Patents

Literature

213results about How to "Simple and inexpensive manner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

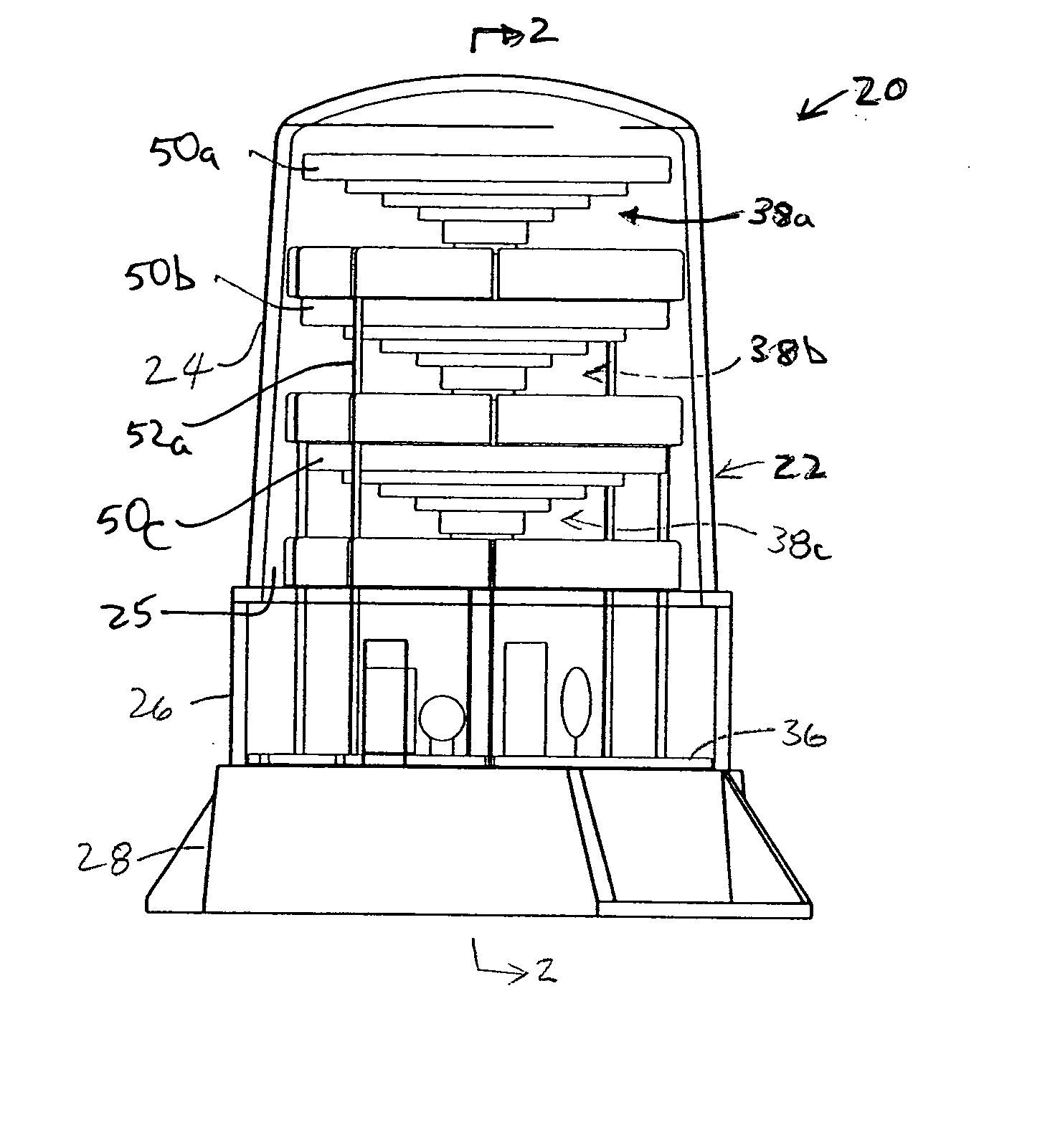

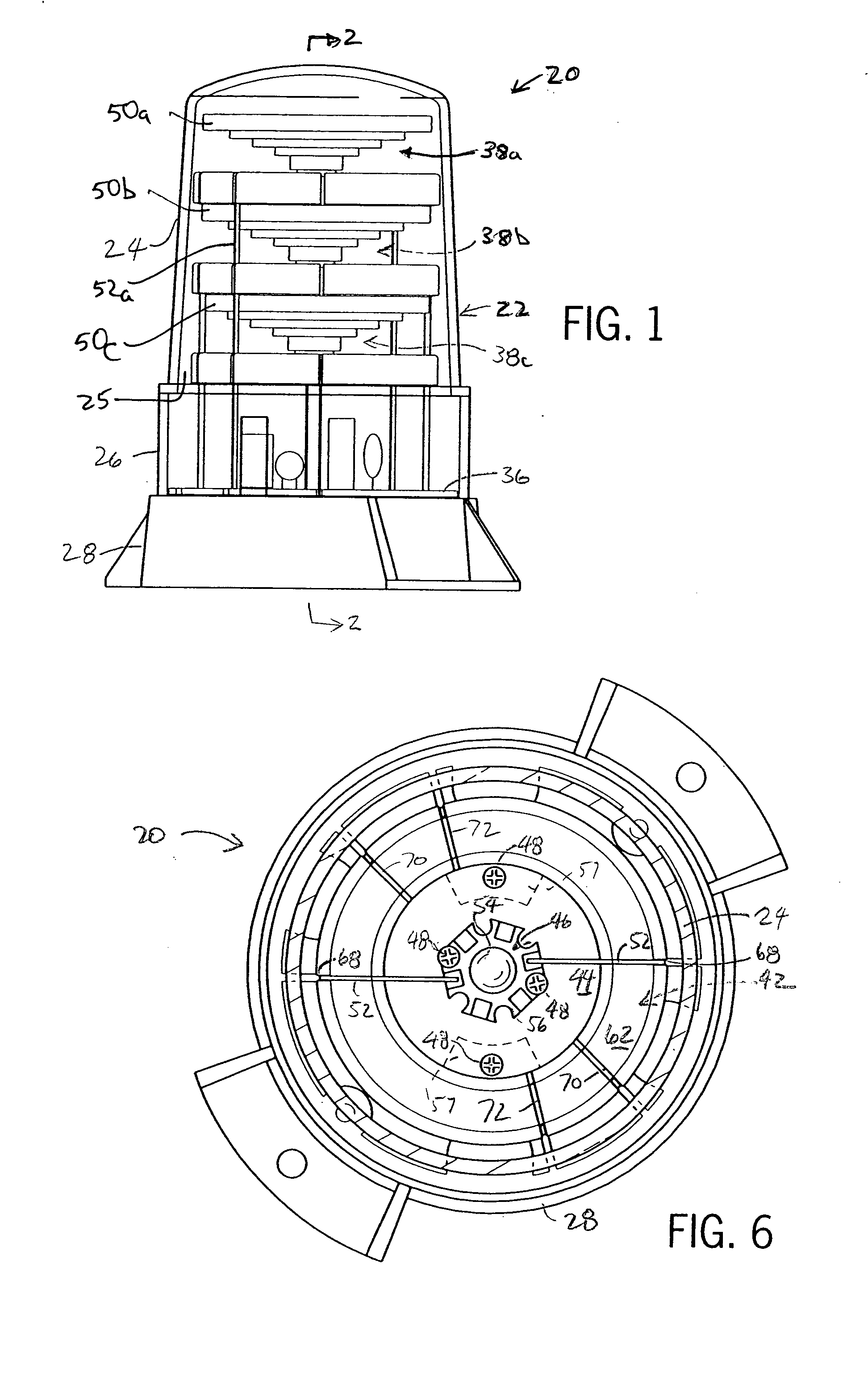

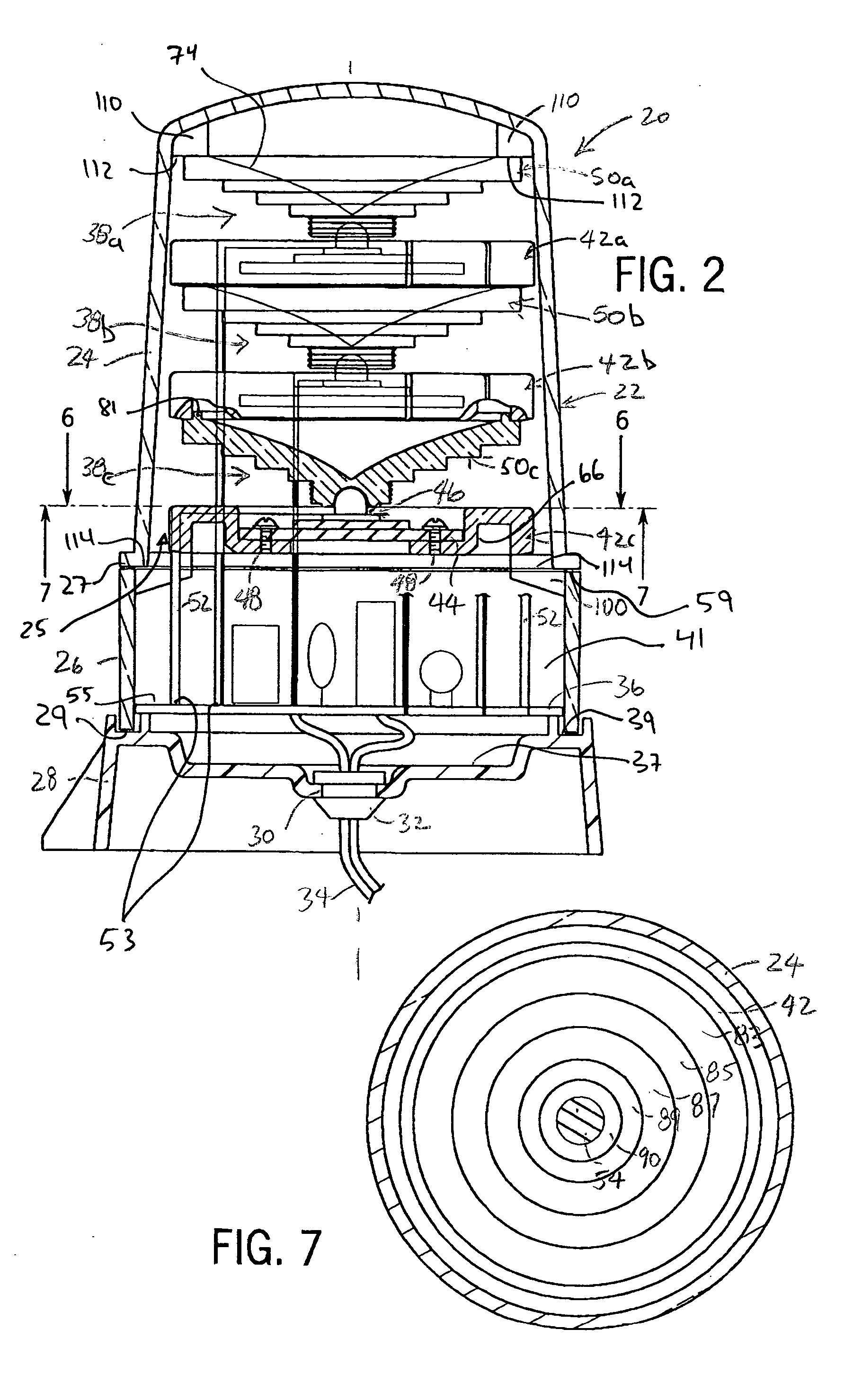

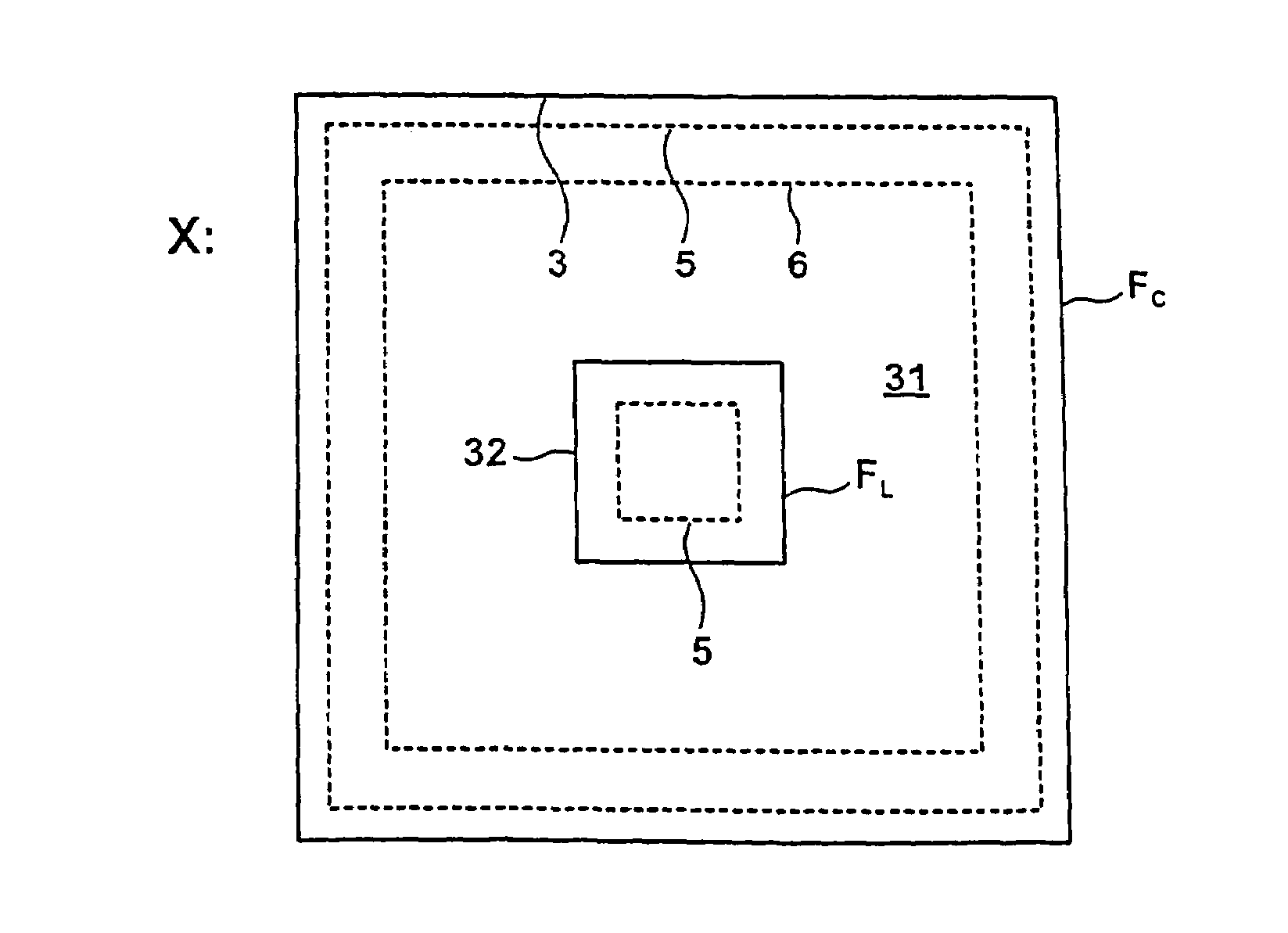

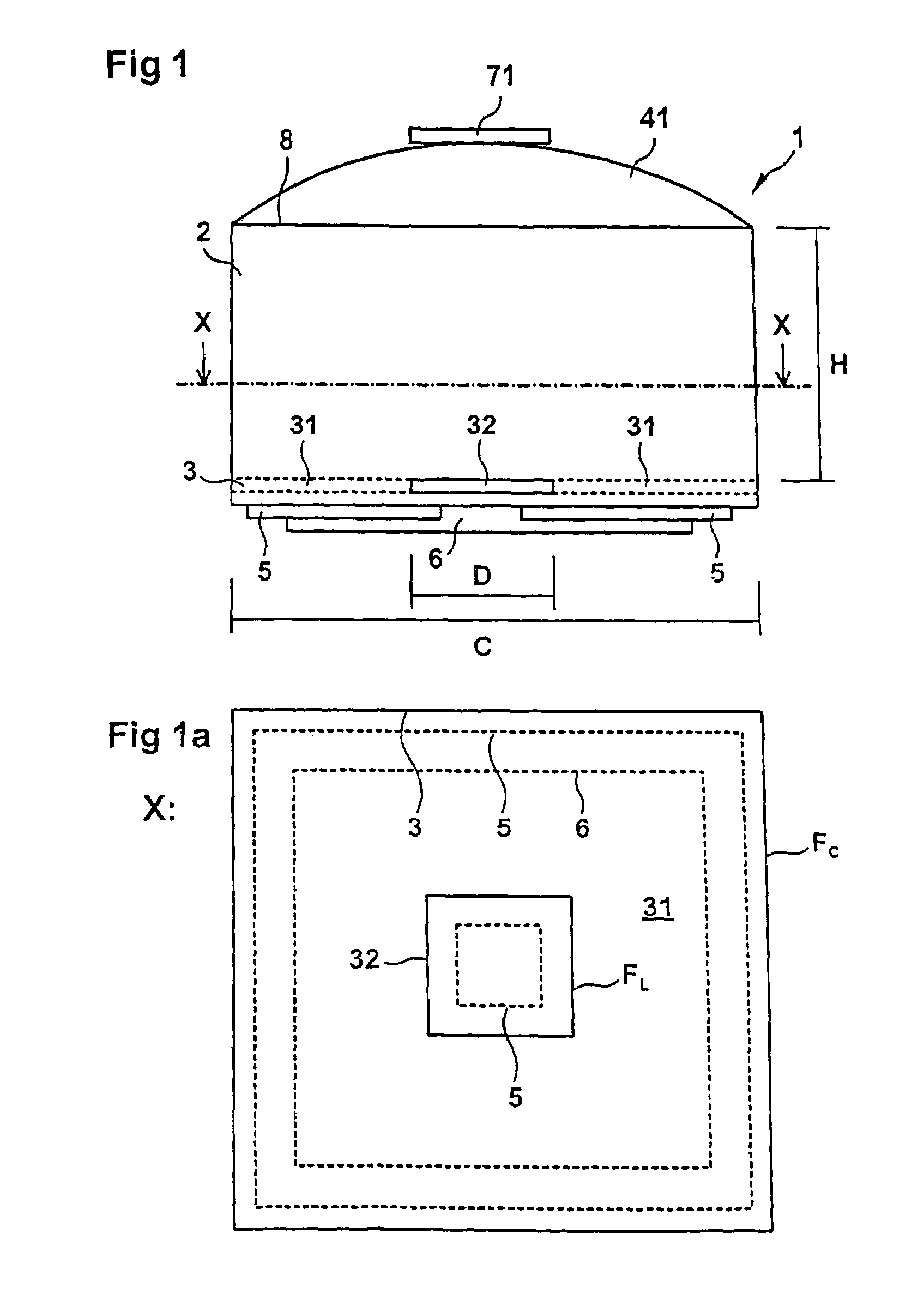

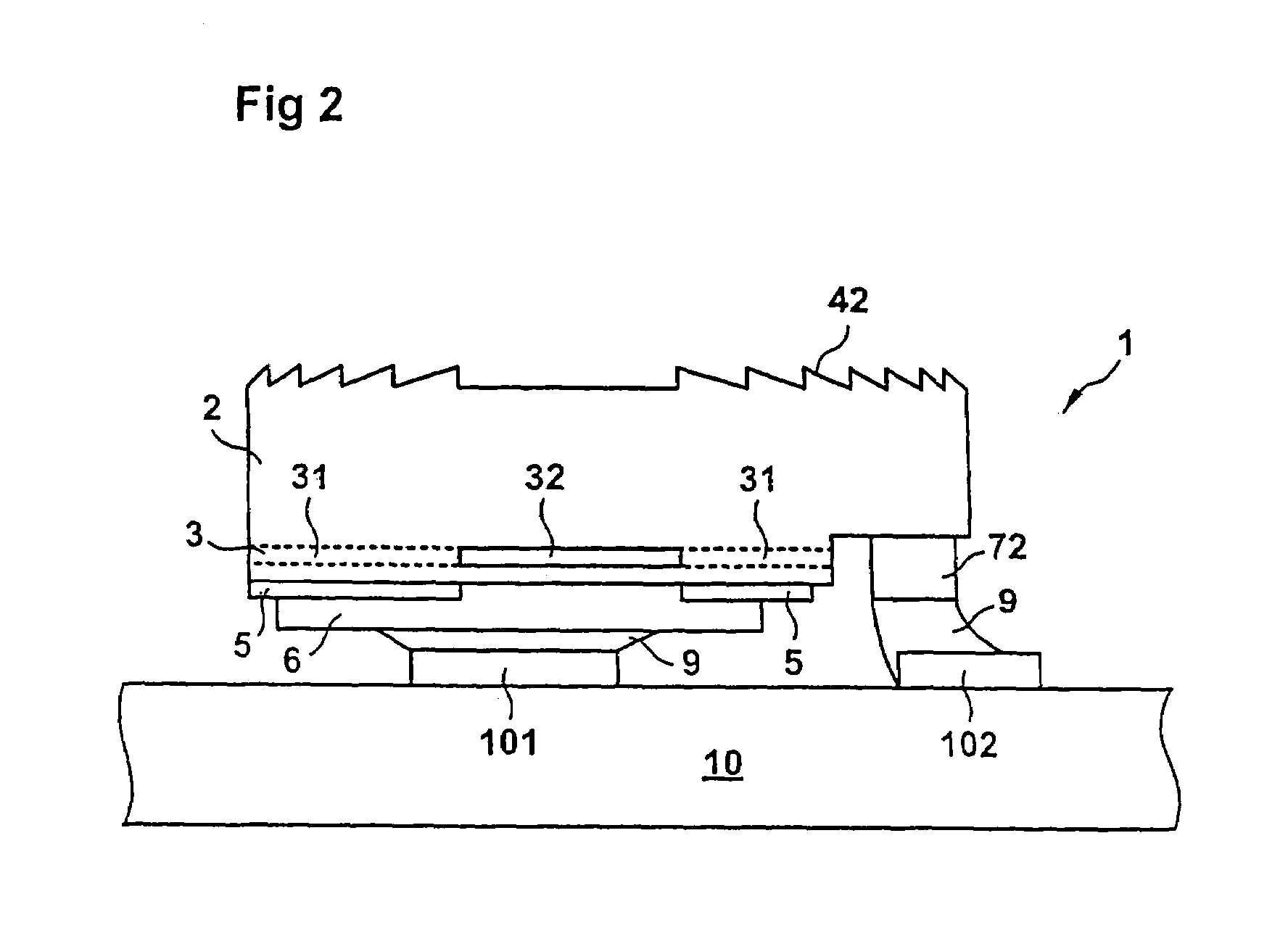

Modular LED light and method

InactiveUS20050068777A1Simple configurationSimple and inexpensive mannerLighting applicationsLight source combinationsEngineeringLight source

An at least partially translucent optical element for distributing light from a light source, the element comprising a hub member formed about a central axis, having an external surface between first and second ends and forming a recess within the first end that extends along the central axis substantially along a length of the hub member between the first and second ends for receiving the source, the external surface forming a lens for dispersing light directed thereat from within the recess out of the element and a reflecting member integral with and extending from the second end, the reflecting member including at least one external reflecting surface that reflects substantially all of the light directed into the reflecting member from within the recess back into the element.

