Patents

Literature

370results about How to "Consistent width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

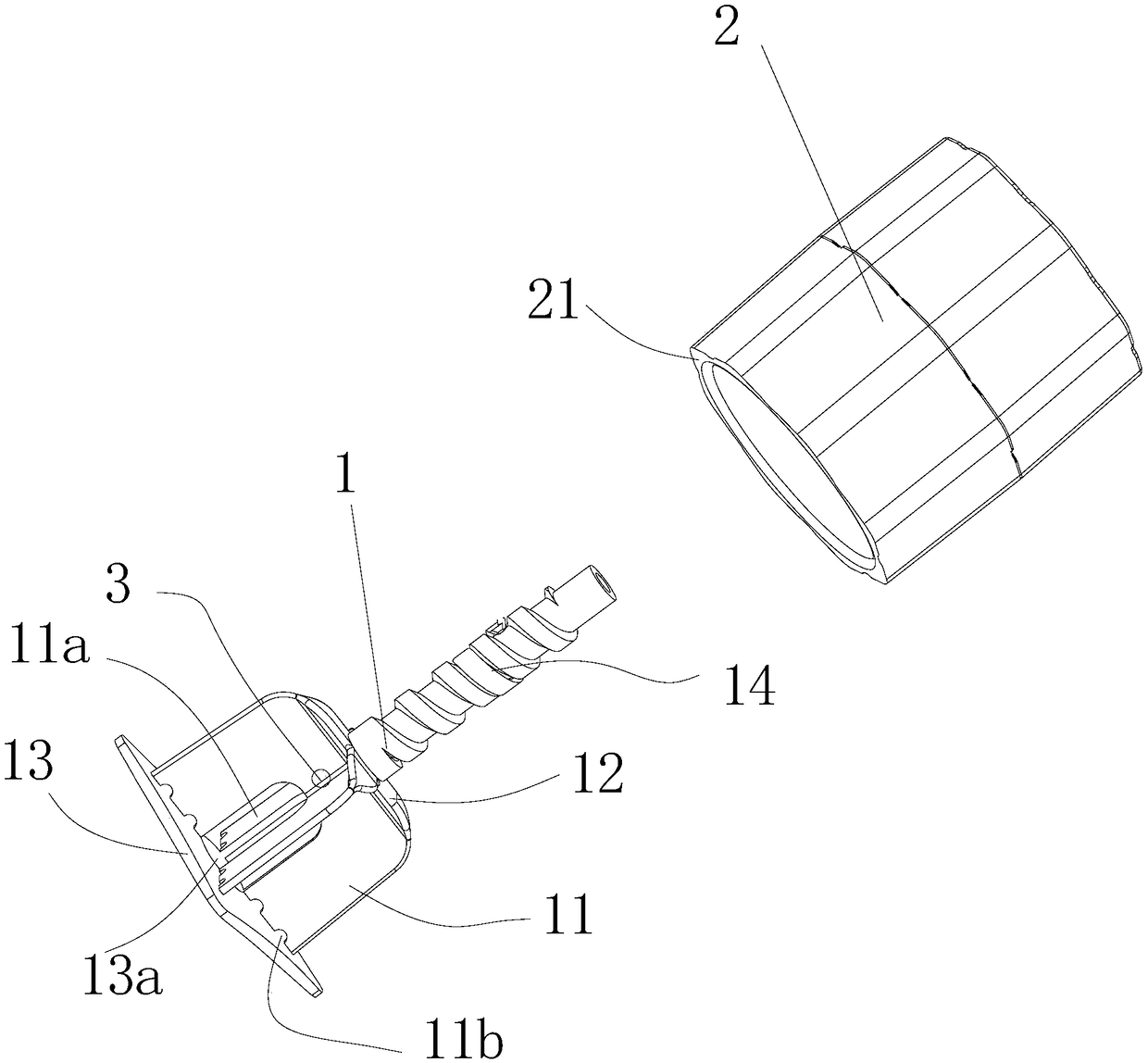

Downhole filter

InactiveUS7188687B2Without complexityWithout expenseDrilling rodsConstructionsParticulatesEngineering

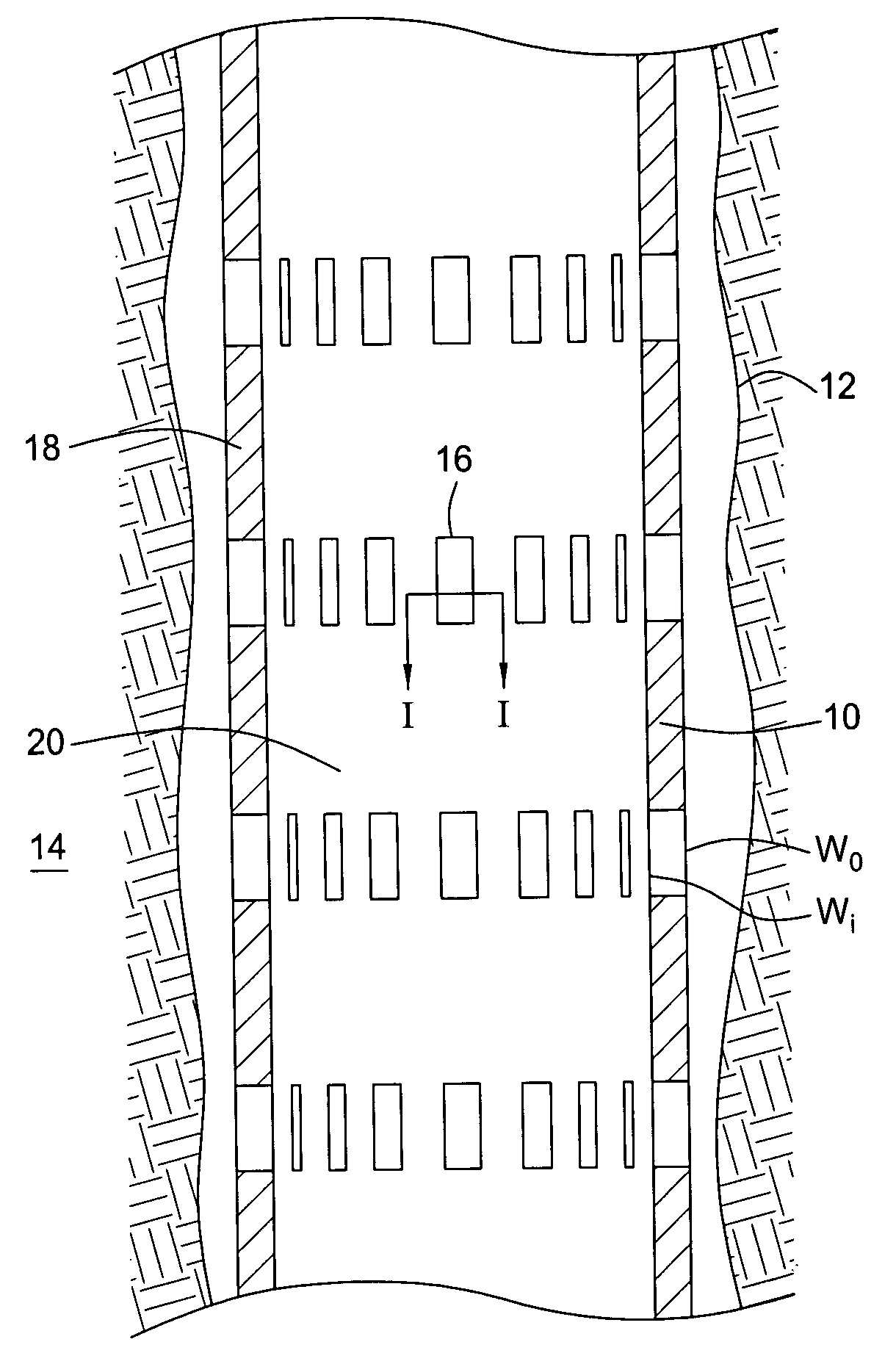

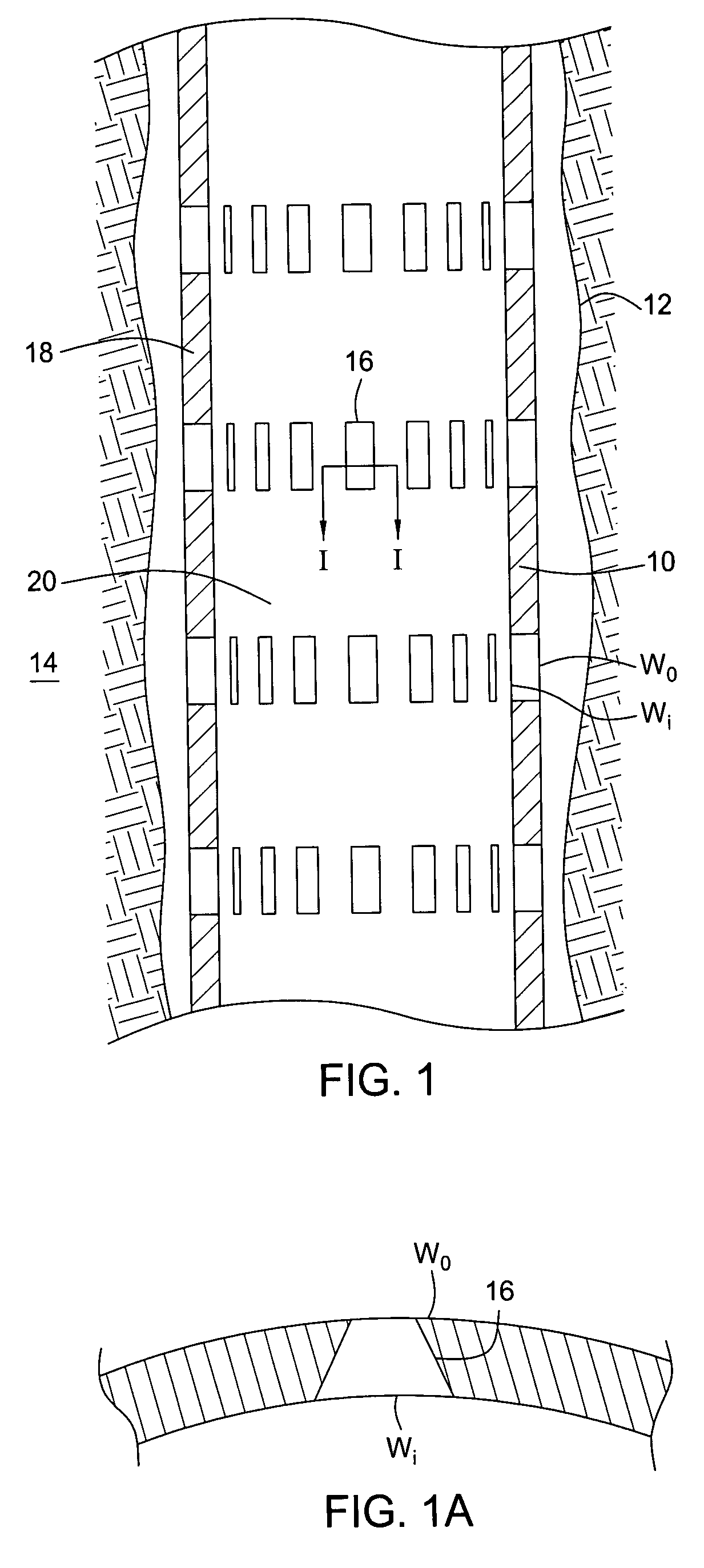

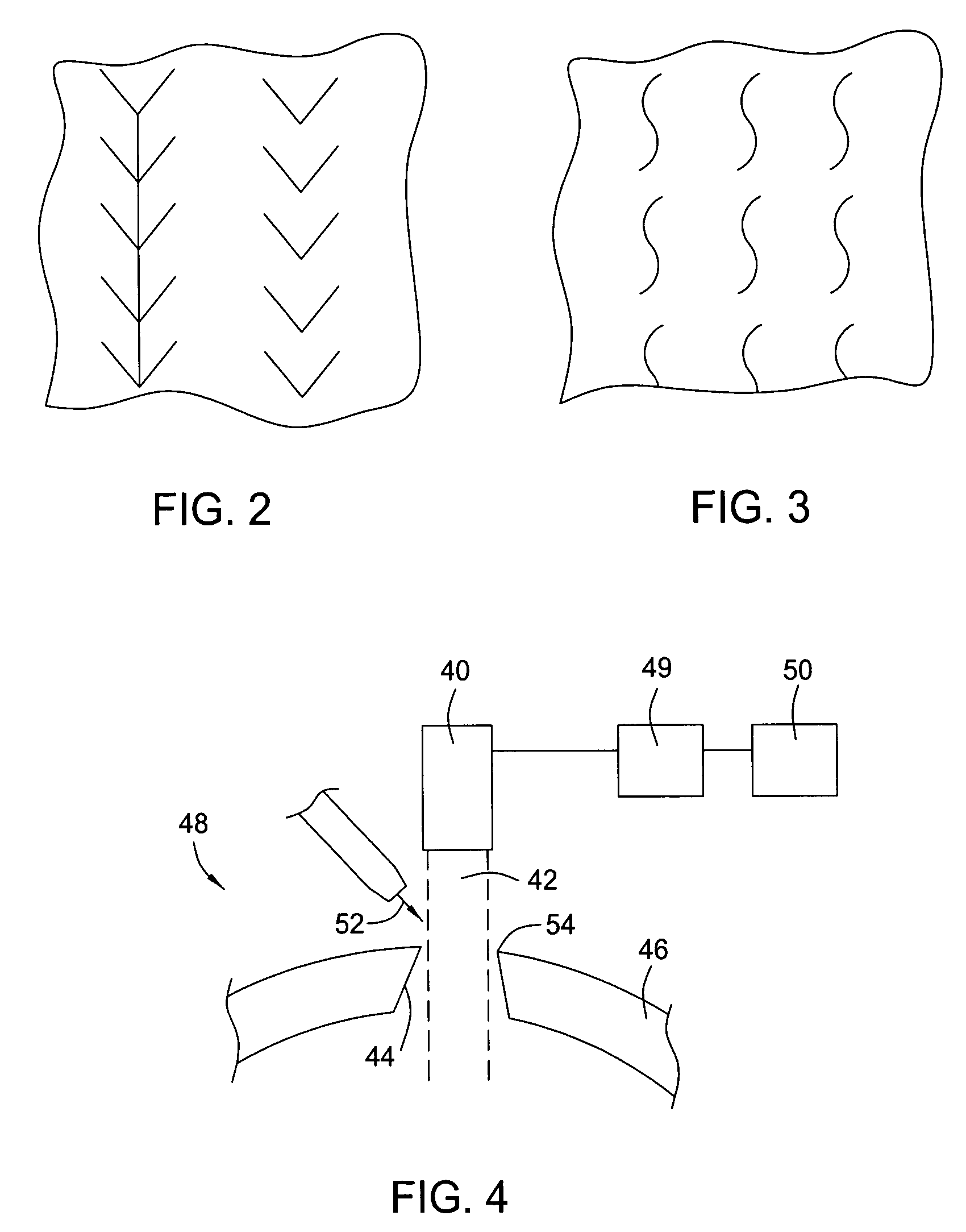

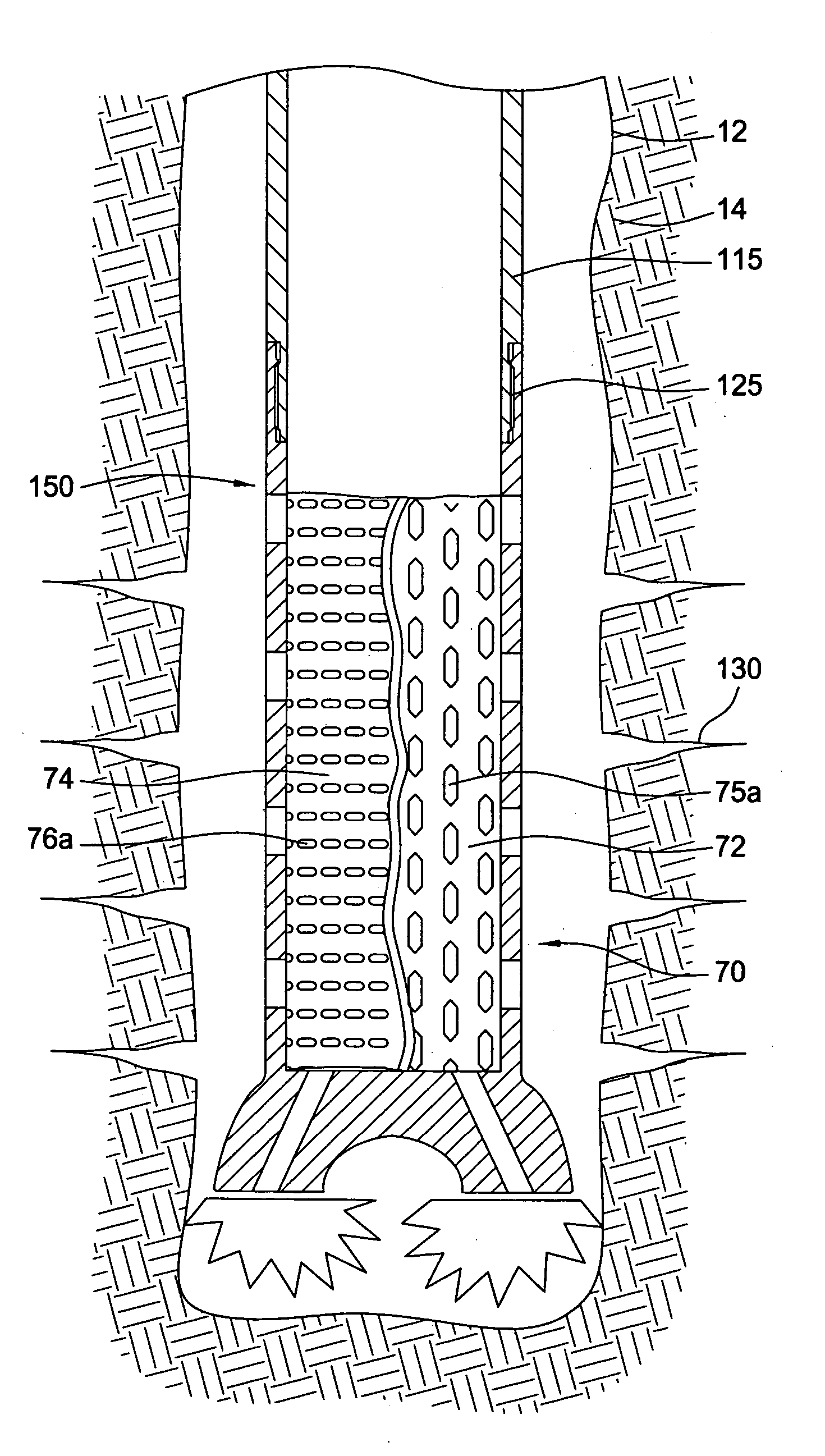

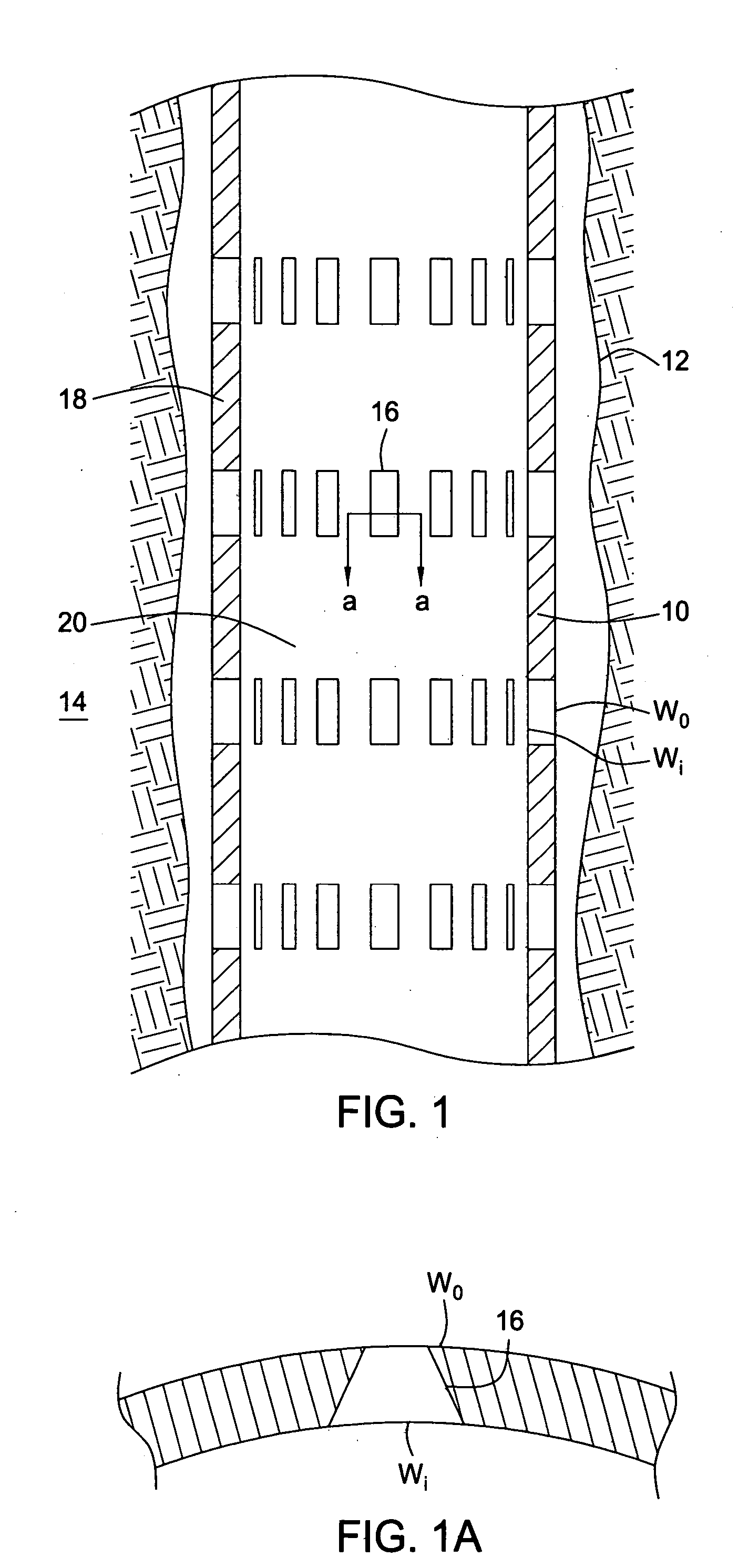

A downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. A method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In another embodiment, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

