Winding method of cable winding and wrapping belt

A technology for wrapping tapes and cables, which is applied to the field of wrapping flexible protective tapes on suspension bridge cables, can solve the problems of poor cable wrapping quality and stability and high wrapping costs, and achieves the need for no rework, high wrapping success rate, and elimination of slack. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing:

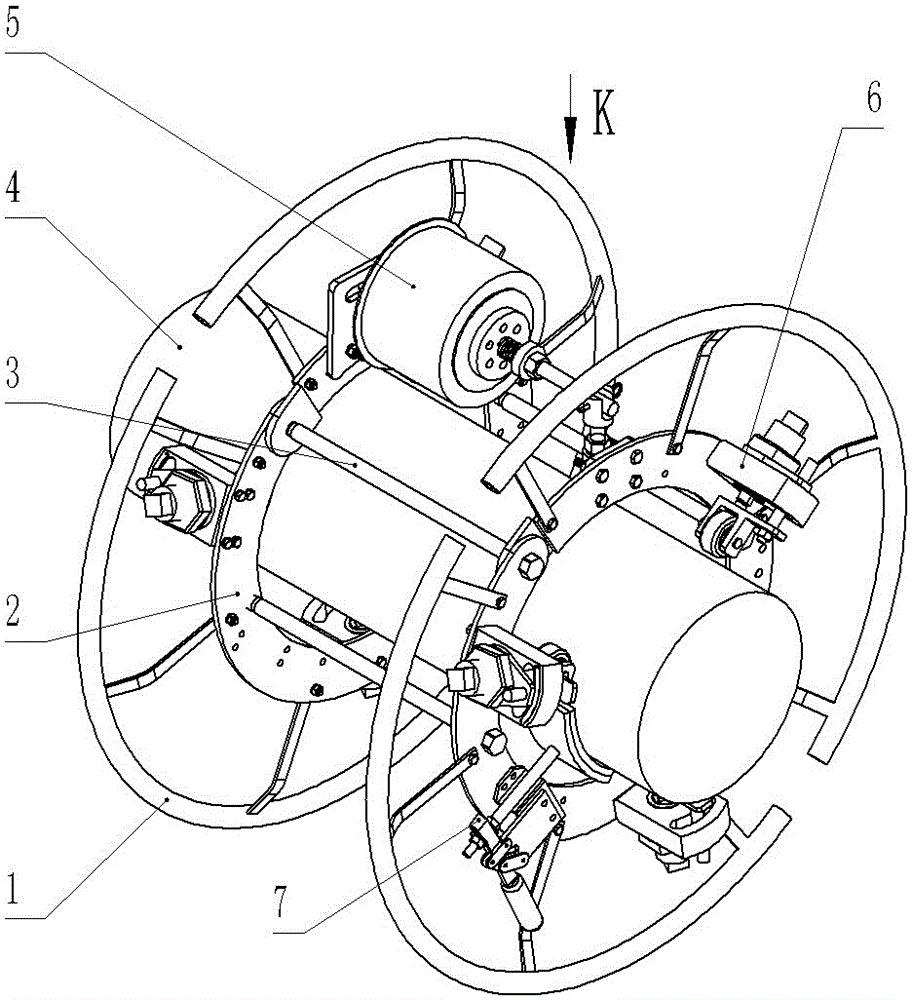

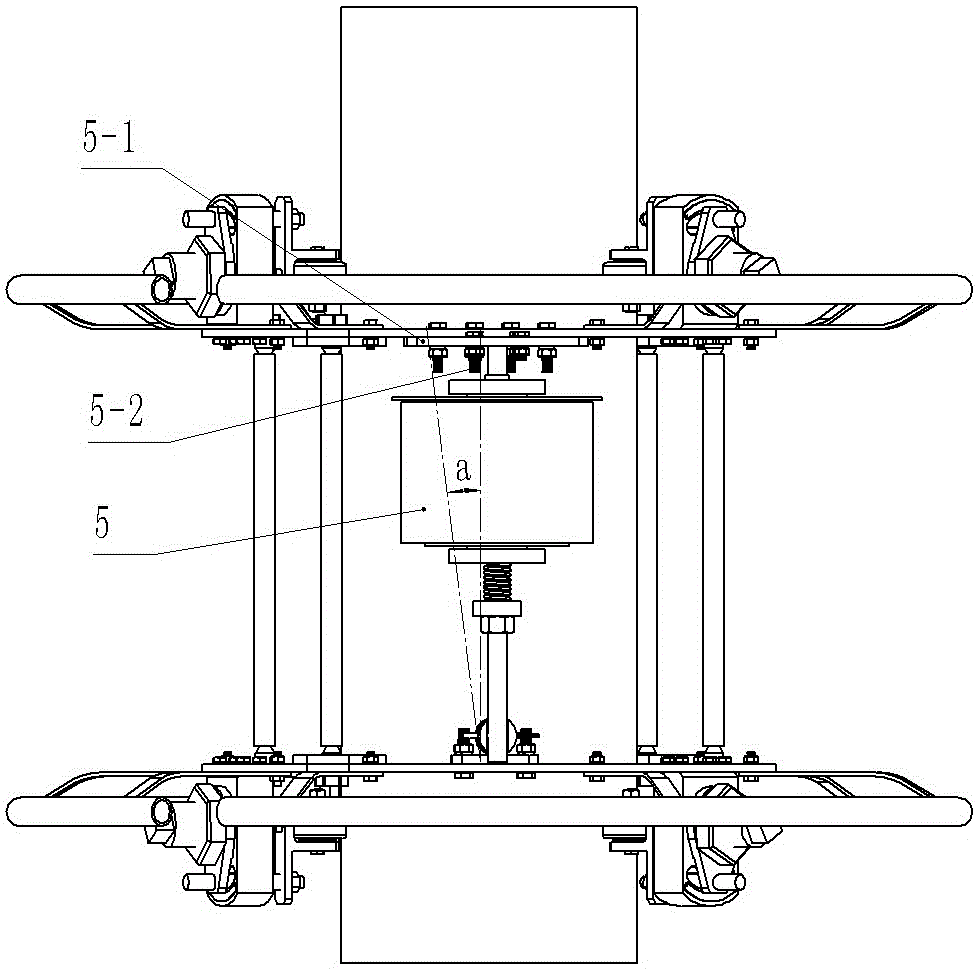

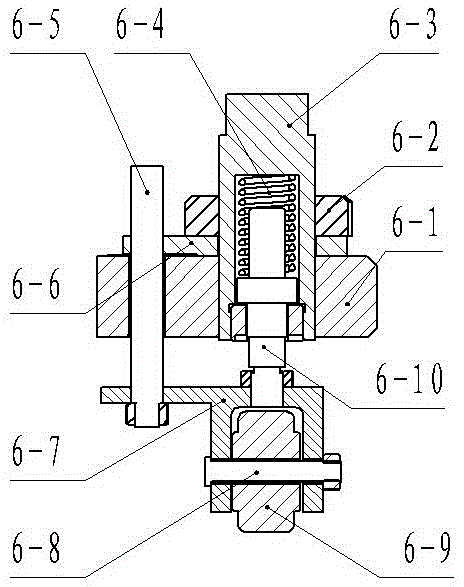

[0024] A winding method for cable wrapping tape, using a figure 1 The cable wrapping machine shown, the cable wrapping machine includes two annular liners with a central hole formed by a plurality of arc-shaped side plates 2 overlapped end to end. The annular liner of this embodiment consists of two overlapping Each arc-shaped side plate 2 is connected with a circular-arc-shaped pull ring 1 by bolts; a plurality of axial The connecting rod 3 is fixedly connected to the two annular liners by nuts screwed on a plurality of axial connecting rods 3 . A plurality of roller telescopic devices 6 are arranged on each annular liner, and in this embodiment, three roller telescopic devices 6 are installed on each annular liner; the roller telescopic device 6 includes two circular arcs mounted on the annular liner The fixed plate 6-1 on the shaped side plate 2 has an arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com