Owner:J W SPEAKER CORP

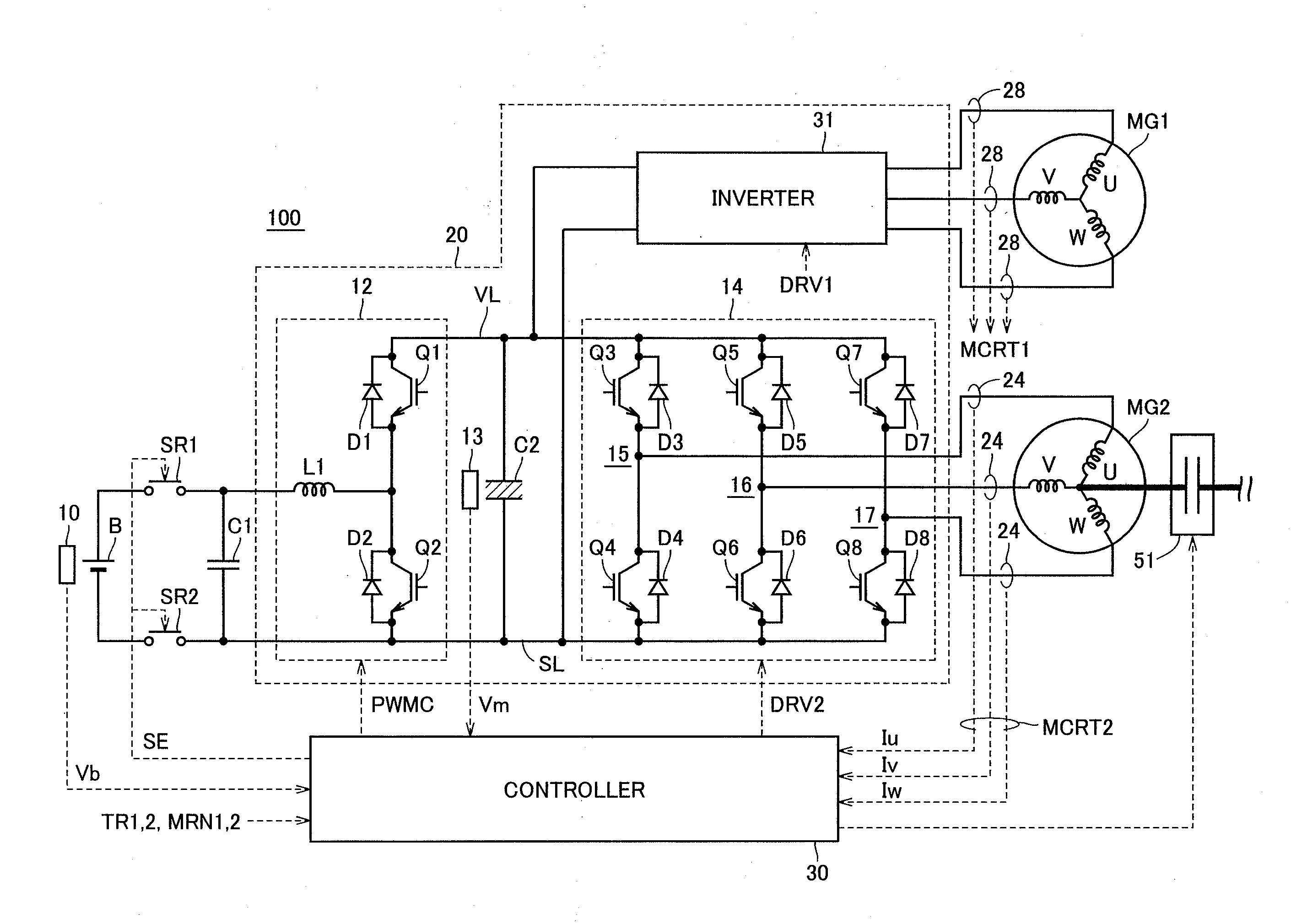

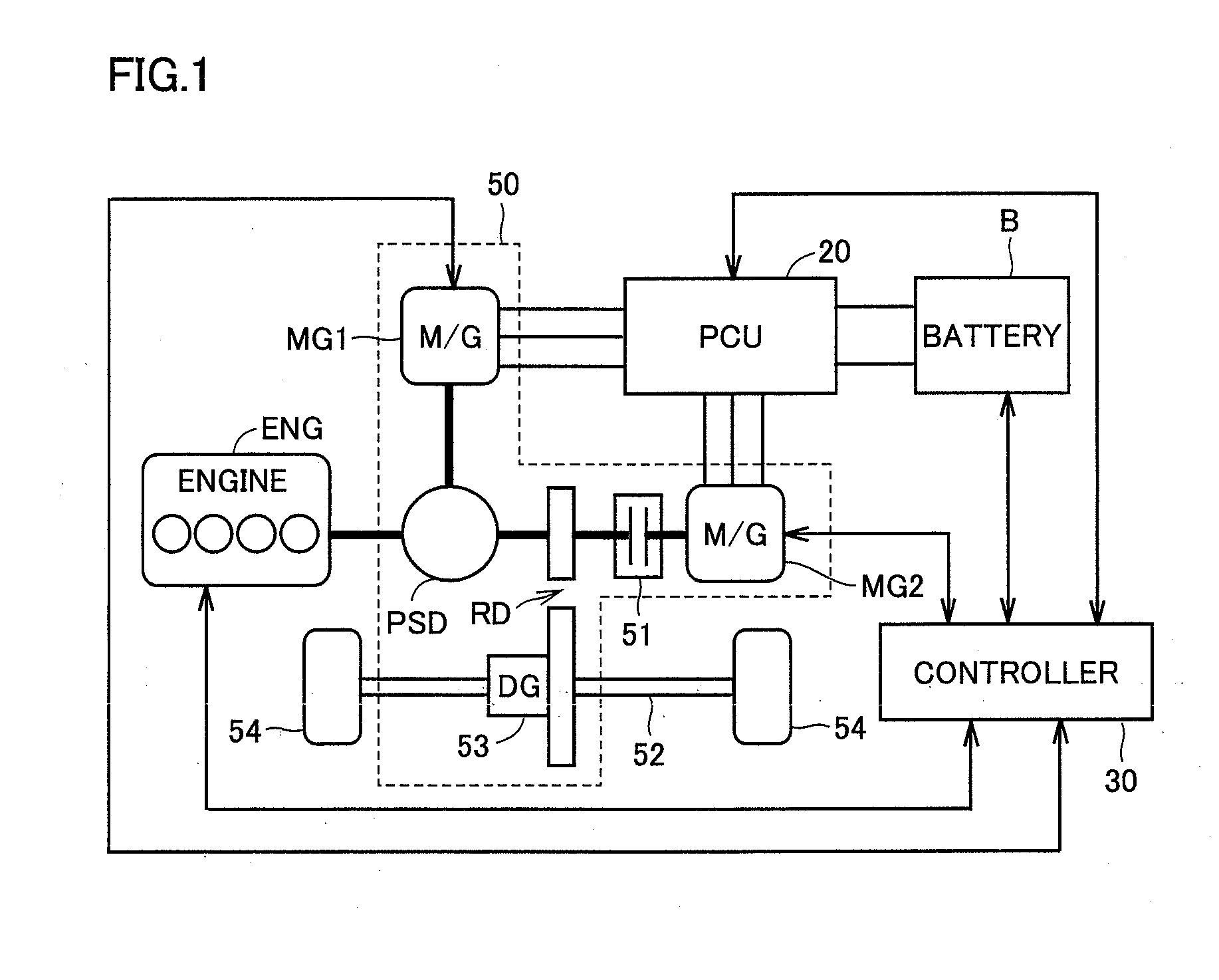

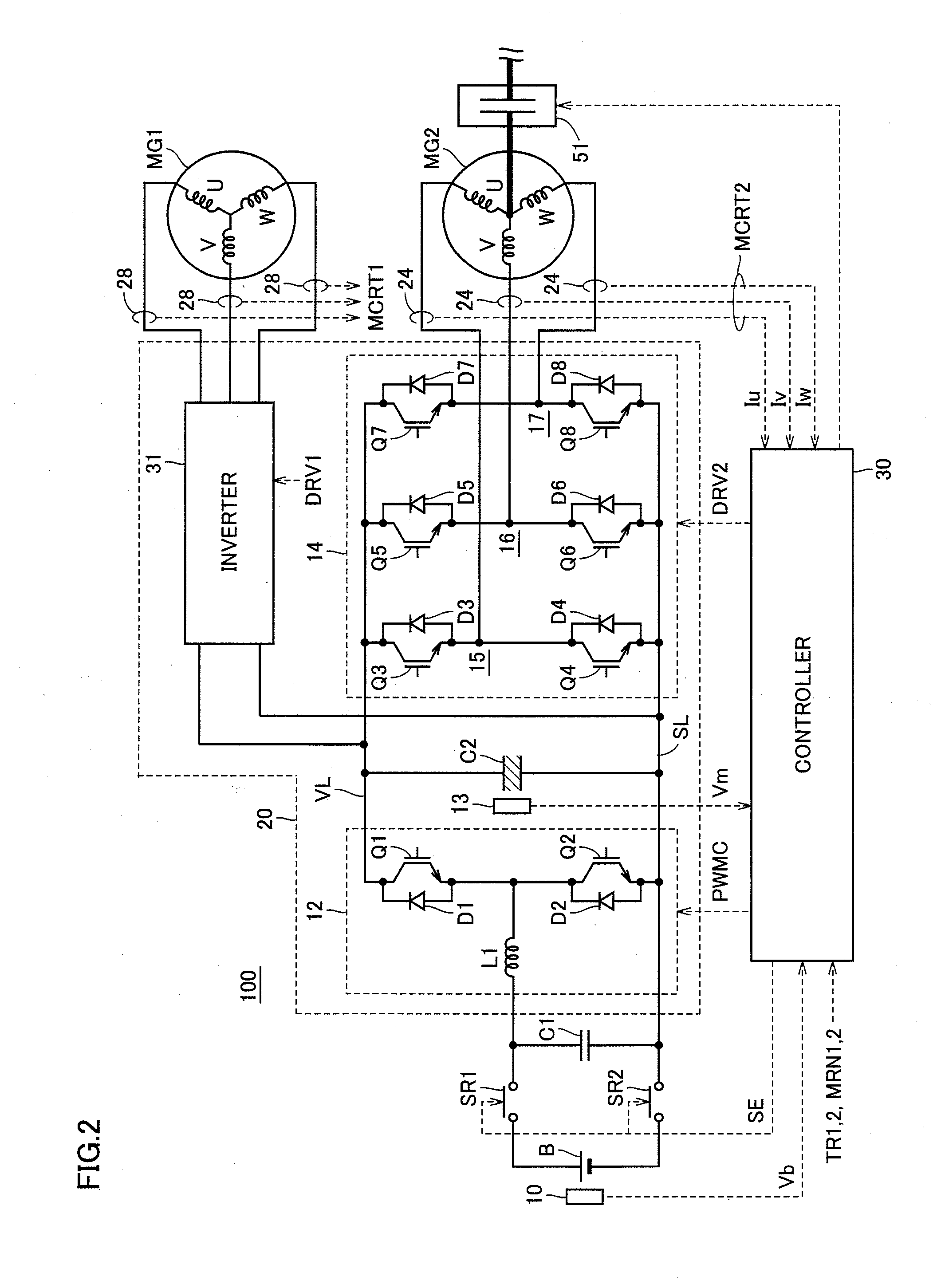

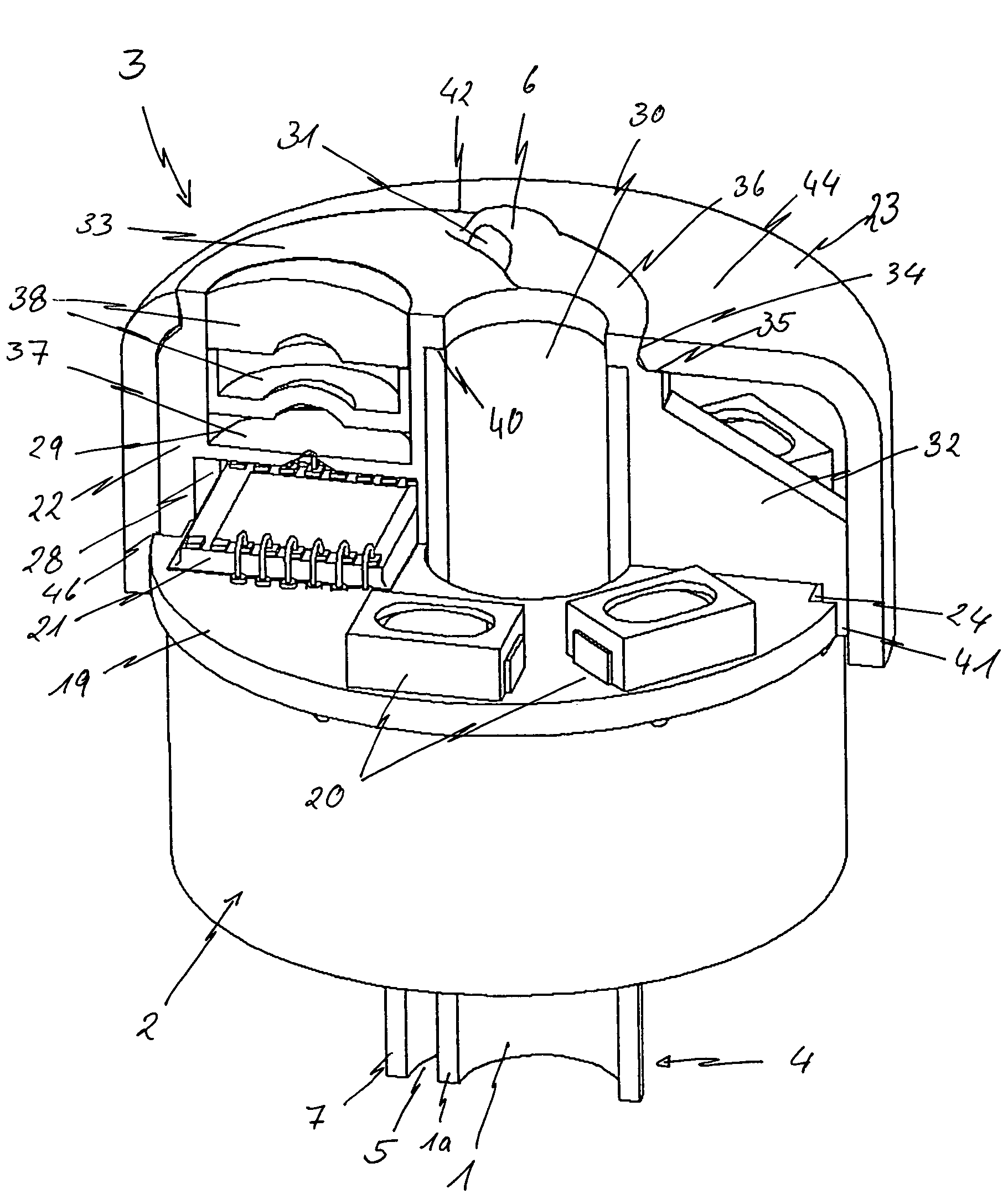

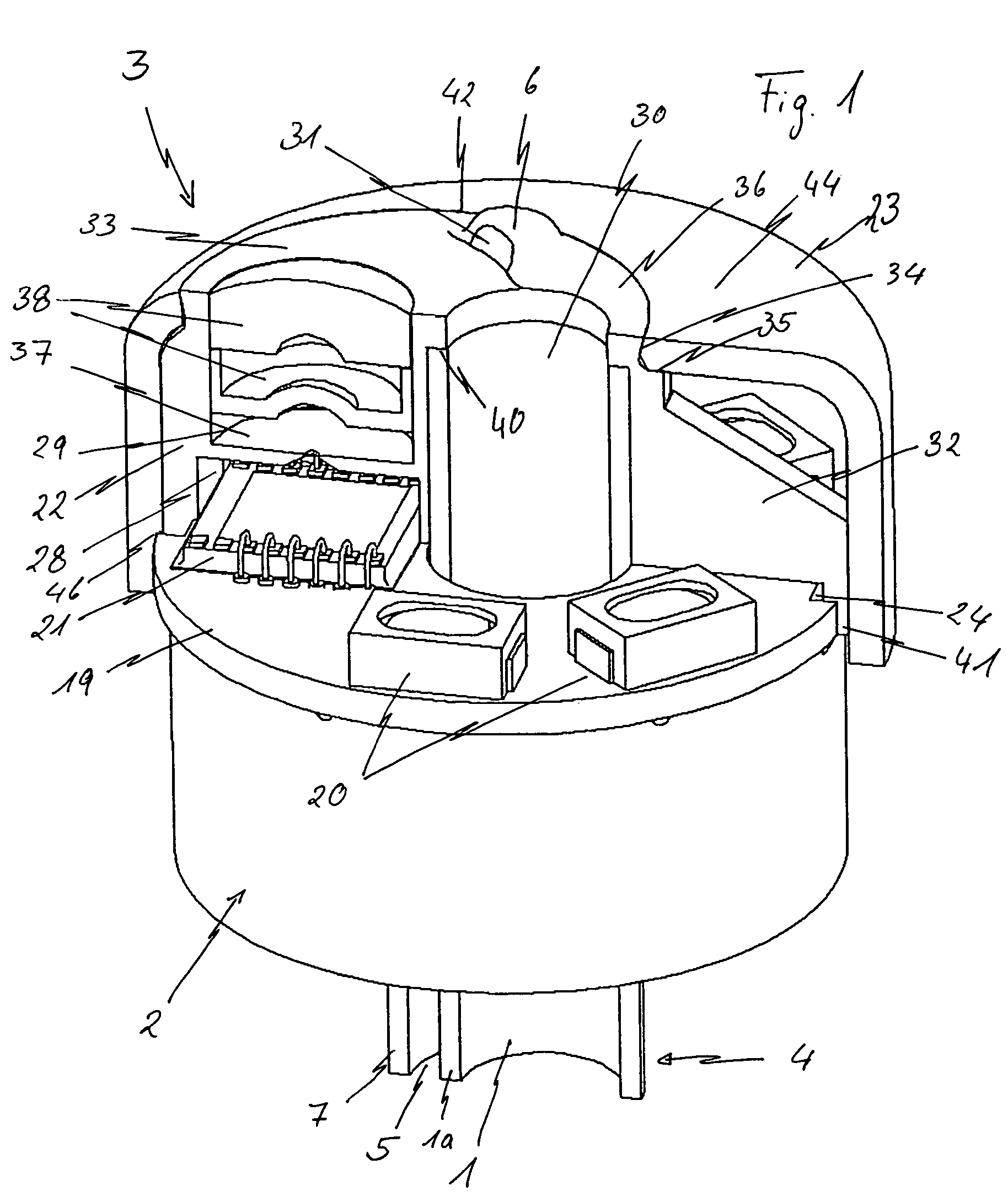

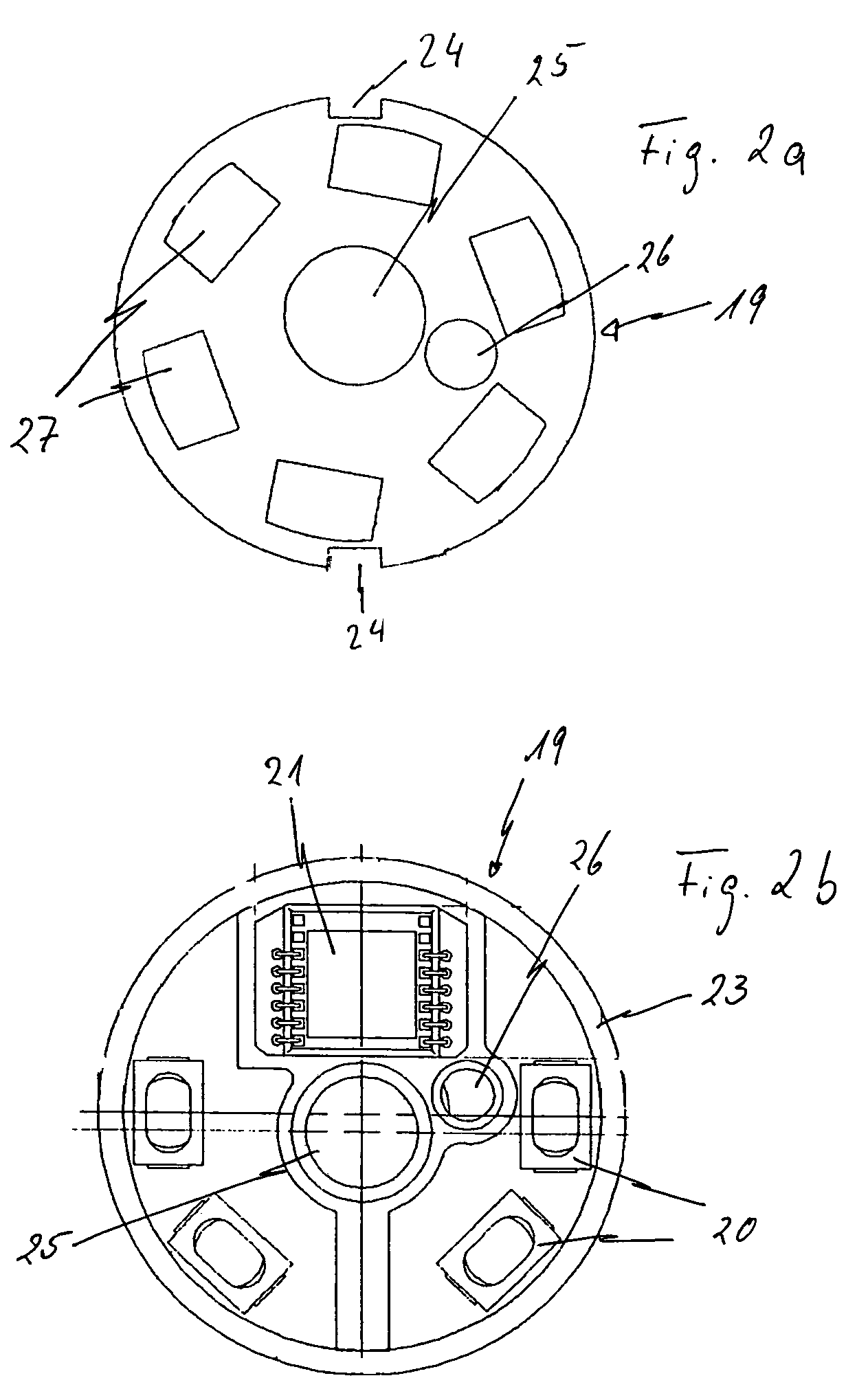

Motor drive device

ActiveUS20090251831A1Improve reliabilitySimple and inexpensive device structureAC motor controlElectric motor controlMotor driveControl theory

When an upper arm of U-phase has failed because of short-circuit, lower arms of V-phase phase and W-phase as the opposite arms are switching-operated. When only the lower arm of V-phase is turned on, a route of motor current passing through an IGBT element from a V-phase coil is formed, and therefore, the motor current returning to the short-circuited phase decreases. Further, by the switching operation of the arm opposite to the short-circuited arm, an AC current is induced in a motor generator. Therefore, it is possible to continuously drive the motor generator while preventing increase in the current passing through the short-circuited phase, without adding a new device structure. This ensures running of the vehicle in the limp mode.

Owner:TOYOTA JIDOSHA KK

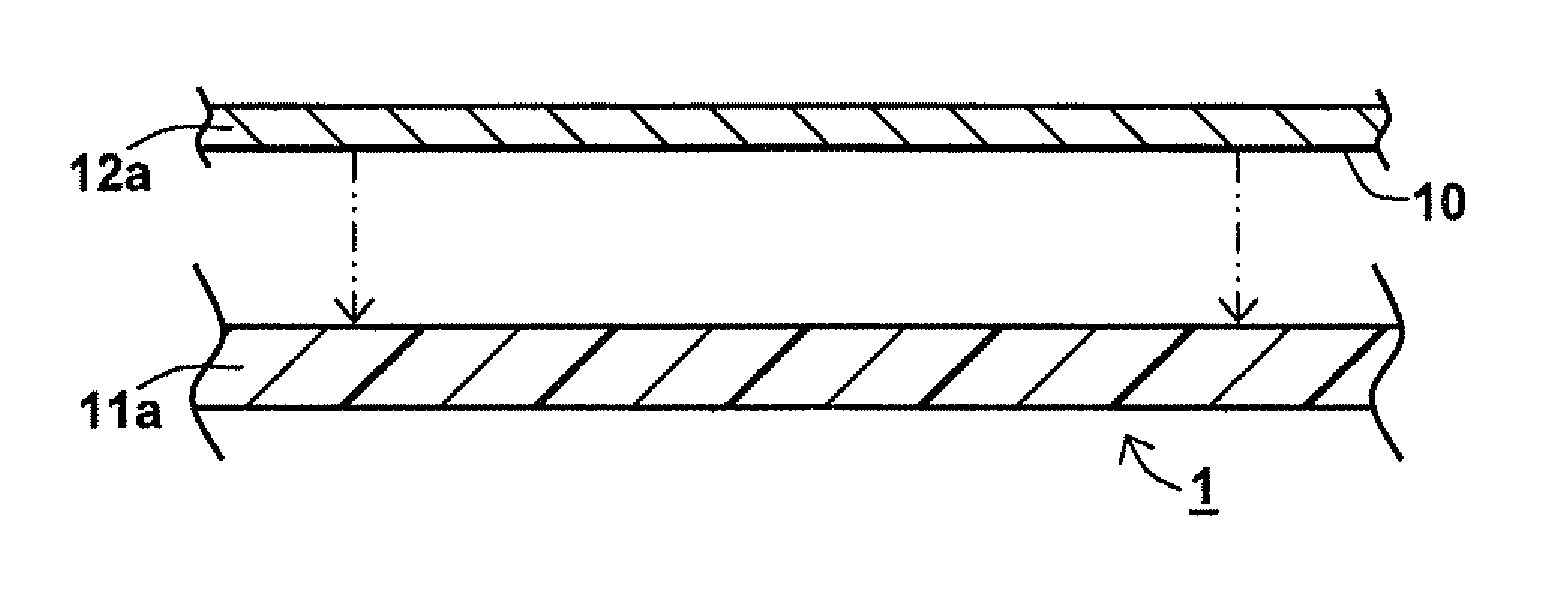

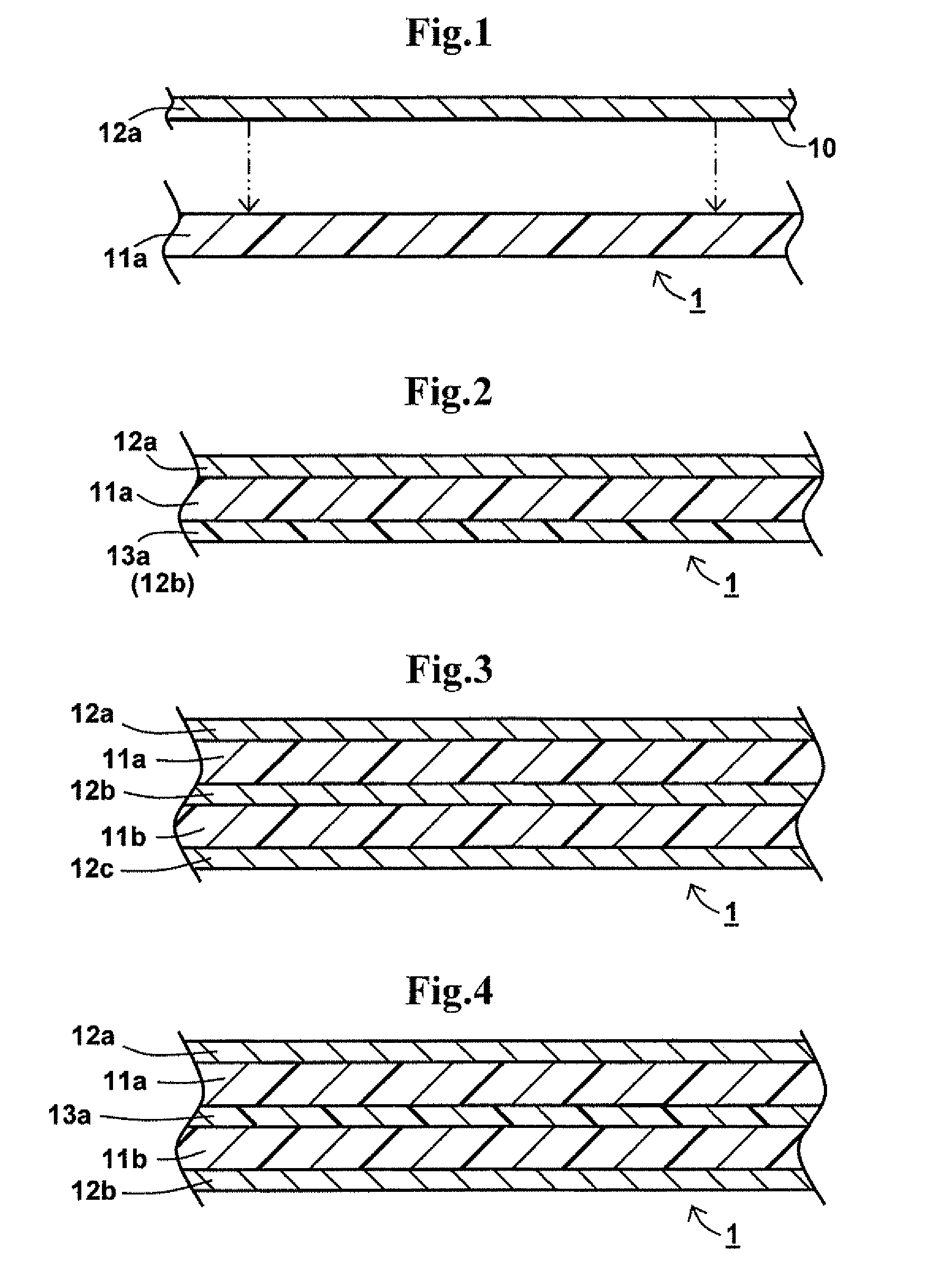

Three-dimensional silicone-rubber bonded object

InactiveUS20110171480A1Simple and inexpensive mannerHigh productivityLamination ancillary operationsSynthetic resin layered productsPressure sensitiveElastic substrate

A simple silicone-rubber bonded object is provided in which non-flowable substrates, i.e., a three-dimensional silicone rubber elastic substrate molded beforehand and an adherend substrate, were able to be tenaciously bonded to each other without using a flowable curable adhesive or pressure-sensitive adhesive and which is inexpensive and has high productivity. The silicone-rubber bonded object comprises a three-dimensional silicone rubber elastic substrate having hydroxyl groups on the surface and an adherend substrate having hydroxyl groups on the surface, the substrates having been laminated to each other through covalent bonding between the hydroxyl groups of both. The elastic substrate and / or the adherend substrate has undergone corona discharge treatment and / or plasma treatment, whereby the hydroxyl groups have been formed on the surface thereof.

Owner:SULFUR CHEM INST INC +1

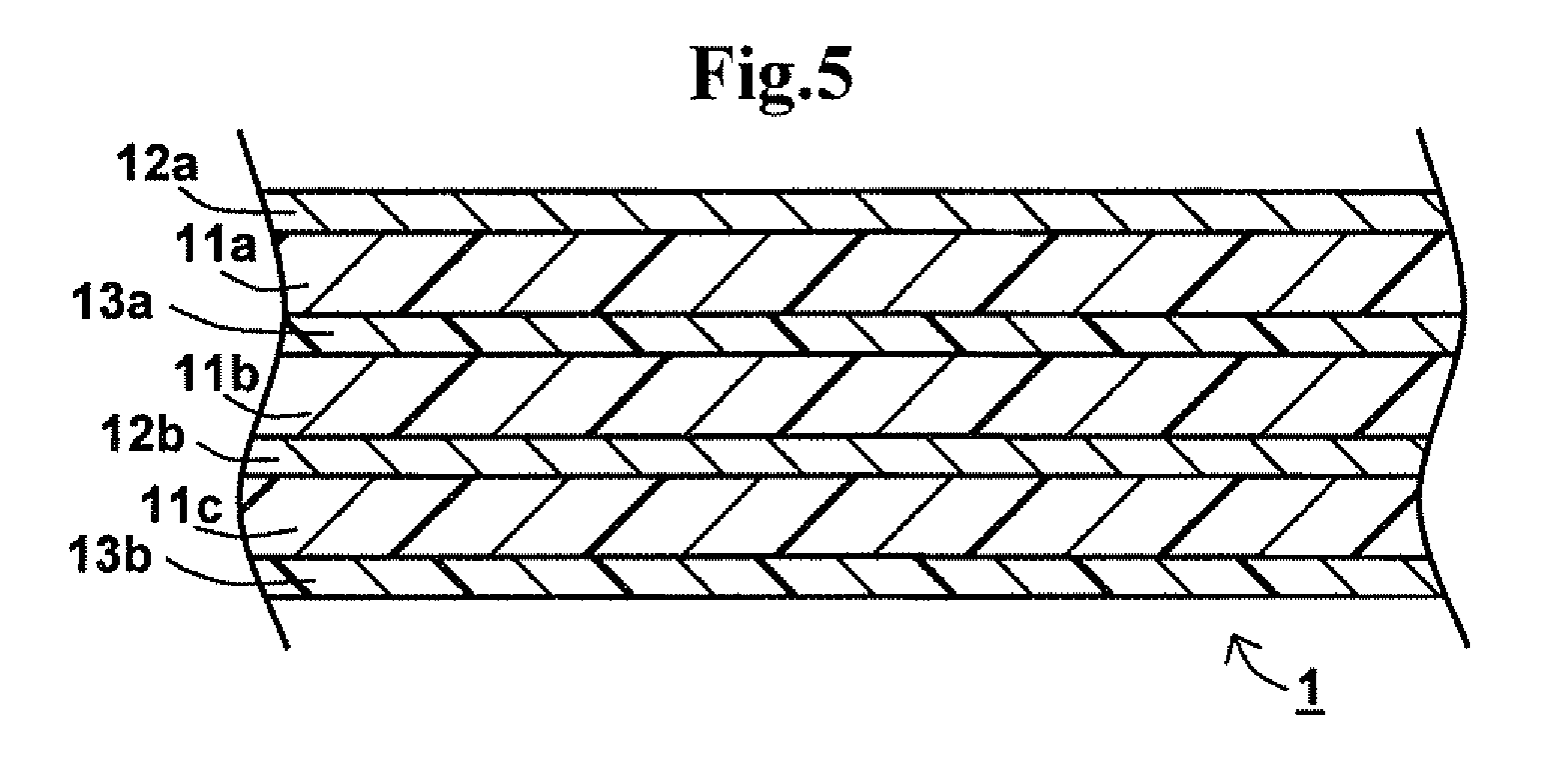

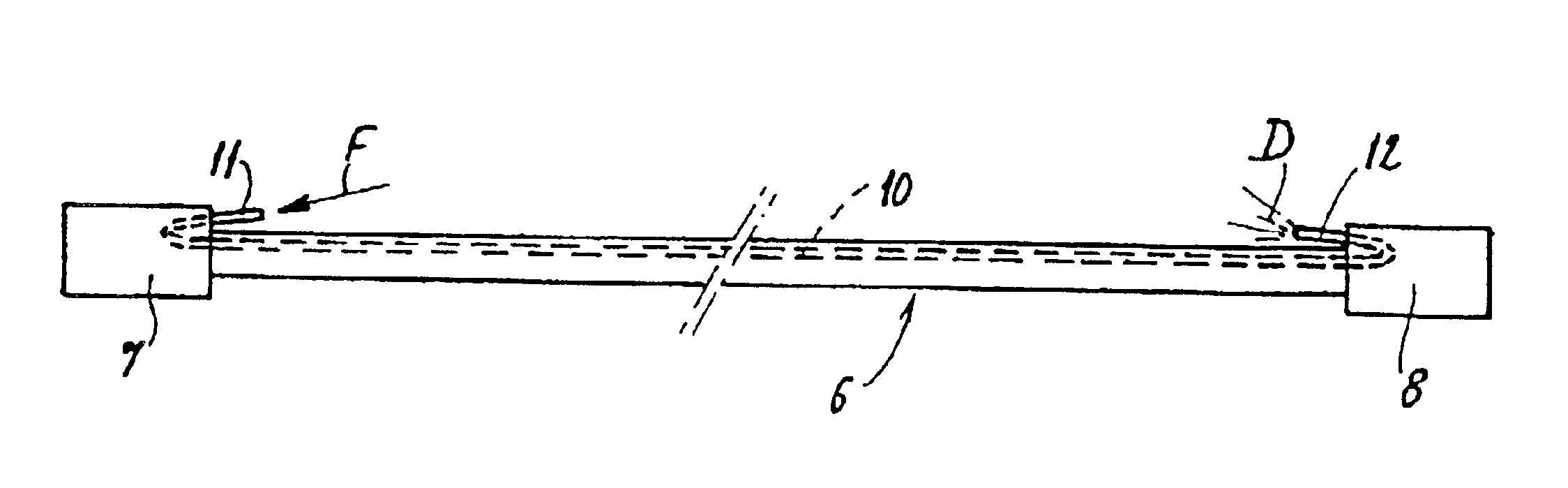

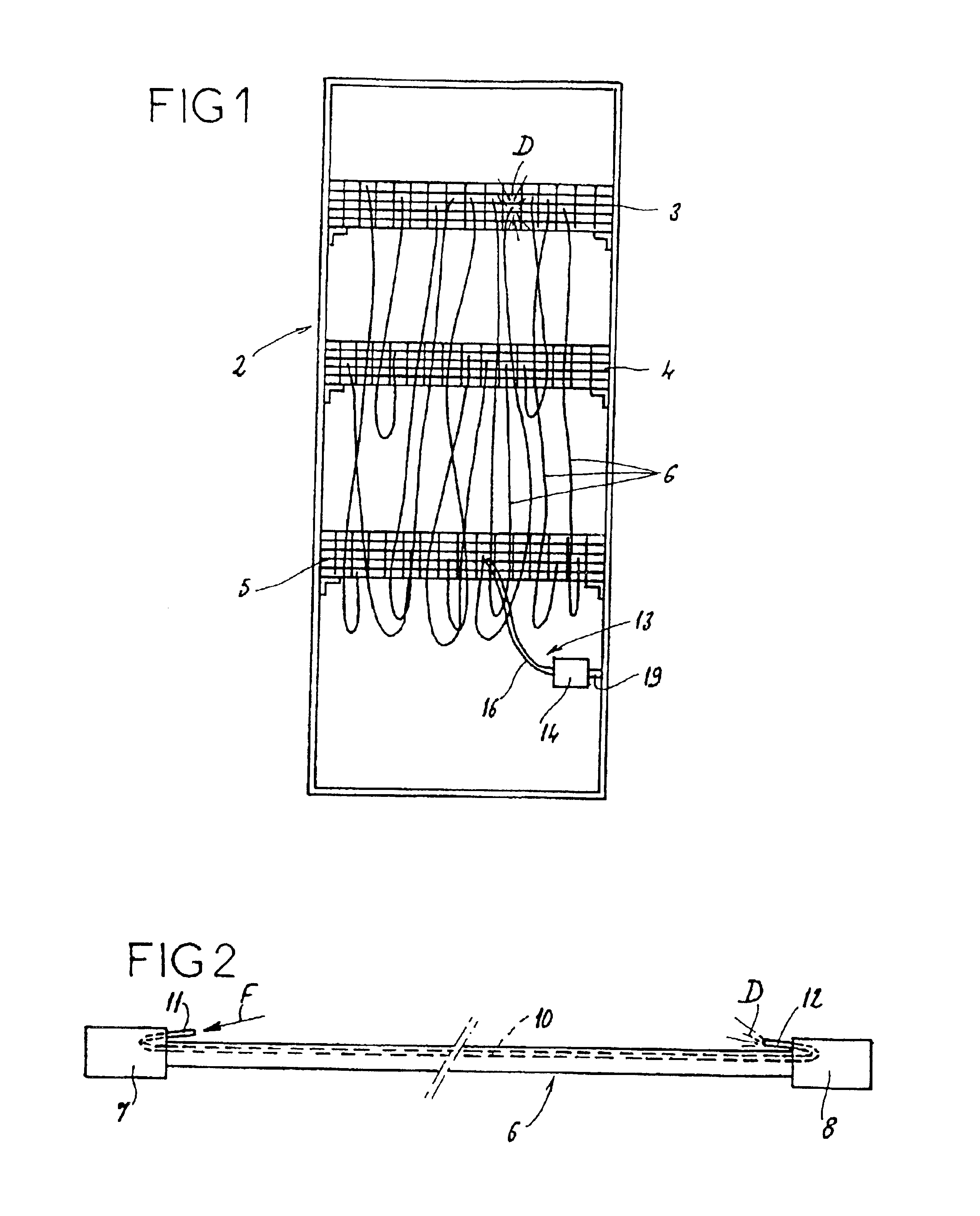

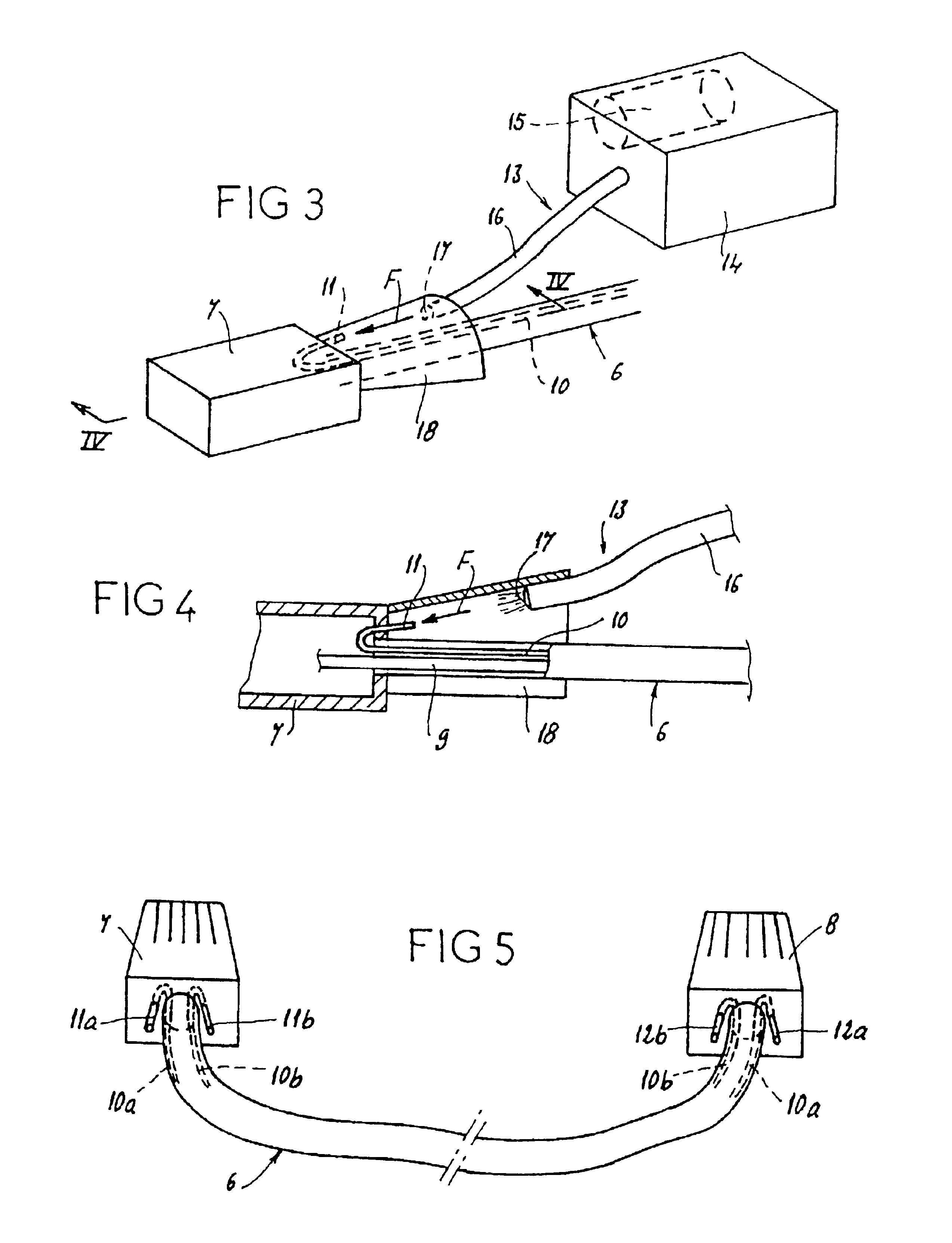

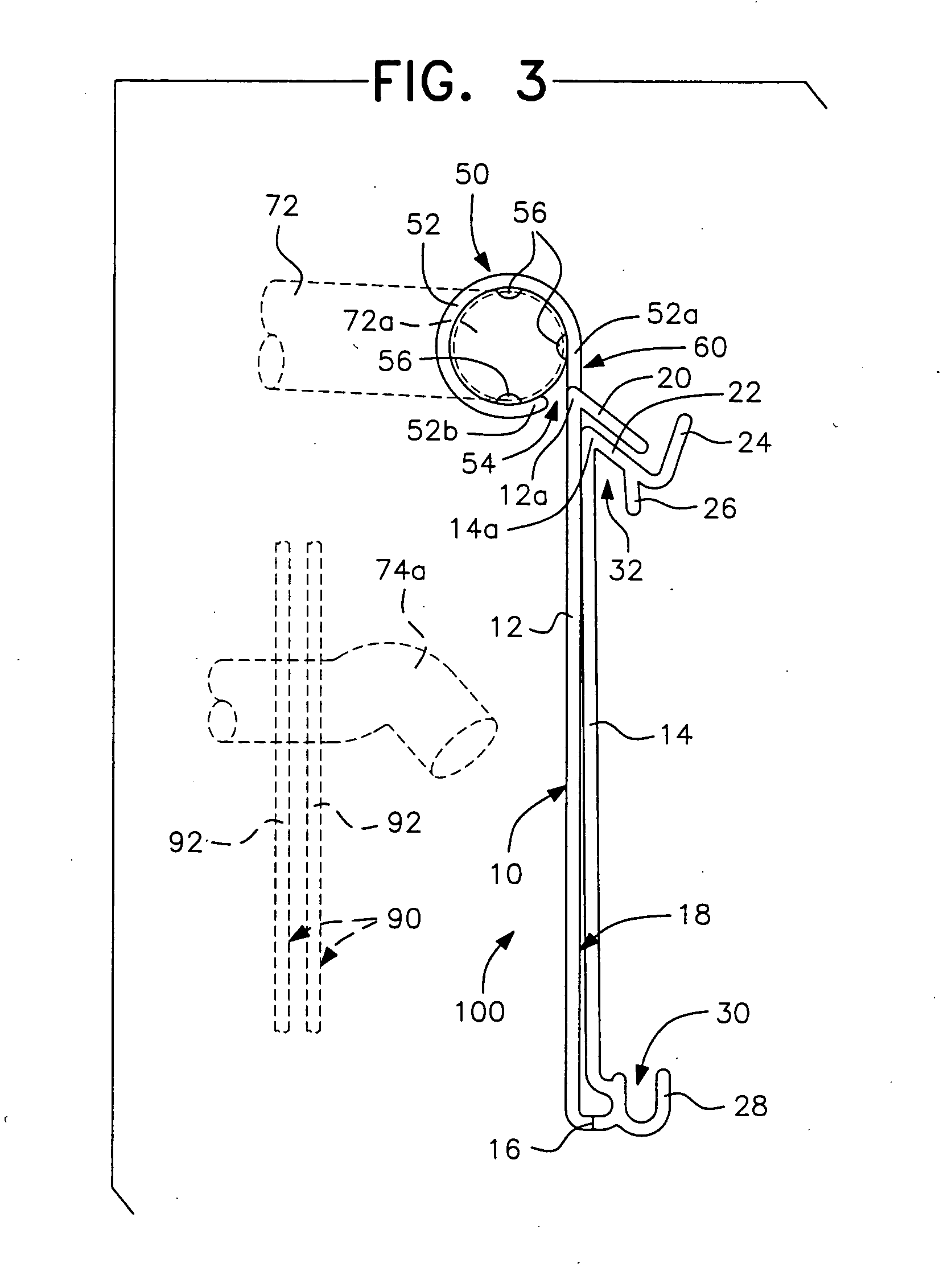

Device for visual identification of cables or conduits

InactiveUS6906505B2Simple and inexpensive mannerDrawback can be obviatedCurrent/voltage measurementCoupling device detailsElectricityFiber

The invention provides a device for accurately locating ends of cords, wires cables or conduits, in particular in the fields of electricity, electronics, telephone and computer. The device includes an optical fiber disposed on a cord and extending from a first end to a second end of the cord. The optical fiber includes a first fiber end disposed at the first end of the cord and a second fiber end disposed at the second end of the cord. The device further includes a means for injecting light disposed proximate the first fiber end, the first fiber end being accessible so as to be illuminated by the means for injecting light and the second fiber end being accessible so as to recover the light injected at the first fiber end. Said device is useful for locating computer switching cords.

