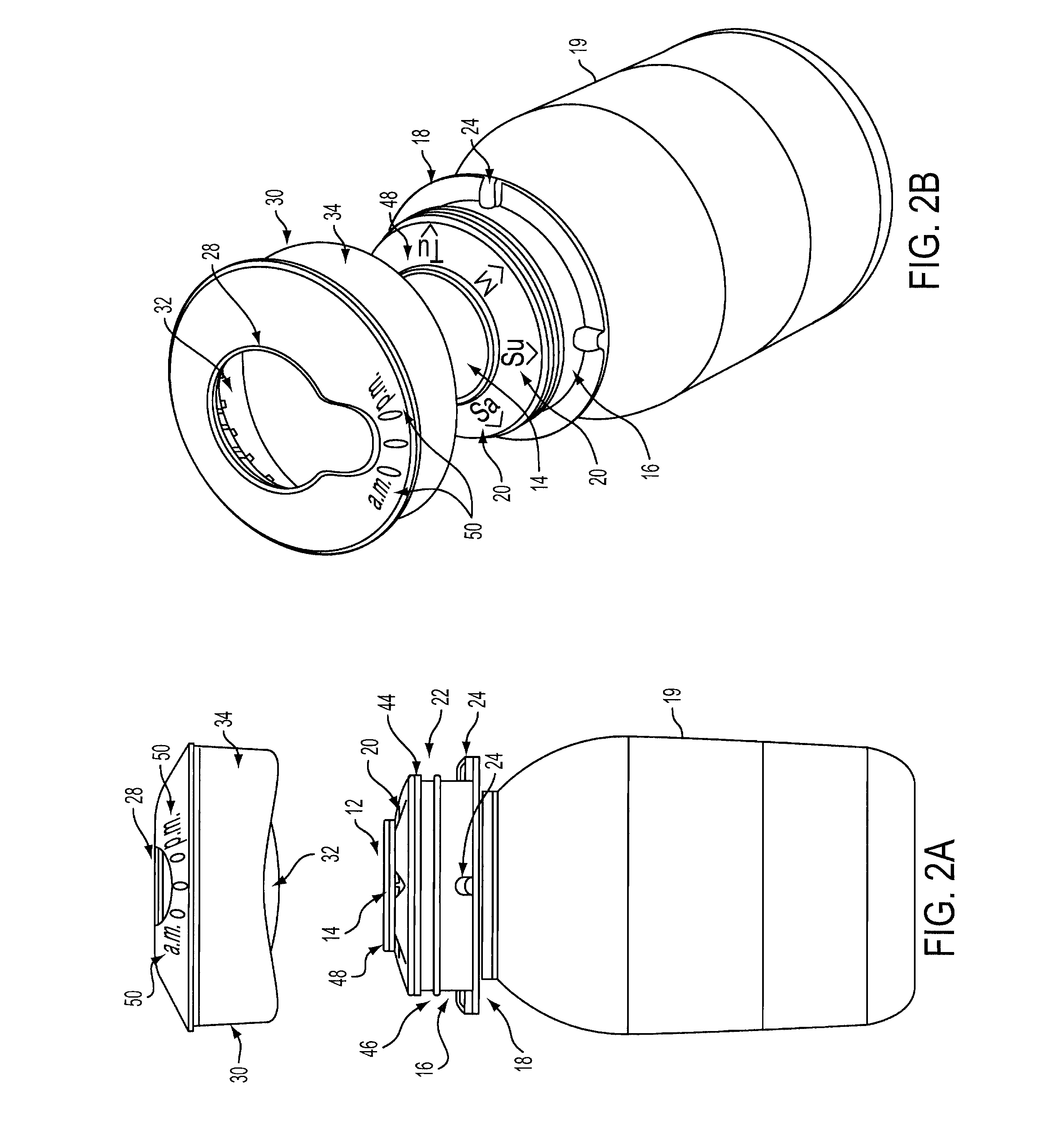

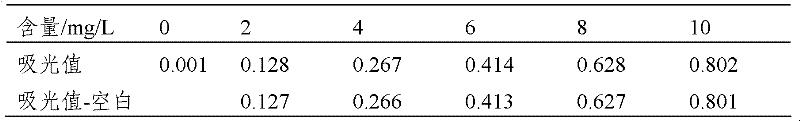

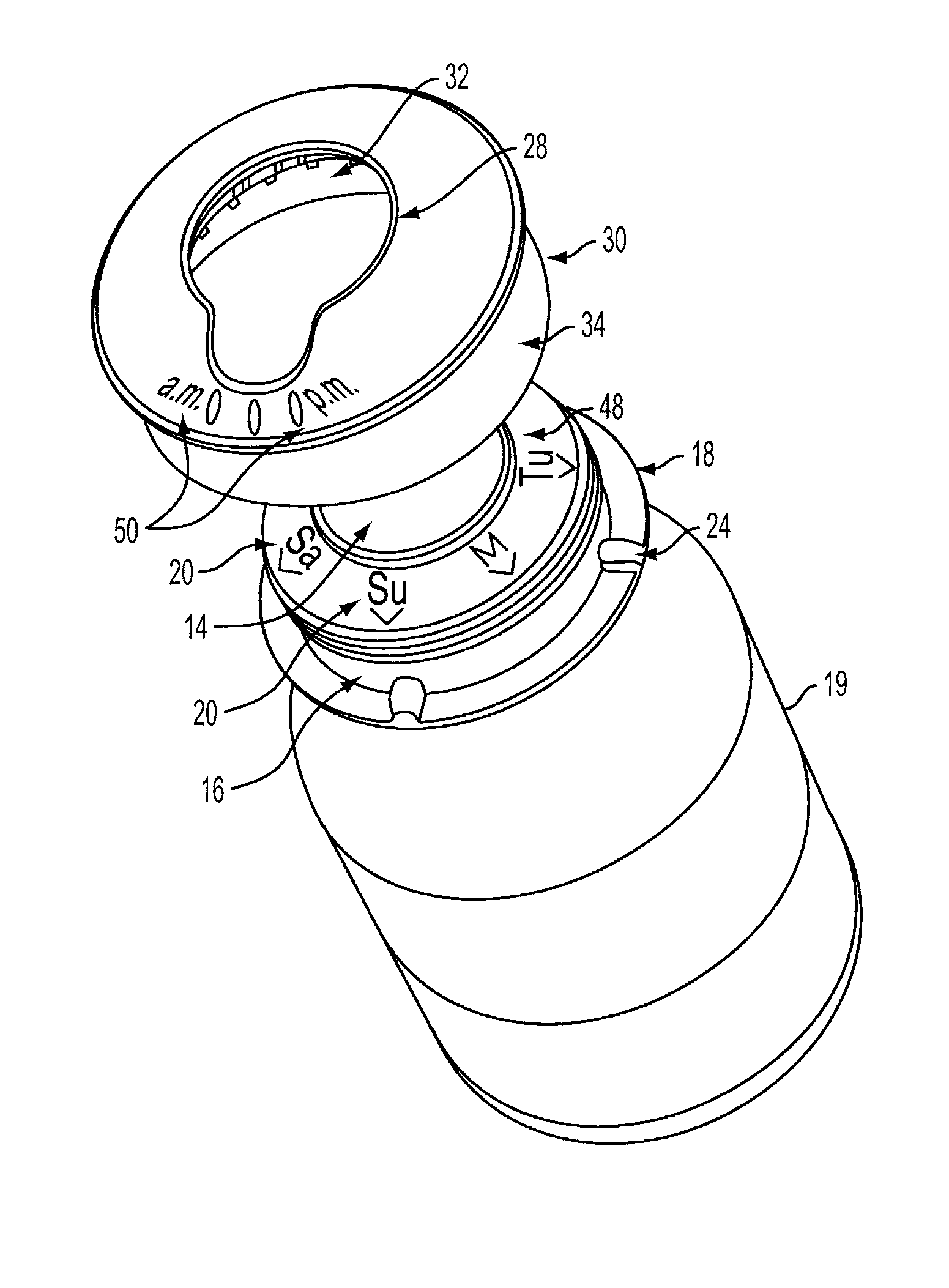

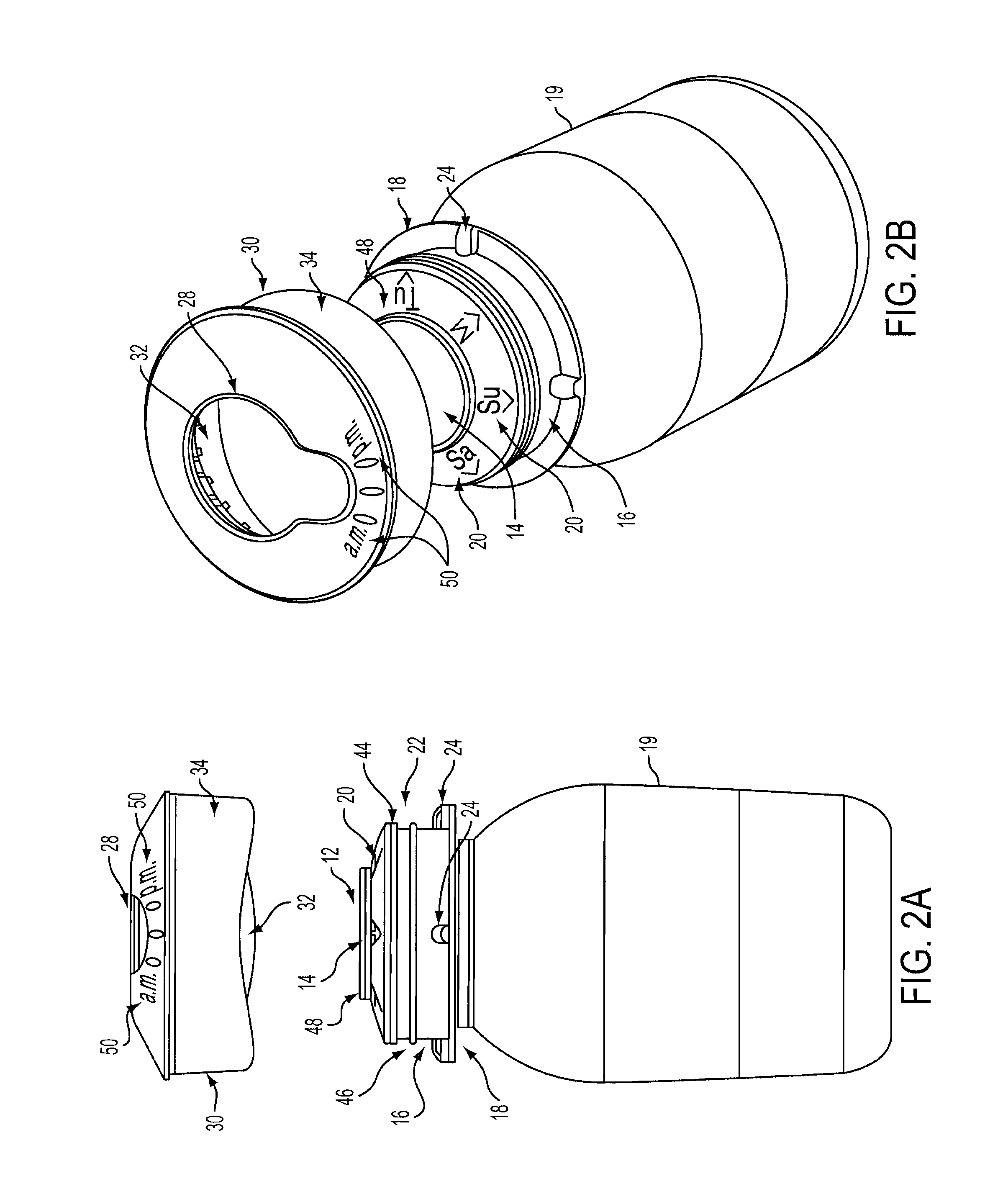

Container with Adjustable Date Indicium

A closure for a container has a plurality of indicia such as date and / or time, disposed on the lid's top surface, with a rotary collar which is adjustable to a fixed position to highlight (select) indicia regarding the contents of the container.

Owner:MEDELA HLDG AG

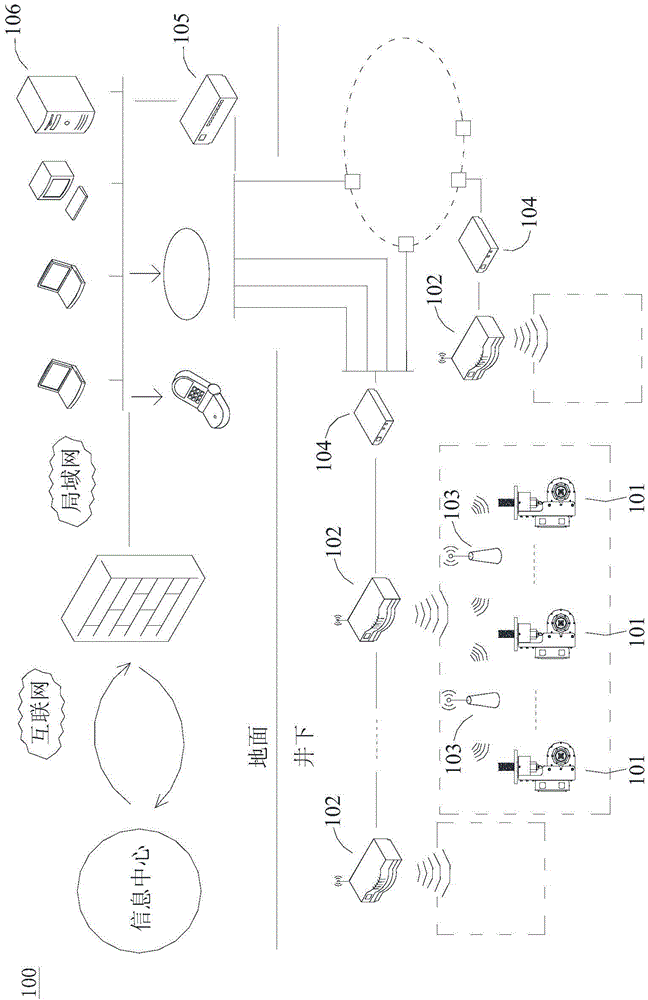

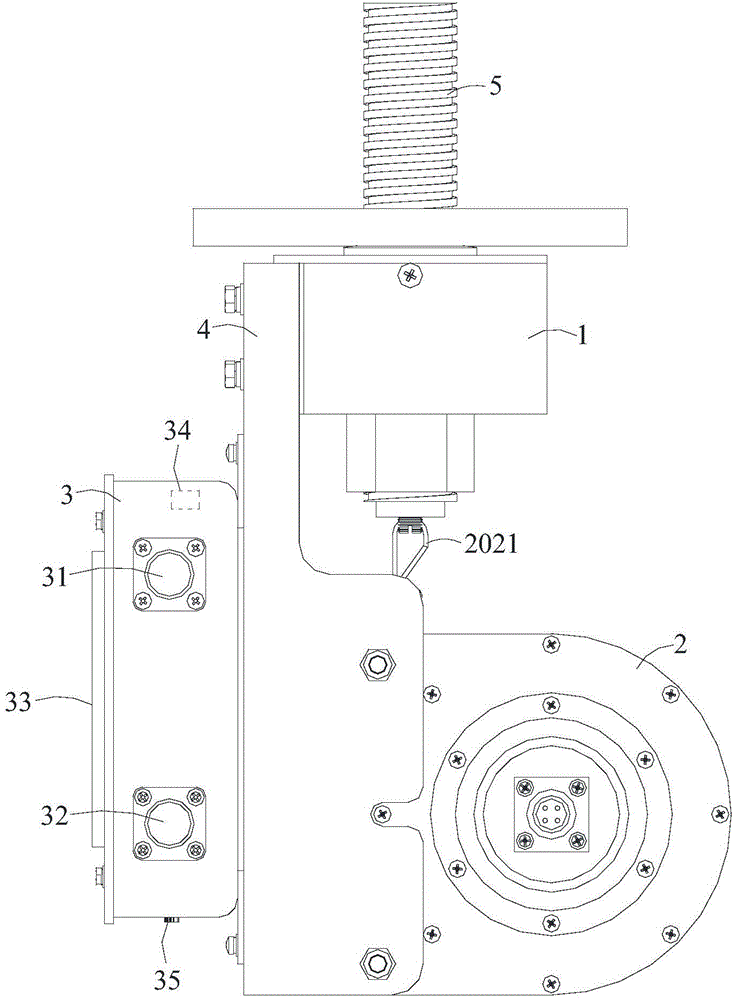

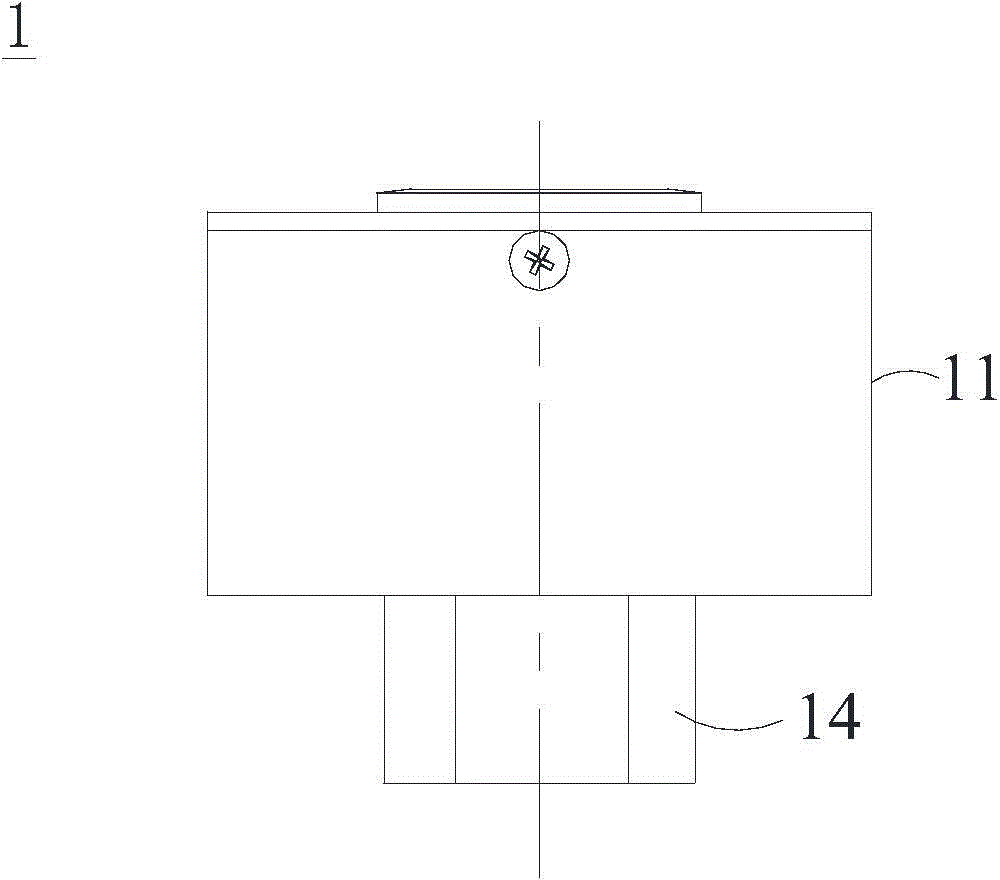

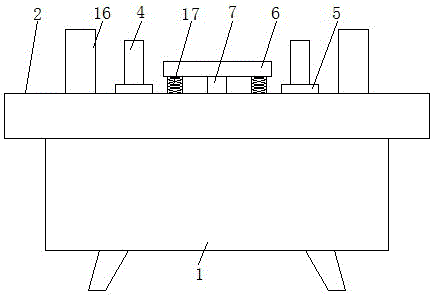

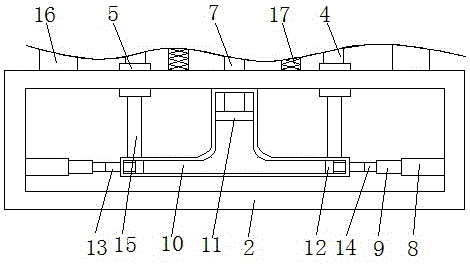

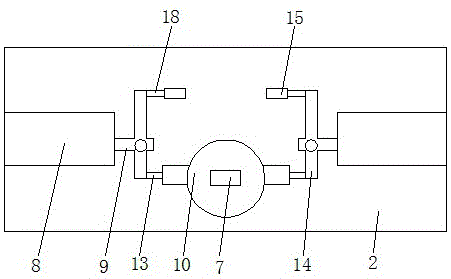

Deformation anchor rod/ anchor cable monitor, monitoring system and monitoring method

