Patents

Literature

171results about "Severing fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

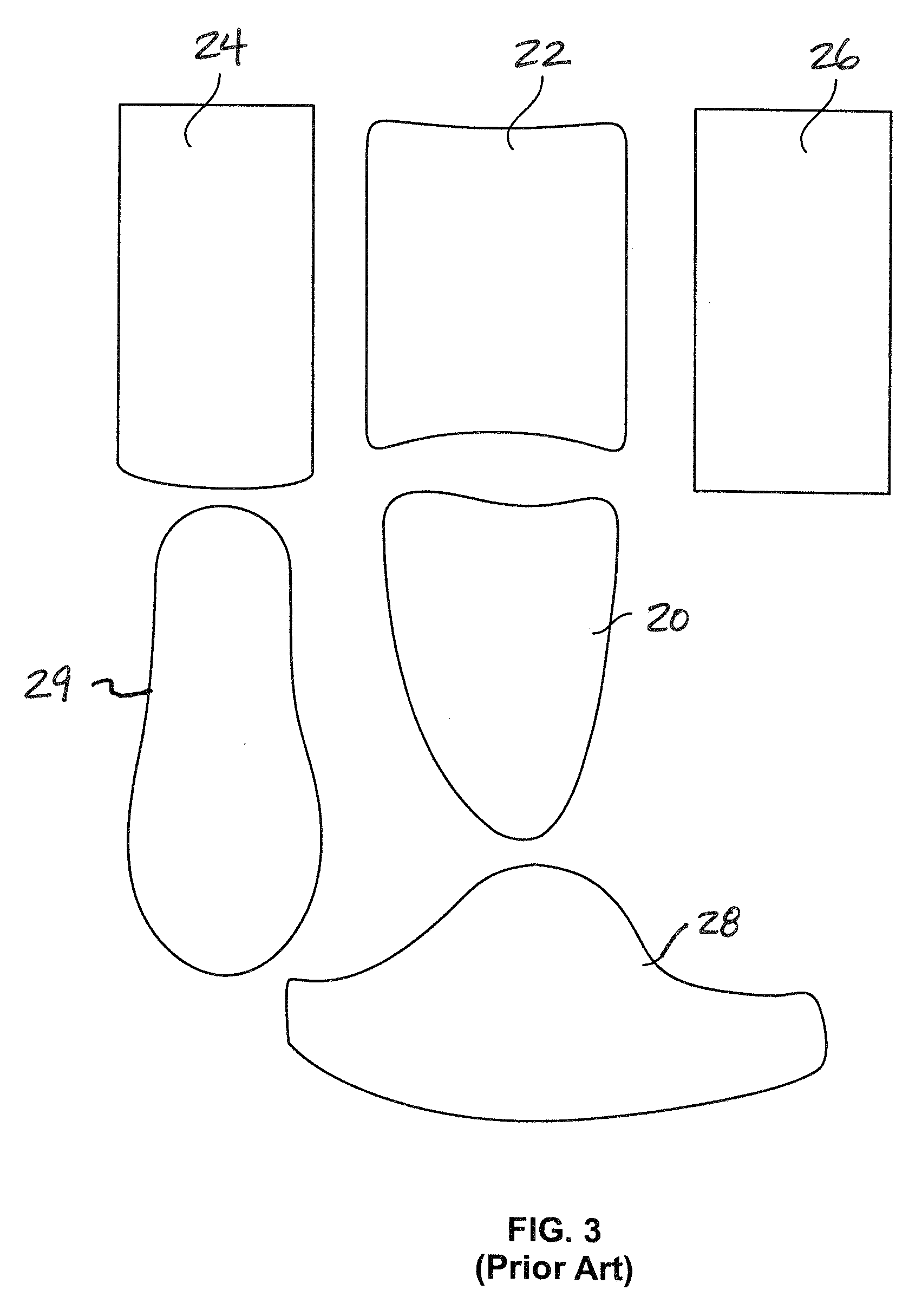

Cotton fiber particulate and method of manufacture

InactiveUS7594619B2Improve abilitiesExcellent characteristicsPulp properties modificationSynthetic resin layered productsParticulatesCotton fibre

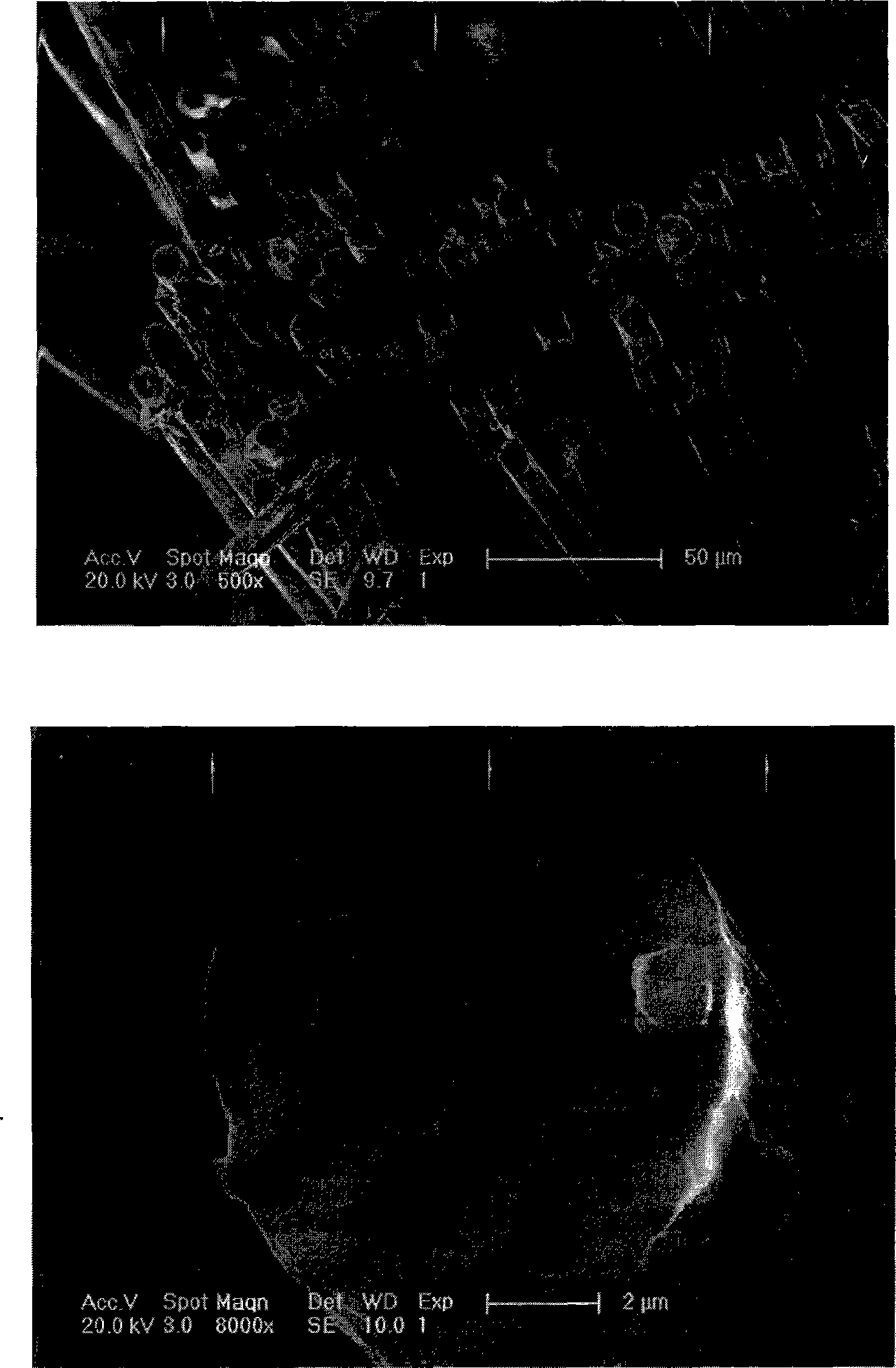

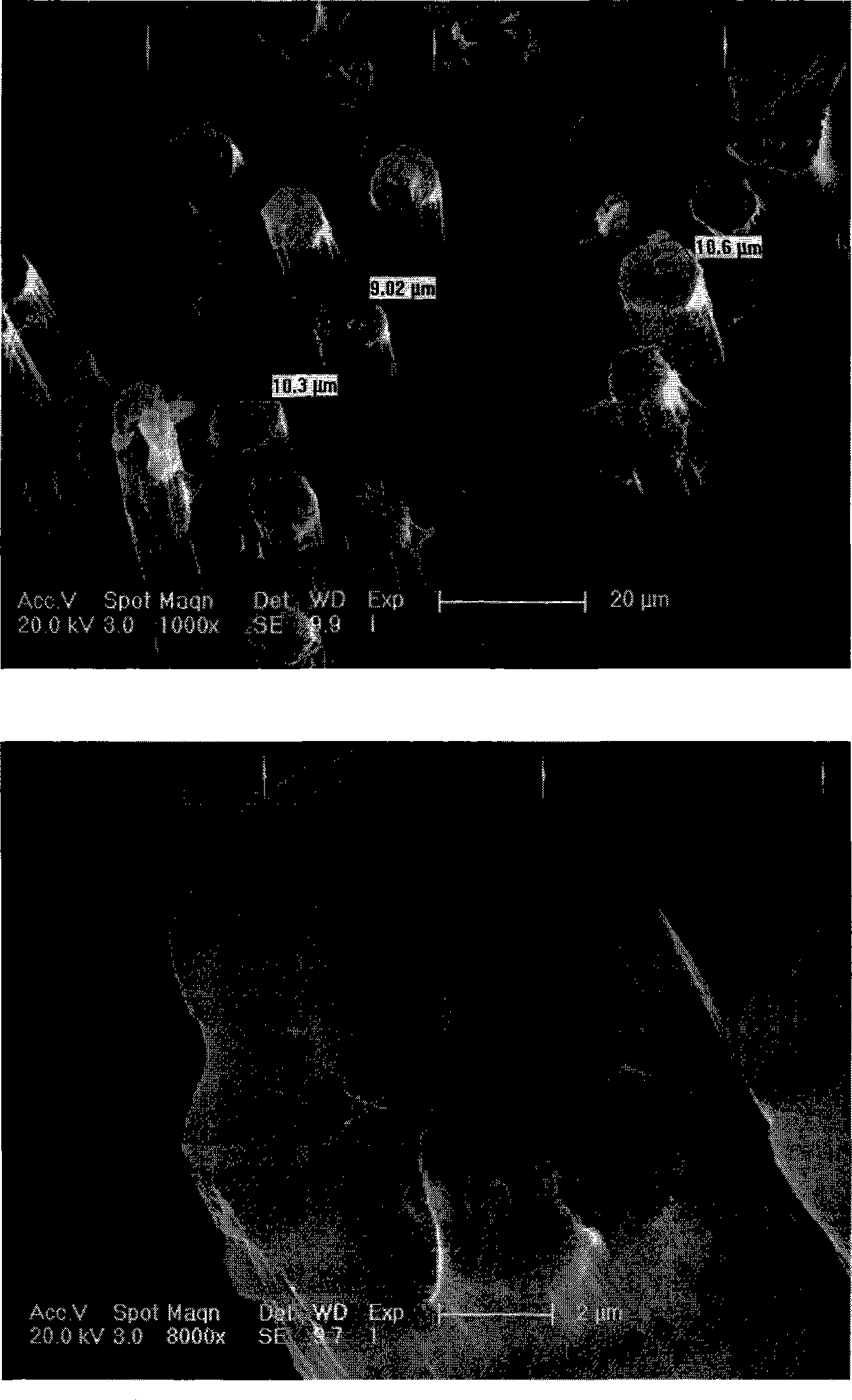

A cotton fiber particulate and method of manufacture including, generally, obtaining cotton fibers; mixing the cotton fibers with a solvent such as water to obtain a fiber furnish; milling the fiber furnish; and drying the fiber furnish to recover the cotton fiber particulate. Other steps include modifying the pH of the fiber furnish with a material such as calcium carbonate in an effort to make the fibers brittle, and filtering the fiber furnish to recover the cotton particulate. The fibers are milled to between 5-25 microns in length with a mean length of less than 50 microns with a mean length of 20 microns preferred.

