Stamping equipment for hardware of plastic-steel door and window

A technology for stamping equipment, plastic steel doors and windows, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as waste, and achieve the effects of avoiding waste, good quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0019] Embodiment: In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

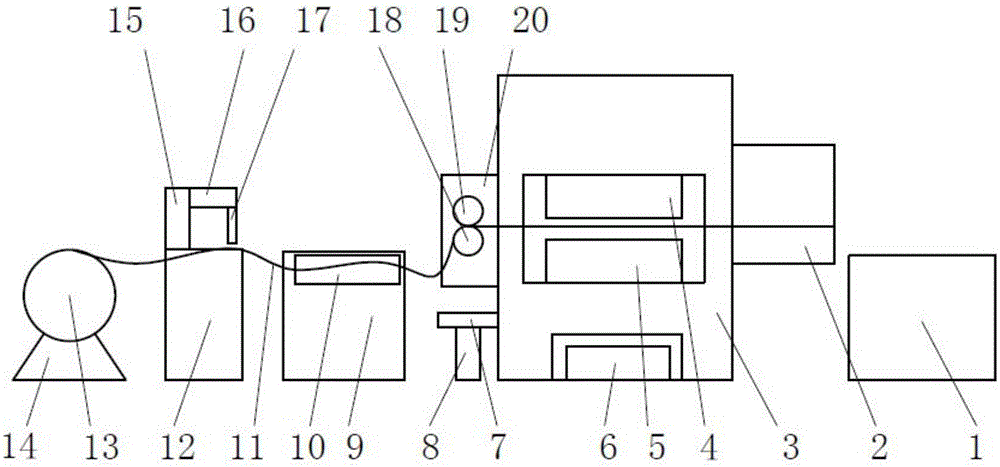

[0020] Such as figure 1 As shown, the present invention provides a stamping equipment for plastic-steel door and window hardware, including a receiving box 1, a throwing device 2, a stamping box 3, an upper mold 4, a lower mold 5, a magnetic conveyor belt 6, a console 7, and a power distribution cabinet 8 , straightening machine 9, straightening tank 10, strip steel 11, welding machine 12, uncoiler 13, uncoiler base 14, welding support 15, welding arm 16, welding head 17, lower roll 18, upper roll 19 and feeder 20. The strip steel 11 is installed on the uncoiler 13, the welding support 15 is provided on the welding machine 12, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com