ActiveCN104913818ASpeed upIncrease spaceMeasurement devicesTransmission systemsMonitoring systemLandslide

The invention relates to a deformation anchor rod / anchor cable monitor, monitoring system and monitoring method. The deformation anchor rod / anchor cable monitor comprises a pressure sensor, a displacement sensor and a monitoring instrument, wherein the pressure sensor and the displacement sensor are arranged on an integration platform and are connected with the monitoring instrument arranged on the integration platform. The displacement sensor comprises a rolling assembly and a sensing device. The rolling assembly is externally wound by a haulage rope, wherein the open end of the haulage rope is connected with the end portion of a deformation anchor rod / anchor cable; the rolling assembly is internally provided with an elastic component to enable the rolling assembly to reset; the rolling assembly is connected with the sensing device; when the anchor rod / anchor cable deforms, the rolling assembly is driven to rotate via the haulage rope, and the sensing device detects the displacement amount of the rolling assembly and transmits the data to the monitoring instrument; and the monitoring instrument can carry out sound-light alarm according to the measured data. The deformation anchor rod / anchor cable monitor is simple in structure, convenient to use and timely in feedback, and can effectively improve production efficiency and reduce the occurance of geological disaster accidents of mine safety accidents and landslides and the like.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST +1

Anti-freezing and heat preserving method for greening trees in northeast China

InactiveCN104429734AWorks well togetherLess likely to make mistakesPlant protectionAnti freezingPlastic film

The invention provides an anti-freezing and heat preserving method for greening trees in northeast China, and relates to the technical field of greening tree winter protection. The method is characterized by comprising the steps of root collar ridging, soil covering, windbreak erecting, whitewashing and white spraying, plastic film winter protection and medicament prevention and control. The method is reasonable, convenient to implement, and prevention and control of the greening trees can be conveniently achieved.

Owner:安徽省龙海种业有限公司

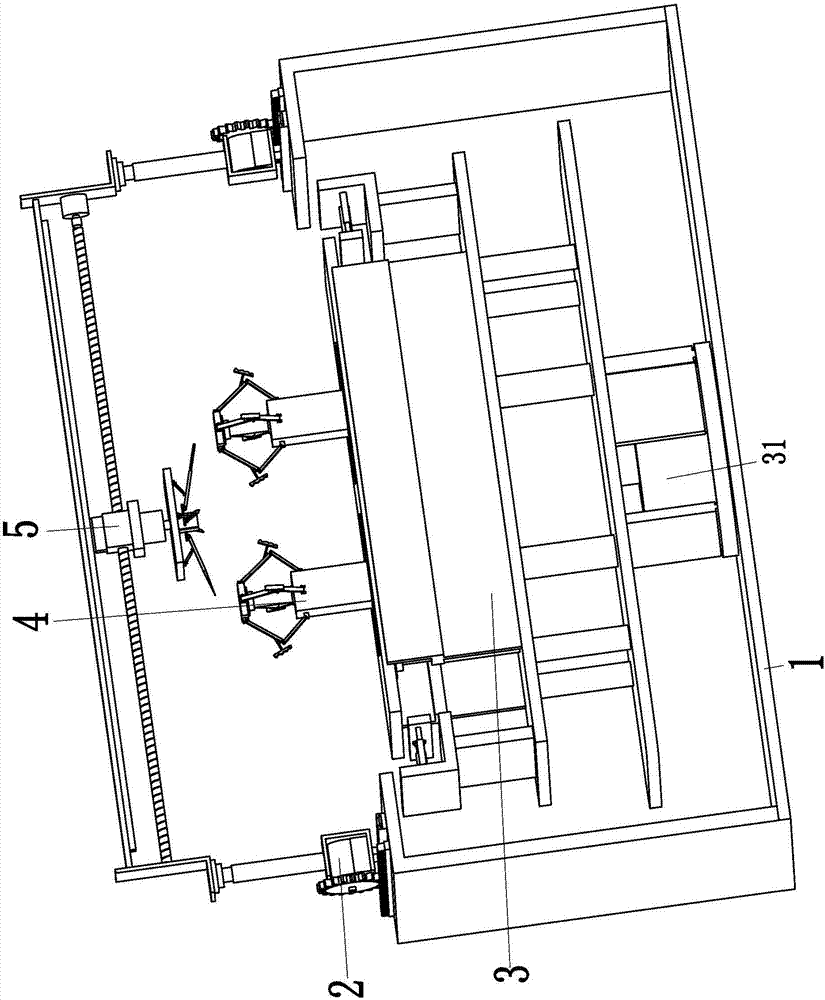

Automatic clamping sawing machine

InactiveCN106112597AAchieve clampingIncrease production capacityPositioning apparatusMetal-working holdersEngineeringMachining process

The invention discloses an automatic clamping sawing machine which comprises a base. The top of the base is fixedly connected with a supporting table. Symmetric sliding grooves are formed in the top of the supporting table. Symmetric clamping plates are arranged on the top of the two sliding grooves. The bottom of each of the two clamping plates is fixedly connected with a sliding block which is movably connected in the corresponding sliding groove. A supporting plate is arranged between the two clamping plates. The bottom of the supporting plate is fixedly connected with a stretching rod, and the other end of the stretching rod penetrates the supporting table and extends into the supporting table. The inner wall of the supporting table is fixedly connected with symmetric first connecting rods, and one end of each first connecting rod is fixedly connected with a second connecting rod. According to the automatic clamping sawing machine, parts can be automatically clamped, when the parts are produced in a manufacturer in batches, repeated manual clamping does not need to be conducted on each part, the production capability is improved, the working efficiency is improved, the accidental injury brought by multiple times of manual clamping is effectively avoided, the parts are stable in the machining process, and errors are not likely to be generated.

Owner:无锡欧玛森远洋工程设备有限公司

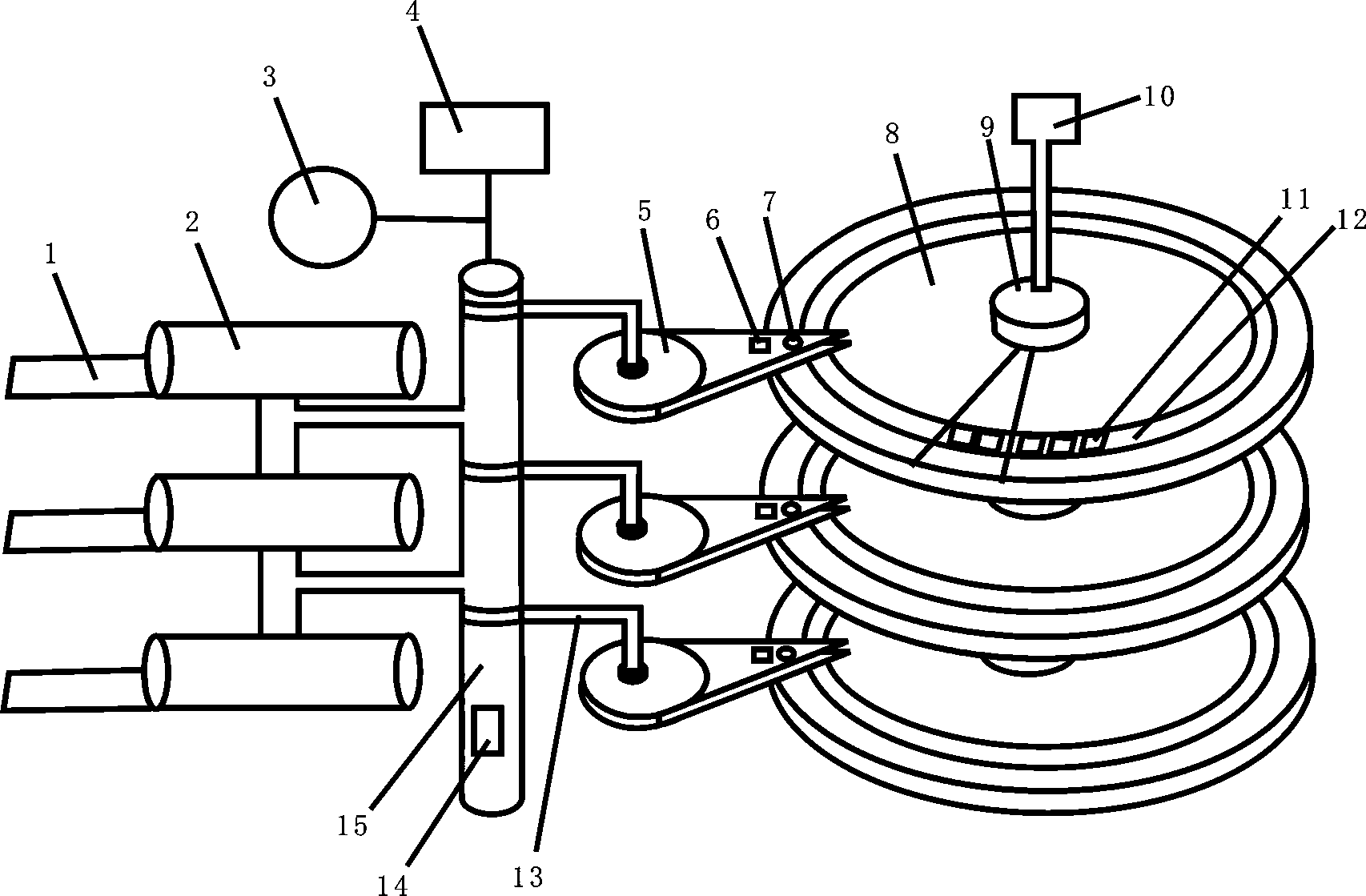

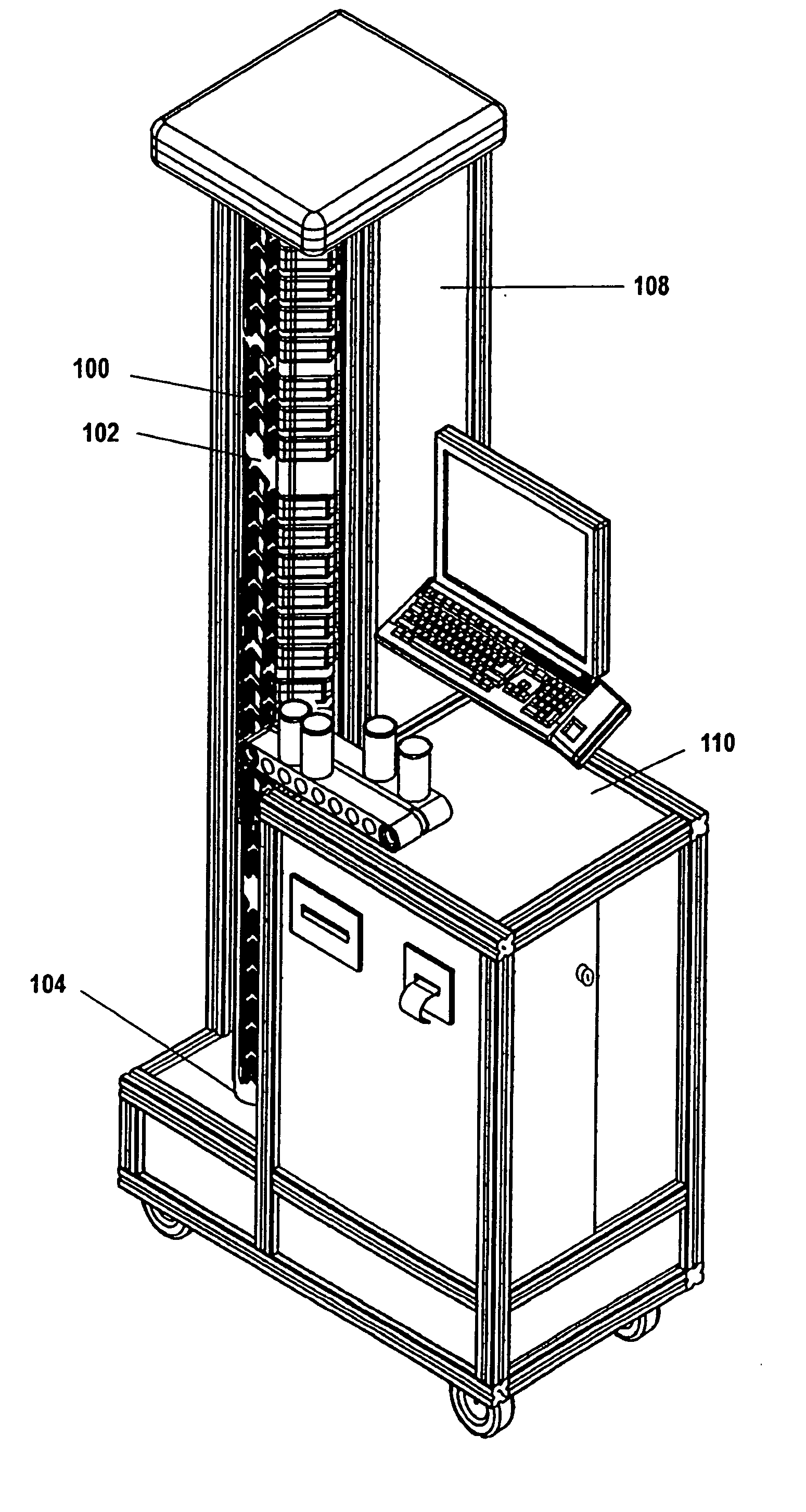

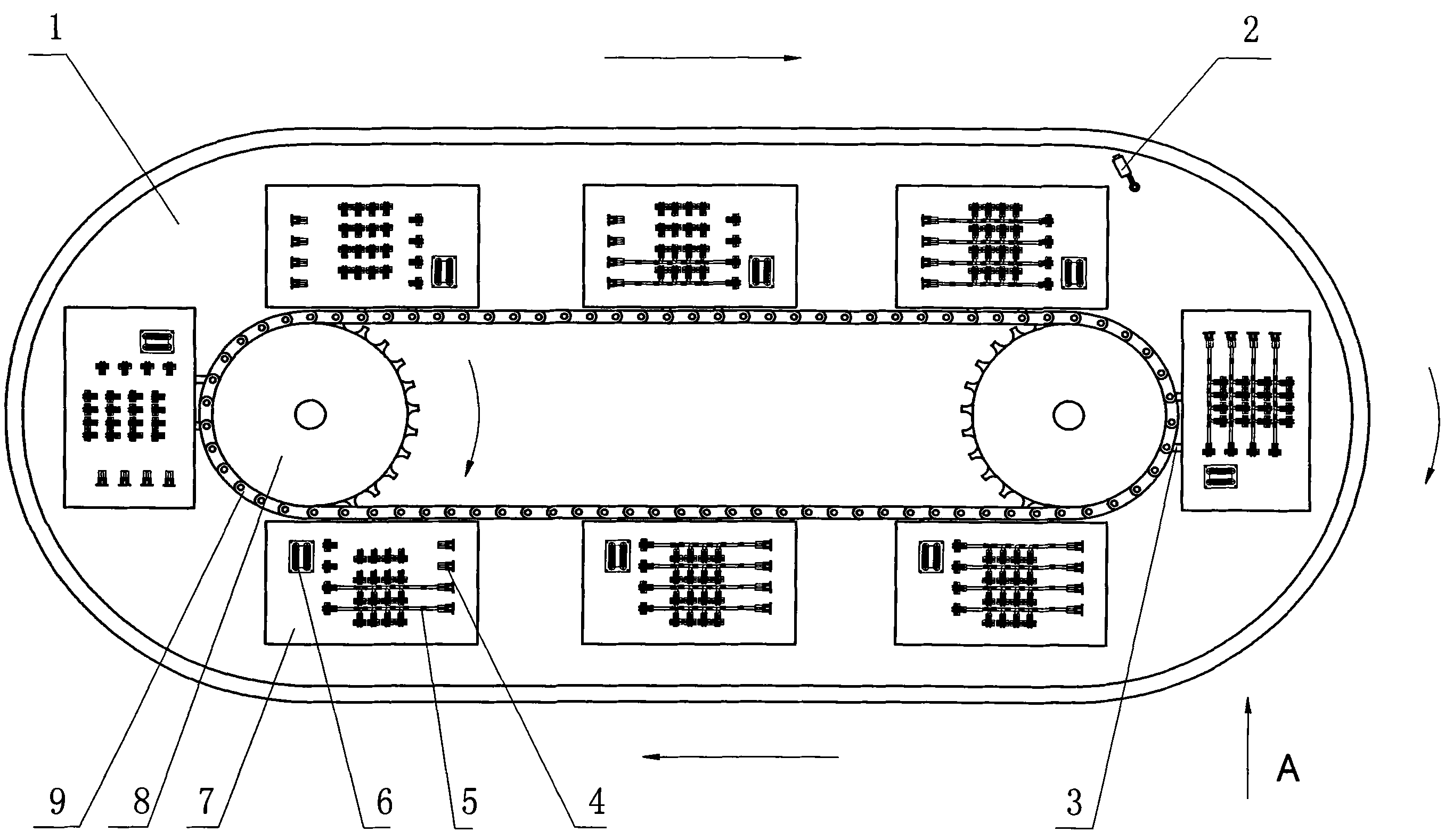

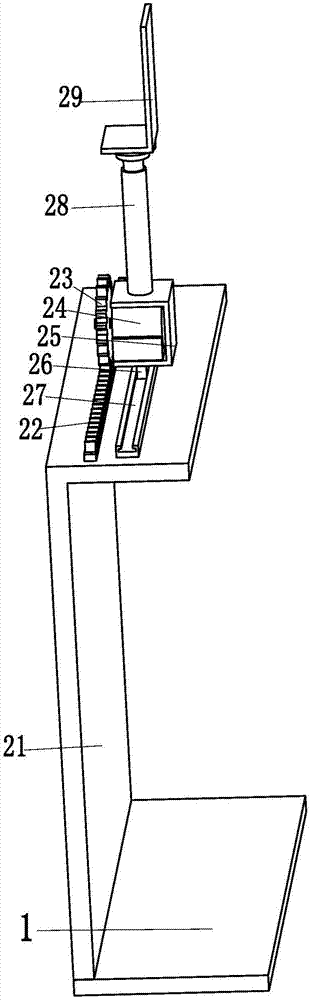

Automatic file storing and taking device

InactiveCN103645724AThe overall structure is simpleEasy to operateTotal factory controlManipulatorDrive motorAutomation

The invention discloses an automatic file storing and taking device. The automatic file storing and taking device comprises a main shaft, disc sheets, suction disc components, drive arms, a drive shaft, a singlechip controller, piers, conveyers, an alternating current motor and a relay protector, wherein the disc sheets serve as a main part; the middle parts of the disc sheets are provided with disc holes connected with the main shaft; the main shaft comprises a driving motor and bearings; the top of the main shaft is provided with the driving motor; the main shaft passes through the disc holes of the three disc sheets so as to connect the three disc sheets; a plurality of concentric annular grooves are formed in the upper surfaces of the disc sheets; the suction disc components are arranged above the disc sheets, and each suction disc component comprises a suction disc, a vacuum pump and a bar-shaped code scanner; the suction disc components are driven by the drive shaft; the drive arms are connected to the other ends of the suction disc components, and the other ends of the drive arms are connected to the drive shaft; the lower part of the drive shaft is internally provided with the singlechip controller. The automatic file storing and taking device is simple in integral structure, convenient to operate and use, good in stability and high in reliability, reduces the labor intensity, is unlikely to make mistakes in retrieving, and has a high automation degree.