Owner:BRUNET +1

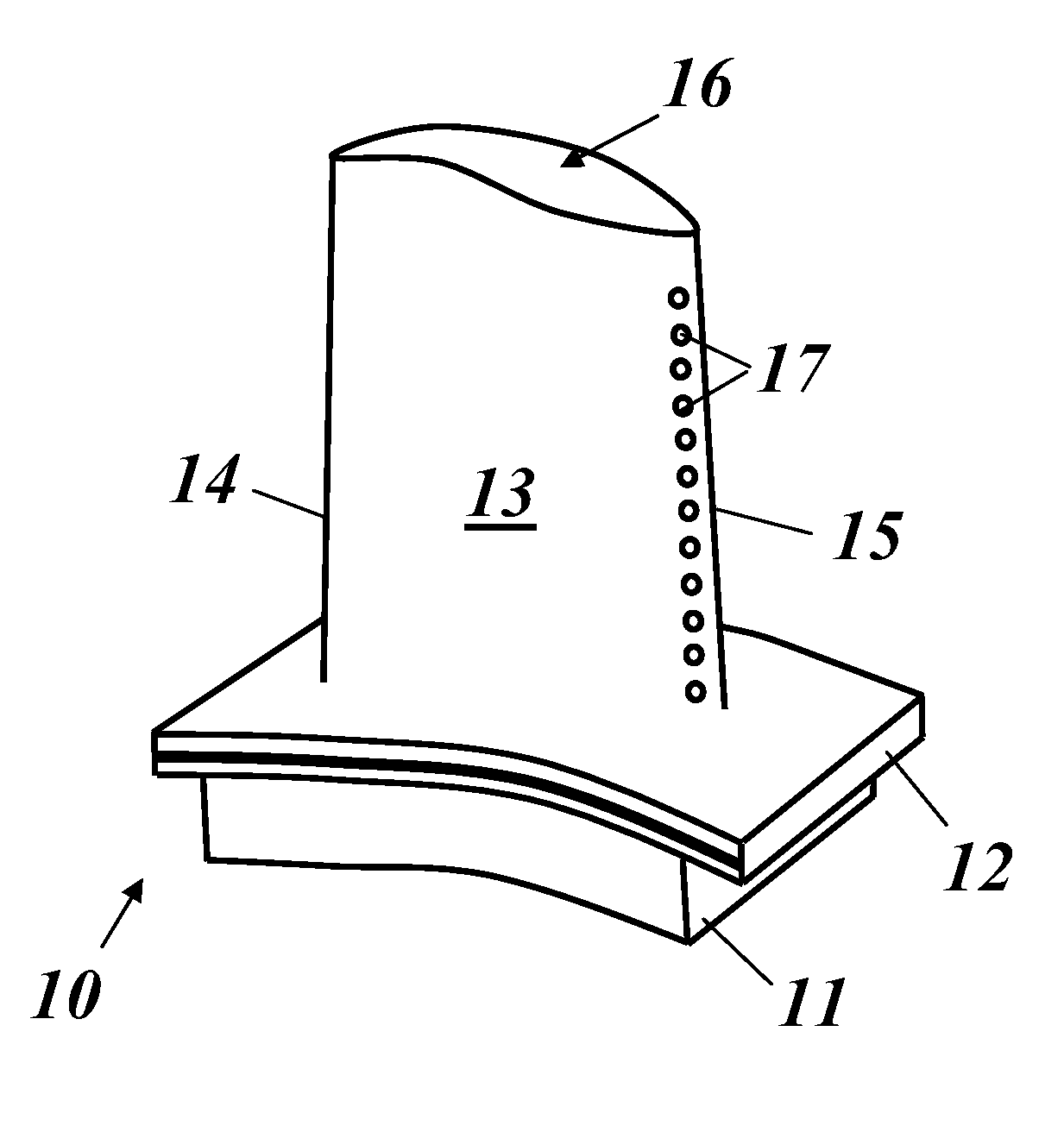

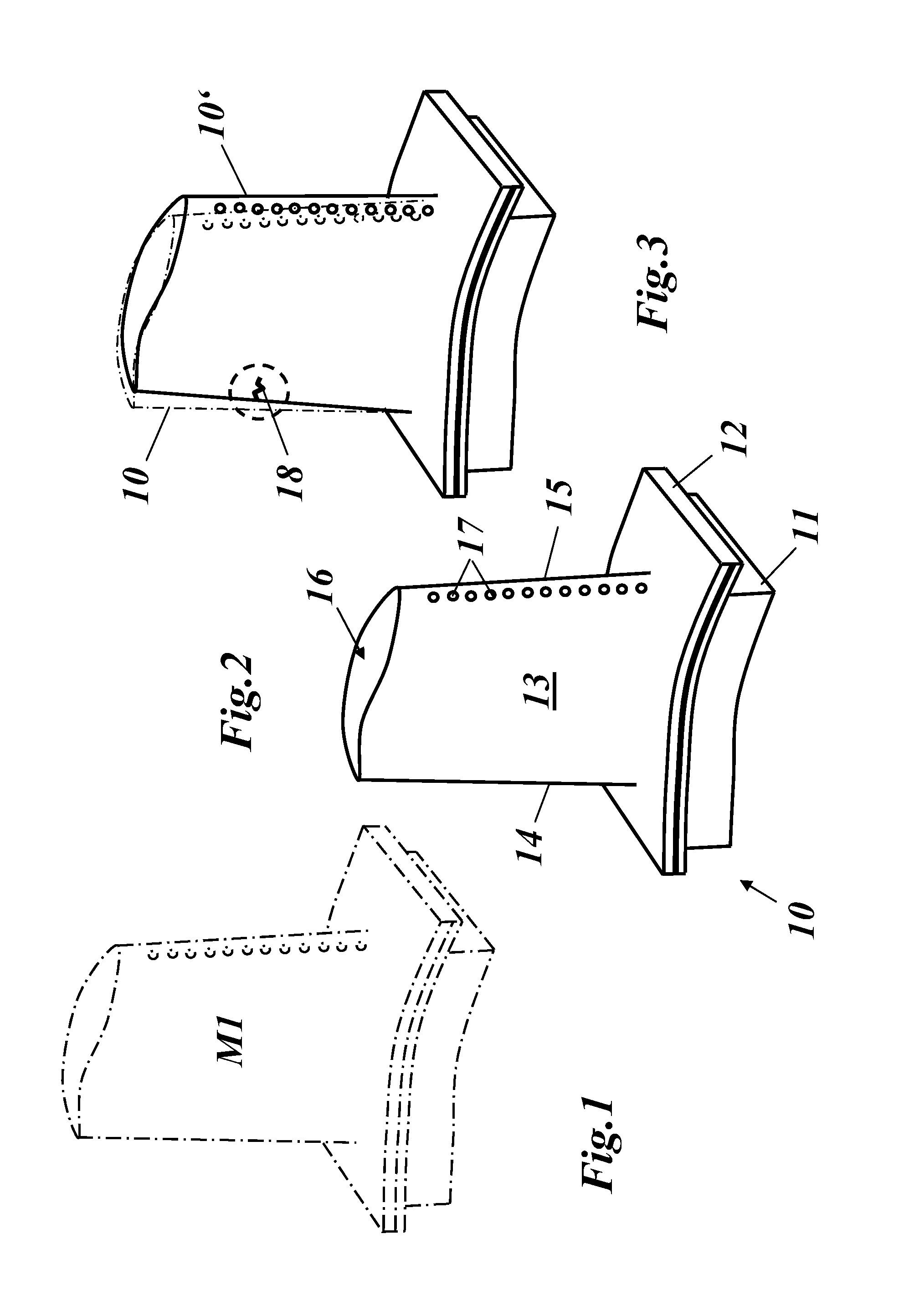

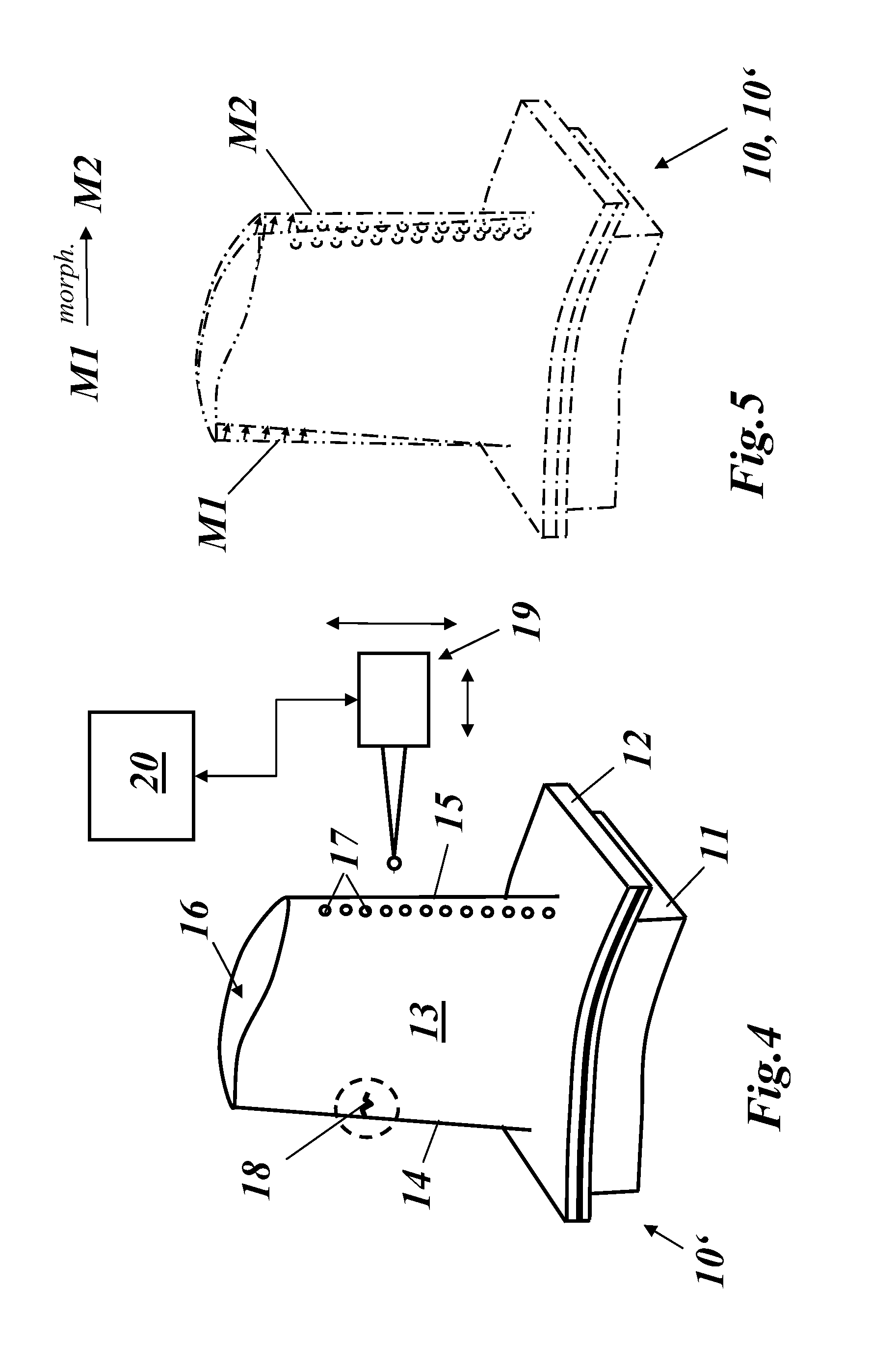

Method for repairing and/or upgrading a component of a gas turbine

InactiveUS20110264413A1Simple and inexpensive mannerAvoid disadvantagesBlade accessoriesMachines/enginesEngineeringGas turbines

In a method for repairing and / or upgrading a component (10′), preferably of a gas turbine, especially a blade (10′), which component has been deformed during operation, a simplification with cost advantages is achieved by a first nominal CAD model (M1) of the non-deformed component (10) being made available, by the deformed component (10′) being measured, and by the first CAD-model (M1), with the aid of the data determined on the deformed component (10′), being transformed into a second CAD model (M2) of the deformed component (10′) by morphing. A cutting line, which determines a cut-out in the component (10′), and also an insert piece, which can be inserted in the cut-out, is established in the second CAD model (M2). A cut-out is introduced into the component (10′) in accordance with the cutting line, an insert piece for inserting in the cut-out is manufactured in accordance with the cutting line, the manufactured insert piece is inserted in the cut-out, and the inserted insert piece is connected to the component (10′) in a materially bonding manner.