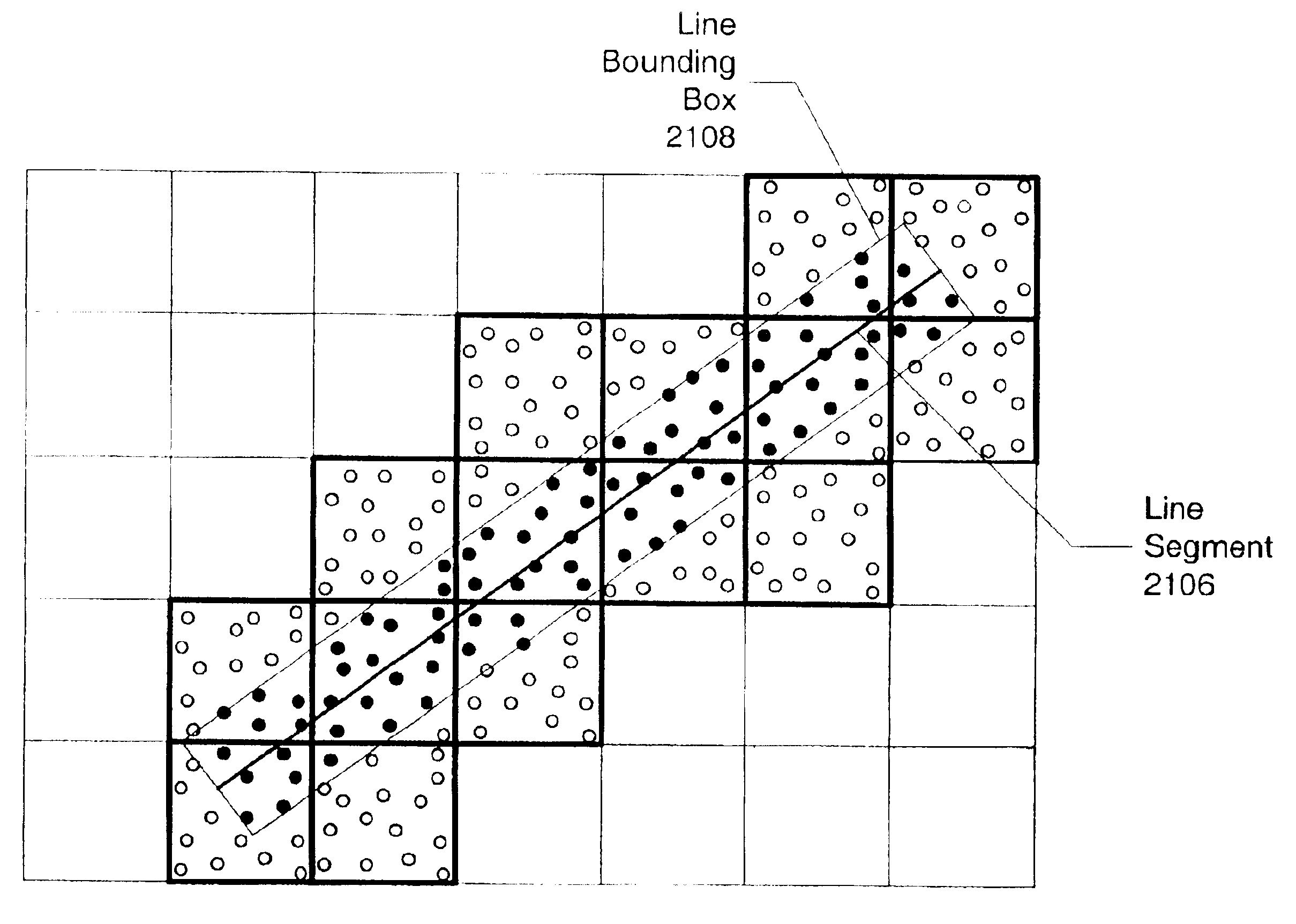

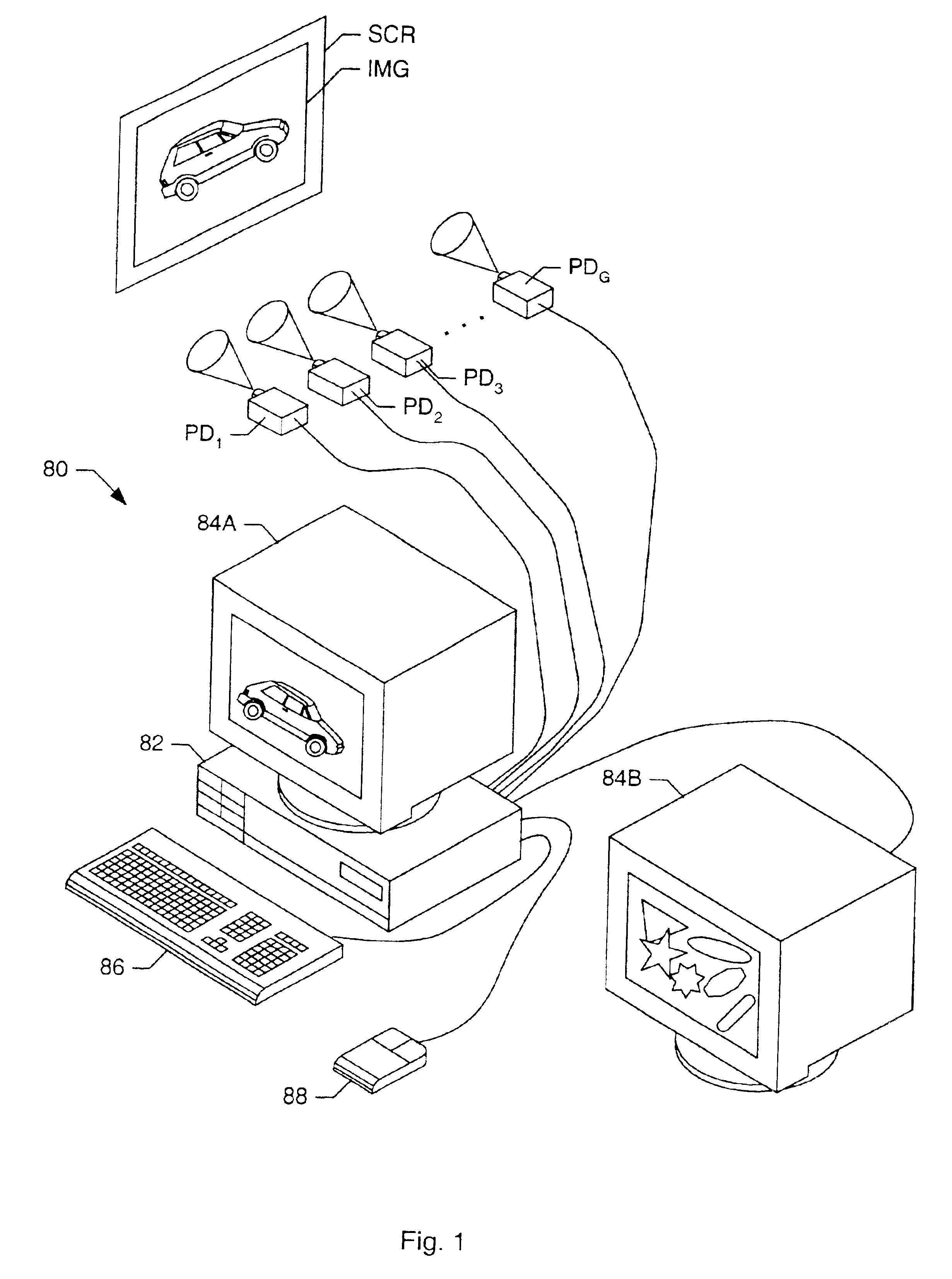

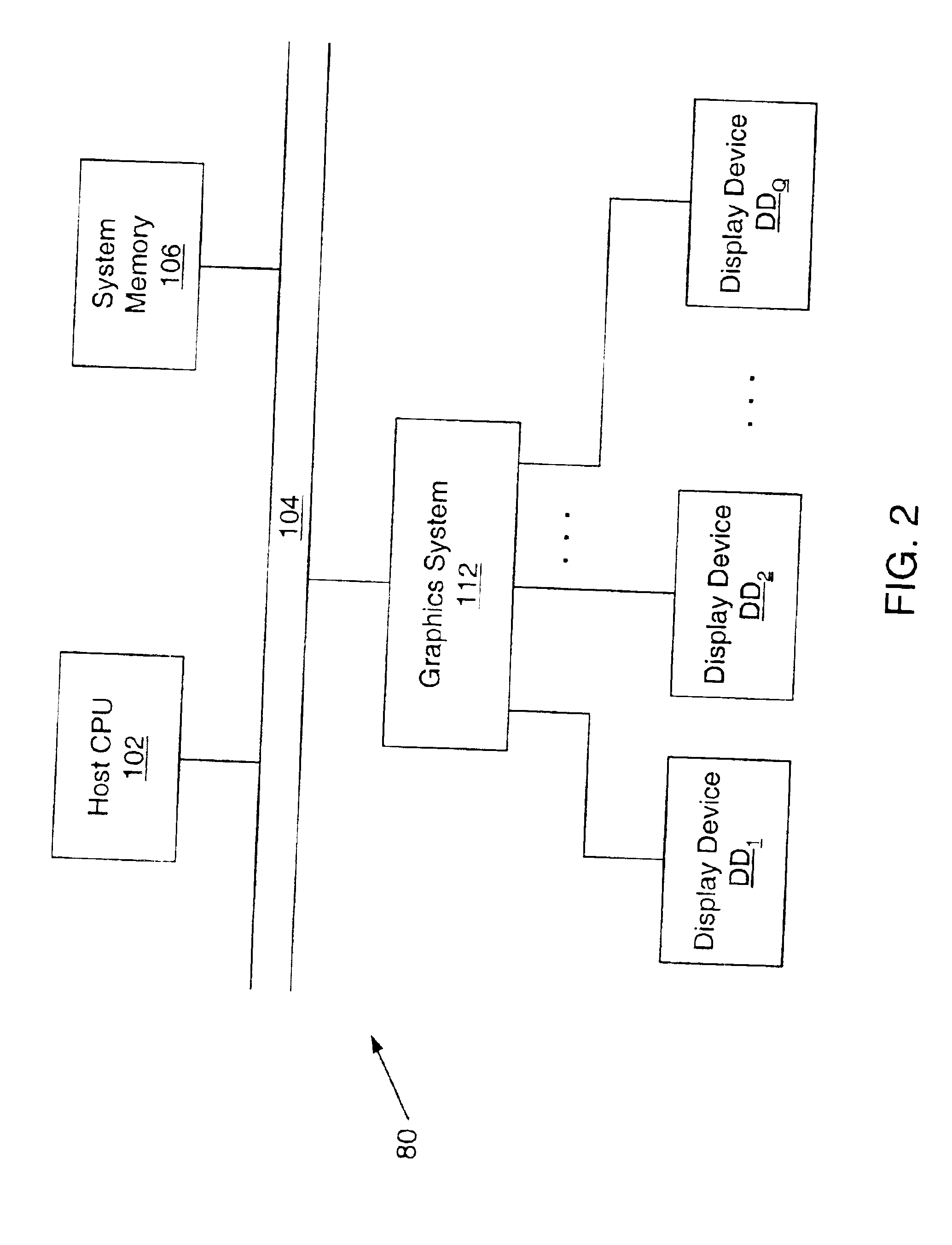

Rendering lines with sample weighting

InactiveUS6947057B2Smooth transitionExpanding effect on the width of the displayed linesDrawing from basic elementsMemory adressing/allocation/relocationGraphicsGraphic system

Owner:ORACLE INT CORP

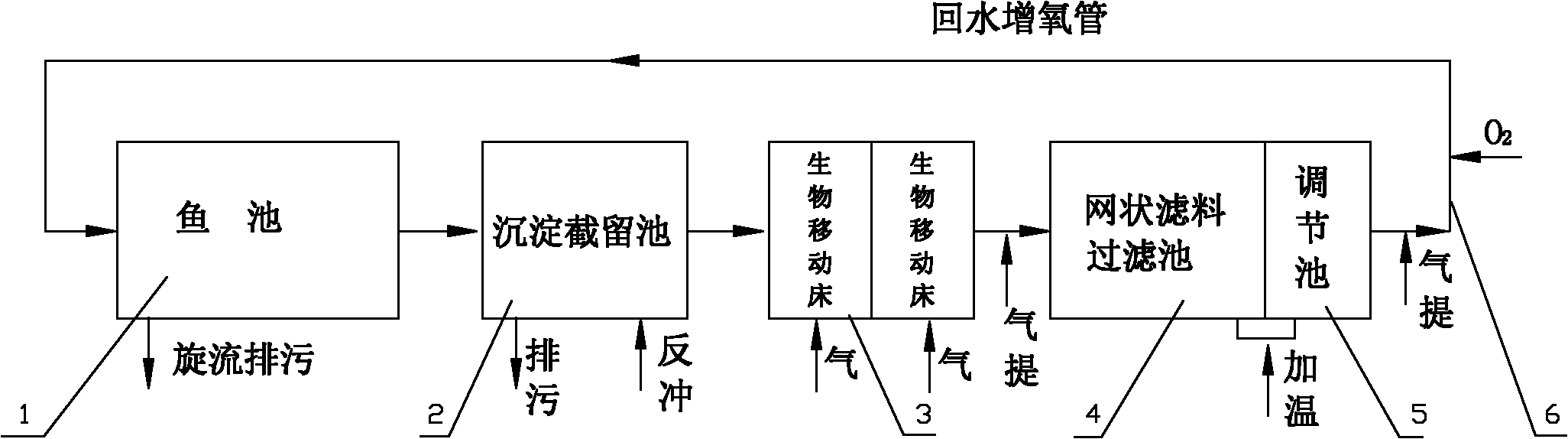

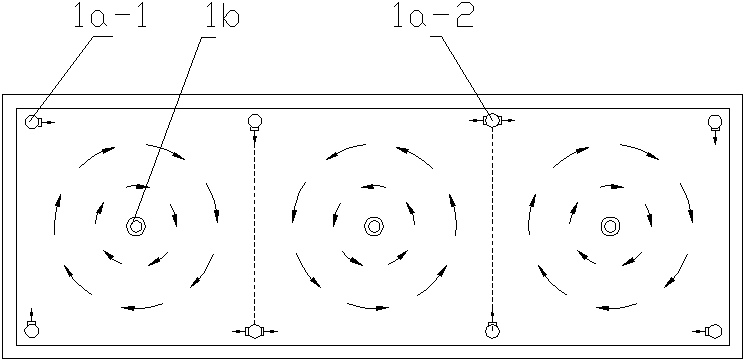

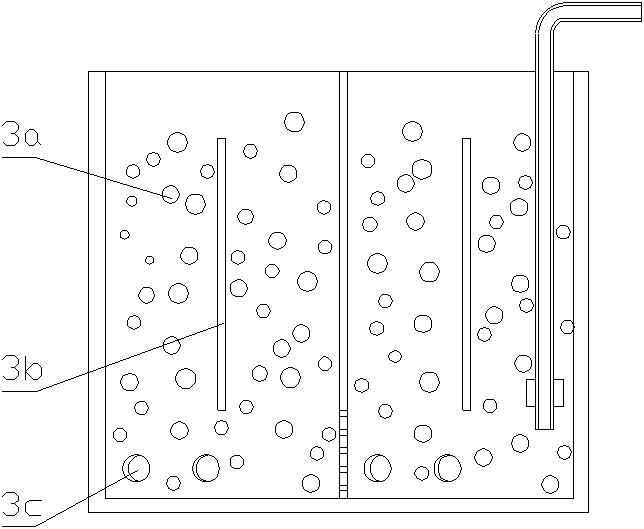

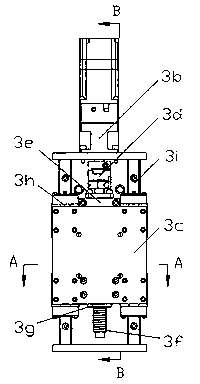

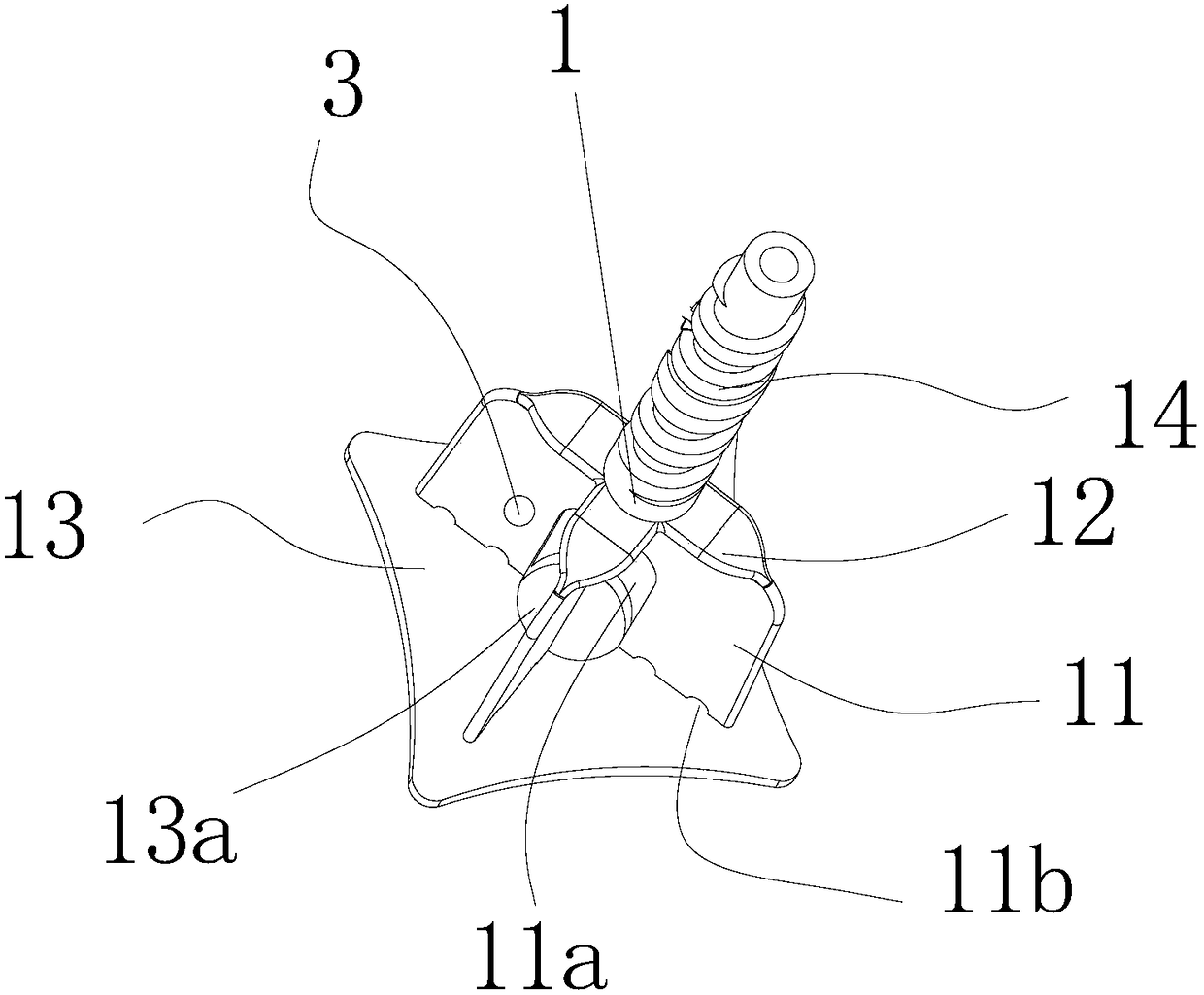

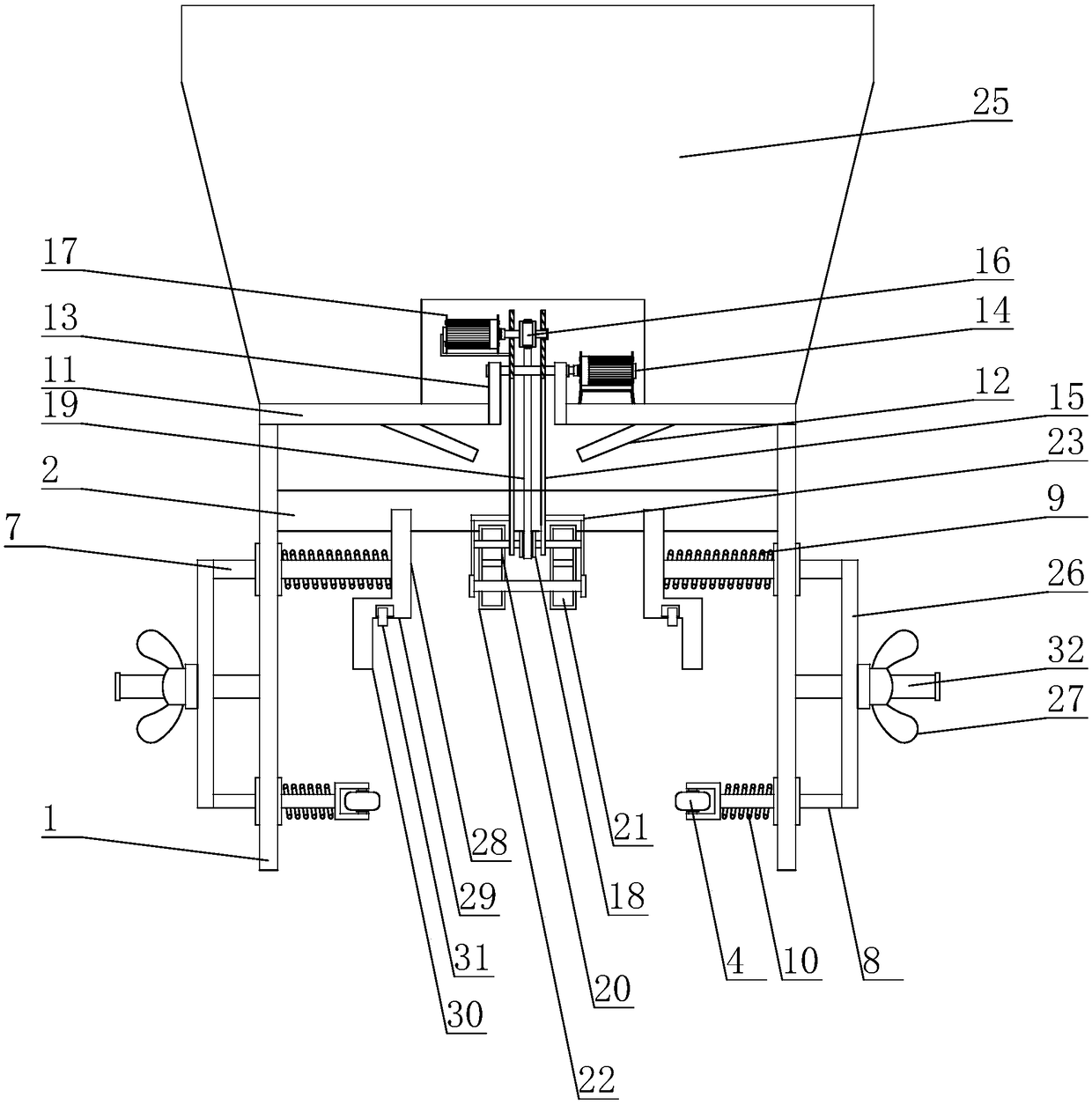

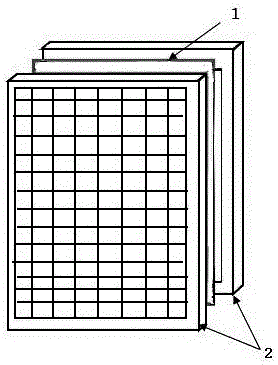

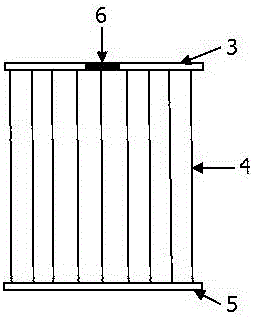

Factory circulating water fish culture system and using method thereof

InactiveCN102124992AImprove functionality and efficiencyConsistent widthPisciculture and aquariaElectricityFilter material

The invention relates to a factory circulating water fish culture system and a using method thereof, relating to the technical field of aquaculture. The factory circulating water fish culture system comprises a fishpond (1), a sedimentation interception pond (2), a biological moving bed (3), a reticular filter material filtering pond (4), a regulation pond (5) and a backwater oxygenation pipe (6), wherein the fishpond (1) is in a rectangular shape, water inside each unit can rotationally flow in one direction, and the rotational directions of adjacent units are inverse; the front half part of the sedimentation interception pond (2) is provided with a multi-bucket sewage collecting tank and a drainage through pipe, and the rear half part of the sedimentation interception pond (2) is provided with three-dimensional elastic packing; the biological moving bed (3) is formed by in series connecting a front group with a rear group, the lower part of a middle partition wall is provided with a plurality of large through hole structures, the middle of each group is provided with a partition plate (3b), suspended filter materials (3a) are placed in a cavity, and an aeration through pipe (3c) is horizontally arranged; the reticular filter material filtering pond (4) and the regulation pond (5) are connected in parallel, the lower part of the reticular filter material filtering ponds (4) and the lower part of the regulation pond (5) are communicated, reticular filter materials are taken, and a filter screen covers on the reticular filter materials; and the regulation pond (5) is used for replenishing the water, regulating pH concentration and increasing temperature and is provided with an air stripping pipe. The invention has low investment, high efficiency, energy and electricity saving and low operating cost and promotes the development of a factory circulating water fish culture career in China.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

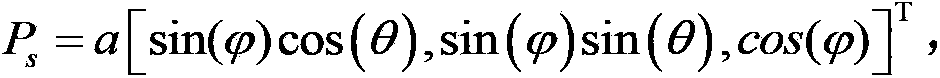

Ship radiation noise source distinguishing method based on super directivity small-bore cylindrical array

InactiveCN103438987ASmall change in main lobeSmall difference in shapeSubsonic/sonic/ultrasonic wave measurementPosition fixationDirectivityEngineering

The invention provides a ship radiation noise source distinguishing method based on a super directivity small-bore cylindrical array so as to realize ship radiation noise source distinguishing through the super directivity small-bore cylindrical array. All array elements of a measurement array are used for receiving correlation properties between ambient noise signals to design a super directivity weight vector so as to form a narrow beam width and high gain processing system; on the assumption of a six-lightspot target model, a ship radiation noise source distinguishing result based on the super directivity small-bore cylindrical array is obtained through computer simulation; a comparison simulation study with conventional beam forming proves the advantages of the ship radiation noise source distinguishing method based on the super directivity small-bore cylindrical array in terms of ship radiation noise source distinguishing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

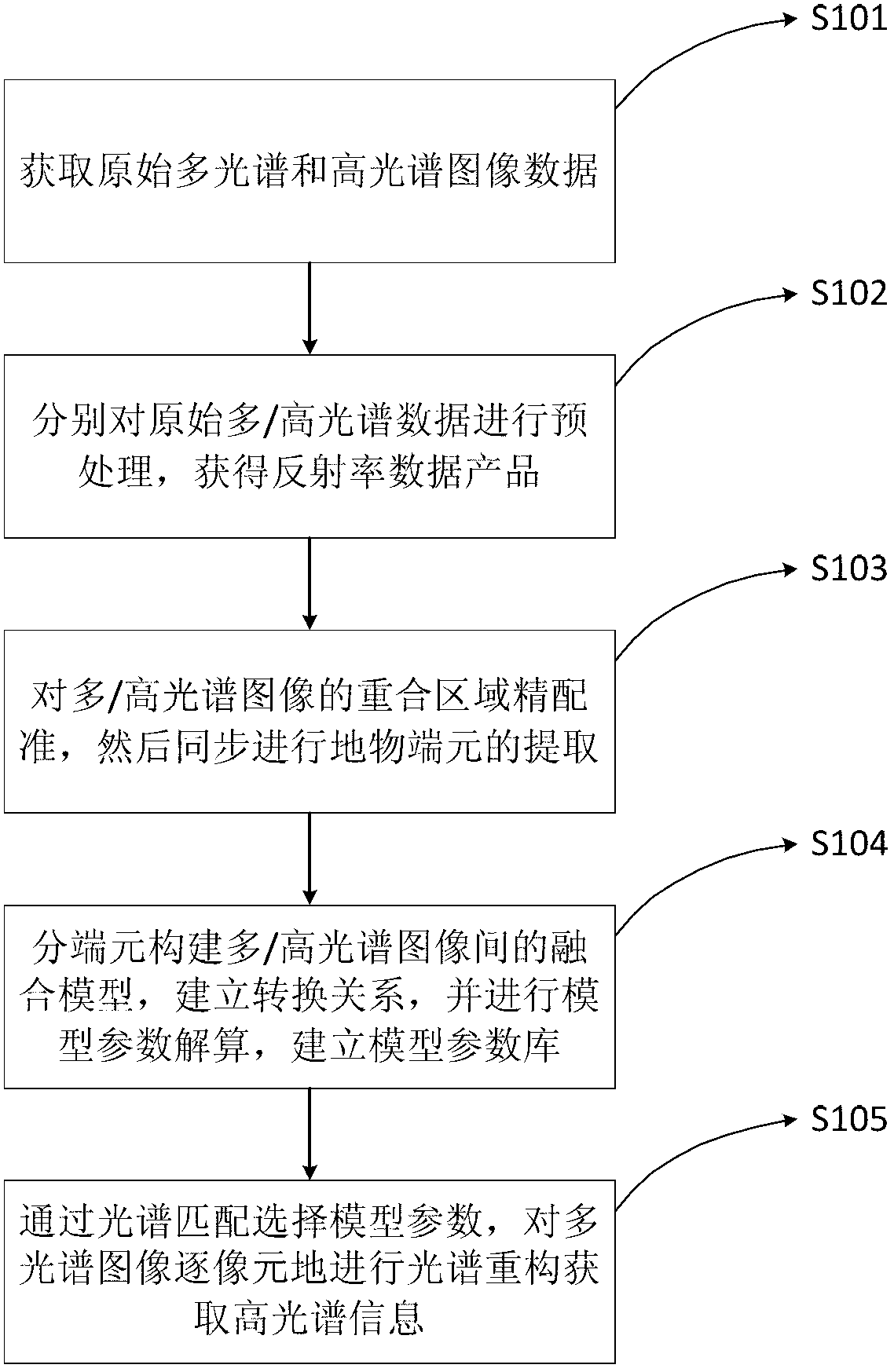

Method for reconstructing wide hyperspectral image based on fusion of multispectral/hyperspectral images

ActiveCN103325096AHigh spectral resolutionConsistent widthImage enhancementSensing dataImage resolution

The invention provides a method for reconstructing a wide hyperspectral image based on fusion of mulspectral / hyperspectral images. The method for reconstructing the wide hyperspectral image based on fusion of the multispectral / hyperspectral images comprises the following steps that surface feature end members are synchronously extracted in an overlapping area of the multispectral / hyperspectral images; a fusion model among the multispectral / hyperspectral images is established according to the end members, a transformational relation is established, model parameters are resolved and calculated, and a model parameter base is established; selection of the model parameters is conducted through spectrum matching, and spectrum reconstruction is conducted on multispectral images pixels by pixels so that hyperspectral information can be obtained. According to the technical scheme, by means of data fusion, successive wide hyperspectral images which have high spectral resolutions can be obtained through reconstruction of other multispectral remote sensing data, the spectral resolutions of the hyperspectral images are identical to data of original hyperspectral images, the spatial resolution and the width are identical to the original multispectral data, the hyperspectral resolutions of the original hyperspectral images is kept, and the spatial resolution and the width of each of the hyperspectral images can be improved.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

