Structure enhanced synthetic fiber for concrete and preparation thereof

A technology of structural reinforcement and synthetic fiber, which is applied in fiber cutting, fiber treatment, spinning solution preparation, etc., can solve the problems of brittleness and weak tensile performance, and achieve the improvement of crush resistance, suppression of connecting cracks, and clear outline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

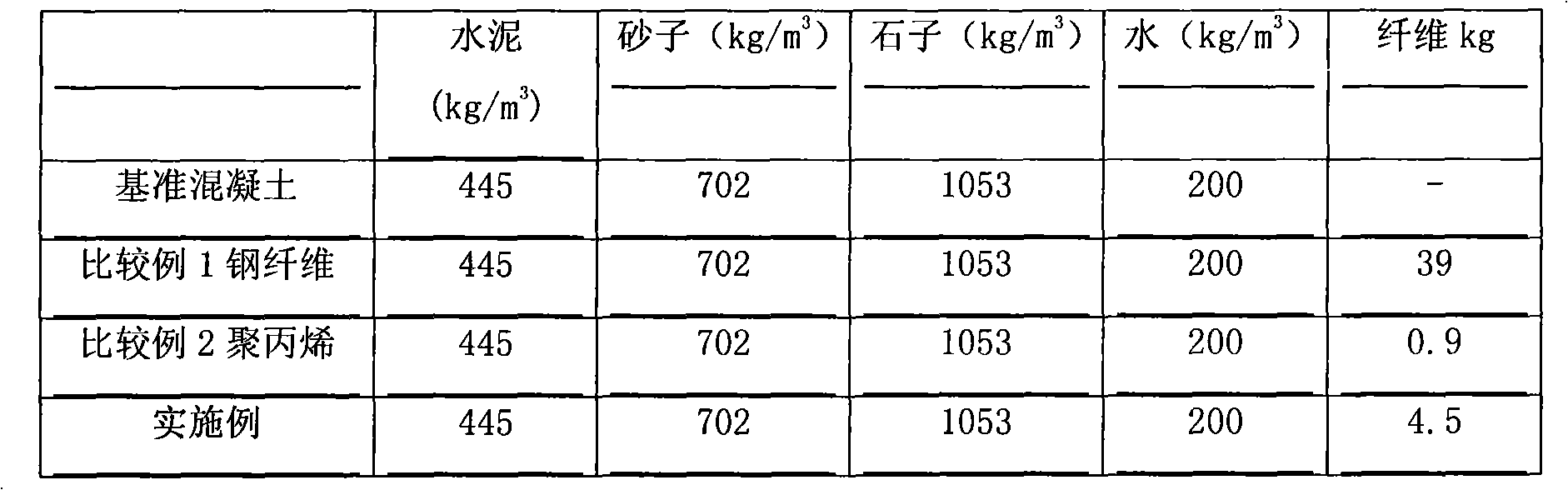

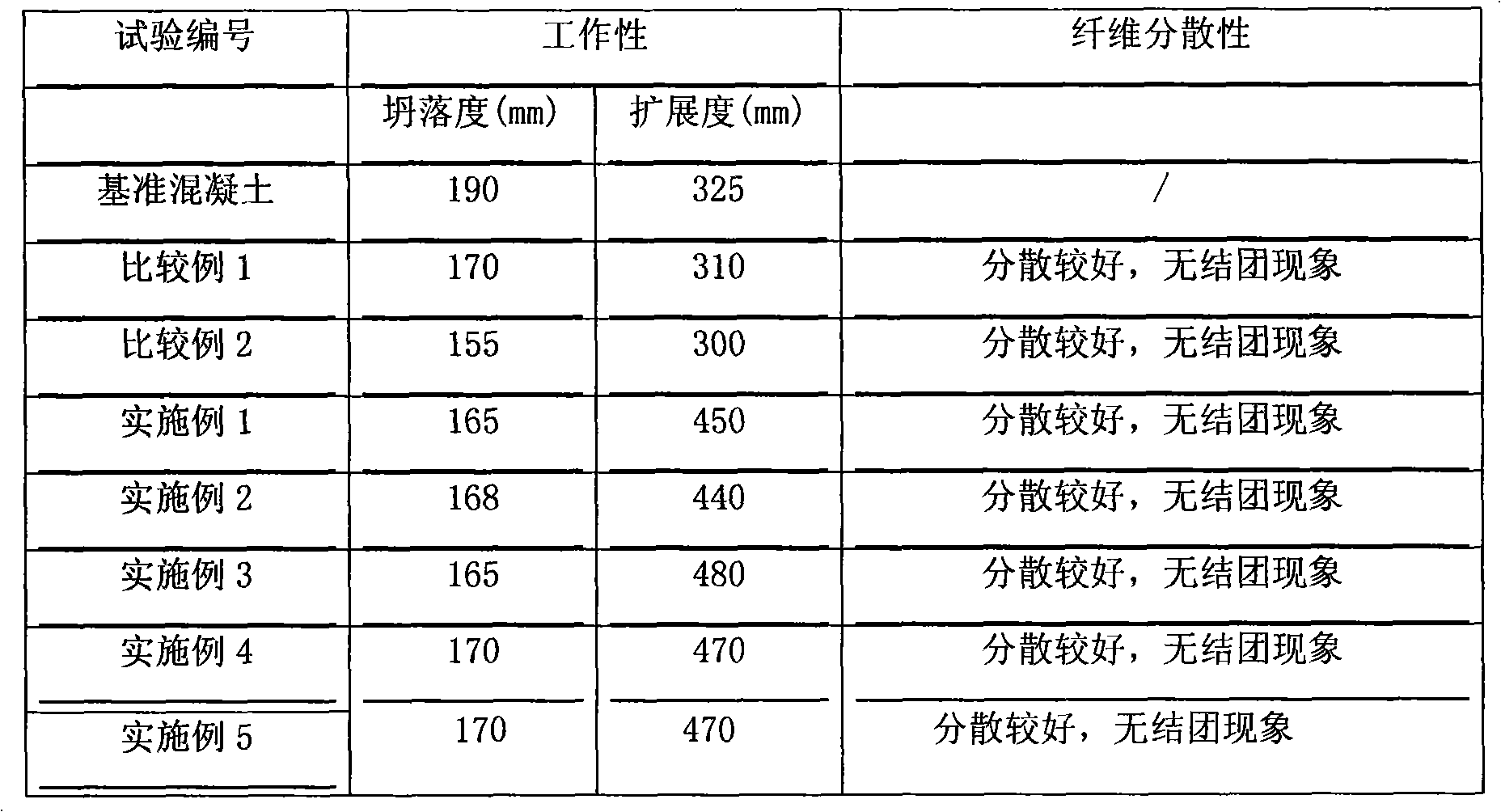

Examples

Embodiment 1

[0051] 1) Melt and mix each raw material at 150-320°C according to the following weight ratio:

[0052] 69.8% polypropylene, 25% polyethylene, 5% polyamide, 0.05% nucleating agent, 0.15% antioxidant;

[0053] 2) sending the molten mixture into a twin-screw extruder for extrusion molding;

[0054] The first zone of the machine head is 150°C, the second zone is 180°C, the third zone is 240°C, and the fourth zone is 320°C;

[0055] 3) Direct injection into the spinneret to extrude the spinneret;

[0056] 4) Water cooling to 20-40°C;

[0057] 5) One traction stretch

[0058] 6) superdispersant oil bath, the weight concentration of soaking dispersant is 1.0%;

[0059] 7) 135 ~ 140 ℃ hot air drying for 2 minutes;

[0060] 8) Secondary traction and stretching to 60-70CN / TEX;

[0061] 9) The wire splitter is bent and wound;

[0062] 10) According to the customer's requirements, the outer dimension is cut into the required length and packed into the warehouse.

Embodiment 2

[0064] The preparation process of embodiment 2 is identical with embodiment, and the weight ratio of each component is as follows:

[0065] 49% polypropylene, 50% polyethylene, 0 polyamide, 0.5% nucleating agent, 0.5% antioxidant.

[0066] Step 6) The weight concentration of the sizing and dispersing agent is 0.5%.

Embodiment 3

[0068] The preparation process of embodiment 3 is identical with embodiment, and the weight ratio of each component is as follows:

[0069] 20% polypropylene, 74.4% polyethylene, 5% polyamide, 0.5% nucleating agent, 0.1% antioxidant.

[0070] Step 6) The weight concentration of the sizing and dispersing agent is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com