Owner:SSI TECH INC

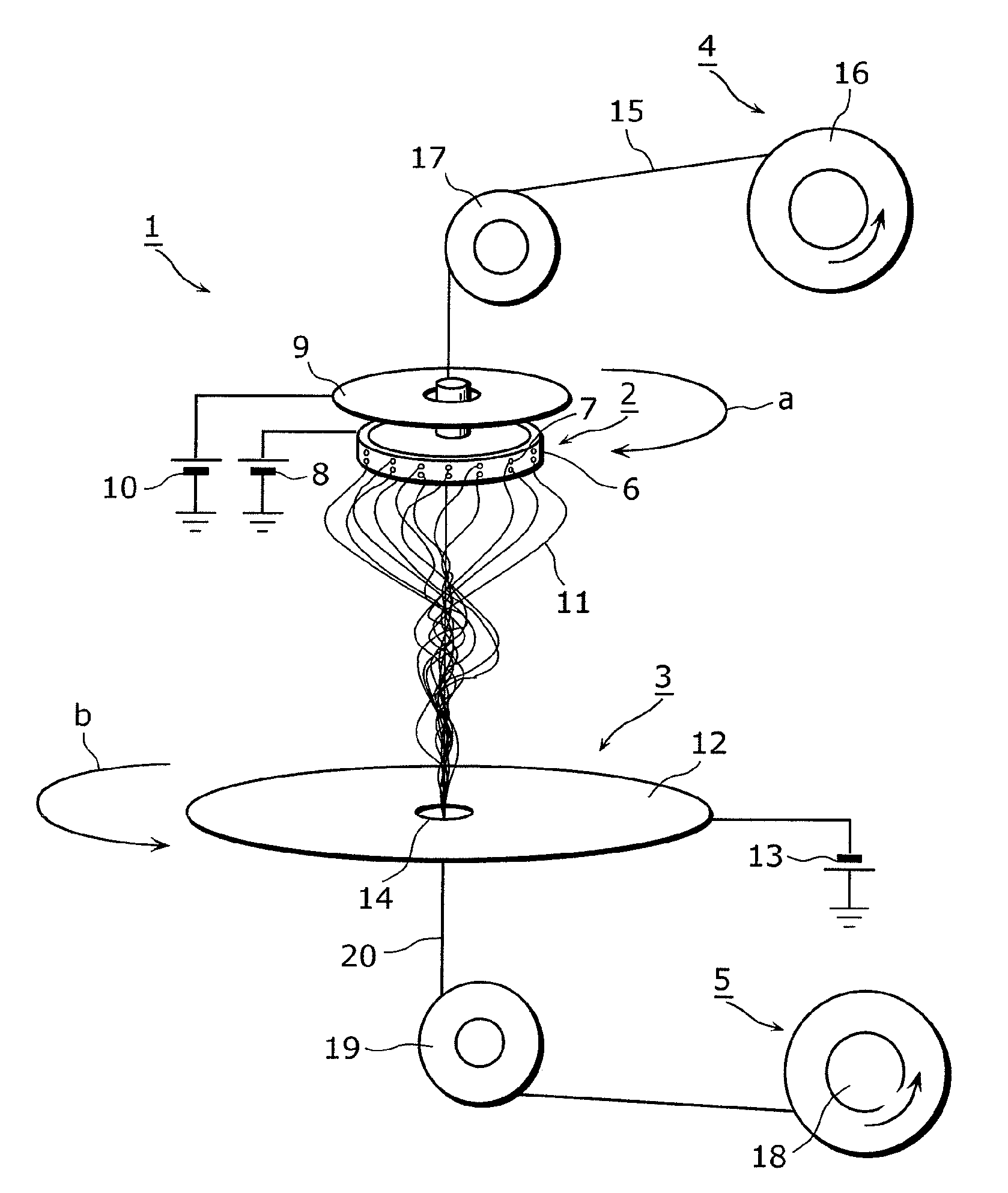

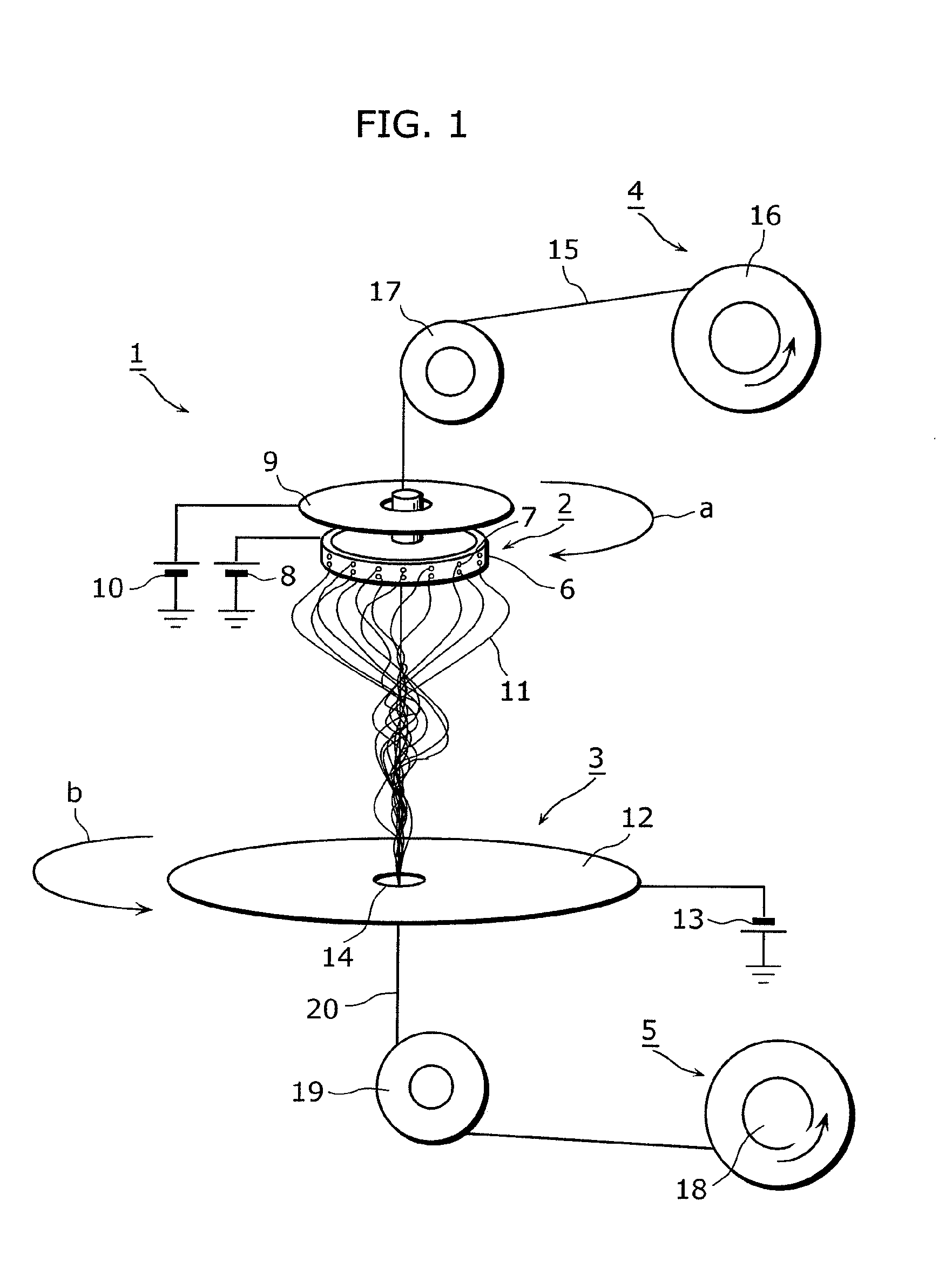

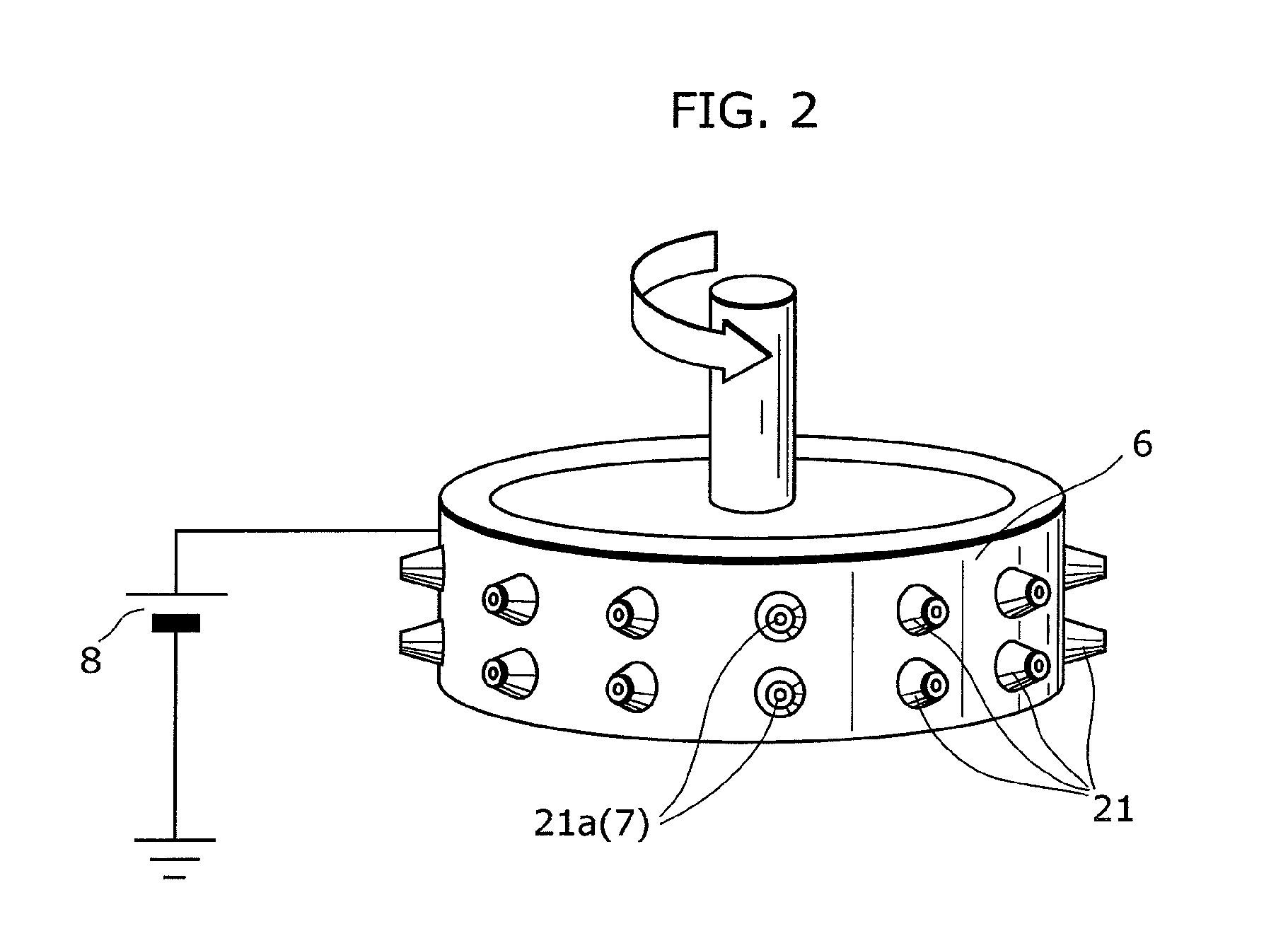

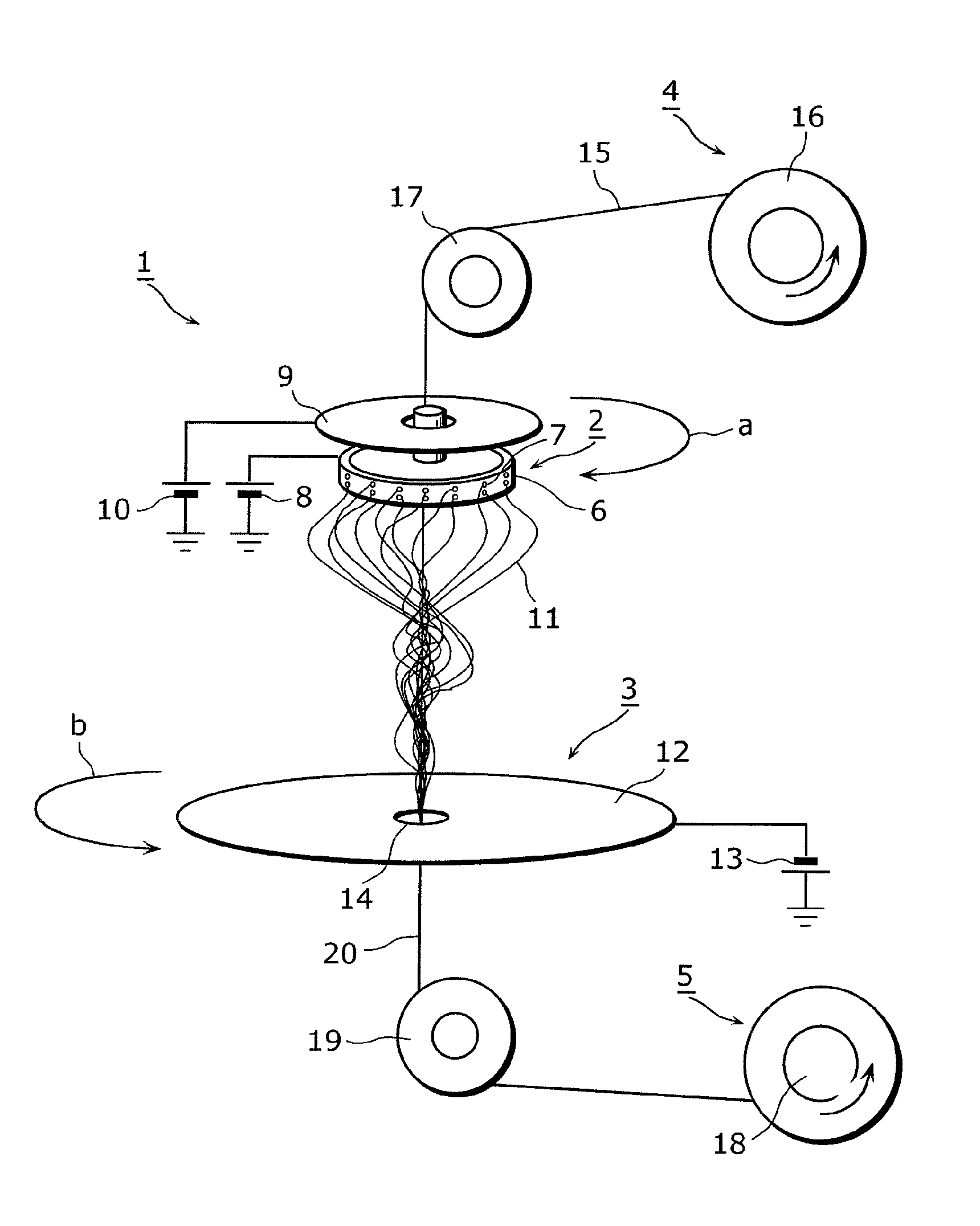

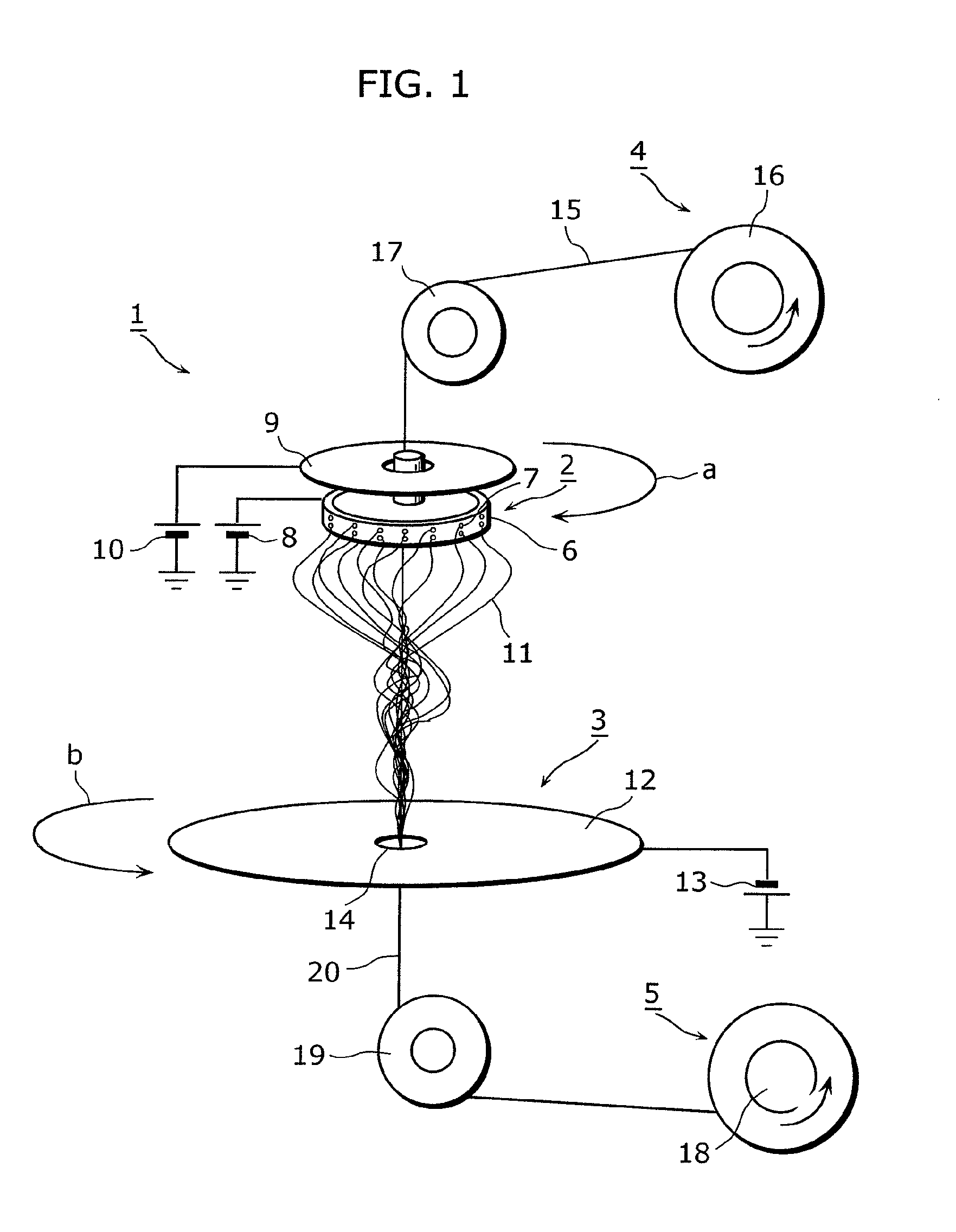

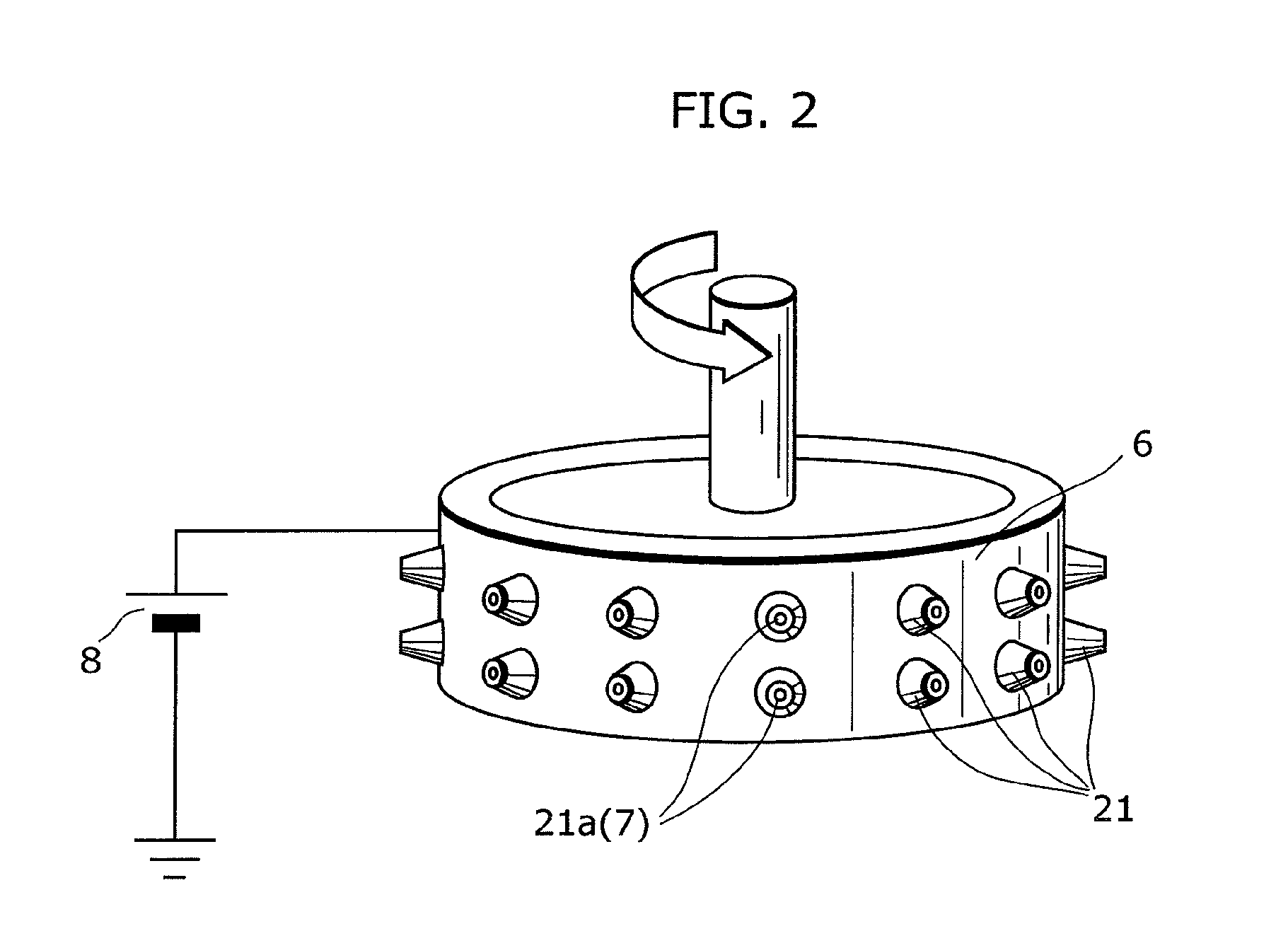

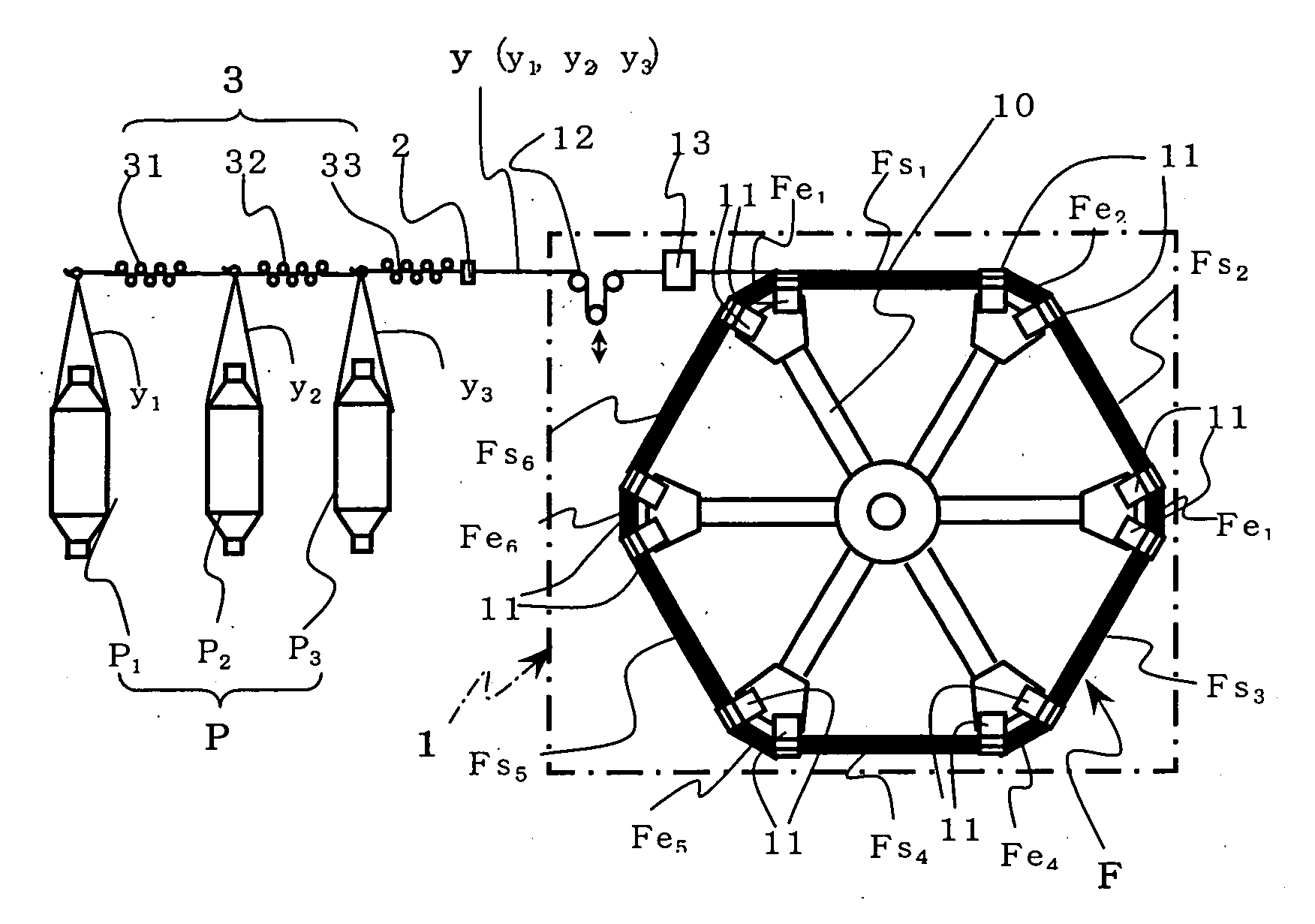

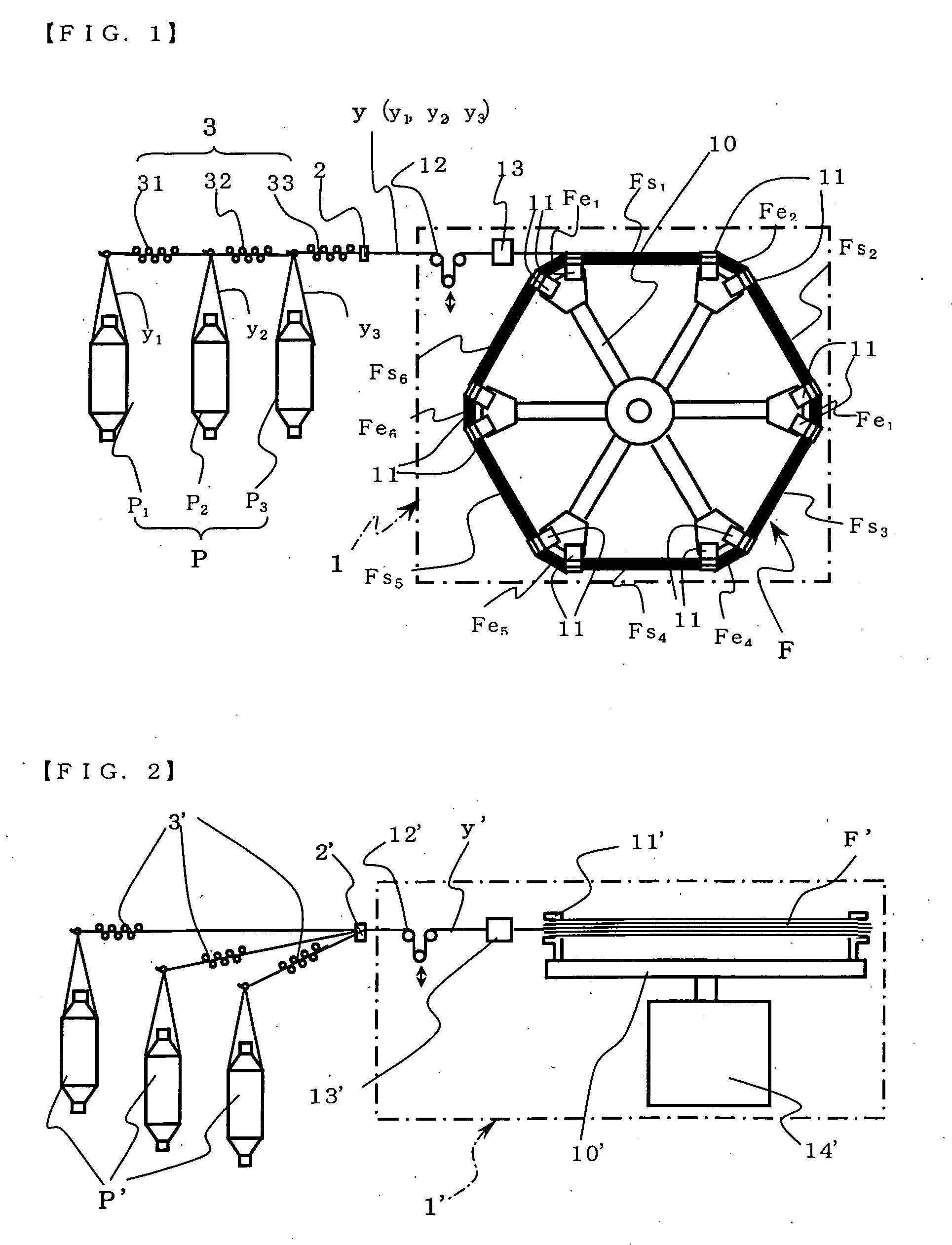

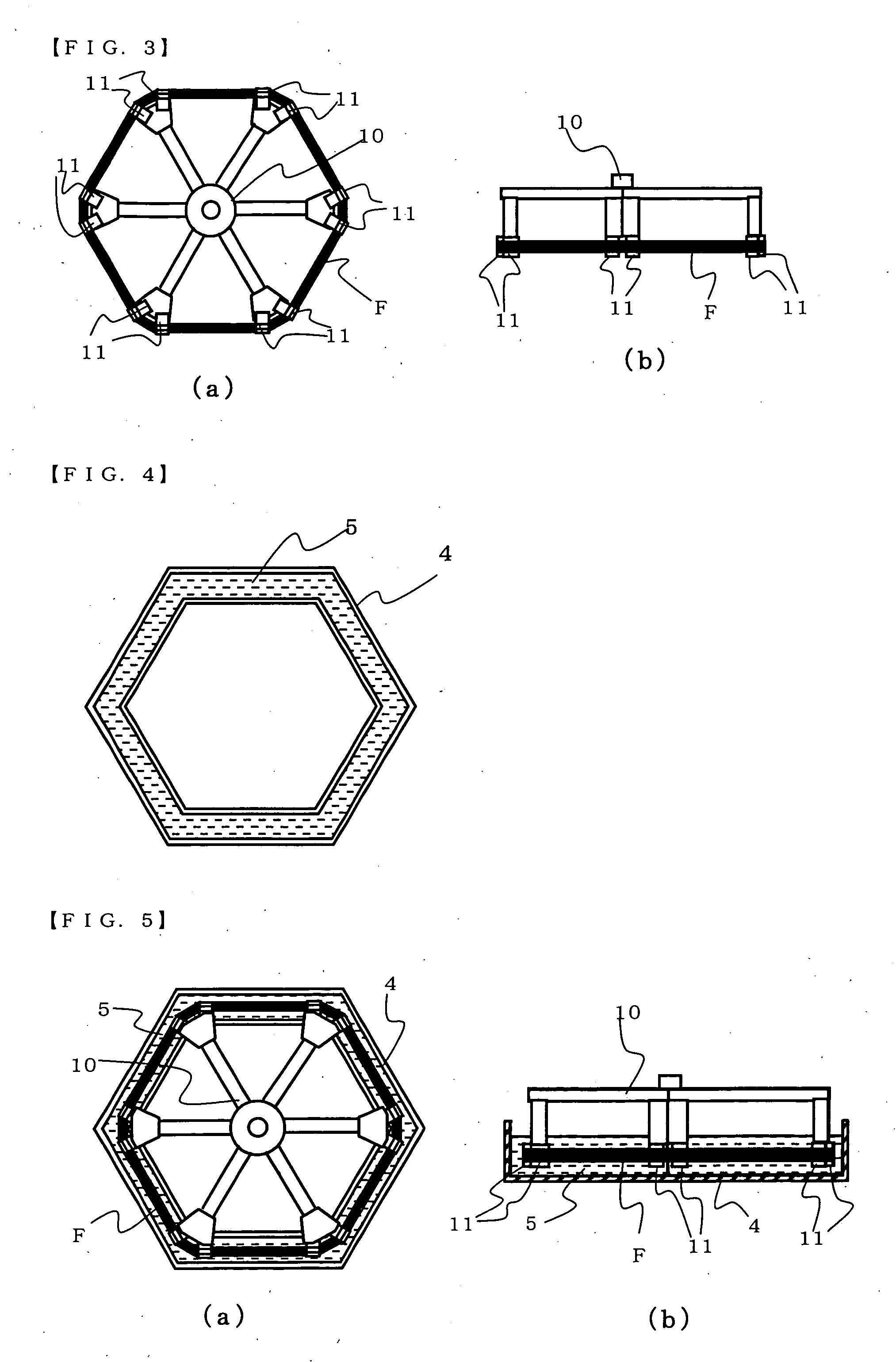

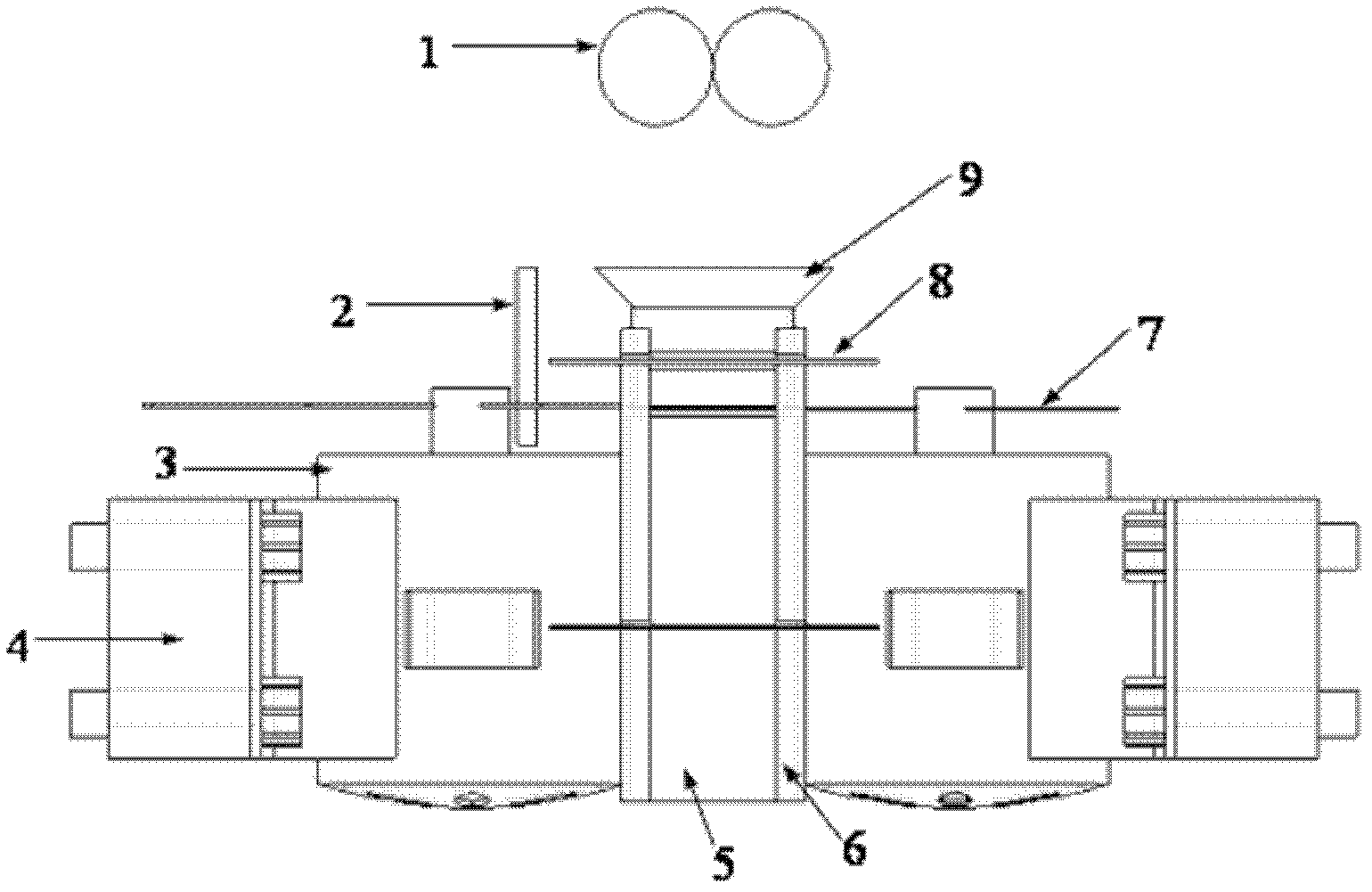

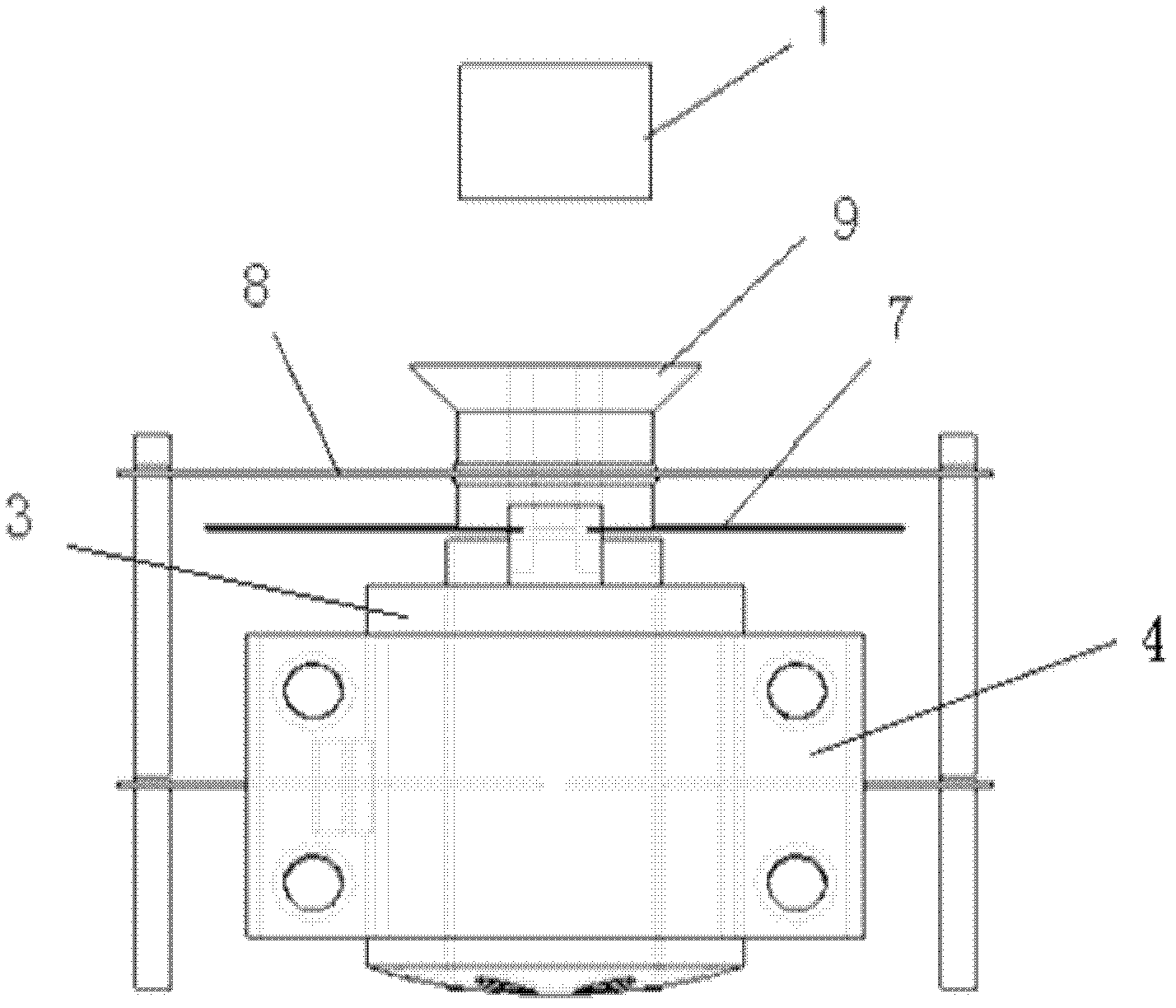

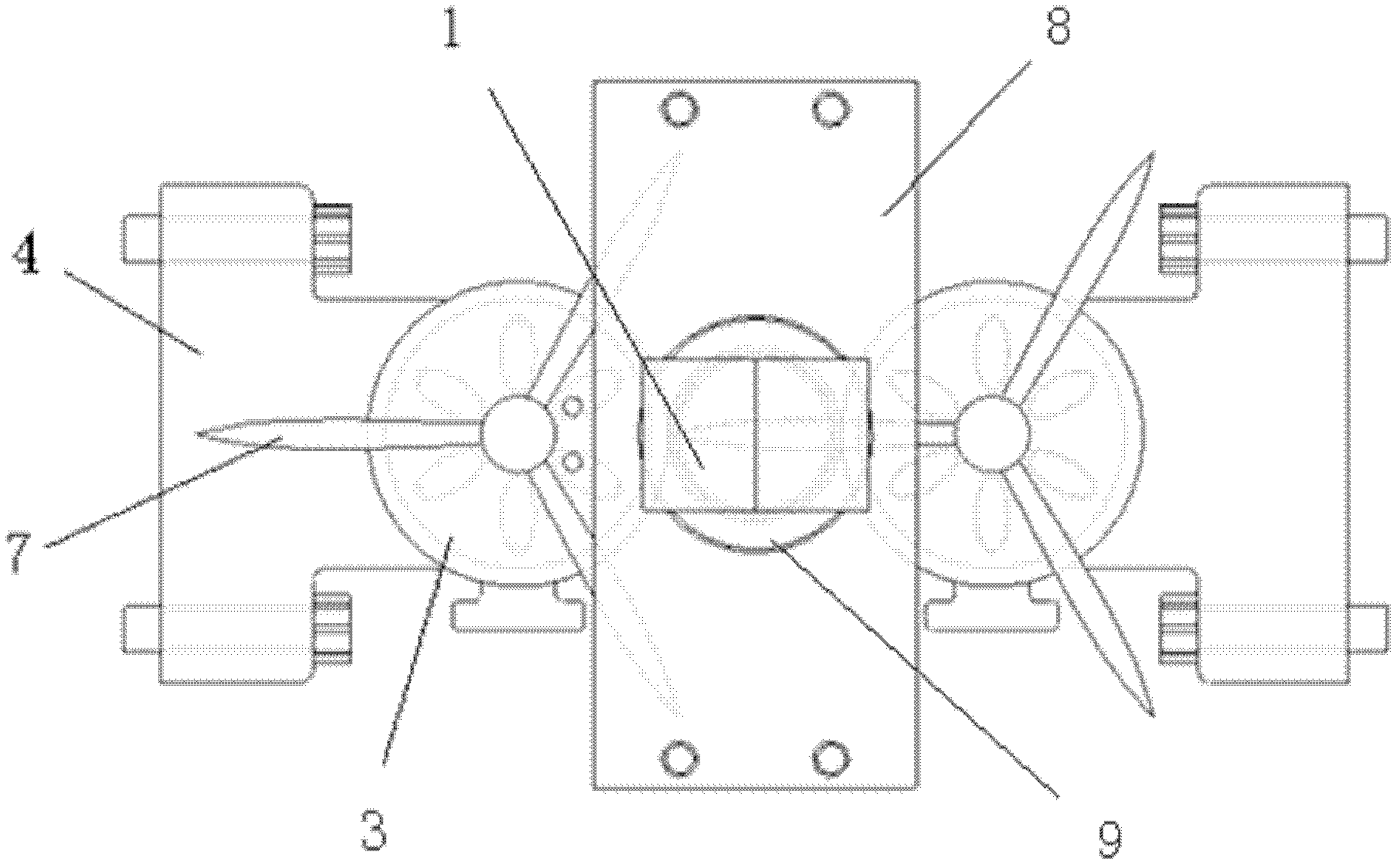

Nanofiber spinning method and device

Provided is a nanofiber spinning method and device for producing a high strength and uniform yarn made of nanofibers with high productivity and at a low cost.The device includes: a nanofiber producing unit (2) which produces nanofibers (11) by extruding polymer solution, prepared by dissolving polymeric substances in a solvent, through small holes (7) and charging the polymer solution, and by allowing the polymer solution to be stretched by an electrostatic explosion, and which allows the nanofibers to travel in a single direction; a collecting electrode unit (3) to which an electric potential different from that of the charged polymer solution is applied, and which attracts the produced nanofibers (11) while simultaneously rotating and twisting the nanofibers, and gathers them for forming a yarn (20) made of the nanofibers (11); and a collecting unit (5) which collects the yarn (20) passed through the center of the collecting electrode unit (3).

Owner:PANASONIC CORP

Cotton fiber particulate and method of manufacture

InactiveUS20070062009A1Increased uniformity in fiber lengthShorten the lengthPulp properties modificationSynthetic resin layered productsParticulatesCotton fibre

A cotton fiber particulate and method of manufacture including, generally, obtaining cotton fibers; mixing the cotton fibers with a solvent such as water to obtain a fiber furnish; milling the fiber furnish; and drying the fiber furnish to recover the cotton fiber particulate. Other steps include modifying the pH of the fiber furnish with a material such as calcium carbonate in an effort to make the fibers brittle, and filtering the fiber furnish to recover the cotton particulate. The fibers are milled to between 5-25 microns in length with a mean length of less than 50 microns with a mean length of 20 microns preferred.

Owner:SSI TECH INC

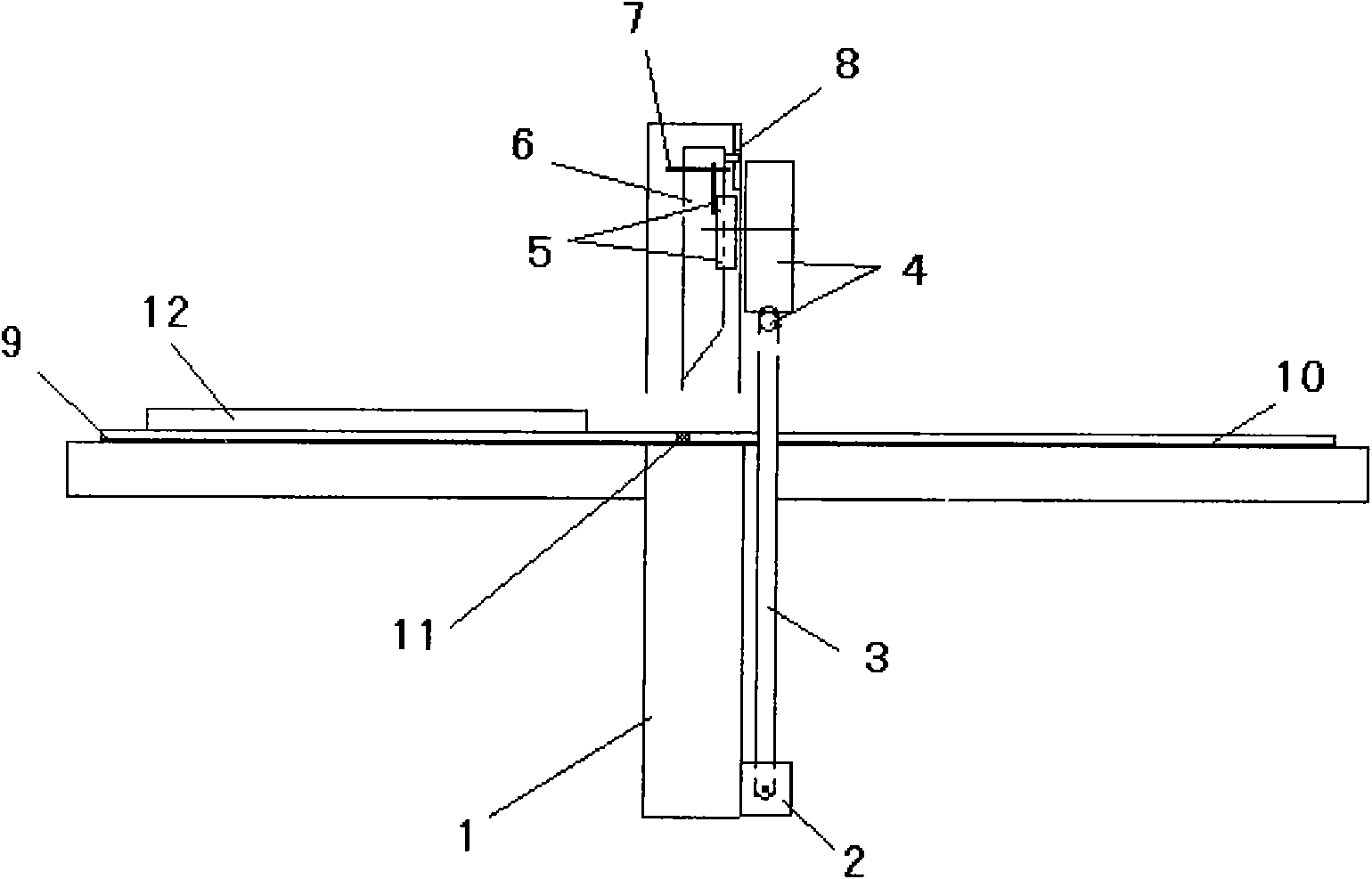

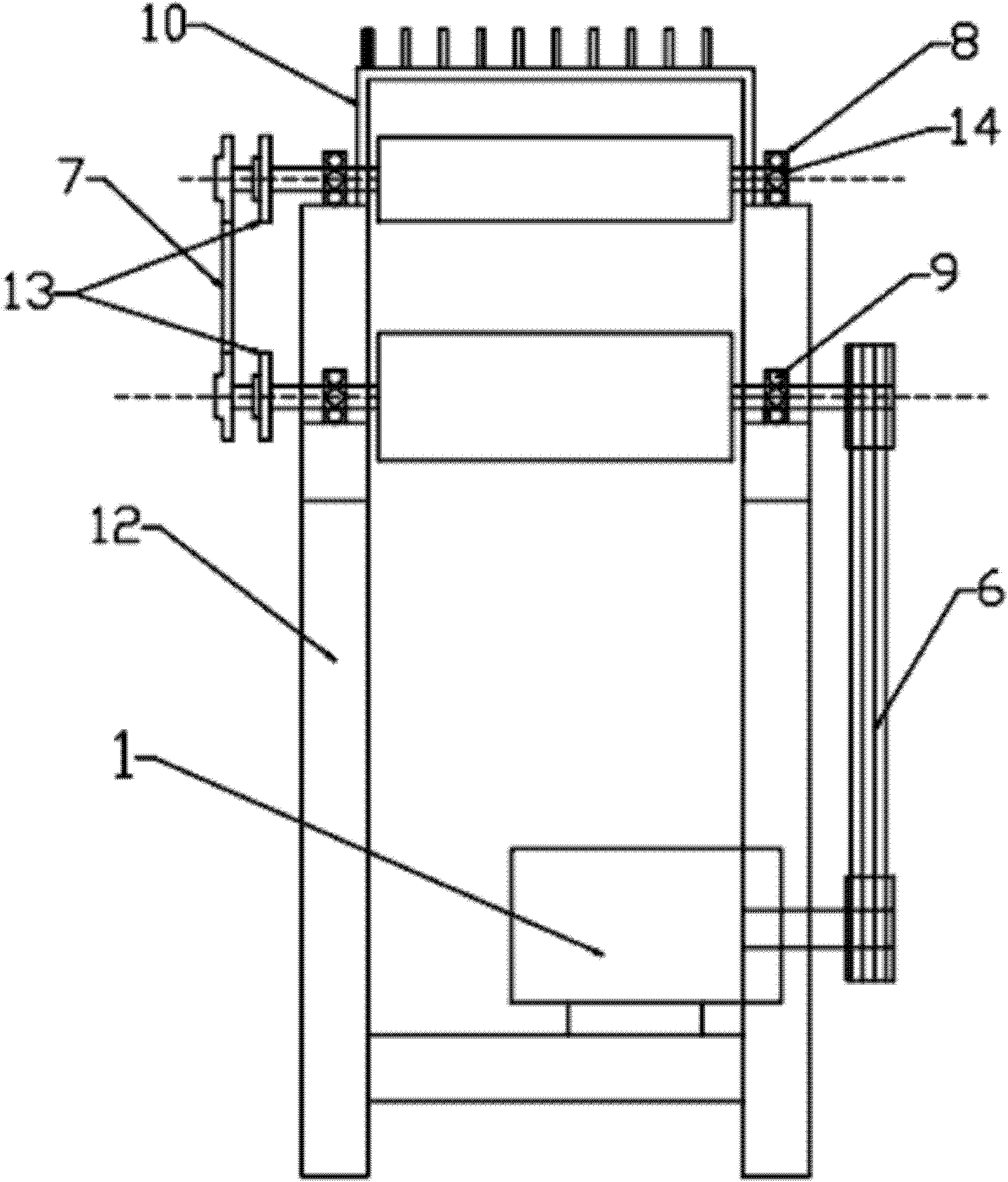