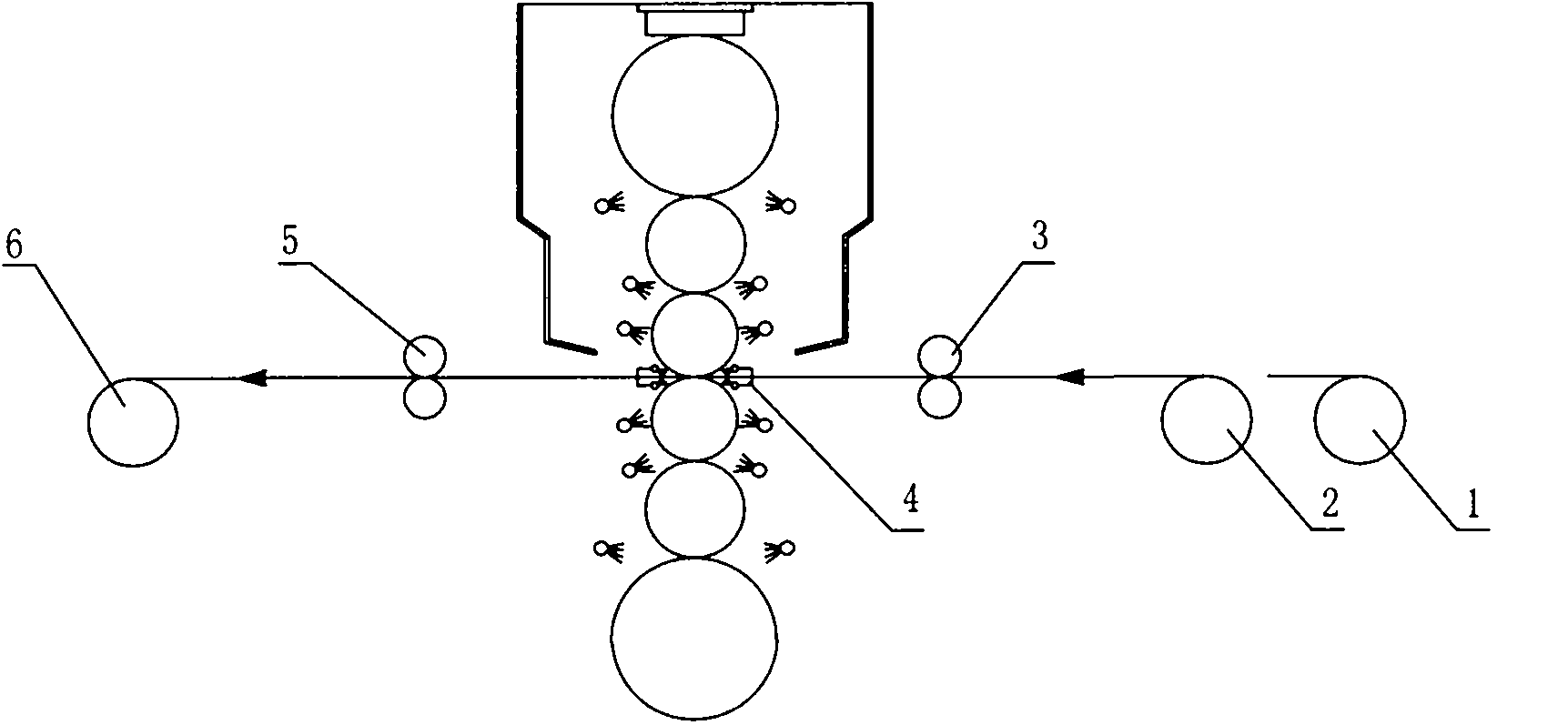

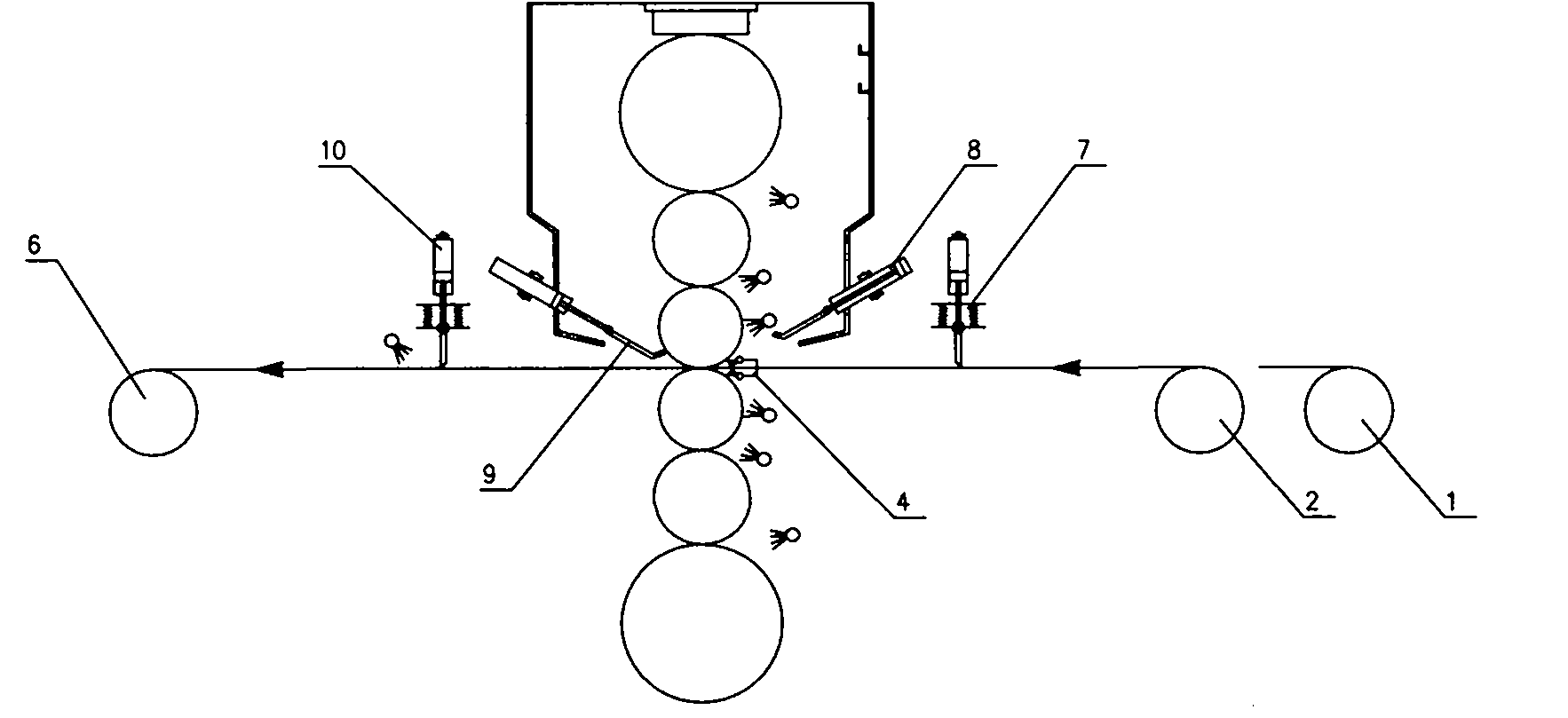

Blowing-free emulsion residue removal method

ActiveCN101829693AImprove surface qualityReduce noise pollutionRollsWork cleaning devicesEmulsionRolling mill

The invention belongs to the technical field of cold-rolled emulsion spot treatment, and in particular relates to a blowing-free emulsion residue removal method, which is applied to various cold-rolling mills. The blowing-free emulsion residue removal method is characterized by comprising the following steps of: 1) blocking low inertia force return of the emulsion; 2) blocking side fluid channeling of the emulsion; 3) blocking fluid channeling of intermediate roll shifting empty emulsion; 4) blocking the condensate of the emulsion; 5) rapidly draining the injection beam of the emulsion; and 6) preventing splashing. The blowing-free emulsion residue removal method has the advantages of simpleness and excellent treatment efficiency.

Owner:WISDRI ENG & RES INC LTD

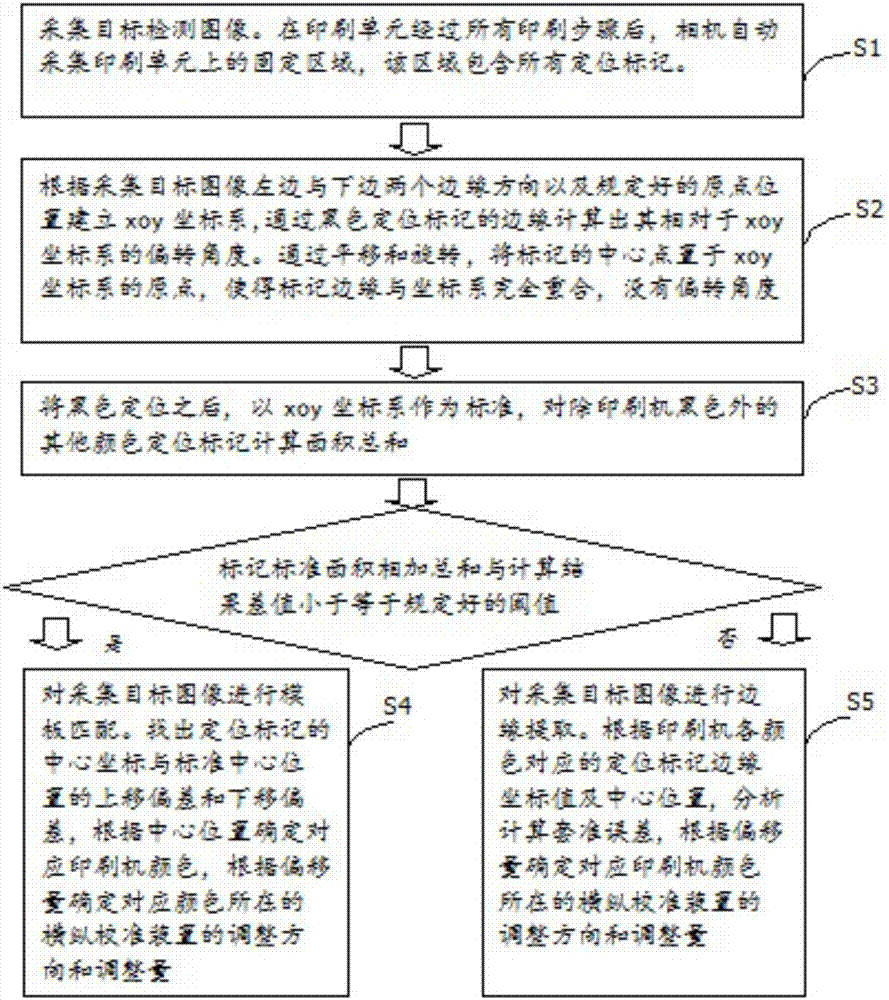

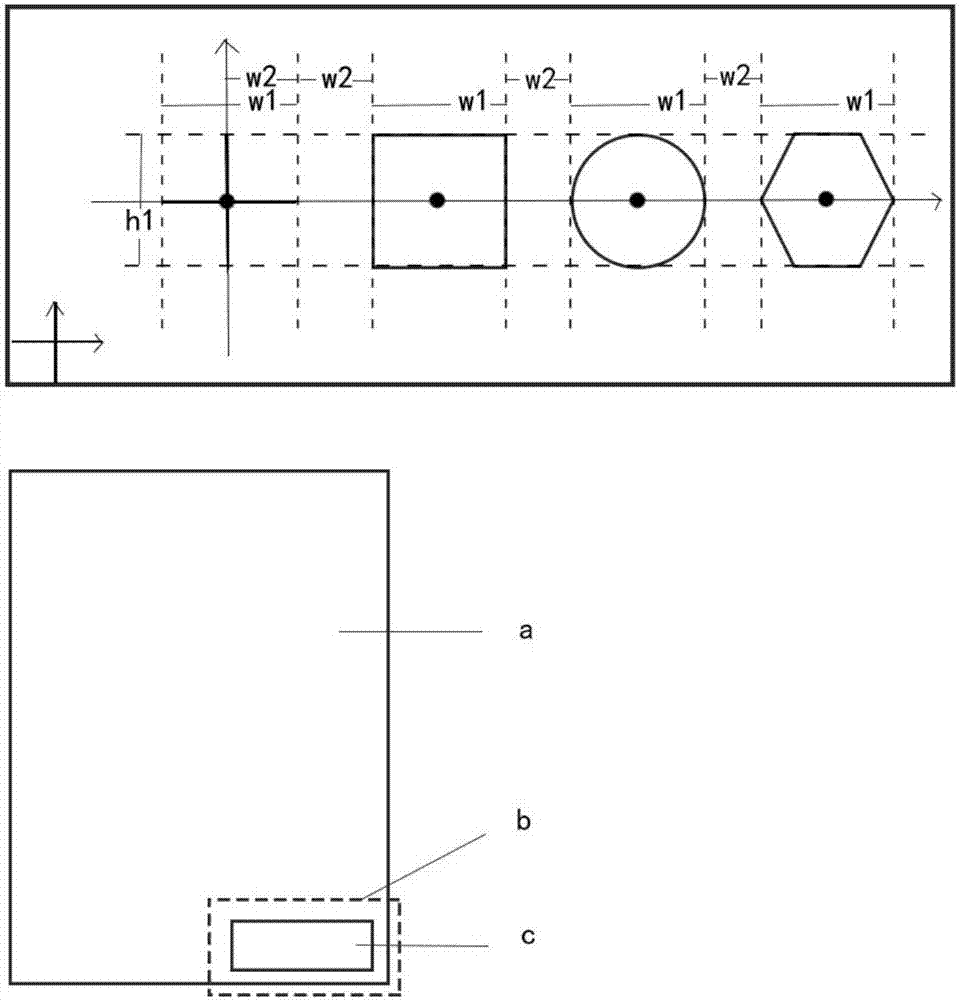

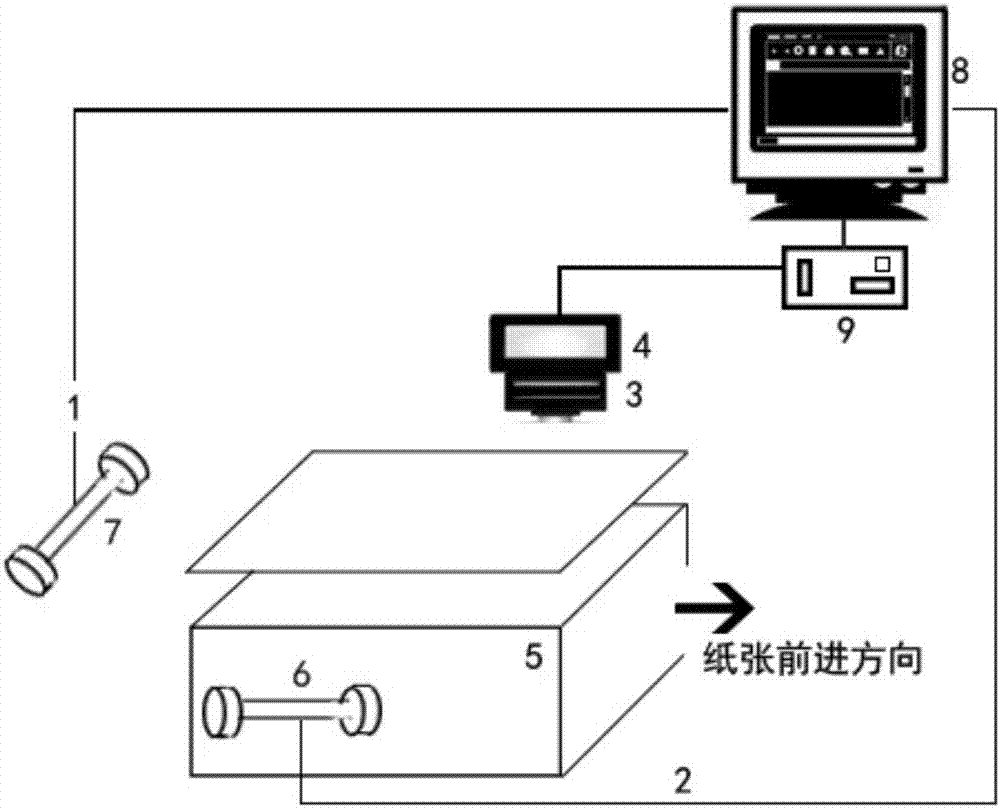

Machine vision-based overprint error detection method

The present invention provides a machine vision-based overprint error detection method. According to the method, a target image is acquired through a camera, wherein the target image contains a plurality of positioning marks; the area of the positioning marks is calculated, if the difference value of the area of the positioning marks and a standard area is not larger than a specified threshold value, and template matching is used to extract the centers of the positioning marks; overprint error is detected according to the deviation quantity of the positions of the centers and standard positions; if the difference value of the area of the positioning marks and the standard area is larger than the specified threshold value, edge segmentation is adopted to extract the edges of the positioning marks, and overprint error is detected according to the deviation quantity of the positions of the edges and standard positions; and after the error detection is completed, and a printer is automatically adjusted. According to the method of the invention, the image segmentation and the template matching are utilized, so that the technical problems of large computation quantity, large error, low robustness and incapability of performing automatic adjustment according to error in the prior art can be solved. The method is suitable for being popularized in the printing industry.