Owner:刘茂祥

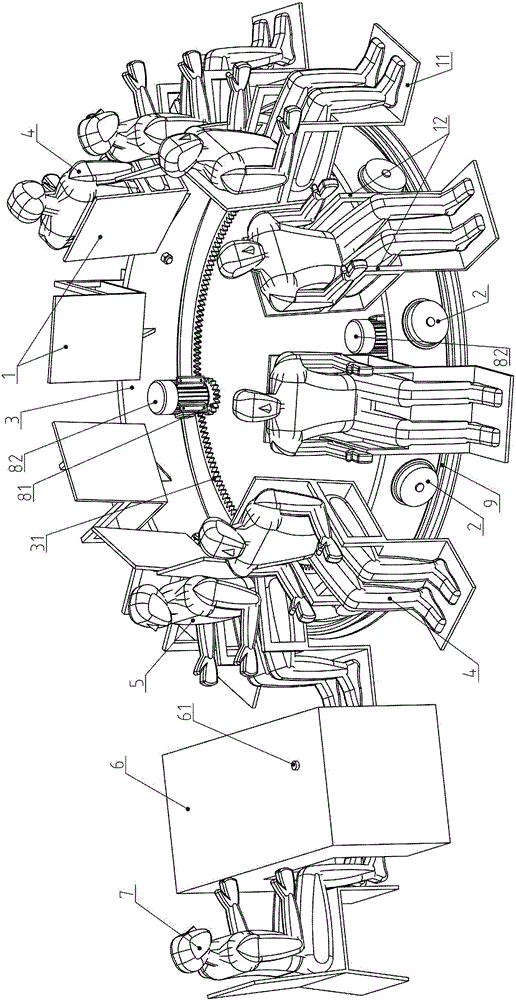

Seat moving type queuing machine

The invention belongs to the technical field of public service equipment and relates to a queuing machine, in particular to a seat moving type queuing machine. The seat moving type queuing machine comprises a support, a traveling mechanism and a plurality of seats. The seats are connected to the support, and rollers are arranged on the support and move along a rail. Motors drive the seats to move along with the support, and customers sit on the seats to wait for services. The customers cannot miss service chances and can put heart and soul into other things at the same time by queuing up through the seat moving type queuing machine, and accordingly time of the customers is saved, paper and ink are saved, and quietness of a service hall can be kept.

Owner:杜昌峰

Container with adjustable date indicium

A closure for a container has a plurality of indicia such as date and / or time, disposed on the lid's top surface, with a rotary collar which is adjustable to a fixed position to highlight (select) indicia regarding the contents of the container.

Owner:MEDELA HLDG AG

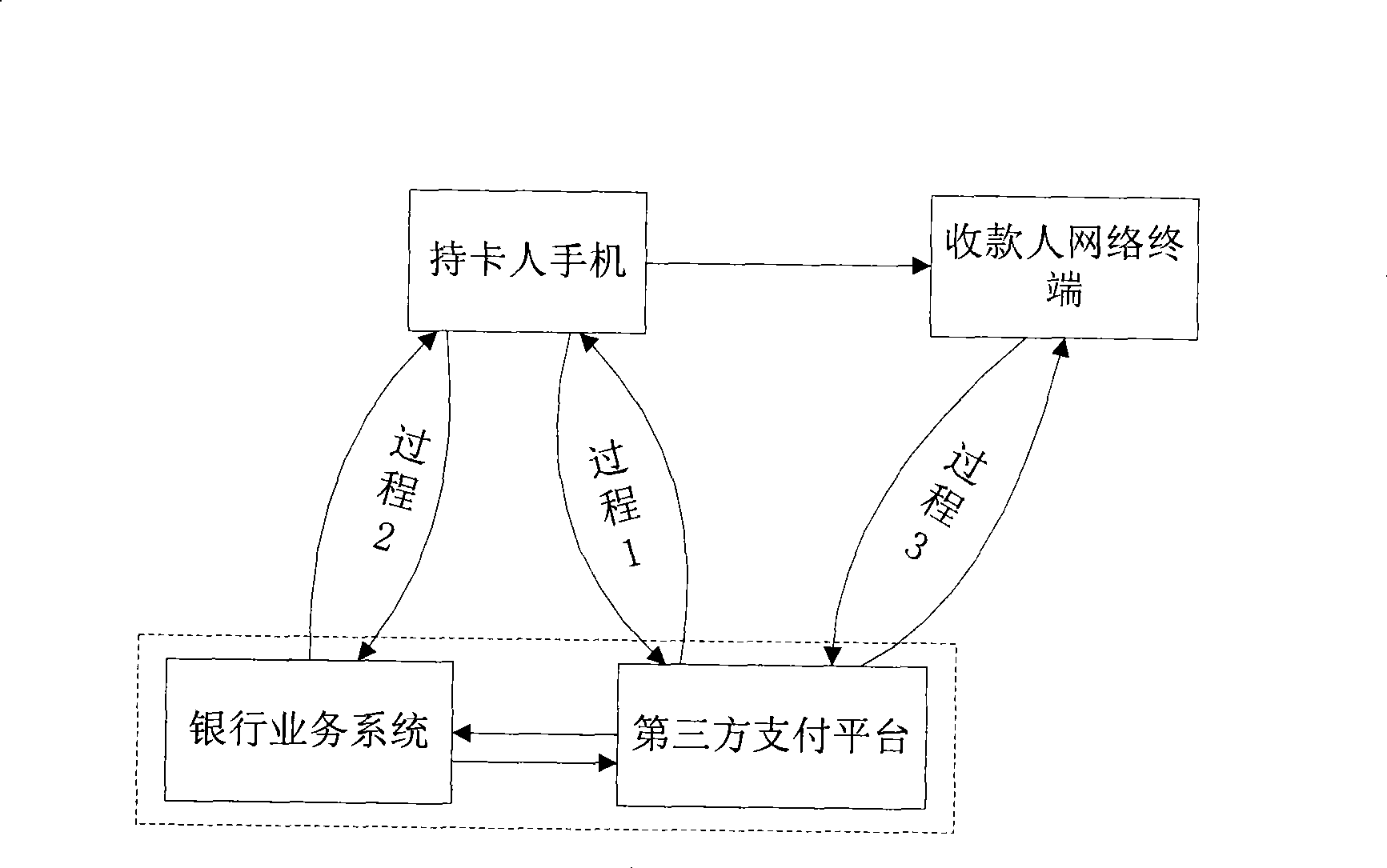

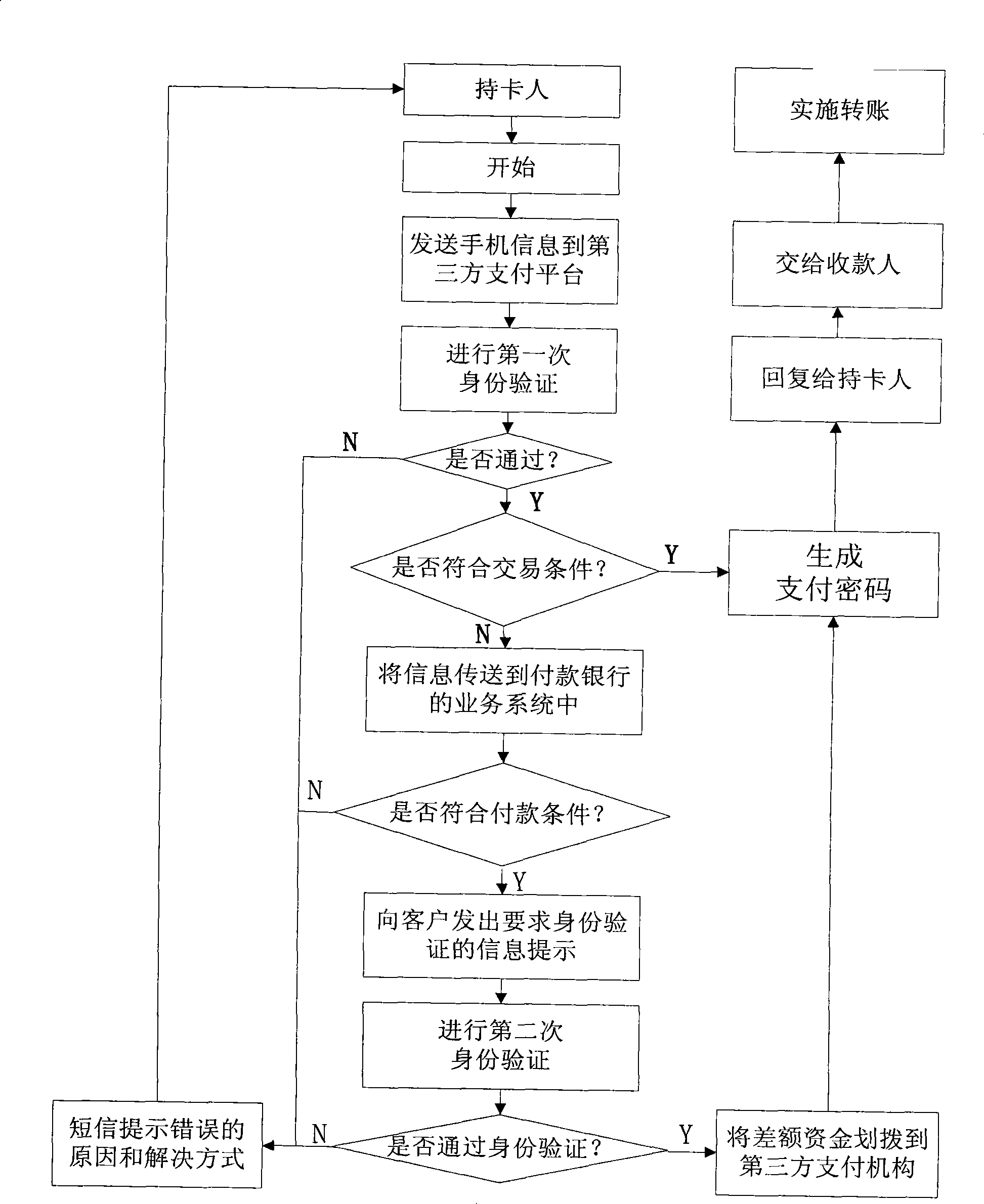

Method for safely replacing bank POS machine

InactiveCN101441747AReduce operating costsSave equipment investment and equipment maintenance costsFinancePayments involving neutral partyService systemThird-Party Payments

The invention provides a method for safely replacing a bank POS machine. The method comprises the following four parts: a mobile phone of a cardholder, a network terminal of a payee, a third-party payment platform and a bank service system; firstly, the cardholder sends a transaction request message to the third-party payment platform through a short message of the mobile phone; if capital saved in the third-party payment platform by the cardholder is more than the sum which needs to be traded by the cardholder, the third-party payment platform generates a payment cipher for the cardholder; otherwise, the third-party payment platform emits an instruction message for replenishing transaction amount to a paying bank; after the paying bank completes authentication and capital with certain amount is allocated to the third-party payment platform, the third-party payment platform generates the payment cipher for the cardholder; the payment cipher is replied to the cardholder in a short message mode of the mobile phone; and the payee completes capital allocation in the third-party payment platform according to the payment cipher.

Owner:王忠杰

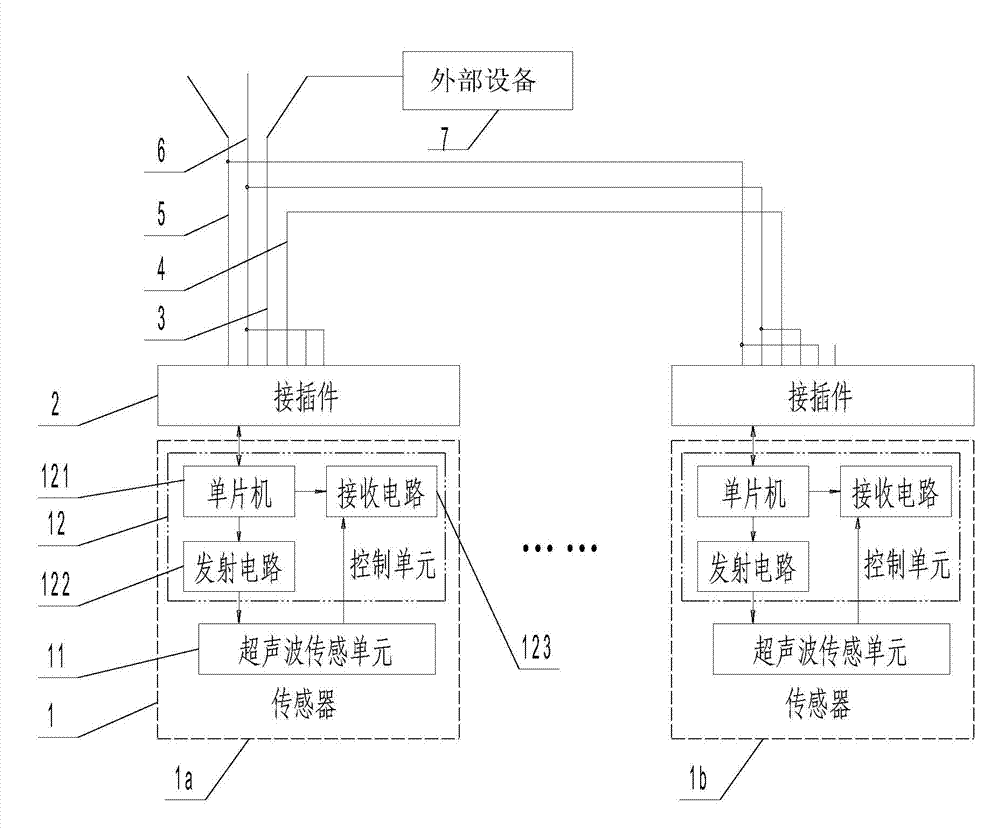

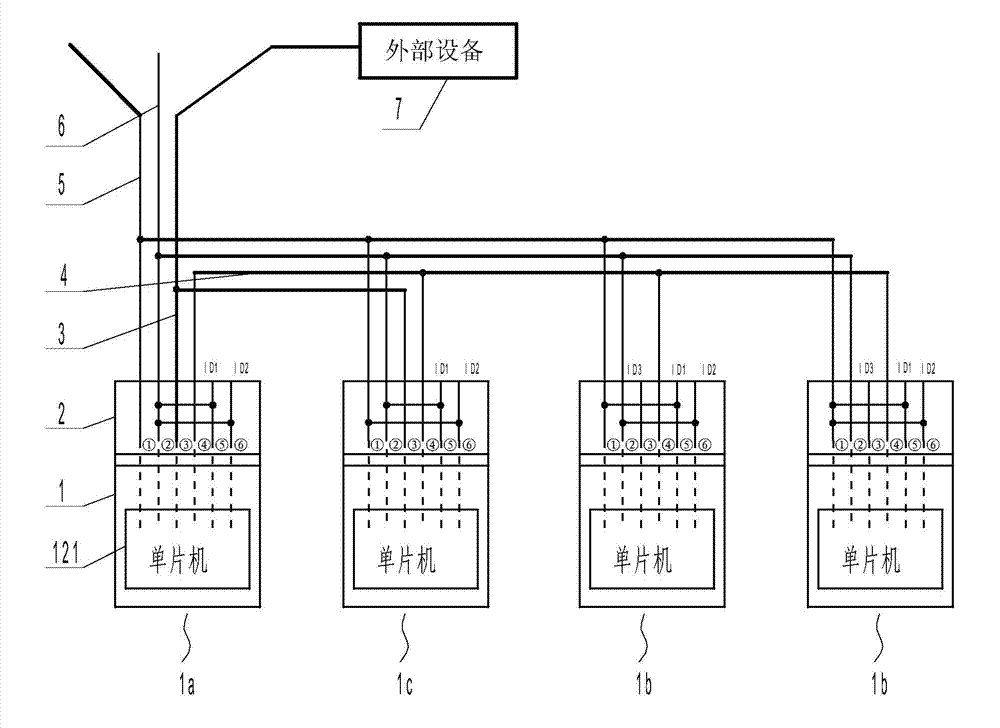

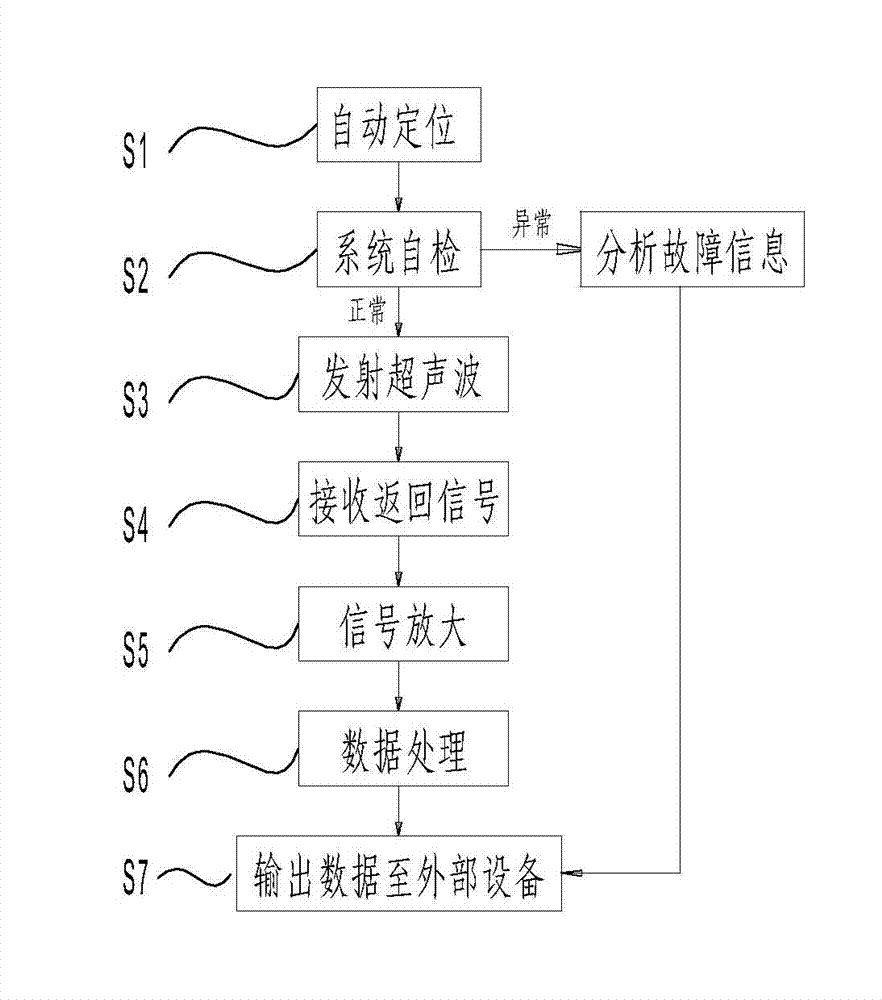

Intelligent reversing radar system and automatic control method thereof

InactiveCN103499817ASimple hardware circuitAvoid multiple wiring harnessesVehicle componentsAcoustic wave reradiationRadar systemsAutomatic control