Cutting device of phloem fiber

The invention relates to a cutting device of phloem fiber, which is characterized in that the cutting device comprises a reverse U-shaped machine frame, one side of the machine frame is provided with a motor, the motor drives a group of worm and gear mechanisms through a transmission mechanism, worm wheels in the worm and gear mechanisms are coaxially connected with a crank disc of a crank connecting rod mechanism, a connecting rod is eccentricly connected on the crank disc, the other end of the connecting rod is connected with a cutter, the cutter spans between two vertical beams of the machine frame and is movably supported on the cross beam of the machine frame, the cutter is provided with a guide block and a guide groove in inclined movement correspondingly to the cross beams of the machine frame, both sides of the machine frame under the cutter are respectively provided with a material inlet support plate and a material outlet support plate, a cutter falling groove right aligned with the cutter is connected between the material inlet support plate and the material outlet support plate, and a hard pad block is arranged in the cutter falling groove. When the device provided by the invention is used for cutting the phloem fiber, the time and the labor can be saved, the cutting length required by the technology can be realized, the manual operation error can be reduced, and the production efficiency is high.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

Nanofiber spinning method and device

A nanofiber spinning method and device for producing a high strength and uniform yarn made of nanofibers. The device includes: a nanofiber producing unit (2) which produces nanofibers (11) by extruding polymer solution, prepared by dissolving polymeric substances in a solvent, through small holes (7) and charging the polymer solution, and by allowing the polymer solution to be stretched by an electrostatic explosion, and which allows the nanofibers to travel in a single direction; a collecting electrode unit (3) to which an electric potential different from that of the charged polymer solution is applied, and which attracts the produced nanofibers (11) while simultaneously rotating and twisting the nanofibers, and gathers them for forming a yarn (20) made of the nanofibers (11); and a collecting unit (5) which collects the yarn (20) passed through the center of the collecting electrode unit (3).