Owner:TONGJI UNIV

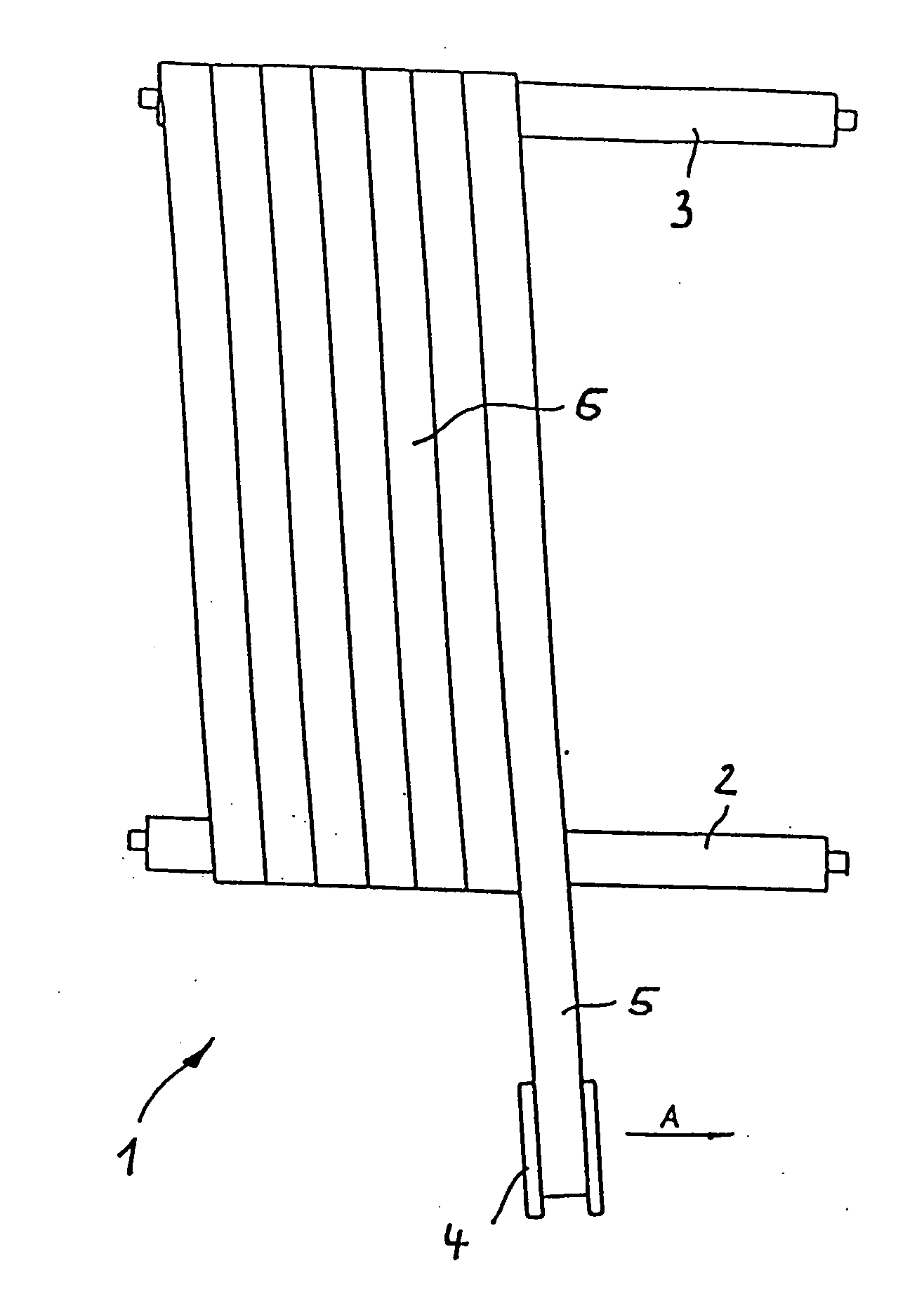

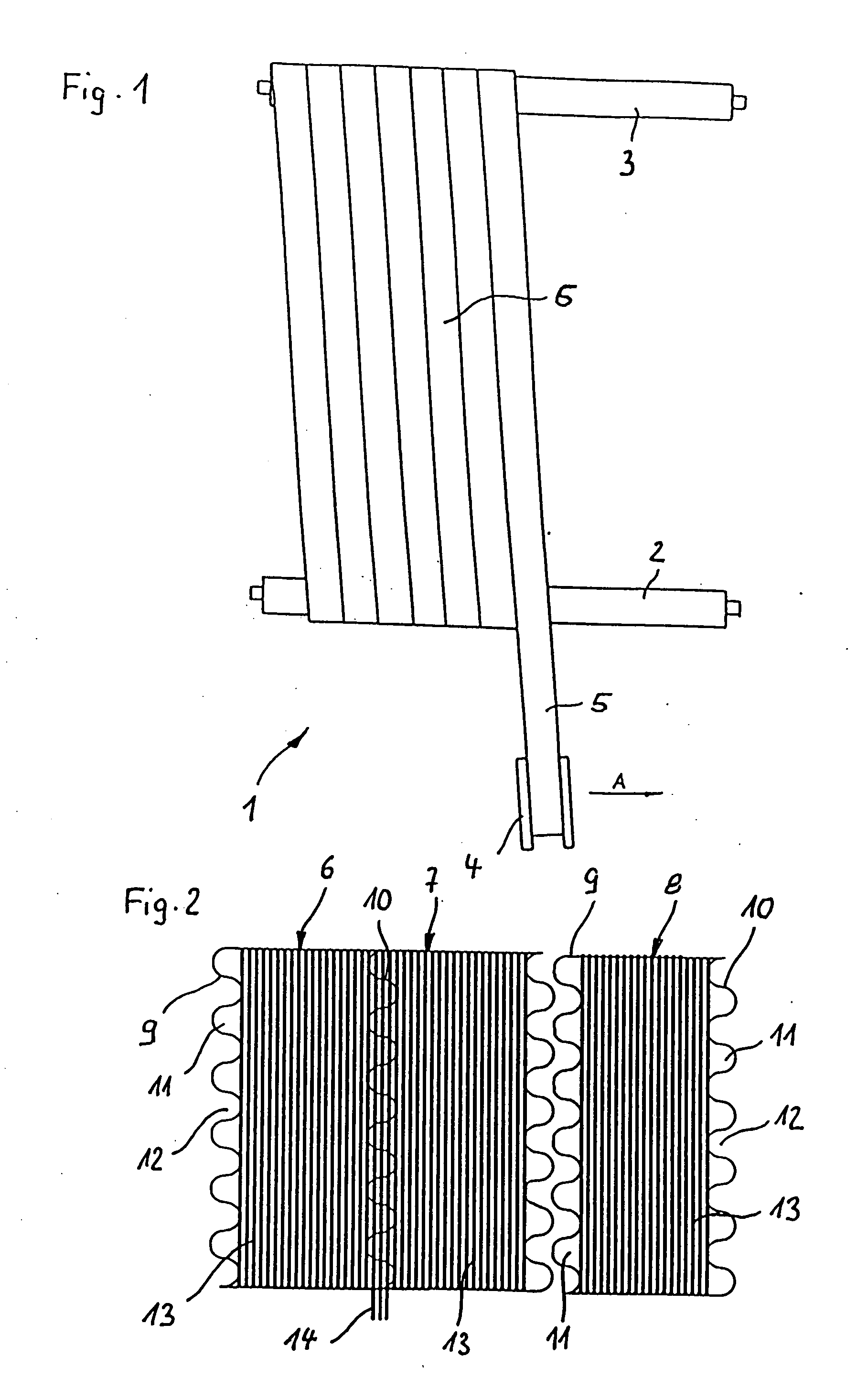

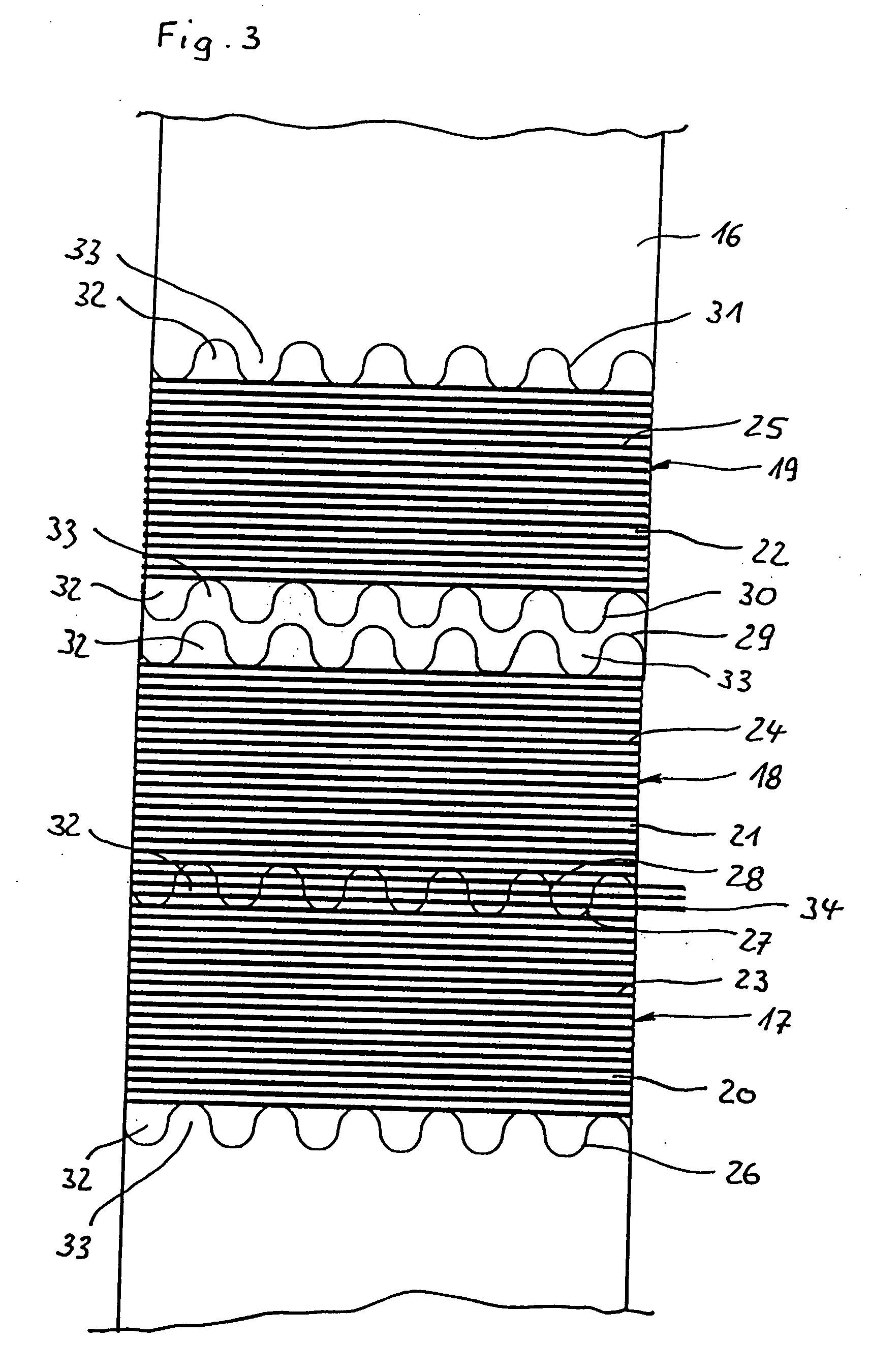

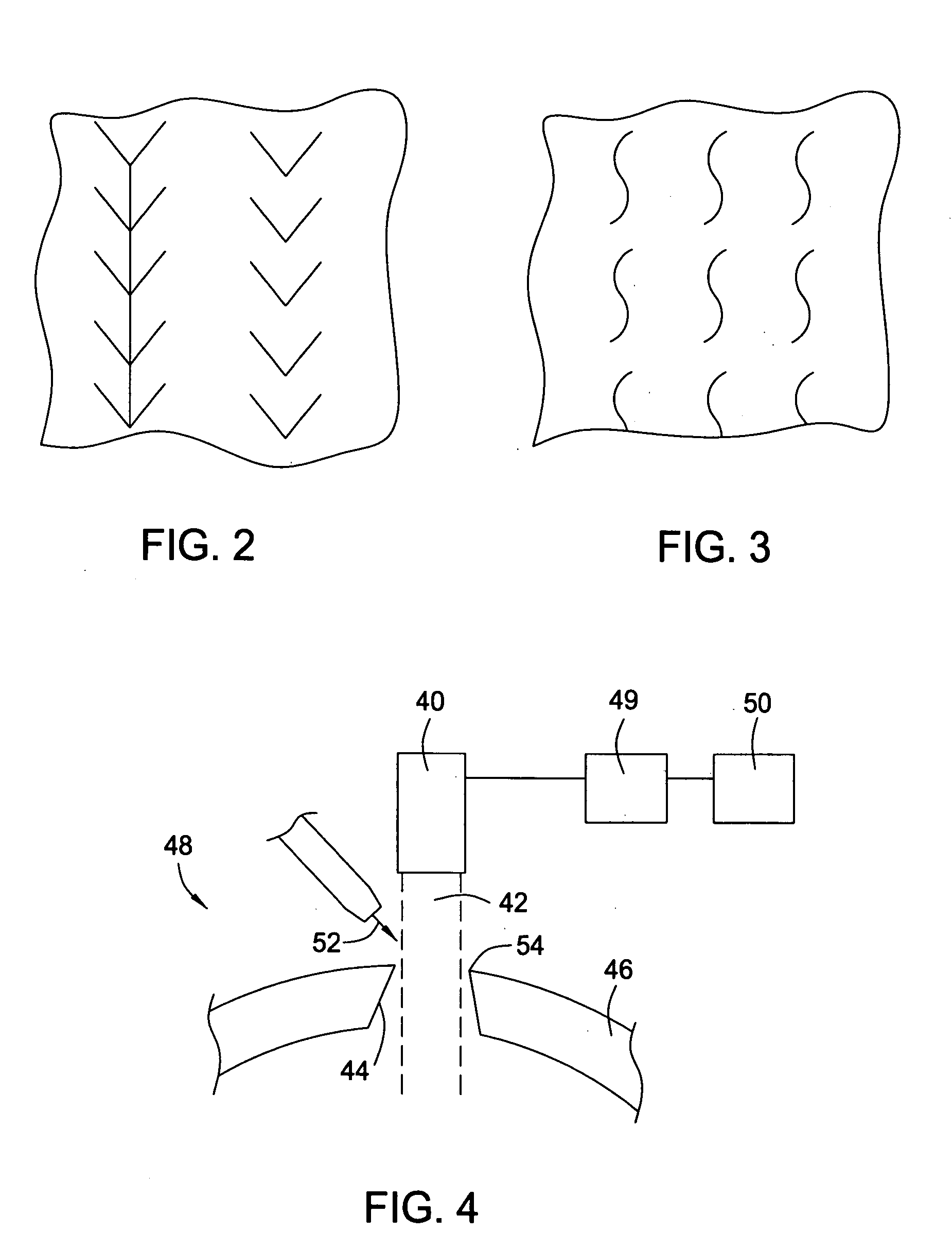

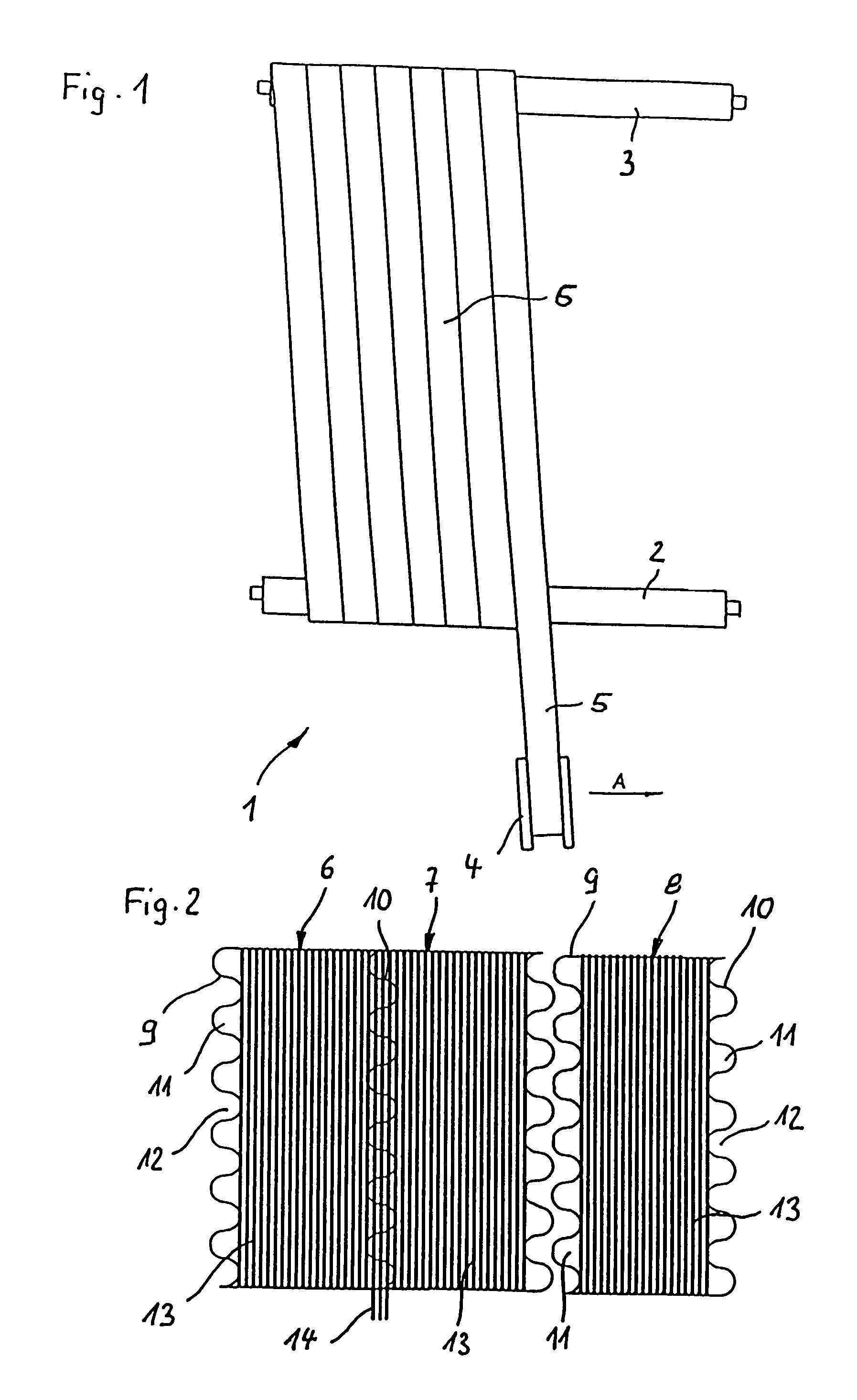

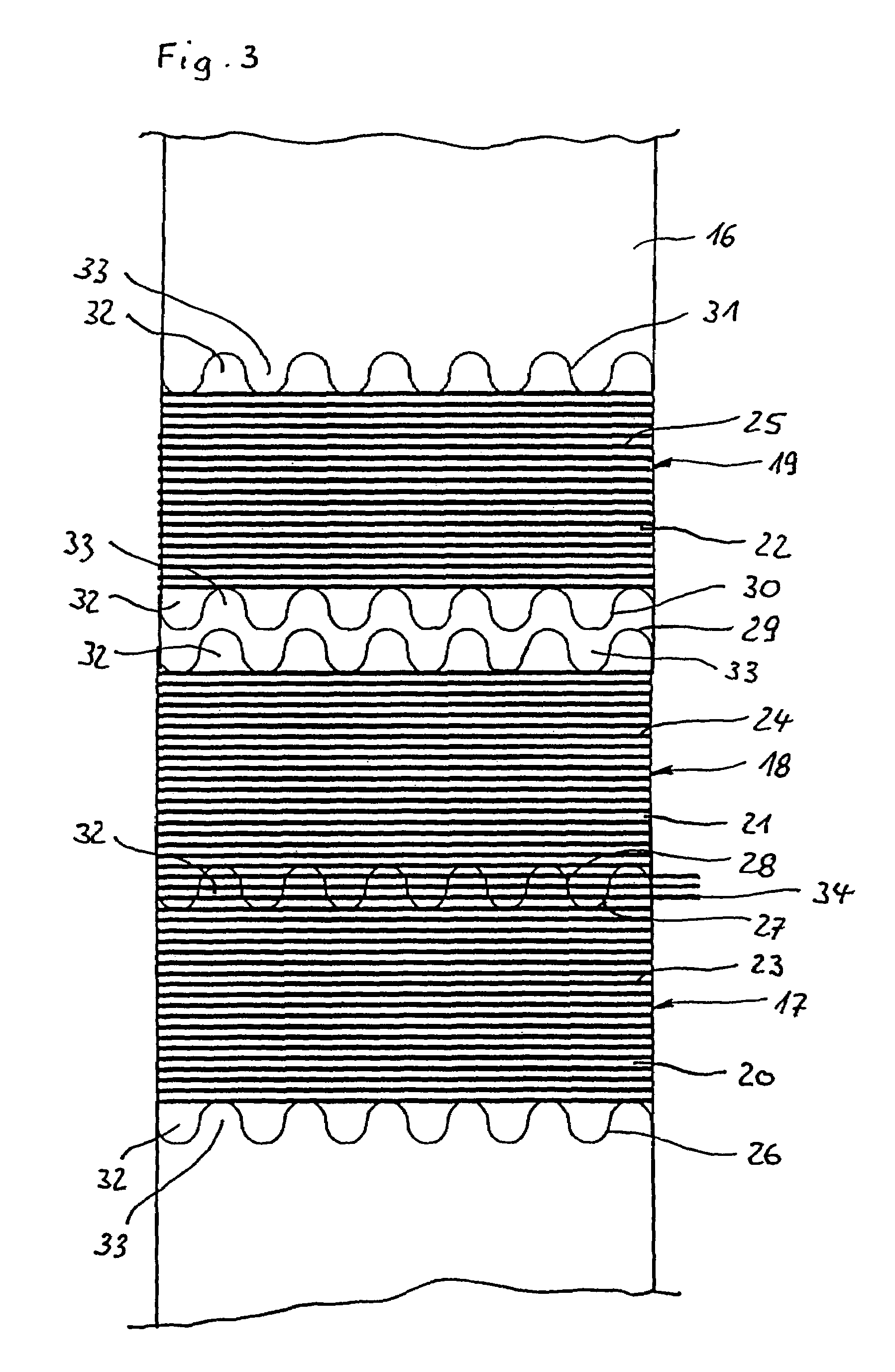

Method for manufacturing a felt belt, and felt belt

ActiveUS20070235155A1Economical fashionImprove lateral strengthLamination ancillary operationsCellulosic plastic layered productsYarnFiber matrix

The invention is a method for manufacturing a felt belt having a support which is embedded in a fiber matrix and is made up of at least two yarn layers arranged one above another, at least one is a longitudinal yarn layer made up of longitudinal yarns extending in parallel fashion, and at least one is a transverse yarn layer made up of transverse yarns extending in parallel fashion, transverse yarns being present that are continuous over the width of the felt belt. For each longitudinal yarn layer, a first support module is manufactured, by means of a first auxiliary support web, at a width that is less than the width of the completed felt belt, the first auxiliary support web being wound in helical fashion, before, during, or after the application of yarns, to a width that corresponds to the width necessary for manufacture of the completed felt belt.

Owner:HEIMBACH GMBH & CO KG

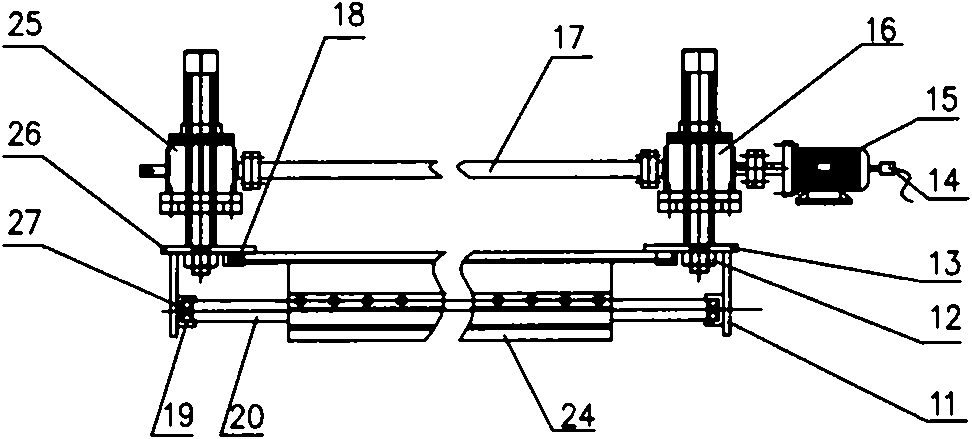

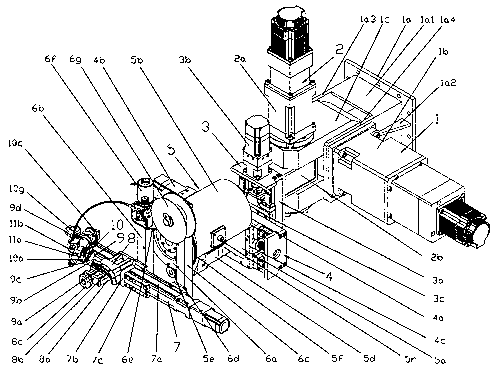

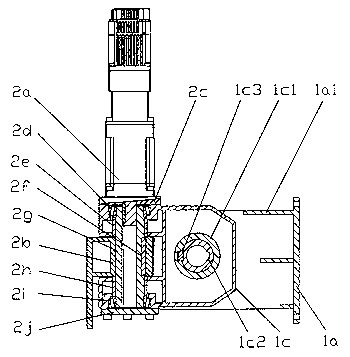

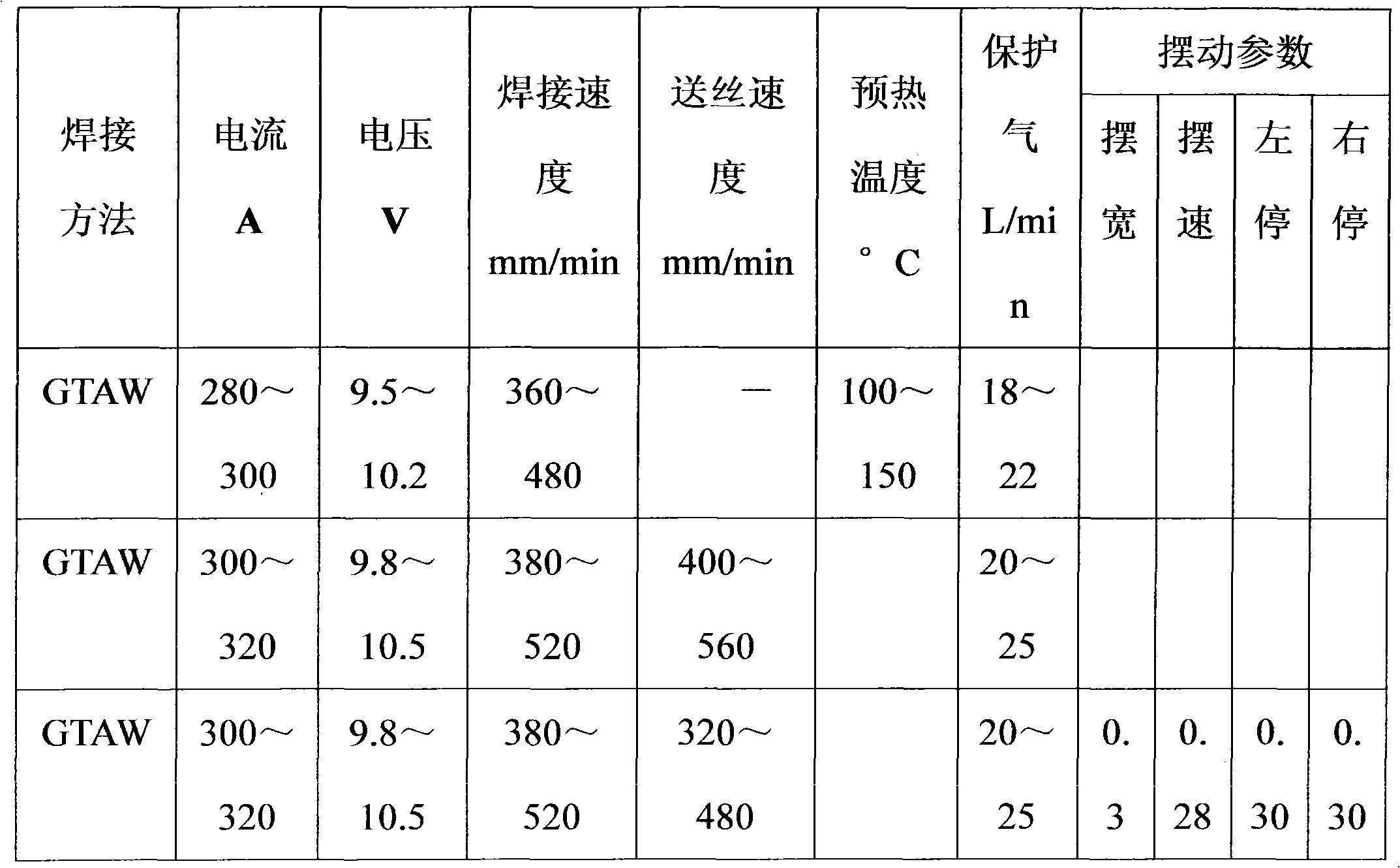

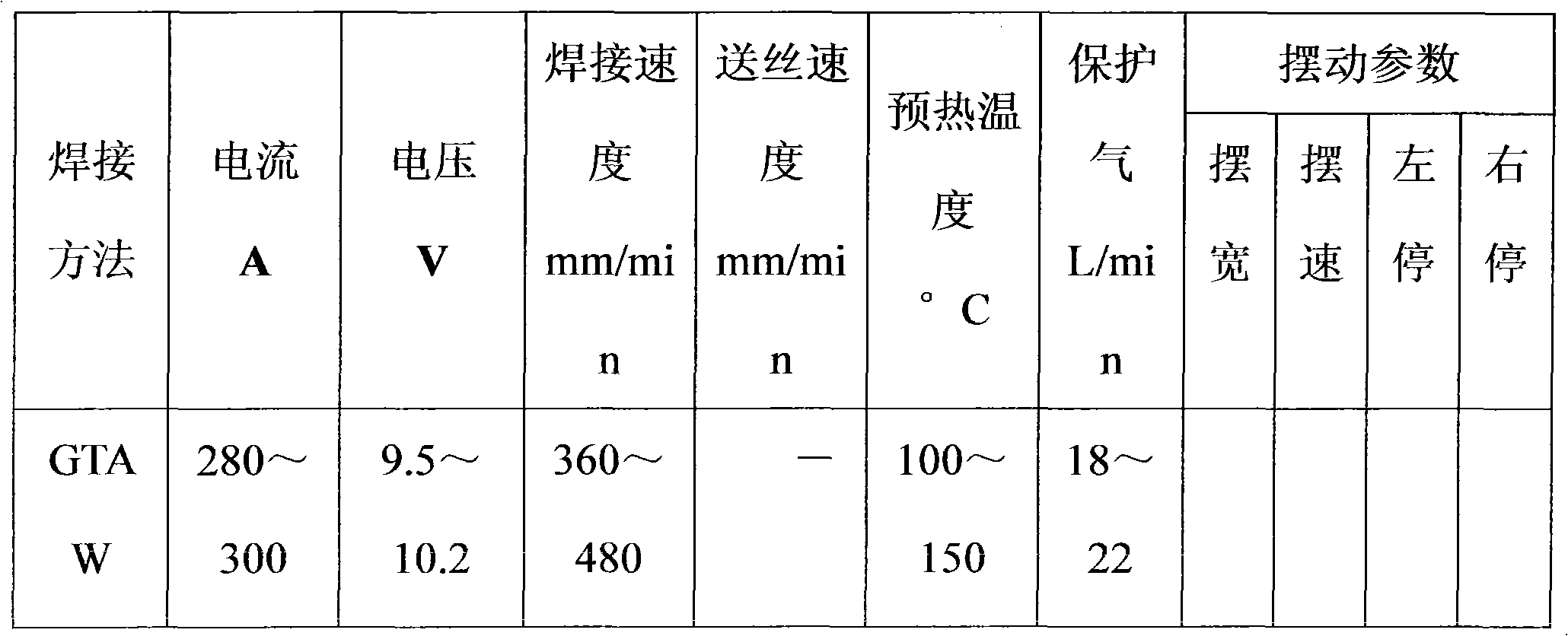

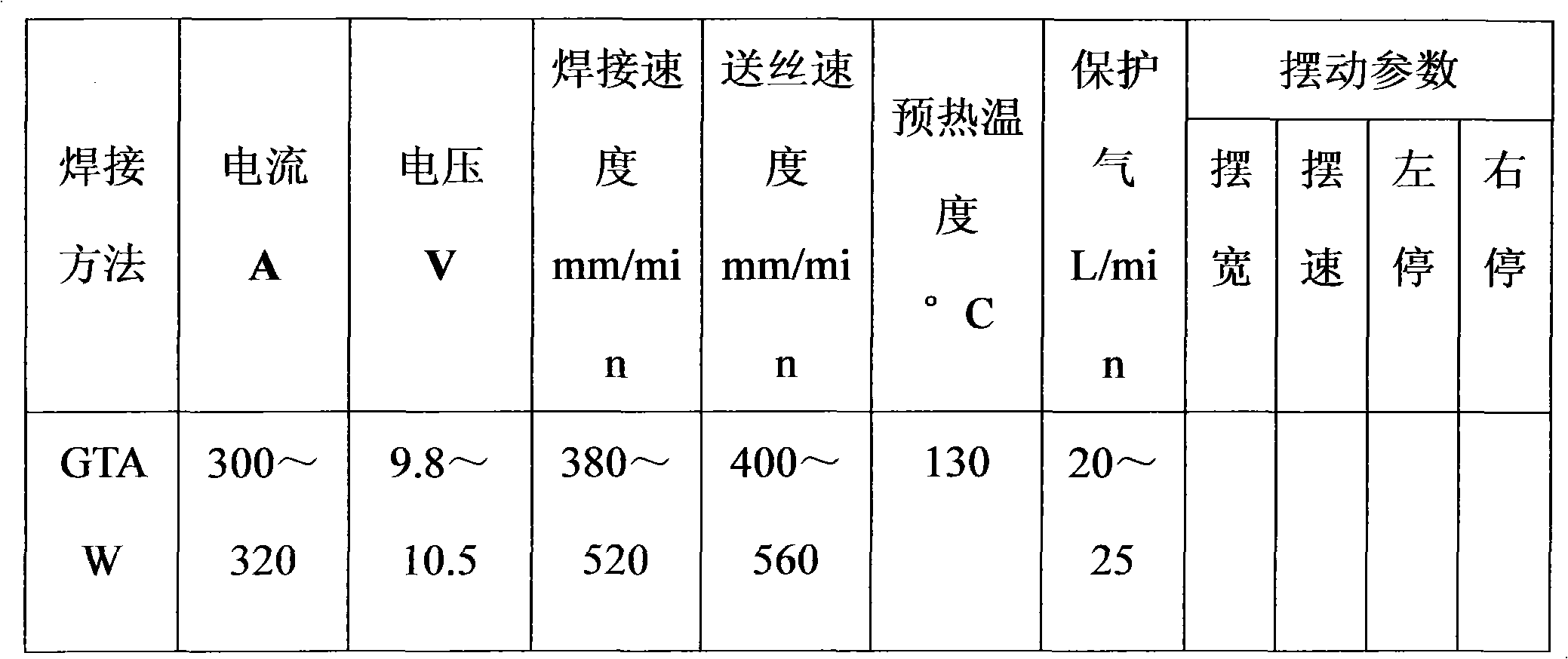

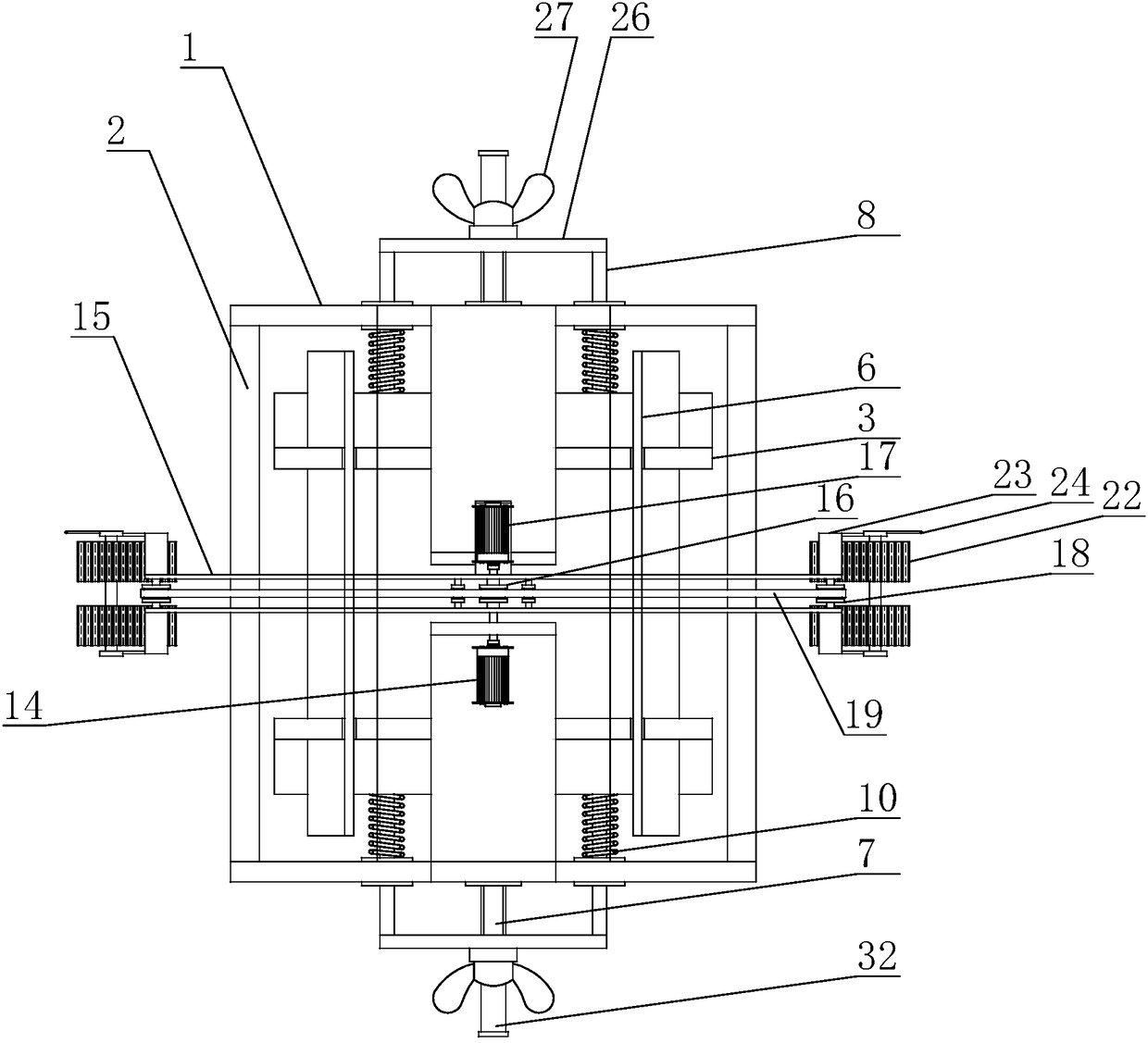

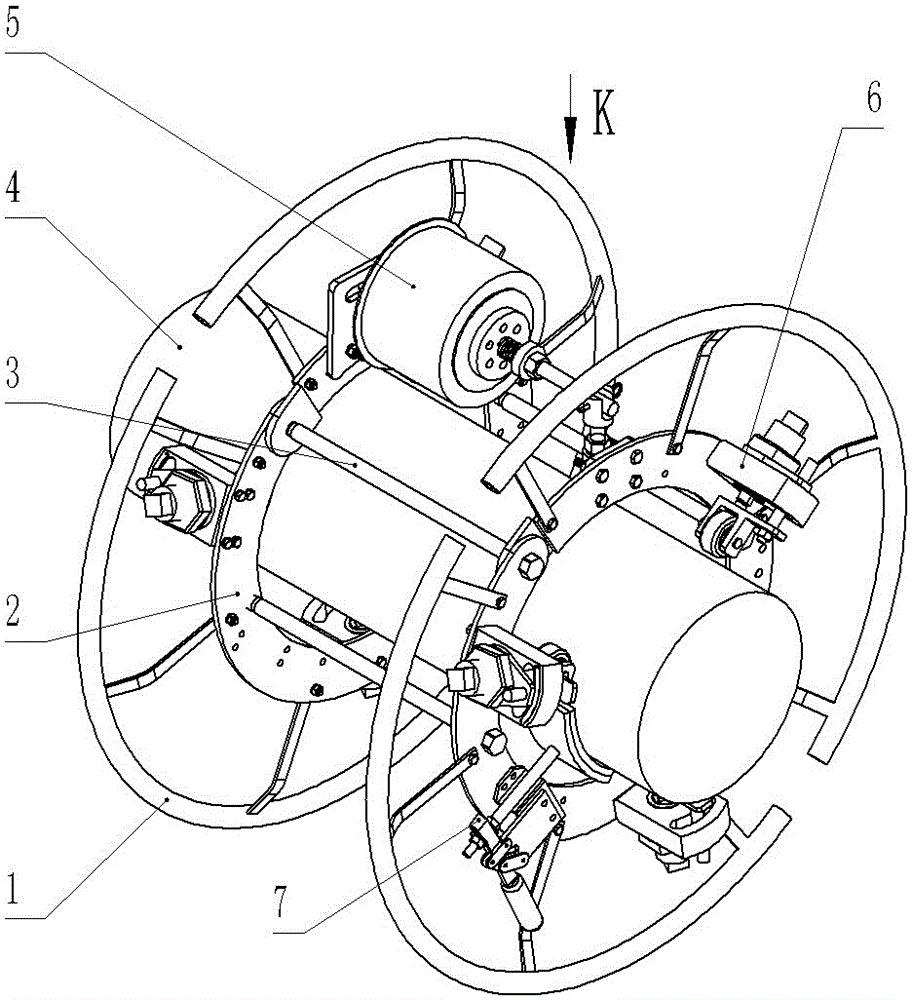

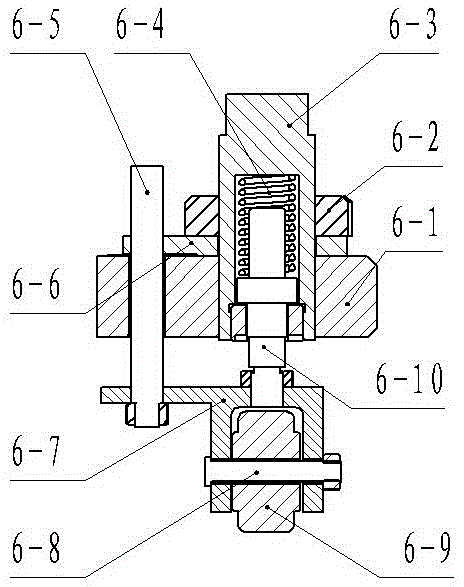

Flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and welding method thereof

InactiveCN102825368AExcellent surfacing qualityEasy post-weld processingArc welding apparatusElectrical controlElectric control

The invention provides a flange sealing groove inner surface annular all-position TIG (Tungsten Inert Gas) automatic surface welding equipment and a welding method thereof, belonging to the technical field of automatic welding equipments and welding methods. The automatic welding equipment mainly comprises a position regulation mechanism and a TIG rotary welding head, wherein the TIG rotary welding head is used for regulating a surface welding position of a flange sealing groove through the position regulation mechanism. An electric control device is used for setting parameters such as welding current, a wire feed speed, a welding speed and arc voltage control according to the circumferential position located by the welding head and a cycle of 12 preset partitions so as to carry out welding control. The rotational radius of the welding head can be automatically changed inwards or outwards according to set width after a cycle of welding is finished, so that surface welding in the flange sealing groove is realized, and surface welding on the side surface of the flange sealing groove is carried out after an angle of a welding gun is changed until one end surface is piled up. The surface welding surface is smooth, so that the problems of cutter beating and long processing time in the process of processing the flange sealing groove by manual surface welding at a later stage are avoided, surface welding quality is superior to quality of manual surface welding, and the problem that a product is repaired due to defects after manual surface welding is reduced.