An intelligent reversing radar system and an automatic control method thereof relate to a radar system and a control method thereof. The system comprises at least two sensors; each sensor comprises an ultrasonic sensing unit and a control unit; each control unit comprises a single-chip microcomputer, an emitting circuit and a receiving circuit, which are connected in sequence; the single-chip microcomputer of each sensor is connected with a connector; the single-chip microcomputer of the main control sensor is connected with external equipment by an external data line; all single-chip microcomputers are connected by an internal communication line and are respectively connected with a reversing lamp signal line and a grounding line. The method comprises the steps that the system is subjected to self-inspection after all sensors realize automatic positioning; the system emits an ultrasonic wave and receives a returning signal; the signal is subjected to data processing after being amplified and is finally output to the external equipment by the main control sensor. According to the intelligent radar reversing radar system and the automatic control method thereof, a hardware circuit can be simplified, the performances are stable and reliable, the positions of the sensors can be fast and accurately identified, and the radar system can be simply and reliably controlled and is suitable for the configuration of different vehicle models.

Owner:柳州市华航电器有限公司

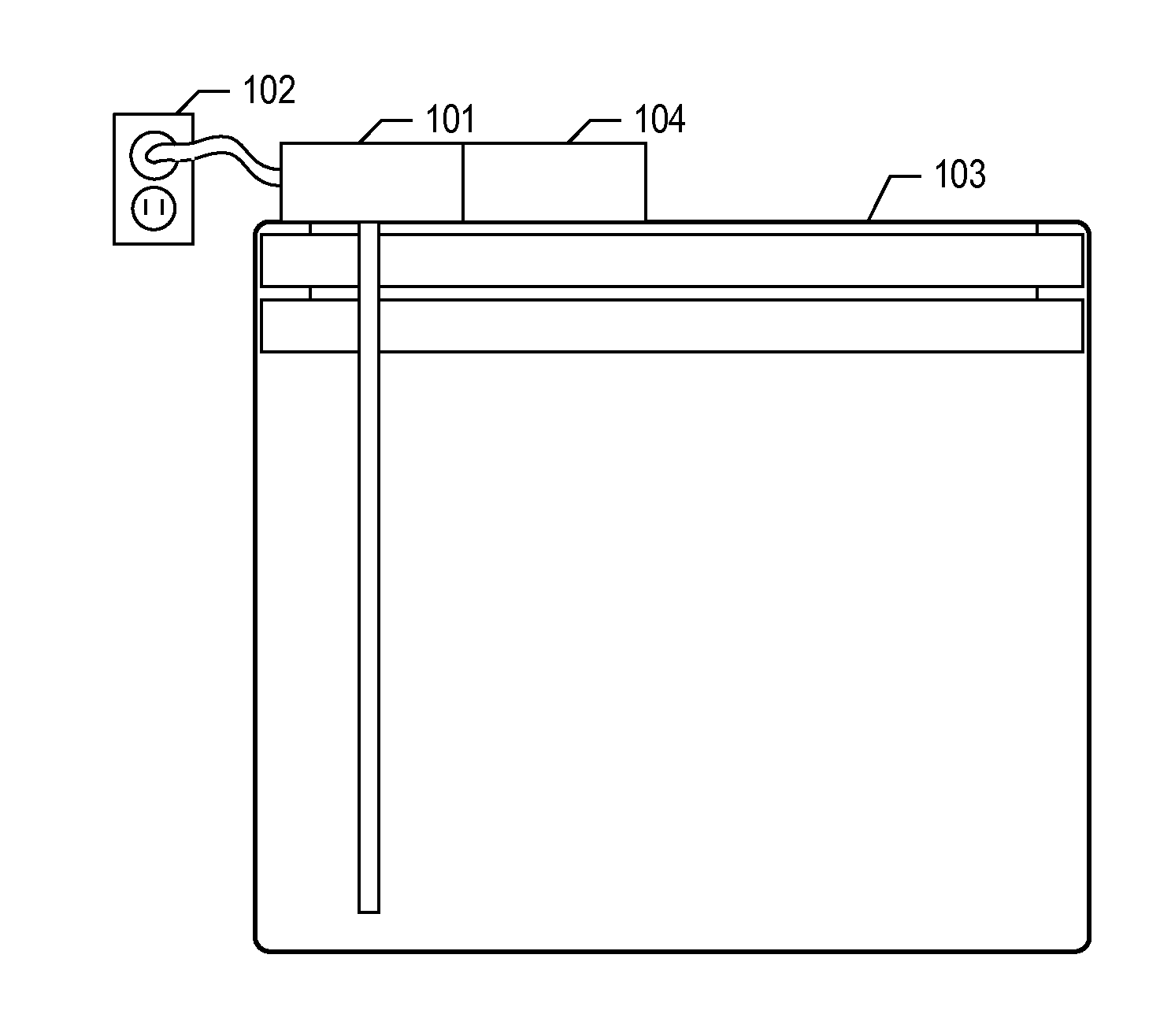

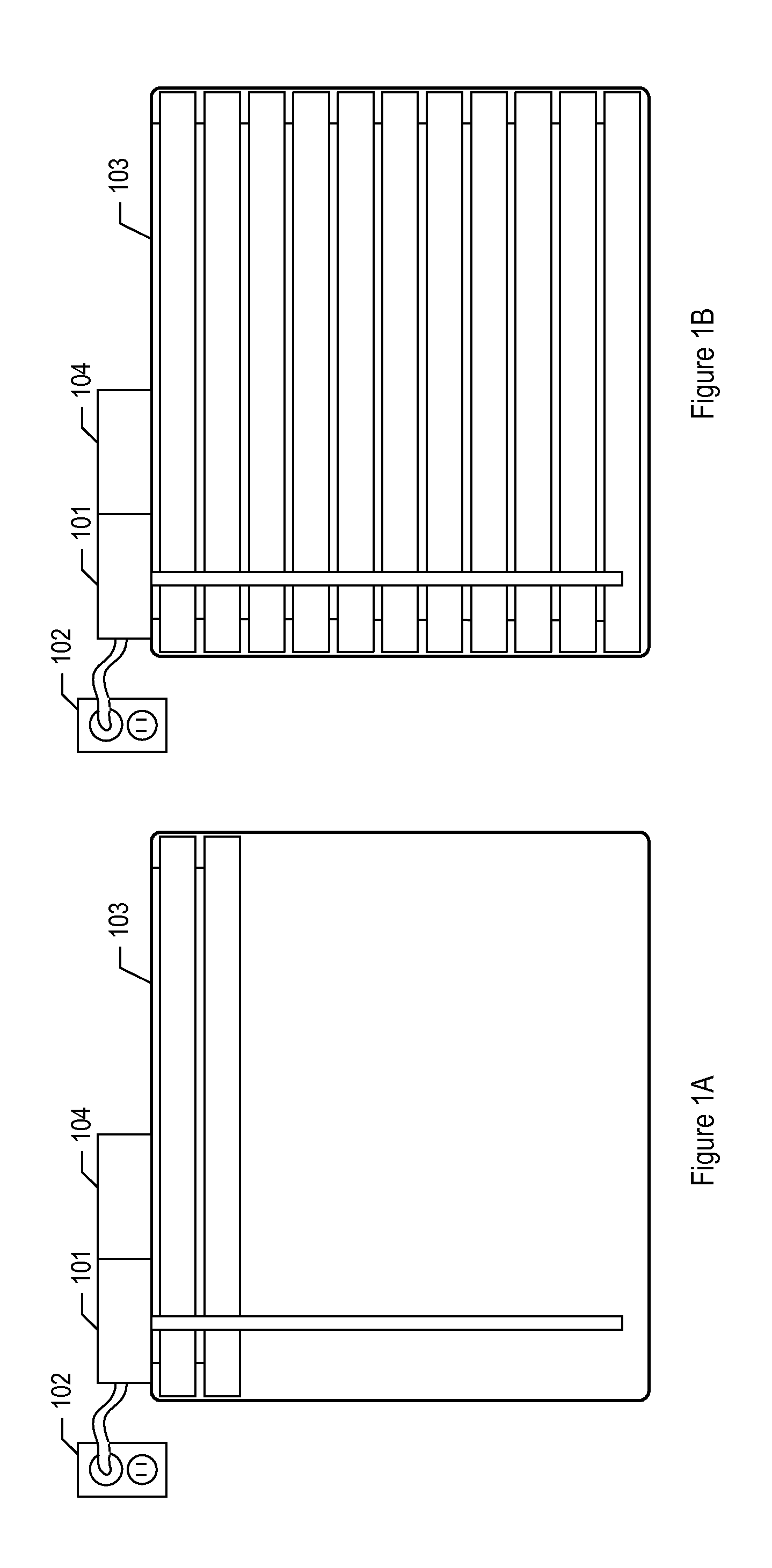

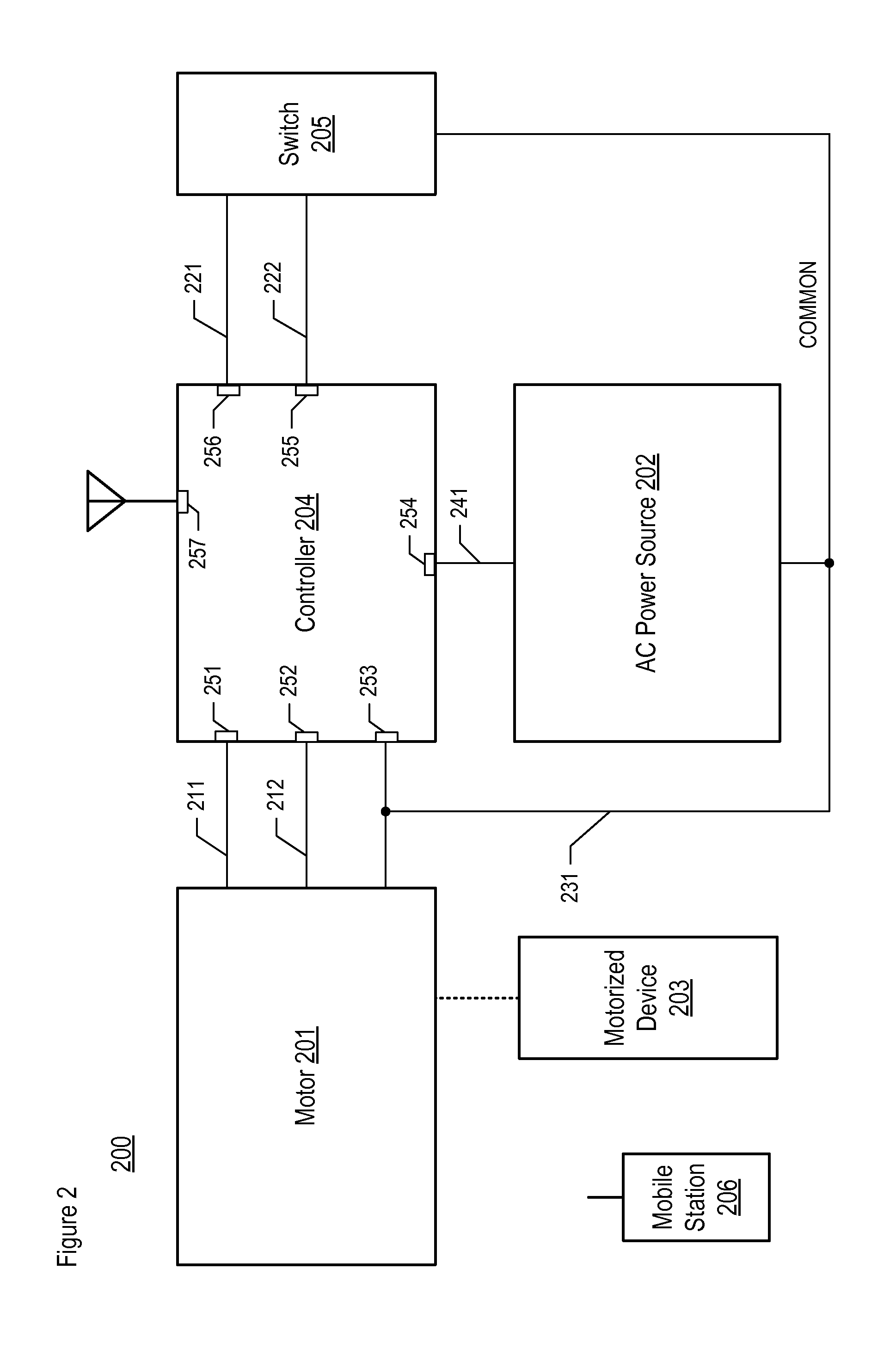

Motorized System with Position Calibration, Circuit Protection and Detection of Motor Stoppage

ActiveUS20150376943A1Advantage in costLess prone to human errorDoor/window protective devicesLimiting/preventing/returning movement of partsTransient-voltage-suppression diodeCircuit protection

A motorized system that allows for calibration by a user, and that features circuit protection and detection of motor stoppage. A motorized window-blind system is an example of such a system and is disclosed herein. In particular, a circuit is featured that comprises a TRIAC, or “triode for alternating current,” and TVS diodes, or “transient-voltage-suppression diodes,” providing voltage protection to various types of motor-related electronic components. A controller is disclosed that features measurement of voltage that is induced on a secondary winding of a motor, in order to detect certain events that occur during the operation of the motor. A calibration method is also disclosed that can account for one or both of the protection circuit and event-detecting controller. The calibration method accounts for human interaction and, in doing so, is intended toward making a calibration process of a motorized household system less prone to human error.

Owner:SILVAIR SP ZOO

Smart tray for dispensing medicaments

InactiveUS20060058725A1Extended shelf lifeLess prone to errorElectrotherapyDrug and medicationsBiomedical engineering

The invention relates to a method and system that utilizes one or more cassettes or trays, which hold one or more types of medicaments, the cassettes or trays being configured for secure and intelligent dispensing of the medicaments. In one embodiment, a smart tray for dispensing medicaments includes: a housing; a chamber within the housing to store the medicament units; an outlet defined in the housing to dispense the medicament units; and a rotatable disk within the housing and defining at least one radial groove configured to hold at least one medicament unit, the rotatable disk being positioned between the storage chamber and the outlet whereby when the rotatable disk rotates, the at least one radial groove carries the at least one medicament unit from the chamber to the outlet. In a further embodiment, the smart tray includes a memory device within the housing to store information pertaining to the medicament units stored in the tray and / or information pertaining to the status or operation of the tray.