Owner:PANASONIC CORP

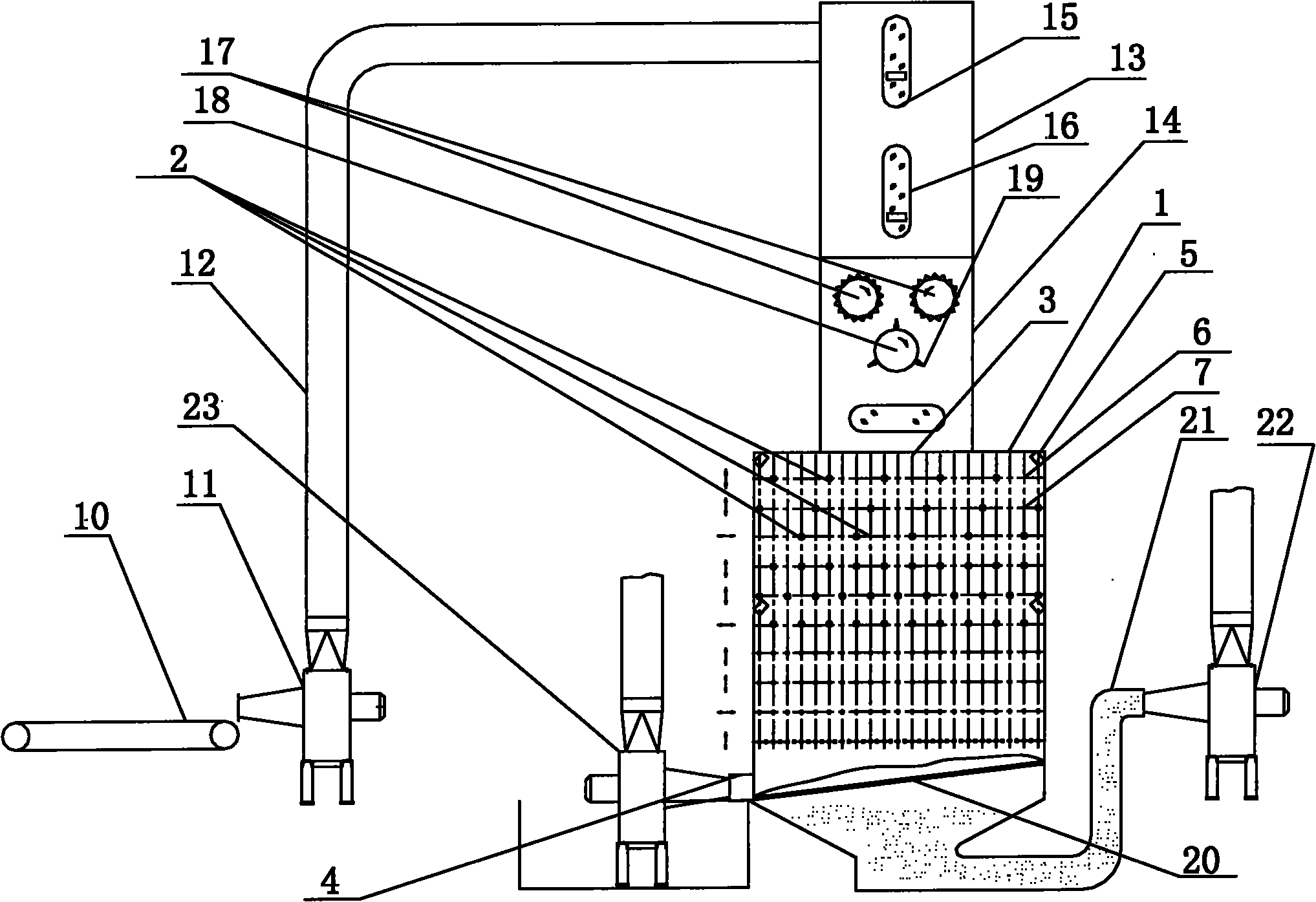

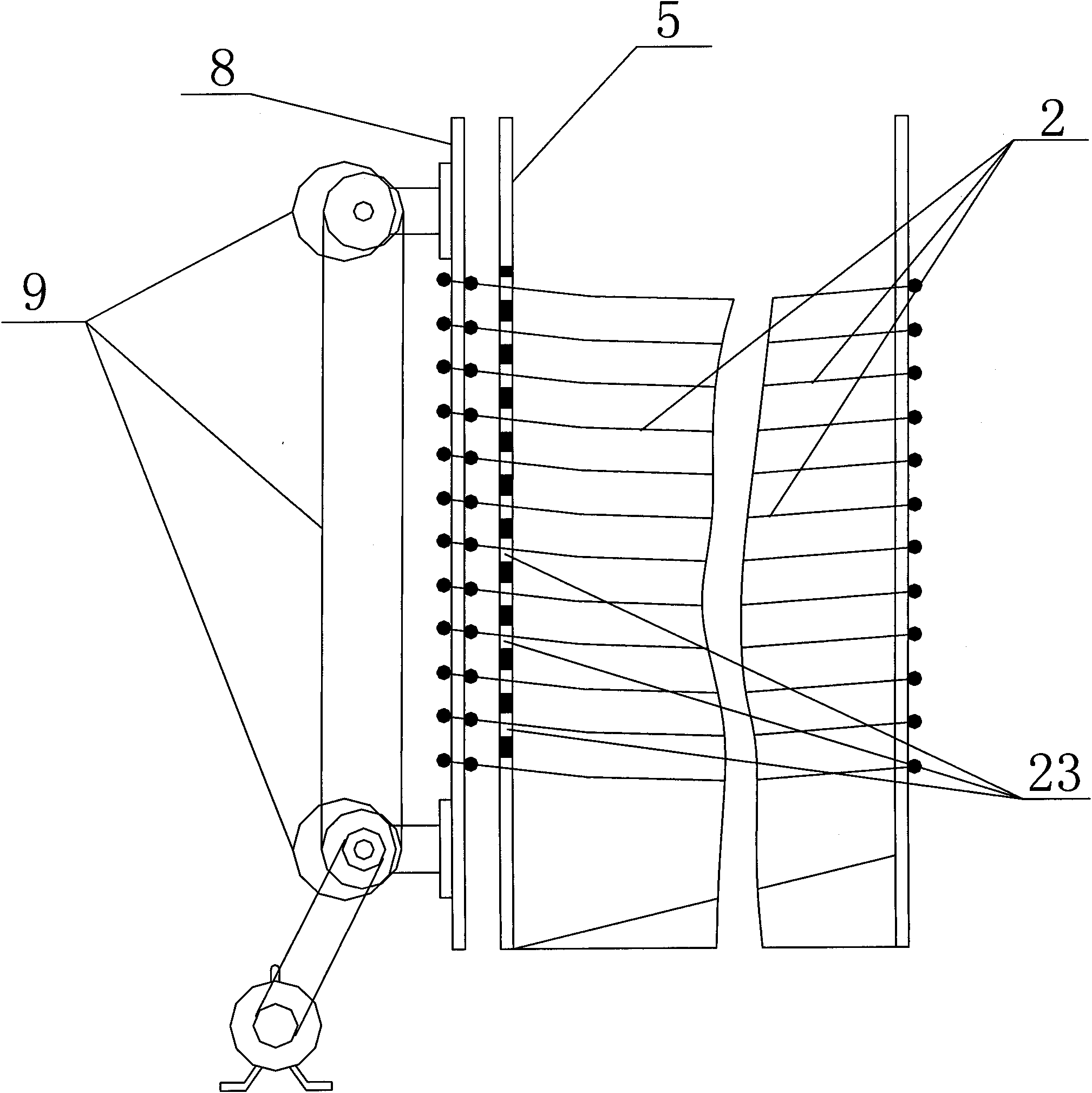

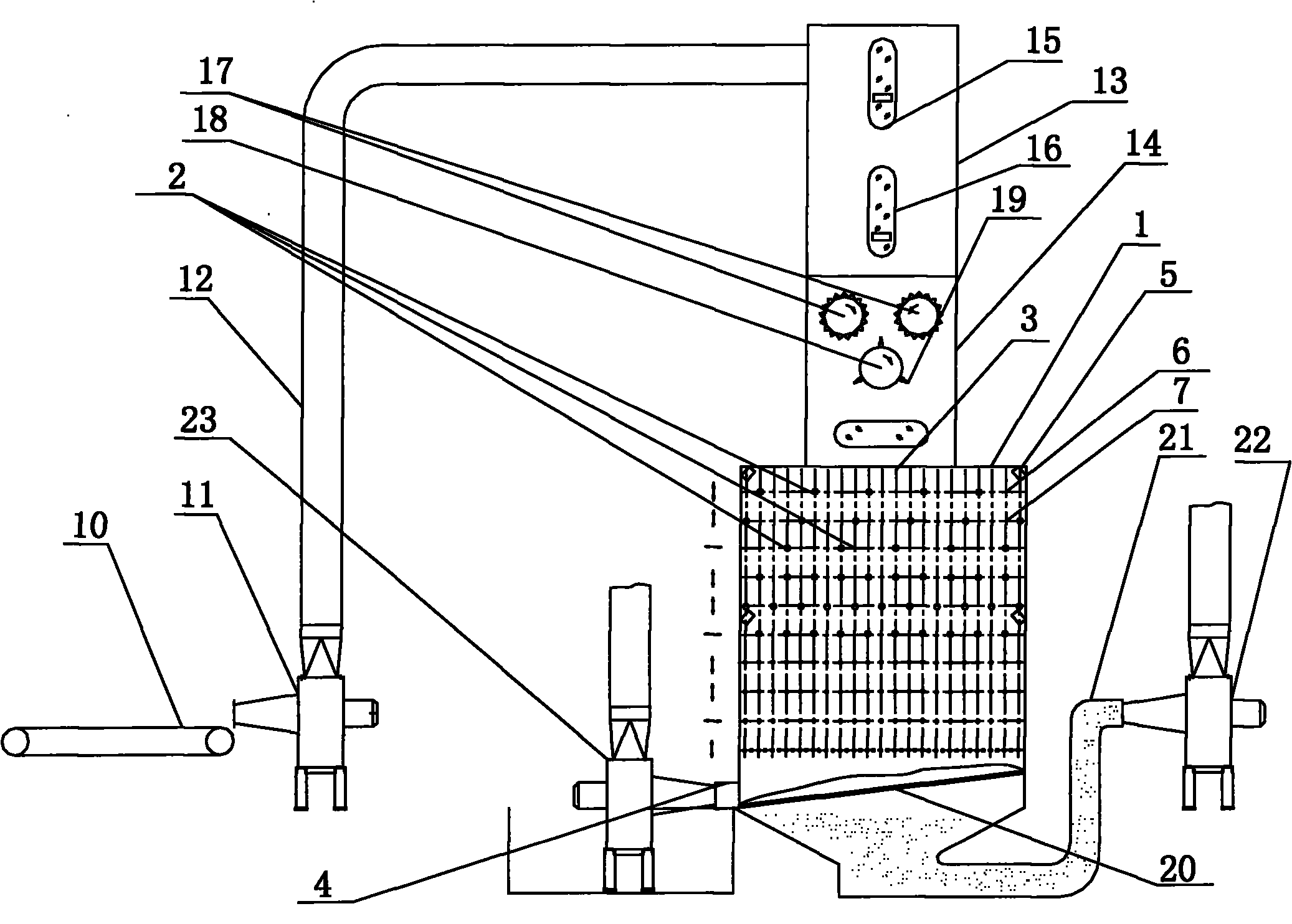

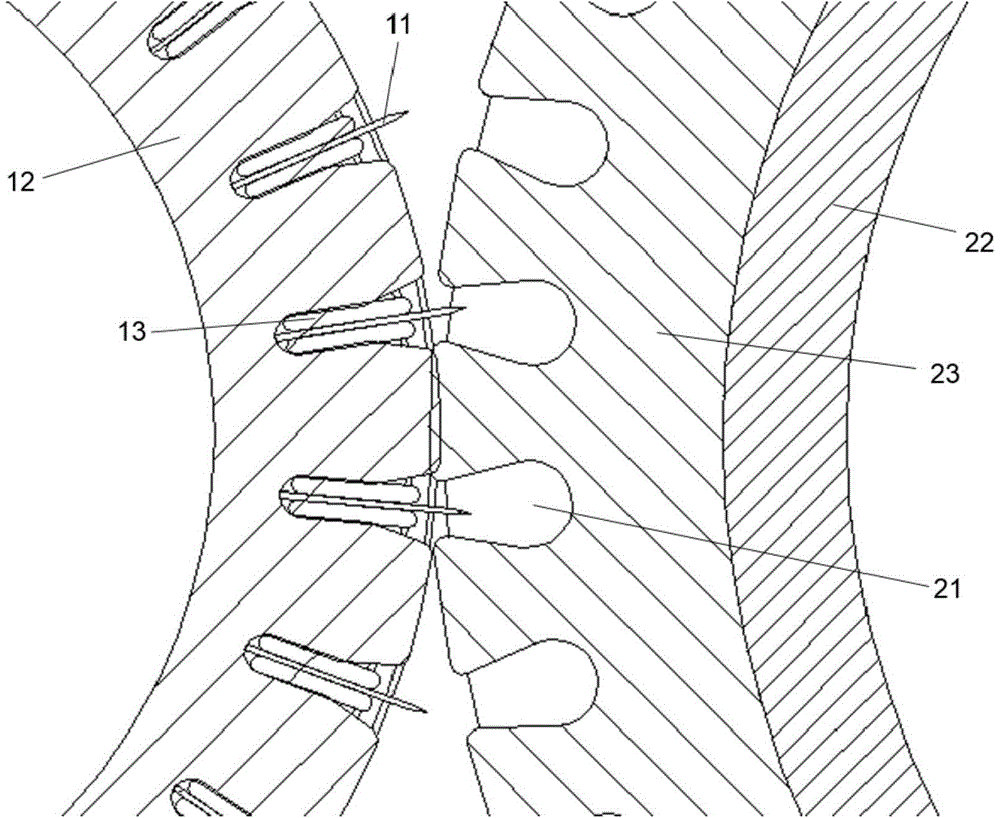

Vibration type opener

InactiveCN102181965AReduce damagePass smoothlyFibre cleaning/opening machinesSevering fibresCardingLongitudinal wave

The invention discloses a vibration type opener. The opener comprises a feeding mechanism and a vibrating opener, wherein a fiber feeding inlet is arranged at the top of the vibrating opener; a fiber outlet is arranged at the bottom of the vibrating opener; the feeding mechanism is connected with the fiber feeding inlet on the vibrating opener; a plurality of first opening layers and second opening layers are arranged in the vibrating opener; the first opening layers and the second opening layers are alternately arranged from top to bottom; each first opening layer is formed by a plurality ofsilk threads which can synchronously act similar to longitudinal wave amplitude shaped vibration and can be pulled up transversely; and each second opening layer is formed by a plurality of silk threads which can synchronously act similar to transverse wave amplitude shaped vibration and can be pulled up transversely. The opener has the following beneficial effects: the first opening layers and the second opening layers are arranged in the vibrating opener, thus changing the traditional card wire pin roller type opening or sawtooth clothing carding type opening and farthest reducing the degree of damage on the fibers in the fiber opening process; and when passing through the first opening layers and the second opening layers, the fibers are elastically hit by the silk threads repeatedly, thus fully opening the fibers.

Owner:青岛东佳纺机(集团)有限公司

Fluorochemical-containing textile finishes that exhibit wash-durable soil release and moisture wicking properties

Wash-durable fluorochemical-containing textile and / or fiber treatments that simultaneously impart soil resistance (or soil-release) properties and moisture wicking characteristics to target fabric substrates are provided. Such treatments surprisingly impart these two simultaneous effects to target fabrics and / or fibers because fluorochemicals generally provide moisture repellency rather than moisture wicking capabilities. As prior soil release / moisture wicking treatments do not function properly, or, alternatively, compromise hand or other properties of certain target textiles after treatment application, a new, effective, soil release / moisture wicking formulation for such purposes was needed. The inventive treatment is extremely durable on such fabric substrates; after a substantial number of standard launderings and dryings, the treatment does not wear away in any appreciable amount and thus the substrate retains its soil release / moisture wicking properties. The method of adherence to the target yarn, fiber, and / or fabric may be performed any number of ways, most preferably through the utilization of a jet dyeing system or through a steam-transfer method. The particular methods of adherence, as well as the treated textile fabrics and individual fibers are also encompassed within this invention.

Owner:MILLIKEN & CO

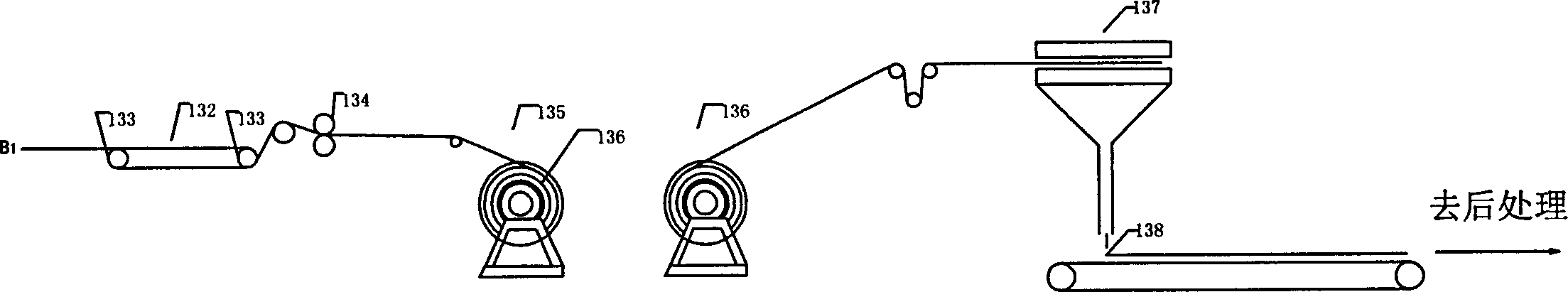

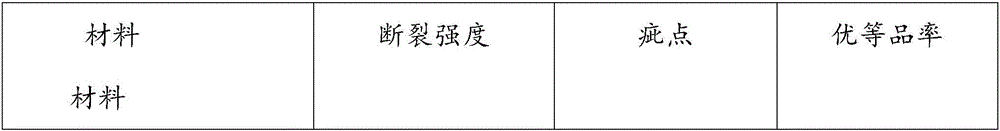

Velveteen regeneration polyester super-short fiber and production technique thereof

InactiveCN102605447AQuality assuranceLow costNew-spun product collectionFilament/thread formingPolyesterDrum drying

The invention discloses velveteen regeneration polyester super-short fiber and production technique thereof. The velveteen regeneration polyester super-short fiber is prepared from regenerative PET materials by raw material pre-treatment, rotary drum drying, melt spinning, cooling forming, wire placing barrel falling after winding, bundling, drafting, curling, oiling, heat setting and cutting to obtain the product fiber. According to the production technique of the invention, the velveteen regeneration polyester super-short fiber can save cost, protect environment and further ensure the product quality and further prevent the super-long and over-length fibers from being generated in the production process; the cut length of the obtained product is uniform and precise and controlled within 3 to 12mm and the product has the similar appearance and hand feel similar to the down. The velveteen regeneration polyester super-short fiber has smooth hand feel and ideal down filling effect; the suitable fiber length of the velveteen regeneration polyester super-short fiber is convenient for the downstream producers to realize the fully-automatic filling, improve the production efficiency and have higher cost performance in compared with the super-short fiber spun by the raw material.

Owner:HANGZHOU BEST CHEM FIBER

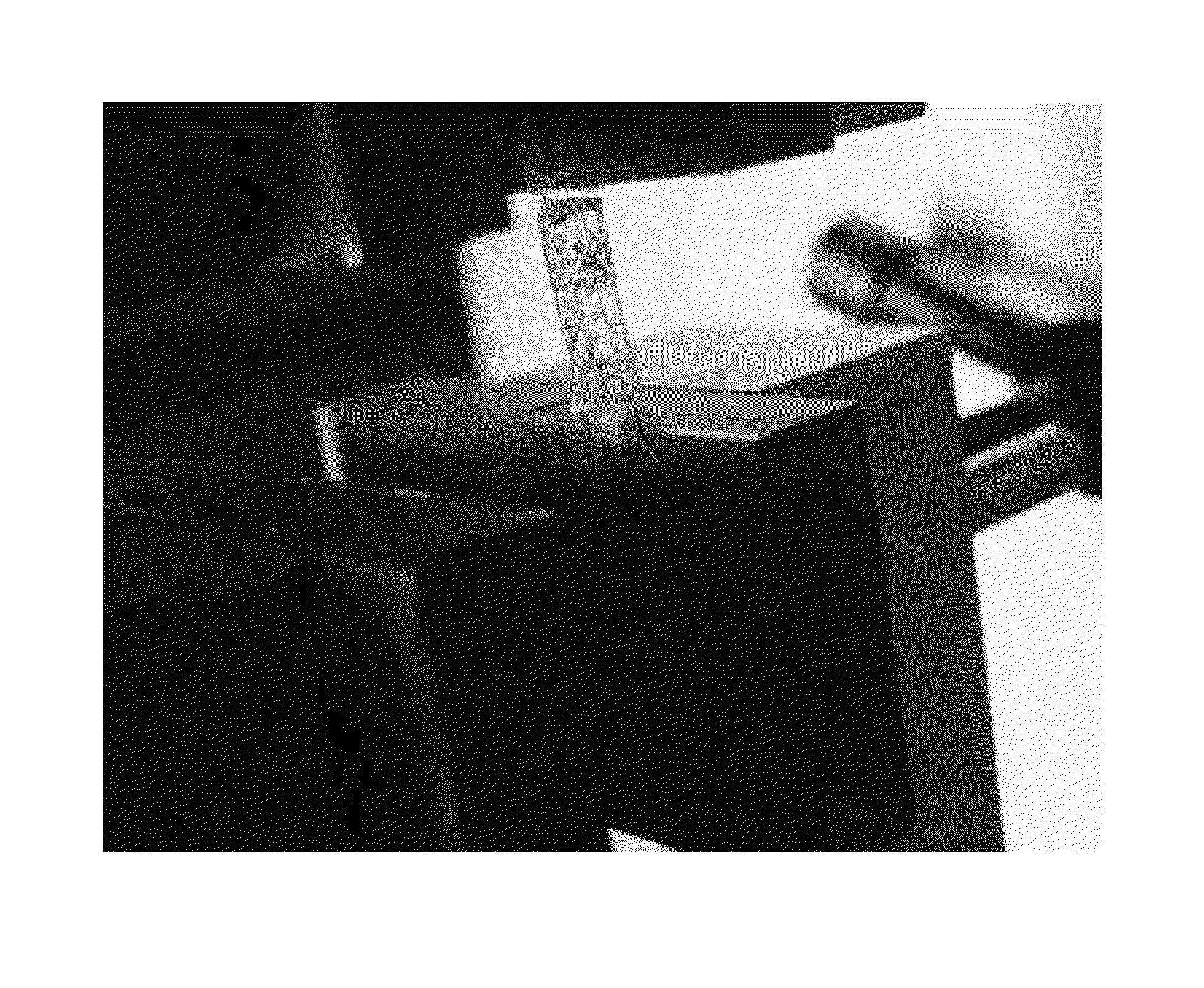

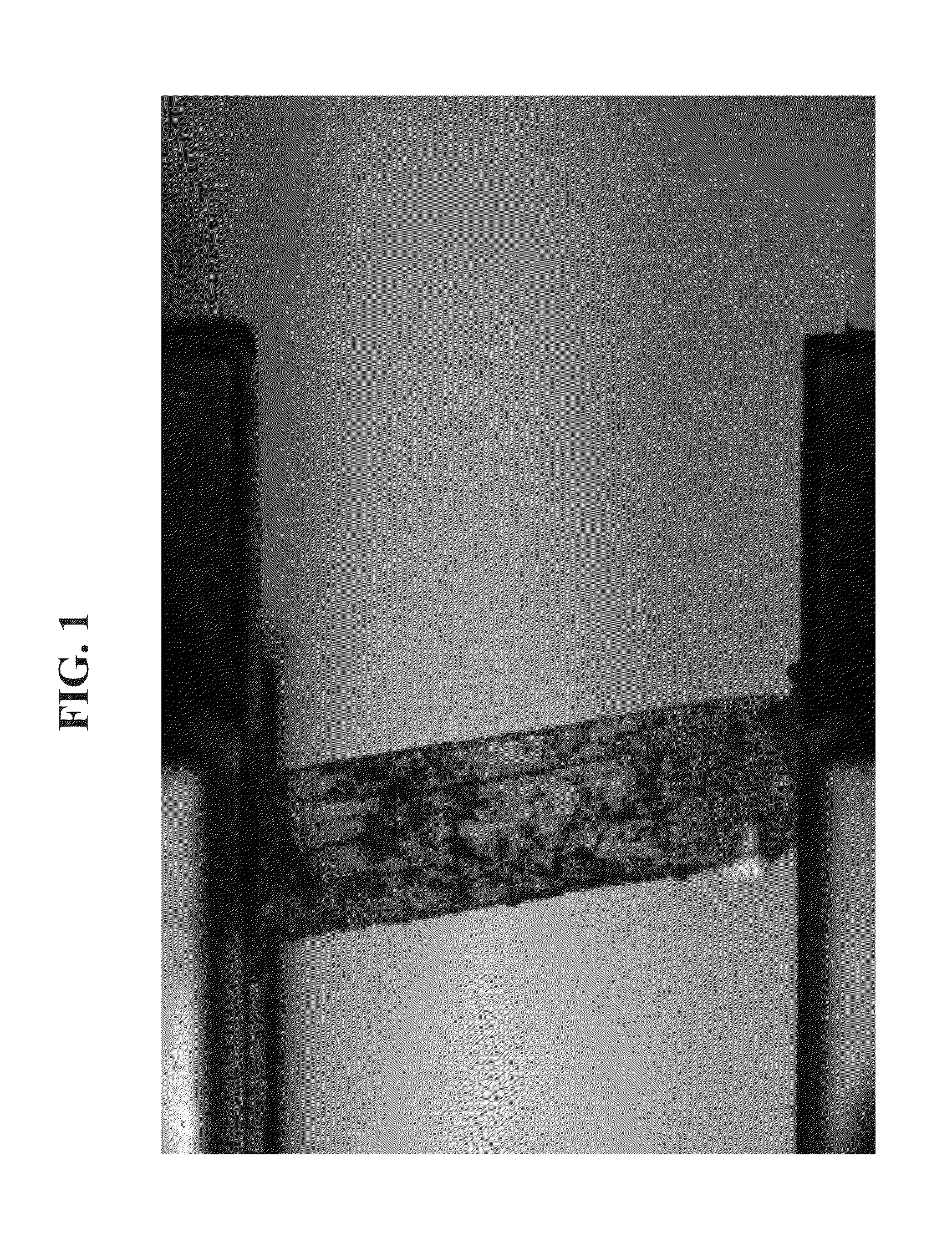

Method and device for manufacturing extremely short fiber

InactiveUS20060225252A1Stable productionMinimizing miscuttingSevering fibresFiber bundleMaterials science

It is an object to provide a process and an apparatus which allow stable production of ultrashort-cut fibers having fiber lengths of no greater than 0.1 mm while minimizing miscutting, the object being achieved by a process and apparatus whereby numerous individual filament groups are bound to form a fiber bundle, an embedding material which is solidified by cooling and gasified or liquefied by heating is gasified or liquefied, the fiber bundle is embedded with the gasified or liquefied embedding material, and the edge of the embedded fiber bundle is thinly shaved at a temperature at which the embedding material does not gasify or liquefy, to obtain ultrashort-cut fibers having cut fiber lengths of no greater than 1.0 mm.