Owner:CHINA FIRST HEAVY IND +1

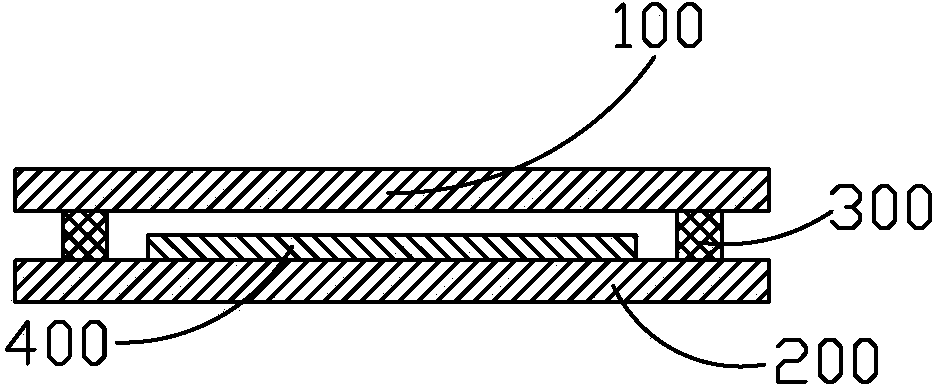

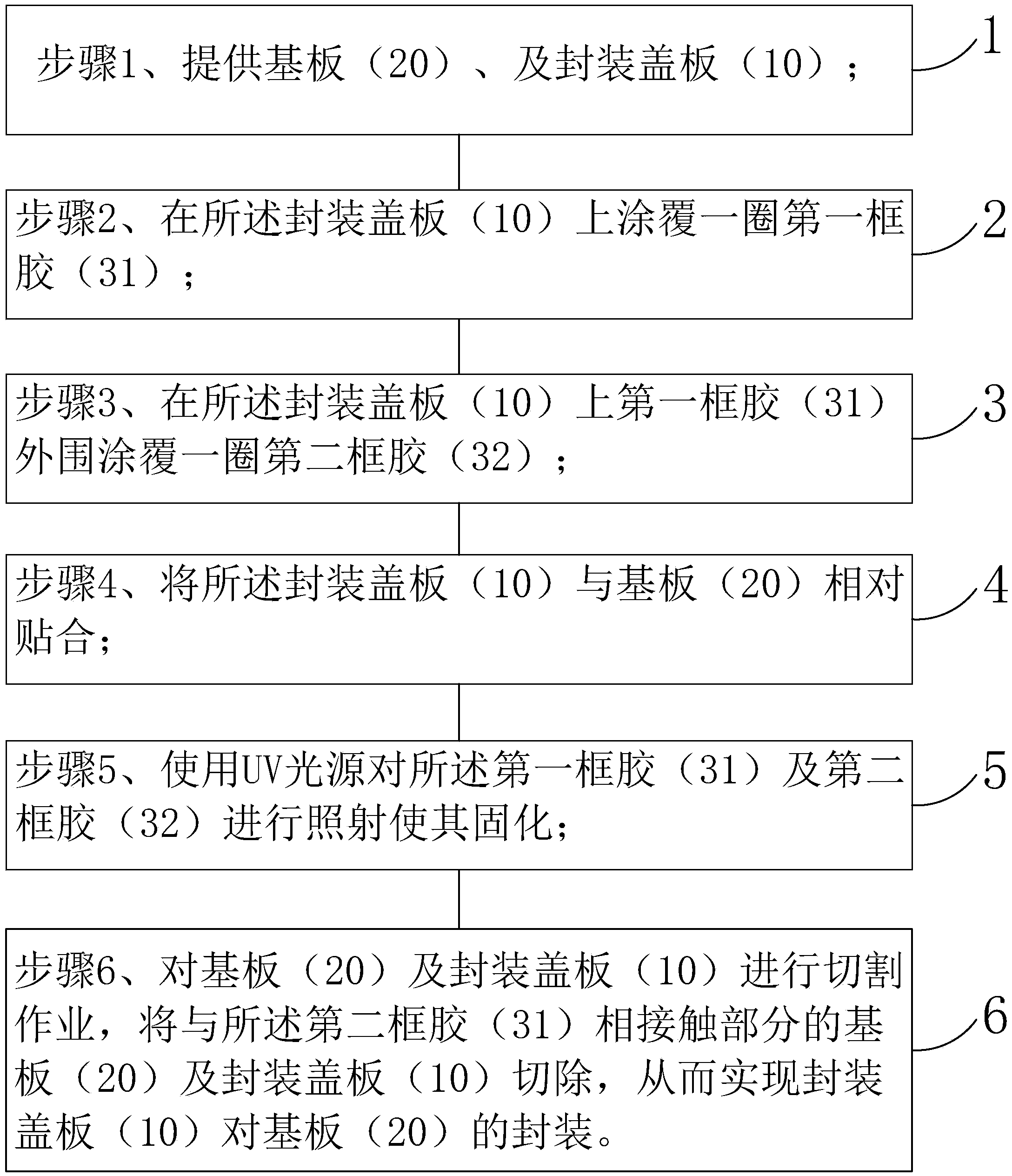

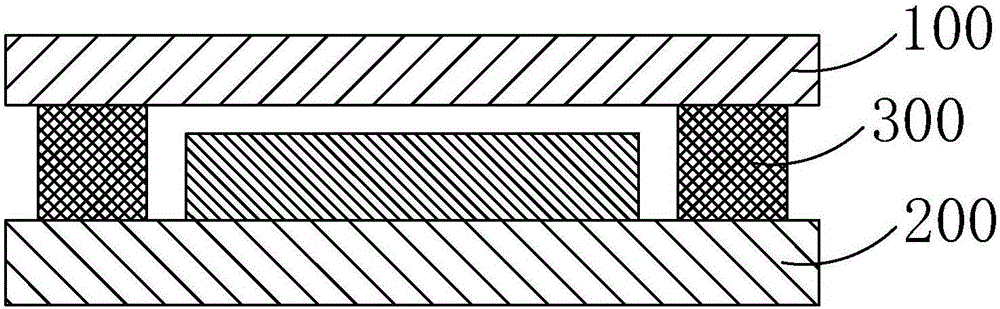

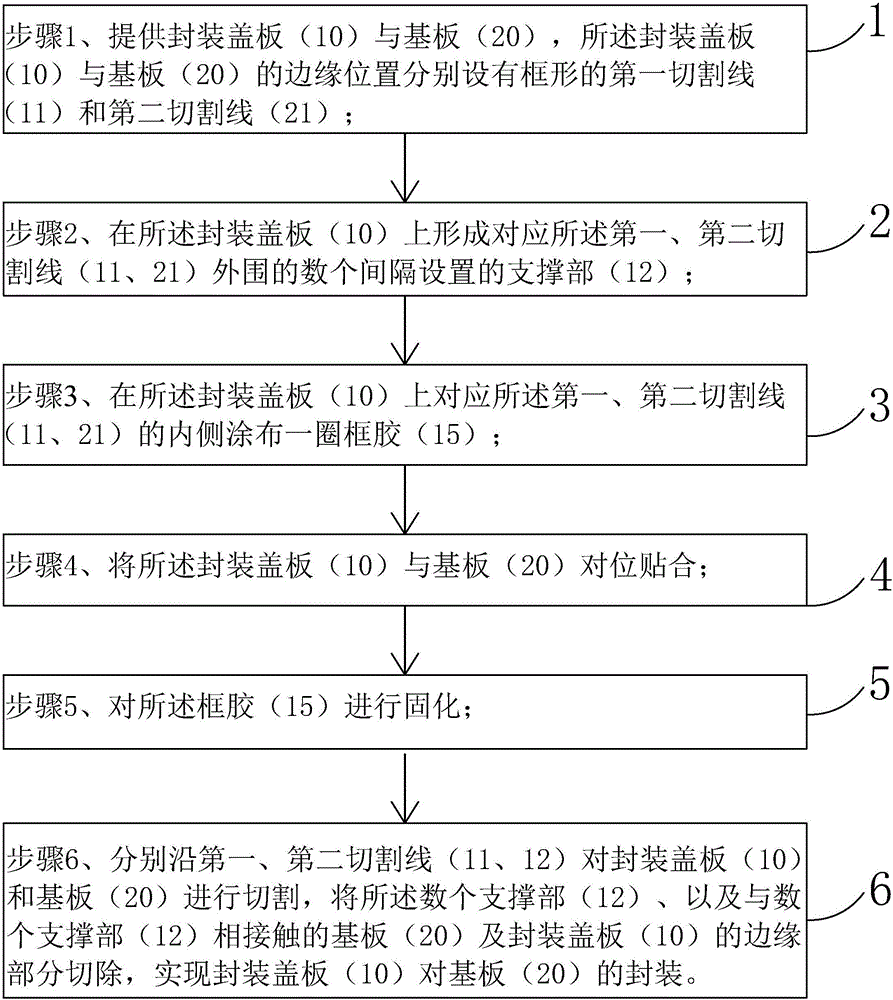

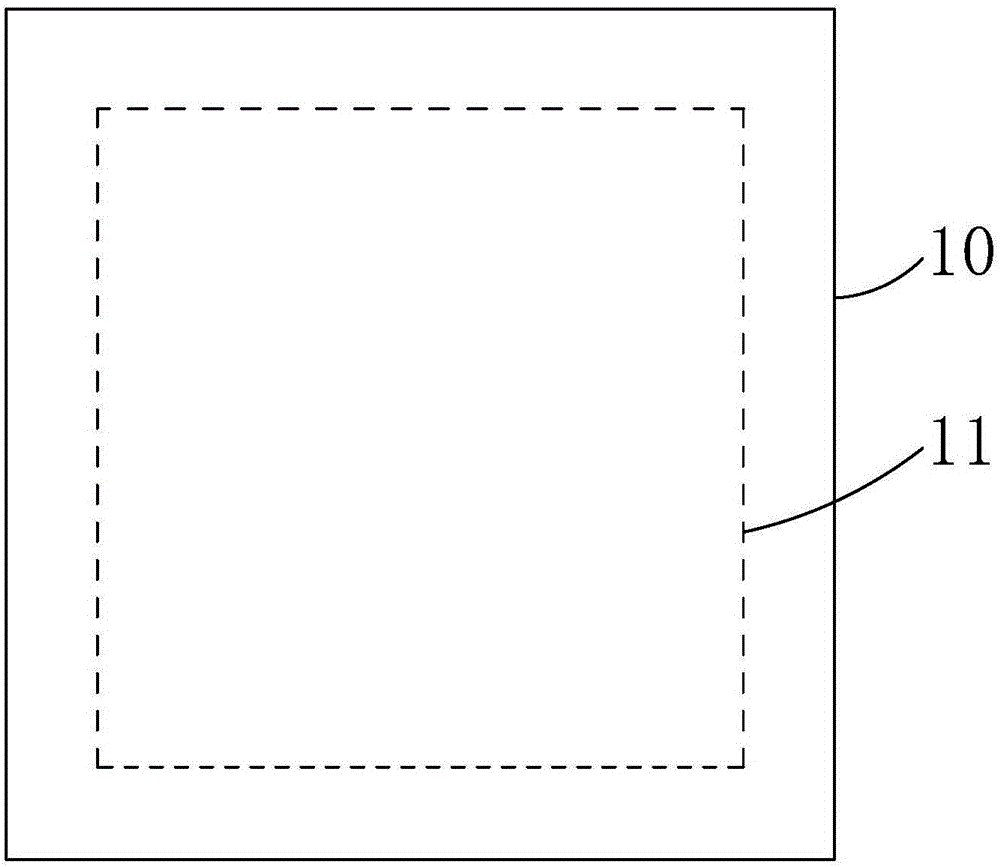

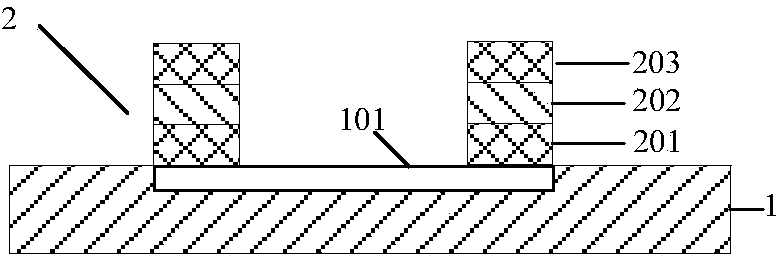

Substrate packaging method and structure

ActiveCN104362243AConsistent widthGood encapsulation effectNon-linear opticsSemiconductor devicesAdhesiveEngineering

The invention provides a substrate packaging method and structure. The substrate packaging method includes the steps of 1), providing a substrate and a packaging cover plate; 2), coating the packaging cover plate with a first box adhesive in a ring; 3), coating the packaging cover plate with a second box adhesive on the outer periphery of the first box adhesive in a ring; 4), allowing the packaging cover plate to be oppositely adhered to the substrate; 5), using an UV (ultraviolet) light source to irradiate to the first and second box adhesives to have the same cured; 6), performing cutting operation on the substrate and the packaging cover plate and cutting the portions, contacting with the second box adhesive, of substrate and the packaging cover plate so as to achieve packaging of the packaging cover plate and the base plate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

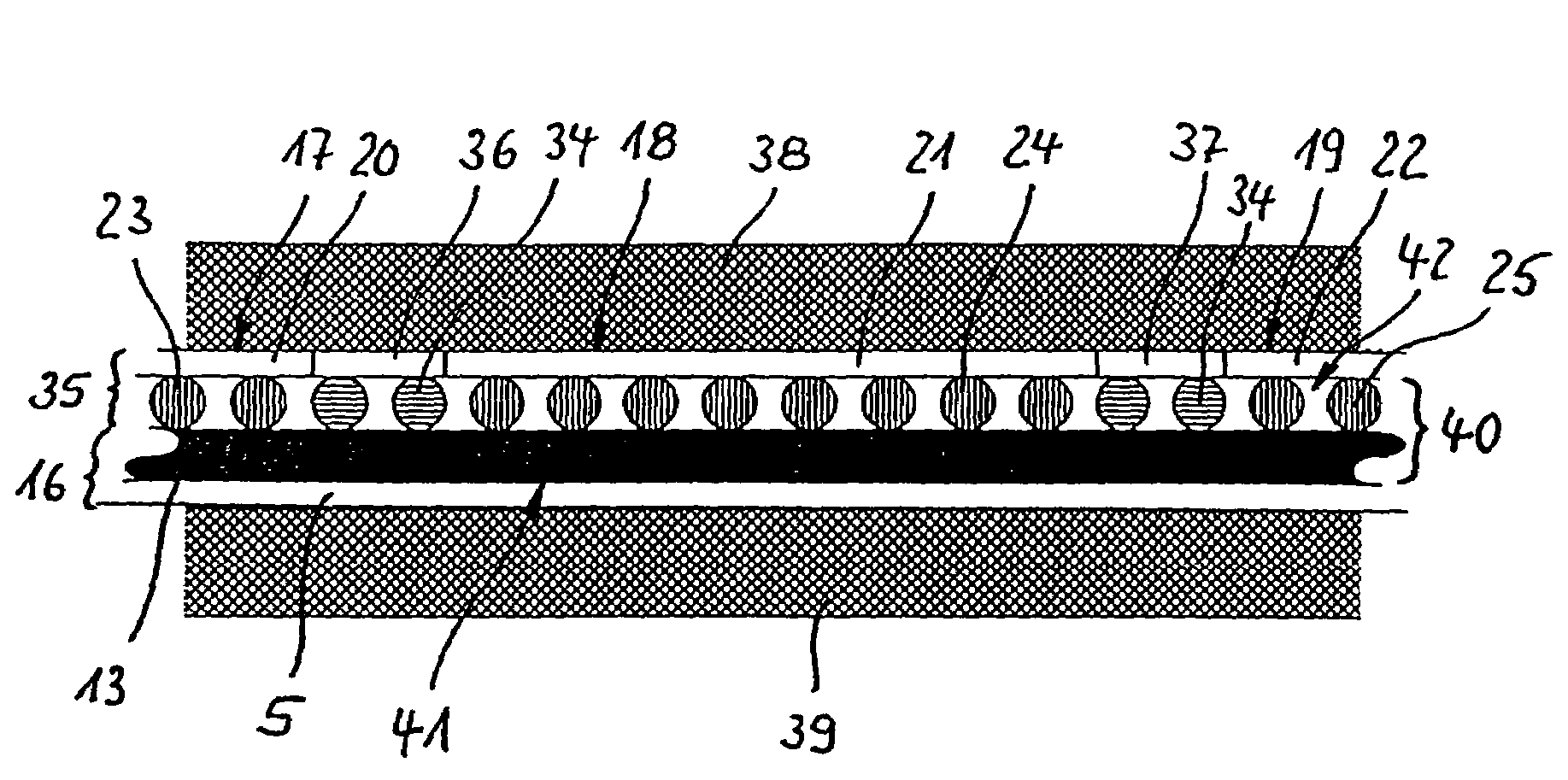

Downhole filter

InactiveUS20050121232A1Least riskEasy to manufactureDrilling rodsConstructionsParticulatesEngineering

In one aspect, a downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. In another aspect, a method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In yet another aspect, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

Method for manufacturing a felt belt, and felt belt

ActiveUS7722743B2Economical fashionImprove lateral strengthLamination ancillary operationsCellulosic plastic layered productsYarnFiber matrix

The invention is a method for manufacturing a felt belt having a support which is embedded in a fiber matrix and is made up of at least two yarn layers arranged one above another, at least one is a longitudinal yarn layer made up of longitudinal yarns extending in parallel fashion, and at least one is a transverse yarn layer made up of transverse yarns extending in parallel fashion, transverse yarns being present that are continuous over the width of the felt belt. For each longitudinal yarn layer, a first support module is manufactured, by means of a first auxiliary support web, at a width that is less than the width of the completed felt belt, the first auxiliary support web being wound in helical fashion, before, during, or after the application of yarns, to a width that corresponds to the width necessary for manufacture of the completed felt belt.

Owner:HEIMBACH GMBH & CO KG

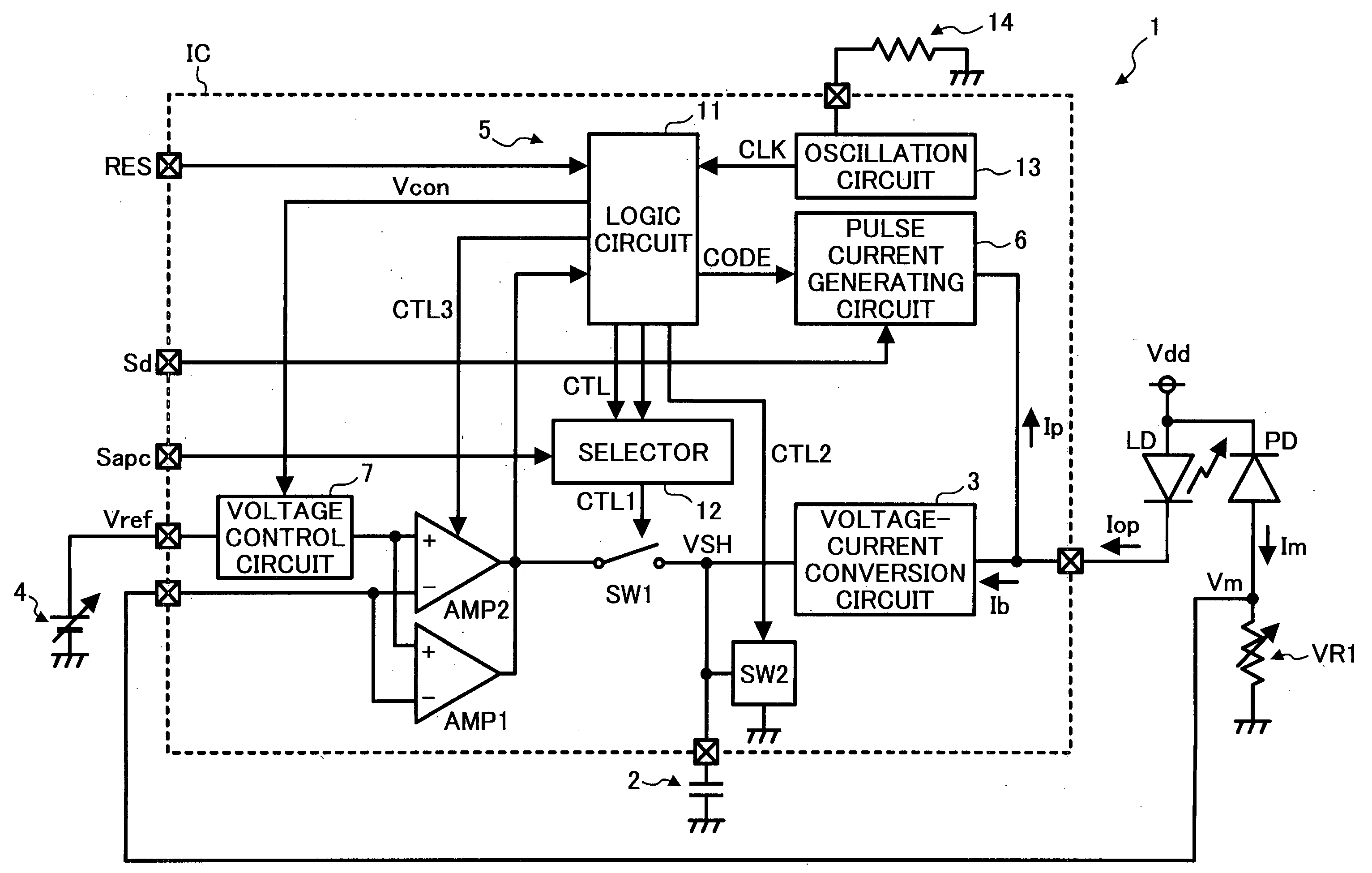

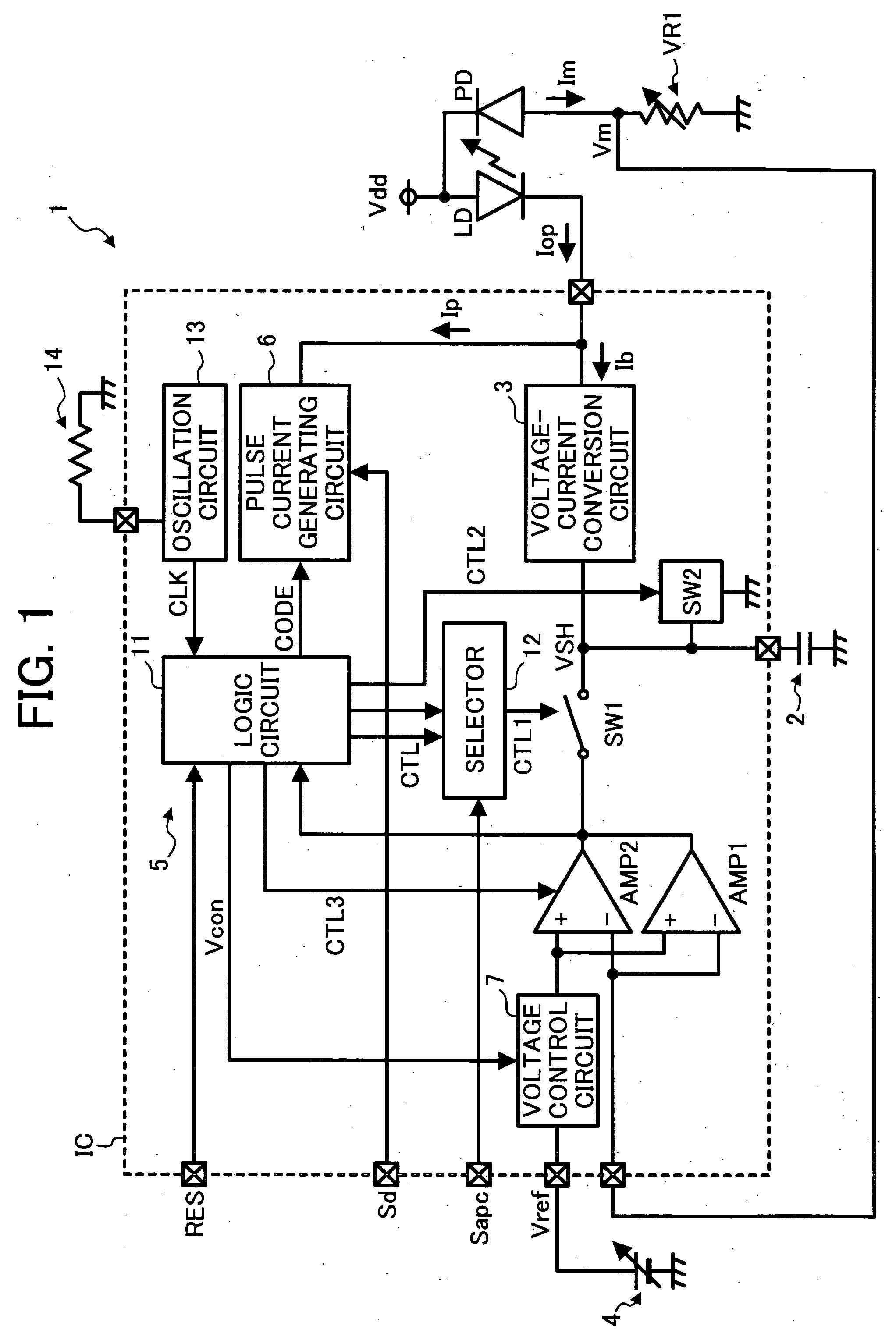

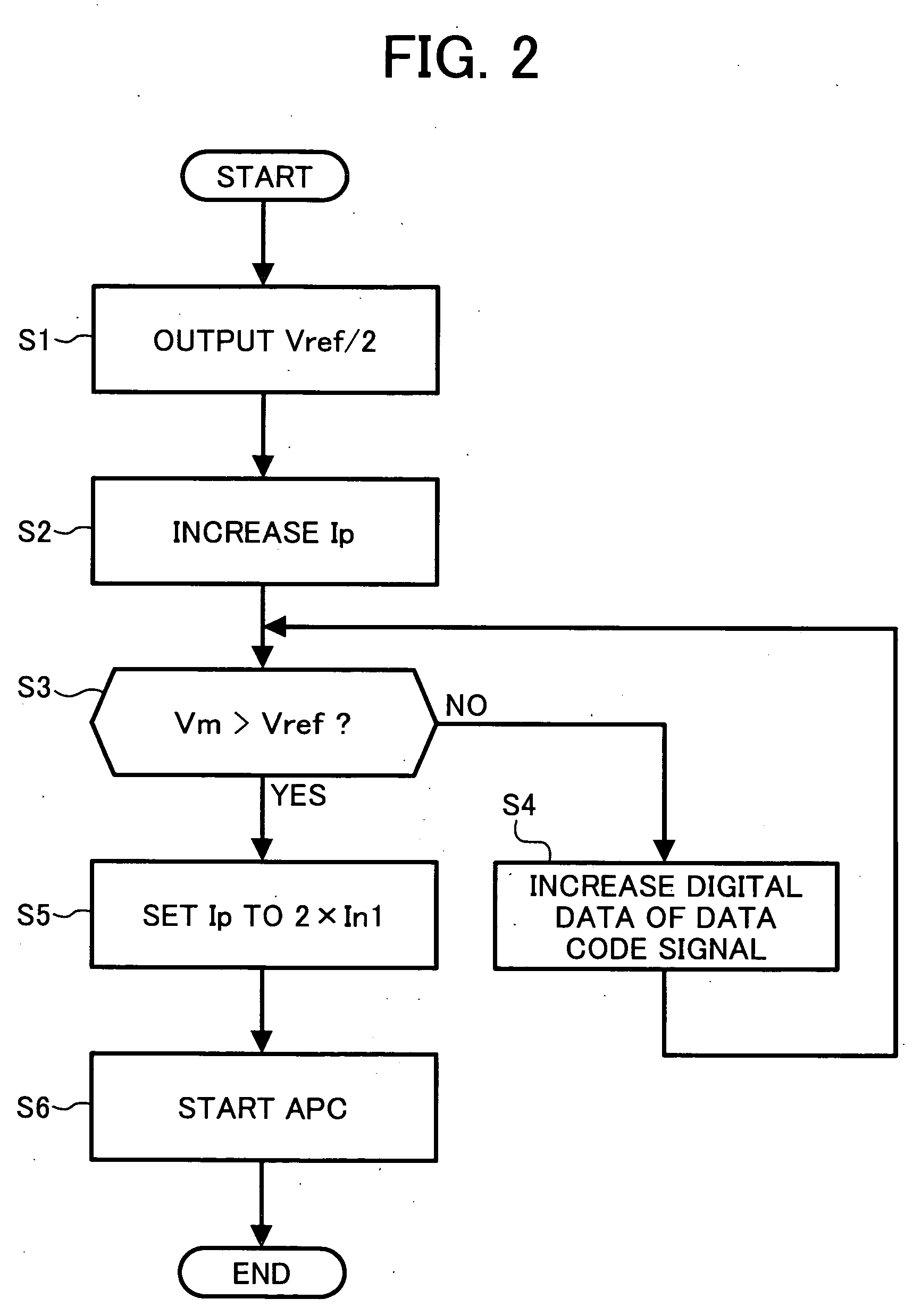

Method and apparatus for semiconductor laser driving capable of stably generating consistent optical pulse widths of laser diodes

InactiveUS20050141576A1Consistent widthShorten the time periodLaser detailsSemiconductor lasersDifferential quantum efficiencySemiconductor

A semiconductor laser driving circuit includes a light amount detector, a frequency determiner, and an initialization circuit. The light amount detector detects an amount of light emitted by a laser diode, and outputs a first voltage corresponding to the amount of light. The frequency determiner determines a frequency for determining a time period of a detecting operation to detect differential quantum efficiency of the laser diode. The initialization circuit performs an initialization operation to detect differential quantum efficiency of the laser diode with a variation of the time period of the initialization operation according to the frequency determined by the frequency determiner.