Owner:HANDFIELD MICHAEL +1

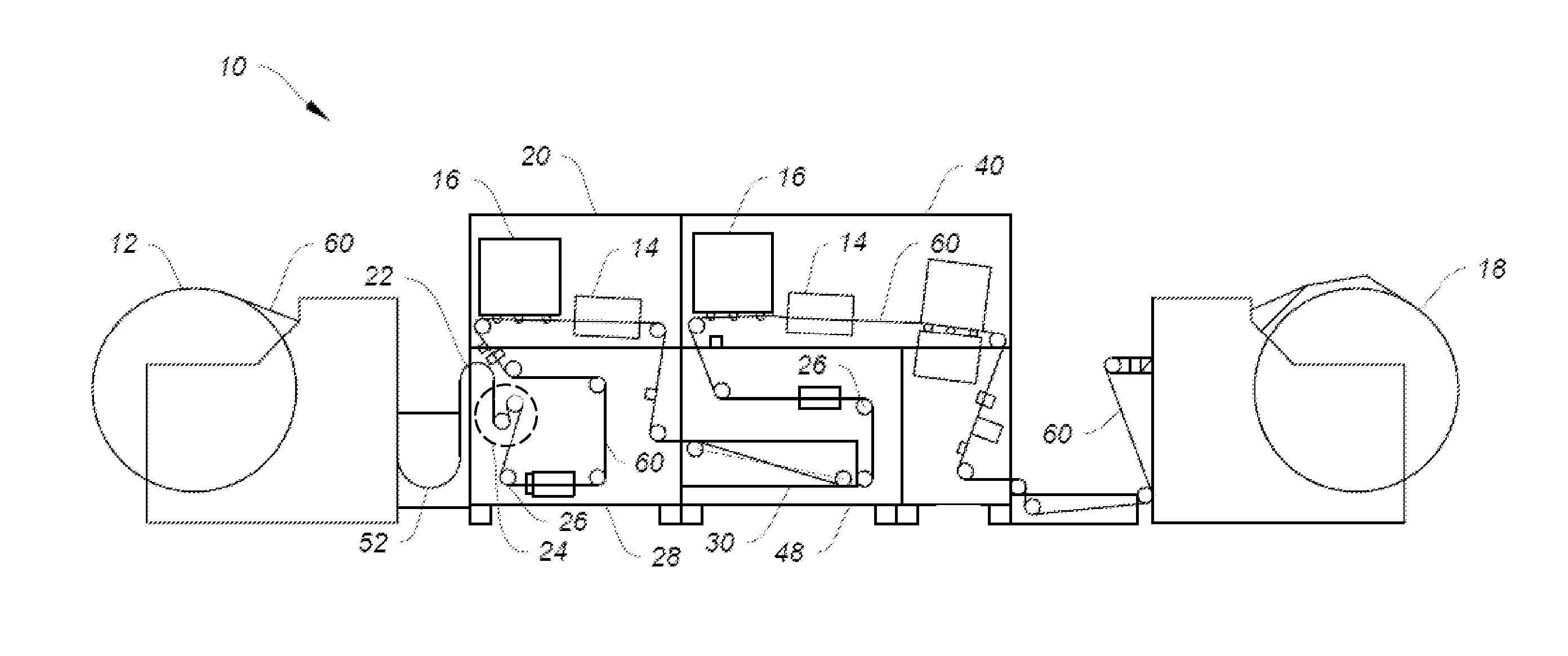

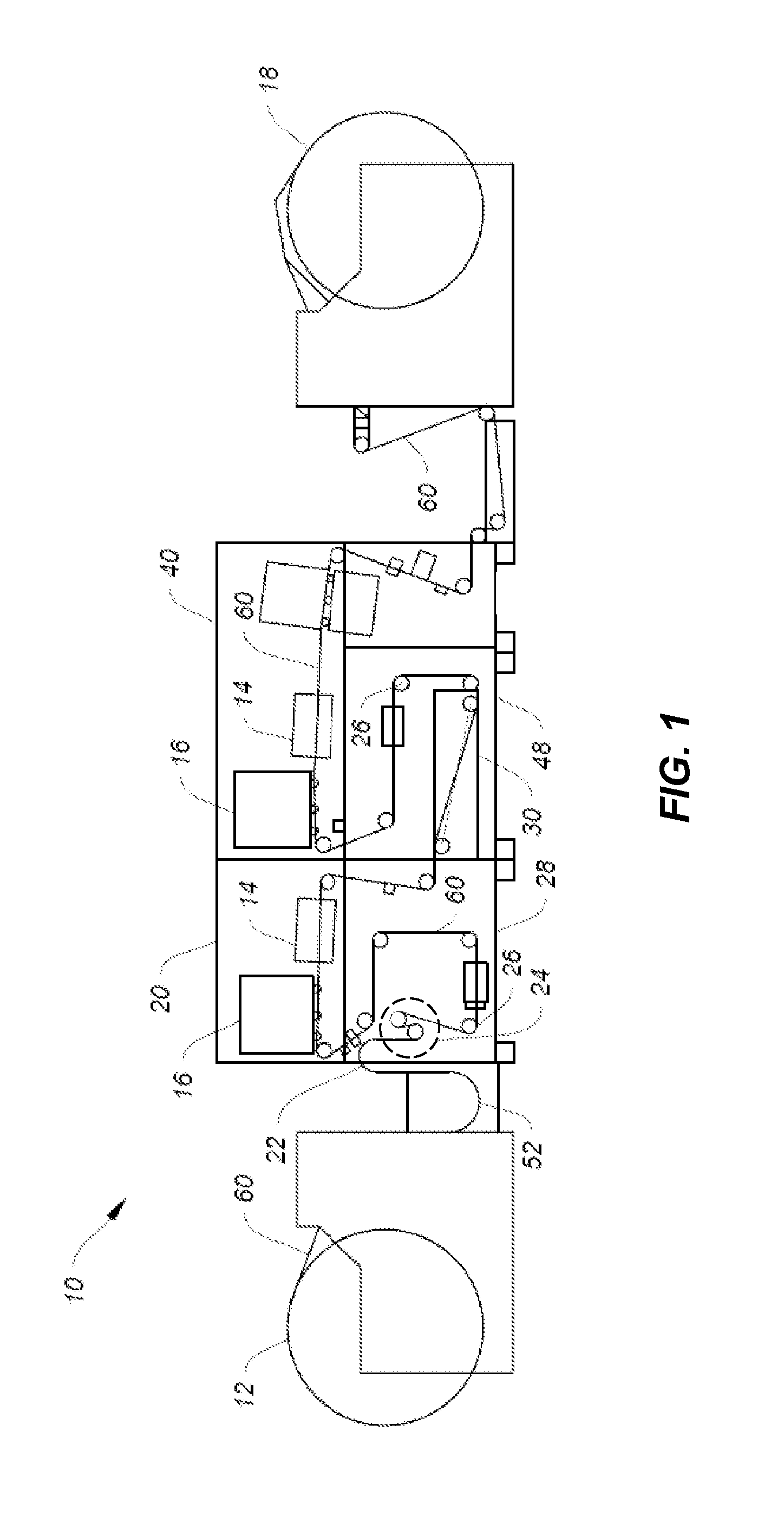

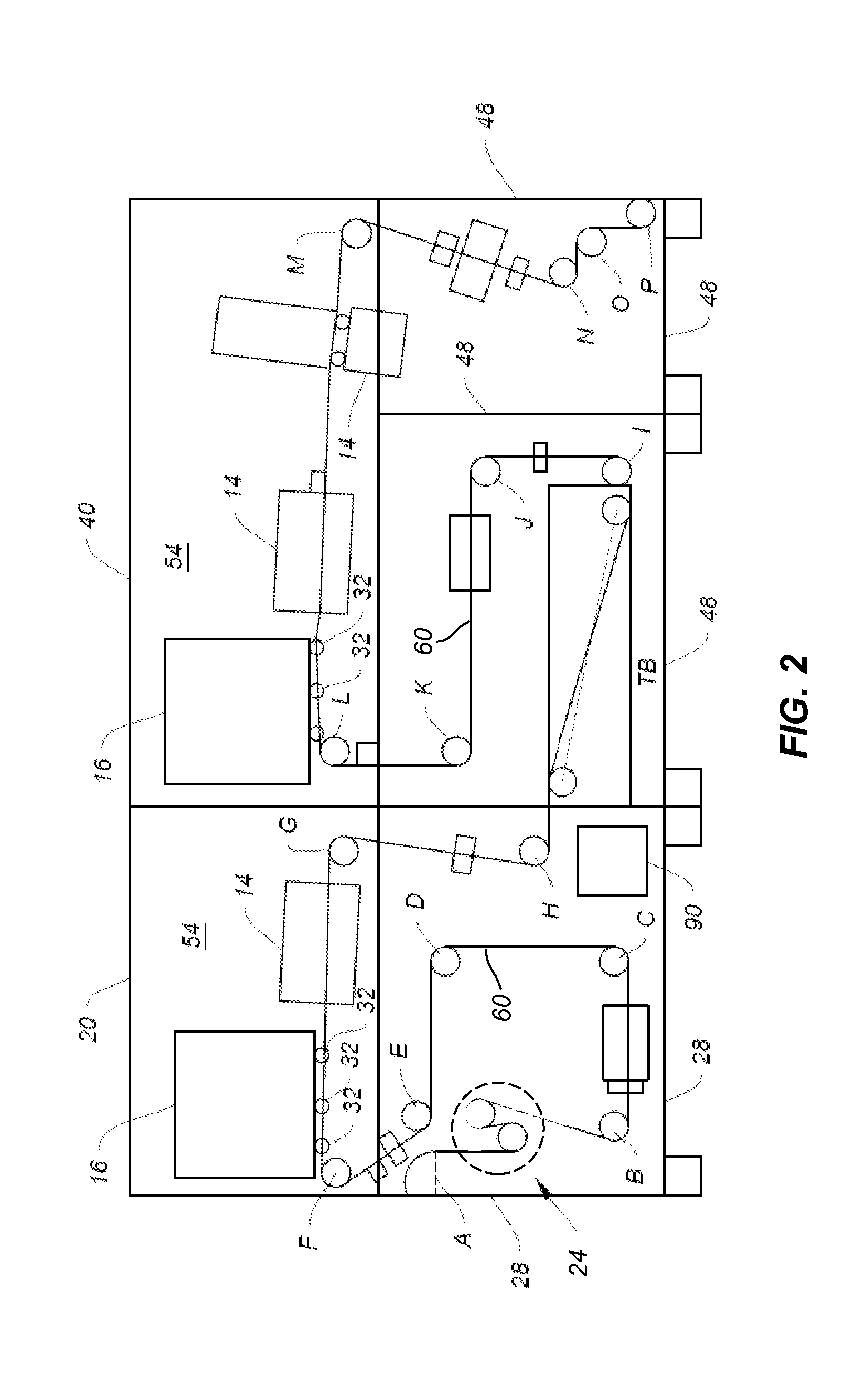

Method for automatically-adjusting web media tension

InactiveUS20130284846A1Sufficient preloadLess prone to errorFilament handlingWebs handlingFixed positionComputer science

A method for automatically adjusting a level of tension in web media being transported in a roll-fed web media transport system, comprising: receiving web media from a source roller, feeding the web media through an S-shaped media path in an automatically-adjusting tensioning mechanism where the web media is wrapped around curved surfaces on first and second tensioning shoes, and pulling the web media through the automatically-adjusting tensioning mechanism using a feed mechanism. The tensioning mechanism includes: a bracket assembly mounted to a frame which is adapted to freely pivot around a pivot axis. A pivot angle of the bracket assembly automatically adjusts in response to differences in a coefficient of friction between the web media and the tensioning shoes such that the tension in the web media has a reduced level of variability relative to configurations where the bracket assembly is held in a fixed position.