Owner:TEJIN FIBERS LTD

Polytetrafluoroethylene fiber with antistatic function of and preparation method thereof

InactiveCN101985783AEasy to combReduce wasteElectroconductive/antistatic filament manufactureFilament/thread formingCarbon fibersNano carbon

The invention discloses a modified polytetrafluoroethylene fiber and a preparation method thereof, in particular to a polytetrafluoroethylene fiber with an antistatic function and a preparation method thereof. The fiber comprises the following components by weight percent: 98.5-99.5% of polytetrafluoroethylene and 0.5-1.5% of nano carbon fiber powder. The preparation method of the fiber comprises the following steps of preparation, blending, oil addition, compaction, extruding, rolling, sintering, drafting, splitting, carding, winding, curling, sizing and chopping so as to obtain a chopped fiber. The invention has the beneficial effects that as long as the polytetrafluoroethylene fiber with an antistatic function contacts with an escaping approach, the charge generated by the fiber can be released in time, thereby enabling the fiber to have no static electricity charges or reduce the static electricity charge quantity. In the preparation method in the invention, because the nano carbon fiber is added, the mesh interspace among the polytetrafluoroethylene molecules is filled, the fiber strength is improved, and the physics plastic deformation property of the polytetrafluoroethylene is effectively improved, thereby enabling the fiber to have creep resistance. The finished product obtained by the method is the fiber with the functions of anti-static electricity, creep resistance and high strength; and the self-deashing capability of the polytetrafluoroethylene is improved by adding the nano carbon fiber powder in the method.

Owner:山东嘉年华氟纶有限公司

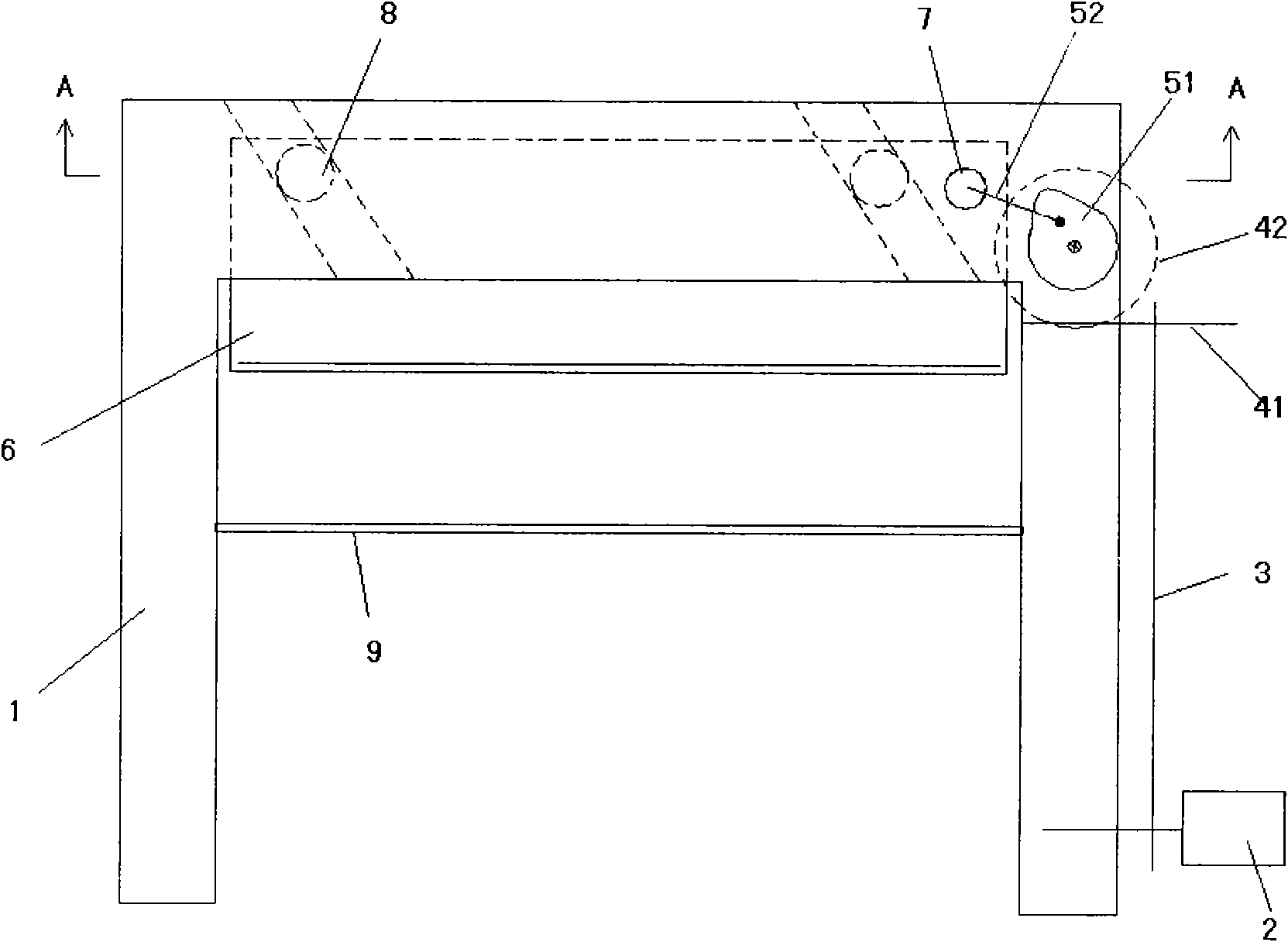

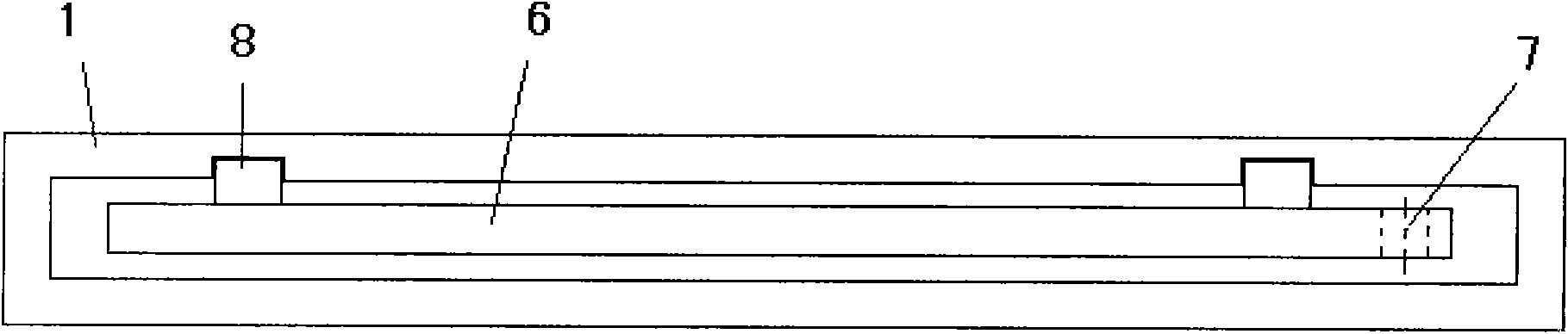

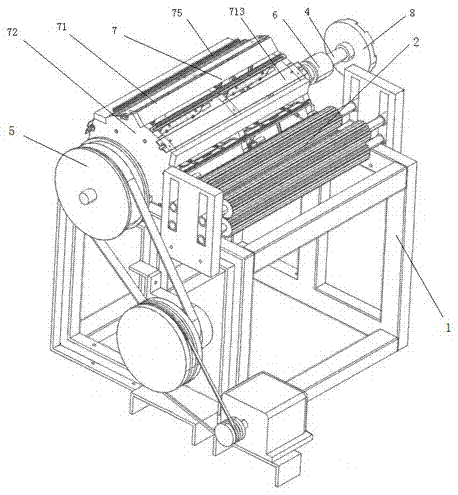

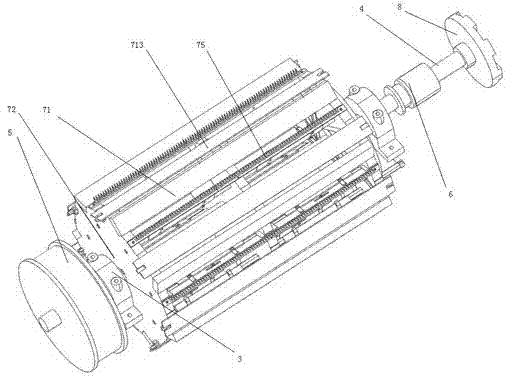

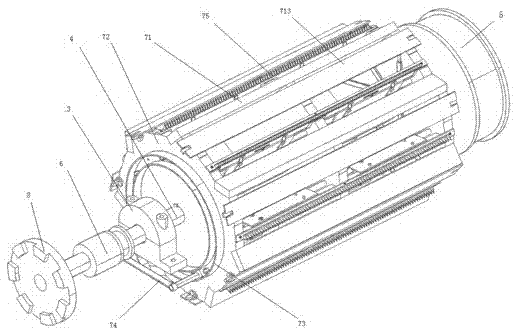

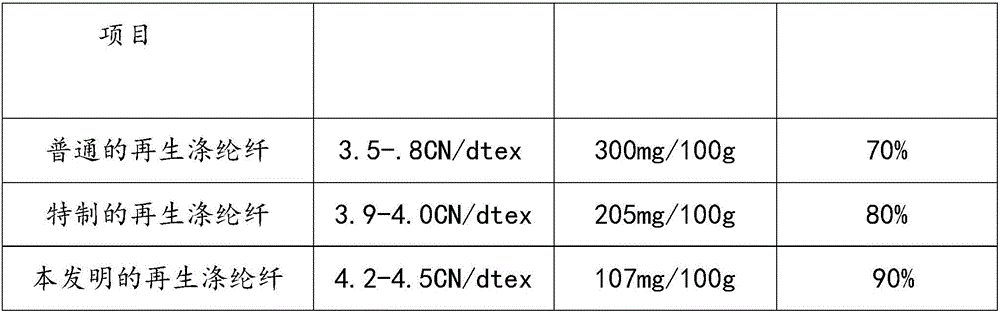

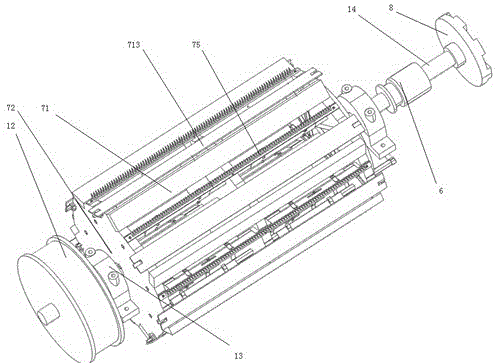

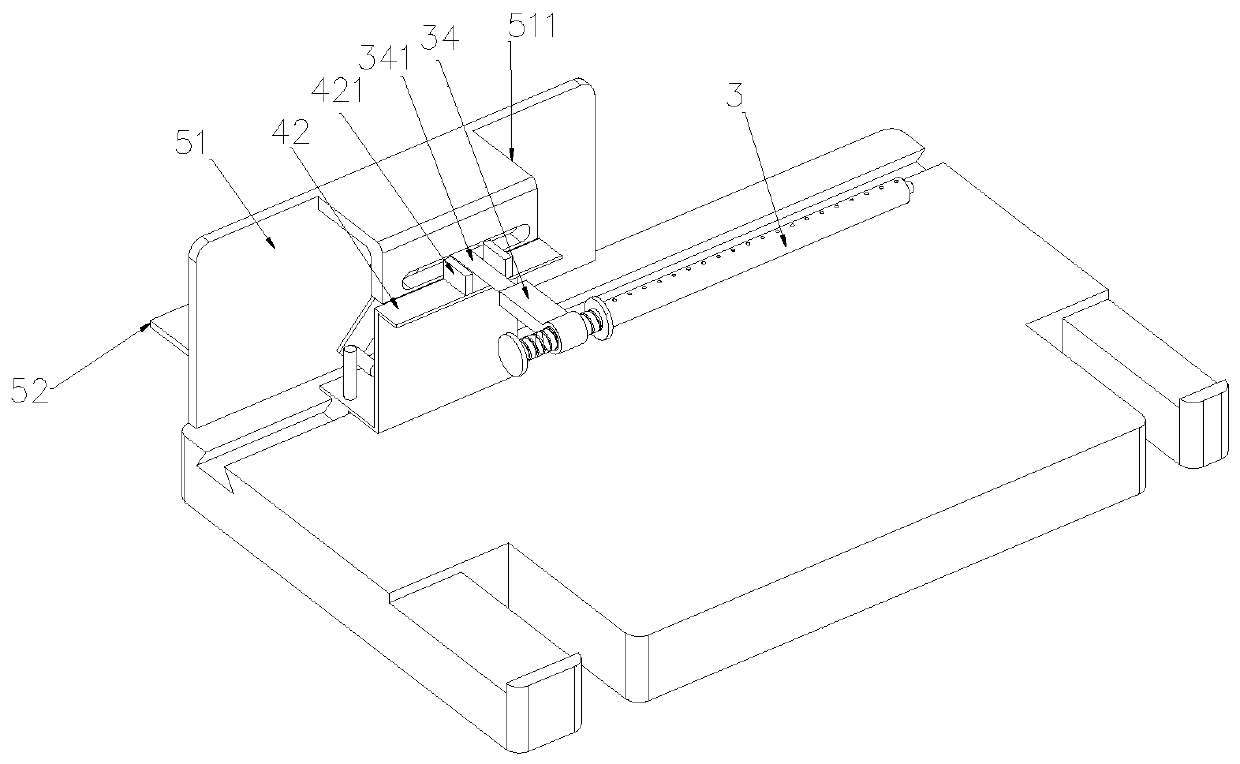

Cotton cutting drum for full-automatic cotton cutting machine

ActiveCN105442101AAvoid situations where it is impossible to cut allFully automatic cotton cuttingSevering fibresElectromagnetic clutchEngineering

The invention relates to a cotton cutting drum for a full-automatic cotton cutting machine. A cotton cutting drum body is arranged behind a roller of a cotton cutting machine body, the cotton cutting drum is fixed between two drum fixing stands of the cotton cutting machine body through rotating shafts at the two ends, a transmission wheel is arranged at the end, close to a rotating shaft on one side of an electromagnetic clutch of the cotton cutting machine, of the cotton cutting drum body, the transmission wheel and a shaft of the electromagnetic clutch are sleeved with a belt, a clutch is arranged at the end, on the other side of the cotton cutting drum body, of a connecting shaft, a side clutch is located on one side of the clutch, the cotton cutting drum body comprises at least six fallers, three drum blades, at least six cutter mechanisms, a cotton cutting sliding block and at least six cotton drawing devices, and each faller corresponds to one cutter mechanism and one cotton drawing device. The cotton cutting drum for the full-automatic cotton cutting machine is redesigned, the automation strength of whole cotton cutting operation can be greatly improved when the cotton cutting drum is used in cooperation with the corresponding cotton cutting machine, and thus the purpose of reducing labor can be achieved.

Owner:JINLING INST OF TECH

Composites comprising collagen extracted from sarcophyton sp. coral

Isolated composites are disclosed comprising collagen fibers isolated from a Sarcophyton sp. coral. An exemplary composite comprises as a first component a bundle of collagen fibers, the collagen fibers being isolated from a Sarcophyton sp. coral, and a second component selected from the group consisting of a polysaccharide, a polypeptide, polylipid, a synthetic polymer, a metal and a mineral, wherein the bundle of collagen fibers comprise woven fibers, twisted fibers, braided fibers, knitted fibers, tied fibers, or sutured fibers. Uses thereof and method of generating are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

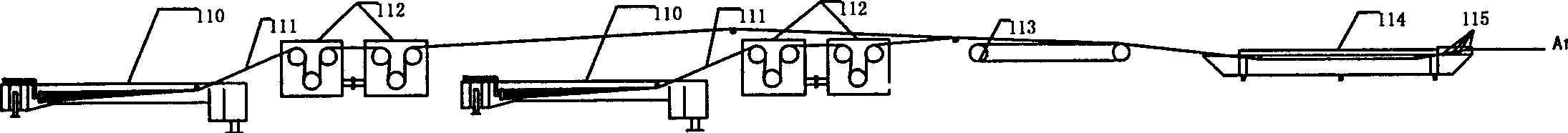

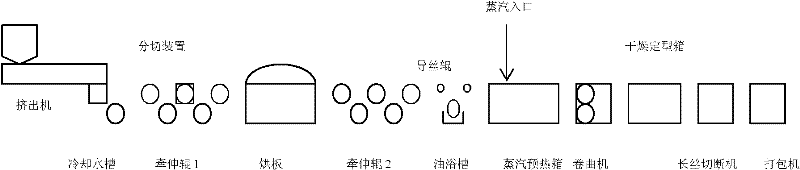

Process and apparatus for manufacturing vinylon filament

ActiveCN1804156AIncrease profitReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsFiberYarn

The related preparation method for vinylon filament comprises: spinning the dope polyvinyl alcohol by a large-capacity spinning machine into multi-sheet large-fold primary tow; drafting with guide roller, hot-wet drafting, dry-hot drafting, tension thermal treating, shrinking, cooling, folding, winding and obtaining the vinylon filament; finally, cutting into staple fiber. This invention can treat one or more yarns, has large productivity with low cost, and fit to build the 3000-5000ton large-capacity vinylon spinning product line or technical innovation.

Owner:SINOPEC SICHUAN VINYLON FACTORY

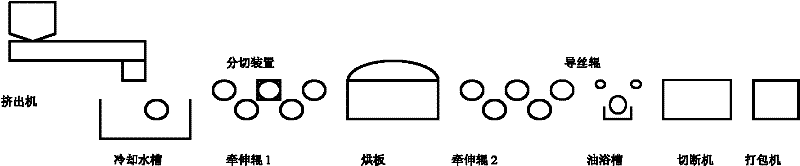

Method for producing colored short fibers by using regenerated polylactic acid slices

InactiveCN106868626ALow costPromote environmental protectionMelt spinning methodsFilament-forming treatmentLinear densityHeat setting

The invention relates to a method for producing colored short fibers by using regenerated polylactic acid slices. A regenerated PLA material is used as a raw material. The method comprises the following specific production steps of: (1) pretreatment; (2) rotary drum drying; (3) melt spinning; (4) cooling molding; (5) winding; (6) drafting; (7) curling; (8) curling; (9) heat setting; and (10) cutting off. The method of the invention has the advantages that the regenerated PLA material is used as the raw material, the cost is reduced, the environmental protection is favorable, the finished product has low linear density, feels smooth, and has bright and uniform color, and high color fastness. The characteristics of polylactic acid short fiber are kept, the damage of post-dyeing to the polylactic acid short fiber property is also avoided, the pollution of dyeing to the environment is reduced, and the method is extremely beneficial to a spinning material and environmental protection.

Owner:HENAN LONGDU BIOLOGY TECH

Method for producing incombustible acrylic yarn and incombustible acrylic yarn manufactured by method

InactiveCN101545164AImprove spinnabilityMonocomponent synthetic polymer artificial filamentYarnYarnCarbon fibers

The invention relates to a method for producing an incombustible acrylic yarn and the incombustible acrylic yarn manufactured by the method and also relates to a middle product in the process of producing the incombustible acrylic yarn, wherein the middle product is incombustible spinnable acrylic fibre, incombustible spinnable acrylic carbon fibre and incombustible carded sliver. The method for producing the incombustible acrylic yarn comprises the following steps: preoxidation: polyacrylonitrile protofilament is preoxidated in a phased heating mode; the temperature difference between the phases is between 1 and 5 DEG C; carbonization: the carbonization temperature is between 300 and 1,000 DEG C; the manufacture of the carded silver by a precutting method: the incombustible spinnable acrylic fibre or the incombustible spinnable acrylic carbon fibre is precut to form a plurality of precutting points so as to form the carded silver; and manufacturing the incombustible carded silver into the incombustible acrylic yarns.

Owner:孙致明

Fluorochemical-containing textile finishes that exhibit wash-durable soil release and moisture wicking properties

Wash-durable fluorochemical-containing textile and / or fiber treatments that simultaneously impart soil resistance (or soil-release) properties and moisture wicking characteristics to target fabric substrates are provided. Such treatments surprisingly impart these two simultaneous effects to target fabrics and / or fibers because fluorochemicals generally provide moisture repellency rather than moisture wicking capabilities. As prior soil release / moisture wicking treatments do not function properly, or, alternatively, compromise hand or other properties of certain target textiles after treatment application, a new, effective, soil release / moisture wicking formulation for such purposes was needed. The inventive treatment is extremely durable on such fabric substrates; after a substantial number of standard launderings and dryings, the treatment does not wear away in any appreciable amount and thus the substrate retains its soil release / moisture wicking properties. The method of adherence to the target yarn, fiber, and / or fabric may be performed any number of ways, most preferably through the utilization of a jet dyeing system or through a steam-transfer method. The particular methods of adherence, as well as the treated textile fabrics and individual fibers are also encompassed within this invention.