Owner:RICOH KK

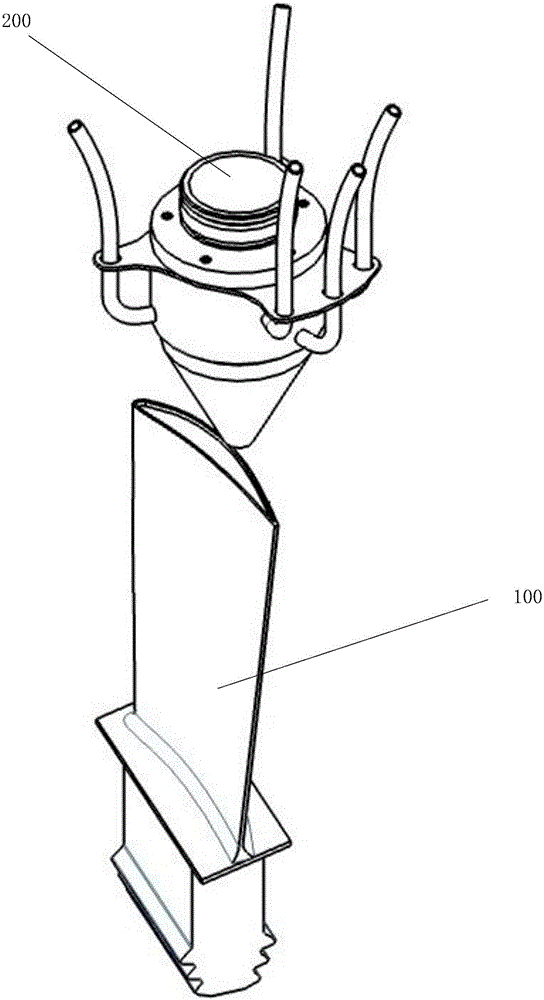

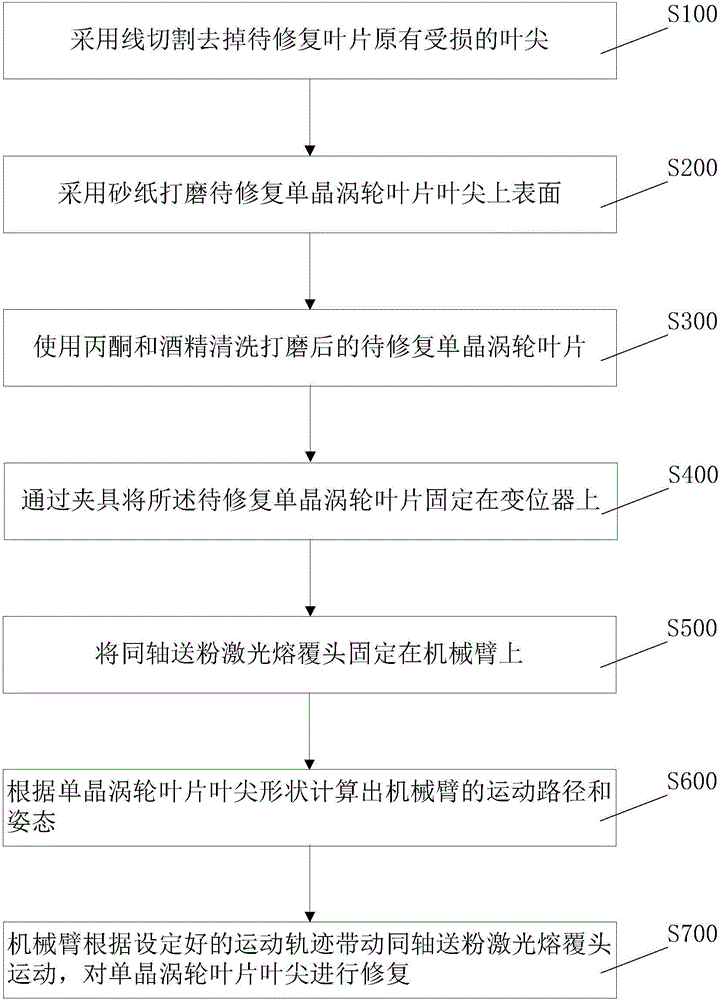

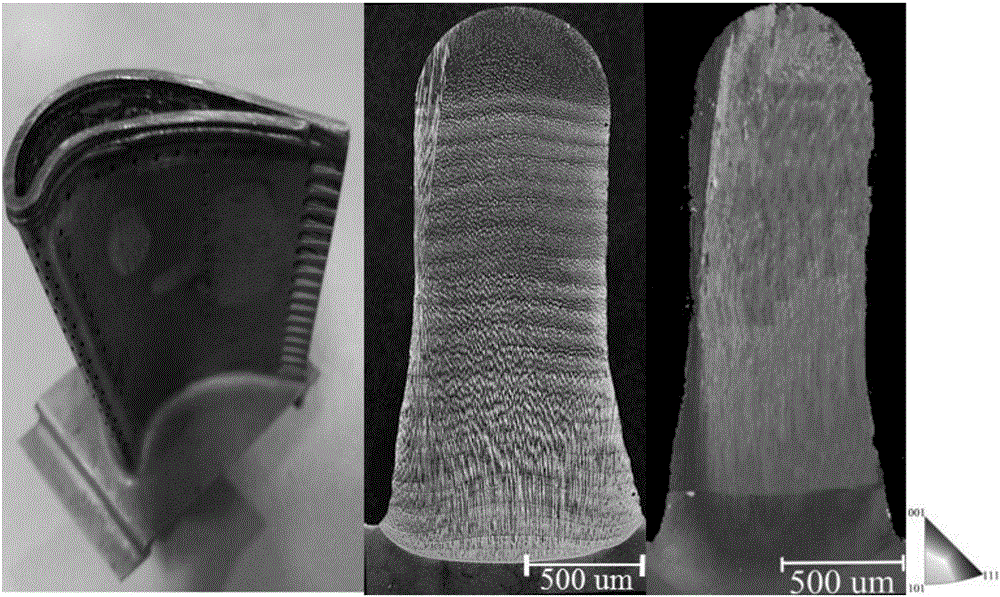

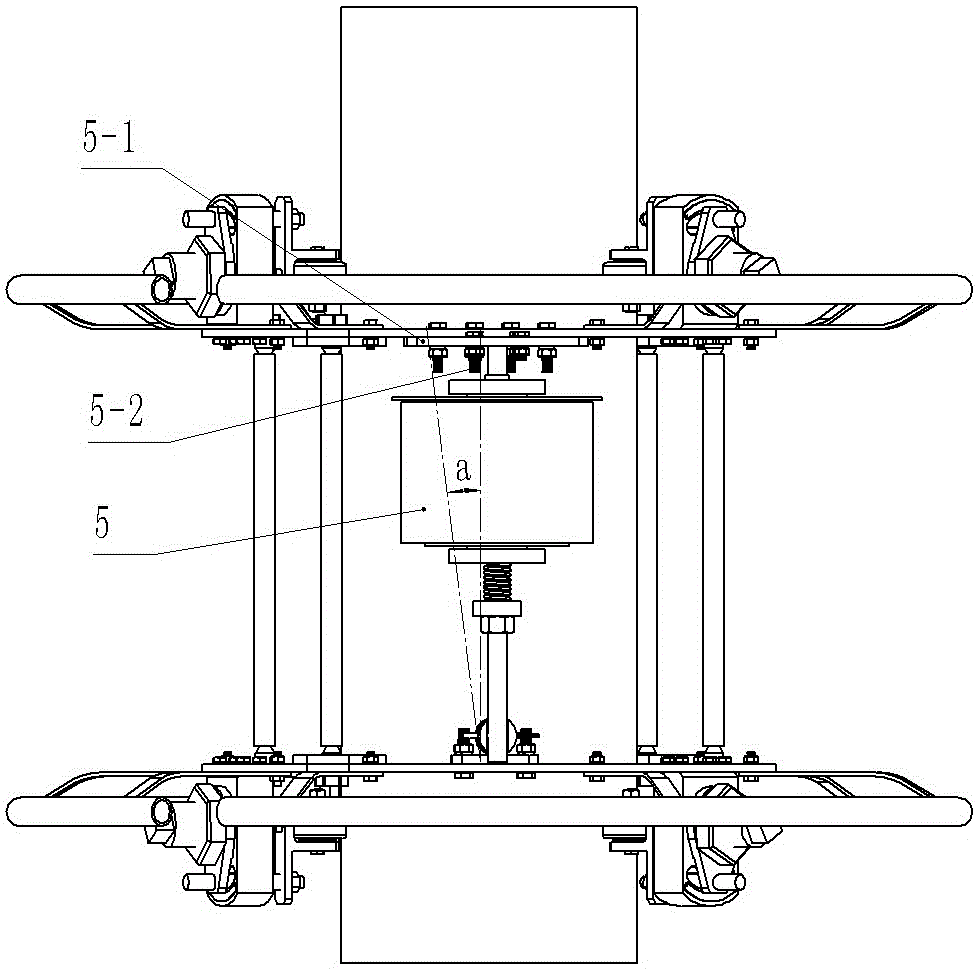

System and method for repairing nickel-based monocrystal high-temperature alloy turbine blade tip

InactiveCN105695986AConsistent widthMeet the use requirementsMetallic material coating processesTurbine bladeSingle crystal

The invention provides a system and method for repairing a nickel-based monocrystal high-temperature alloy turbine blade tip. The system comprises a laser device, a powder feeder, a mechanical arm, a controller, a positioner and a coaxial powder feeding cladding head. The method comprises the steps that a monocrystal turbine blade to be repaired is ground, cleaned and fixed to the positioner through a clamp, the laser device and the powder feeder are connected to the coaxial powder feeding cladding head, the coaxial powder feeding cladding head is fixed to the mechanical arm and is perpendicular to the surface of the monocrystal turbine blade tip, and the controller controls the motion path of the mechanical arm. By the adoption of the system and method for repairing the nickel-based monocrystal high-temperature alloy turbine blade tip, the monocrystal turbine blade tip can be successfully repaired through net shaping, the interior of the repaired monocrystal blade tip is compact and continuous monocrystal structures, and the using requirements of the monocrystal blade can be completely met through subsequent machining.

Owner:SHANGHAI JIAO TONG UNIV

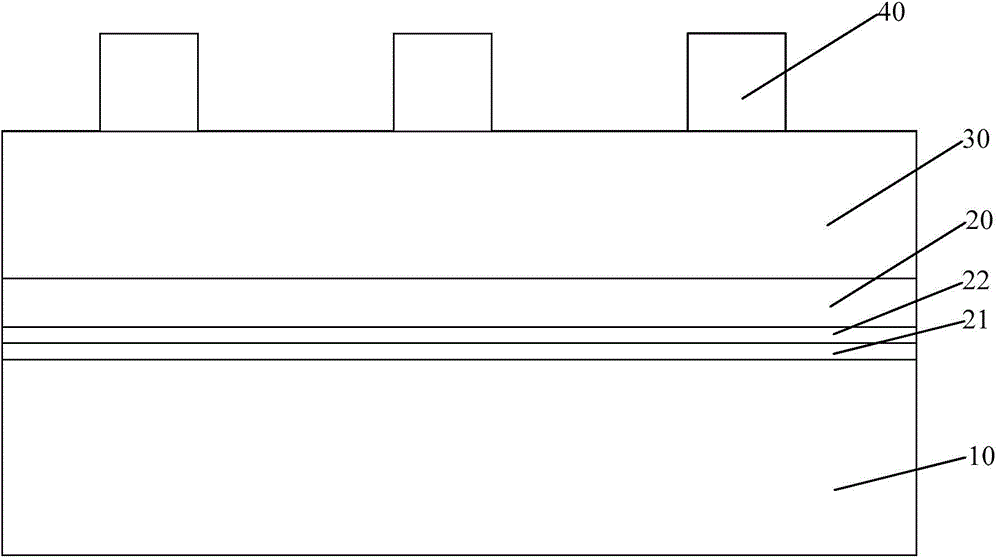

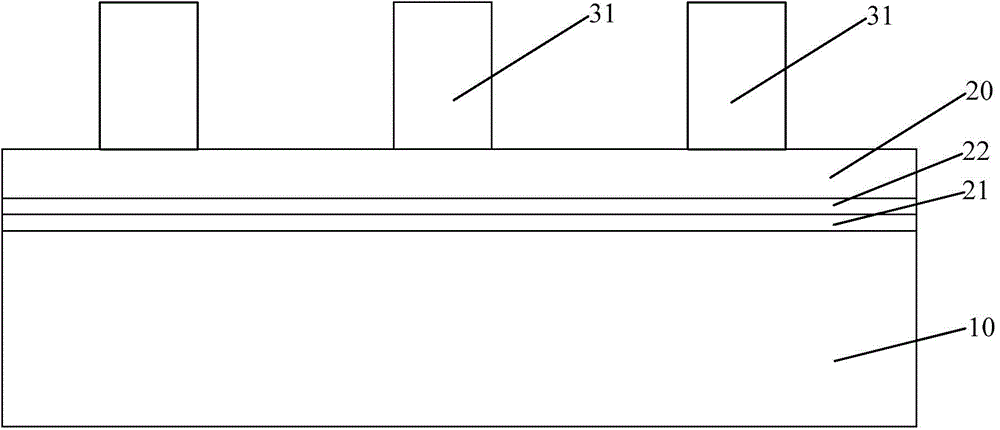

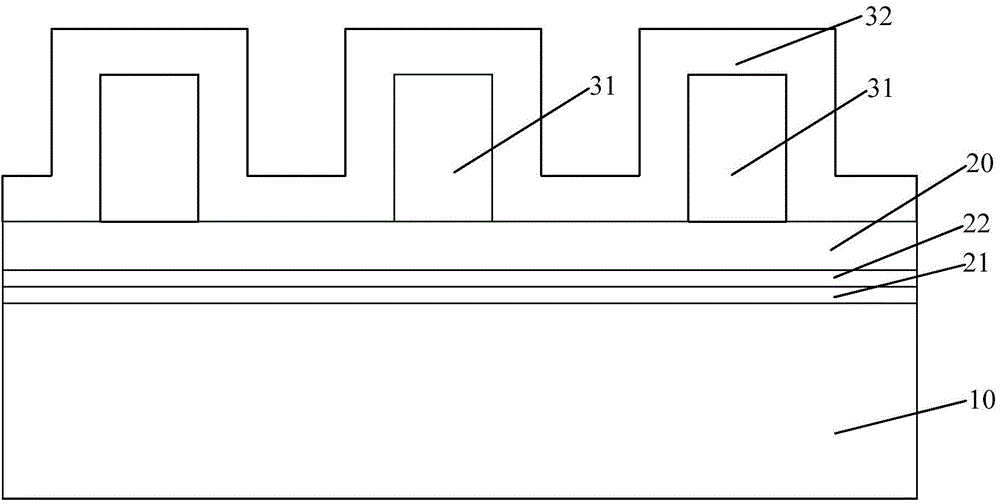

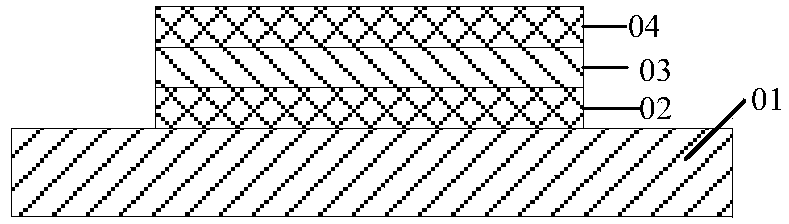

Semiconductor structure and forming method thereof

ActiveCN106206307ASmall sizeConsistent widthSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention provides a semiconductor structure and a forming method thereof. The forming method of the semiconductor structure comprises the steps that a semiconductor substrate is provided; a mask layer and a sacrificial material layer located on the surface of the mask layer are sequentially formed on the surface of the semiconductor substrate; the sacrificial material layer is etched to form a plurality of discrete sacrificial layers; side walls are formed on the side wall surfaces of the sacrificial layers; the sacrificial layers are removed; and supplement side walls are formed on the side wall surfaces of the side walls. By the method, improvement of the performance of the formed semiconductor structure is facilitated.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of aluminum alloy butted circular seam

InactiveCN102079004AReduce distortionHigh degree of welding automationArc welding apparatusStainless steel wireAutomation

The invention relates to an automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of an aluminum alloy butted circular seam, which comprises the following steps of: before welding, cleaning greasy dirt at the periphery of a cylinder butted circular seam with acetone; removing an oxide film in the periphery of the cylinder butted circular seam by a stainless steel wire wheel; preheating before welding; debugging a control panel for controlling welding current and voltage, welding speed and wire feeding speed to match in real time; and welding by adopting an automatic TIG machine, wherein a welding wire is not added for back formation when a first layer is welded, a welding wire is added for filling when a second layer is welded, a welding wire is added when a third layer is welded, and a welding gun swings for cover surface forming. The automatic TIG welding method has the advantages of simple equipment, convenience in operation, stable welding, high welding speed, low production cost, fewer filled welding wires, fewer welding layers, small deformation, no need of correction after welding, attractive formed appearance and high welding seam quality and realizes welding automation.

Owner:陕西国德电气制造有限公司

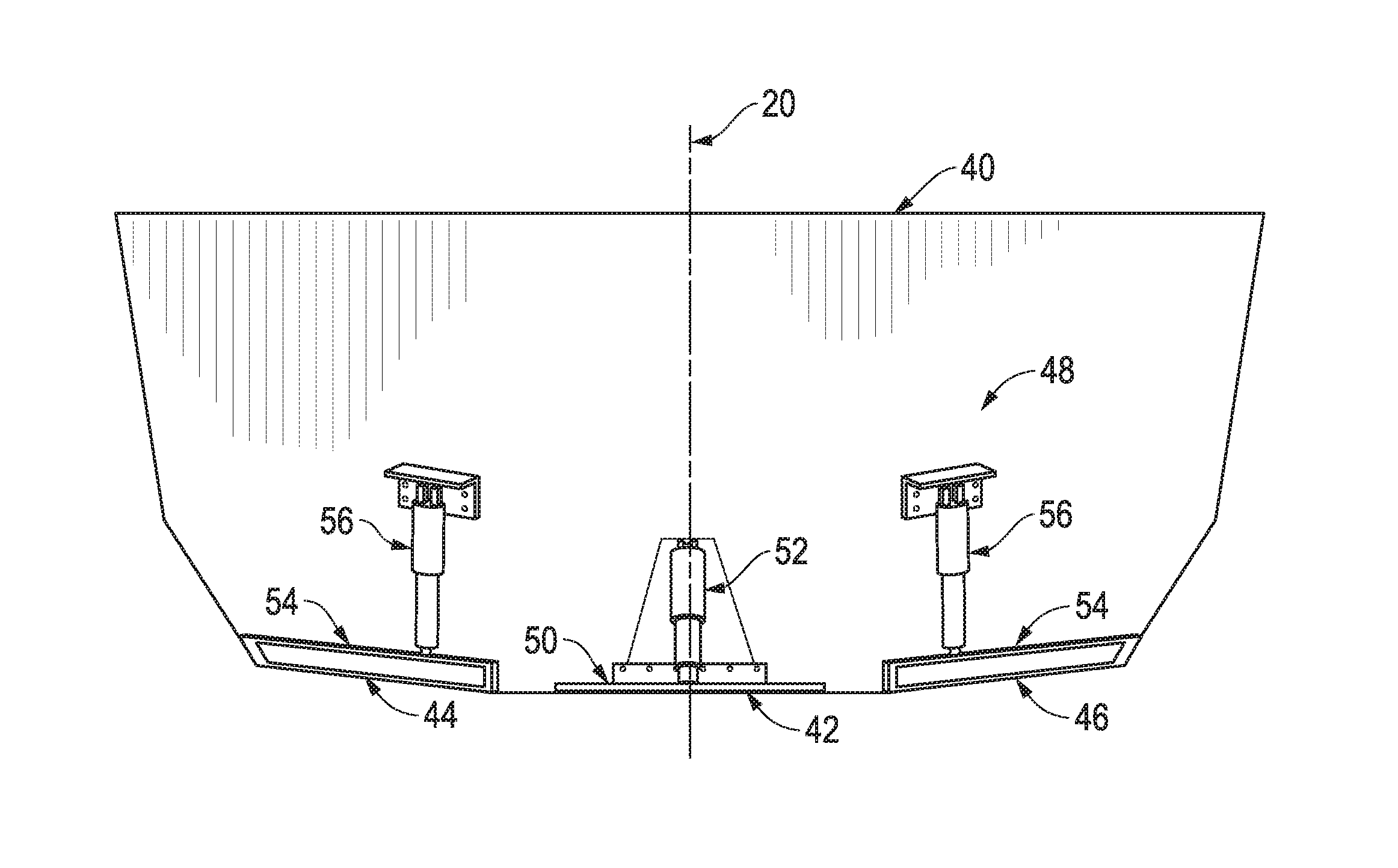

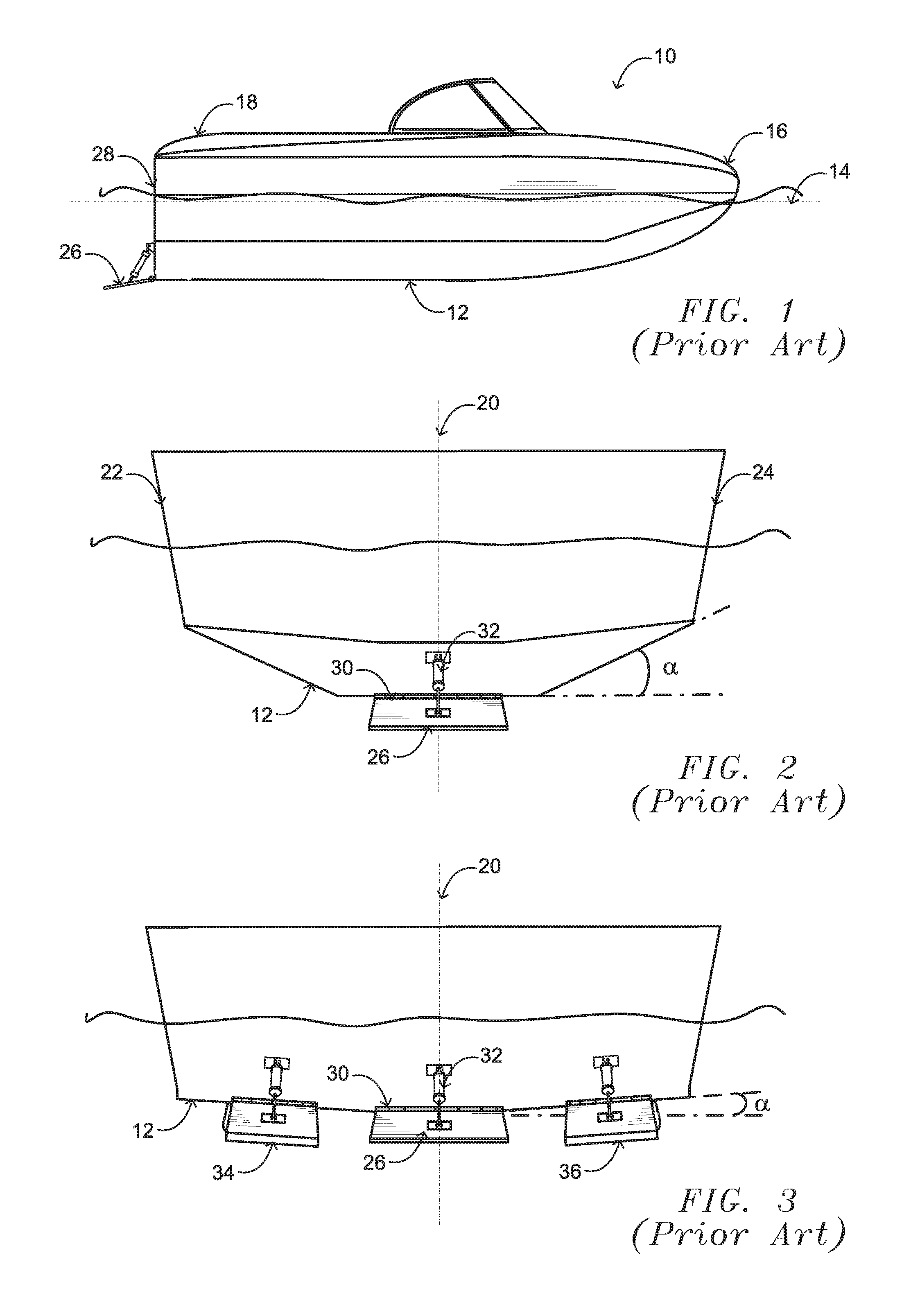

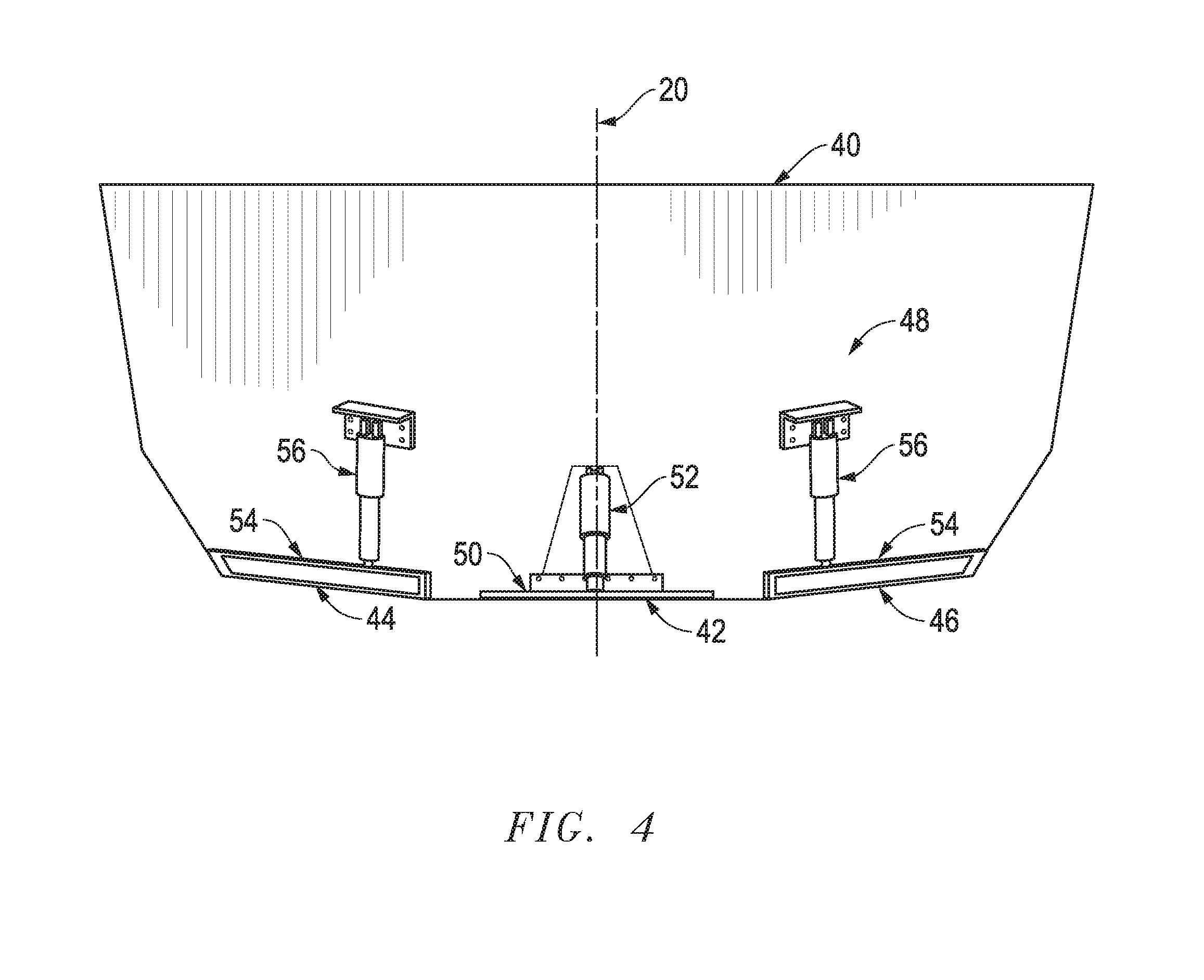

Boat and improved wake-modifying device for manipulating the size and shape of the wake

ActiveUS9573655B1Long and smoother wakeLarge wakeWave generating vesselsWater sport boardsTrim tabWater channel

Various configurations of improved wake-modifying devices for a power boat are provided herein. All such configurations provide a water channel and (optional) wedge for capturing and redirecting significantly more of the water flowing past the transom of the boat than conventional trim tabs consisting primarily of a flat plate. This increases the upward force applied to the deployed wake-modifying device and raises the stern of the boat on the non-surf side to list the boat to the surf side, producing a larger wake on the surf side. Some configurations provide a convergent water channel to produce longer, smoother wakes on the surf side of the boat. Other configurations provide a divergent water channel, which produces a comparatively shorter, taller wake on the surf side of the boat.