Owner:ALSTOM TECH LTD

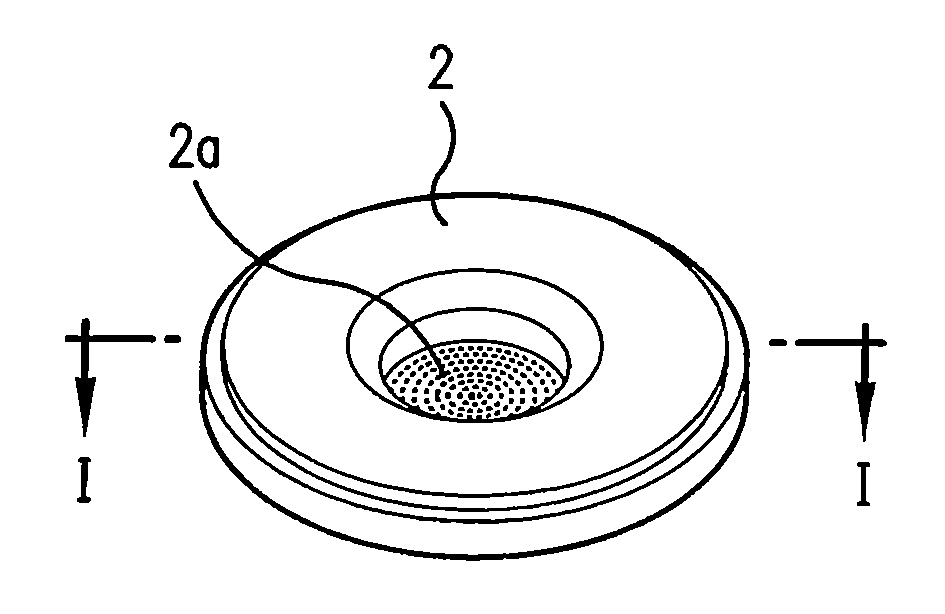

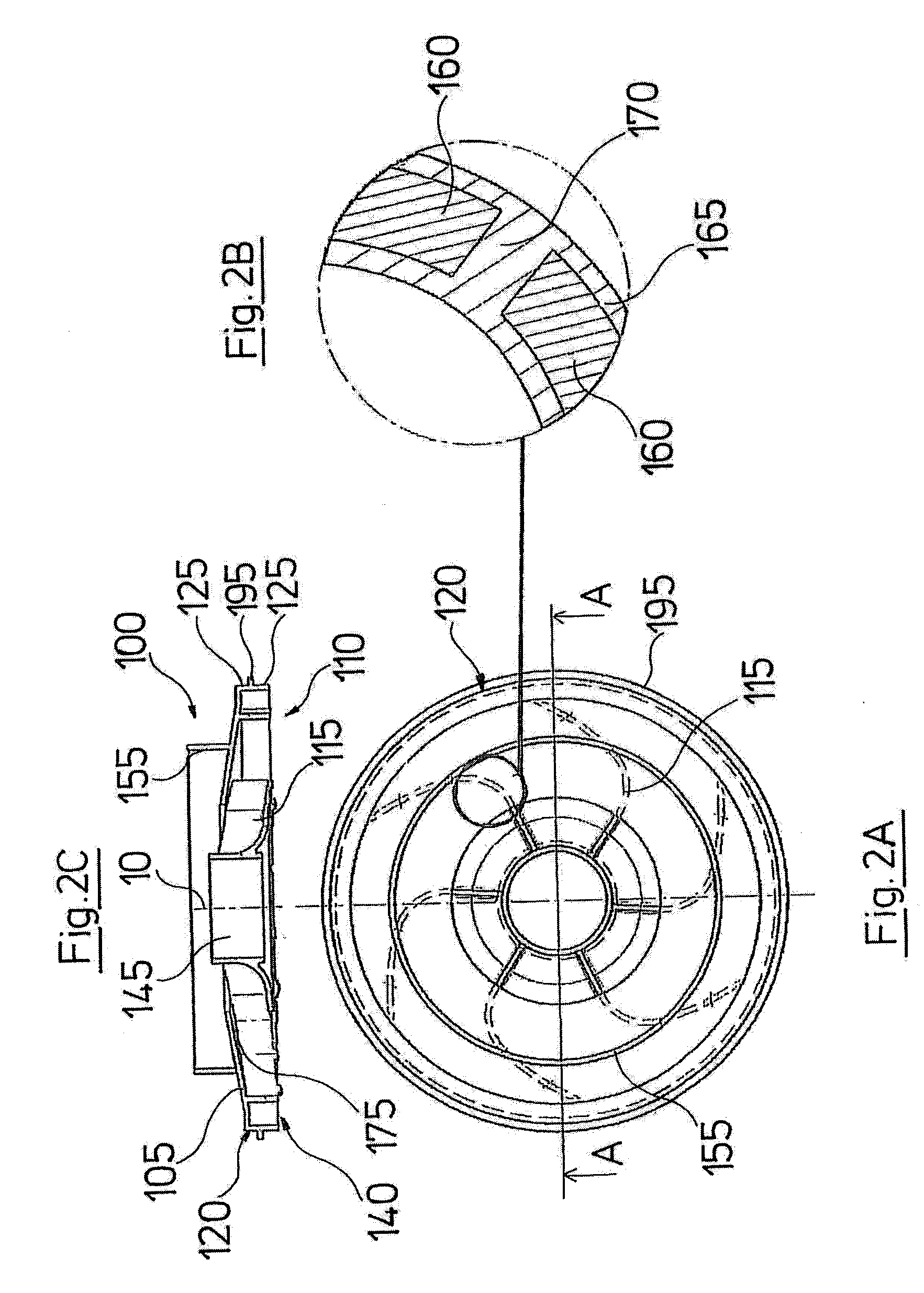

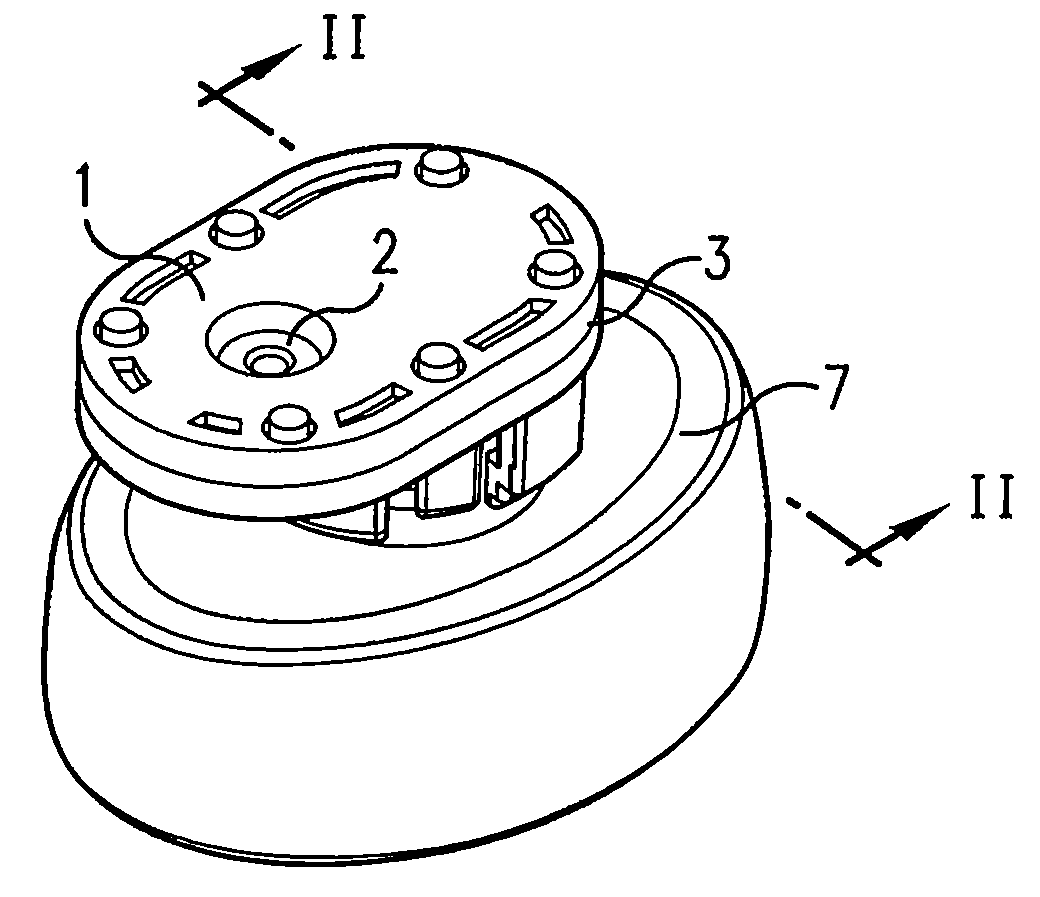

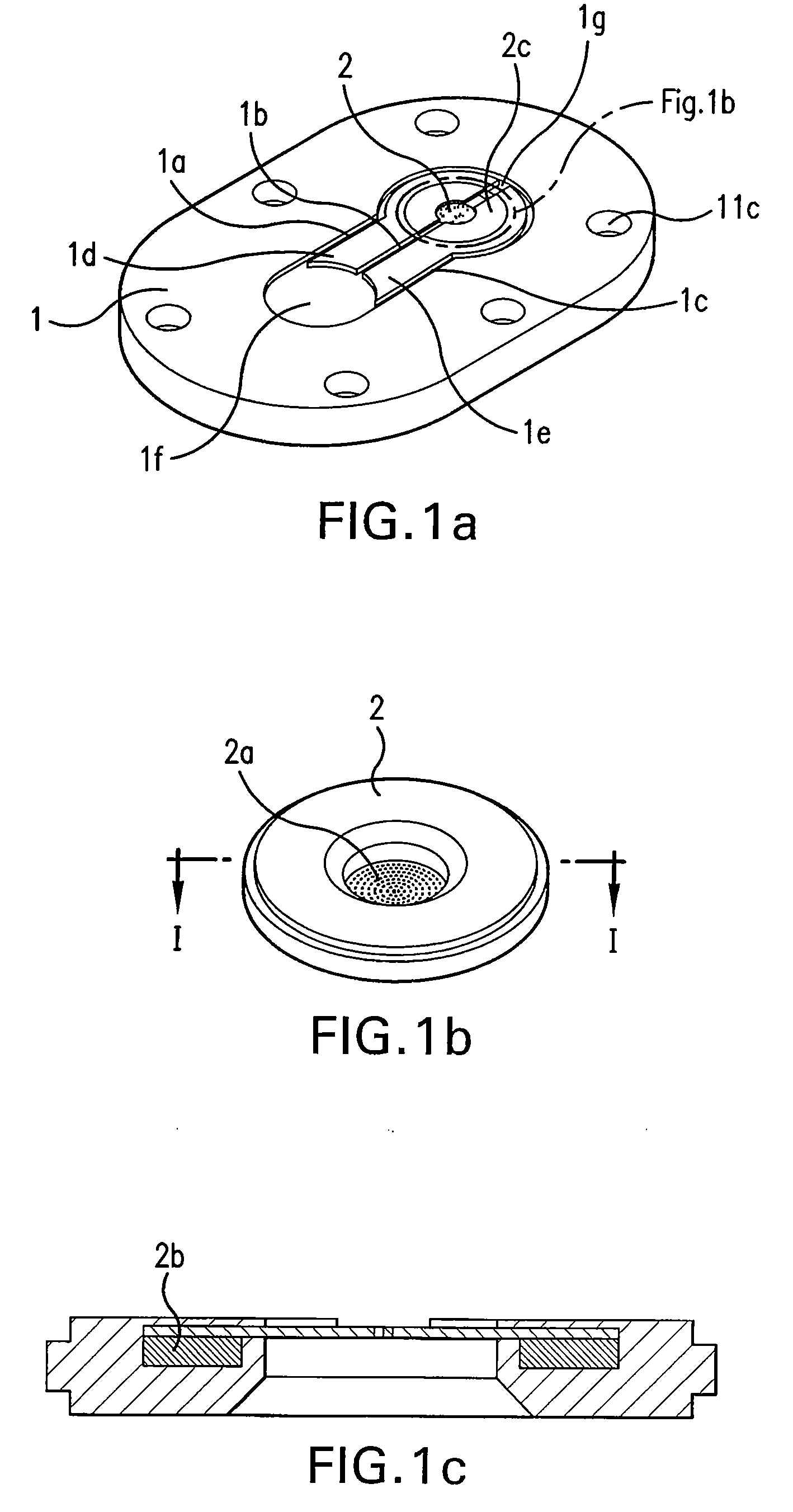

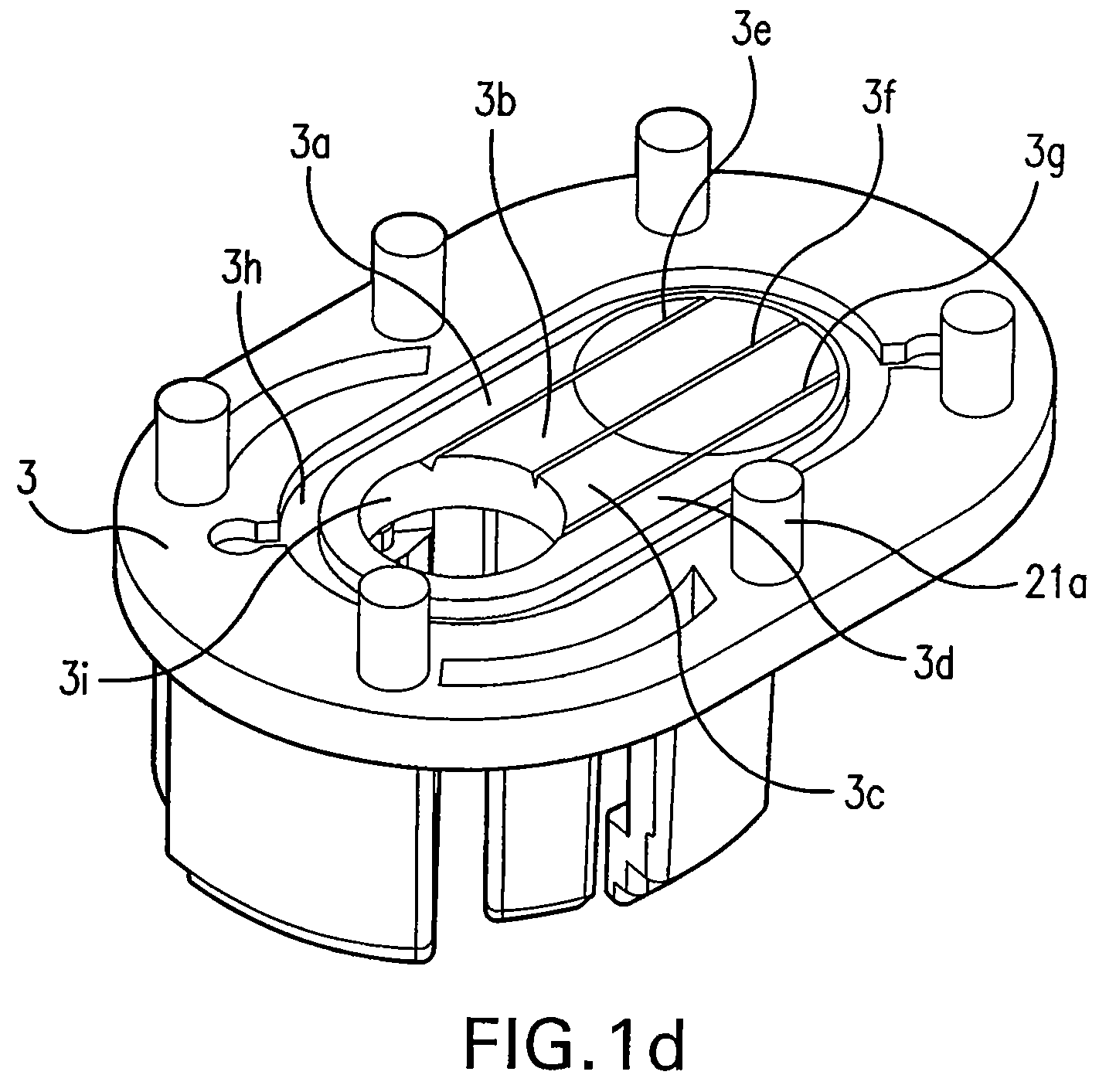

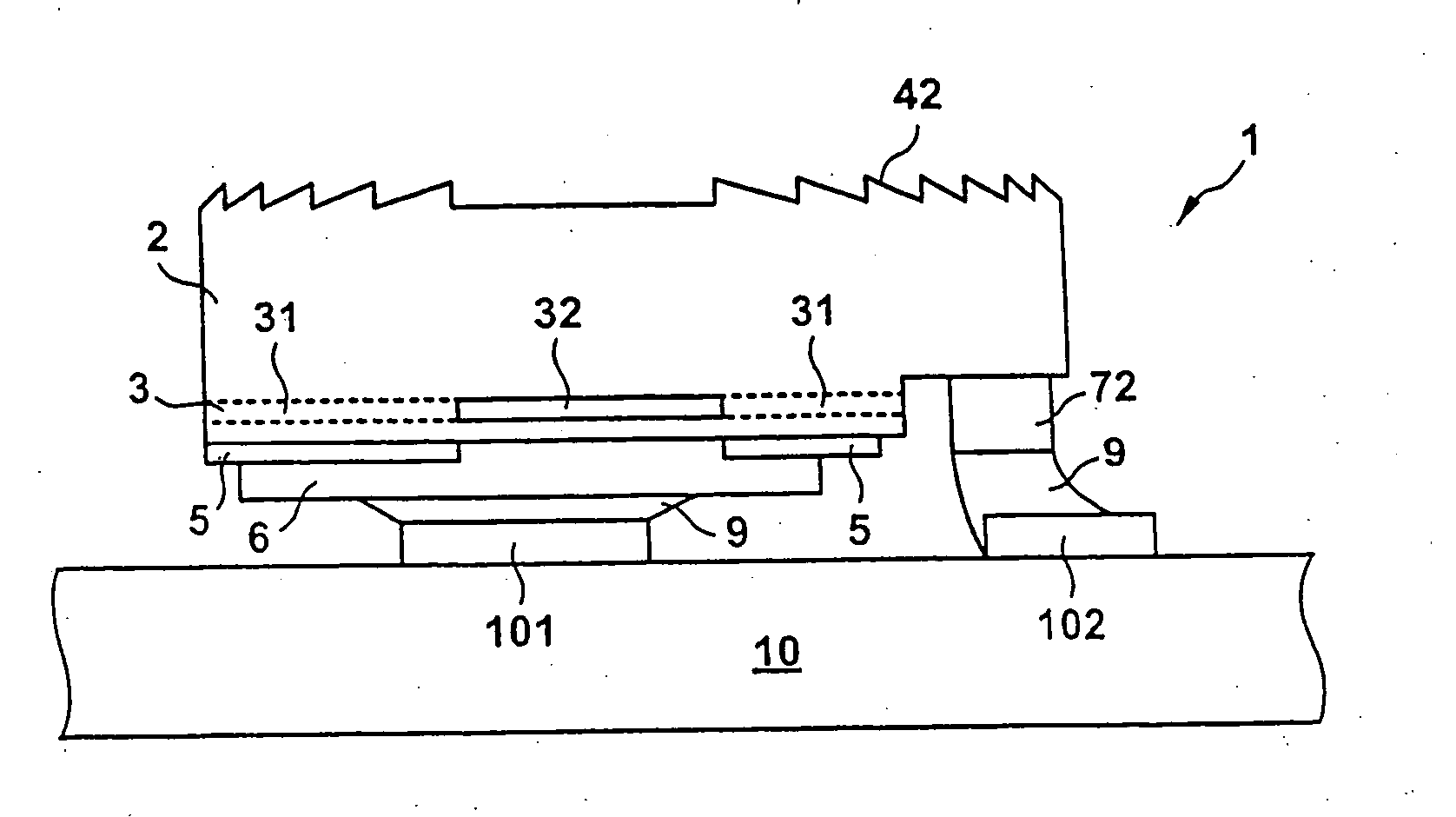

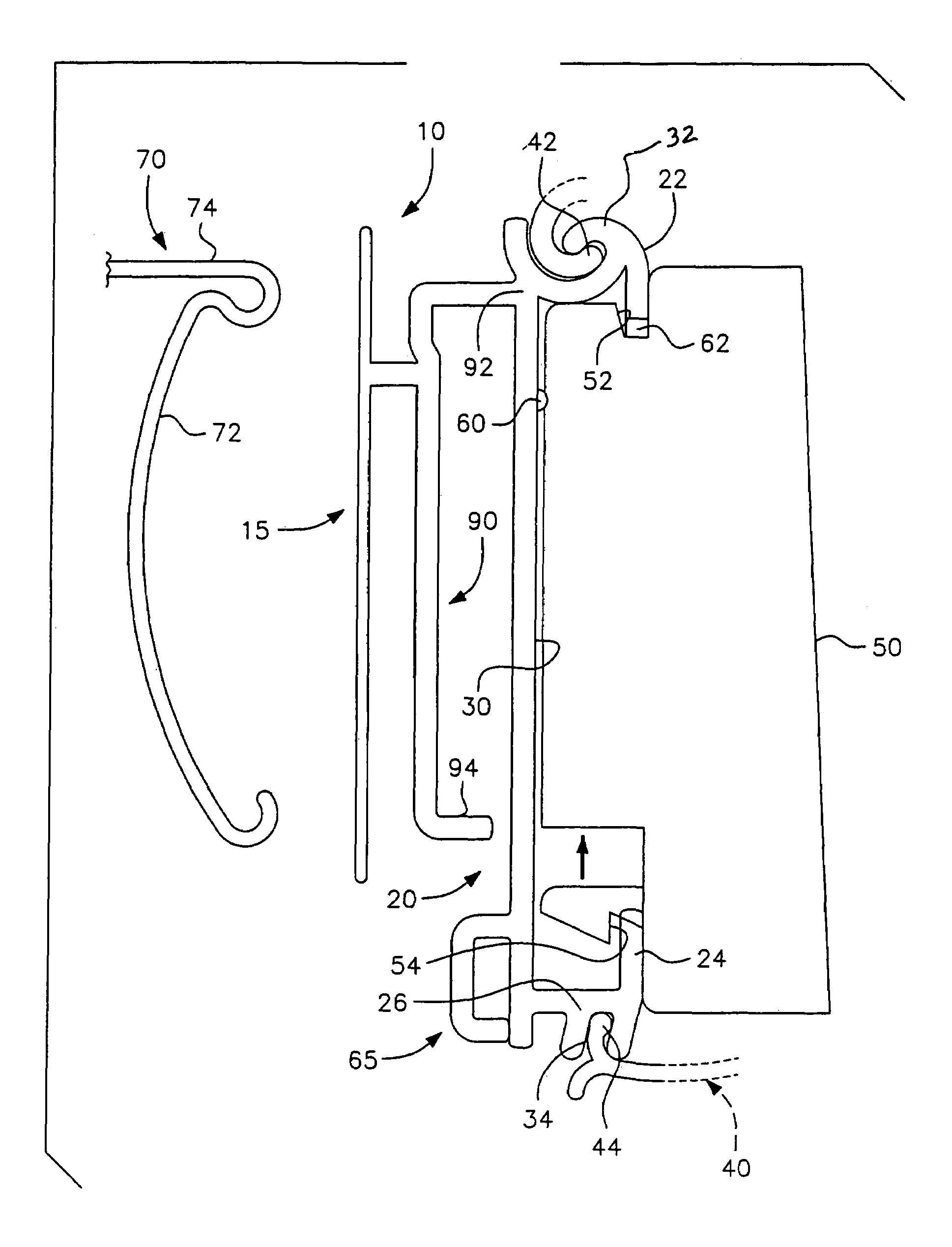

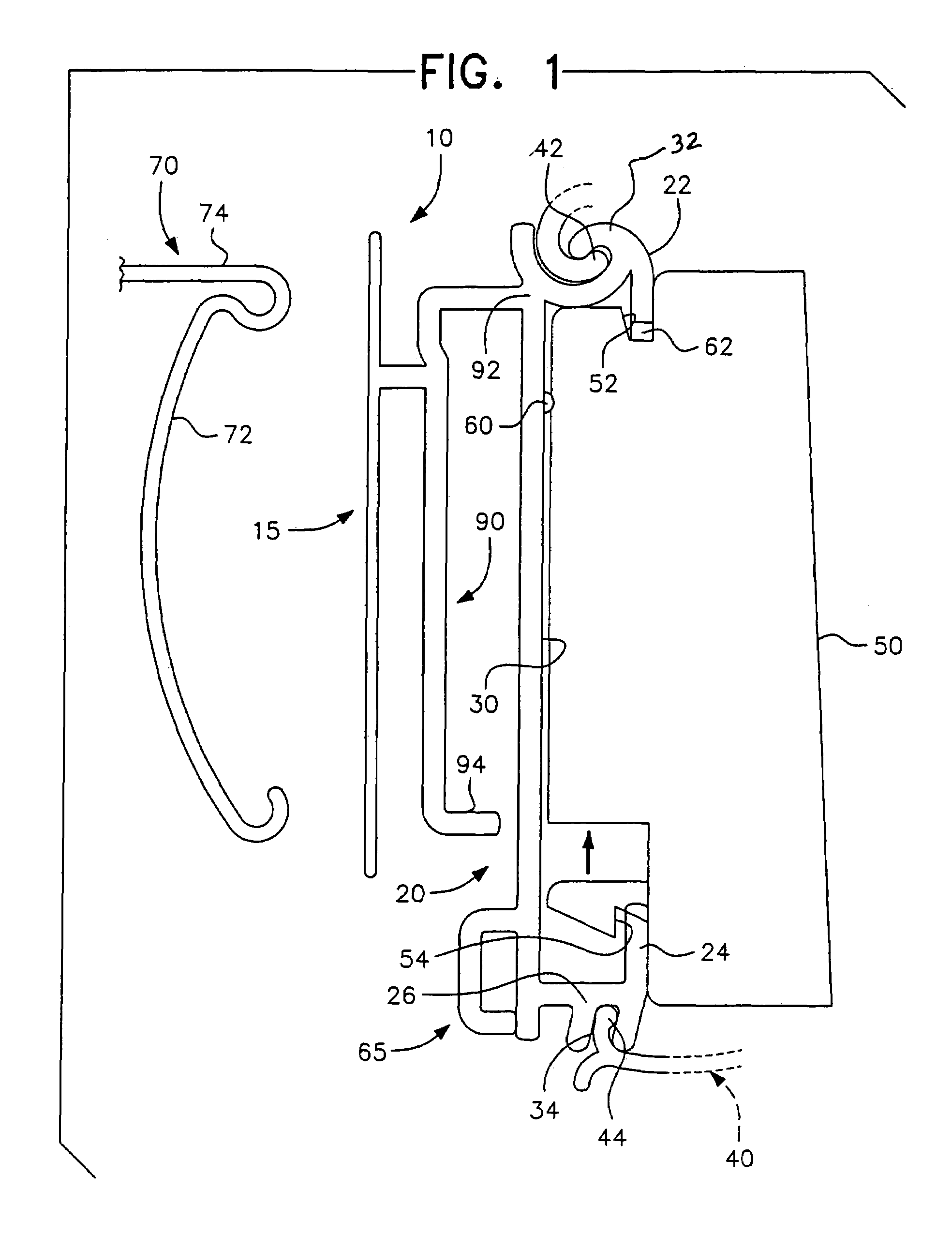

Volatile liquid droplet dispenser device

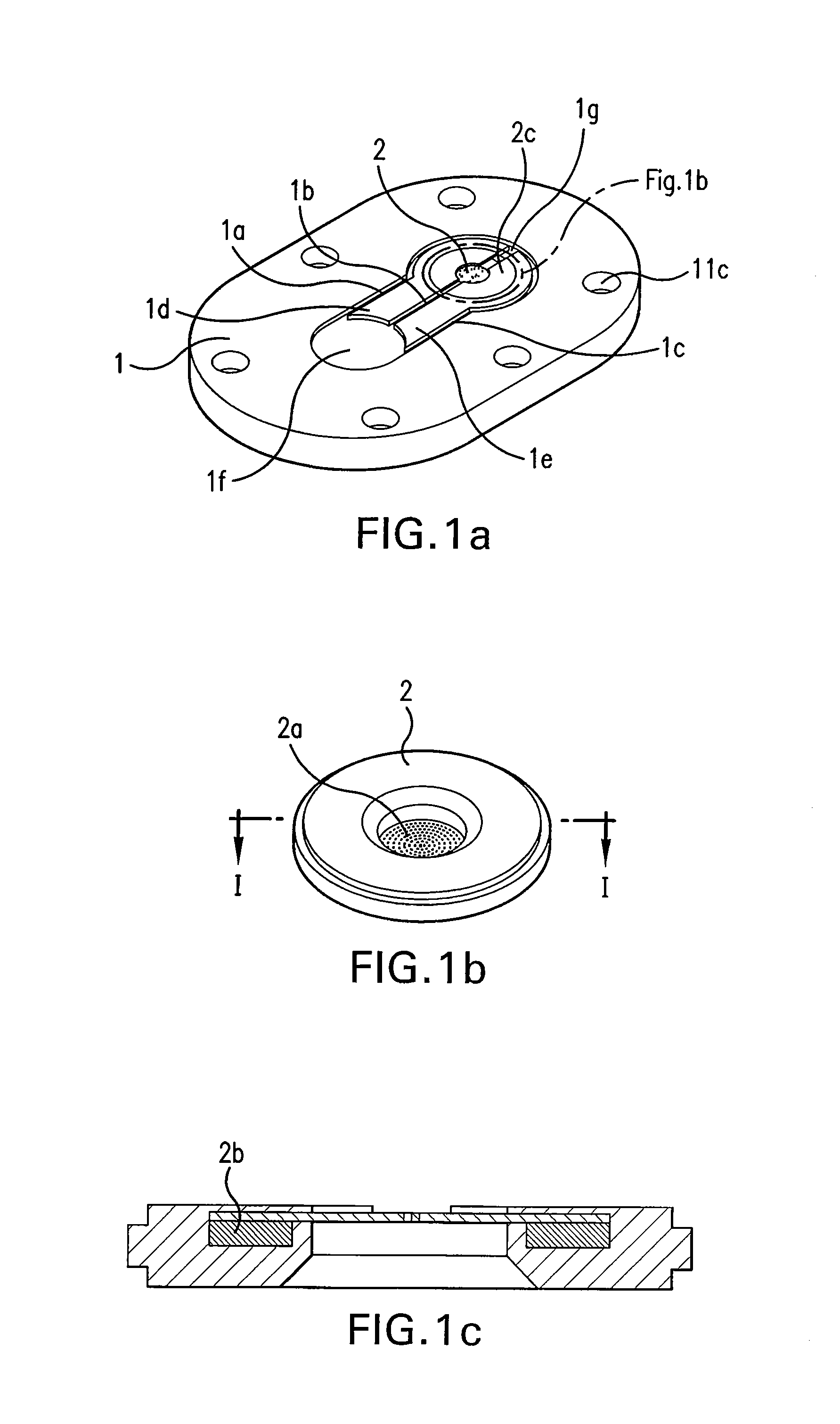

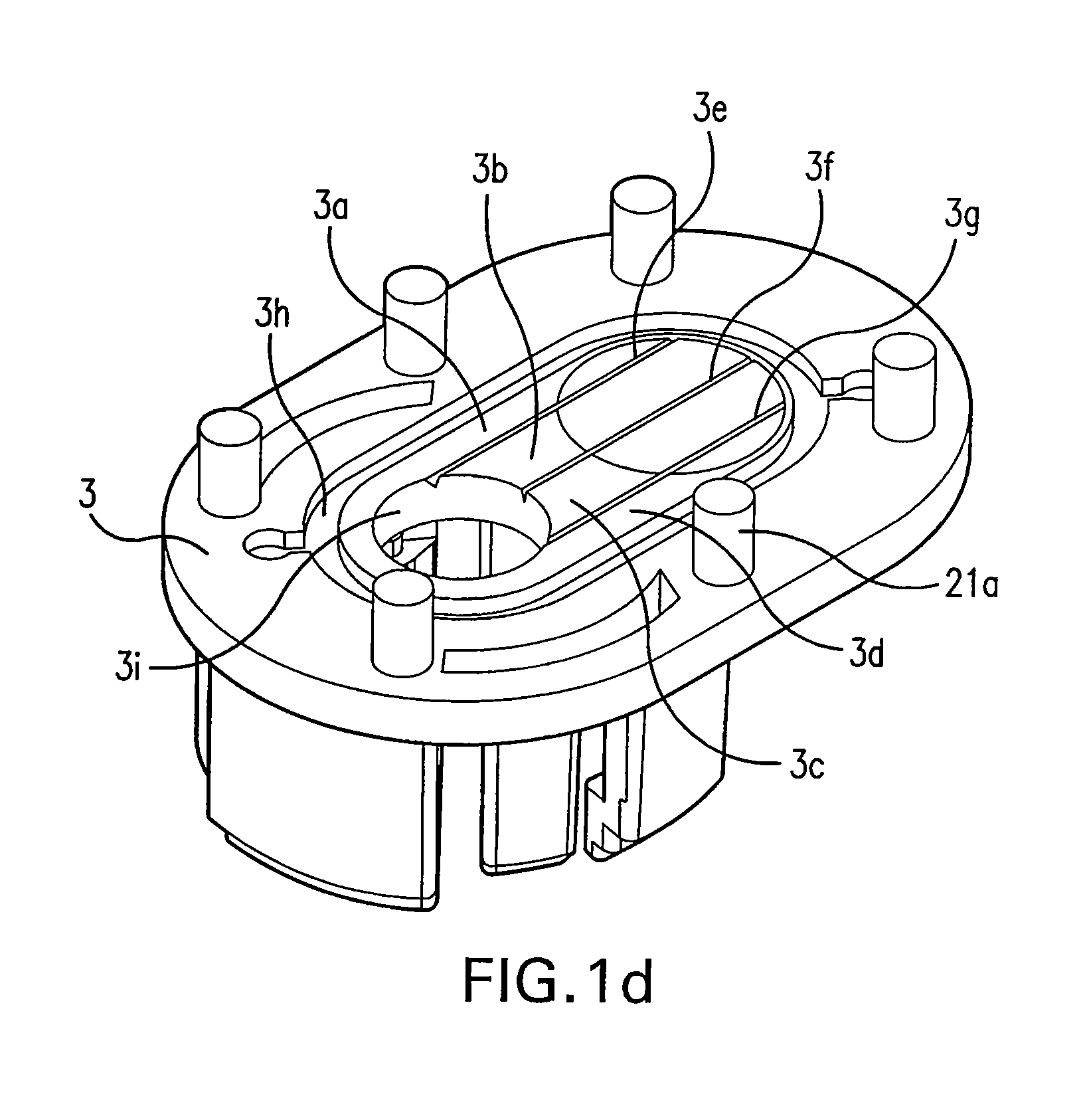

InactiveUS8870090B2Simple and inexpensive mannerPromote exchangeMovable spraying apparatusSpray nozzlesEngineeringLiquid drop

A volatile liquid droplet dispenser device includes: a first substrate (1) having a space (2c) for containing a liquid substance, and having liquid outlet means (2a) for ejecting the liquid substance; a second substrate (3) having a liquid inlet means (3i) for allowing the liquid substance to enter said device; an actuating element (2b, 8, 10) arranged to actuate the liquid substance so as to exit the device as a liquid droplet spray, wherein the liquid outlet means (2a) of the first substrate comprises a perforated nozzle membrane (2a) having a plurality of outlet nozzles, and wherein the first substrate (1) contains at least one fluidic capillary priming channel (1a, 1b, 1c) arranged to receive liquid substance from the space (2c) so as to fill the channel such that the liquid substance is in close proximity to the outlet nozzles for priming the liquid substance for ejection through the nozzle membrane.

Owner:APTAR FRANCE SAS

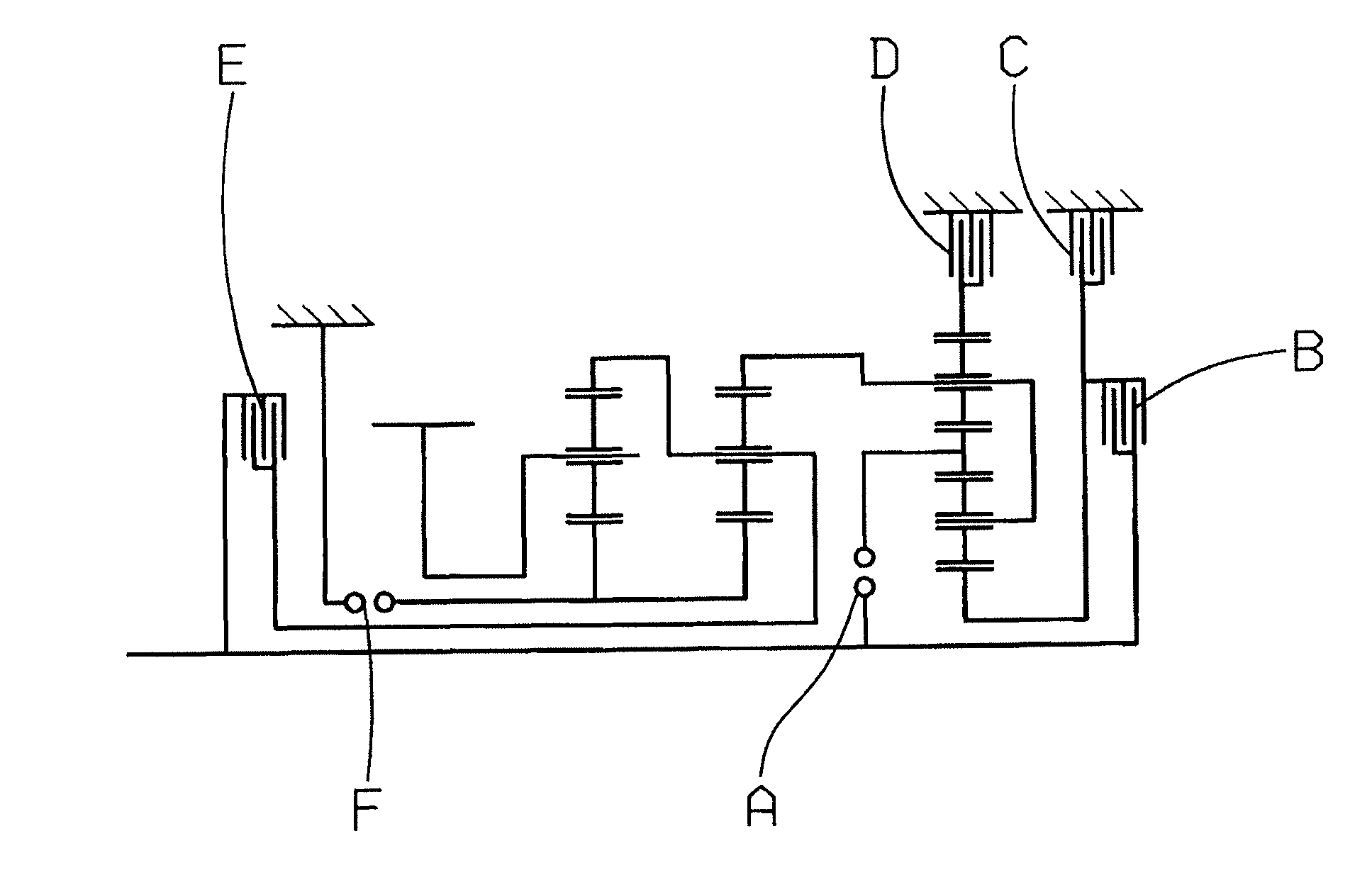

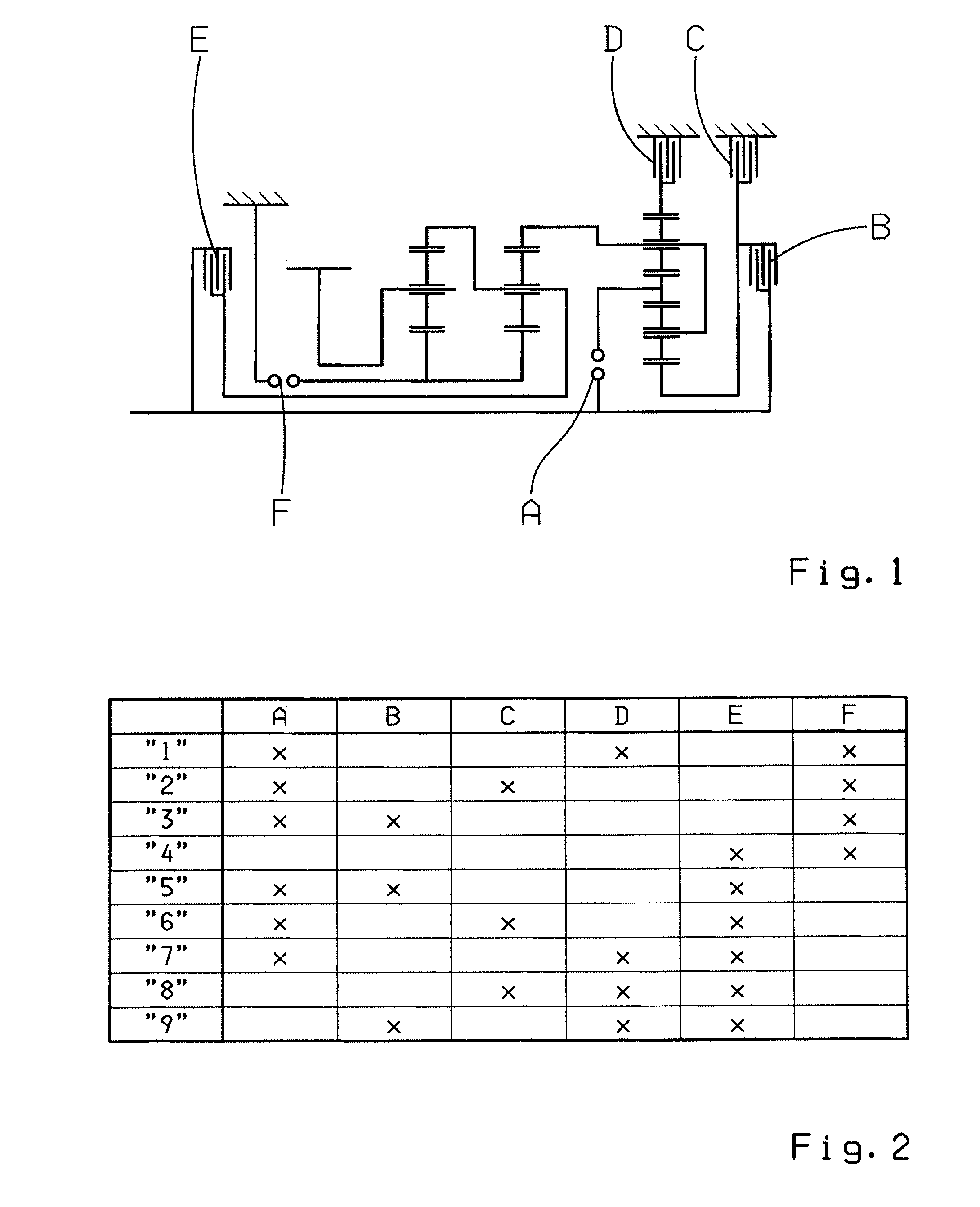

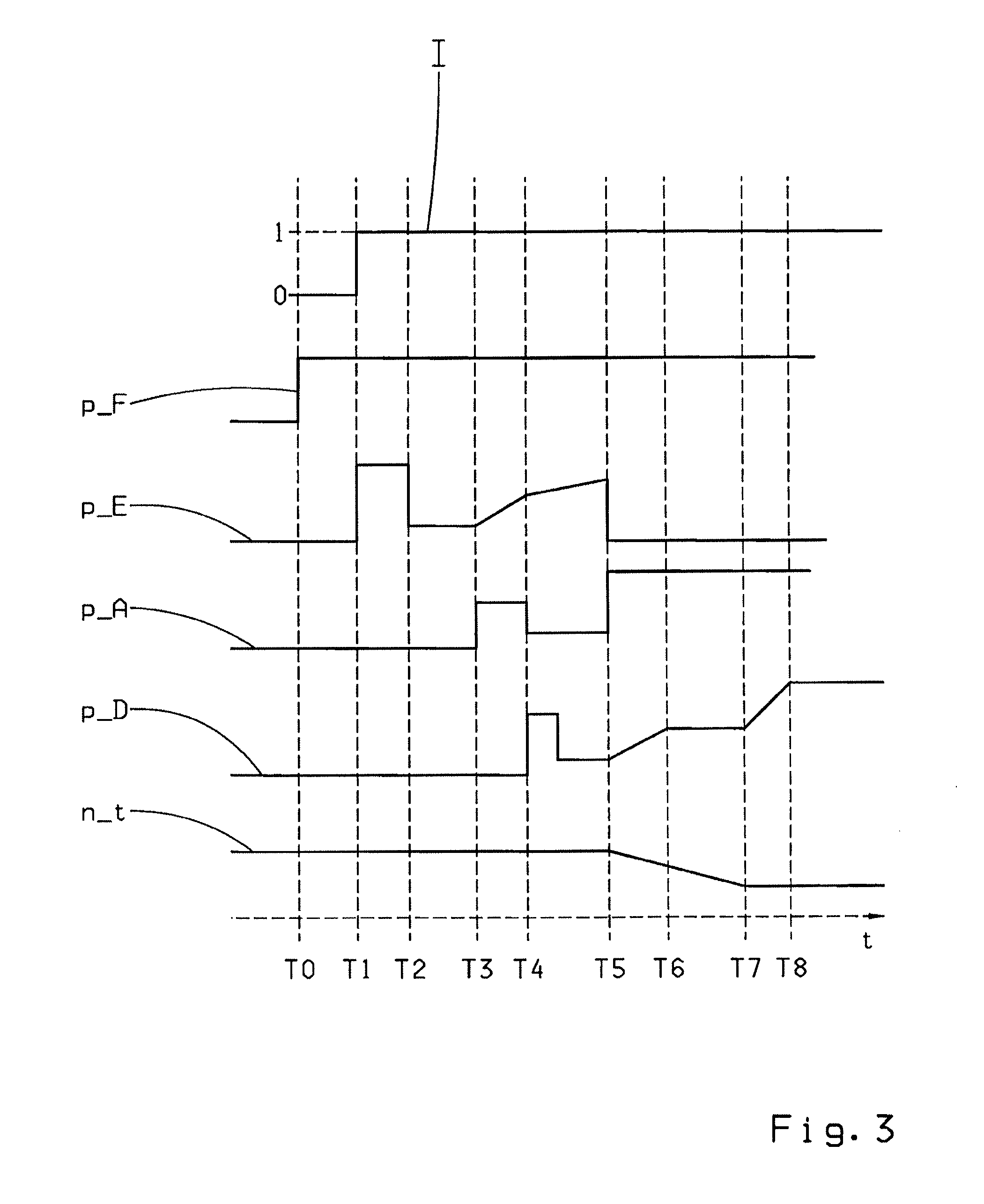

Method for the operation of a transmission device of a vehicle drive train

ActiveUS8500601B2Improve transmission performanceSimple and inexpensive mannerToothed gearingsGearing controlEngineeringGear ratio

A method of operating a transmission of a vehicle drive train with at least one drive machine. The transmission is formed with at least one interlocking shift element and a plurality of frictional shift elements in order to obtain various gear ratios. During an engaging process of the interlocking shift element, starting from a disengaged operating condition, in which halves of the interlocking shift element are out of engagement, to an engaged operating condition, in which the shift element halves are interlocked in a rotationally fixed manner, when interlock between the shift element halves is obstructed, a rotational speed difference is produced at least temporarily between the shift element halves, at which the interlock in the area of the interlocking shift element can be engaged. To produce the speed difference between the shift element halves, the transmission capacity of at least one frictional shift element is increased.

Owner:ZF FRIEDRICHSHAFEN AG

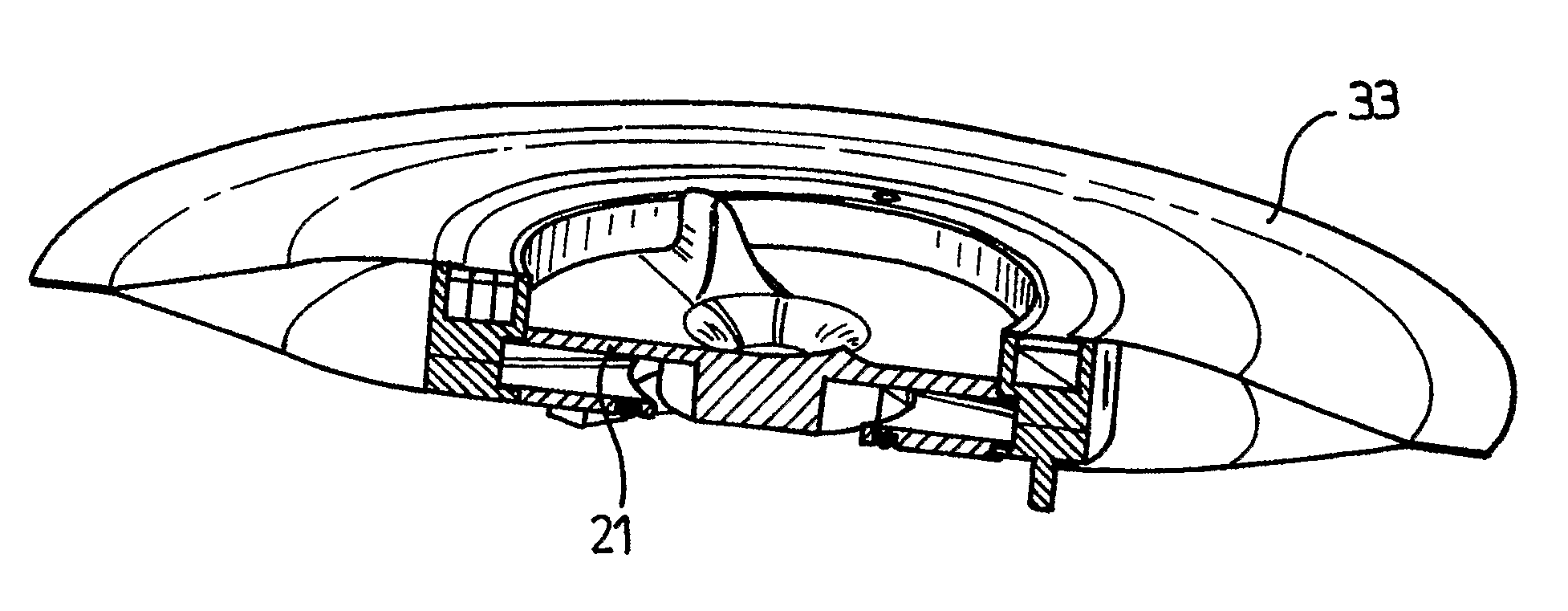

Liquid droplet plug and spray system

InactiveUS8016209B2Simple and inexpensive mannerPromote exchangeMovable spraying apparatusSpray nozzlesEngineeringLiquid drop

The present invention concerns a liquid droplet spray system for atomizing a liquid substance, comprising: a support having a central aperture (27), a liquid droplet spray device in which a space is provided, the space being arranged to receive the liquid substance, and including a nozzle body (28) covering the space such that the liquid substance may exit the space of the device by traversing the nozzle body (28) and the system by traversing the central aperture (27) of the support, a reservoir (33) for containing the liquid substance.

Owner:APTAR FRANCE SAS

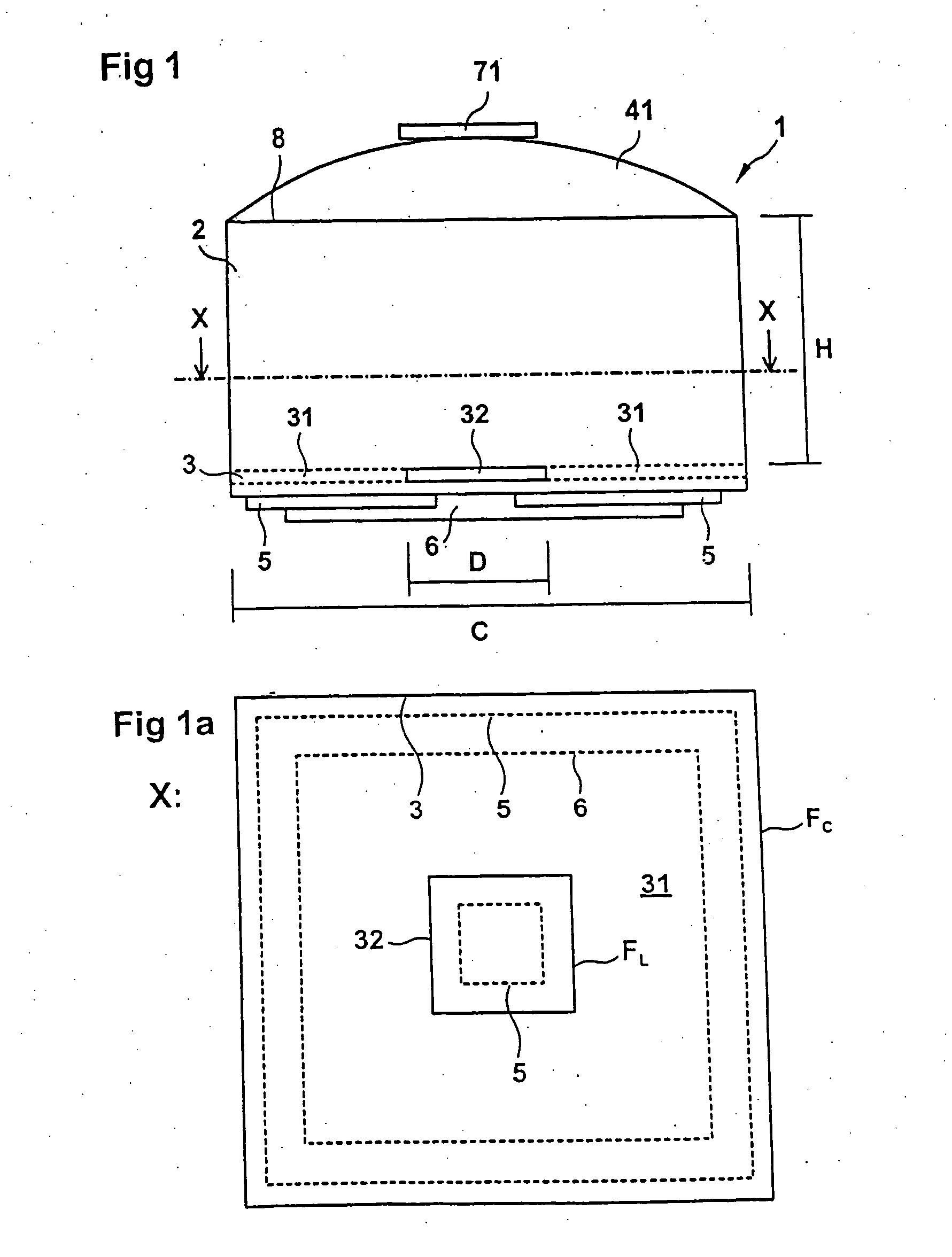

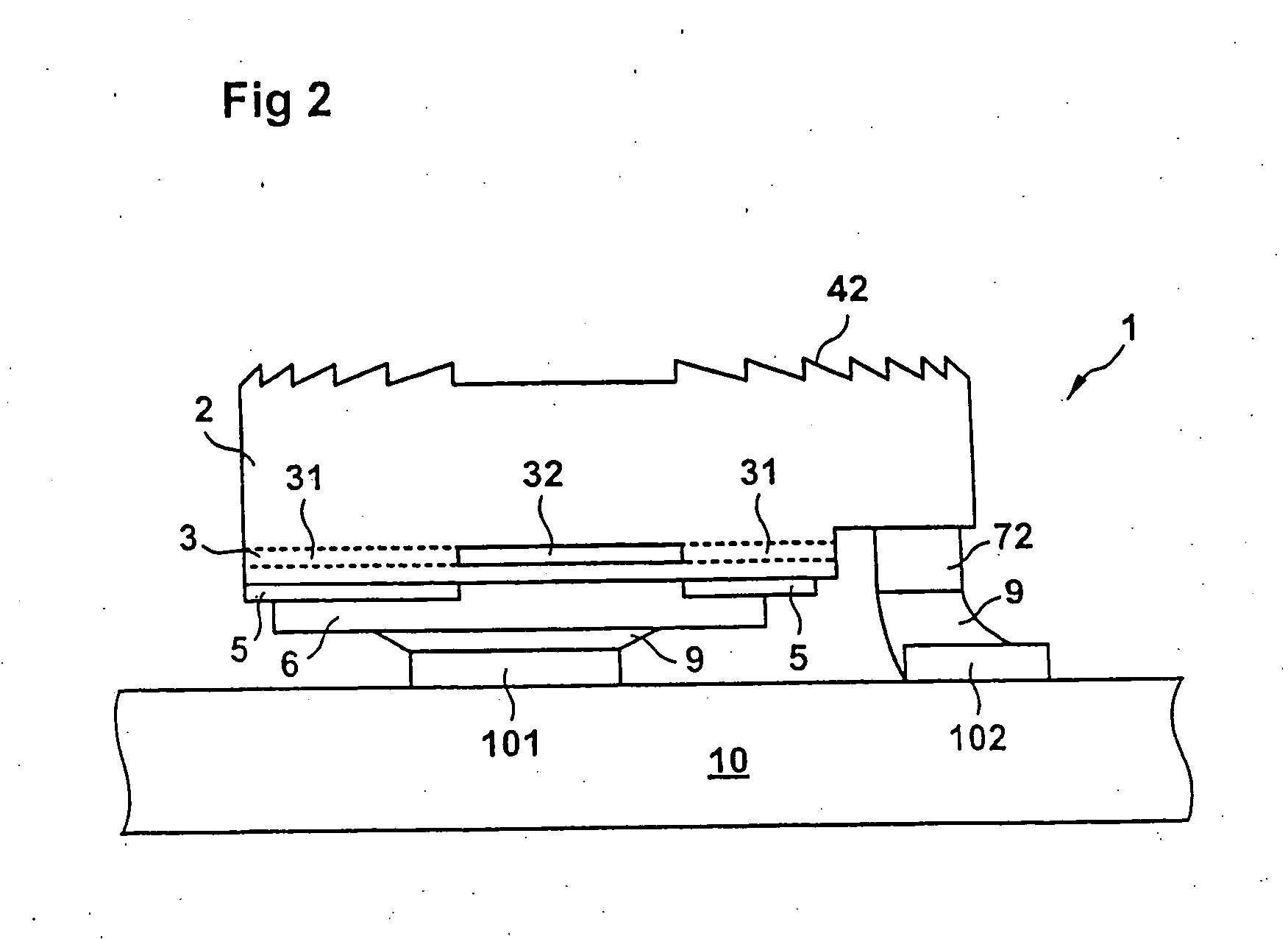

High radiance LED chip and a method for producing same

InactiveUS7306960B2Minimizes supplySimple and inexpensive mannerSolid-state devicesSemiconductor/solid-state device manufacturingRadianceEngineering

The invention concerns a light-emitting diode chip comprising a radiation-emitting active region and a window layer. To increase the luminous efficiency, the cross-sectional area of the radiation-emitting active region is smaller than the cross-sectional area of the window layer available for the decoupling of light.The invention is further directed to a method for fabricating a lens structure on the surface of a light-emitting component.