Owner:MILLIKEN & CO

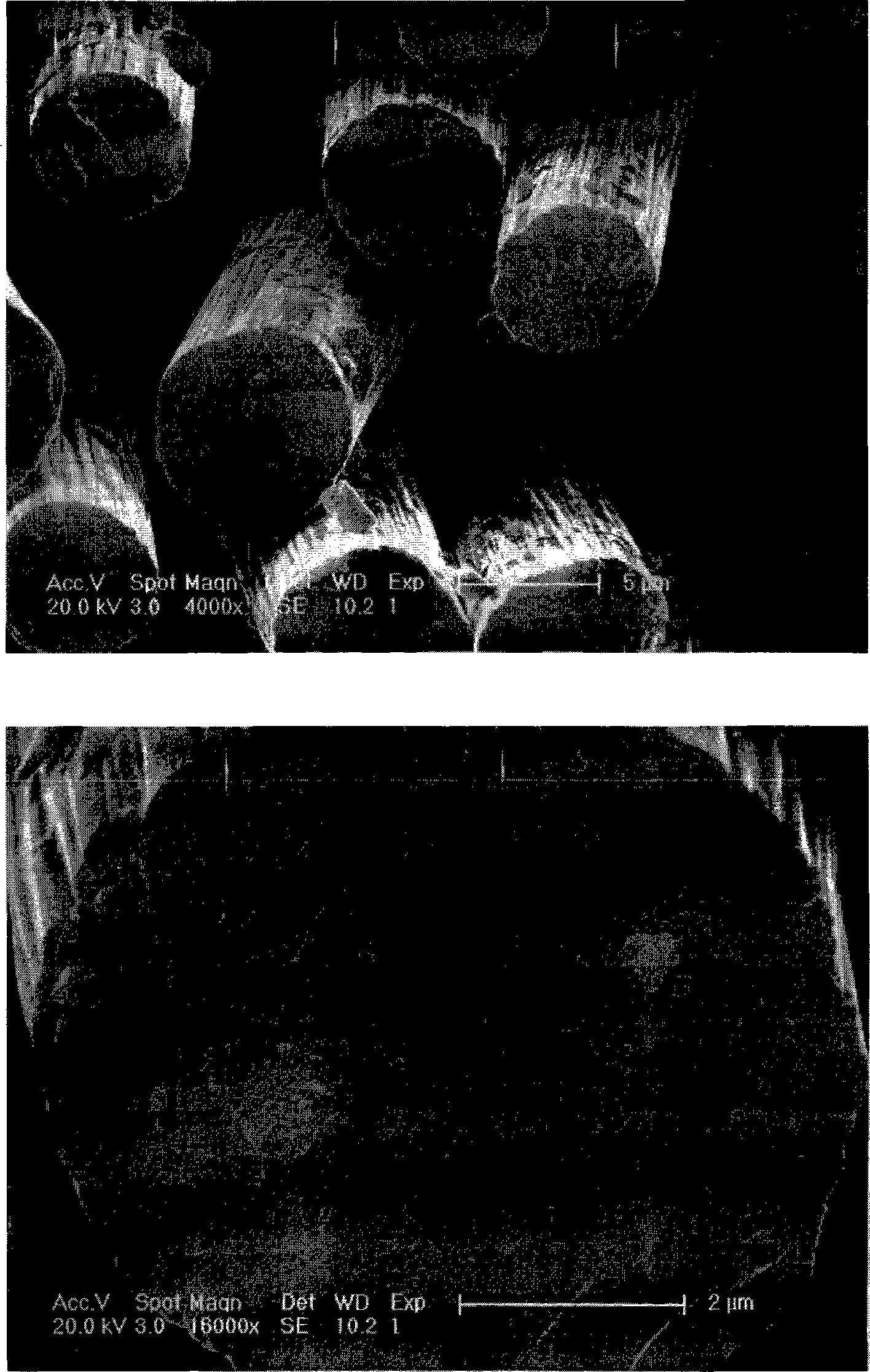

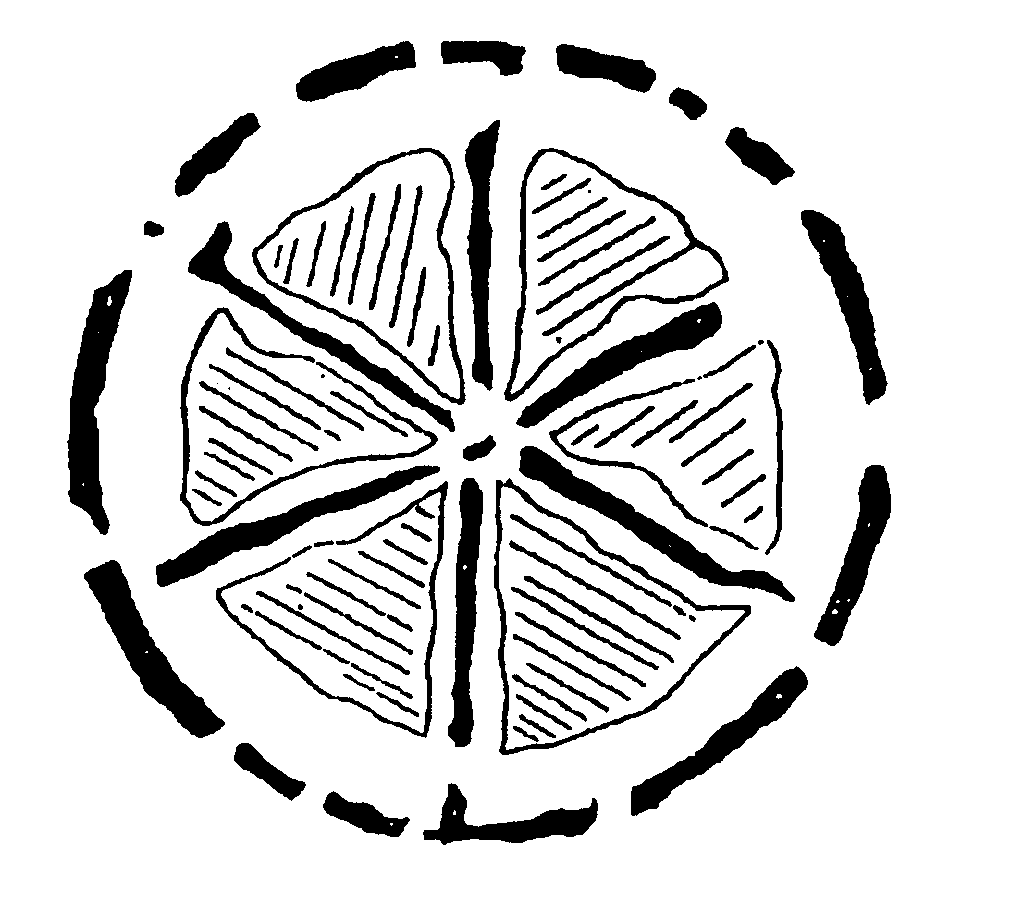

Process of making splittable microfiber substrate

InactiveUS6737004B2Improve compactionFeel goodCarding machinesConjugated synthetic polymer artificial filamentsPolyesterCarding

A microfiber substrate of improved carding ability and its manufacturing method, and more particularly a micro-fiber spun by conjugated melting of crystallization difference of high crystallization polymer and low crystallization polyester, drawn to form an unsplit microfiber staple having a layer of thin film in its surrounding, the microfiber staple which is still kept in unsplitting state during opening, carding and lapping treatment, will be split just at the layer of thin layer of its surrounding of the microfiber staple by spunlace to completely split from the microfiber, knitted to form water-jet punch web, then subject to hot water to shrink to densification. The microfiber nonwoven web excellent in the wiping effect, cleaning effect and microfiber artificial leather excellent in the hand feeling and fluff compaction without environment pollution is enabled to offer the artificial leather more cheaply and easily finished.

Owner:SAN FANG CHEM IND

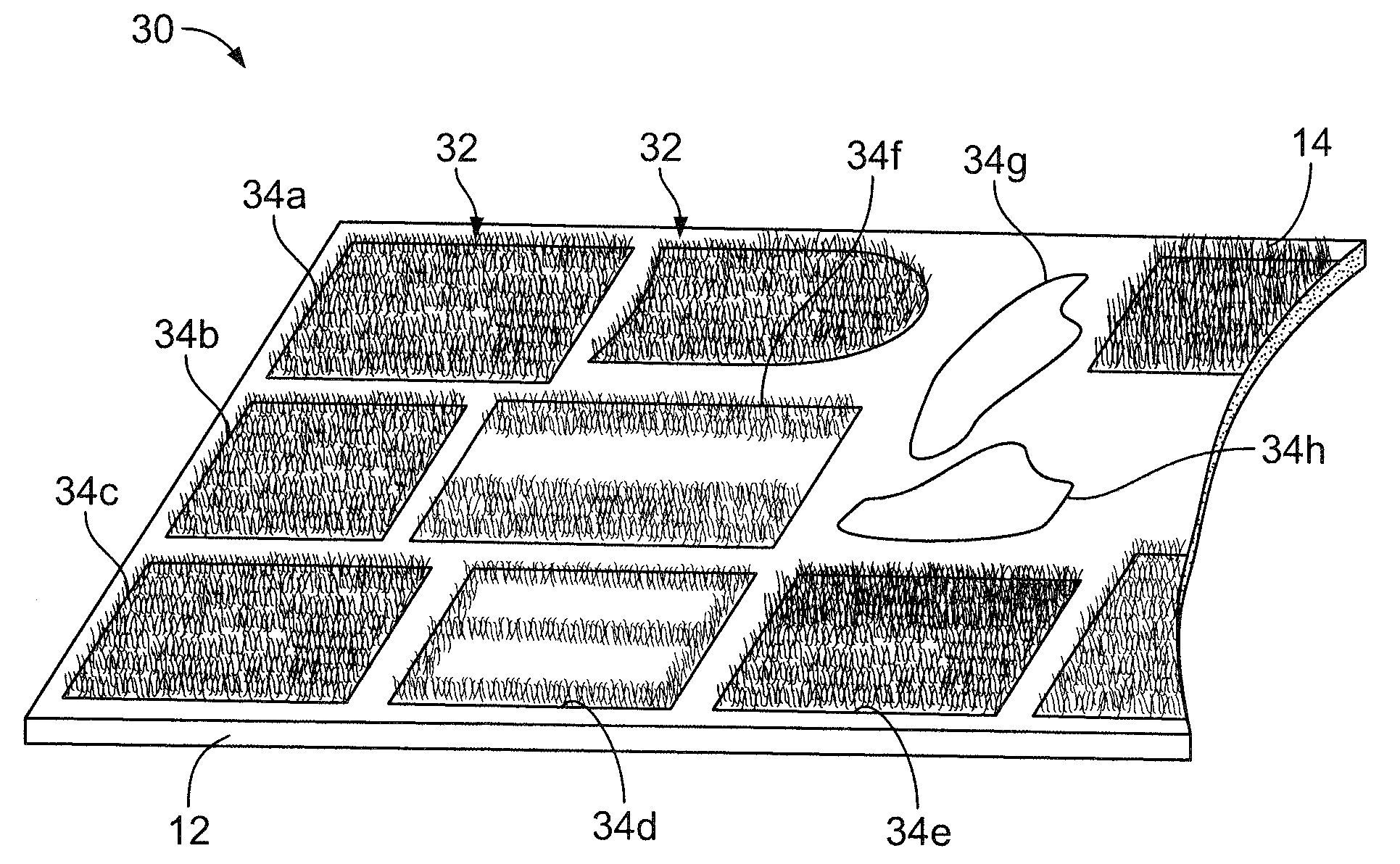

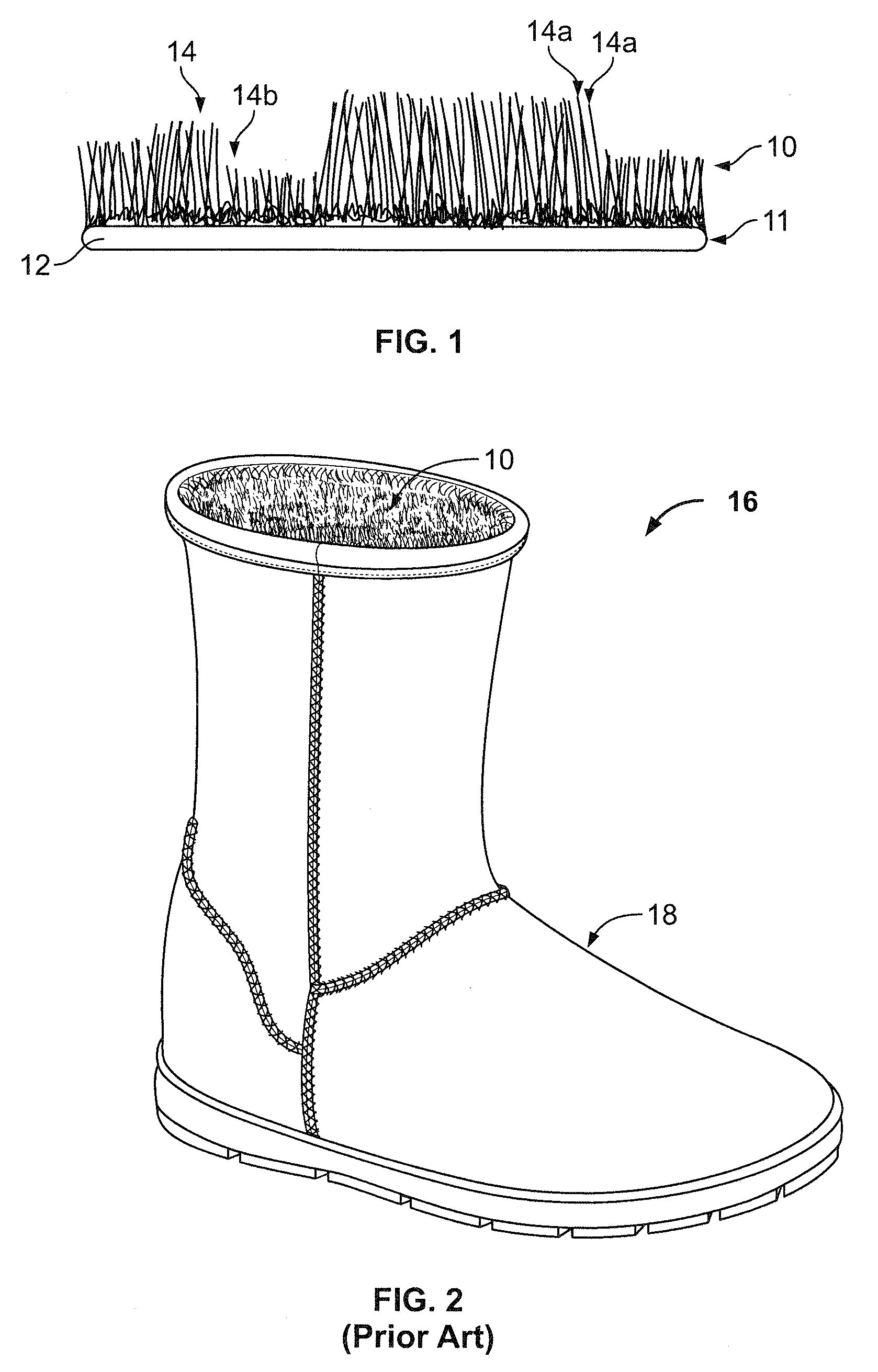

Sheared wool weaving method

ActiveUS20130261785A1Improve production efficiencyReduce material wastePattern makingContinuous processingEngineeringMechanical engineering

A method of manufacturing an article of footwear includes providing a knitting machine having a processor programmed to cause the knitting machine to knit a wool pile fabric having a plurality of footwear components and simultaneously knitting wool fibers and a scrim to form the wool pile fabric including the footwear components.

Owner:DECKERS OUTDOOR CORPORATION

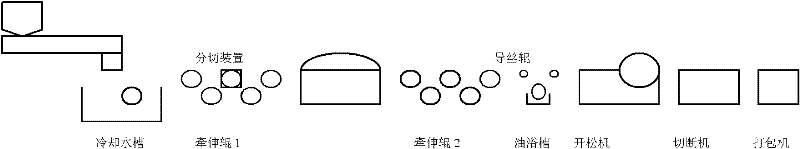

Method for preparing regenerated return polypropylene fibrilled film fibers

InactiveCN102392312AReduce manufacturing costArtificial filament heat treatmentSevering fibresEngineeringPolypropylene fiber

The invention relates to a method for preparing regenerated return polypropylene fibrilled film fibers, which comprises the following steps of extruding return polypropylene, carrying out film splitting on the return polypropylene, slitting the return polypropylene into filaments, coating an oiling agent on the filaments, carrying out steam preheating, curing, drying, cutting and packaging, or comprises the following steps of carrying out film splitting on the return polypropylene, slitting the return polypropylene into filaments, opening, carrying out short-cutting and packaging. In the invention, a fibrilled film filament process is used to carry out spinning, polypropylene regenerated return materials are sufficiently utilized, the production cost of the polypropylene fibers is reduced, and the method has a good application prospect.