Owner:TIGE BOATS

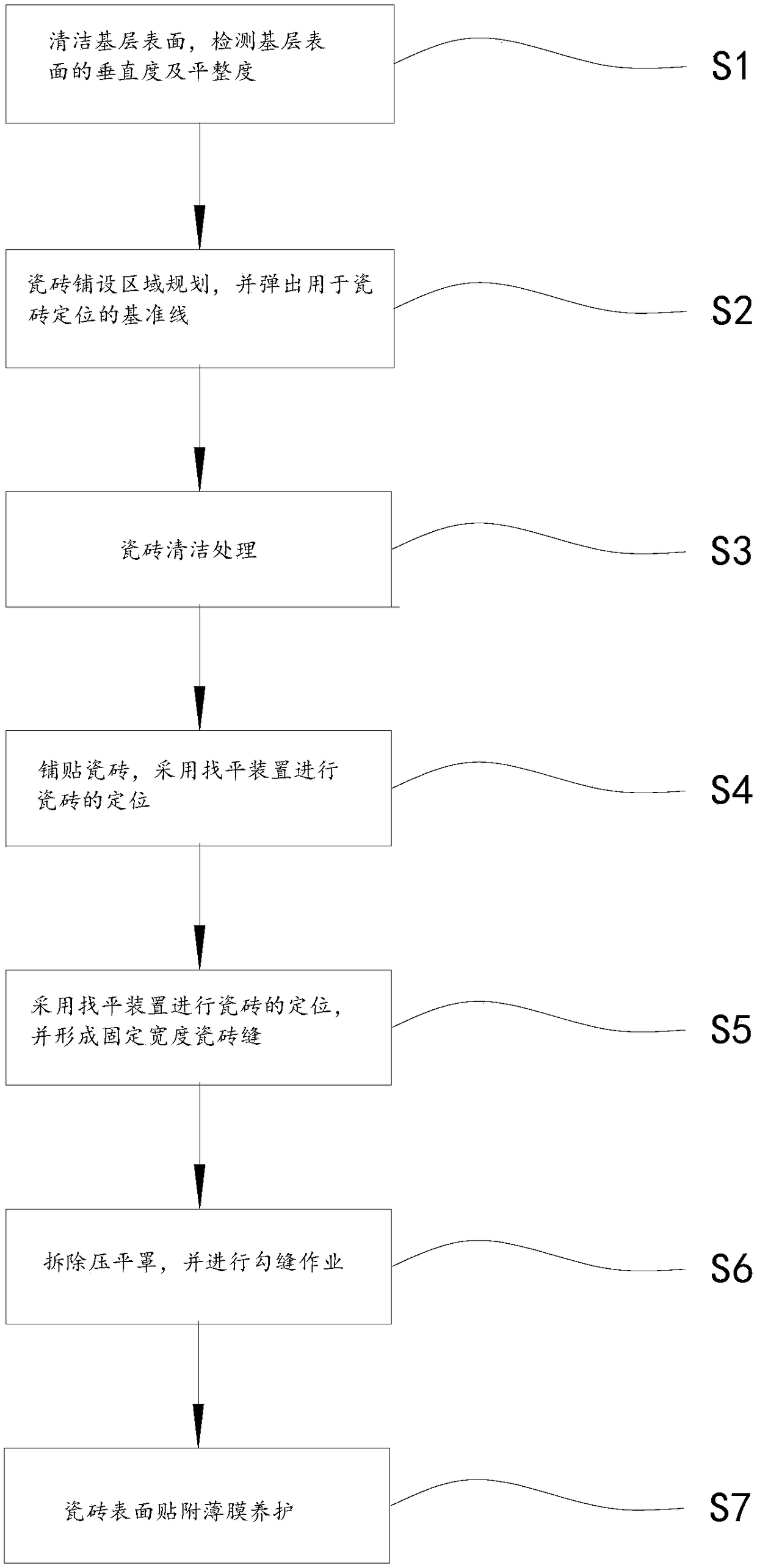

Tile paving method

InactiveCN108222450AAvoid misalignmentGuaranteed aestheticsBuilding constructionsDislocationCivil engineering

The invention provides a tile paving method. The tile paving method comprises the following steps that the base surface is cleaned, and the perpendicularity and flatness of the base surface are detected; planning is carried out according to an area needed to be tiled, and the vertical and horizontal datum lines used for tile positioning are popped up; tiles are cleaned, and it is ensured that corners and the two surfaces of the tiles are free of oil fouling; the tiles are paved, the tiles are positioned using a leveling device, the tiles are leveled using the leveling device, and the tile seamwidth formed between every two adjacent tiles is 1.5-3 mm; after mortar is solidified, a flattening cover is removed, and pointing operation is carried out; and after the pointing is completed, a thin film is attached to the surface of the tiles after paving for conserving for 5-10 days. According to the tile paving method, dislocation phenomenon of the tiles is avoided during leveling, gaps between the tiles are controlled to be reasonable, and the beauty and practicability of the tiles after paving are enhanced.

Owner:广州炬隆卫浴制品有限公司

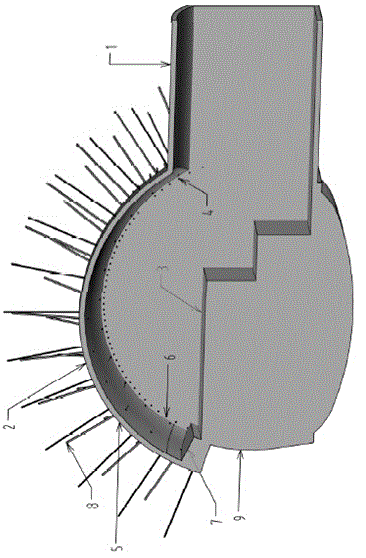

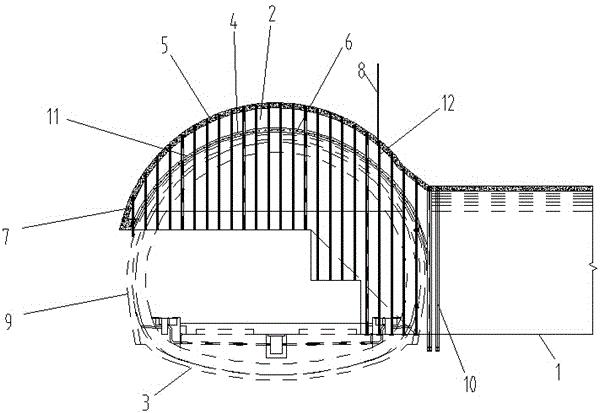

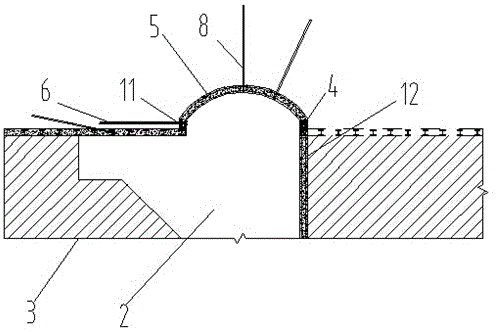

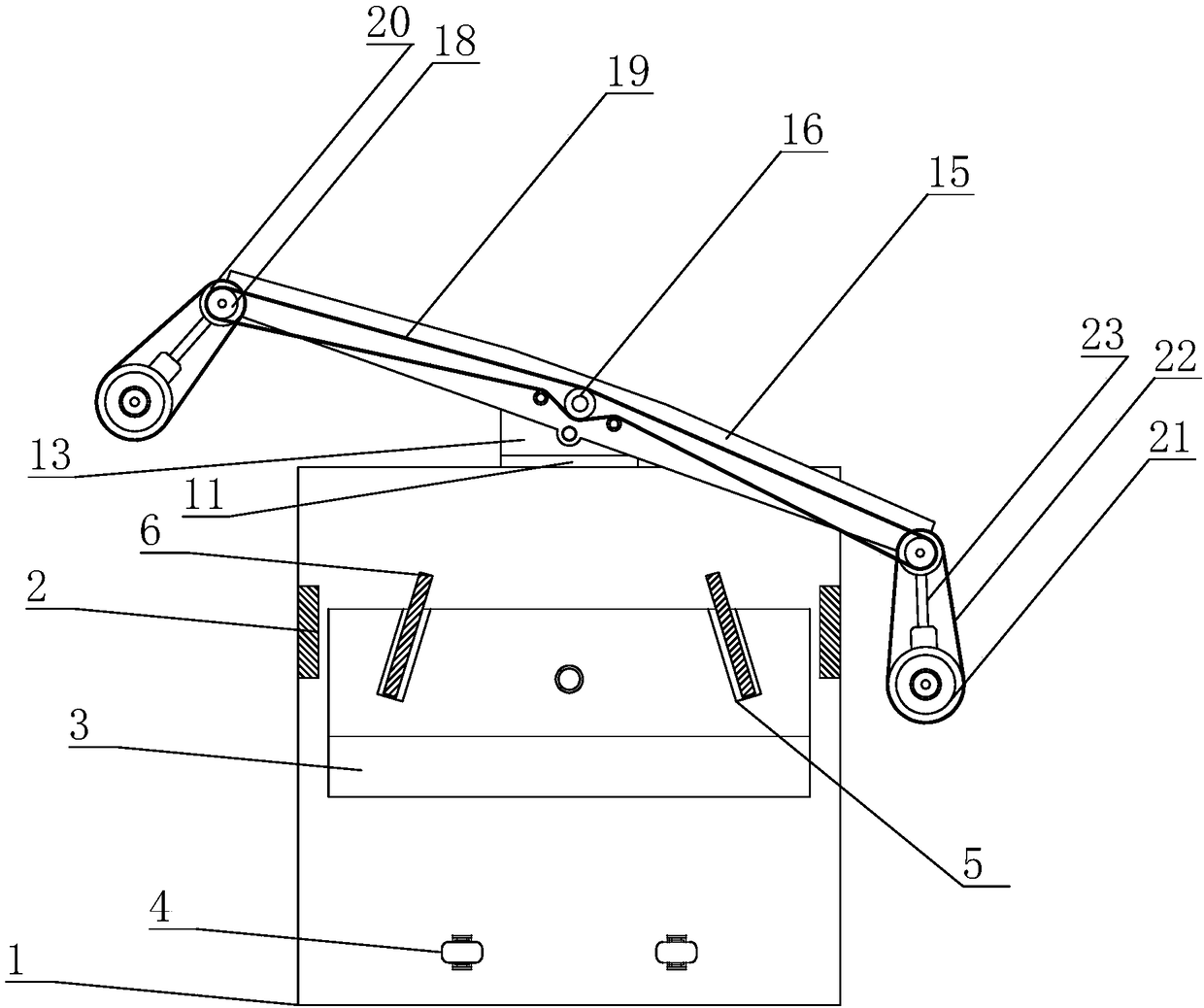

Doubly curved arch construction method for enabling inclined shaft of soft rock tunnel to enter main tunnel

ActiveCN104481546AConsistent widthSimple structureUnderground chambersTunnel liningRock tunnelSingle vehicle

The invention discloses a doubly curved arch construction method for enabling an inclined shaft of a soft rock tunnel to enter a main tunnel. The doubly curved arch construction method comprises the following steps that (1) the inclined shaft is constructed, wherein the inclined shaft is excavated and supported, the inclined shaft which is perpendicular to the main tunnel and is at least 15m is excavated, the inclined shaft is a single-lane cross section, and the horizontal surface and the vertical surface of the inclined shaft are perpendicular to the main tunnel; (2) a pilot tunnel is constructed, wherein the longitudinal surface of the pilot tunnel is arranged along the excavation contour line of the main tunnel; (3) the main tunnel is excavated through a three-step method within the range of one to double tunnel excavation widths in the entrance direction and the exit direction of the main tunnel. The doubly curved arch construction method has the advantages of being simple in structure, convenient to construct, and safe, reliable, economical and practical; safety risks caused by unreasonable and uncertain factors such as unreasonable cross sections of a supporting structure, unreasonable cantilever structures and disassembly of supporting points of previous supports are avoided.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Paper product processing and cutting machine with self-cleaning function

InactiveCN107053314APrevent wanderingAvoid the risk of manual feeding and unloadingDirt cleaningMetal working apparatusWorking environmentEngineering

The invention discloses a paper product processing and cutting machine with the self-cleaning function. The paper product processing and cutting machine comprises a workbench; a material guide groove is formed in the working table; one side of the material guide groove is provided with an electric push rod; one end of the electric push rod is connected to a material pushing plate, and the material pushing plate is arranged in the material guide groove; the other end of the material guide groove is provided with a cutting blade; an air blowing pipe is arranged on one side of the cutting blade and is fixedly connected to an air outlet of an electromagnetic valve; an air inlet of the electromagnetic valve is connected to an air pump through an air pipe; a time relay is arranged on one side of the electromagnetic valve; a dust collector is fixedly arranged on the workbench; and a conveyor belt is arranged on one side of the dust collector. According to the paper product processing and cutting machine with the self-cleaning function, automatic material feeding and material taking can be realized through the electric push rod and an air cylinder, injuries caused by manual operation can be avoided, the working efficiency can be improved, paper scraps adhering to a knife edge can be blown down through the air blowing pipe, the cutting quality can be guaranteed, dust generated in the processing process can be absorbed through the dust collector, and the working environment can be improved.

Owner:BEITANG JUNZHI PRINTING PAPER PROCESSING FACTORY

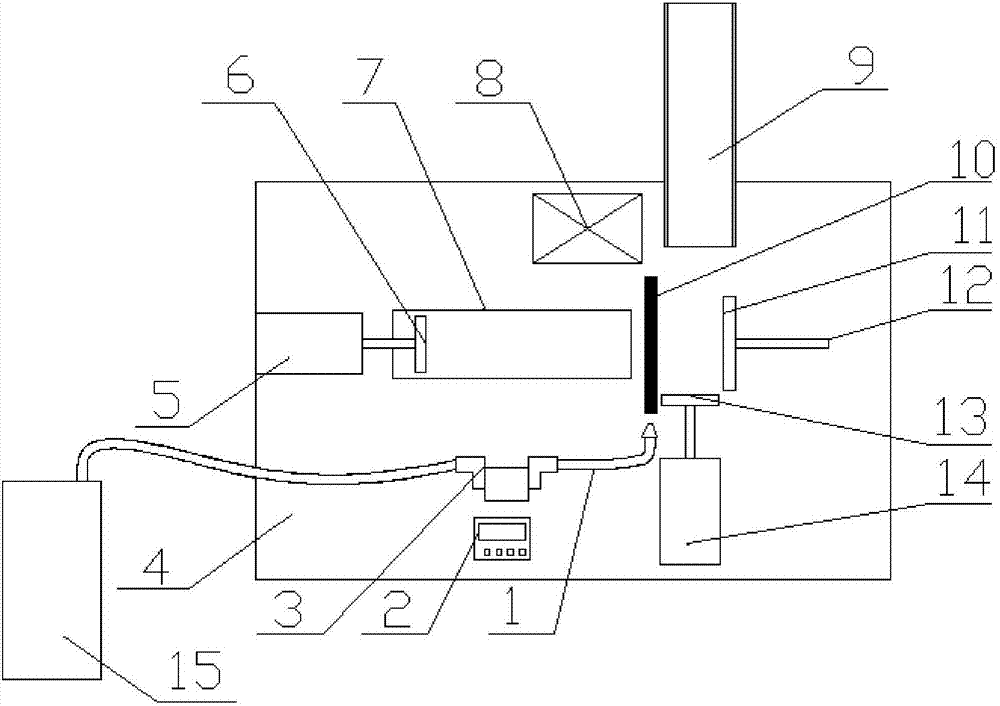

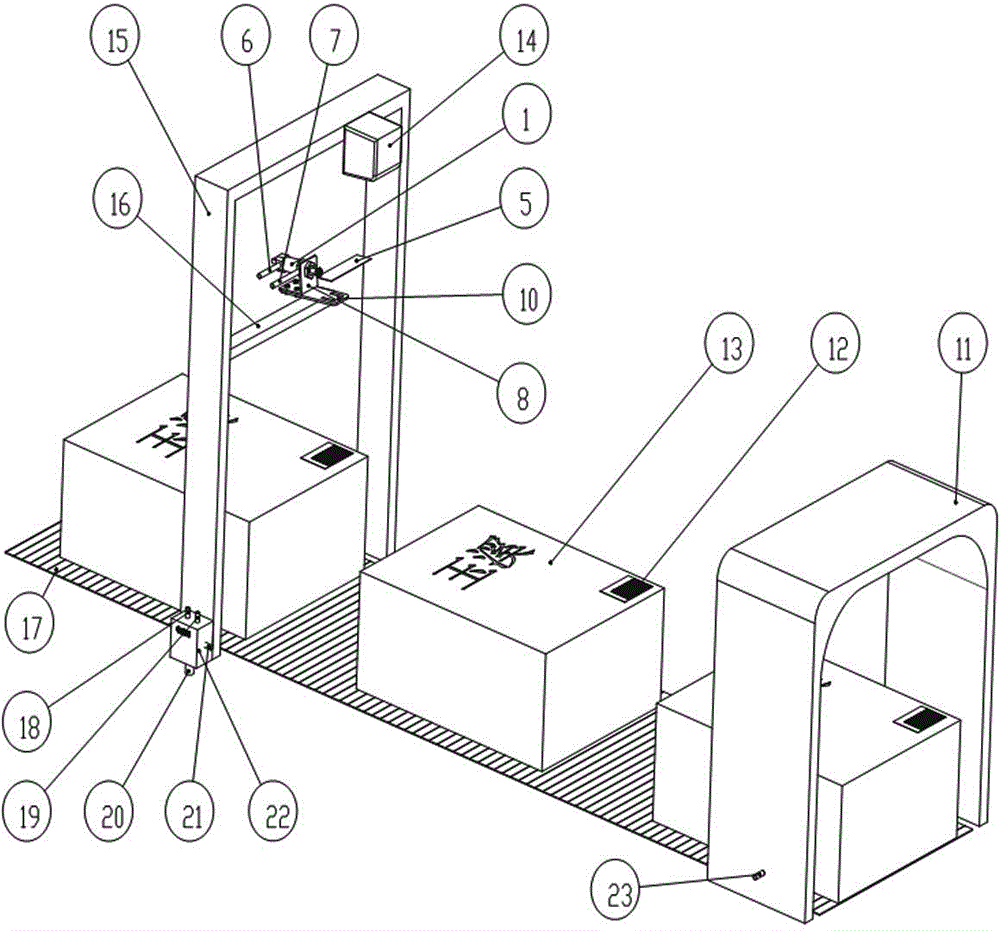

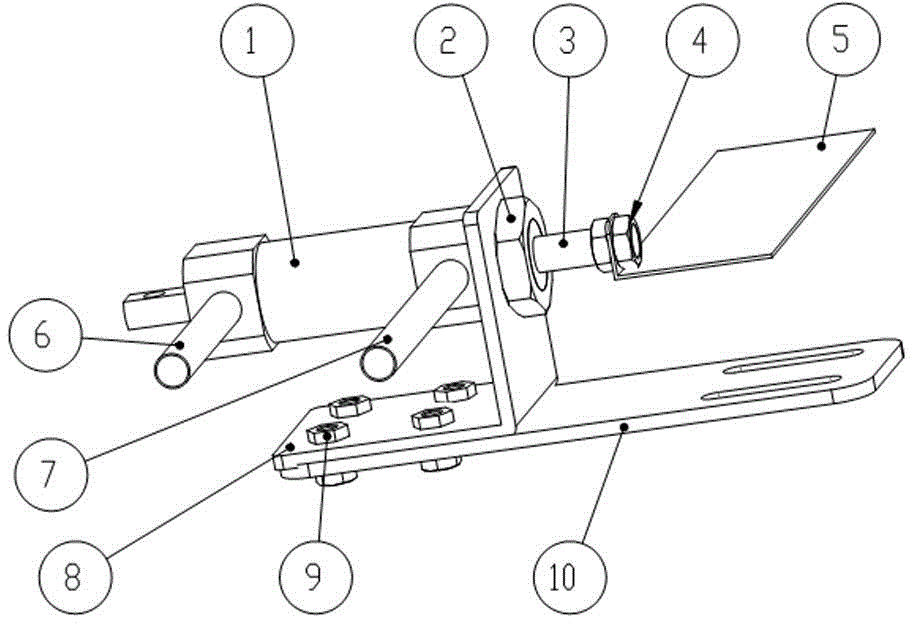

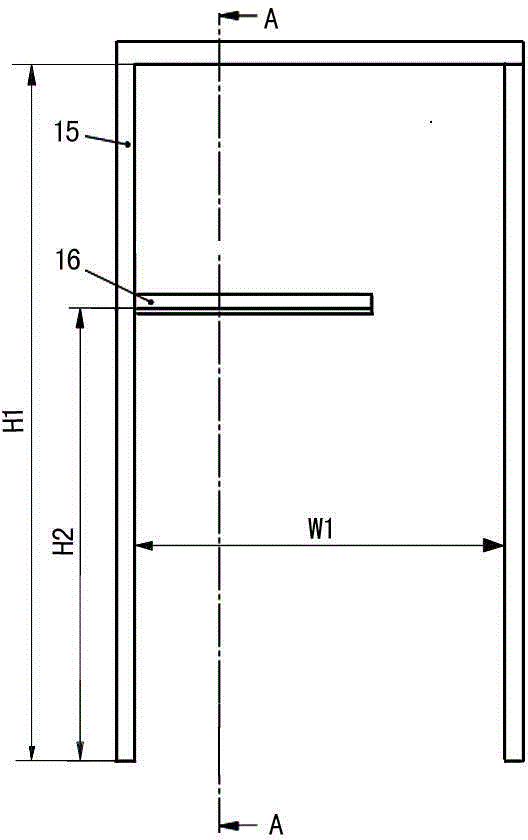

Automatic sorting device for cigarette boxes lack of cartons in cigarette logistics

ActiveCN103144802AImprove sorting efficiencyRealize sortingPackaging automatic controlLogistics managementAgricultural engineering

The invention relates to an automatic sorting device for cigarette boxes lack of cartons in cigarette logistics. The invention relates to the technical field of cigarette logistics delivery in tobacco industry. In particular, the device is used for sorting the cigarette boxes lack of cartons in the delivery process of cigarettes in the cigarette enterprises and is suitable for removing or dividing the cigarette boxes lack of cartons in the high-speed delivery and sorting process, and a bar code scanner does not scan the bar codes on the cigarette boxes lack of cartons. A carton-lacking detection instrument is mounted upstream a logistics delivery belt; a door frame bracket is mounted at downstream the logistics delivery belt; an electromagnetic valve is mounted on the door frame bracket; the bar code scanner is mounted at the upper part of the door frame bracket and opposite to the bar code of the cigarette box; a bar code information shielding mechanism is arranged between the cigarette box and the bar code scanner; a driving mechanism of the bar code information shielding mechanism is connected with the electromagnetic valve; and a driving signal input end of the electromagnetic valve is connected with a signal output end of the carton-lacking detection instrument. The device has the characteristics of simple structure, convenience for mounting and debugging, high sensitivity in information shielding, scanning, and opening, accurate sorting of the cigarette boxes lack of cartons and the like.

Owner:HONGTA TOBACCO GRP

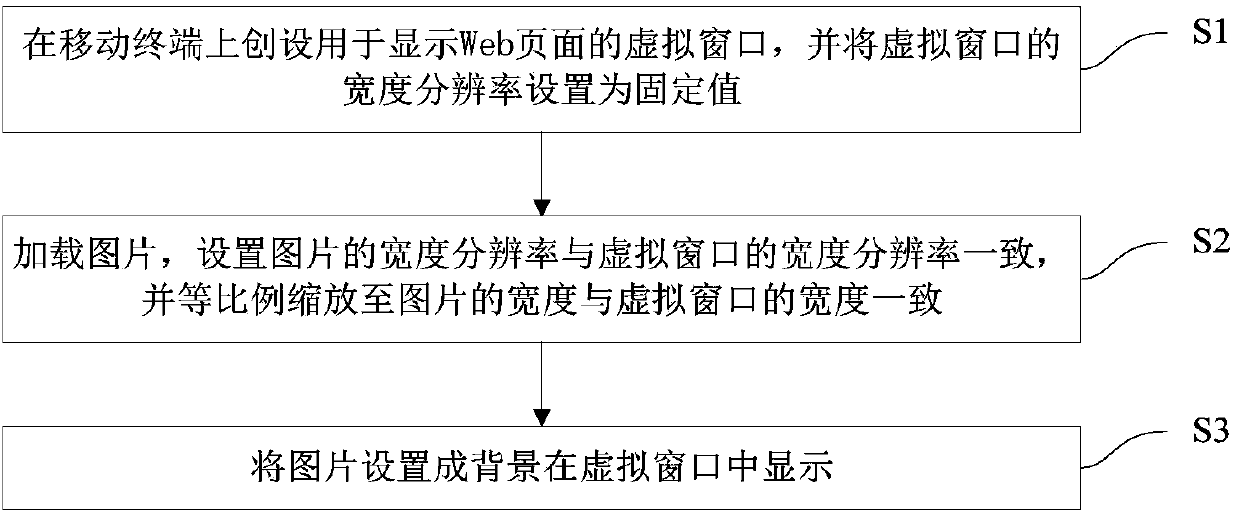

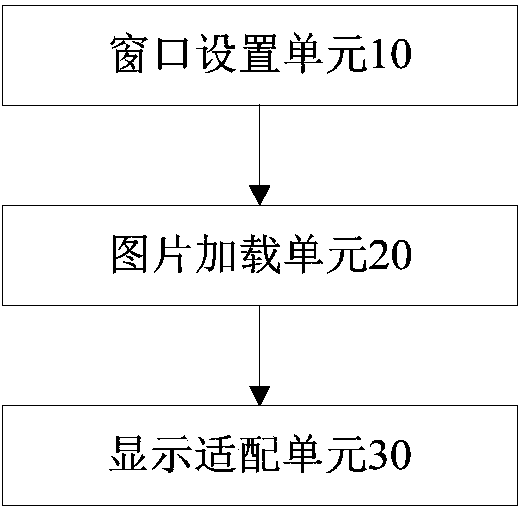

Adaptation method and device for display of web application

ActiveCN104199920ANo deformationGuaranteed DistortionSpecial data processing applicationsWeb data browsing optimisationWeb applicationComputer graphics (images)

The invention discloses an adaptation method and device for display of a web application. The adaptation method for display of the web application comprises the following steps that a virtual window used for displaying a Web page is established on a mobile terminal, and the width resolution ratio of the virtual window is set to be a fixed value; a picture is loaded, the width resolution ratio of the picture is set to be the same as that of the virtual window, and the equal-proportion zooming is conducted on the picture till the width of the image is the same as that of the virtual window; the picture is set to be the background and is displayed in the virtual window. According to the adaptation method for display of the web application, the virtual window with the width resolution ratio being the fixed value is established in the mobile terminal to be used for displaying the Web page, in this way, it is guaranteed that the Web page in the web application of the mobile terminal is displayed consistently, and deformation of the page is avoided; the picture is loaded, the width resolution ratio of the loaded picture is set to be the same as that of the virtual window, the width of the loaded picture is the same as that of the virtual window, then the picture is set to be the background to be displayed, and thus it is guaranteed that distortion does not occur during displaying and user experience is not affected.