Owner:OSRAM GMBH

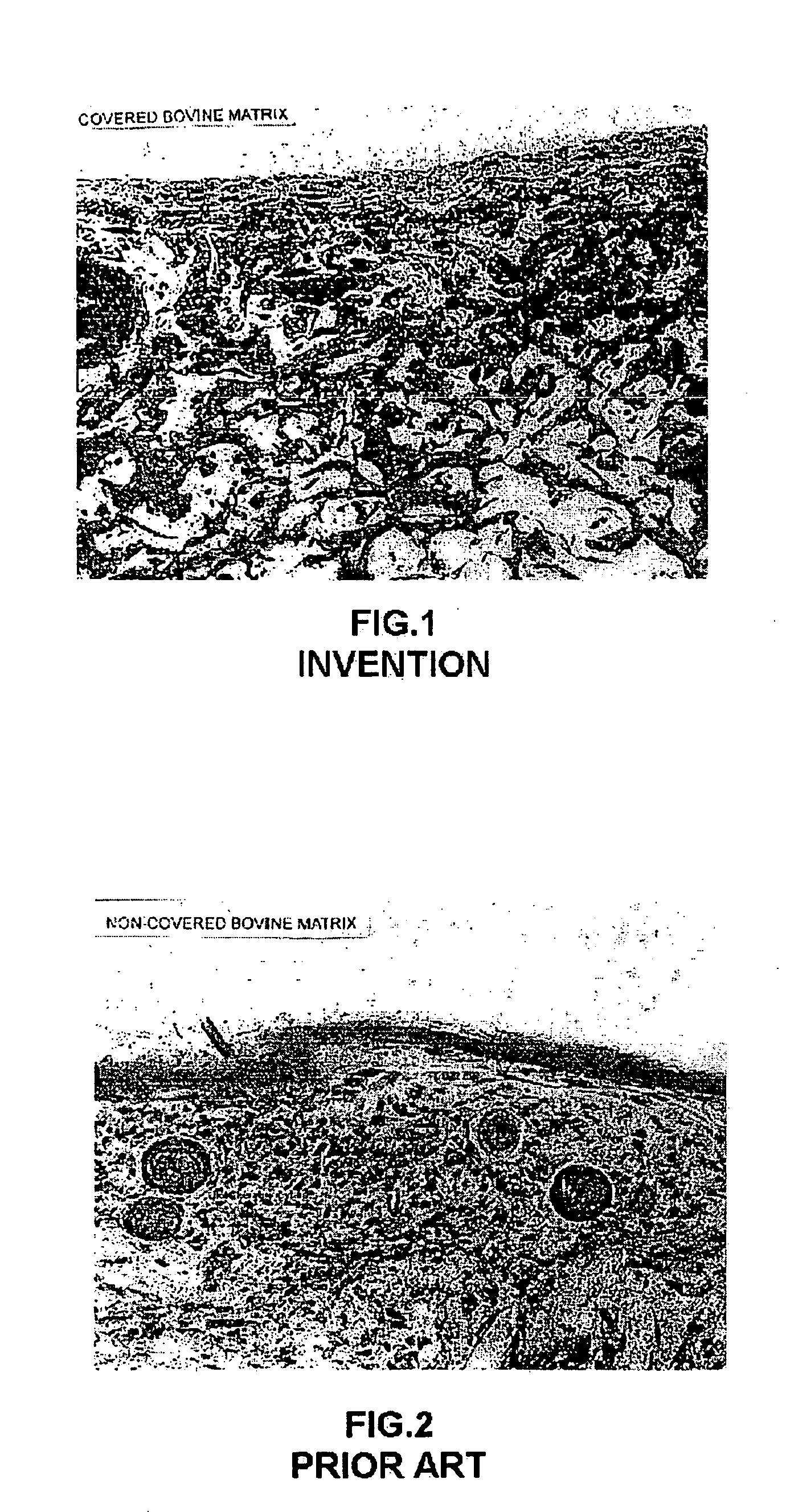

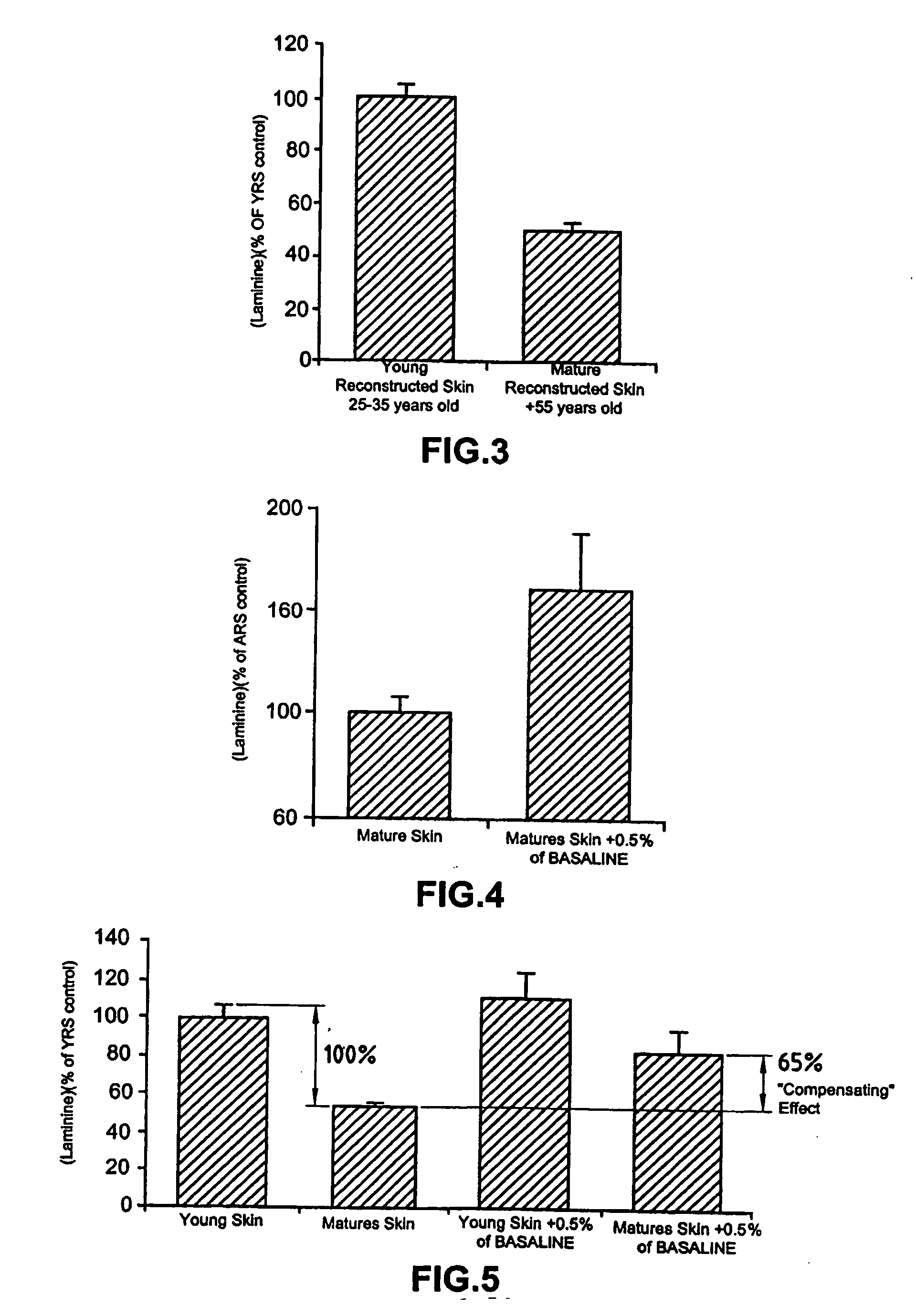

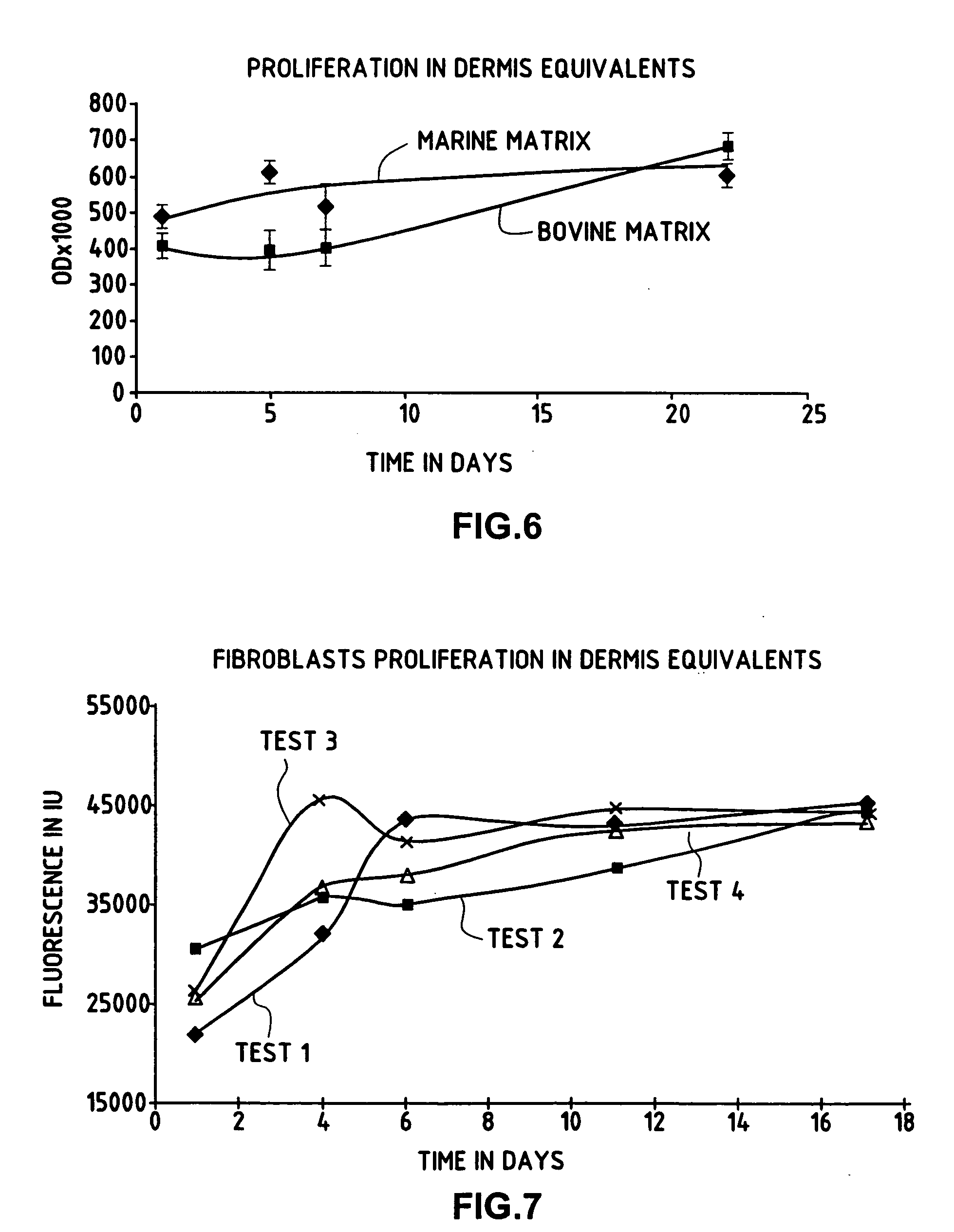

Support with crosslinked marine collagen for tissue engineering and manufacture of biomaterials

InactiveUS20050208478A1Simple and inexpensive mannerBroaden their knowledgeMicrobiological testing/measurementBiological material analysisCollagen spongeTissue engineering

The invention relates to a method of in vitro testing of the efficacy of a potentially active substance comprising monitoring the effect of said potentially active substance on an artificial skin, comprising a composite product forming a collagen support comprising at least one porous collagen layer covered on at least one side with a collagen membrane component selected from the group consisting of a collagen membrane prepared by compression of a collagen sponge at a pressure of at least about 50 bar and of a collagen membrane comprising a collagen film prepared by drying a collagen gel separately from the porous collagen layer, thereby providing a reliable method for finding new potentially active substances.

Owner:COLETICA

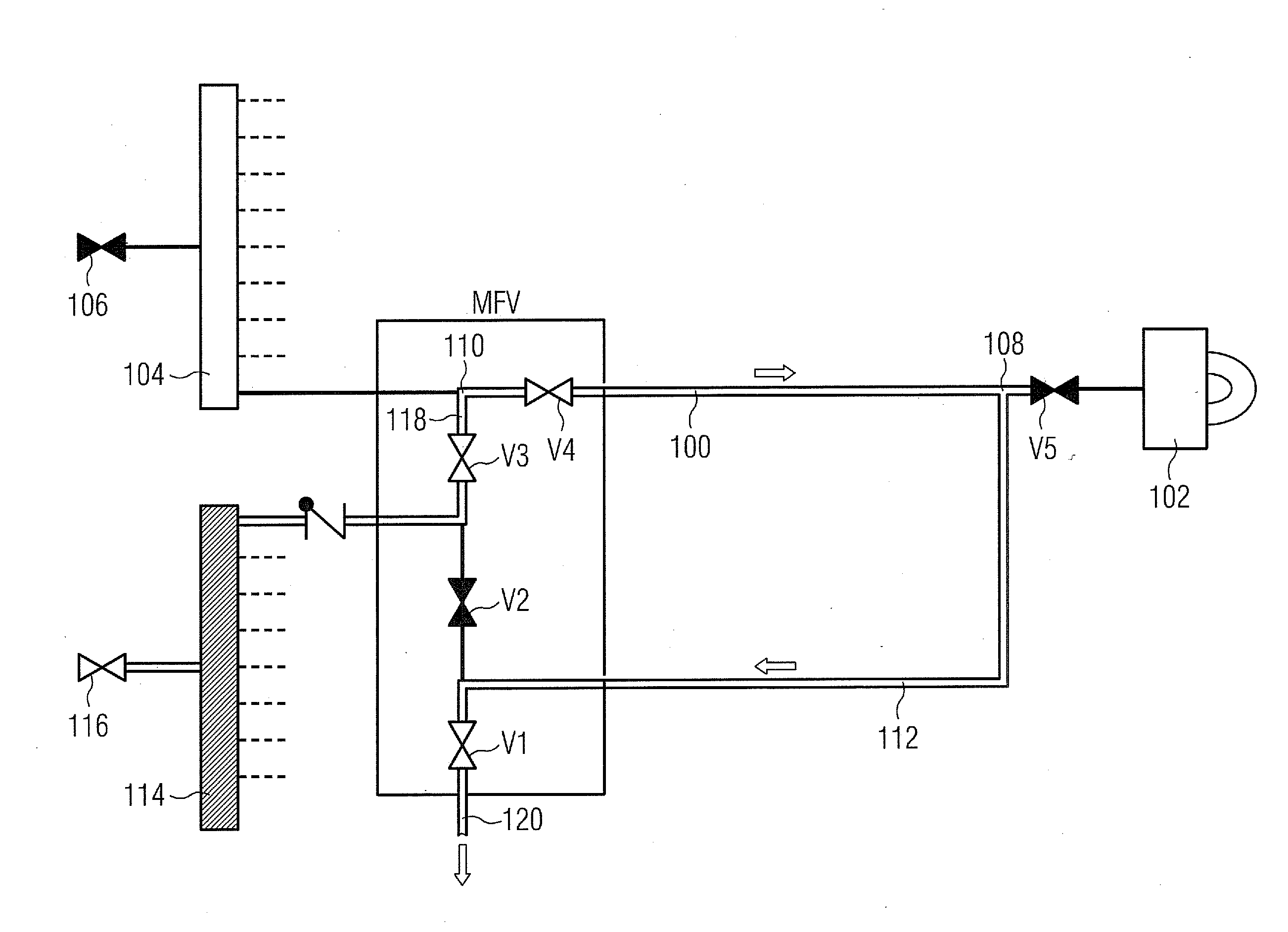

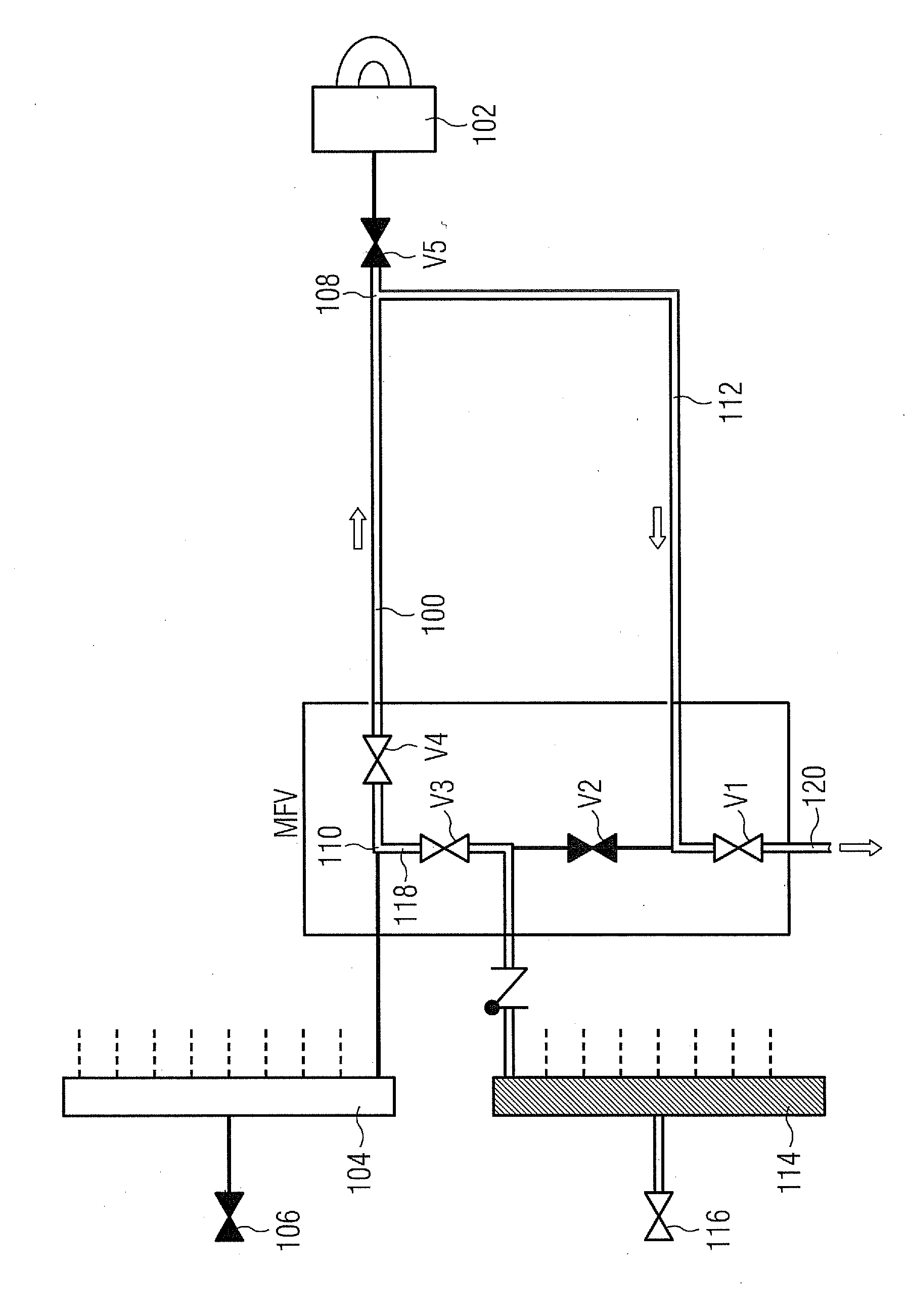

Method for rinsing a fuel system of a gas turbine and associated fuel system

ActiveUS20110146807A1Simple and inexpensive mannerOvercome disadvantagesLiquid fuel feeder/distributionTurbine/propulsion fuel flow conduitsCombustorEngineering

A method for flushing a section of a fuel system of a burner of a gas turbine is provided. The method includes the steps of providing a feed line for feeding fuel from a fuel source to the burner, providing a first feed point close to the burner and a second feed point remote from the burner in the feed line in each case for feeding a medium into the feed line, feeding the medium via the first feed point, and discharging, via the burner, the fuel which is in the feed line between the first feed point and the burner, and also feeding the medium via the second feed point, and discharging, via the first feed point, the fuel which is in the feed line between the second feed point and the first feed point.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Pump

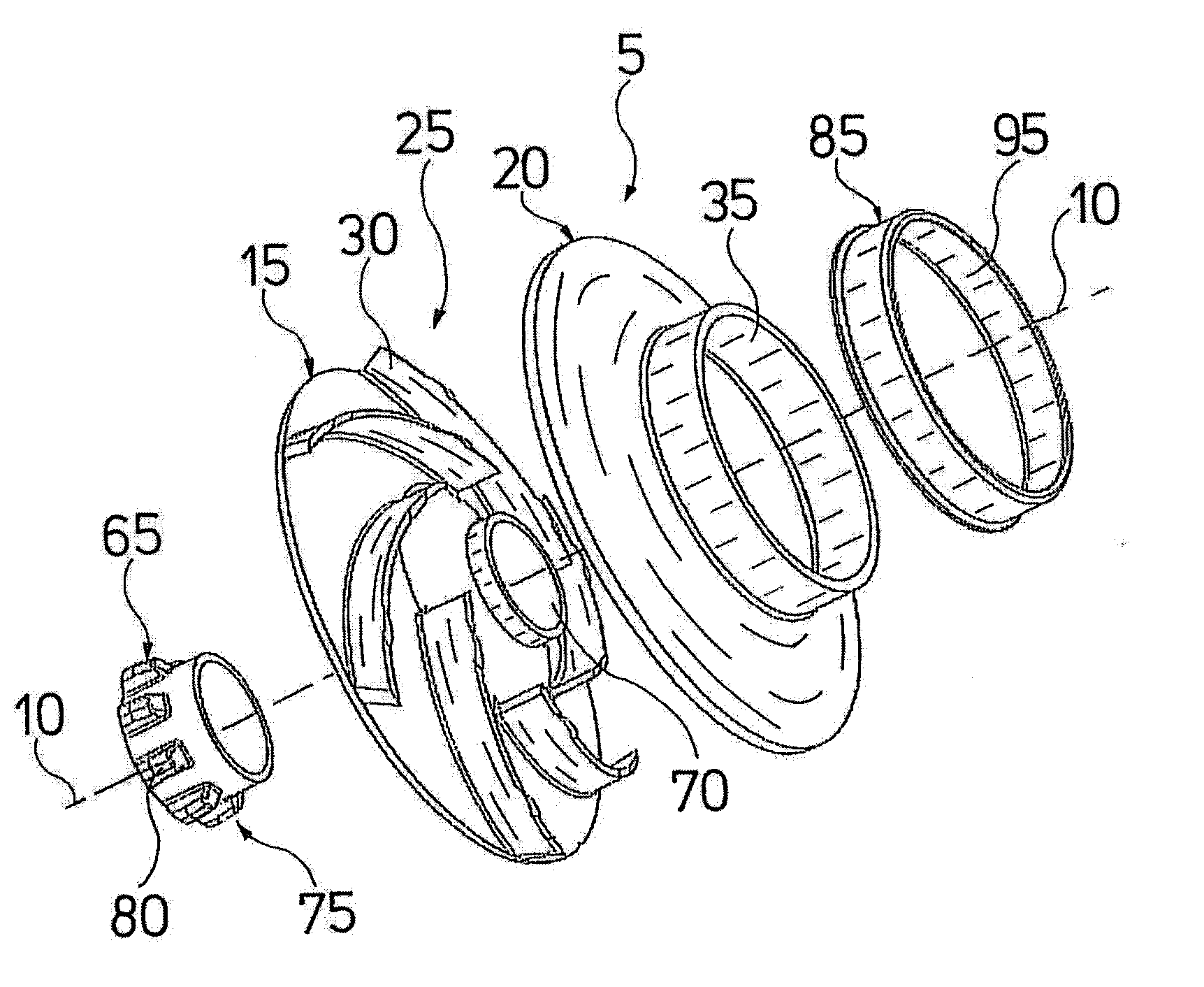

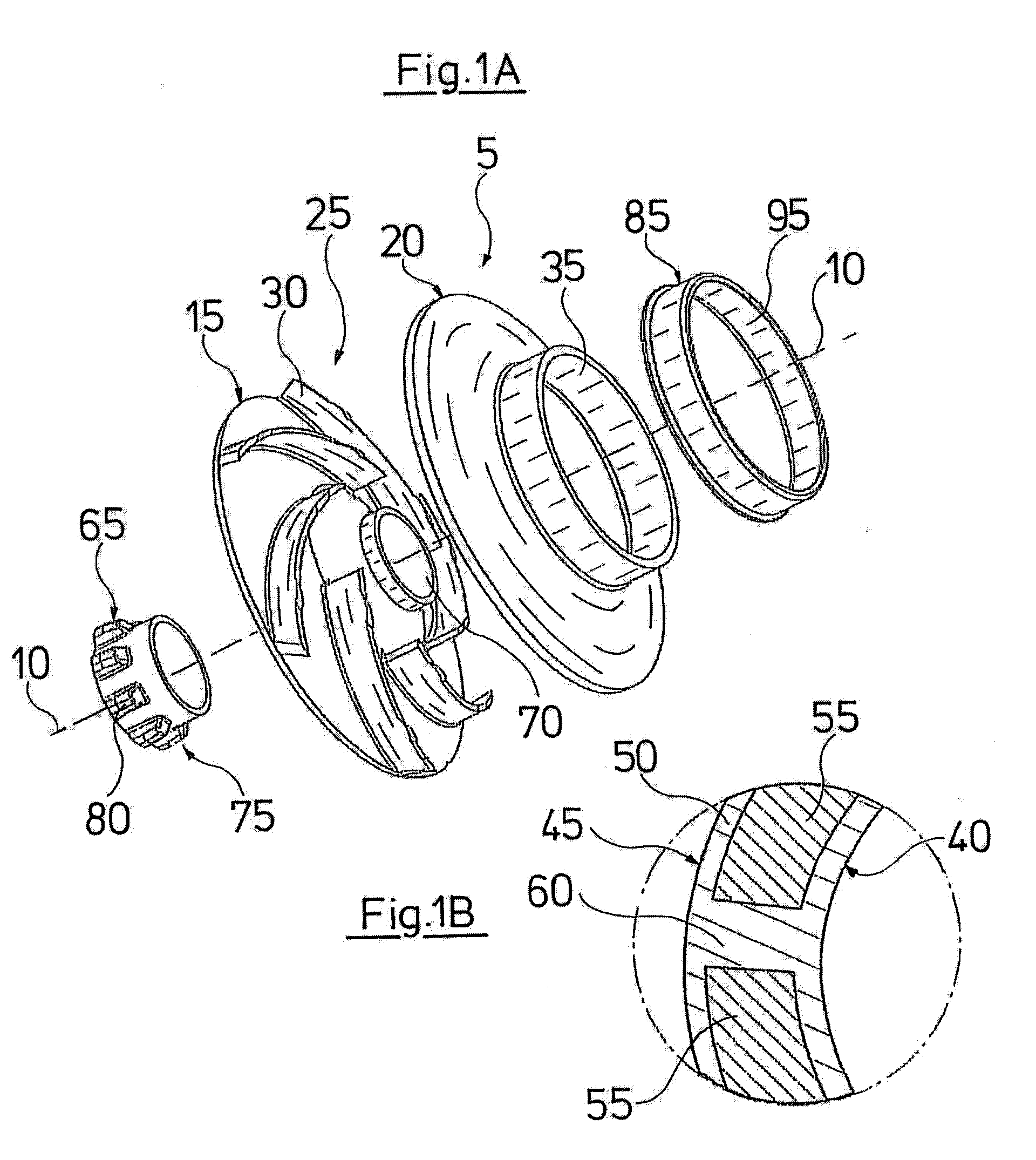

ActiveUS20100008768A1Guaranteed uptimeIncreased durabilitySpecific fluid pumpsEngine manufactureElastomerSurface layer

A pump, in particular a centrifugal pump, includes at least one flow-leading part with an at least regional surface layer (50) of an elastomer. The flow-leading part with the surface layer (50) is formed as a multi-component injection moulded part, with a base structure (55) made of plastic as a first component, and with the elastomer as a second component.

Owner:GRUNDFOS MANAGEMENT AS

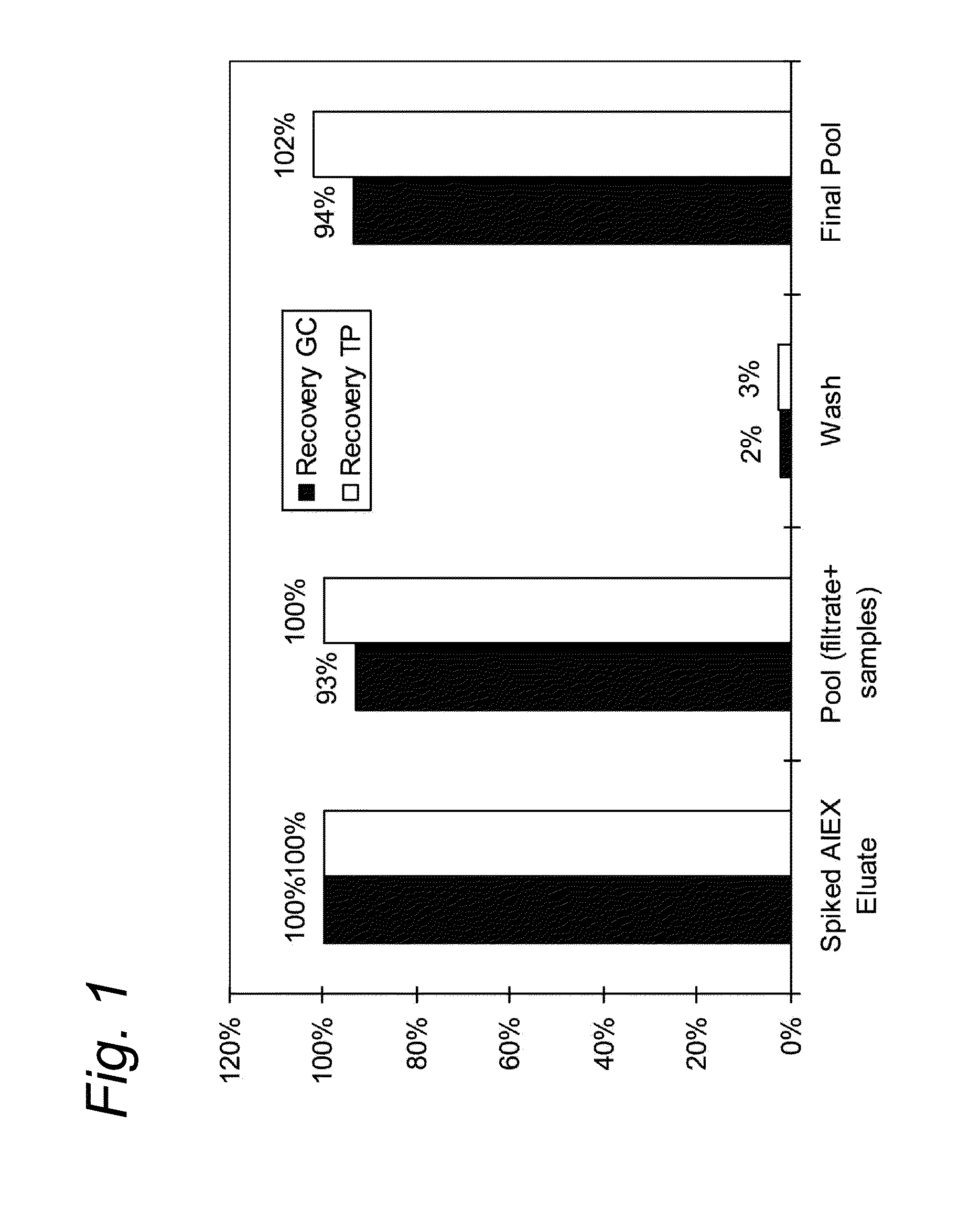

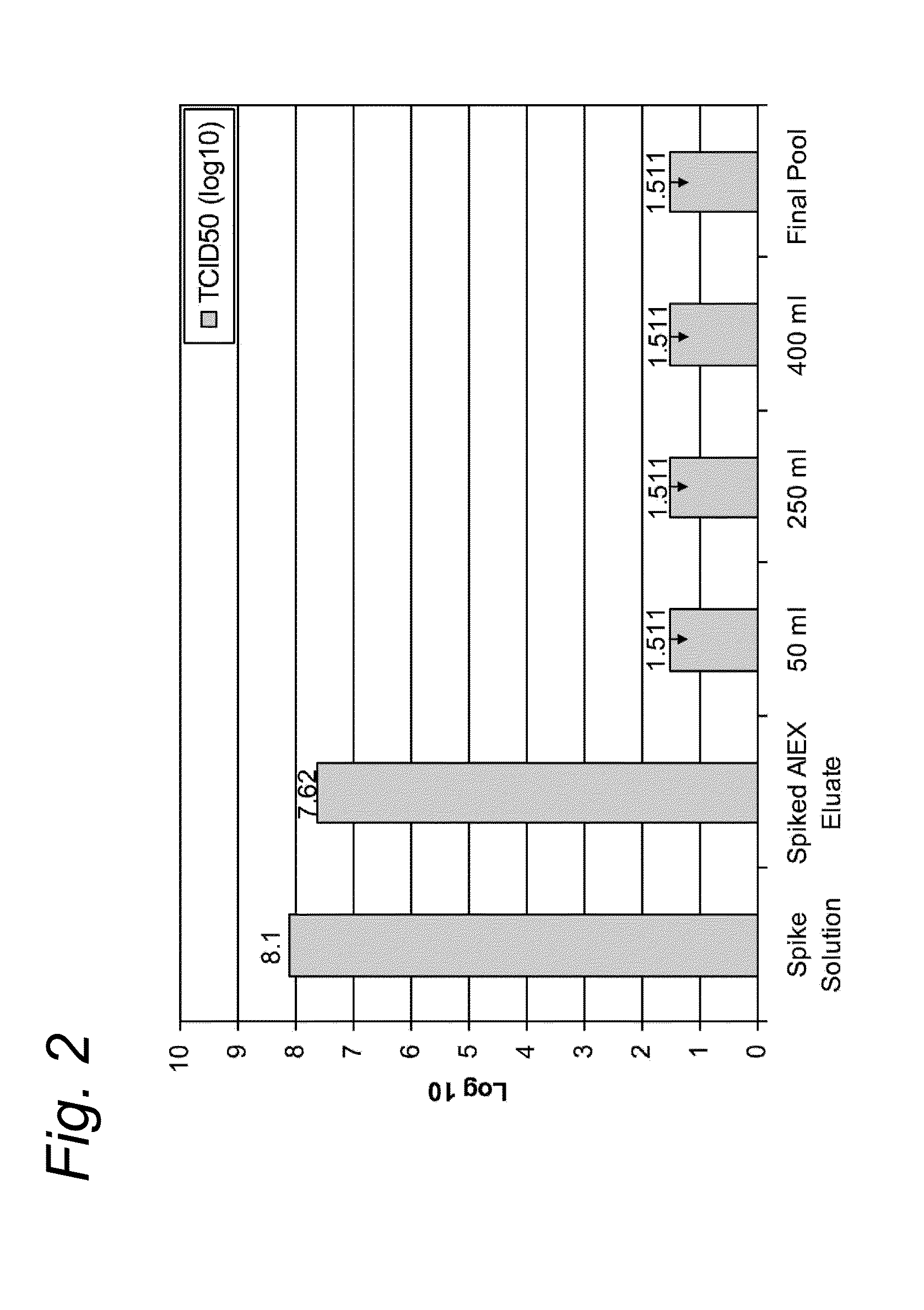

Removal of contaminating viruses from AAV preparations

The present invention relates to a separation of viruses of an essentially spherical shape from viruses with a rod-like shape that are comprised in a sample, wherein the sample comprising the viruses is subjected to filtration.