Owner:EASTMAN KODAK CO

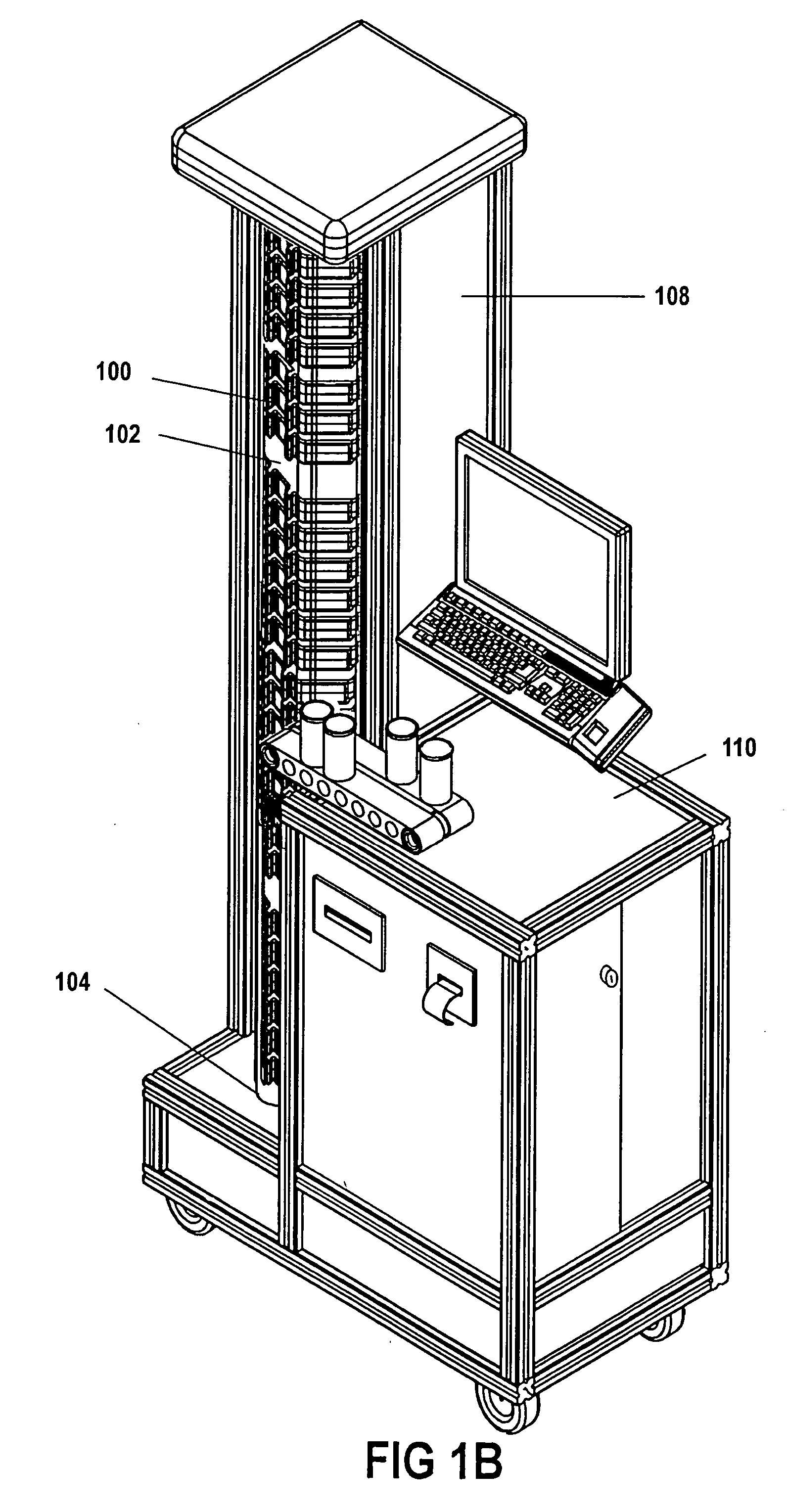

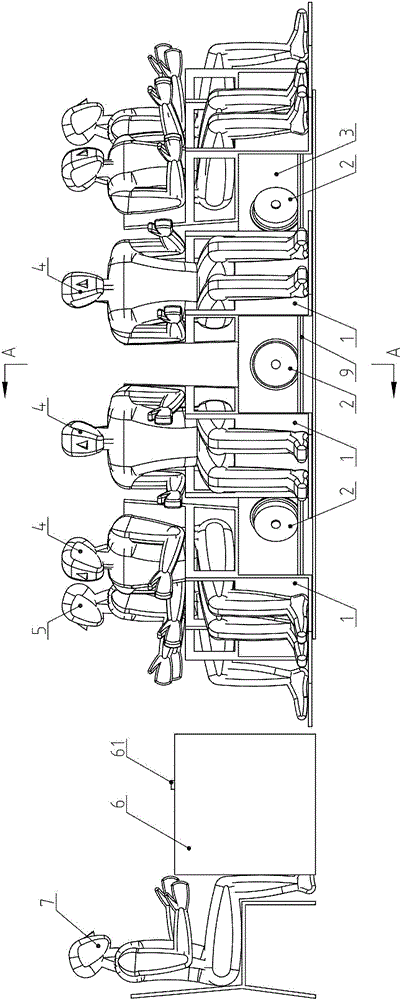

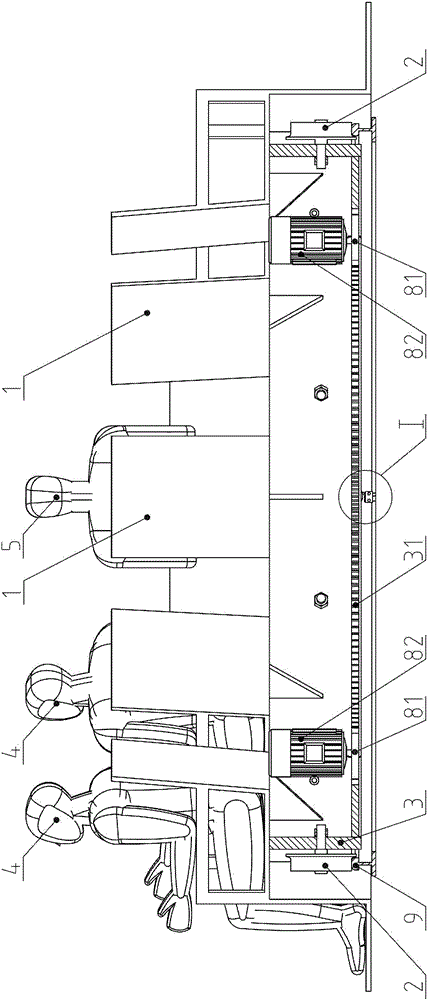

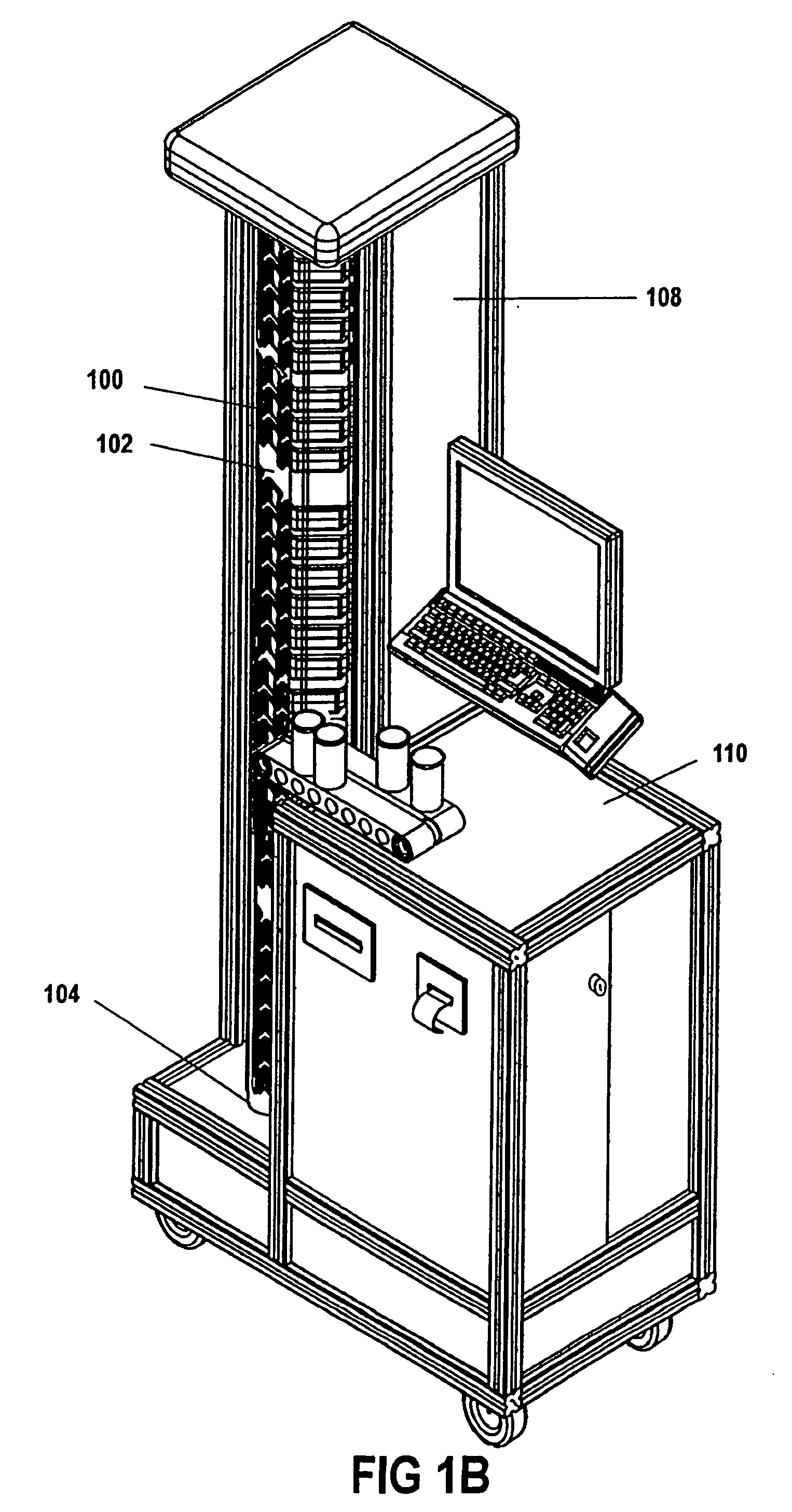

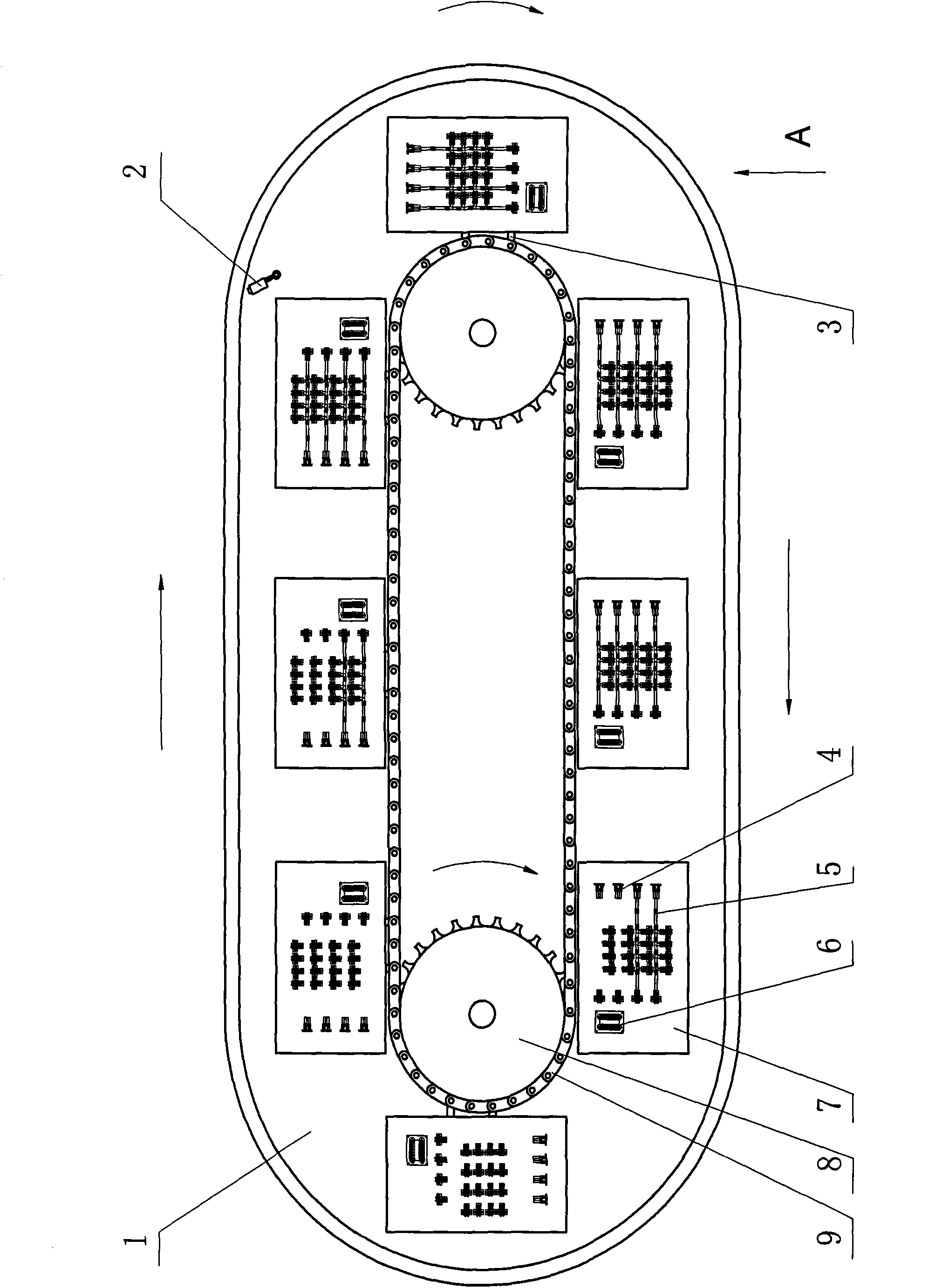

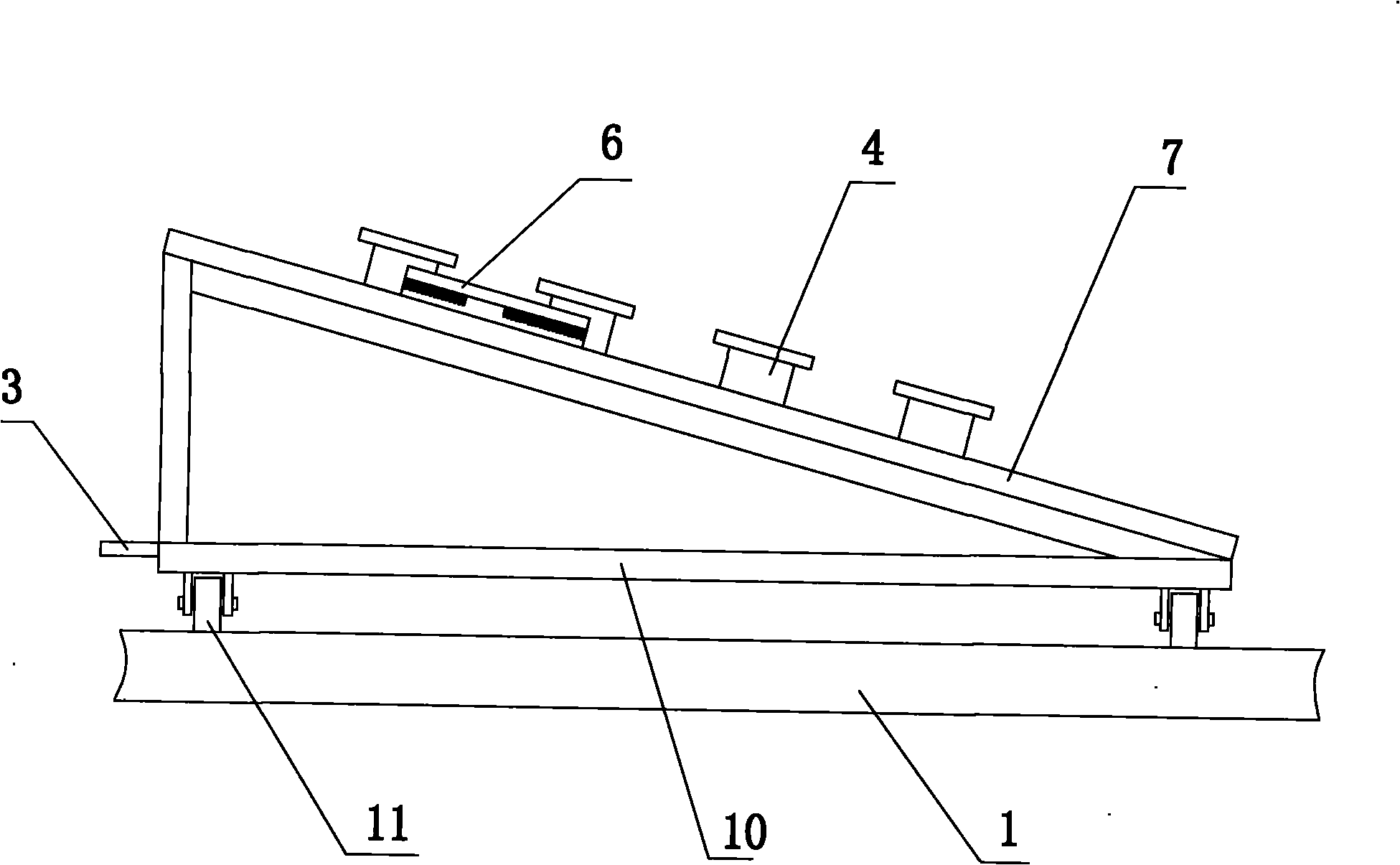

Wire harness test production line

InactiveCN101916628AConvenient CNC testingAccurately Test EfficiencyElectrical testingManufacturing wire harnessesElectricityProduction line

The invention relates to a device for processing an electric appliance wire harness, in particular to a wire harness test production device. According to a wire harness test production line, in a horizontal test platform (1), two horizontally rotating chain wheels (8) are arranged in the length direction, wherein one chain wheel is a driving chain wheel, and the other chain wheel is a driven chain wheel; a chain (9) encircles the two chain wheels (8) to form a circle of conveying chain; a plurality of hooks (3) are outwards extended on the chain (9), every two hooks (3) are connected with a test plate (7), a plurality of groups of wire harness sockets (4) are arranged on the test plate (7), and each group of wire harness sockets (4) is electrically connected with a wire harness tester (6) respectively; and the test plate (7) is arranged on an oblique bracket (10), and the lower part of the oblique bracket (10) is provided with a roller (11). The wire harness test production line relieves the labor intensity, has simple and labor-saving action, is not easy to cause accidents and errors, greatly improves the test speed, has accurate and reliable test result, and improves the turnover efficiency and the speed of the whole work.

Owner:SHANGHAI FEILE ELECTRONICS SYST

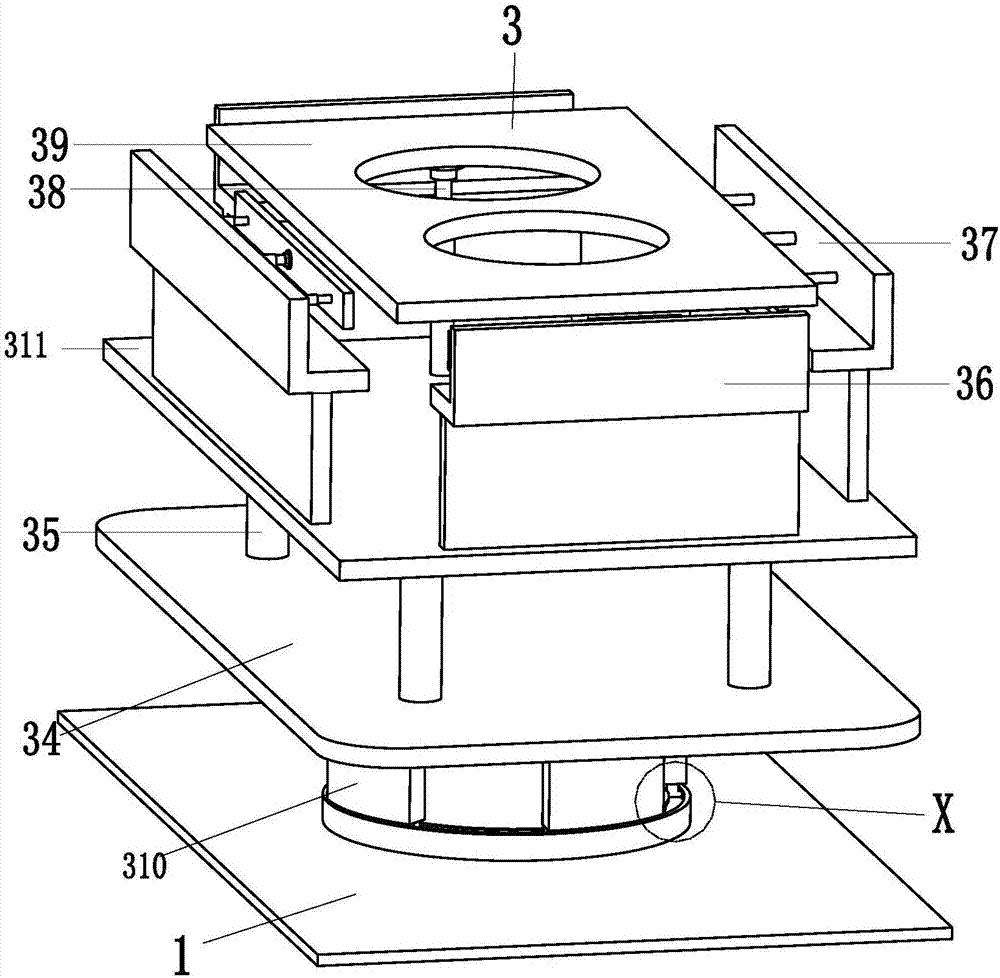

Surface intelligent processing and machining equipment for environment-friendly composite cement hollow bricks

InactiveCN107263742AEasy to convertReduce labor intensityWorking accessoriesStone-like material working toolsBrickCement composites

The invention relates to an environmental protection composite cement hollow brick surface intelligent processing equipment, comprising a bottom plate, two auxiliary moving devices, a rotating support device, two lifting limit devices and a cutter head switching device, and the two auxiliary moving devices are installed symmetrically On the base plate, the rotating support device is installed on the base plate, and the two auxiliary moving devices are symmetrically located on the left and right sides of the rotating support device, the two lifting limit devices are symmetrically installed on the rotating support device, and the cutter head switching device is installed on the two auxiliary moving devices. between mobile devices. The present invention can solve the problem that the existing hollow brick surface processing equipment in the existing process of manually processing the surface of the hollow brick does not unify the processing direction of the hollow brick, the manual clamping of the hollow brick is unstable, the tool change is cumbersome and complicated, and it is complicated to perform multiple surface treatments on the hollow brick. , It is easy to produce errors in the processing process, the time consumption is long, the labor intensity is high and the efficiency is low, and the function of automatic processing of the surface of the hollow brick can be realized.

Owner:冒俊

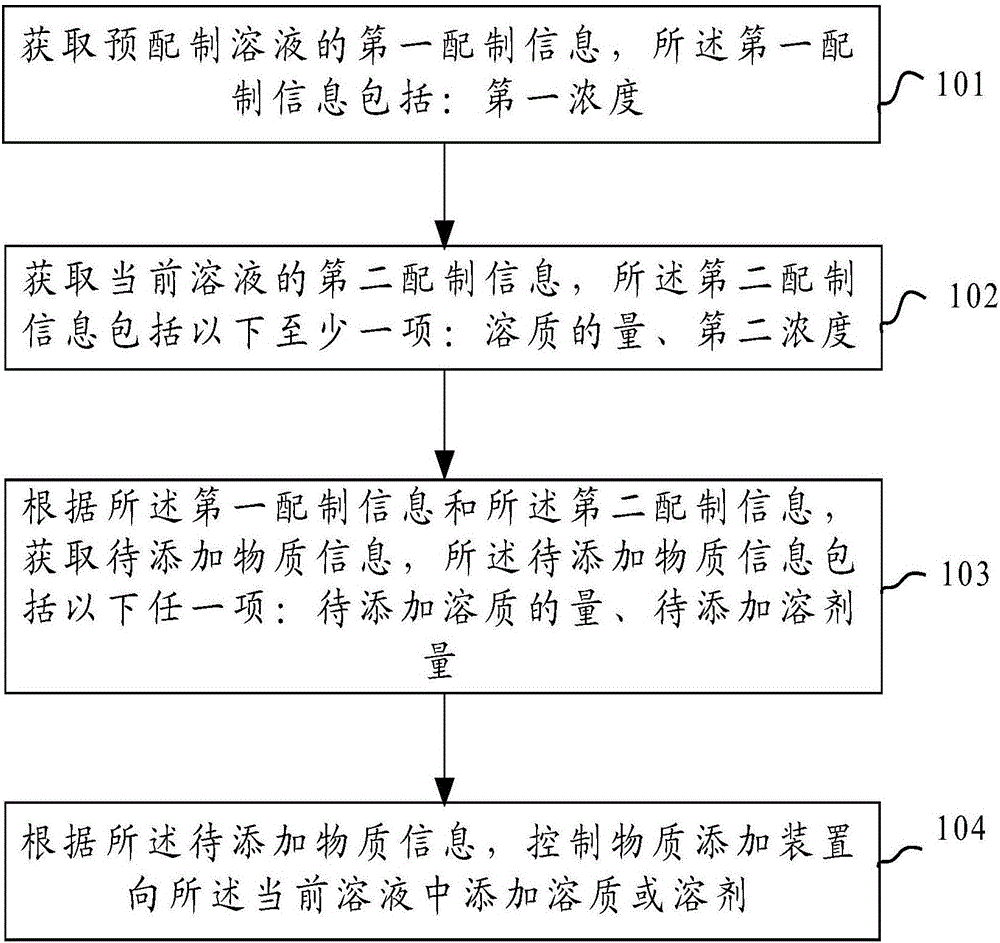

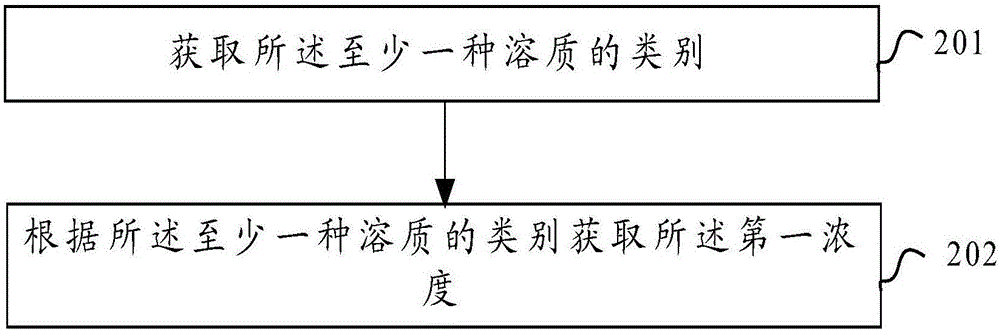

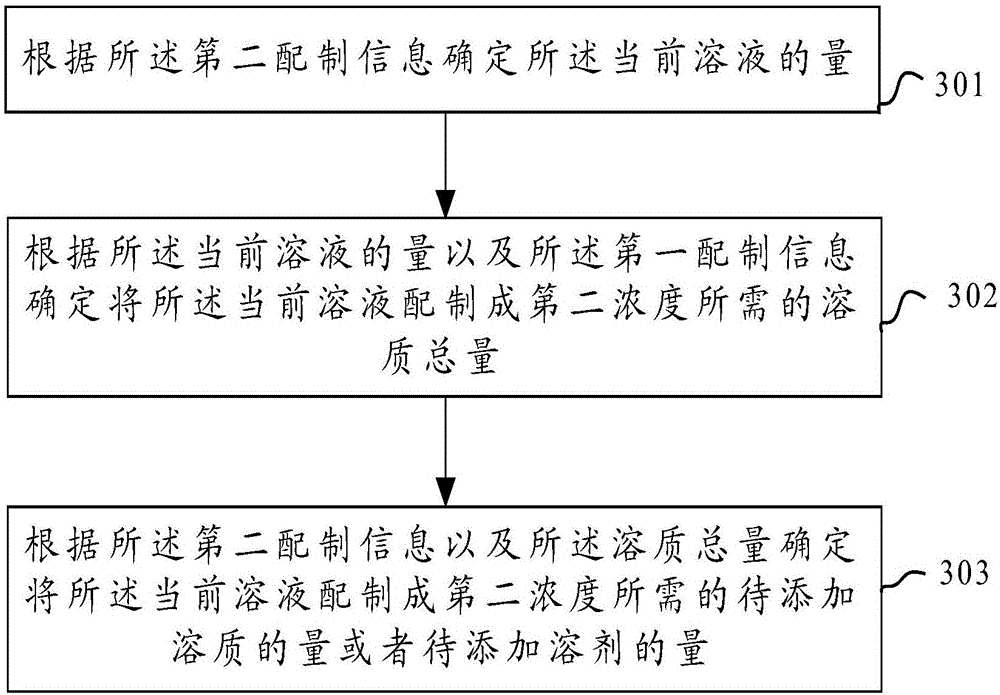

Method and device for preparation of solution

InactiveCN106512845AEasy to operateImprove experienceTransportation and packagingMixer accessoriesSoftware engineeringSolvent