Owner:NINGBO HUAYE MATERIAL TECH

Composites comprising collagen extracted from sarcophyton sp. coral

Owner:RAMOT AT TEL AVIV UNIV LTD

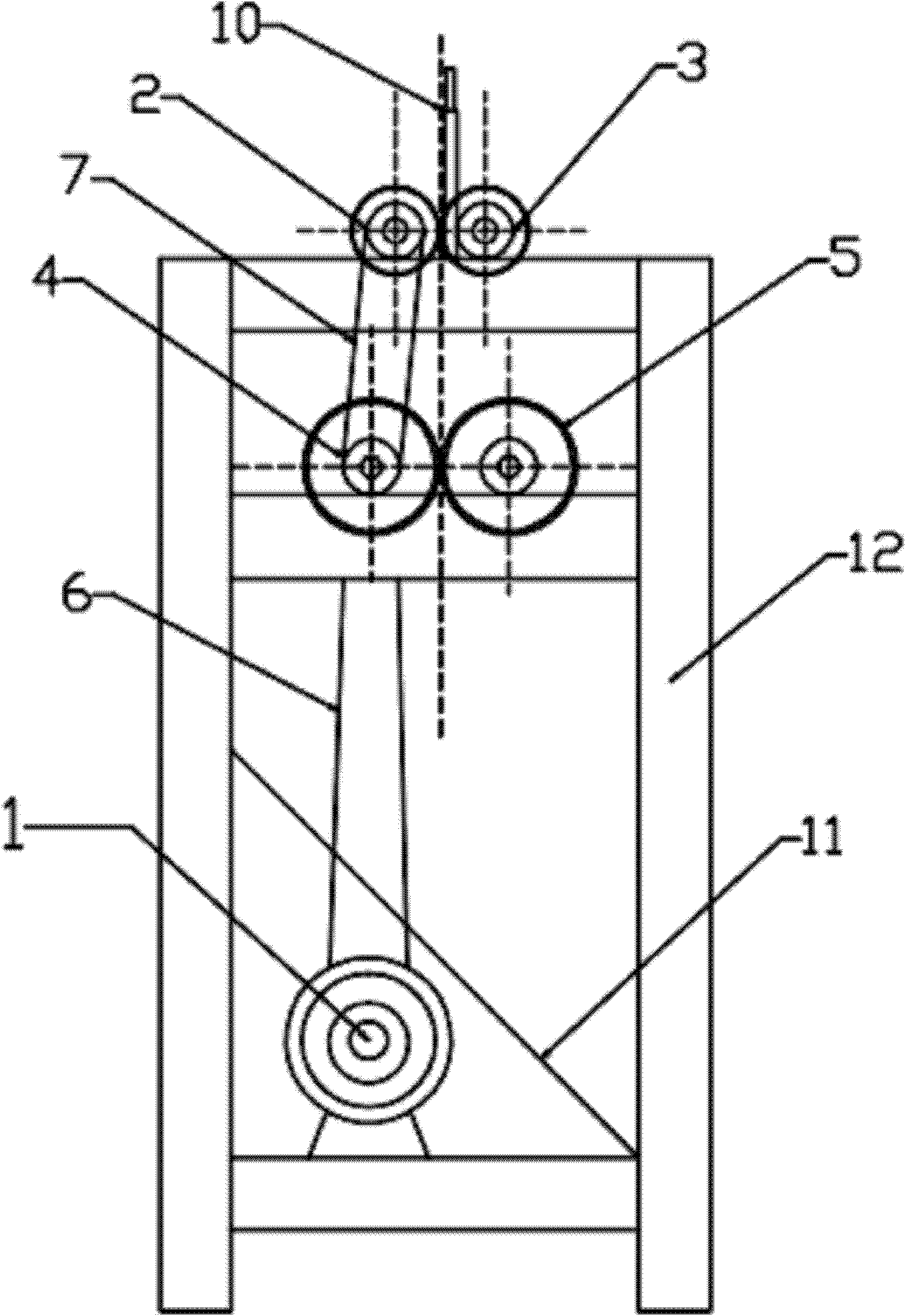

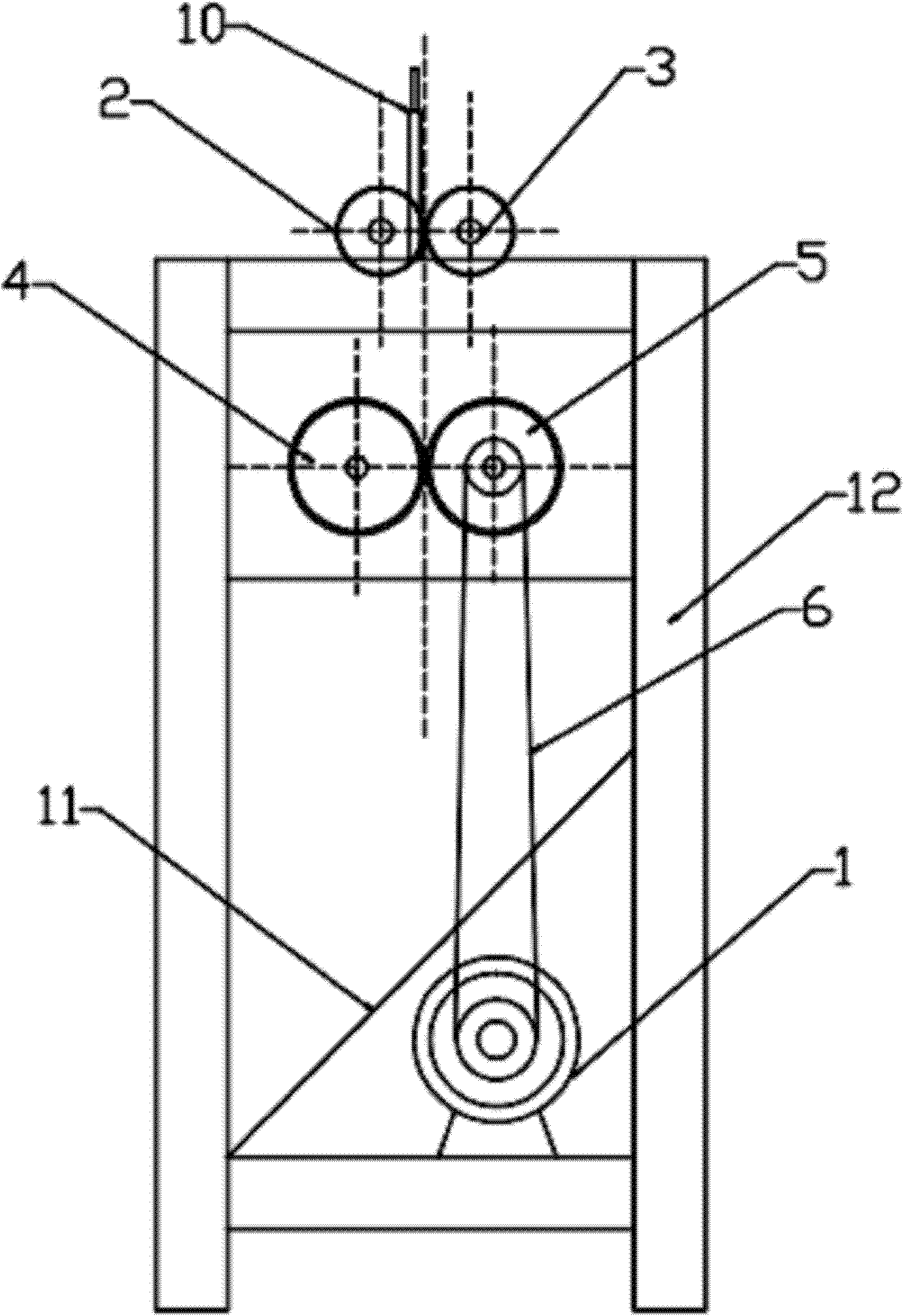

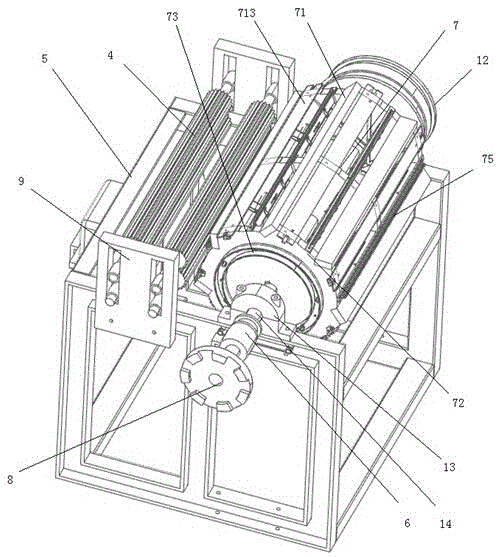

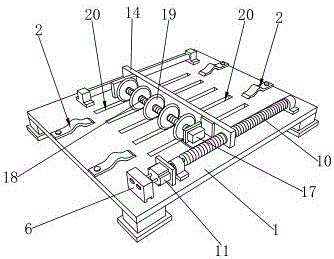

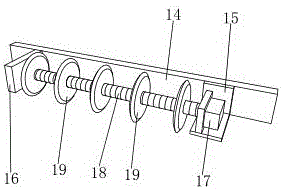

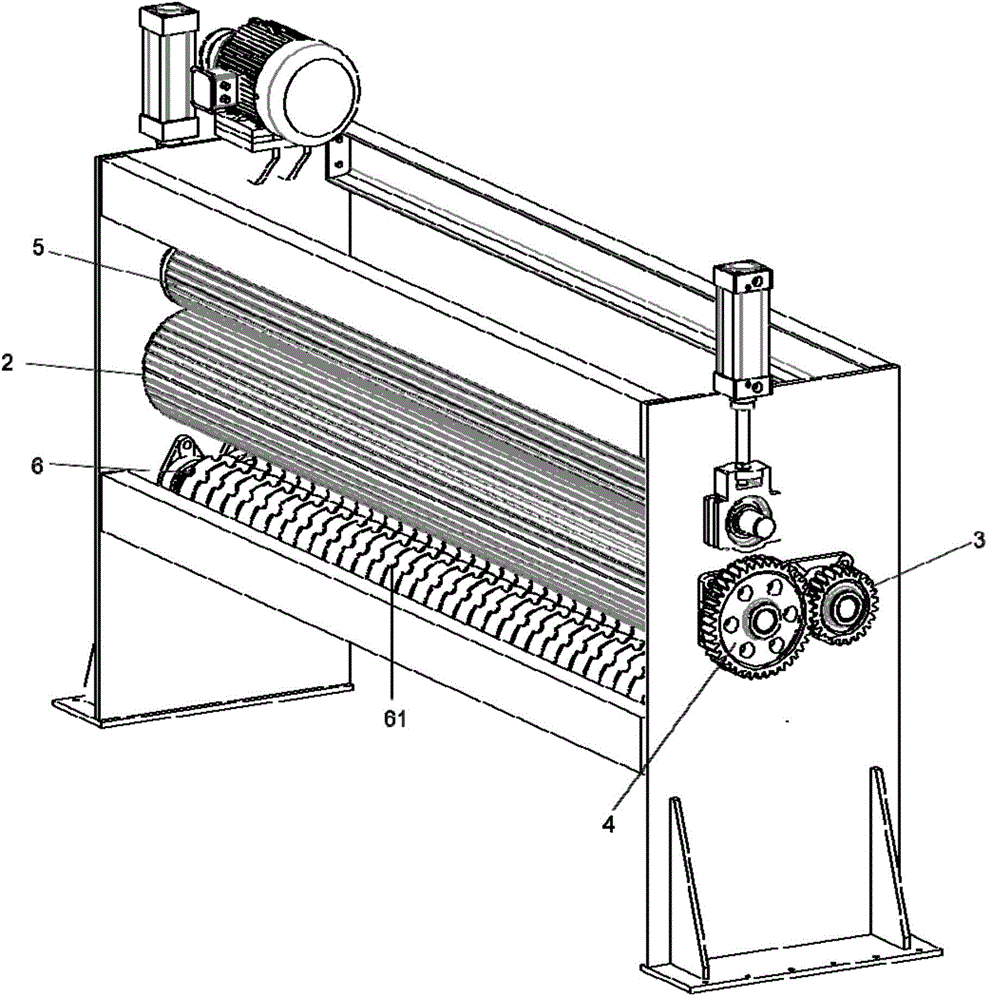

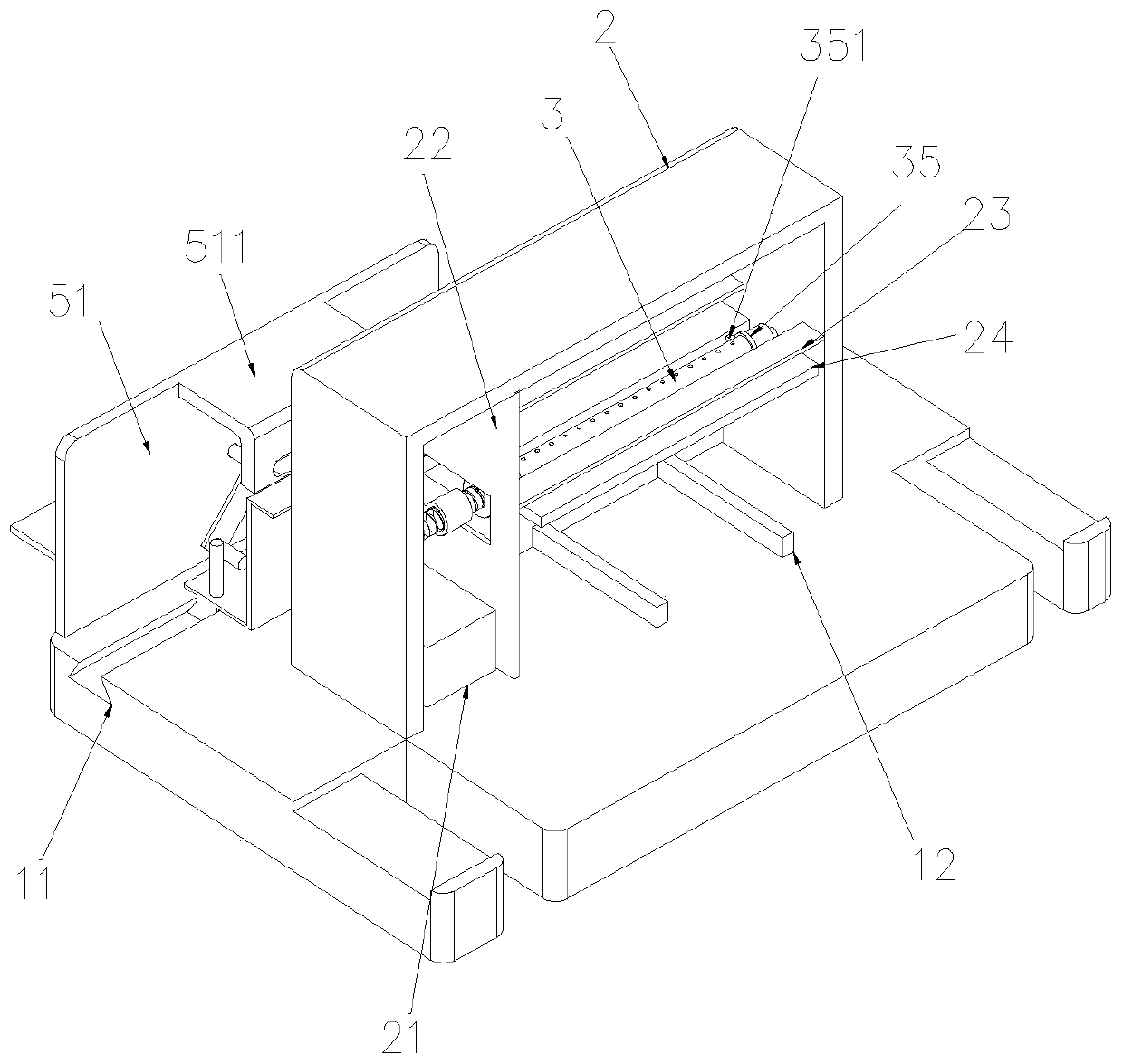

Wool top stretch breaking machine

InactiveCN101851816ACompact structureReasonable designSevering fibresMachine designProduction quality

The wool top stretch breaking machine designed by the invention mainly comprises a motor, a small driving roller, a small driven roller, a large driving roller and a large driven roller, wherein the top end of a frame is provided with the small driving roller and the small driven roller, the corresponding large driving roller and large driven roller are arranged under the contact point of the small driving roller and the small driven roller, the motor is connected with the large driving roller through a belt, the large driving roller is connected with the large driven roller through a gear as well as connected with the small driving roller through a chain simultaneously, the small driving roller is connected with the small driven roller through a gear, bearings are arranged on two ends of the large driving roller, the large driven roller, the small driving roller and the small driven roller and can be fixed on the frame through an adjustable bearing seat, and a wool guide plate is arranged under the large driving roller and the large driven roller. The wool top stretch breaking machine has the characteristics of simple and compact structure, reasonable design, production convenience, high production efficiency, low production cost and improved production quality, and is not easy to breakdown in the production process.

Owner:浙江中鼎纺织股份有限公司

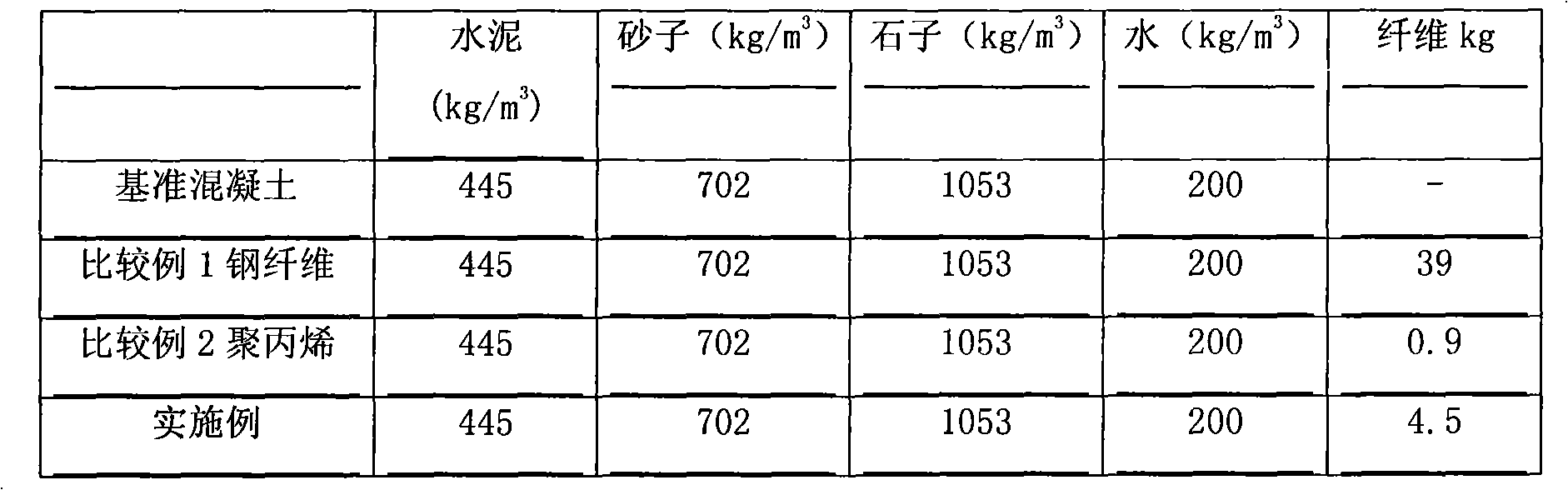

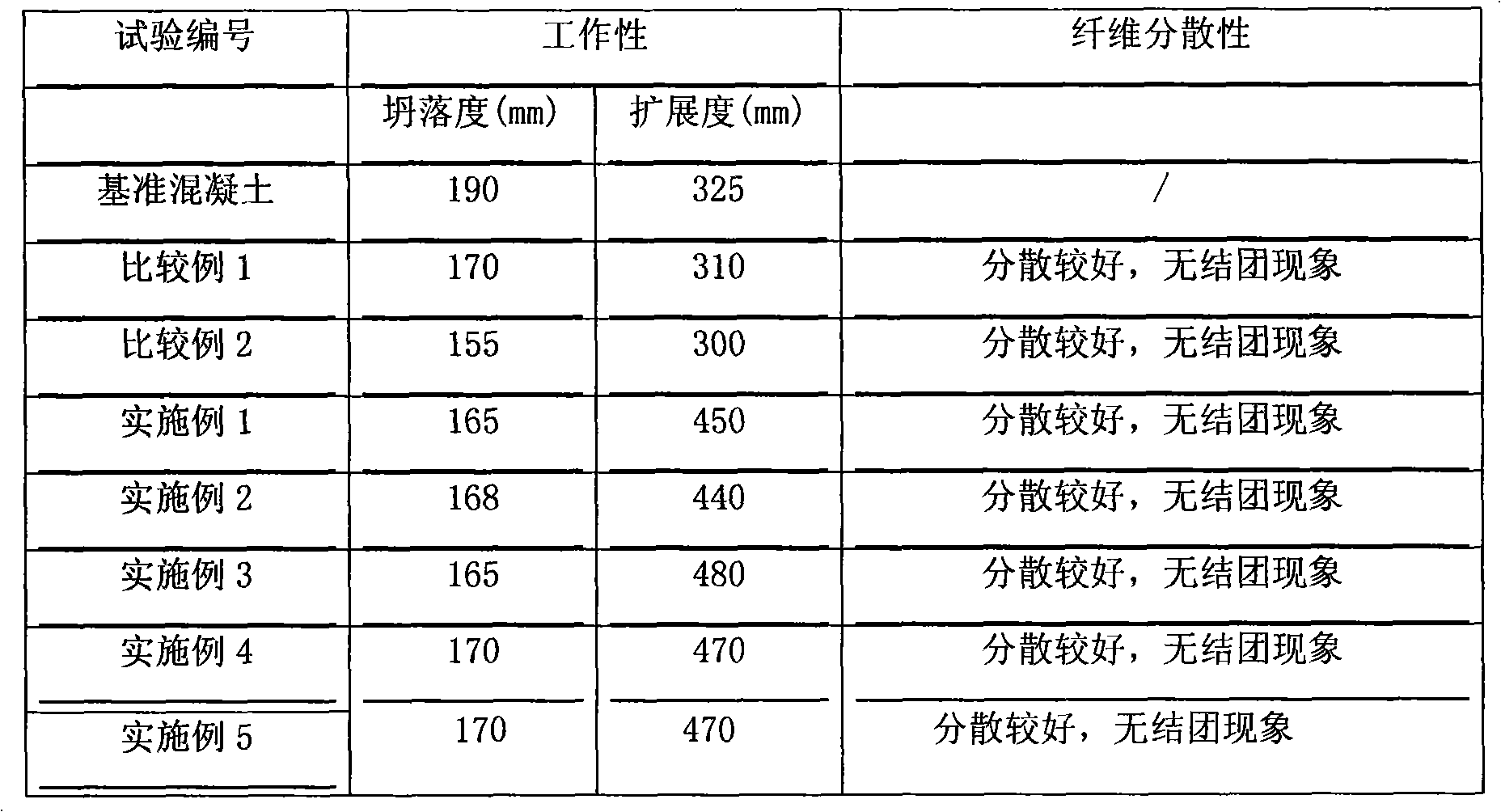

Structure enhanced synthetic fiber for concrete and preparation thereof

InactiveCN101348342AHigh compressive strengthHigh tensile strengthMelt spinning methodsSevering fibresRough surfacePolyamide

The invention relates to a structurally reinforced synthetic fiber for concrete. The synthetic fiber is prepared by processes of fusion, spinning, dispersion and fixing, and the synthetic fiber comprises the following components: 20 to 70 percent of polypropylene, 25 to 75 percent of polyethylene, 0 to 25 percent of polyamide, 0.05 to 0.5 percent of nucleating agent and 0.1 to 0.5 percent of antioxidant. The synthetic fiber of the invention has rough surface and clear contour, and has good dispersibility and cement basal body with excellent cementing property; the product has not only the functions of steel fibers, but also advantages of synthetic fibers, so that the synthetic fibers of the invention is mainly used to replace weld metal screens and steel fibers in the concrete panel structure for improving the bending resistant, shock resistant and fatigue resistant performance of concrete.

Owner:南京派尼尔科技实业有限公司

Regenerated polyester fiber spinning process capable of effectively solving yarn breaking phenomenon

ActiveCN106702503AImprove qualityUniform molecular weightSpinning solution de-aeratingFilament forming substance formingPolyesterYarn

The invention discloses a regenerated polyester fiber spinning process capable of effectively solving the yarn breaking phenomenon. The process comprises the following steps of 1 material mixing, 2 drying, 3 melting, 4 filtering, 5 devolatilization, 6 spinning, 7 cooling shaping, 8 winding, 9 drying and finishing, 10 cutting off and 11 packaging. Due to the fact that a devolatilization system is additionally arranged after the processes of melting and filtering, a certain vacuum degree is kept in the system, small molecule materials and organic gas in melt rapidly break away from the interior of PET melt in the vacuum environment to be volatilized, a series of processes such as condensation and separation are conducted, harmless collection is achieved, and the collected materials serve as the raw materials of factories such as a paint factory. After the PET melt is subjected to devolatilization, the melt quality is significantly improved, the molecular weight is uniform, the organic gas is not carried any more, and the yarn breaking phenomenon in the cooling shaping process is solved.

Owner:浙江逸含化纤有限公司 +1

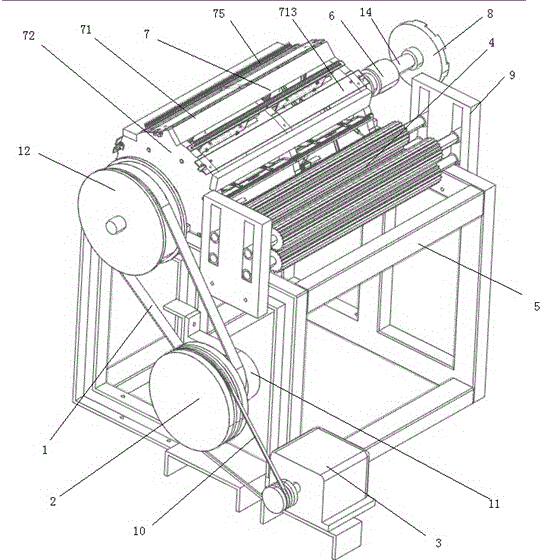

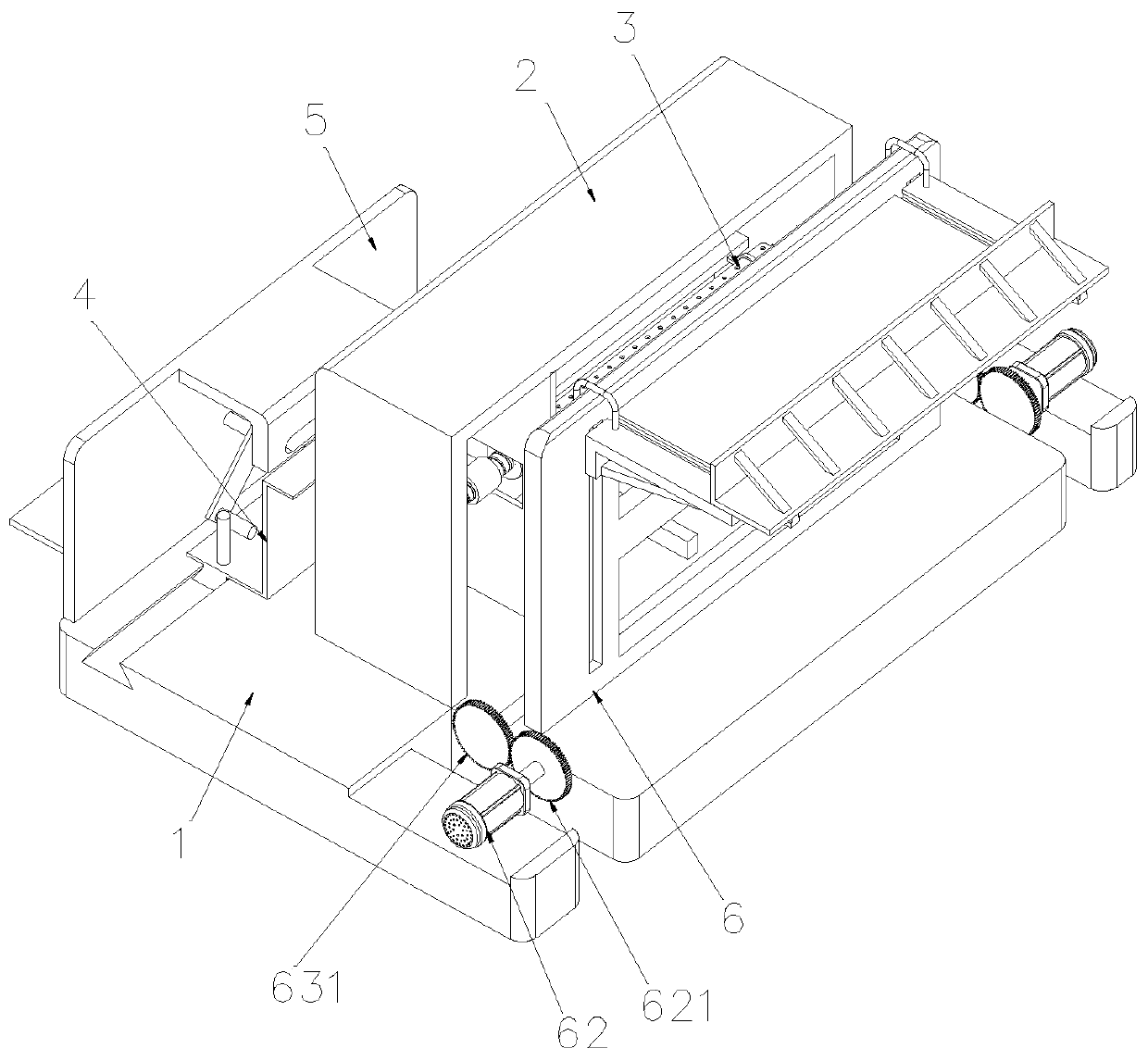

Full-automatic cotton cutting machine

ActiveCN105483865ARealize automatic cotton removalAvoid situations where it is impossible to cut allSevering fibresElectromagnetic clutchEngineering

The invention discloses a full-automatic cotton cutting machine. One side of a support is provided with an electromagnetic clutch fixing frame. An electromagnetic clutch is installed on the outer side of the electromagnetic clutch fixing frame. A motor is arranged on one side of the front end of the support. A rotary shaft of the motor and the electromagnetic clutch are sleeved with a transmission belt. The support is provided with roller fixing frames and rotary drum fixing frames. The two ends of a roller are fixed between the two roller fixing frames. A cotton cutting rotary drum is fixed between the two roller fixing frames through rotary shafts at two ends. The end of the rotary shaft on the side, close to the electromagnetic clutch, of the cotton cutting rotary drum is provided with a transmission wheel. The transmission wheel and a shaft of the electromagnetic clutch are sleeved with a belt. The end of a connection shaft on the other side of the cotton cutting rotary drum is provided with a clutch. A side clutch is arranged on one side of the clutch. The cotton cutting machine is designed again, the automation degree of the whole operation is greatly improved, and therefore the purpose of reducing labor is achieved.