Owner:UNIQURE IP BV

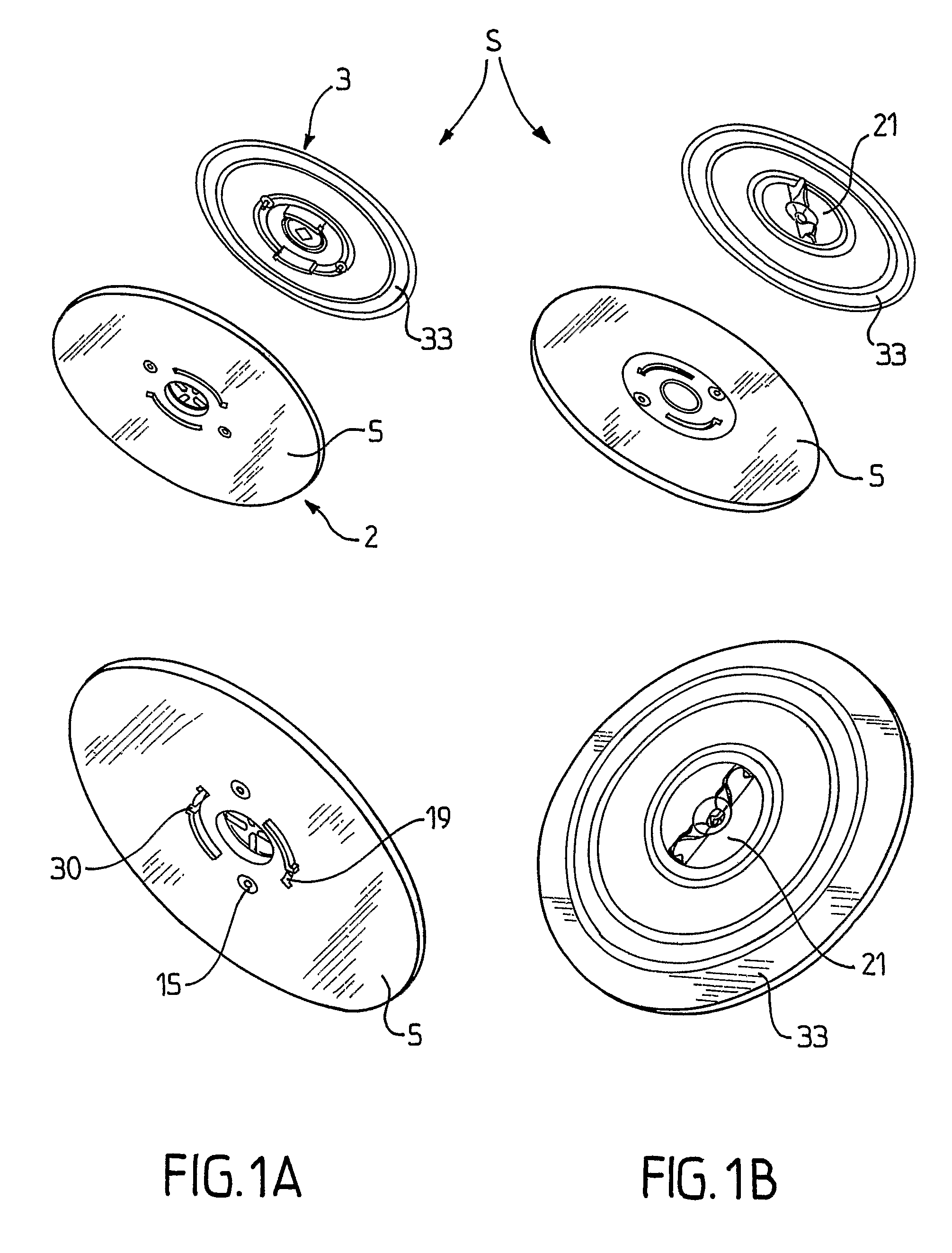

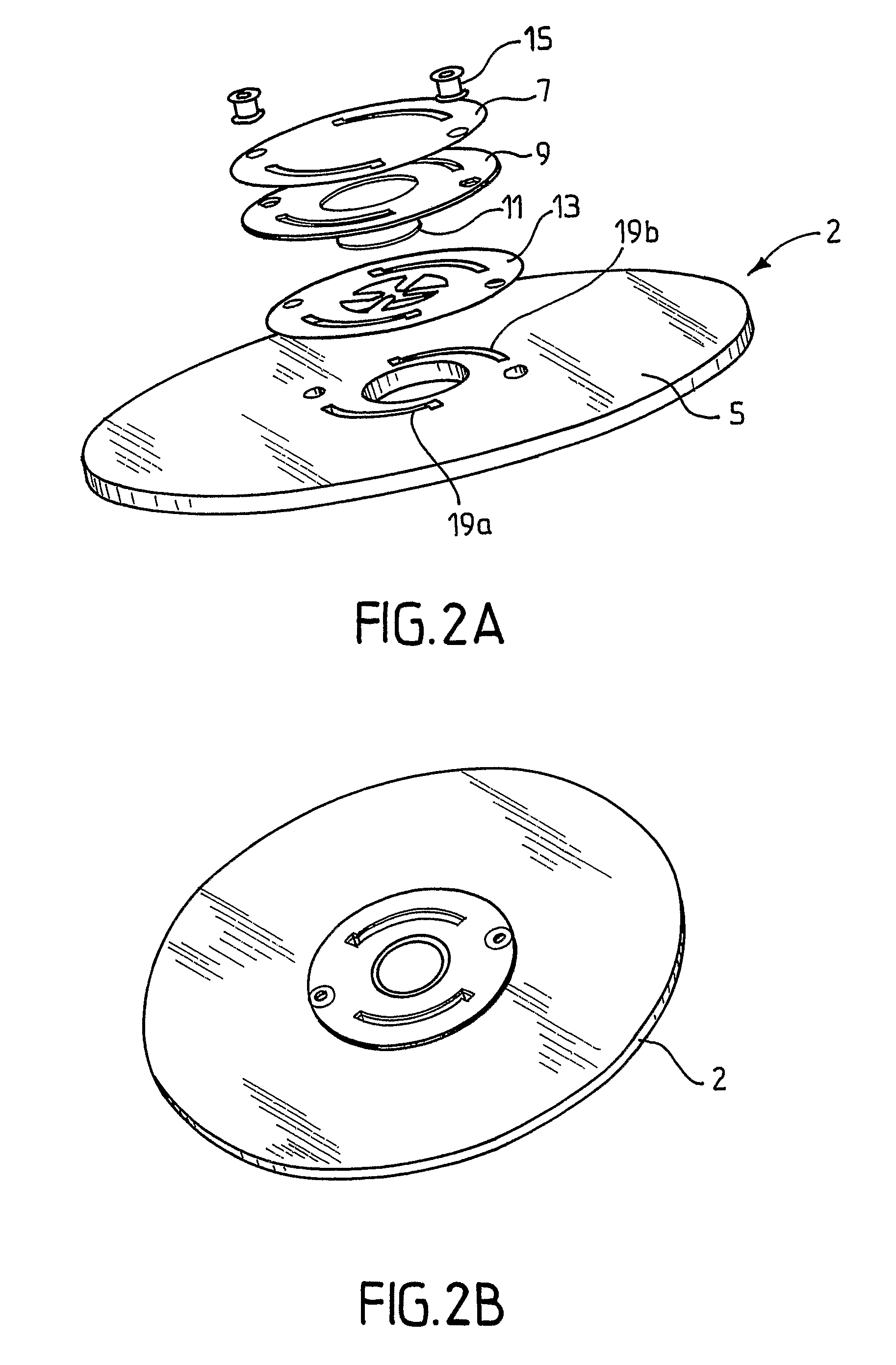

Volatile liquid droplet dispenser device

InactiveUS20080217430A1Simple and inexpensiveSimple and inexpensive mannerFlexible member pumpsMovable spraying apparatusEngineeringMembrane configuration

A volatile liquid droplet dispenser device includes: a first substrate (1) having a space (2c) for containing a liquid substance, and having liquid outlet means (2a) for ejecting the liquid substance; a second substrate (3) having a liquid inlet means (3i) for allowing the liquid substance to enter said device; an actuating element (2b, 8, 10) arranged to actuate the liquid substance so as to exit the device as a liquid droplet spray, wherein the liquid outlet means (2a) of the first substrate comprises a perforated nozzle membrane (2a) having a plurality of outlet nozzles, and wherein the first substrate (1) contains at least one fluidic capillary priming channel (1a, 1b, 1c) arranged to receive liquid substance from the space (2c) so as to fill the channel such that the liquid substance is in close proximity to the outlet nozzles for priming the liquid substance for ejection through the nozzle membrane.

Owner:APTAR FRANCE SAS

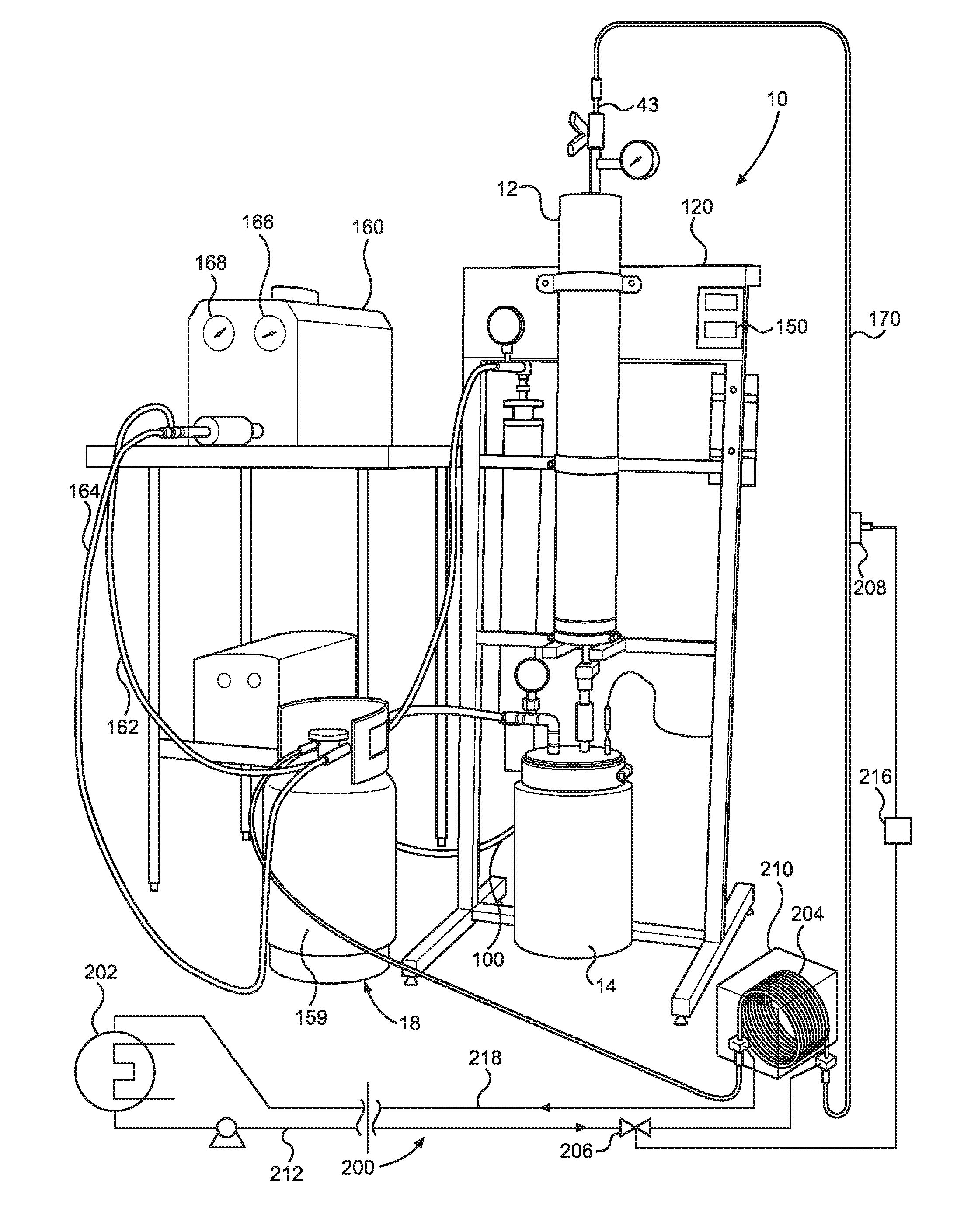

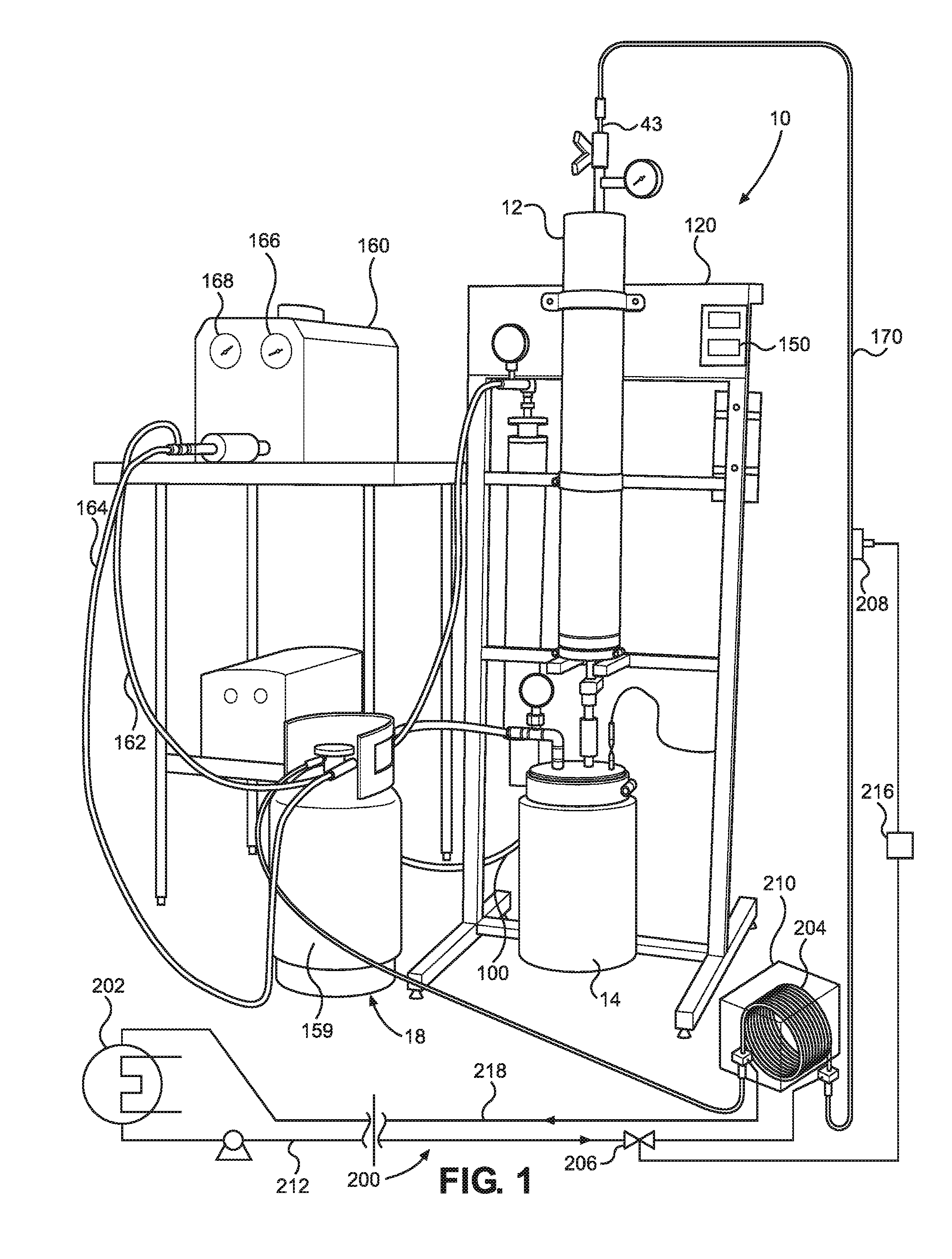

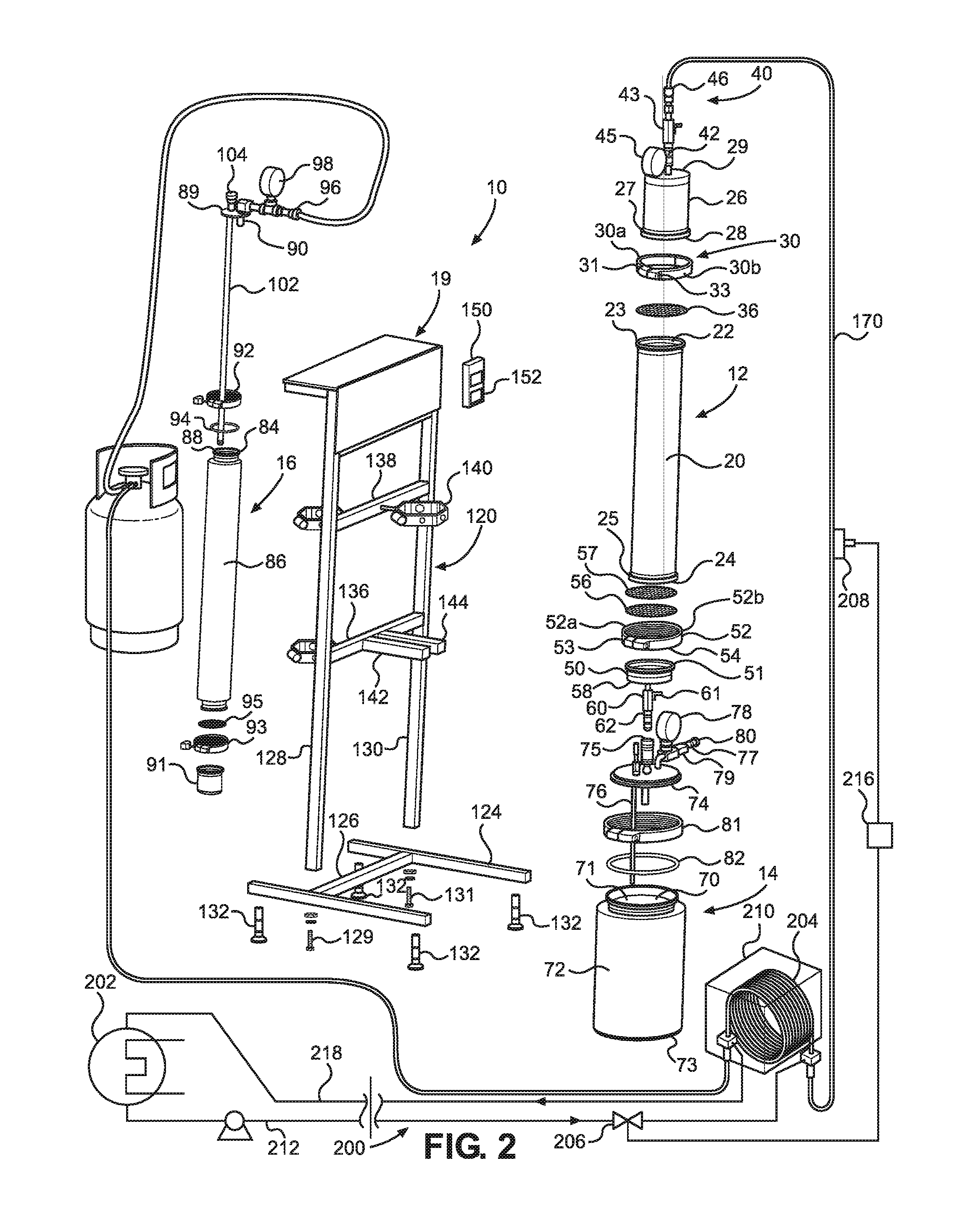

Apparatus for extracting oil from oil-bearing plants

ActiveUS20160303490A1Simple and inexpensive mannerGas solvent extractionFatty-oils/fats productionHydrocarbon solventsTemperature control

A system for extracting oil from oil-bearing plant parts has an extraction vessel supported by an upright stand, a separator vessel mounted below the extraction vessel, and an expansion filter vessel mounted downstream from the separator vessel. A source of hydrocarbon solvent supplies liquid gas to the top of the extraction vessel, while a recycling pump connected to the separator vessel facilitates transport of the solvent through the plant material in the extraction vessel. The solvent is recovered and re-circulated, while extracted oil is removed from the separator. A computer-based temperature control assembly having a cooling device and a jacketed injection coil regulates temperature of the solvent delivered to the extraction assembly. A thermal jacket is mounted on each of the separator vessel and the expansion filter vessel, with the thermal jackets supplying heat and cold to the interior of the separator vessel and the expansion filter vessel and helping evaporate and condense the solvent.

Owner:ELLIS MATTHEW

High radiance LED chip and a method for producing same

InactiveUS20060138439A1Improve luminous efficiencyAvoid lossSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringRadiation

The invention concerns a light-emitting diode chip comprising a radiation-emitting active region and a window layer. To increase the luminous efficiency, the cross-sectional area of the radiation-emitting active region is smaller than the cross-sectional area of the window layer available for the decoupling of light. The invention is further directed to a method for fabricating a lens structure on the surface of a light-emitting component.

Owner:OSRAM GMBH

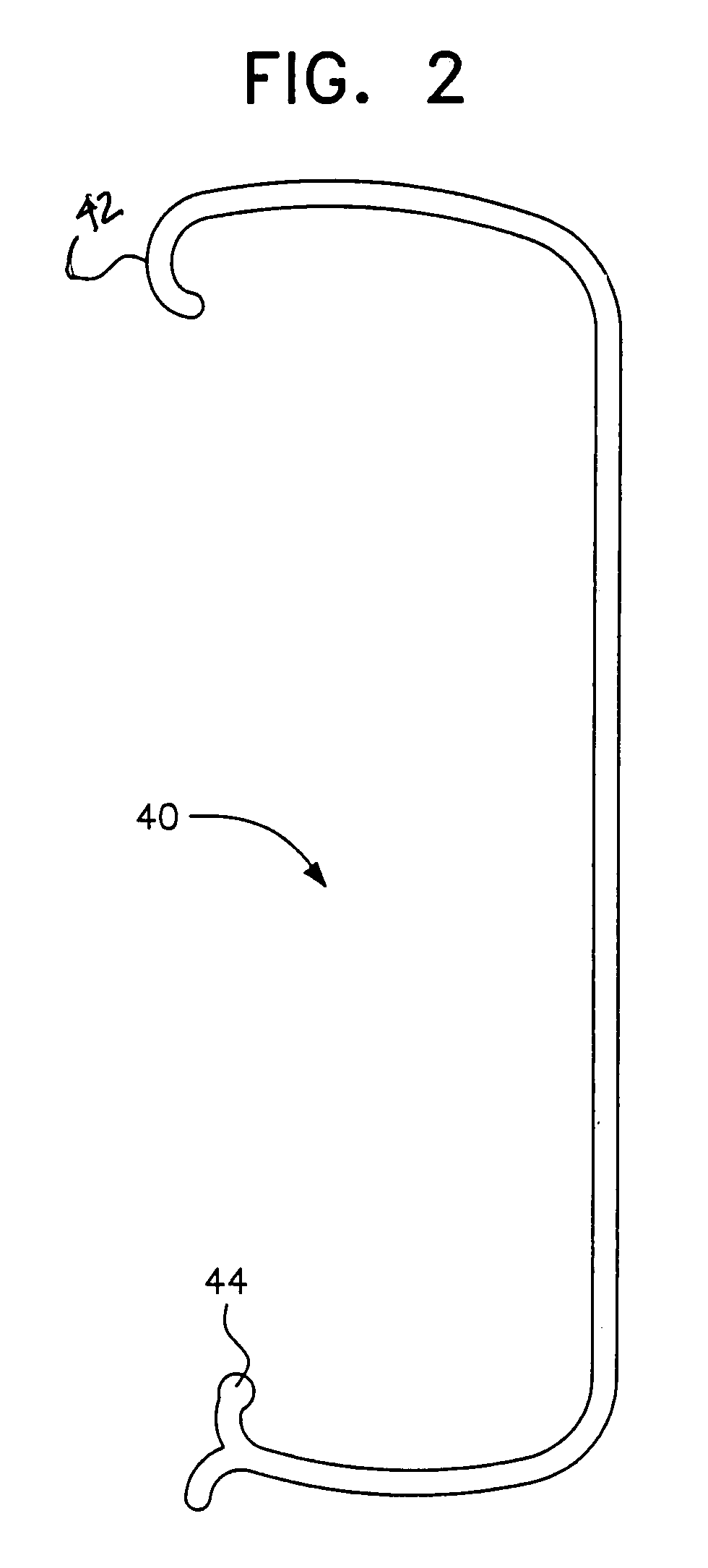

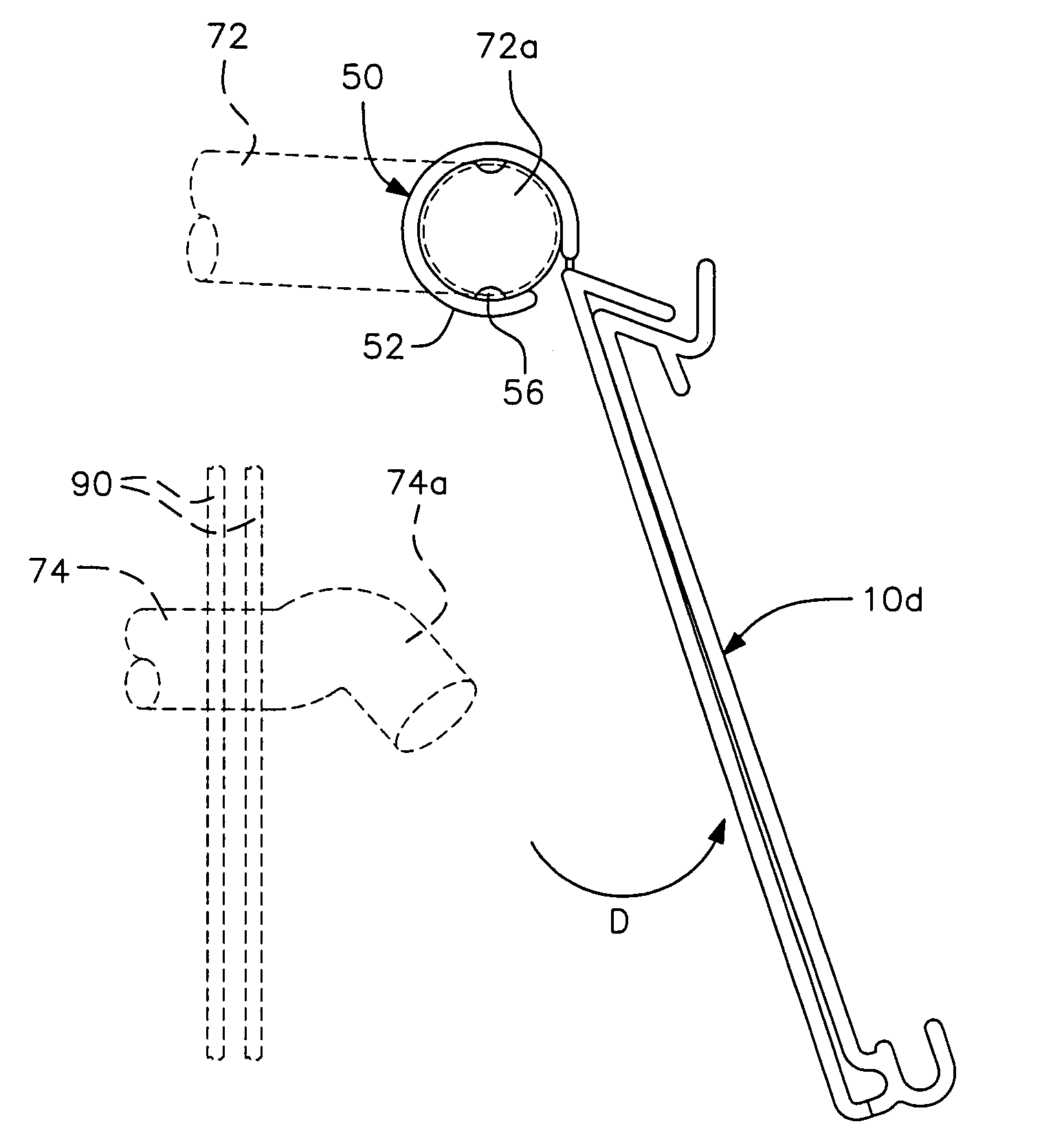

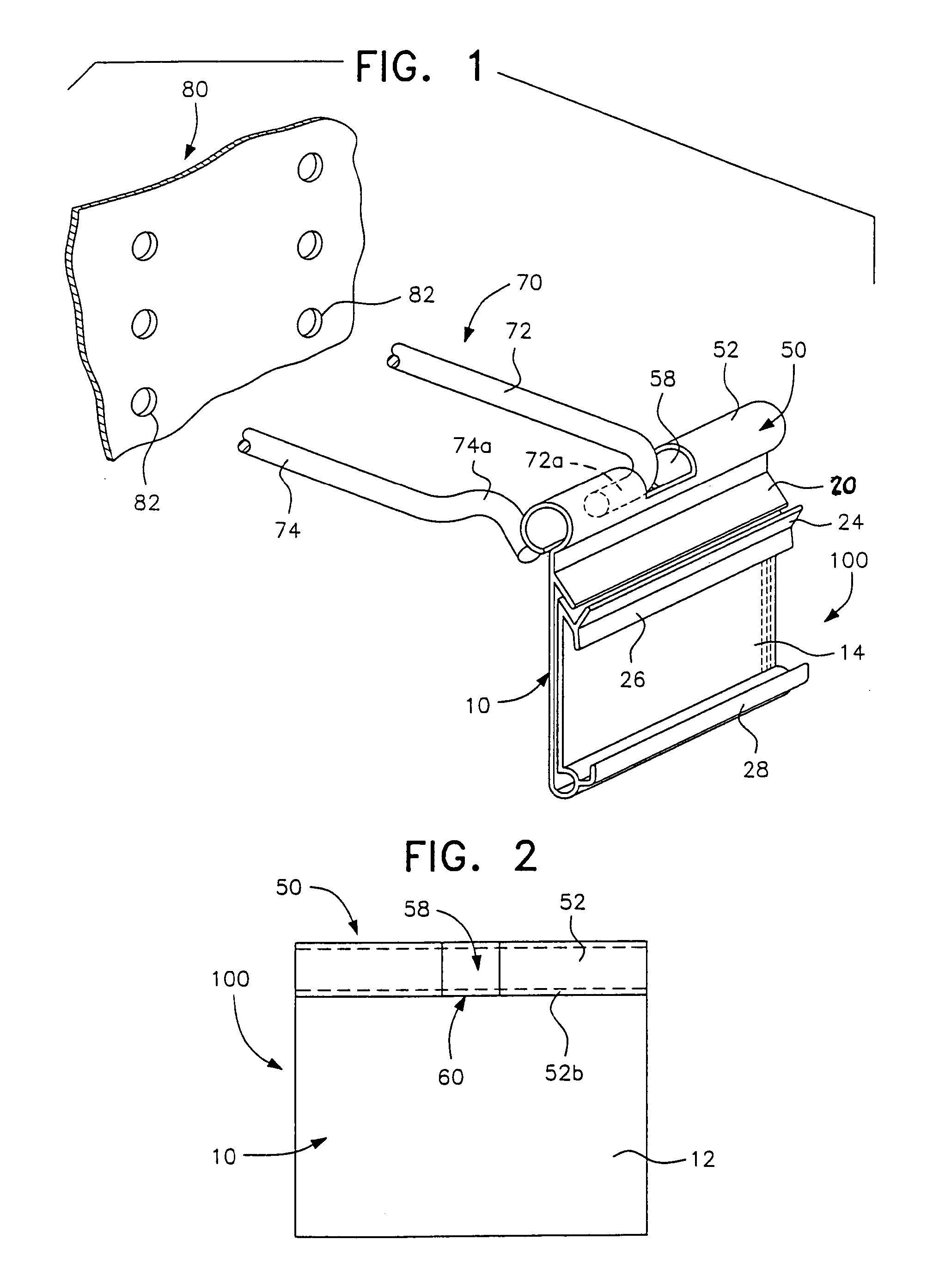

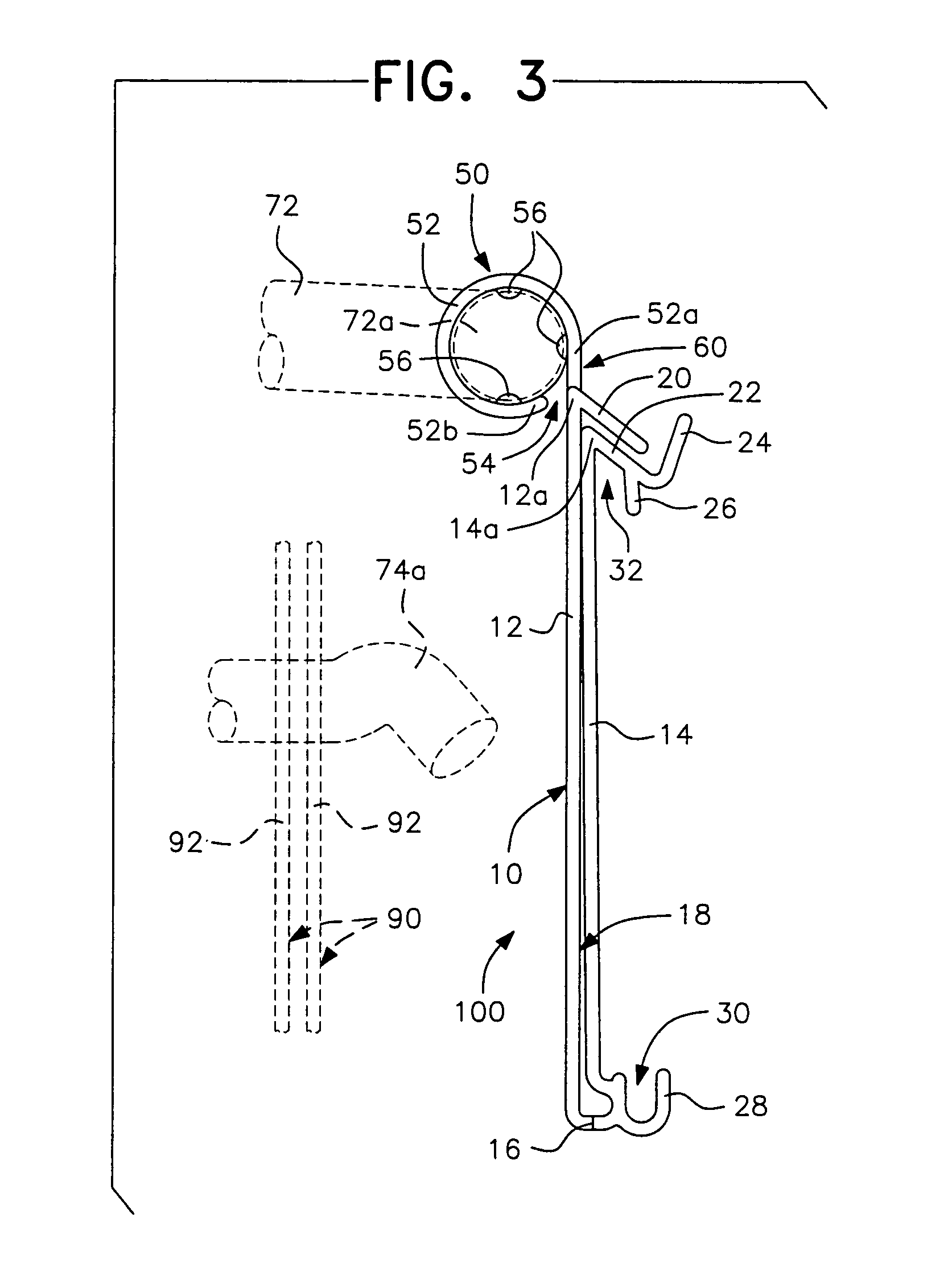

Fixed angle ESL label holder with flex grip and moisture seal

InactiveUS7287350B2Simple and inexpensive mannerTight gripStampsLayered productsElectronic shelf labelCombined use

An electronic shelf label (ESL) holder, including an attachment member portion to be secured to a supporting surface, such as a C-channel, a holder member with protrusions for removably receiving and supporting the ESLs and, optionally, a cover member pivotally carried by the holder member to overly and protect the ESLs. The holder member includes a lip extending from at least one of the top or bottom fingers of the holder formed of flexible PVC material that is flexible relative to the remaining portion of the holder and is compressible for providing a tight fit of the ESL to the holder. The flexible lip is utilized in combination with a backing member which, in one embodiment, is a flexible PVC bead that extends along the length of the holder and, in a second embodiment, includes a relatively broad or wide pad of flexible PVC material that further provides a seal against the battery or other electronics of the ESL.

