Equipment and method for continuous casting and rolling of bimetallic composite plate and strip using single machine and two streams

A composite strip, bimetal technology, applied in metal rolling and other directions, can solve problems such as shortening the process flow, and achieve the effect of shortening the process flow, strong controllability, and improving the interface composite effect and plate quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

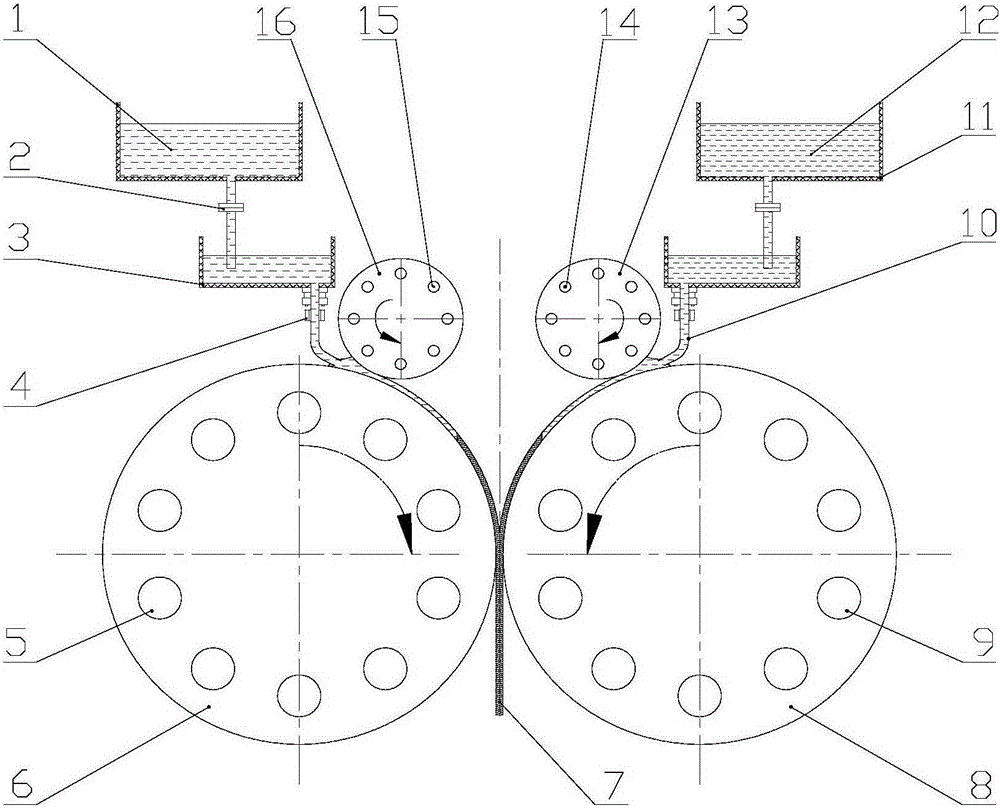

[0020] Taking the copper-aluminum composite board as an example, the method of the present invention is used to process the copper-aluminum composite board. Metal A is made of industrial red copper, and metal B is made of industrial pure aluminum. The size of the composite product is 2mm, and the copper-aluminum thickness ratio is about 1:3. The product width is 300mm. According to the thickness specification of the finished product, the roll gap between the main casting roll (left) 6 and the main casting roll (right) 8 is set to 2 mm, and the composite rolling reduction rate is 50%. Considering the reduction distribution relationship of two different metals, set the roll gap value between the main casting roll (left) 6 and the auxiliary casting roll (left) 16 to 0.94mm, and the main casting roll (right) 8 and the auxiliary casting roll (Right) The roll gap value between 13 and 3.06mm. The speed ratio of the main casting roll and the auxiliary casting roll is controlled to be...

Embodiment 2

[0022] Taking the copper-aluminum composite board as an example, the method of the present invention is used to process the copper-aluminum composite board. Metal A is made of industrial red copper, and metal B is made of industrial pure aluminum. The size of the composite product is 3mm, and the copper-aluminum thickness ratio is about 1:3. The product width is 350mm. According to the thickness specification of the finished product, the roll gap between the main casting roll (left) 6 and the main casting roll (right) 8 is set to 3 mm, and the composite rolling reduction rate is 60%. Considering the reduction distribution relationship of two different metals, set the roll gap value between the main casting roll (left) 6 and the auxiliary casting roll (left) 16 to 1.85mm, and the main casting roll (right) 8 and the auxiliary casting roll (Right) The roll gap value between No. 13 is 5.65mm. The speed ratio of the main casting roll and the auxiliary casting roll is controlled to...

Embodiment 3

[0024]Taking carbon steel-stainless steel composite plate as an example, adopt the method of the present invention to process carbon steel-stainless steel composite plate, metal A selects Q235 carbon steel for use, metal B selects 304 stainless steel for use, and its composite product size is 3mm, and thickness ratio is about 1 :1, the product width is 300mm. According to the thickness specification of the finished product, the roll gap between the main casting roll (left) 6 and the main casting roll (right) 8 is set to 3 mm, and the composite rolling reduction rate is 50%. Set the roll gap value between the main casting roll (left) 6 and the auxiliary casting roll (left) 16 to 3.15mm, and the roll gap value between the main casting roll (right) 8 and the auxiliary casting roll (right) 13 to 2.85mm . The speed ratio of the main casting roll and the auxiliary casting roll is controlled to be 0.9, the cooling water pressure in each casting roll is 0.5 MPa, and the casting machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com