The invention discloses a method and a device for preparation of a solution. The method comprises the following steps: first preparation information of a solution to be prepared is obtained, and the first preparation information contains first concentration; second preparation information of the current solution is obtained, and the second preparation information contains at least one item of solute quantity and second concentration; according to the first preparation information and the second preparation information, information of substances to be added is obtained, and the information of the substances to be added contains any one of the following items: quantity of a solute to be added and quantity of a solvent to be added; and according to the information of the substances to be added, a substance adding device is controlled to add the solute or the solvent into the current solution. According to the above technical scheme, the substance adding device can be controlled for automatic preparation of a solution. The device is convenient for user operation, and errors are not easy to cause. By the method and the device, user experience is enhanced.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

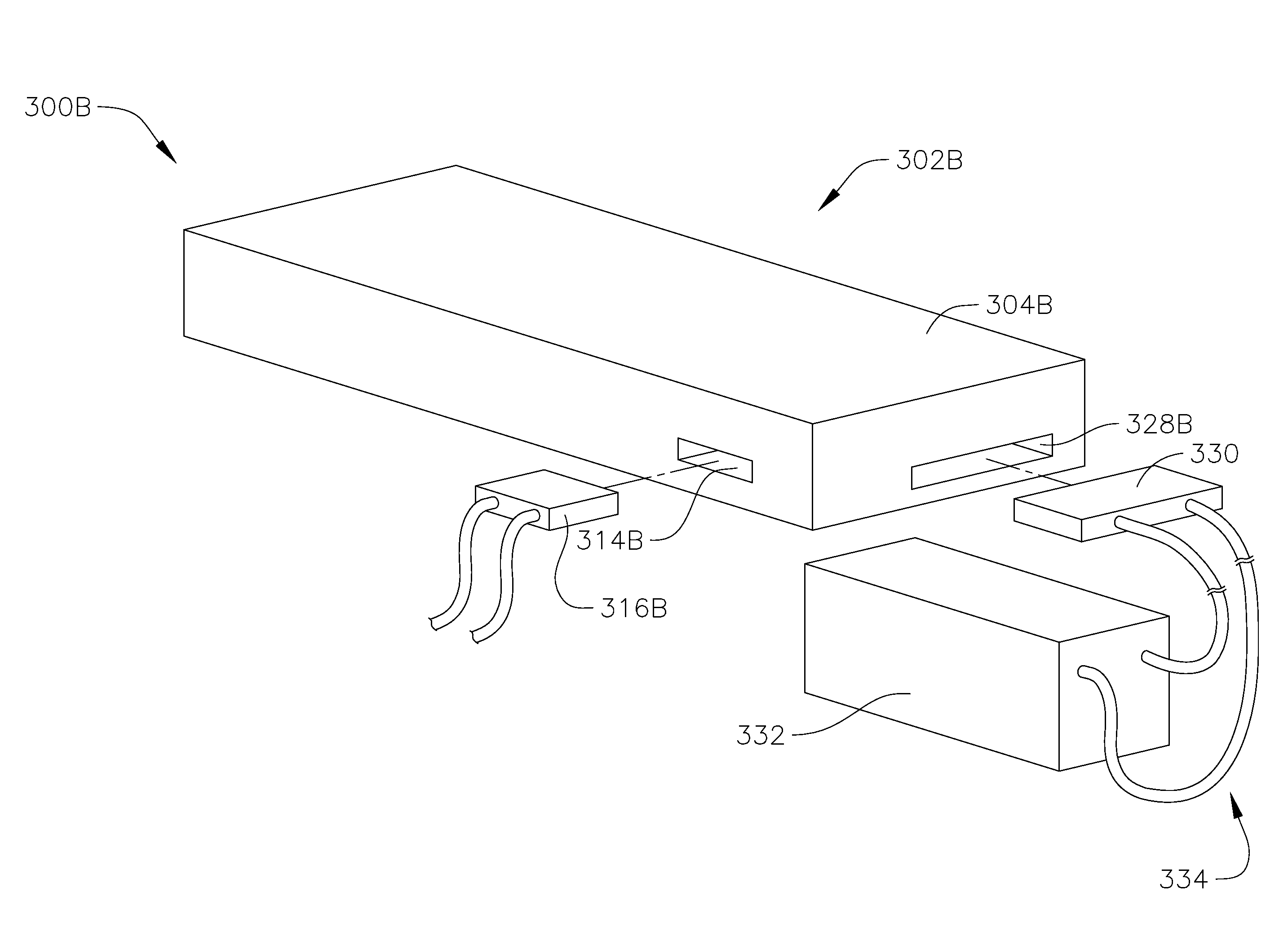

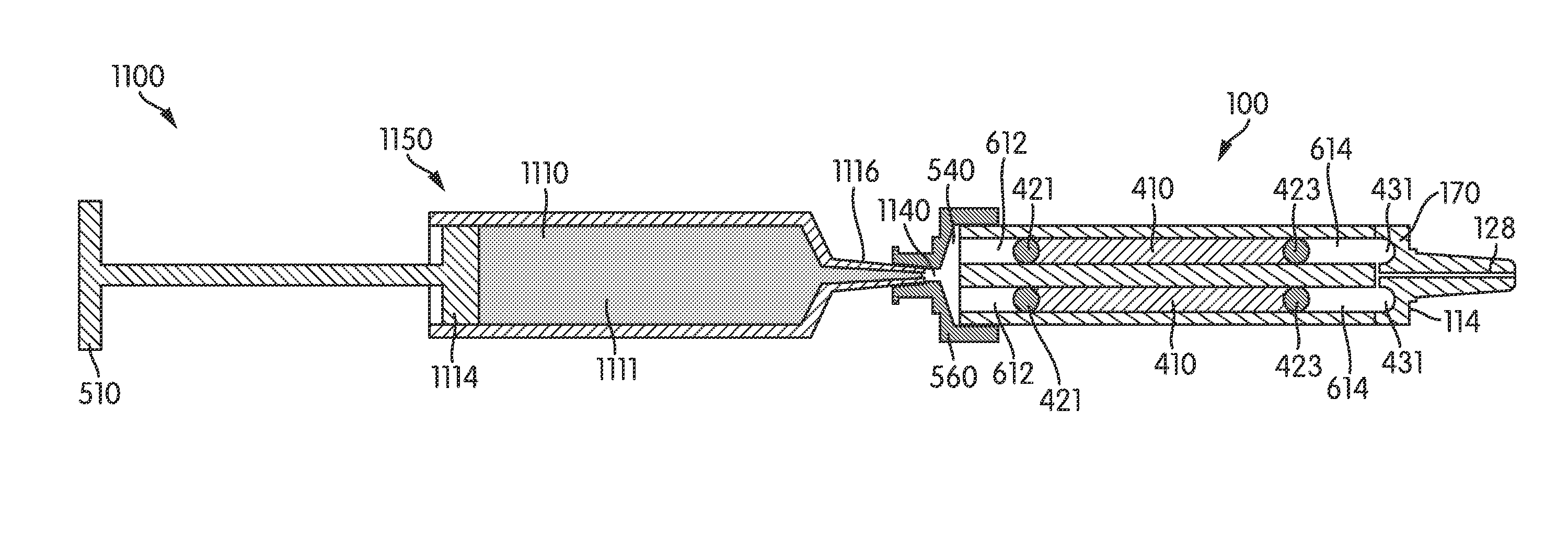

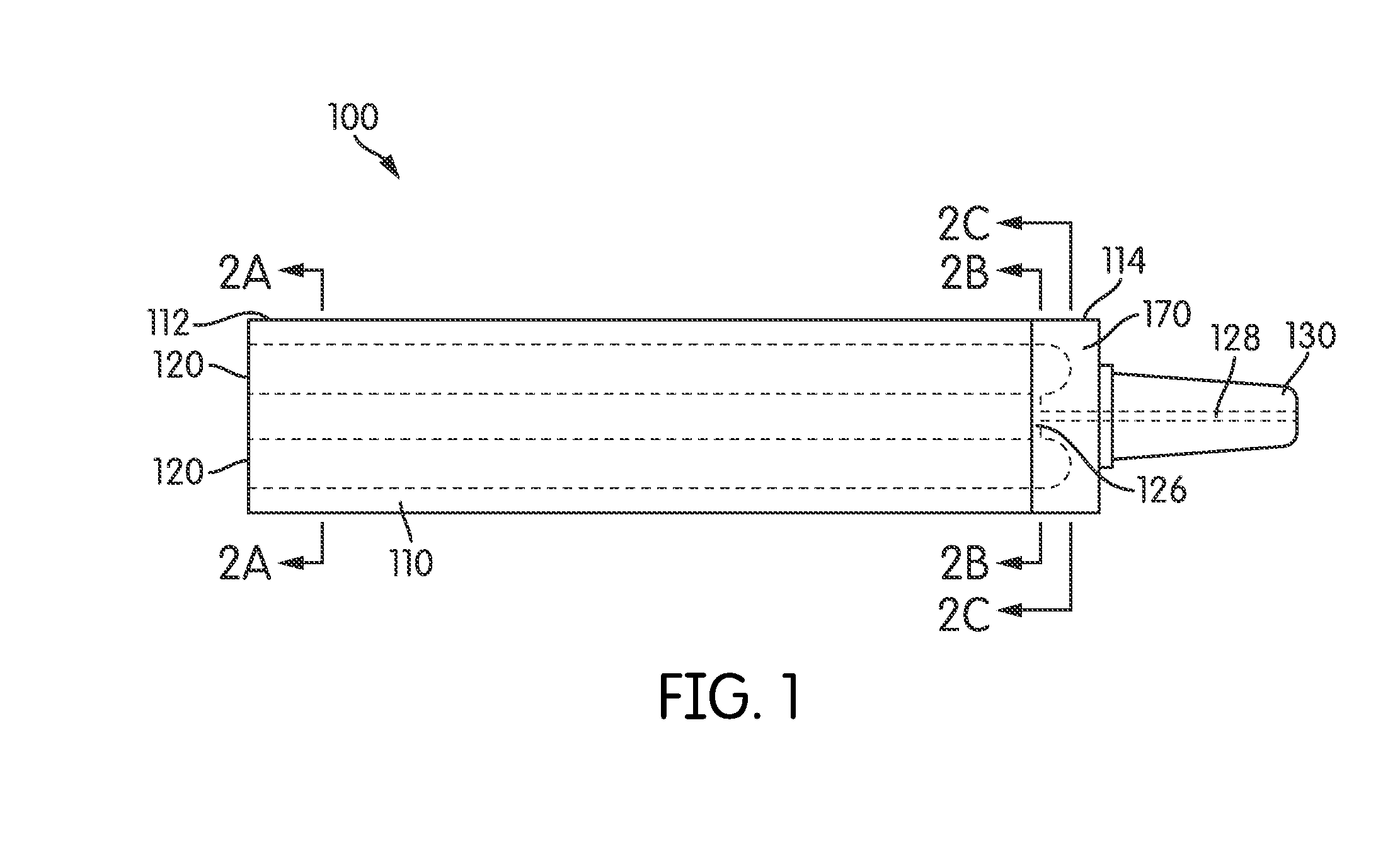

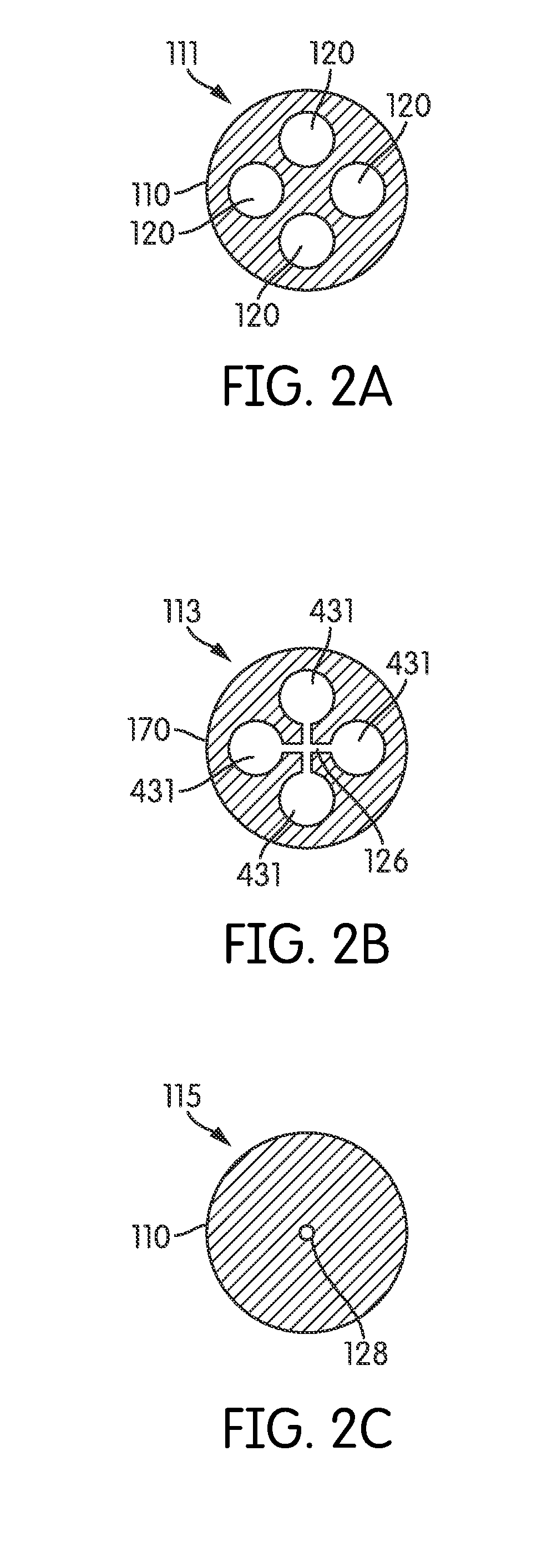

Method of dispensing analytic reference material

InactiveUS20130313281A1Reduce in quantityEliminate riskOpening closed containersBottle/container closureEngineeringBiomedical engineering

A method of dispensing an analytic reference material includes providing a dispensing device including an ampoule having at least two storage lumens extending axially along the length of an ampoule body, an analytic reference material subunit in each of the storage lumens, distal gaskets sealing the analytic reference material subunits from a distal end of the ampoule, and an outlet lumen. The method also includes providing a plunger assembly coupled to a proximal end of the ampoule, the plunger assembly in communication with the storage lumens and depressing the plunger assembly to force the distal gaskets into gasket seats in the dispensing device and expelling the analytic reference material subunits from the storage lumens via the outlet lumen to form the analytic reference material.