Owner:FAST JACOB +1

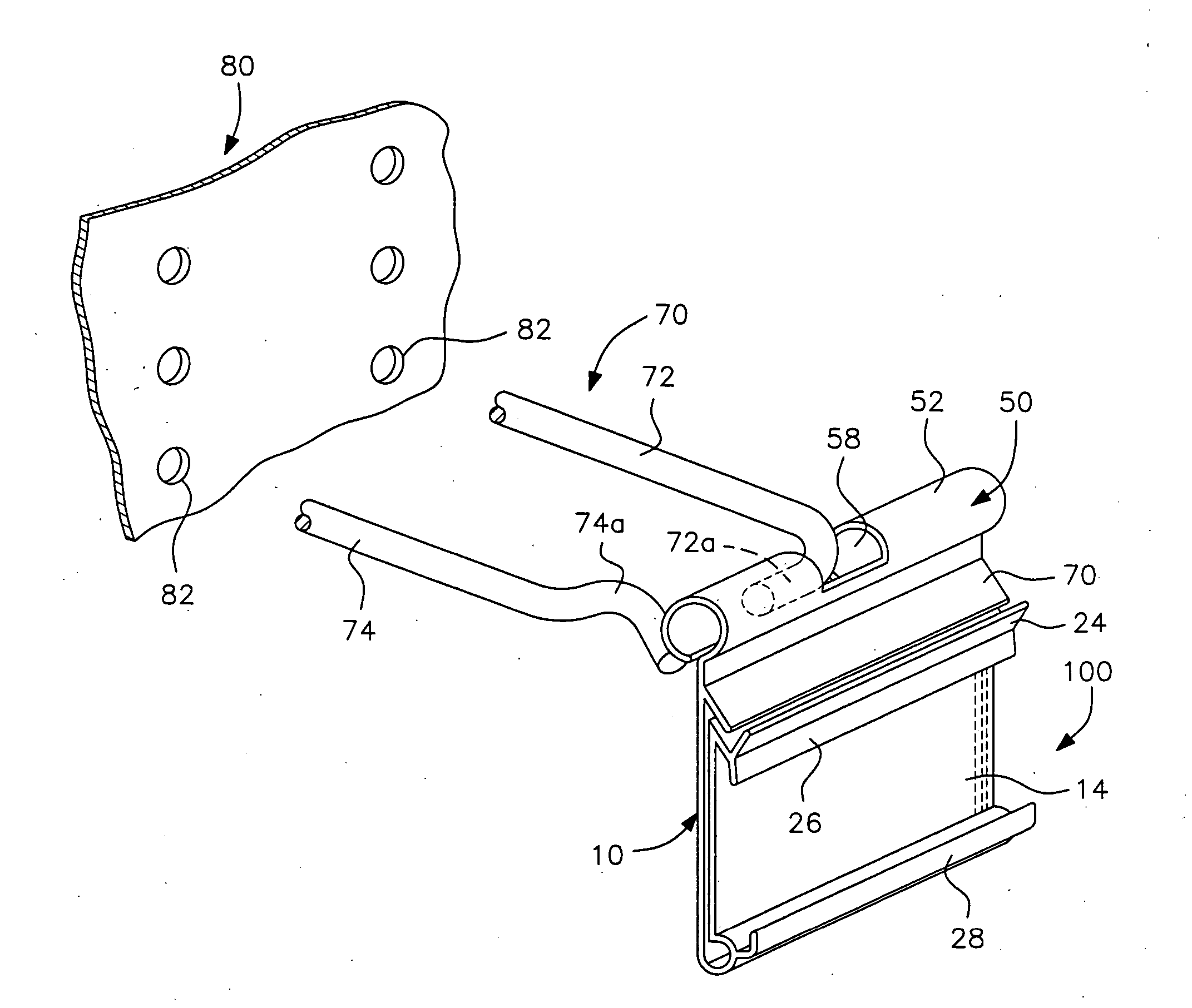

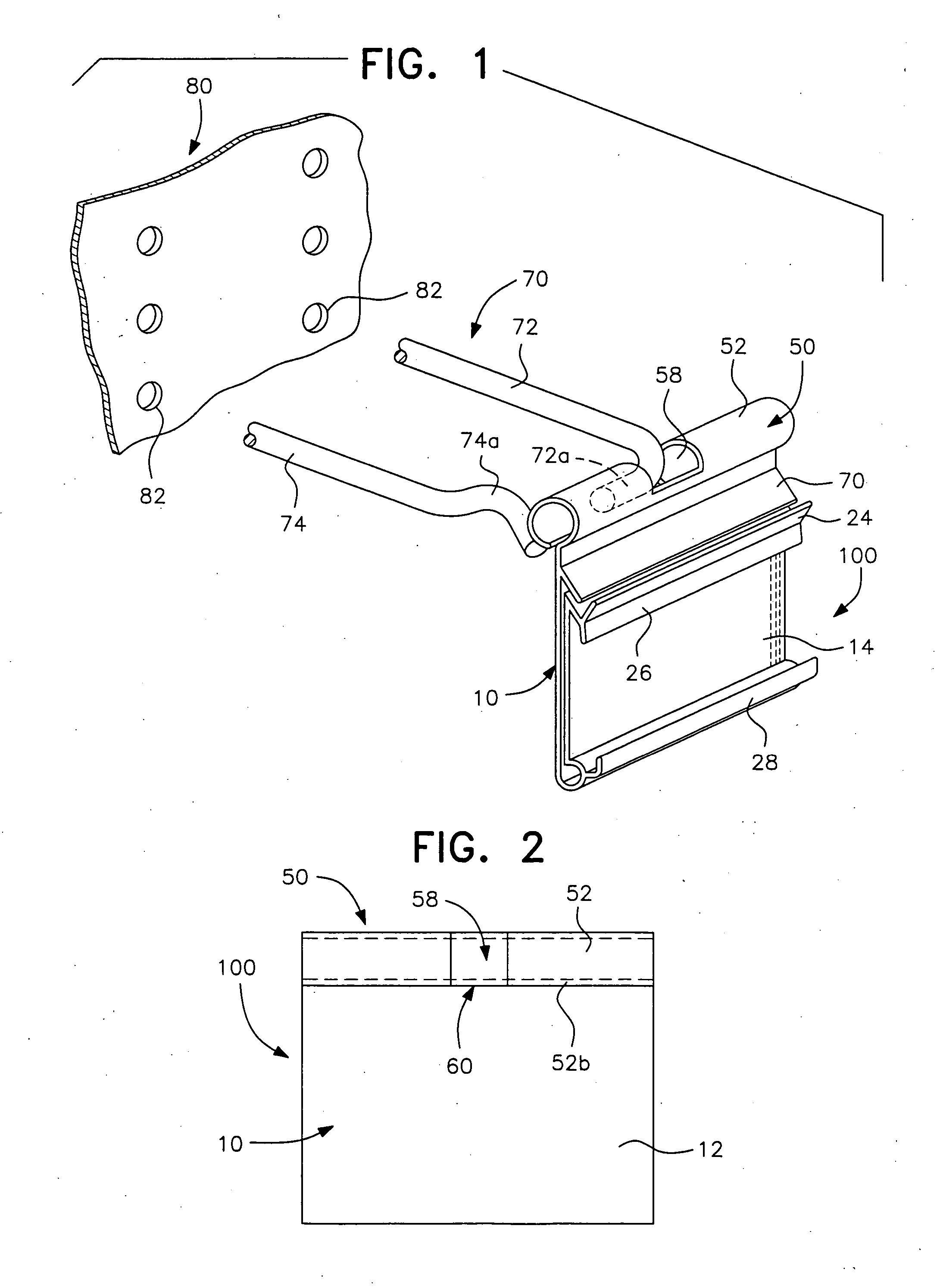

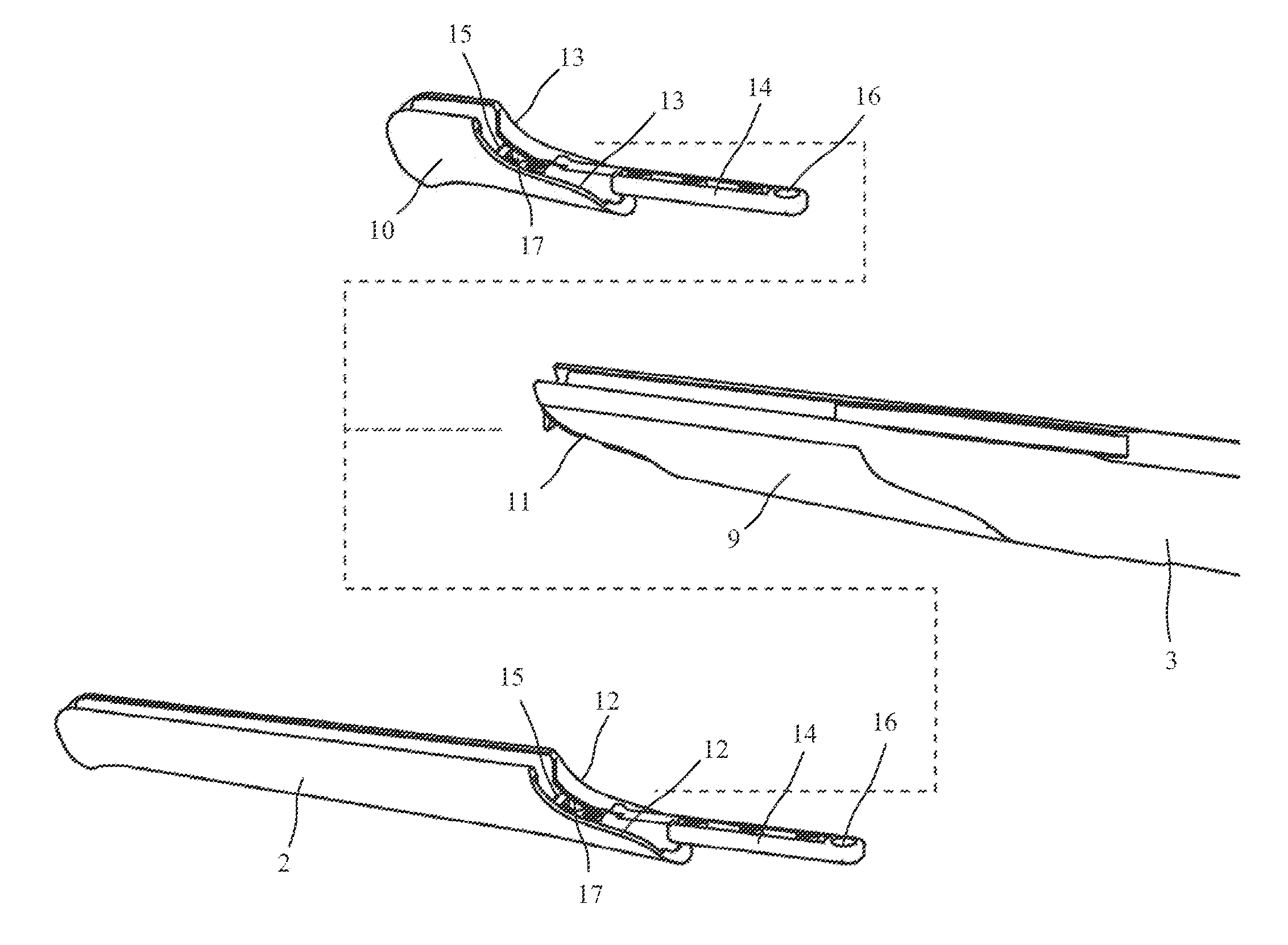

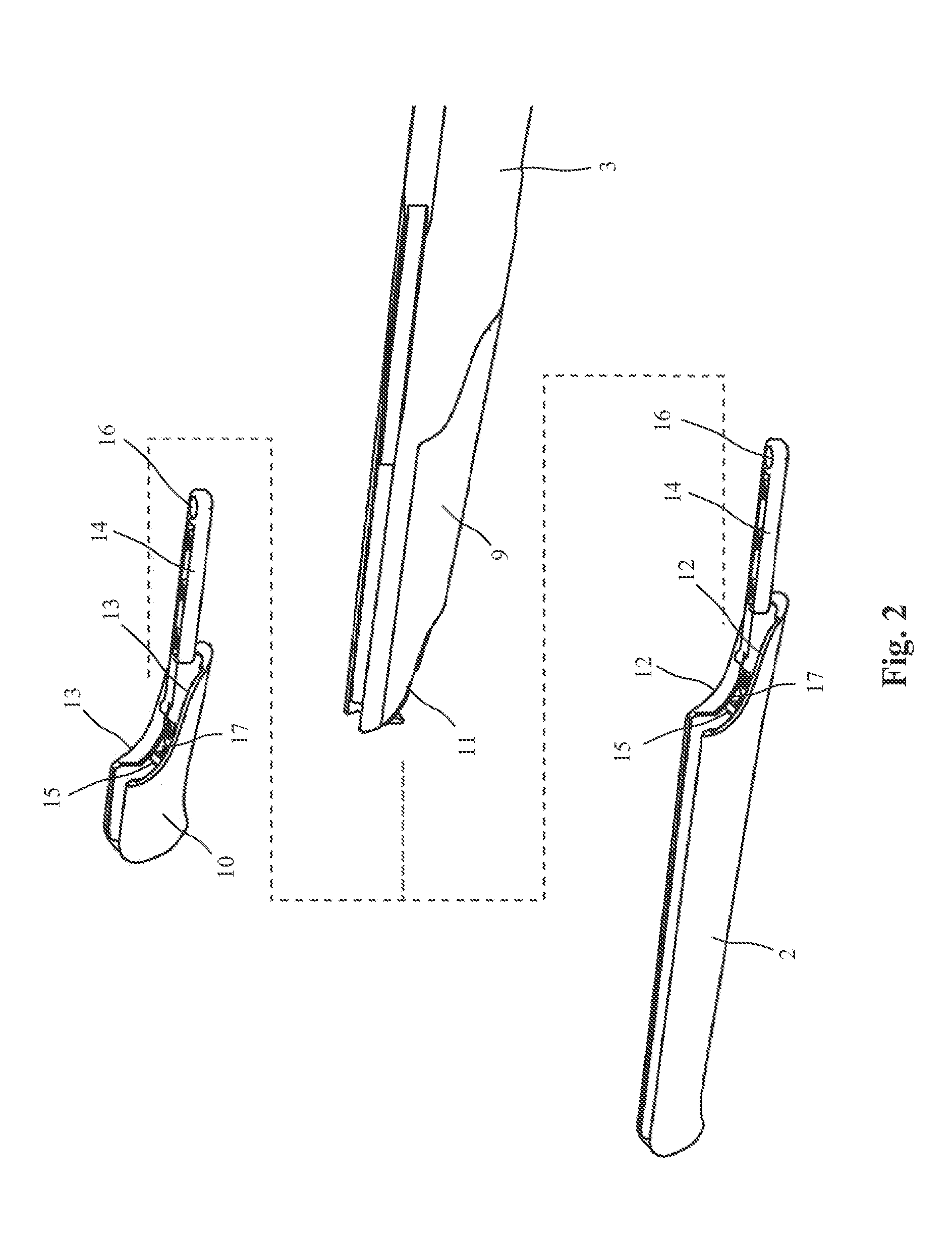

Hinged label holder

InactiveUS7089695B2Simple and inexpensive mannerEasy accessStampsKitchen equipmentEngineeringHinge angle

A label holder is hingedly connected to a clip portion grippingly engaged over a transversely extending rod at the distal end of a merchandise aid, such as a scanner hook or the like, or over a plate on the end of a scanner hook enabling the label holder to be moved forwardly to access or position product on the scanner hook, or, in some applications, rearwardly in the event of impact from a passerby. By selecting the properties of the hinge section, the label holder can be temporarily fixed in a selected angular relationship when the scanner hook extends above or below the eye of a viewer to facilitate reading information on labels carried thereby.

Owner:FAST INDS

Formation of an aluminide coating, incorporating a reactive element, on a metal substrate

InactiveUS20020023696A1Simple and inexpensive mannerImprove efficiencyBlade accessoriesSemiconductor/solid-state device manufacturingAluminideMetal substrate

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

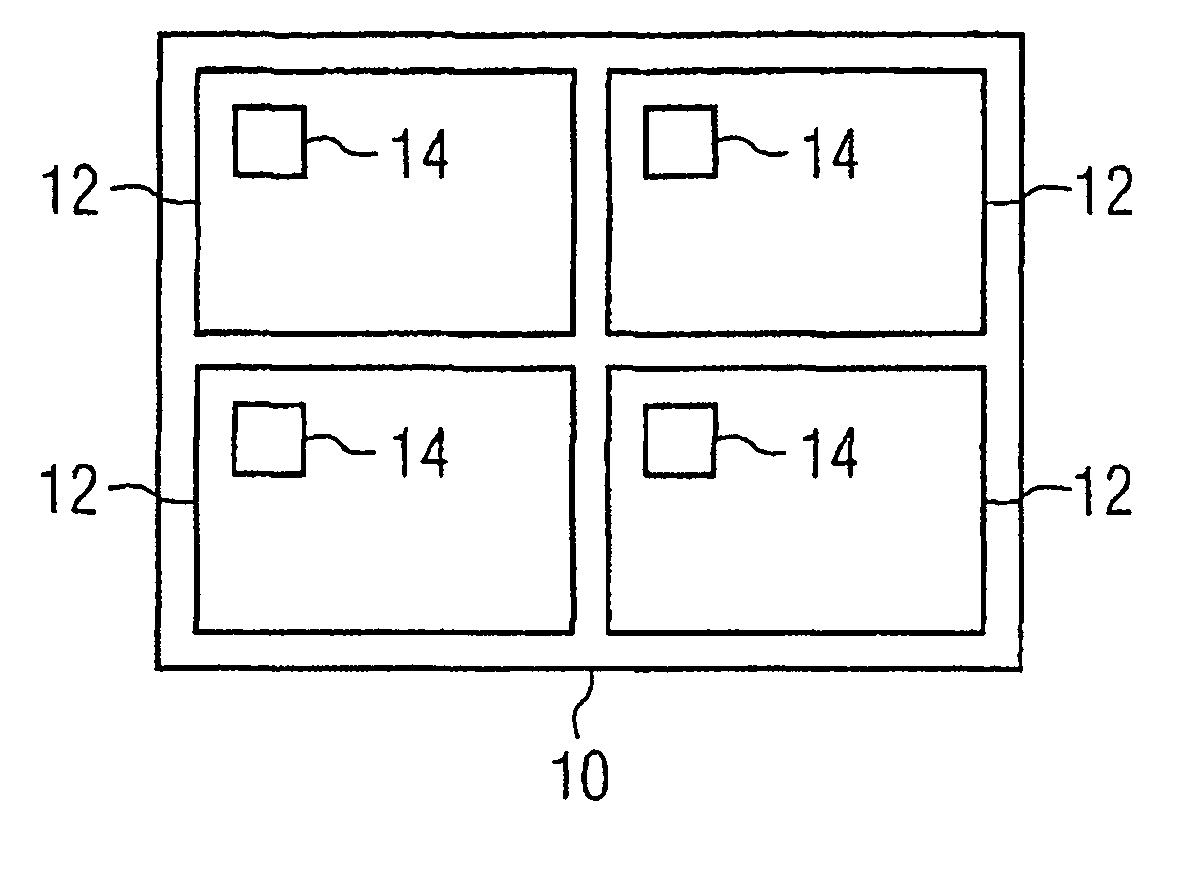

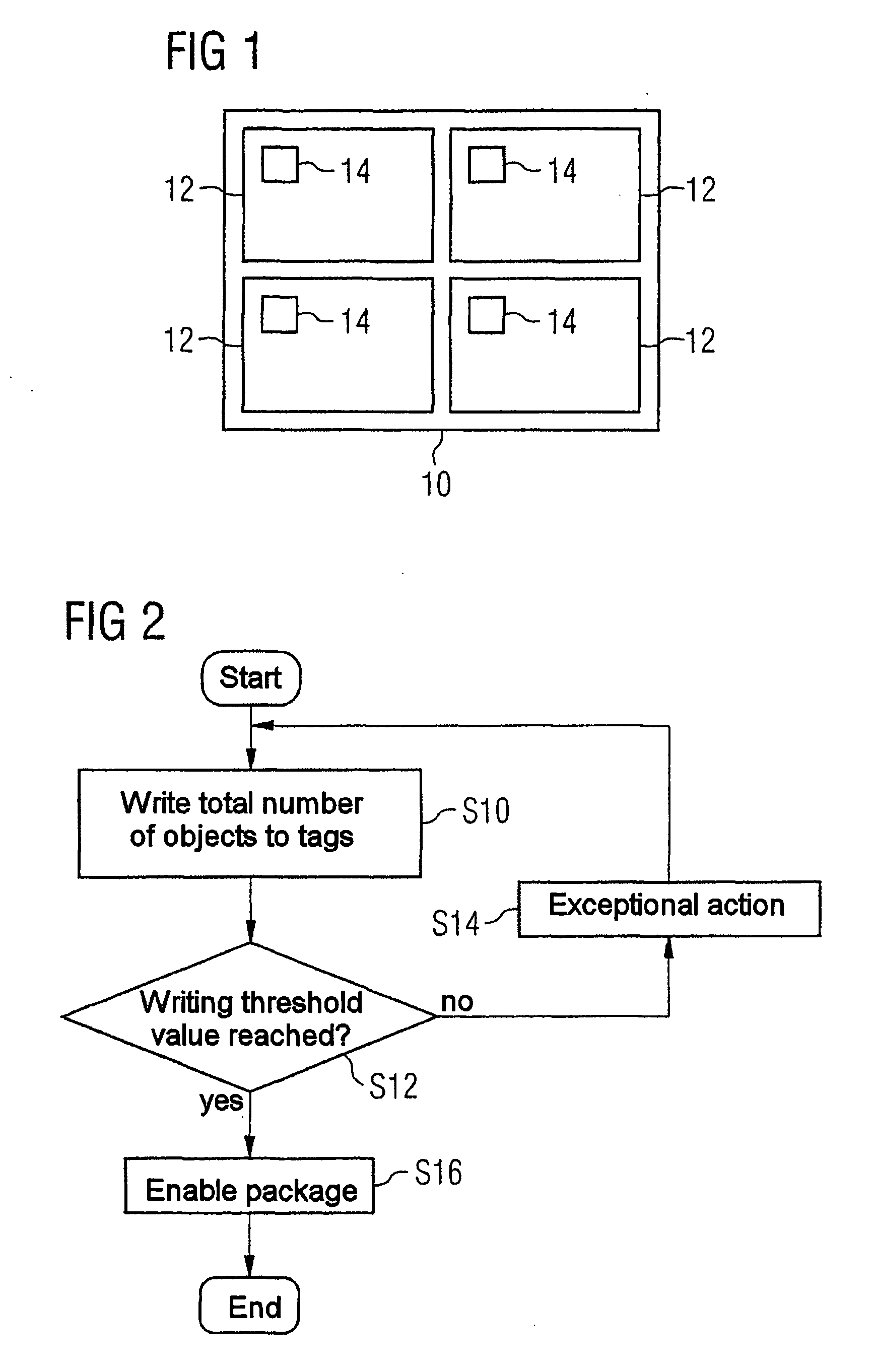

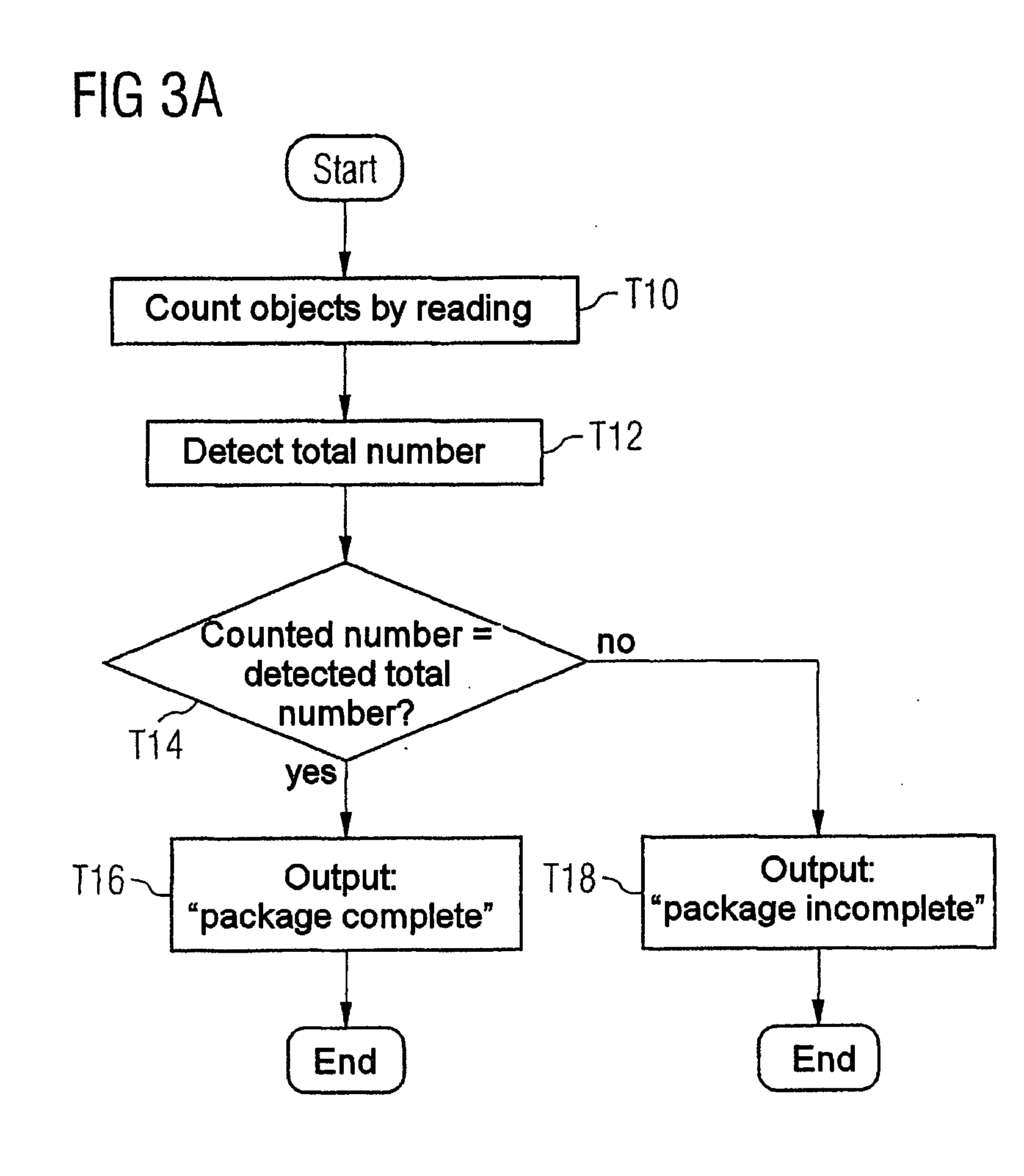

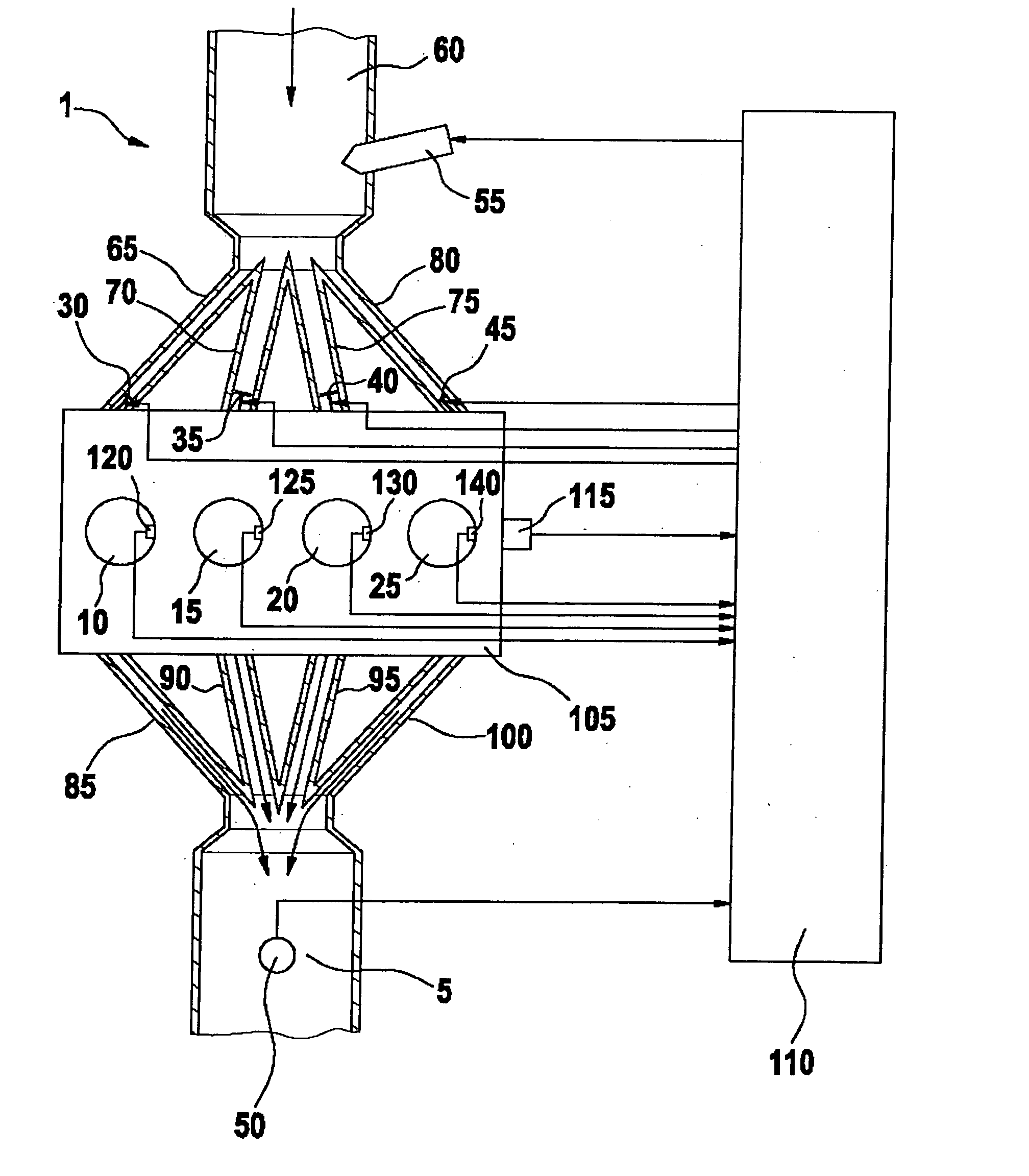

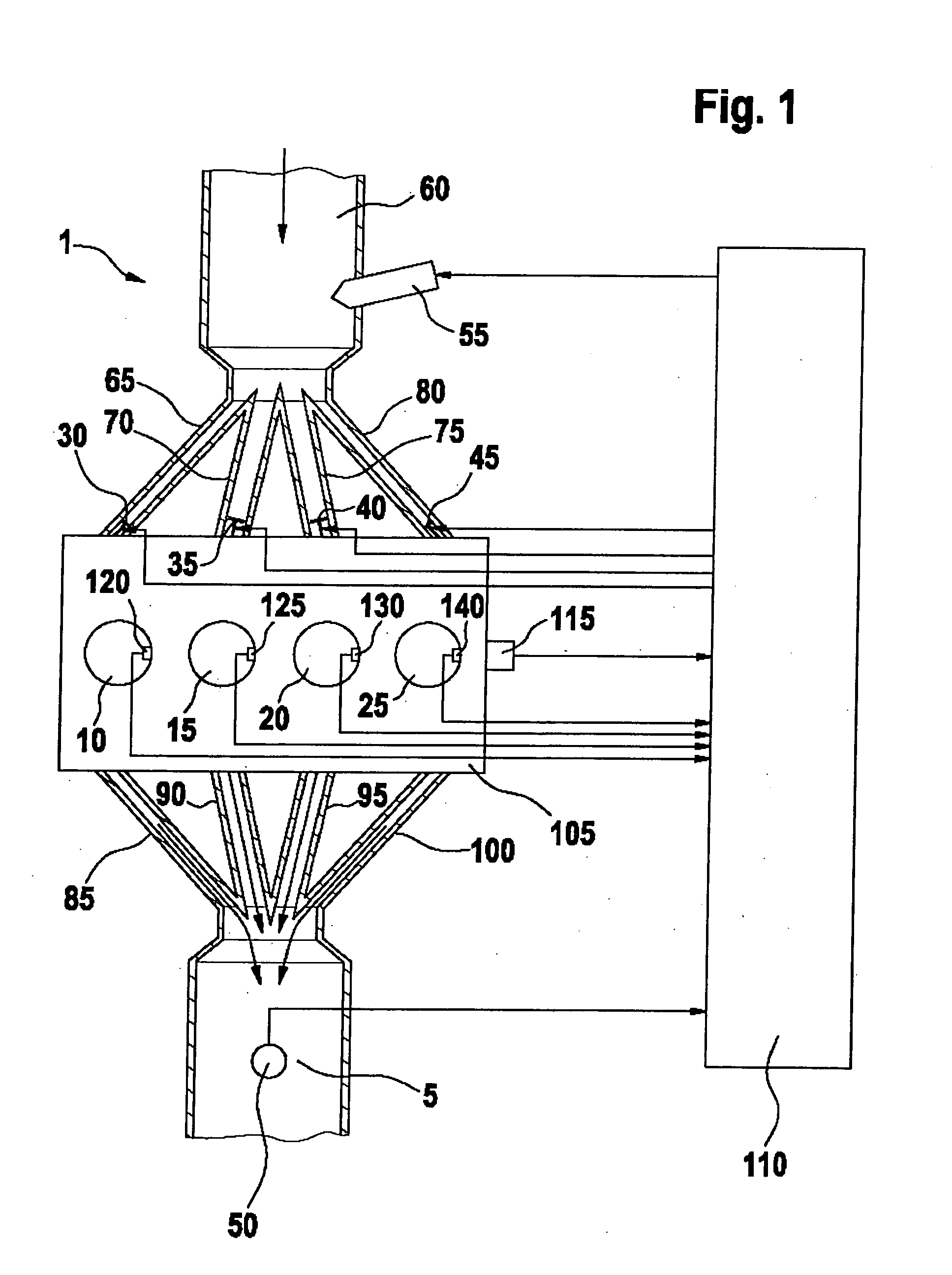

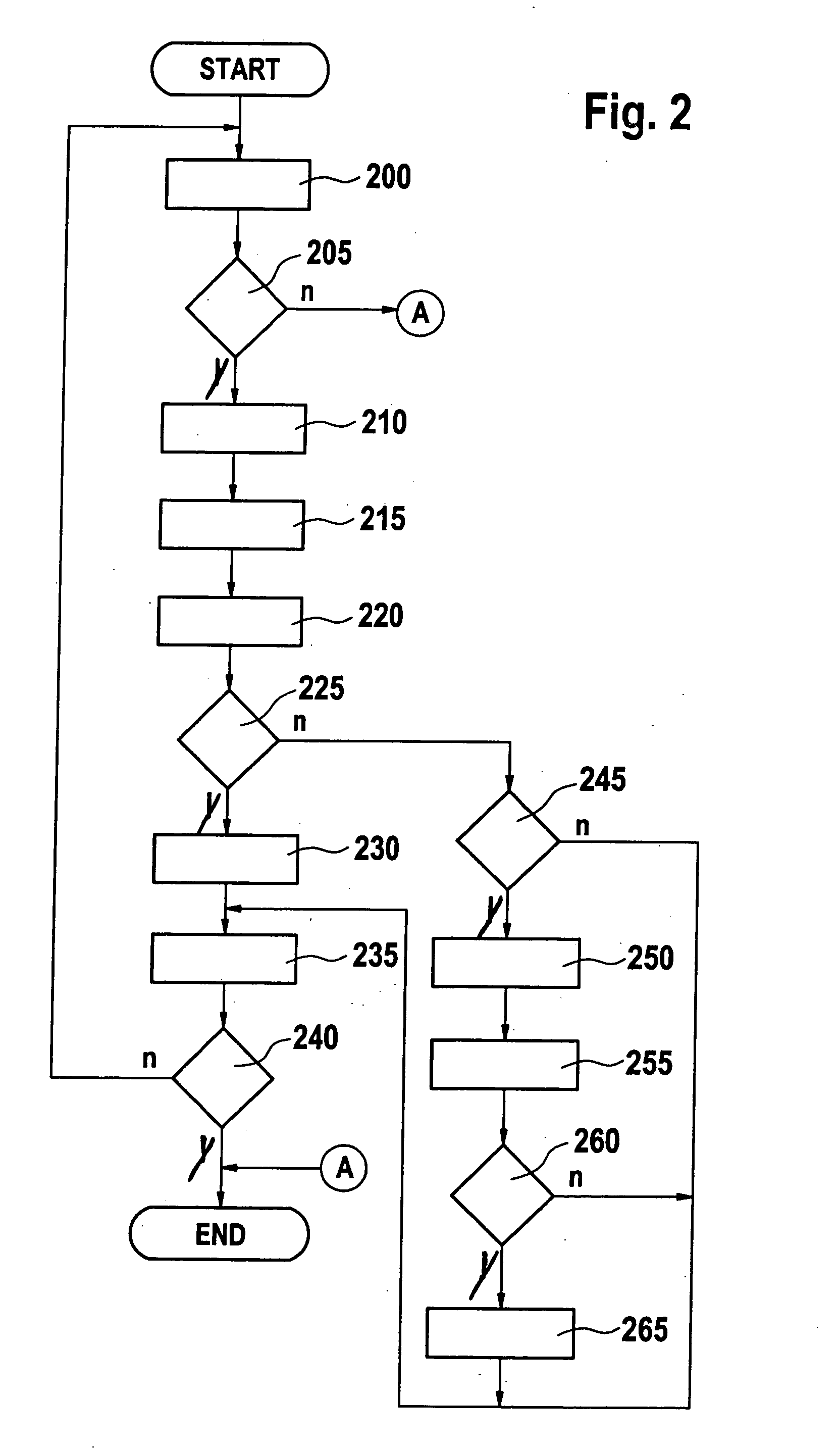

Method and system for checking completeness in a package

ActiveUS20050263592A1Simple and inexpensive mannerElectric signal transmission systemsDigital data processing detailsElectronic informationComputer science

System and method for checking completeness in a package, which comprises a plurality of objects, which are each provided with at least one electronic information storage medium. The method includes the steps of (a) storing in at least one electronic information storage medium, the total number of objects contained in the package and / or the total number of objects provided for the package; (b) detecting the total number of objects contained in the package by reading the stored value from the at least one electronic information storage medium in which the total number has been stored; (c) counting the objects in the package by reading the electronic information storage media arranged on the objects; and (d) outputting a first predetermined signal if the detected total number is not equal to the counted number and / or a second predetermined signal is output if the detected total number is equal to the counted number.