Owner:广州迪派信息科技有限公司

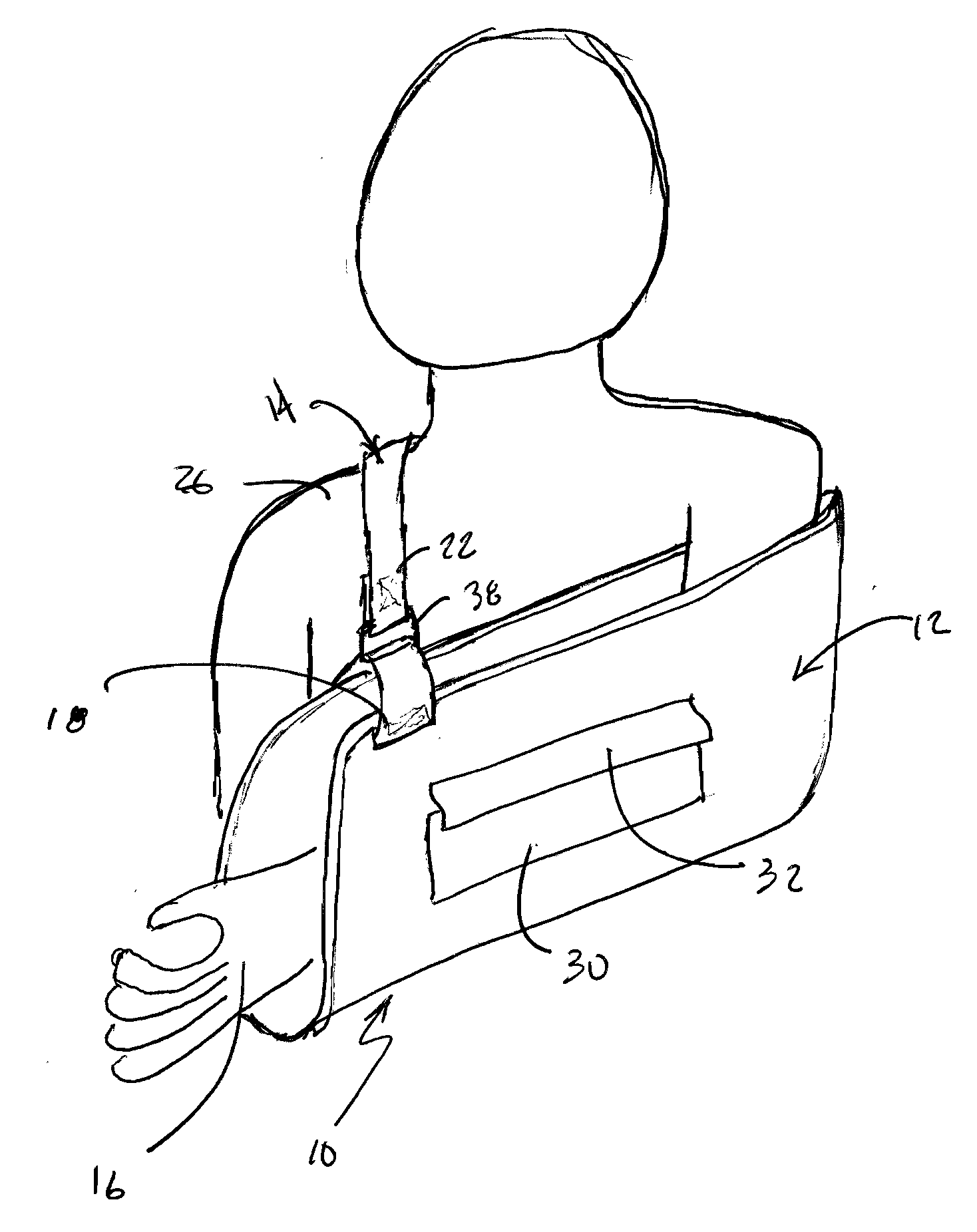

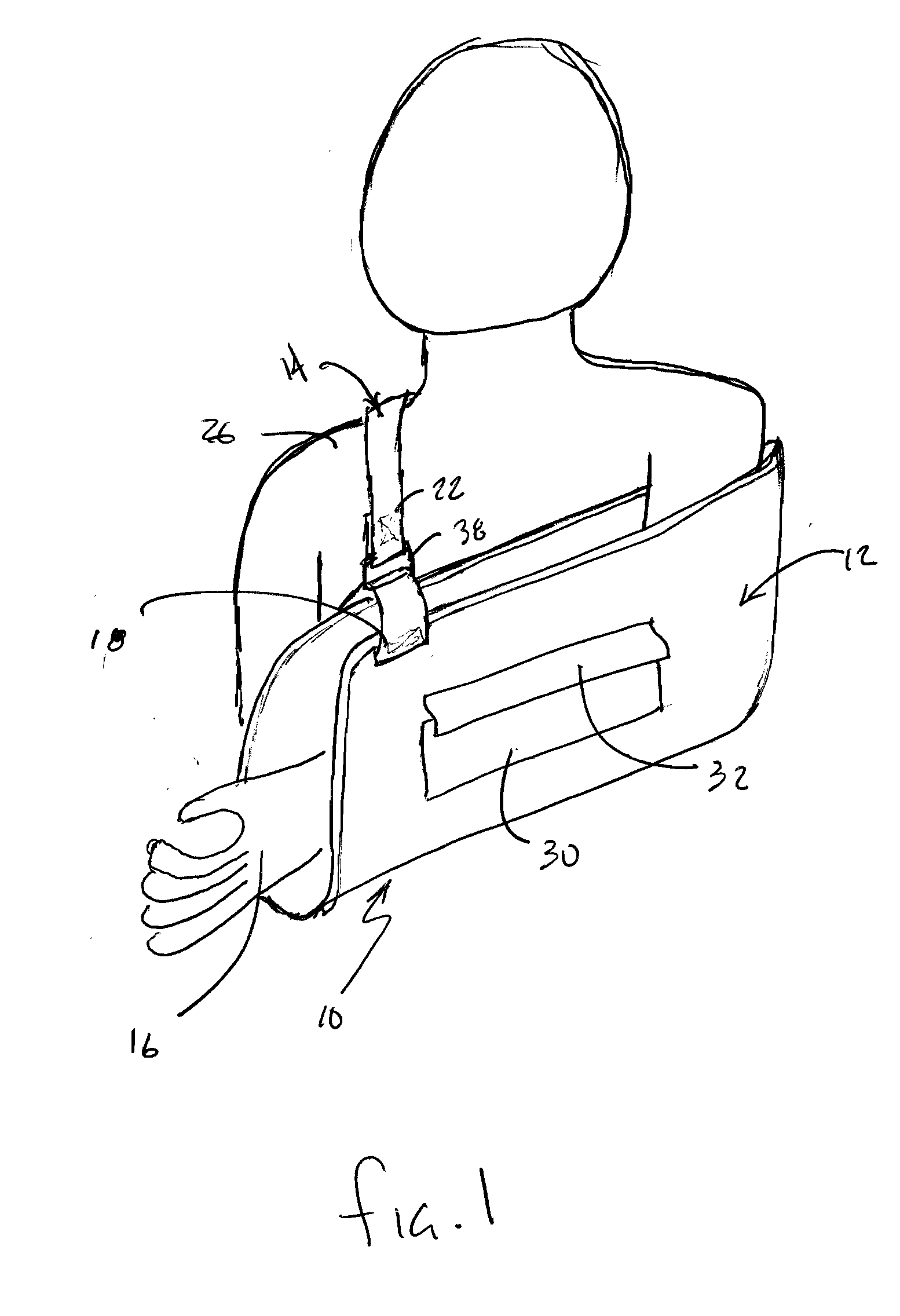

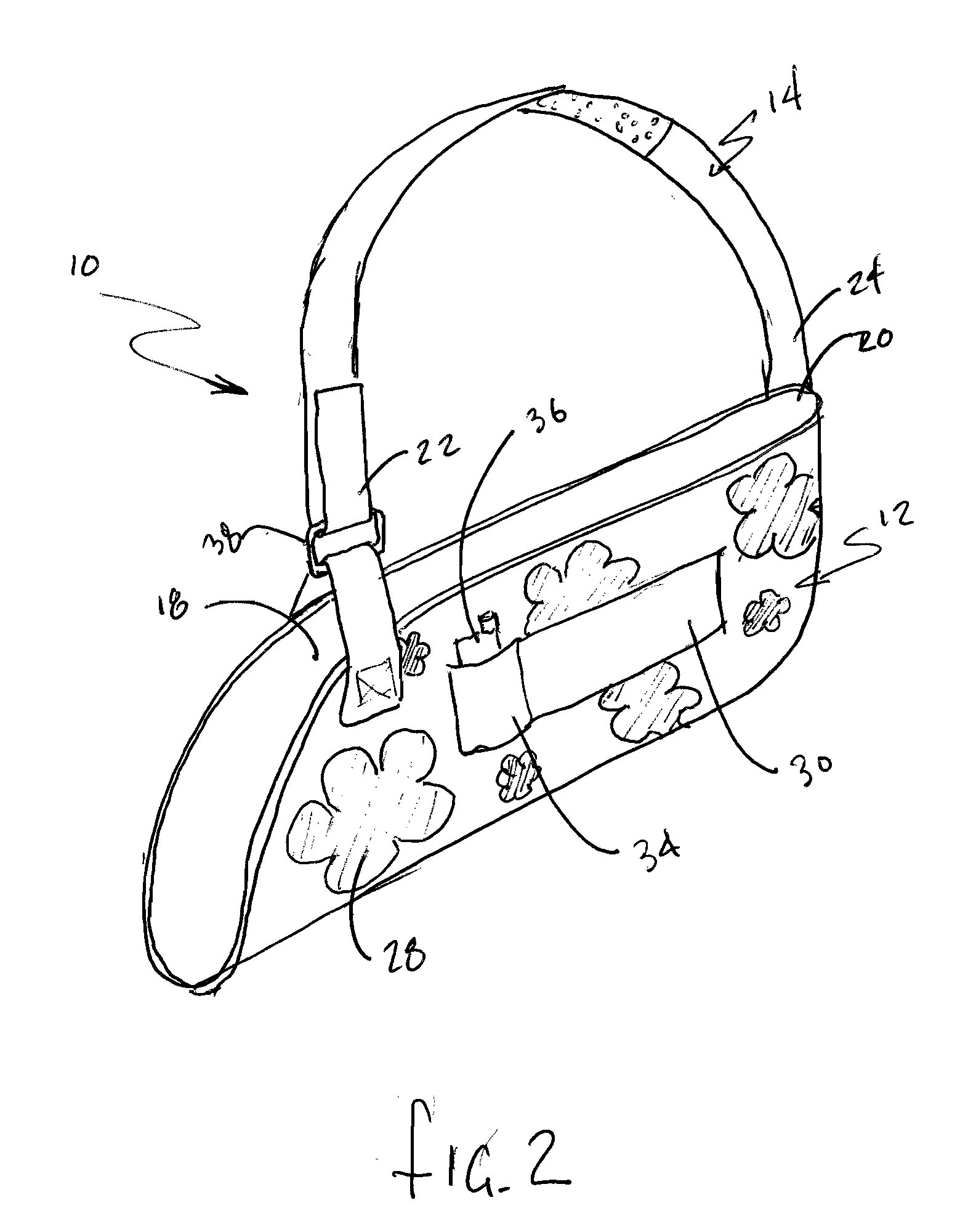

Sling design

InactiveUS20080015479A1Preventing strap bunchingPrevent creepRestraining devicesSuspensory bandagesModularityArchitectural engineering

A sling construction is provided that includes an improved support strap for more uniformly distributing the weight of the supported arm of the wearer's shoulder while preventing strap bunching and creep. The strap is preferably formed from an elastomer or a rubber that is relatively compliant yet has a low coefficient of elongation. This allows the strap to be highly supportive of the sling while also conforming to the contour of the wearer's neck and shoulders in a manner that makes the strap and sling comfortable to wear. The inner contact surface of the strap includes nubs or raised features that prevent the strap from sliding. Further, the improved strap support construction may be used in a modular fashion in conjunction with standard sling pouches or with an enhanced sling pouch in order to greatly improve the performance and appearance of the sling.

Owner:SOSCIA SUSAN

Wall building plastering regulator

ActiveCN108060783ARealize automated constructionRapid Wall ConstructionBuilding material handlingMotor driveBrick

The invention discloses a wall building plastering regulator, and mainly relates to the field of civil construction facilities. The wall building plastering regulator comprises oppositely arranged positioning plates, and clamping plates and clamping wheels are arranged between the positioning plates from top to bottom; the clamping plates are used for bundling the width of a mortar layer, the clamping wheels are used for clamping a wall face, a travelling frame is hinged to the upper portions of the positioning plates, and the two ends of the travelling frame are provided with track mechanisms; a swinging motor and a travelling motor are mounted on the travelling frame, the swinging motor drives the travelling frame to tilt left and right by a certain angle, and the travelling motor drivesthe track mechanisms to travel; and positive and negative rotation of the travelling motor and swinging of the swinging motor are triggered by sensors arranged at the outer ends of the track mechanisms. The wall building plastering regulator has the beneficial effects that the wall building plastering regulator can realize automation construction of plastering operation, and by cooperating with manual brick stacking, wall building construction can be quickly finished at a high quality.

Owner:DIER GRP CO LTD

Packaging method for substrate

ActiveCN105810849AGuaranteed rubber widthConsistent widthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCoating

The invention provides a packaging method for a substrate. Multiple supporting parts arranged at intervals are formed on the edge of a packaging cover plate; after the packaging cover plate is aligned to and fitted with the to-be-packaged substrate, the gap between the packaging cover plate and the substrate is limited; the height of seal without spacers is ensured; the width of the seal is ensured as well under a certain seal coating amount; in addition, the supporting parts, the substrate in contact with the supporting parts and the edge part of the packaging cover plate are cut after packaging, so that the substrate packaged by the seal without spacers is obtained; it is ensured that the seal has consistent height and width; and in addition, the packaging method is simple and convenient in process, and good in packaging effect.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

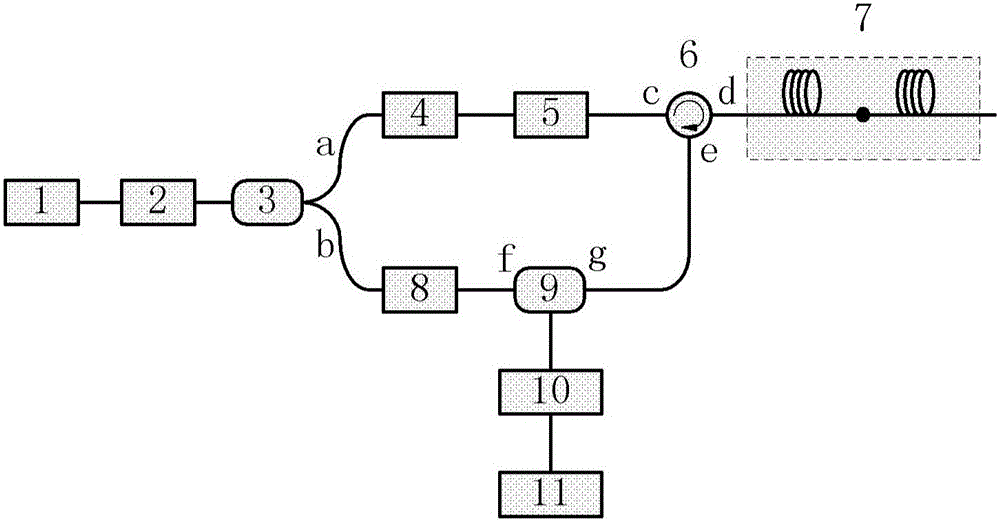

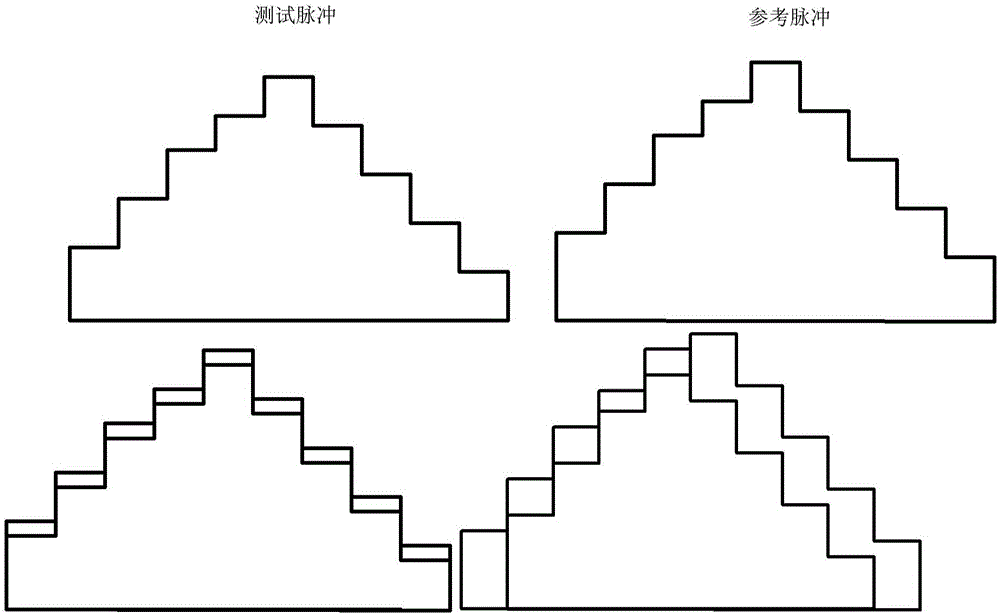

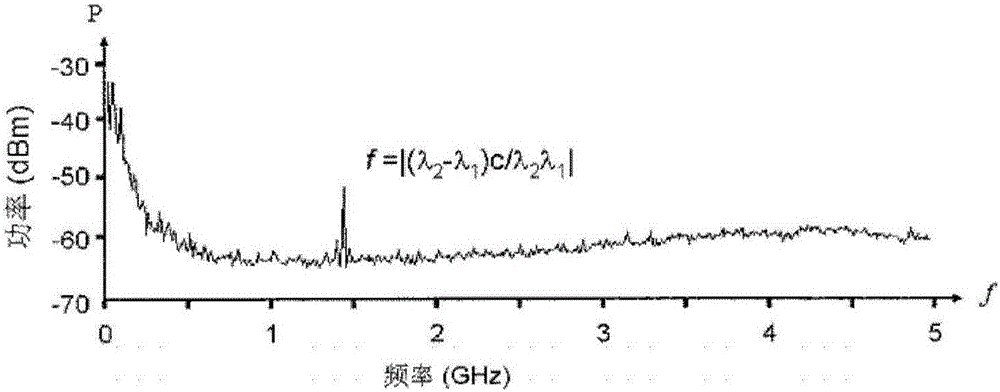

Optical time-domain reflectometer system and measuring and using method thereof

InactiveCN105871457AConsistent widthImprove detection efficiencyElectromagnetic receiversLine widthOptical fiber coupler

The invention provides an optical time domain reflectometer system with high resolution, large dynamic range and simple structure and its measurement method, which includes a narrow linewidth laser, an optical fiber amplifier, an optical fiber coupler, an optical wavelength encoder, an optical isolator, Optical fiber coupler optical circulator, optical fiber link under test, optical wavelength encoder, optical coupler, photodetector and signal detection device. The invention is used to solve the problem that the traditional OTDR resolution and dynamic range cannot be improved simultaneously.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

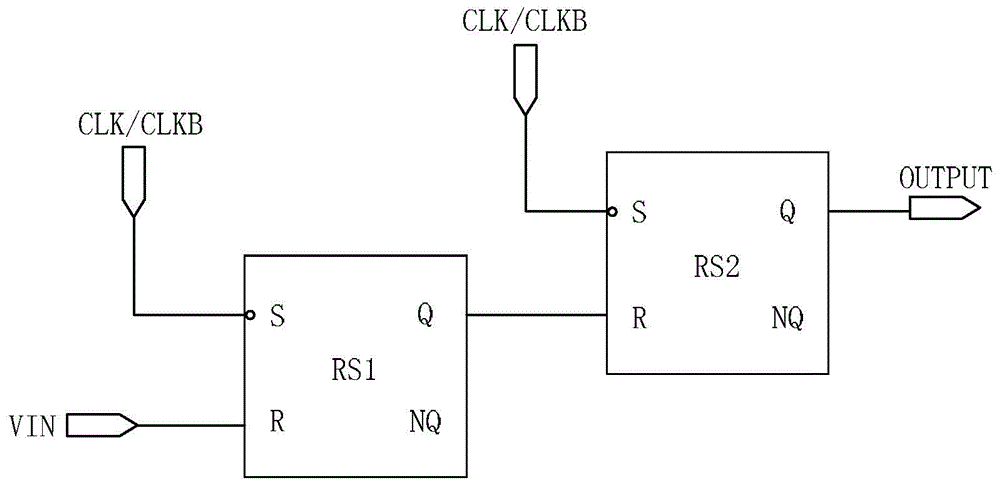

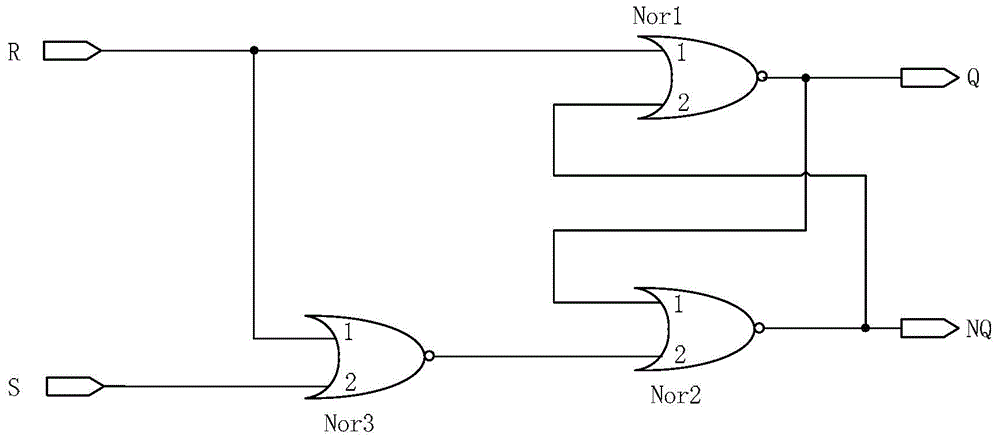

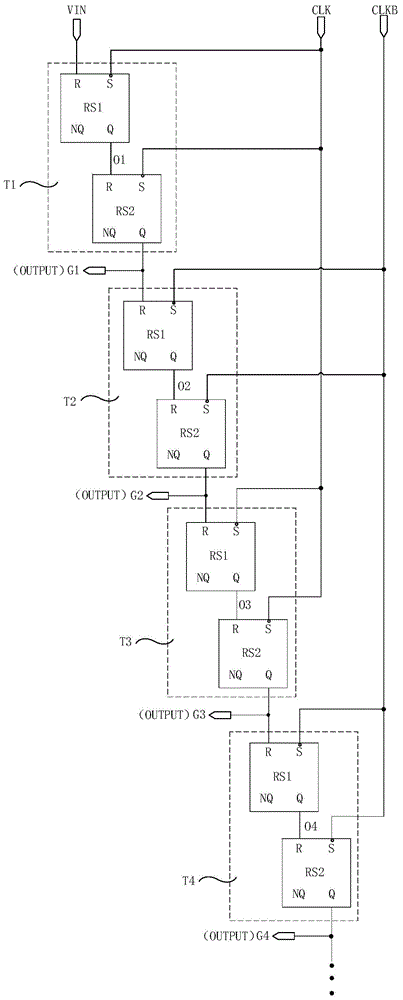

Shifting register unit, gate driving circuit and display device

ActiveCN104658508AImprove stabilityAvoid mistakesStatic indicating devicesDigital storageShift registerDisplay device

The embodiment of the invention provides a shifting register unit, a gate driving circuit and a display device, relating to the technical field of display. According to the shifting register unit, the gate driving circuit and the display device, the problem that the stability of a GOA (Gate Driver on Array) circuit is decreased due to fault caused when a node is charged and discharged in the prior art can be solved. The shifting register unit comprises a first latch module and a second latch module, wherein a first input end of the first latch module is connected with a first clock signal end or a second clock signal end, a second input end is used for receiving pulse signals, and an output end of the first latch module is connected with a second input end of the second latch module; a first input end of the second latch module is connected with the first clock signal end or the second clock signal end, and an output end of the second latch module is connected with a signal output end of the shifting register unit; the first input ends of the first latch module and the second latch module are connected with a same signal end.

Owner:BOE TECH GRP CO LTD

Active static anti-haze screen window

InactiveCN106368594ASimple structureEasy to cleanInsect protectionElectrostatic separation detailsElectricityHigh-voltage direct current

The invention discloses an active static anti-haze screen window. The window is composed of two outer metal filter screens, a built-in threadlike high voltage electrode layer and a high voltage direct current static generator circuit. Outdoor haze particles are effectively prevented from entering the interior through the coulomb force by means of the polarization and charging actions of a high voltage static field to small dust, and indoor air is purified. When in use, firstly, a high voltage direct current static generator power supply switch is turned on, the negative electrode of a high voltage output end is connected with the outer metal filter screens, the positive electrode of the high voltage output end is connected with a high voltage electrode terminal of the built-in threadlike high voltage electrode layer, and a high voltage symmetrical uneven static field is formed in the screen window; and then, the screen window is opened for ventilation, and the outdoor haze is blocked and the indoor air is purified in the flowing process of natural air. According to the active static anti-haze screen window, the overall structure is simple, and processing and manufacturing are easy; two gears are provided, the lower gear is used for blocking the outdoor haze, and no ozone is generated at the moment; and the higher gear is used for blocking the outdoor haze and can further purify the indoor air.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Film bulk acoustic resonator and method for manufacturing same

InactiveCN103414446AReduce difficultyConsistent widthImpedence networksThin-film bulk acoustic resonatorAcoustic wave

The invention provides a film bulk acoustic resonator, a method for manufacturing the film bulk acoustic resonator and a filter, an oscillator and a radio frequency module which respectively comprise the film bulk acoustic resonator. According to the film bulk acoustic resonator, a function layer is arranged to be of an annular structure, so that after vertical voltage is applied to a piezoelectric material through a first electrode and a second electrode, sound waves perpendicular to an electric field, namely the sound waves in the horizontal direction, are stimulated by the utilization of the d31 piezoelectric coefficient of the piezoelectric material, and therefore the resonant frequency is related to the width of a device, namely the width of the piezoelectric material. In an existing integrated circuit micromachining technology, the control precision of plane sizes is far higher than the control precision of thicknesses, for example, through the CMOS65 nanometer technology, very accurate 65-nanometer plane nodes can be realized and the precision of the nodes can reach the nanometer level, so that the FBAR can guarantee that the resonant frequencies of resonators on the same wafer are highly uniform, and therefore the processing difficulty of the device is greatly lowered and the yield is greatly improved.

Owner:张家港恩达通讯科技有限公司

Winding method of cable winding and wrapping belt

The invention discloses a winding method of a cable winding and wrapping belt. A cable winding and wrapping machine is used for winding a cable. The method comprises the following operation steps that A, two annular lining plates of the cable winding and wrapping machine are arranged on the cable in a penetrating manner through central holes of the lining plates, each adjusting shaft is adjusted, and a roller is connected with the outer edge of the cable in an abutting manner; B, the position of a shifting rod in an arc-shaped groove of a fixed plate is adjusted, and a walking rolling angle b of the roller is set; C, a flexible protection belt is wound on a core shaft with a tensioning device, the position of a sliding block in a sliding groove of the adjusting plate is adjusted, and the swing angle a of a rolling shaft is set; D, a tensioning nut is adjusted to extrude a second friction piece through a damping spring, an inner blocking piece enables a flexible protection belt roll to extrude one side of a first friction piece, and tensioning force is applied to the flexible protection belt roll; and E, the flexible protection belt released out of the core shaft winds the cable. Compared with the prior art, the method has the beneficial effect that the problems that existing cable winding packaging is poor in stability and high in cost are solved.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com