Owner:RESTEK

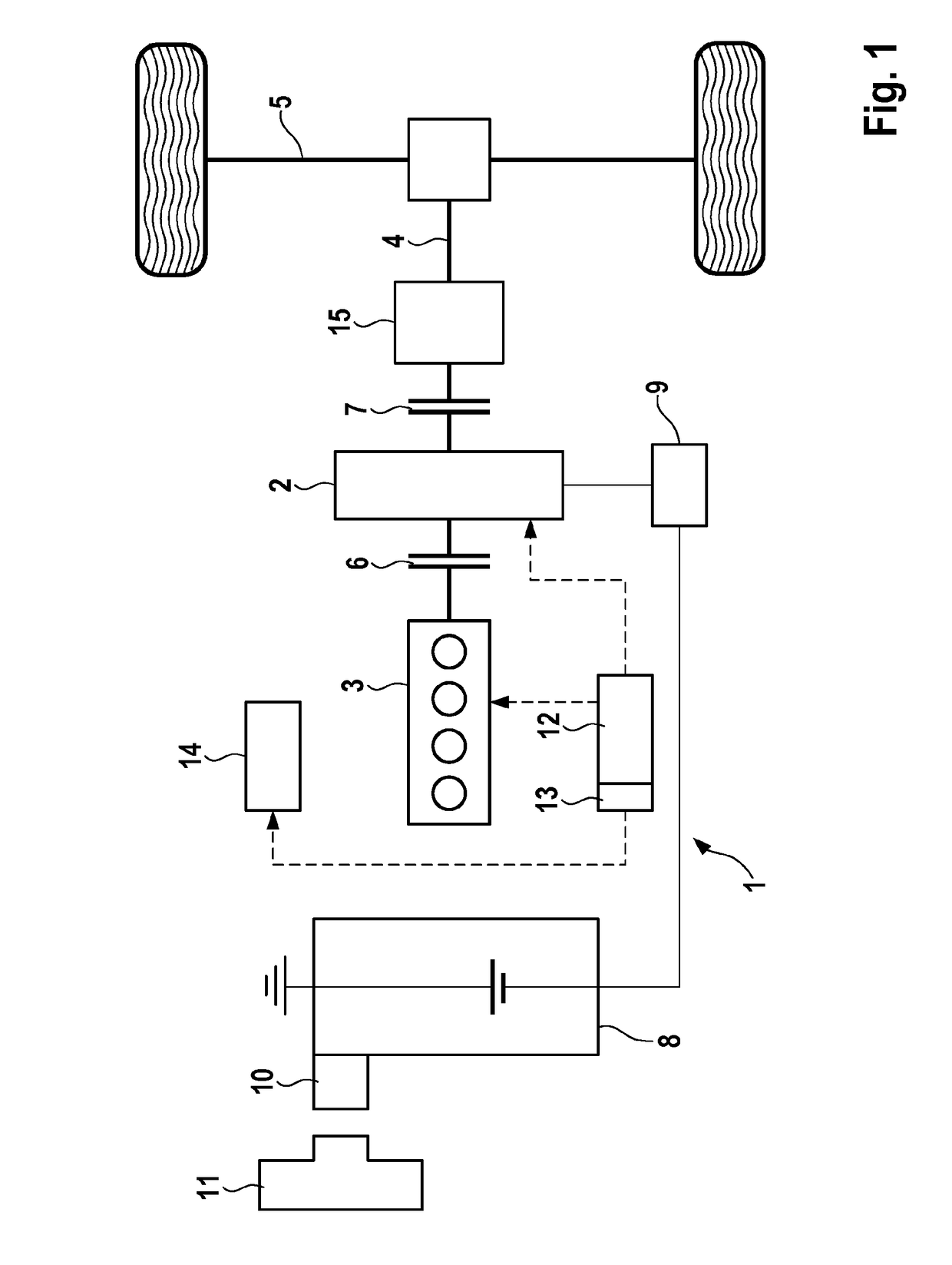

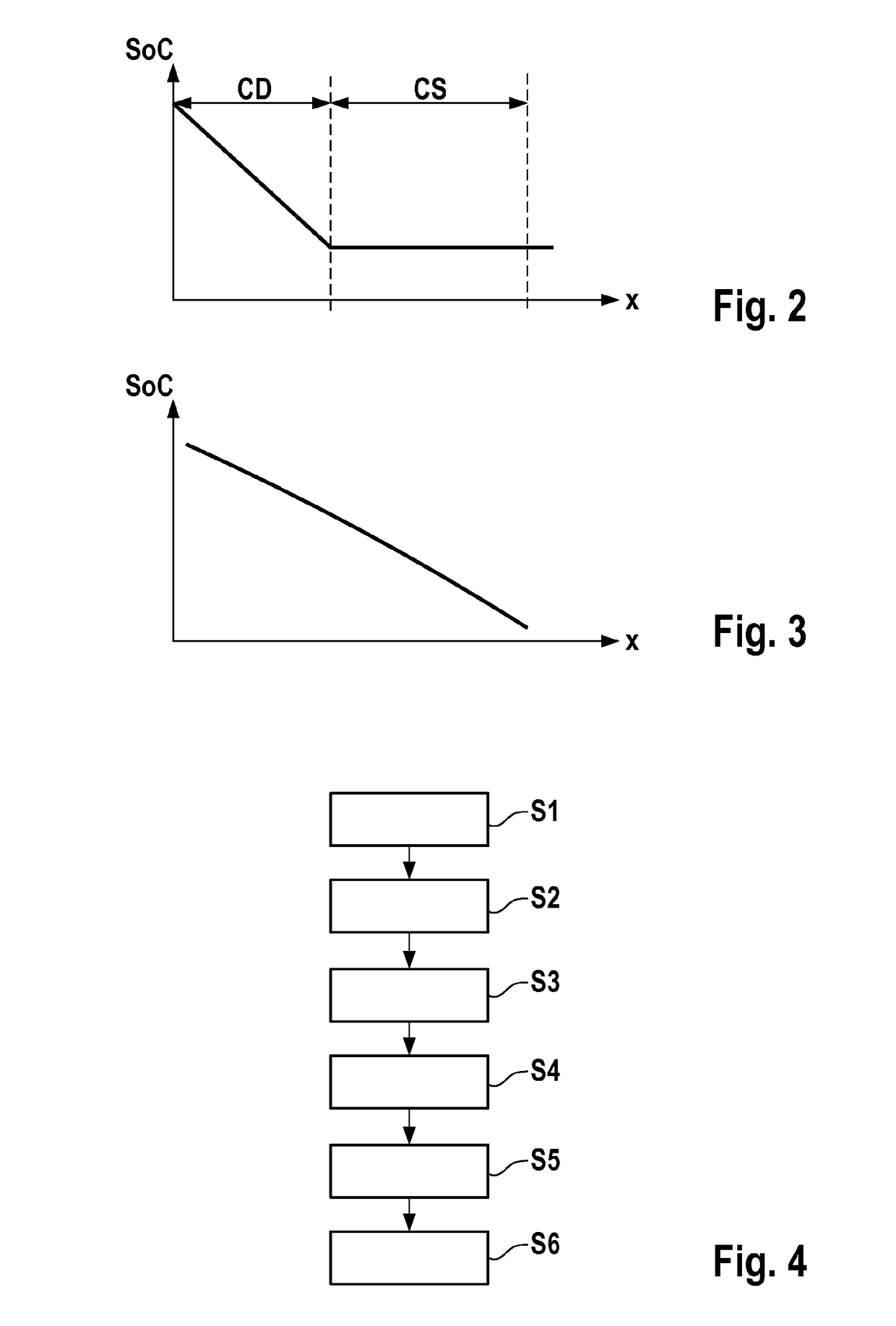

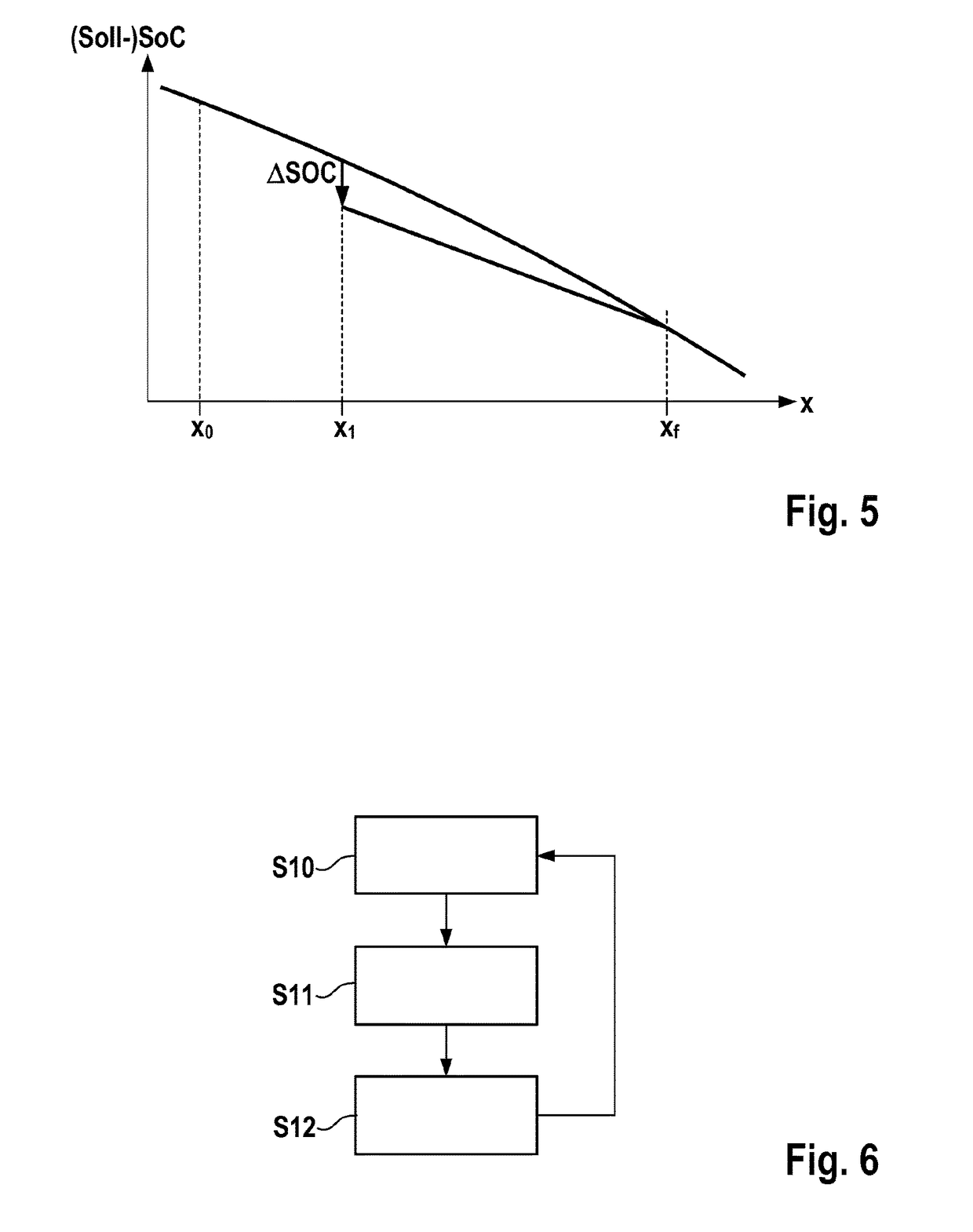

Method for operating a motor vehicle, control unit for a drive system, and a drive system

ActiveUS20190001959A1Less prone to errorHigh CO2-economization potentialHybrid vehiclesInternal combustion piston enginesElectricityState of charge

A method for operating a hybrid drive system for a motor vehicle having an internal combustion engine and an electrical drive, which is supplied by an electrical energy store, the required powers of the internal combustion engine and / or of the electrical drive being set in accordance with a specified load distribution, including: regulating the load distribution between the electrical drive and the internal combustion engine based on a current setpoint state of charge of the electrical energy store; and determining the current setpoint state of charge from a specified linear setpoint state of charge curve between a current position of the motor vehicle and a destination.

Owner:ROBERT BOSCH GMBH

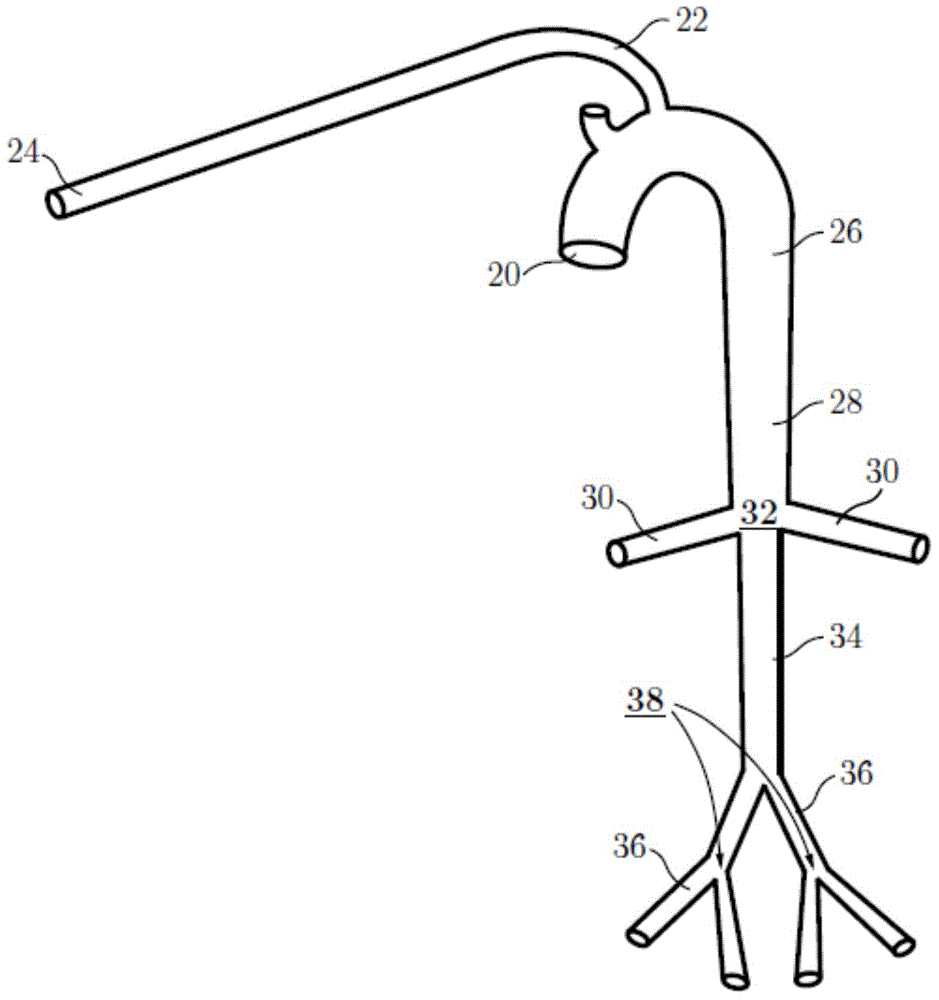

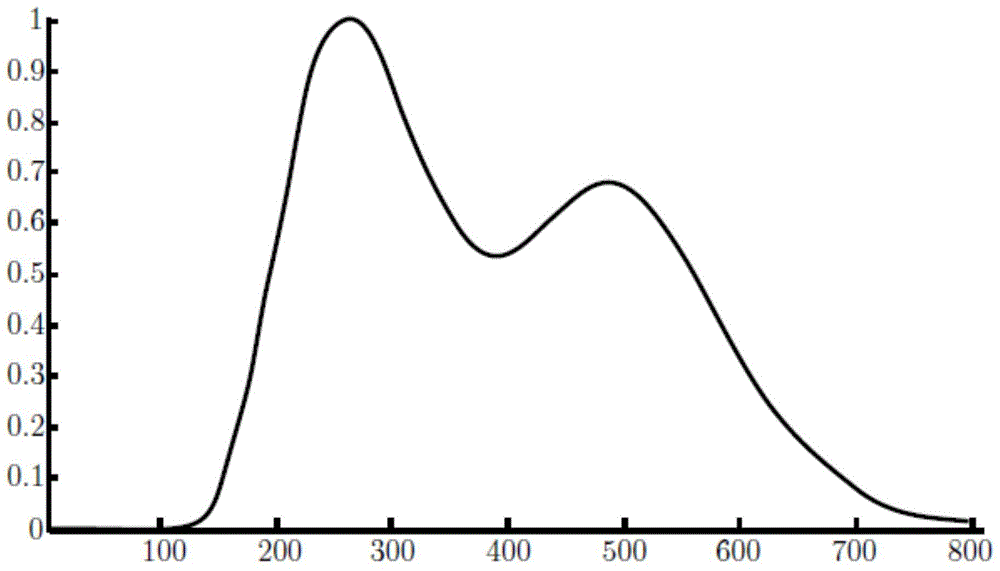

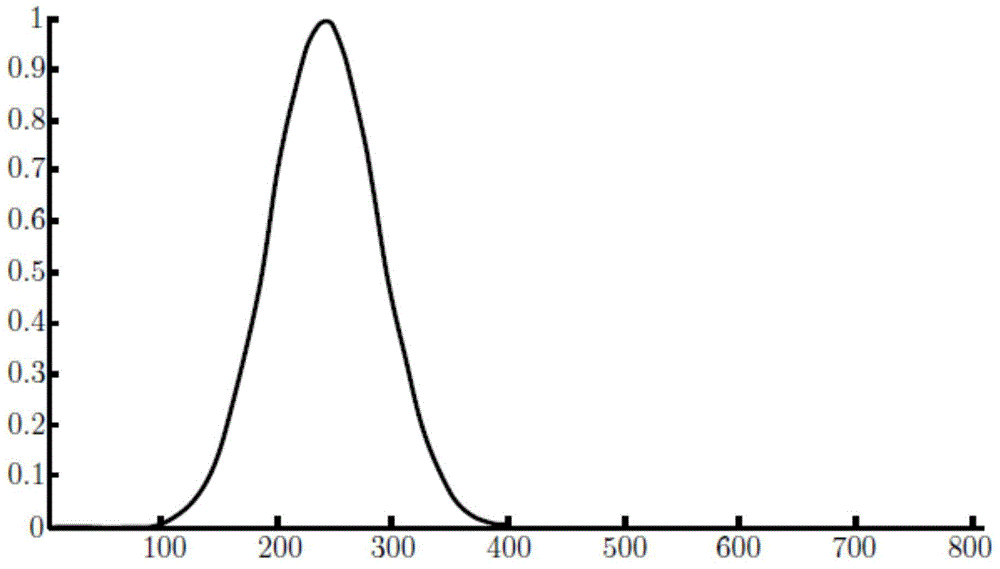

System for measuring hardening index of artery network

ActiveCN104146692ALess prone to errorHigh precisionCatheterDiagnostic recording/measuringPulse waveformIndex score

The invention discloses a system for measuring a hardening index of an artery network. The system comprises a pressure sensor used for acquiring a pulse waveform associated with the artery network; and a microprocessor connected to the pressure sensor. The microprocessor obtains the pulse waveform through the pressure sensor, and estimates a source pulse according to at least one preset feature of the pulse waveform; determines a plurality of attributive features of the pulse waveform according to the relation between the pulse waveform and the source waveform; and calculates the hardening index of the artery network according to the plurality of attributive features of the pulse waveform. The system provided by the invention has low computing requirements, is less sensitive to noise, is not prone to generate errors and improves the precision.

Owner:HONG KONG APPLIED SCI & TECH RES INST

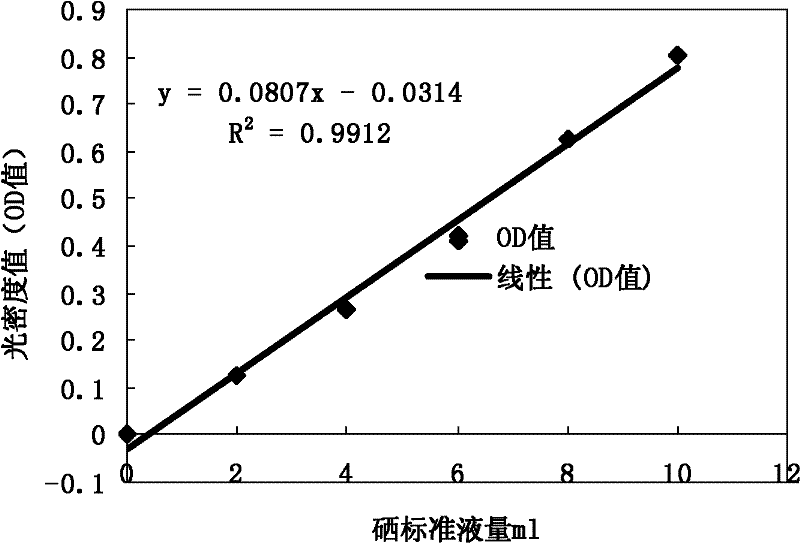

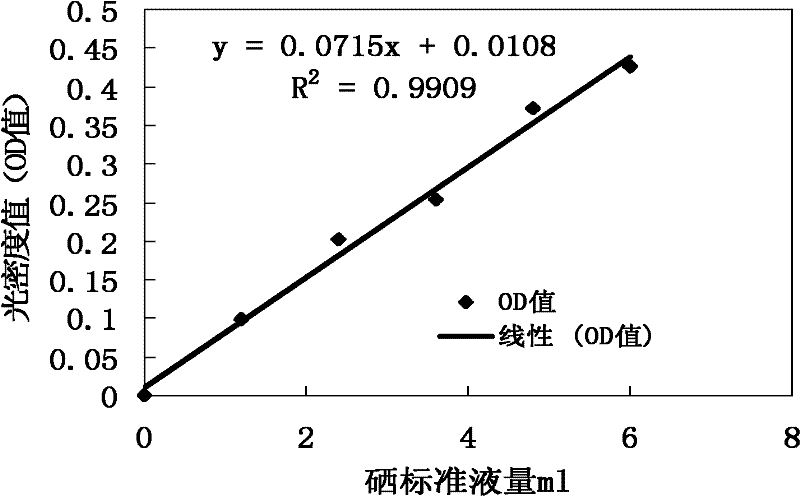

Method for detecting total selenium content

InactiveCN102175673AStandard sample preparation is simpleLess prone to errorMaterial analysis by observing effect on chemical indicatorSe elementChemistry

The invention relates to a method for detecting total selenium content in selenium-enriched yeast. In the method, the total selenium content in yeast selenium is measured by taking sodium selenite as a guide sample. Compared with the convention method for detecting the total selenium content in the yeast selenium, the method has the advantages that: the guide sample is easy to prepare, errors are difficult to generate, and measuring results are accurate.

Owner:安徽泰格生物技术股份有限公司

Container with Adjustable Date Indicium

ActiveUS20130062346A1Simple instructionsEasy to useCapsMeasurement apparatus componentsFixed position

Owner:MEDELA HLDG AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com