Carbon fiber cutting device

A cutting device and carbon fiber technology, applied in fiber cutting, fiber processing, textiles and paper making, etc., can solve the problems of inconsistent cutting width, increase production cost, expensive cutting machine, etc., achieve consistent width, improve stability and cutting efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

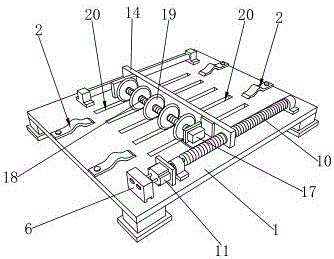

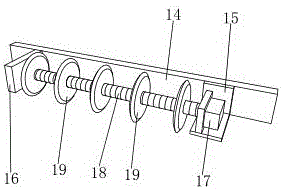

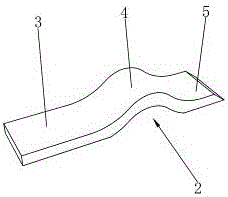

[0019] Such as Figure 1 to Figure 5 As shown, it is a carbon fiber cutting device of the present invention, which includes a workbench 1, and elastic fixing pieces 2 are symmetrically distributed on the workbench 1. The elastic fixing piece 2 includes a fixing part 3, a bending part 4 and a pressing part 5. The fixing part 3 , The bending part 4 and the pressing part 5 are integrally structured, the bending part 4 is connected to the fixing part 3 and the pressing part 5, the fixing part 3 is arranged on the workbench 1, and when the carbon fiber filament is manually fixed, because the bending part 4 has elasticity, The pressing part 5 can be pulled up, the carbon fiber filament can be placed flat on the workbench 1, the pressing part 5 can be loosened, and the rebound force of the bending part 4 can be transmitted to the pressing part 5, so that the pressing part 5 can press the carbon fiber length The two ends are fixed by wire, which is stable and firm. The elastic fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com