Owner:JINLING INST OF TECH

Carbon fiber cutting device

The invention discloses a carbon fiber cutting device which comprises a working table. The working table is provided with a controller, a driving mechanism and a fixed component, the controller is connected with the driving mechanism, a sliding base is arranged between the driving mechanism and the fixed component, an L-shaped base and a support plate are arranged on the sliding base, a motor is arranged on the L-shaped base, a rotating shaft is arranged on the motor, one end of the rotating shaft penetrates through the support plate, rotary knives are uniformly distributed on the rotating shaft, knife grooves are uniformly distributed in the working table, the knife grooves are located under the rotary knives, and elastic fixed plates are symmetrically distributed on the working table. The carbon fiber cutting device is simple in structure, automatic cutting is achieved, the cutting efficiency is high, the effect of finished products obtained after cutting is good, and the cost is low.

Owner:王梅春

Fiber shearing device

InactiveCN102534871ANot easy to wearReduce contact timeMetal working apparatusSevering fibresFiberUltimate tensile strength

The invention discloses a fiber shearing device. An inlet of a conveying pipeline (5) aligns to an outlet of a guider (9), and a movable shearing tool (7) is mounted on a rotary shaft of a motor (3),arranged between the guider (9) and the conveying pipeline (5) and close to the outlet of the guider (9). The fiber shearing device is long in service life, high in production efficiency, low in production cost and labor intensity. Long fibers can be sheared into short fibers of a certain length, shearing efficiency is improved and abrasion of the movable shearing tool is reduced.

Owner:HUNAN UNIV

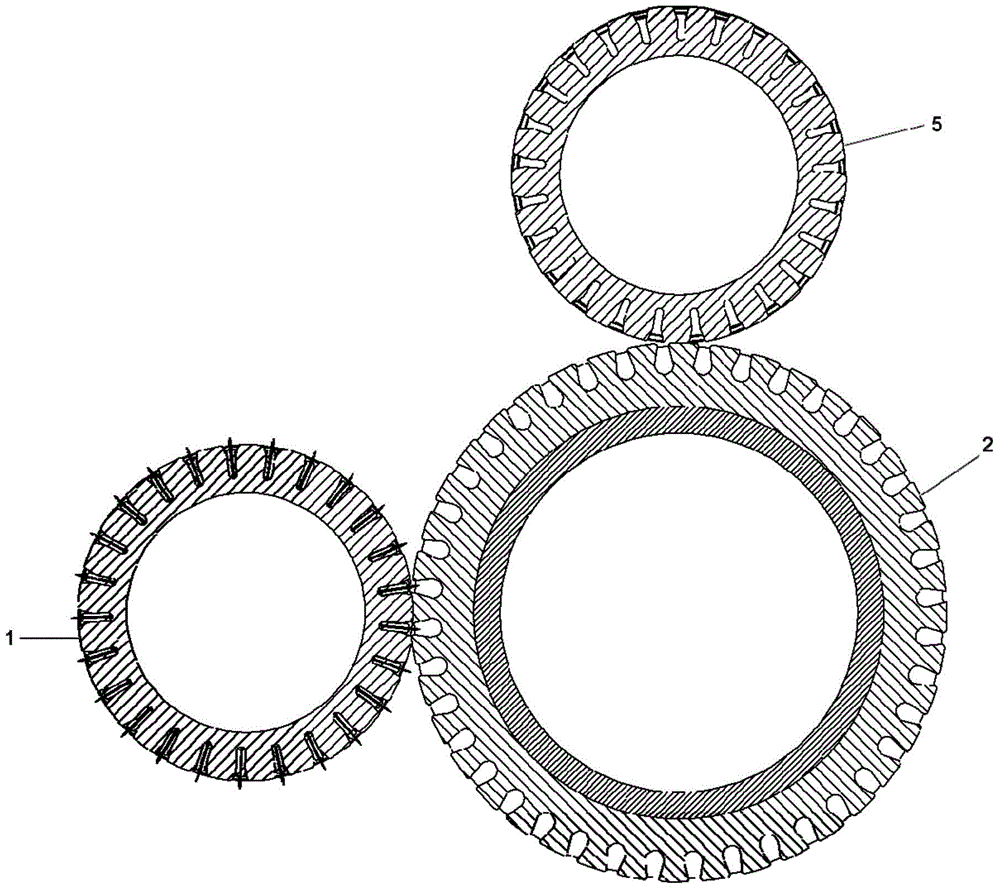

Non-abrasion fiber cutting equipment

The invention provides non-abrasion fiber cutting equipment, which comprises a yarn cutting knife roll and a pressure roll, wherein the pressure roll is arranged near the side surface of the yarn cutting knife roll, a plurality of yarn cutting knife blades are uniformly arranged at the circumference surface of the yarn cutting knife roll, a plurality of hollow yarn cutting knife grooves are uniformly formed in the circumference surface of the pressure roll, the yarn cutting knife roll comprises a knife holder roll, the knife holder roll is of an axial hollow structure and is provided with a first hollow cavity, a plurality of grooves are uniformly formed in the circumference surface of the outer circle of the knife holder roll, a knife clip is arranged in each groove, each yarn cutting knife blade is clamped between the corresponding knife clips, and the position of each yarn cutting knife blade corresponds to the corresponding yarn cutting groove. The non-abrasion fiber cutting equipment has the advantage that as the position of each yarn cutting knife blade corresponds to the corresponding yarn cutting groove, and each yarn cutting knife blade is not in direct contact with the outer surface of the pressure roll, the service lives of each yarn cutting knife blade and the pressure roll are prolonged, the yarn cutting effect is better, and the yarn cutting efficiency is higher.

Owner:秦皇岛洛克维德新材料技术有限公司

Preparation device and method for composite down-like thermal insulation material

ActiveCN110863249AHeating evenlyAvoid overheatingArtificial filament washing/dryingFilament/thread formingThermal insulationStructural engineering

The invention discloses a preparation device and method of a composite down-like thermal insulation material. The preparation device comprise a base, wherein a pushing device, a drying rack and a feeding device are arranged on the upper surface of the base, the drying rack is positioned between the pushing device and the feeding device, a movable rack is slidably arranged on the upper surface of the base, and the movable rack is positioned between the pushing device and the drying rack; the pushing device drives the movable rack to move back and forth, an exhaust pipe is driven to rotate backand forth, meanwhile, a heating fan blows hot air to the exhaust pipe, and the exhaust pipe finally blows hot air to the surface of a down-like material, so that the purposes of uniform heating and over-heating prevention are achieved; when the material is transported, workers only need to place the down-like material on a base plate, then move the base plate to a corresponding position, push thepush plate to enable the material to stably move forwards to the drying rack, and toppling does not occur in the whole process; and the elastic recovery capability is high, the bulkiness is good, thecost control is low, and the preparation device is widely applied to the fields of filling and the like.

Owner:LUAN VOCATIONAL TECHNOLOGICAL COLLEGE

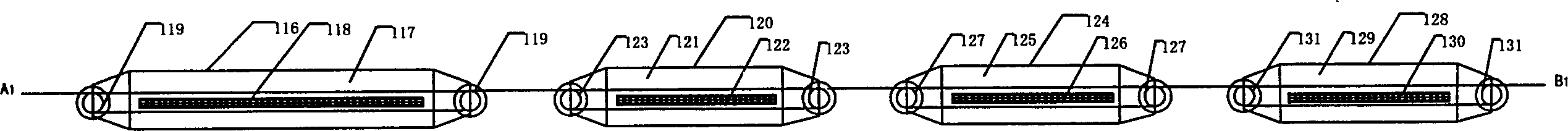

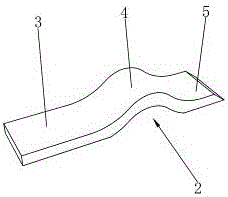

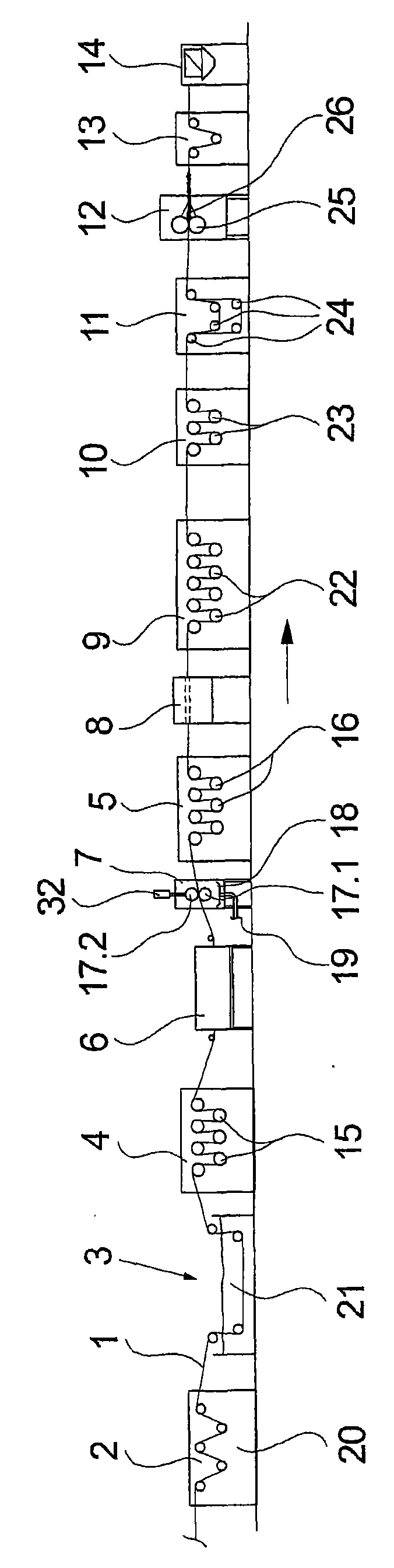

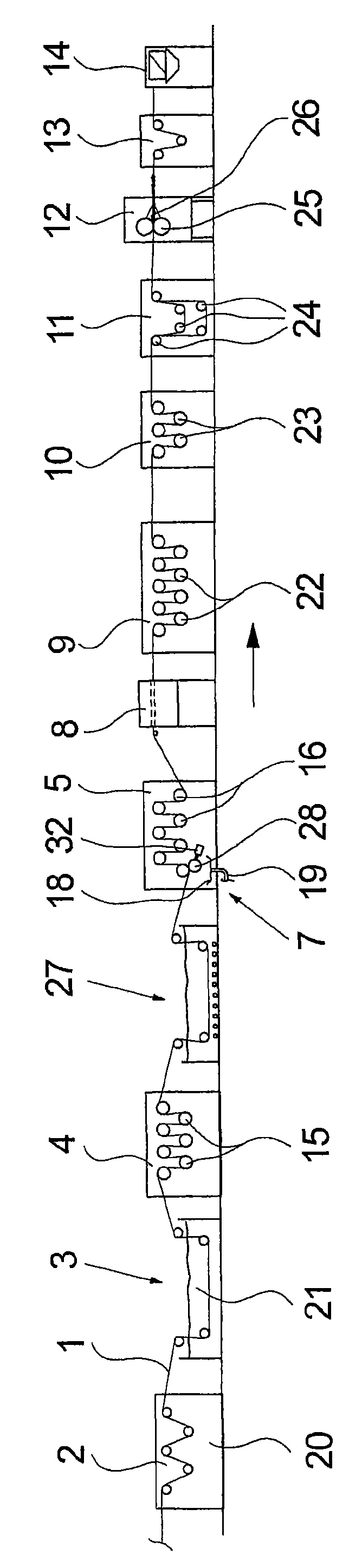

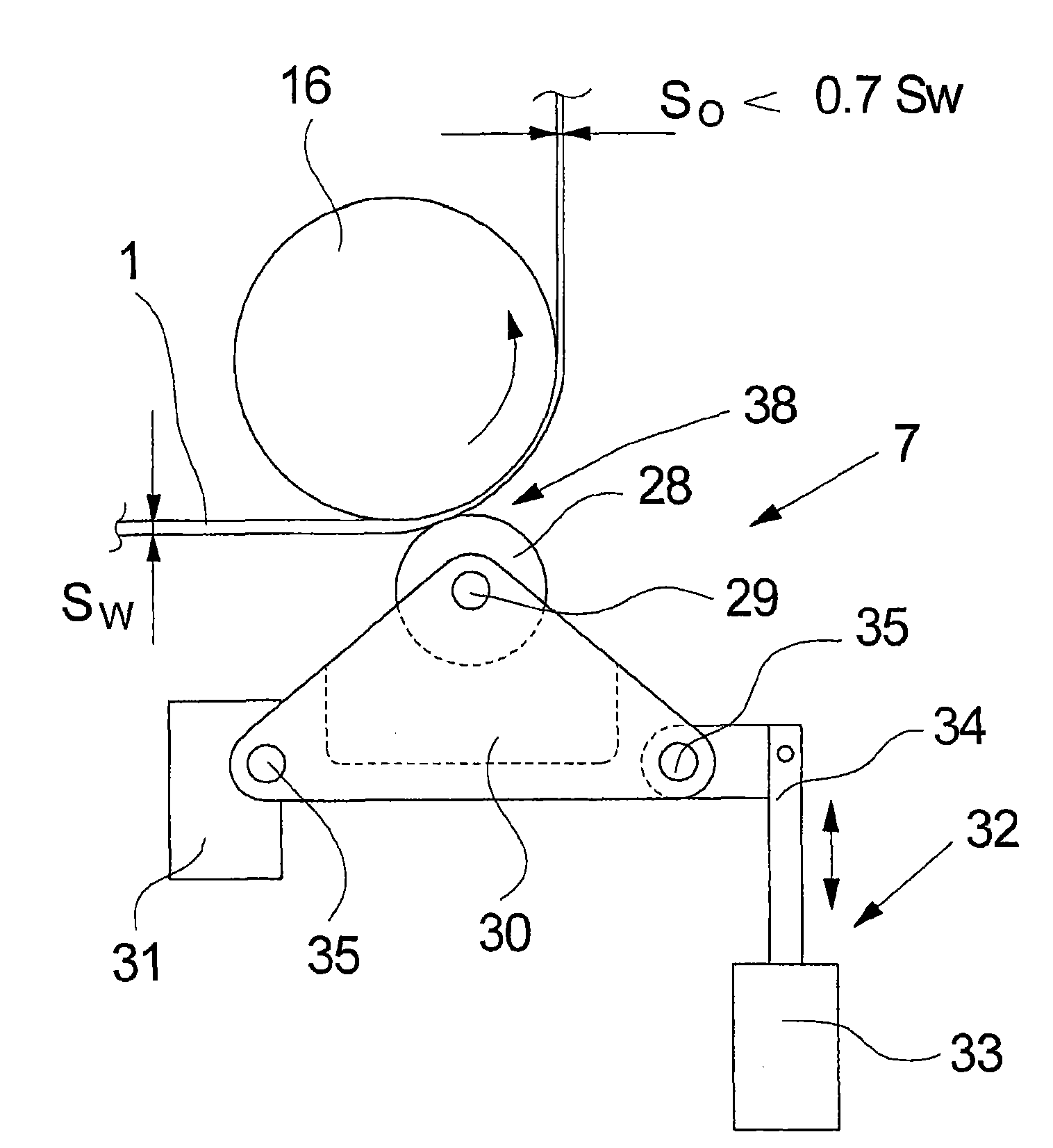

Method and device for treating a fibre cable

InactiveCN101528992AKeep Filament FlowLow costArtificial filament heat treatmentSevering fibresFiberEngineering

The invention relates to a method for treating a fibre cable for the production of stacked fibres and to a device for carrying out said method. The fibre cable is drawn in a drawing zone before being cut into stacked fibres, wherein the fibre cable is treated with a fluid prior to the drawing process. After drawing, the fibre cable undergoes a thermal treatment in order to immobilize the fibre material, the fluid contained in the fibre cable before the thermal treatment is reduced by pinching the fibre cable. In order to adjust the fluid content in the fibre cable to the respective treatment stages, the fibre cable is already pinched within the drawing zone over its width to such an extent that an evenly distributed proportion of weight of <10 % of the fluid is achieved over the width of the fibre cable. For this purpose, the device comprises a pinching device which is arranged within the drawing zone and provided with flexurally rigid pinching means.

Owner:OERLIKON TEXTILE GMBH & CO KG

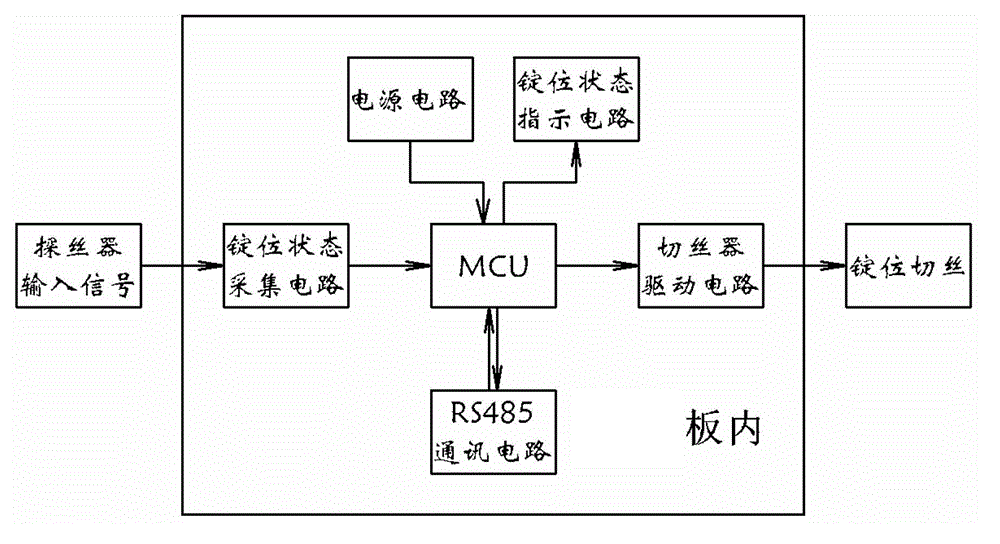

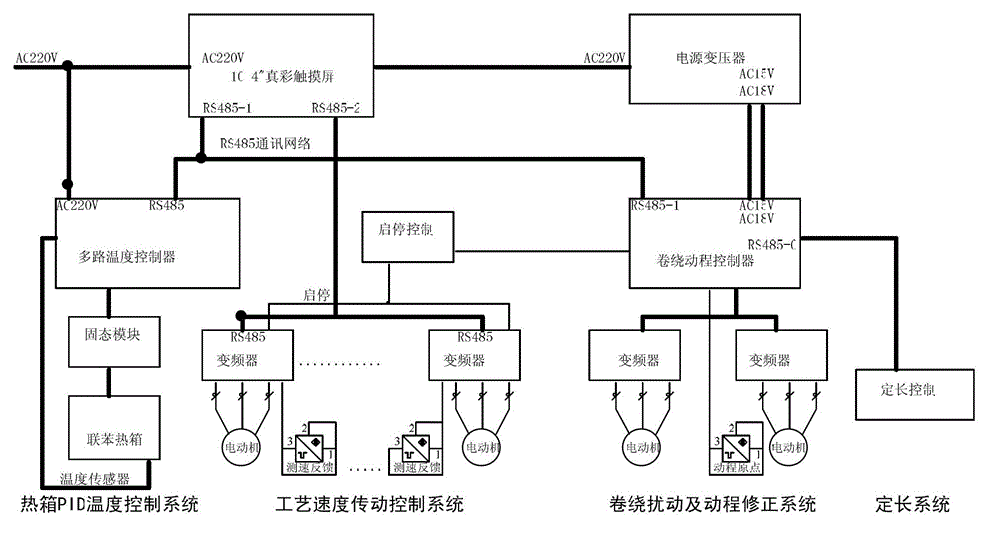

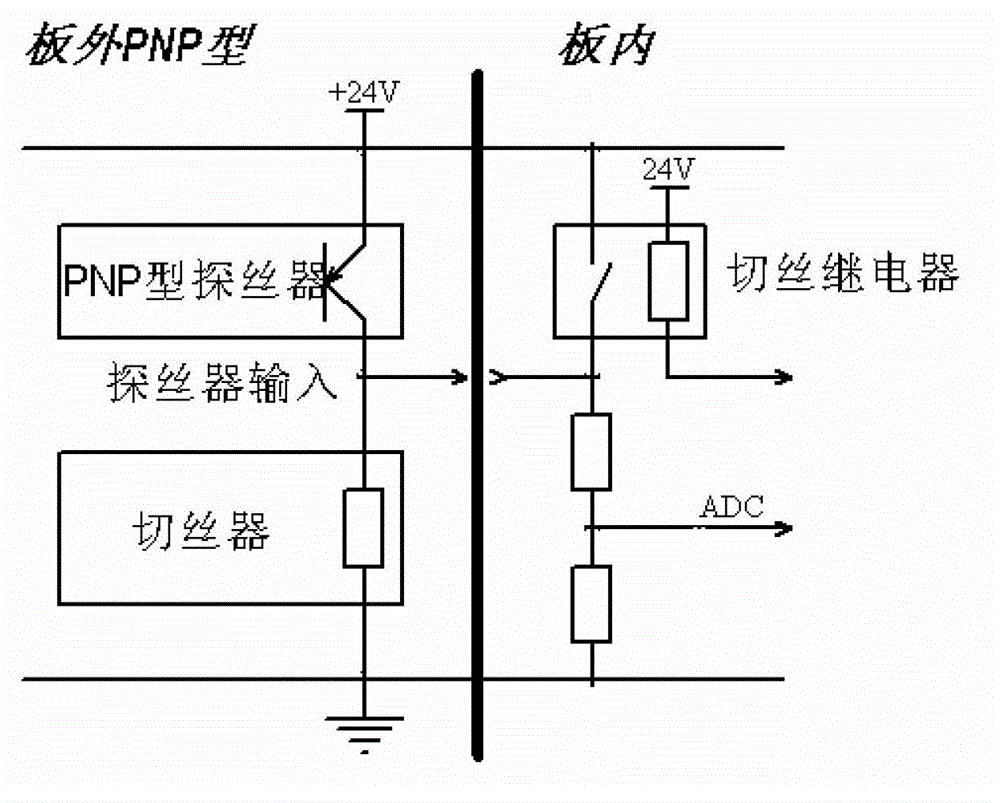

High-speed stretch yarn machine length control system with yarn-cutting control function

ActiveCN102877172AEasy to useOptimize production management processTotal factory controlSevering fibresYarnFiber

The invention discloses a high-speed stretch yarn machine length control system with a yarn-cutting control function. The system is used for the production process of chemical fiber silk in the textile industry. A spindle position state acquisition circuit is used for acquiring analog signals input by different types of yarn sensors and performing state recognition, performing analog / digital (A / D) conversion according to the analog signals input by 12 channels of spindle position yarn sensors, automatically analyzing whether spindle positions are in a yarn state or in a yarn-free state, and communicating with a human-machine interface through an RS485 communication circuit. According to the system, an arrival signal is received by a micro controller unit (MCU), and a yarn at a spindle position is forcibly cut through a yarn cutter driving circuit after yarn-cutting delay time. By the system, the misoperation caused by human factors in the production process can be greatly reduced, the labor intensity can be reduced, the production efficiency can be improved, and social resources can be well optimized and human resources of enterprises can be well saved.

Owner:无锡市百川科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com