Owner:DETEGO GMBH

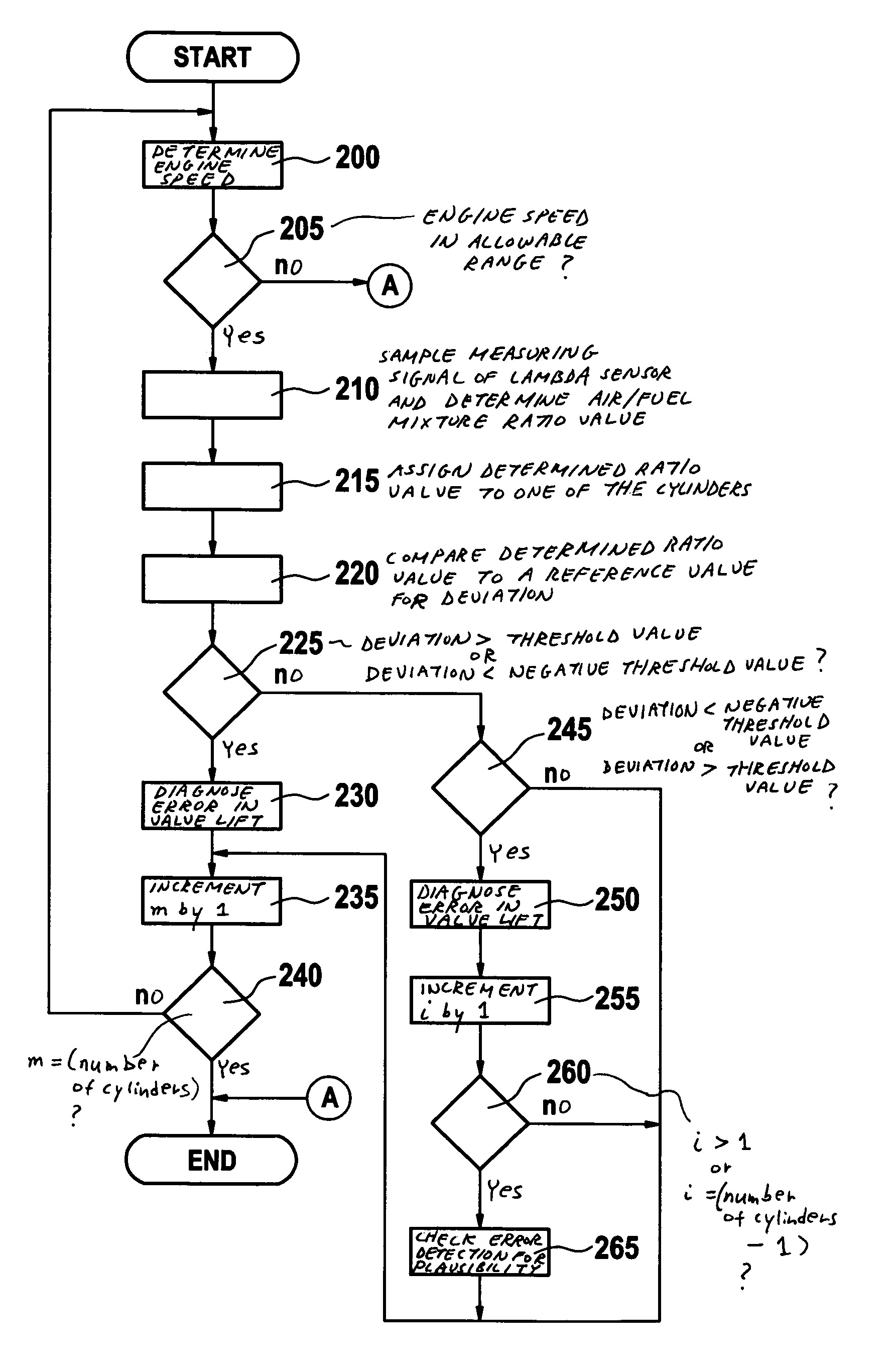

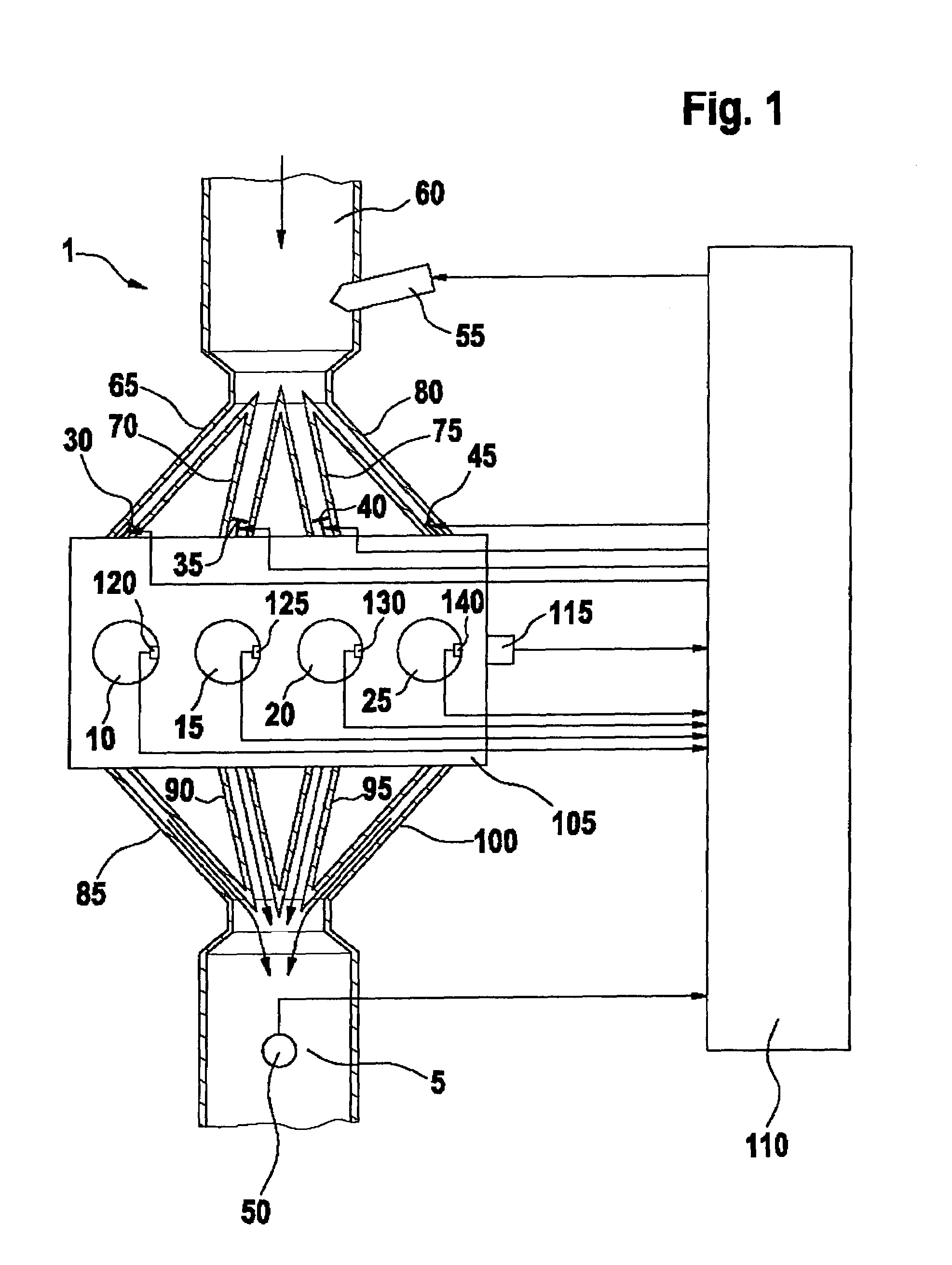

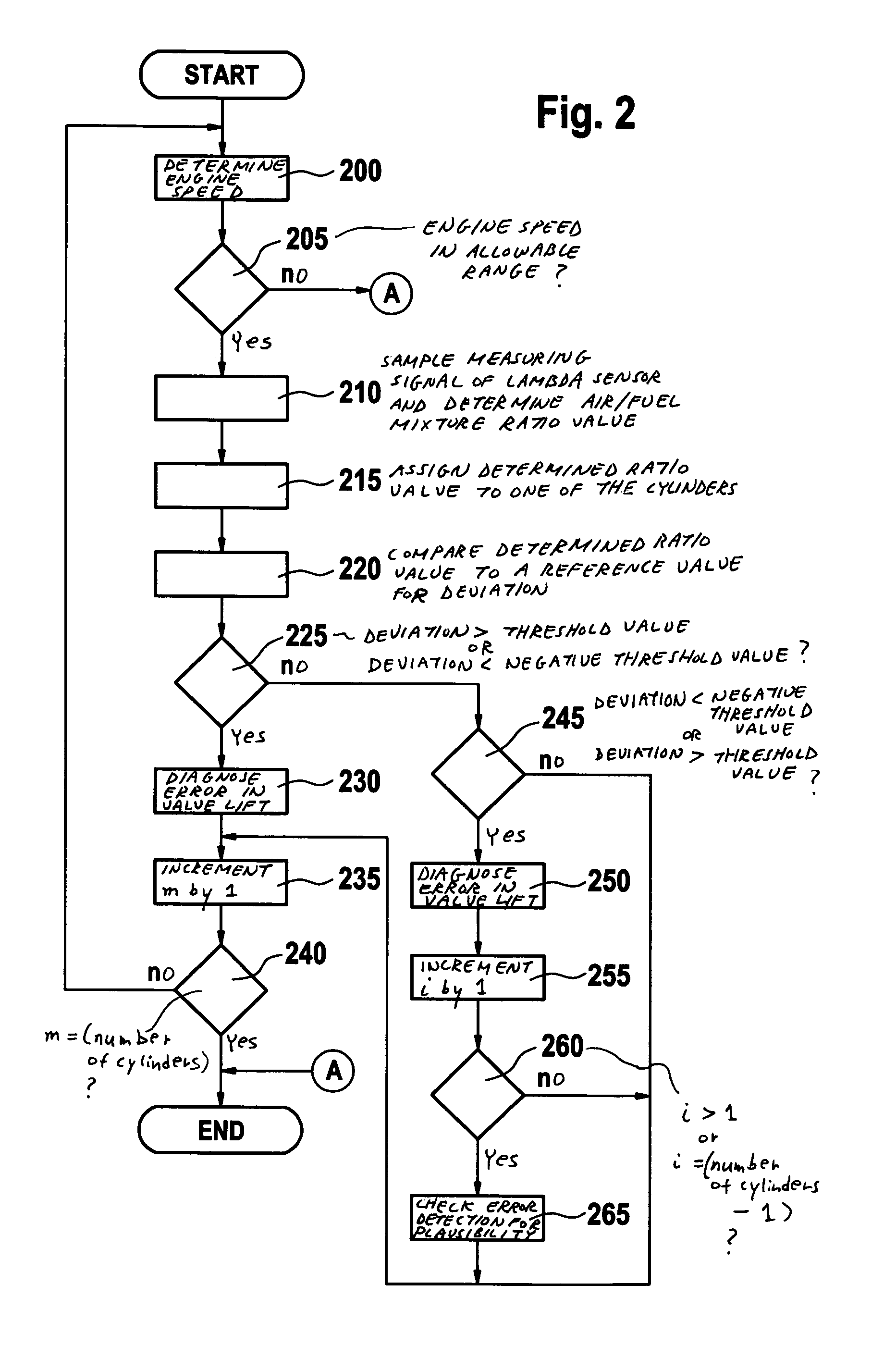

Method for operating an internal combustion engine

InactiveUS20050125139A1Diagnose erroneous valve liftDiagnose the valve liftAnalogue computers for vehiclesElectrical controlInternal combustion engineVALVE PORT

A method for operating an internal combustion engine, in which an erroneous lift of an intake valve of a cylinder is directly determined. The lift of an intake valve of at least one cylinder of the internal combustion engine is diagnosed. A value for a specific cylinder which is representative of the air / fuel ratio in the respective cylinder is determined in an exhaust system branch of the internal combustion engine. At least one such value is compared to a predefined value. An erroneous lift of the intake valve is diagnosed as a function of the deviation of this at least one value from the predefined value.

Owner:ROBERT BOSCH GMBH

Hinged label holder

InactiveUS20050081418A1Simple and inexpensive mannerEasy accessStampsKitchen equipmentEngineeringHinge angle

A label holder is hingedly connected to a clip portion grippingly engaged over a transversely extending rod at the distal end of a merchandise aid, such as a scanner hook or the like, or over a plate on the end of a scanner hook enabling the label holder to be moved forwardly to access or position product on the scanner hook, or, in some applications, rearwardly in the event of impact from a passerby. By selecting the properties of the hinge section, the label holder can be temporarily fixed in a selected angular relationship when the scanner hook extends above or below the eye of a viewer to facilitate reading information on labels carried thereby.

Owner:FAST INDS

Formation of an aluminide coating, incorporating a reactive element, on a metal substrate

InactiveUS6673709B2Simple and inexpensive mannerImprove efficiencyBlade accessoriesSemiconductor/solid-state device manufacturingAluminideMetallic substrate

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Endoscope head

ActiveUS7371209B2Reduce manufacturing costMounted inexpensivelySurgeryEndoscopesCamera lensEndoscope

The invention relates to an endoscope head which is equipped with a plurality of function-related units such as an optical / lens system, illuminating elements, rinsing nozzles and the like. The endoscope head substantially comprises a plurality of modular plug-in or click-in function-related supports for receiving and / or forming the function-related units.

Owner:INVENDO MEDICAL GMBH

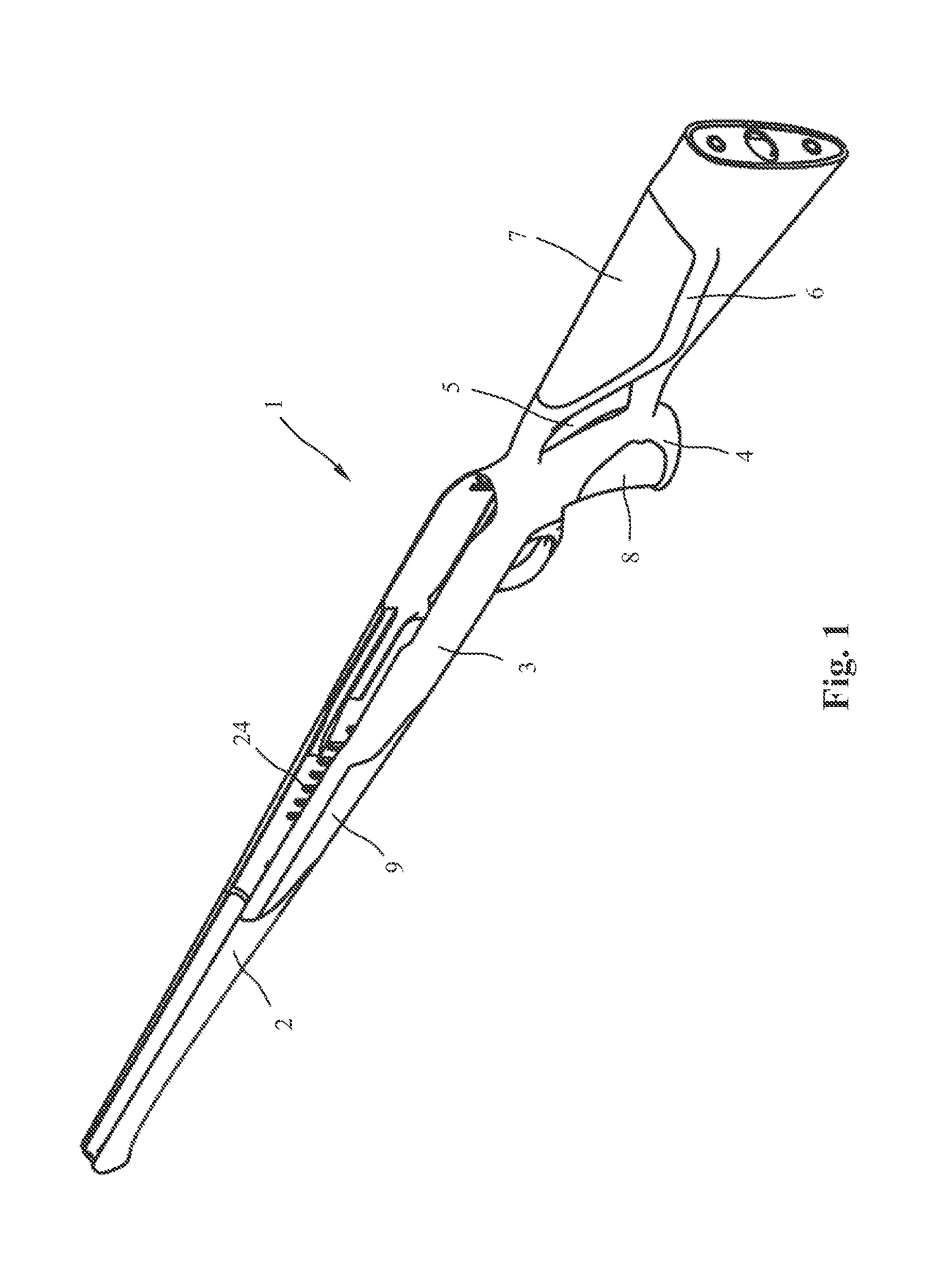

Stutzen stock

A Stutzen stock of a repeating rifle that includes a stock front portion and a stock rear portion. To make available a more versatile Stutzen stock, the stock front portion is detachably connected to the stock rear portion.

Owner:BLASER FINANZHLDG

Method for operating an internal combustion engine

InactiveUS7069142B2Diagnose erroneous valve liftDiagnose the valve liftInternal-combustion engine testingAnalogue computers for vehiclesInlet valveInternal combustion engine

A method for operating an internal combustion engine, in which an erroneous lift of an intake valve of a cylinder is directly determined. The lift of an intake valve of at least one cylinder of the internal combustion engine is diagnosed. A value for a specific cylinder which is representative of the air / fuel ratio in the respective cylinder is determined in an exhaust system branch of the internal combustion engine. At least one such value is compared to a predefined value. An erroneous lift of the intake valve is diagnosed as a function of the deviation of this at least one value from the predefined value.

Owner:ROBERT BOSCH GMBH

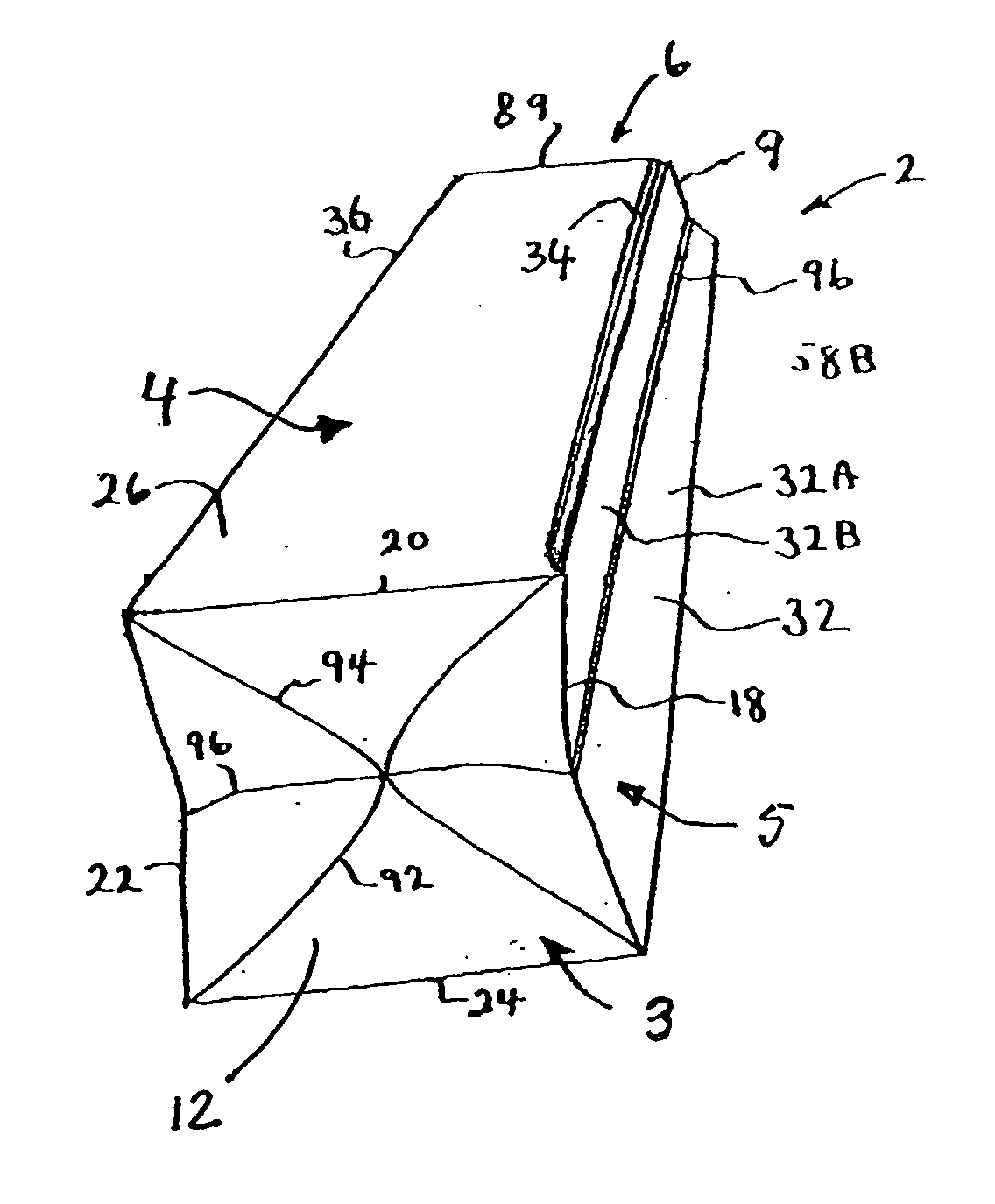

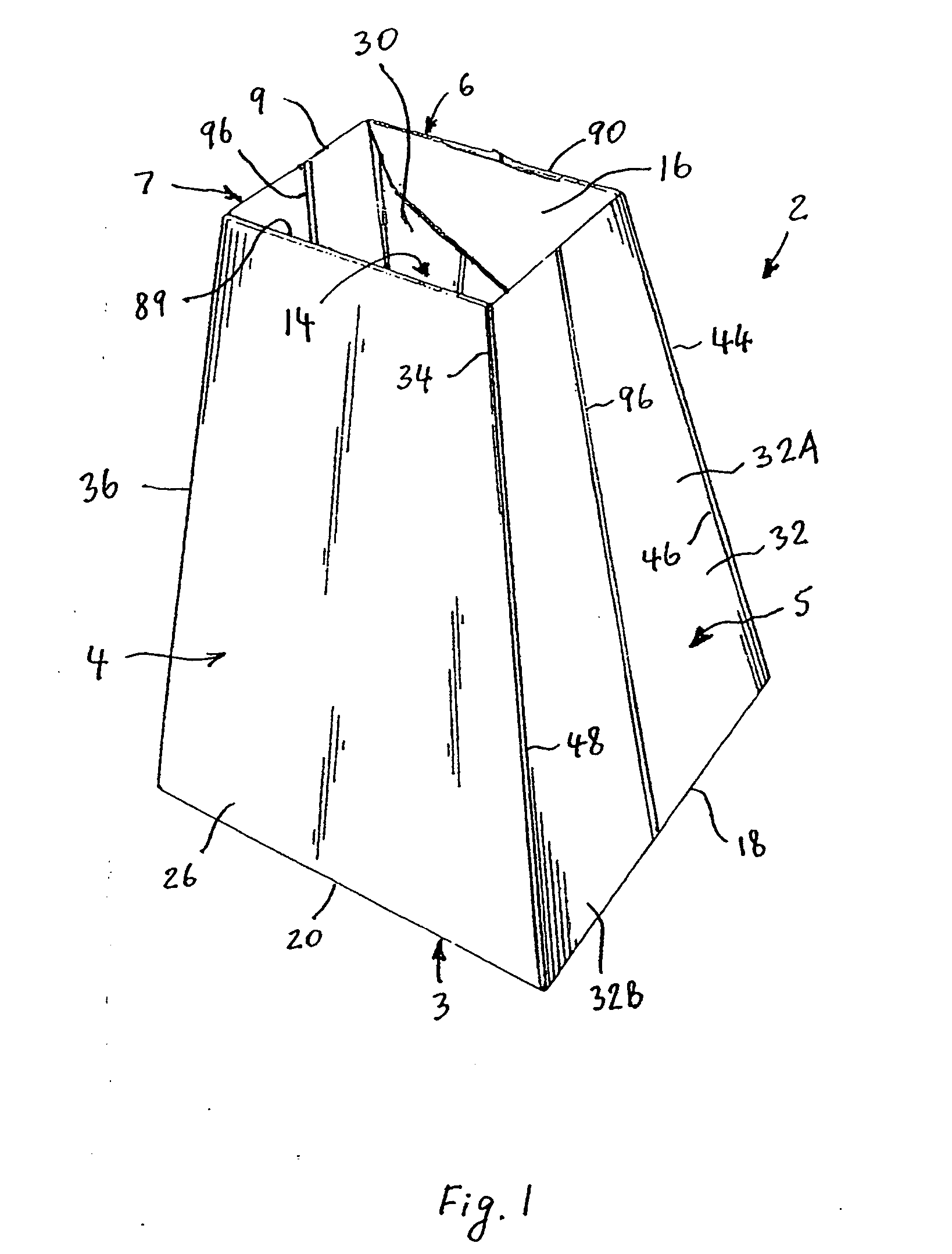

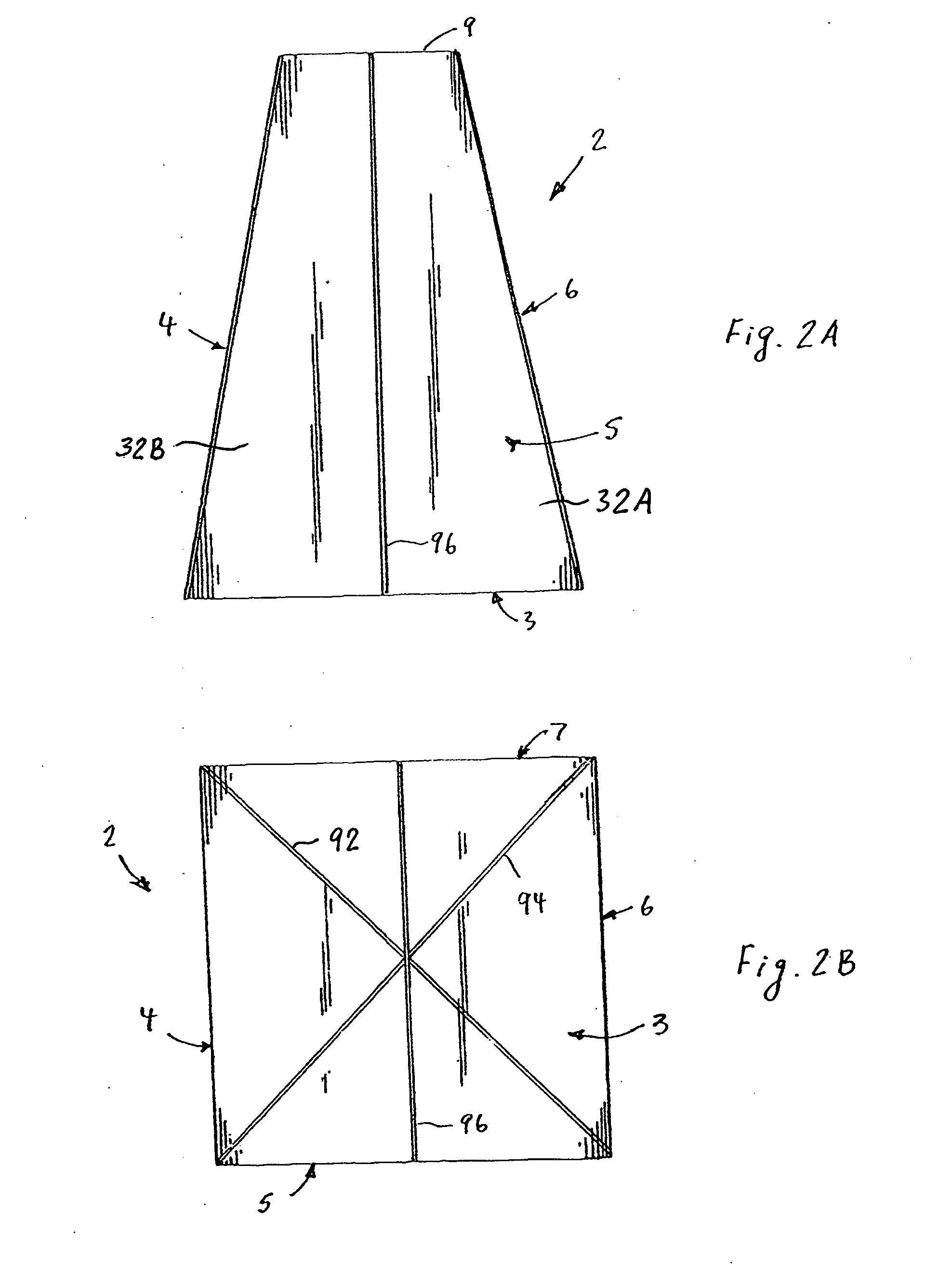

Foldable container

InactiveUS20070257093A1Easy to manufactureEasy to shipFlower vasesRigid containersDiagonalSurface plate

Owner:THE IDEA NETWORK

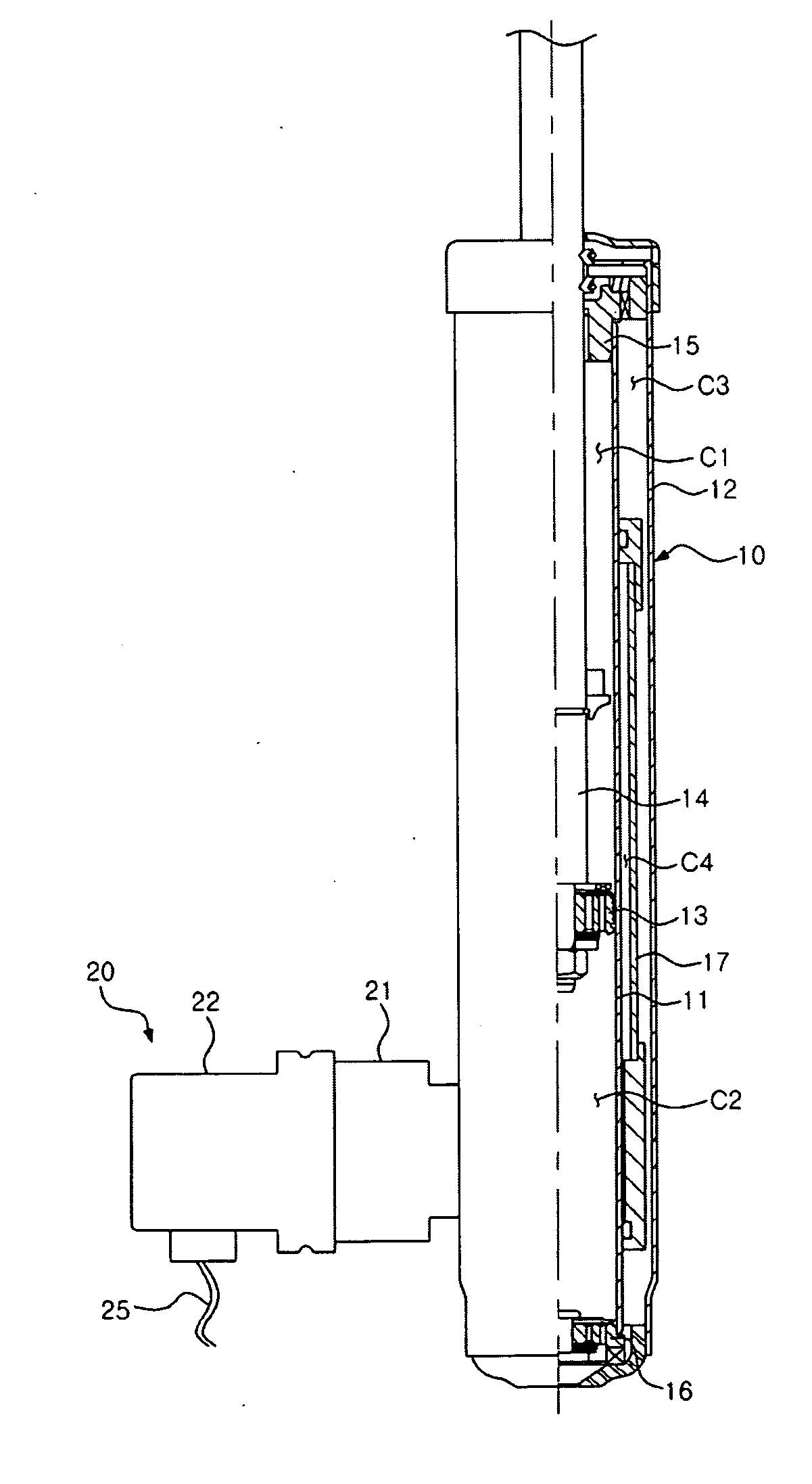

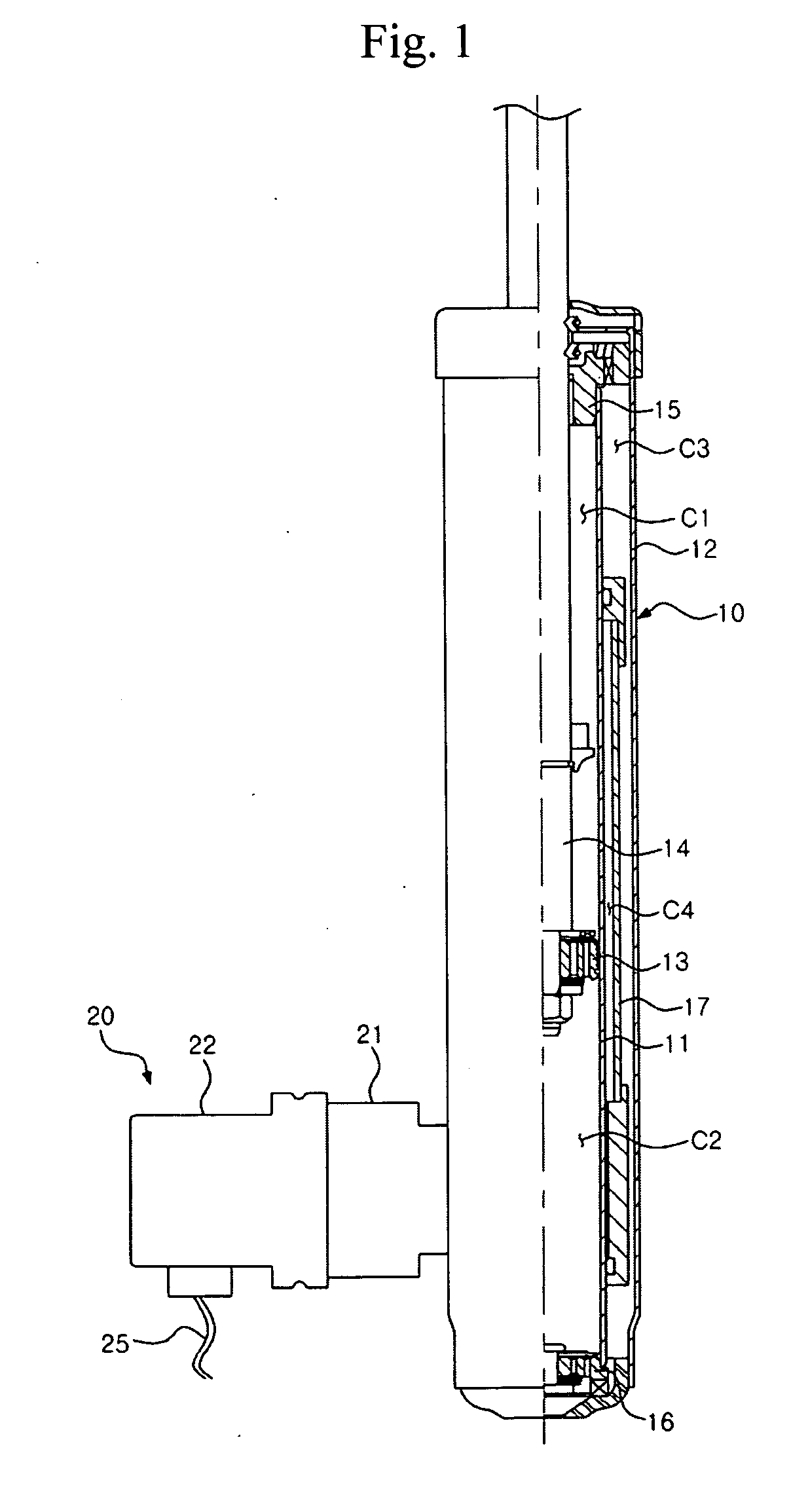

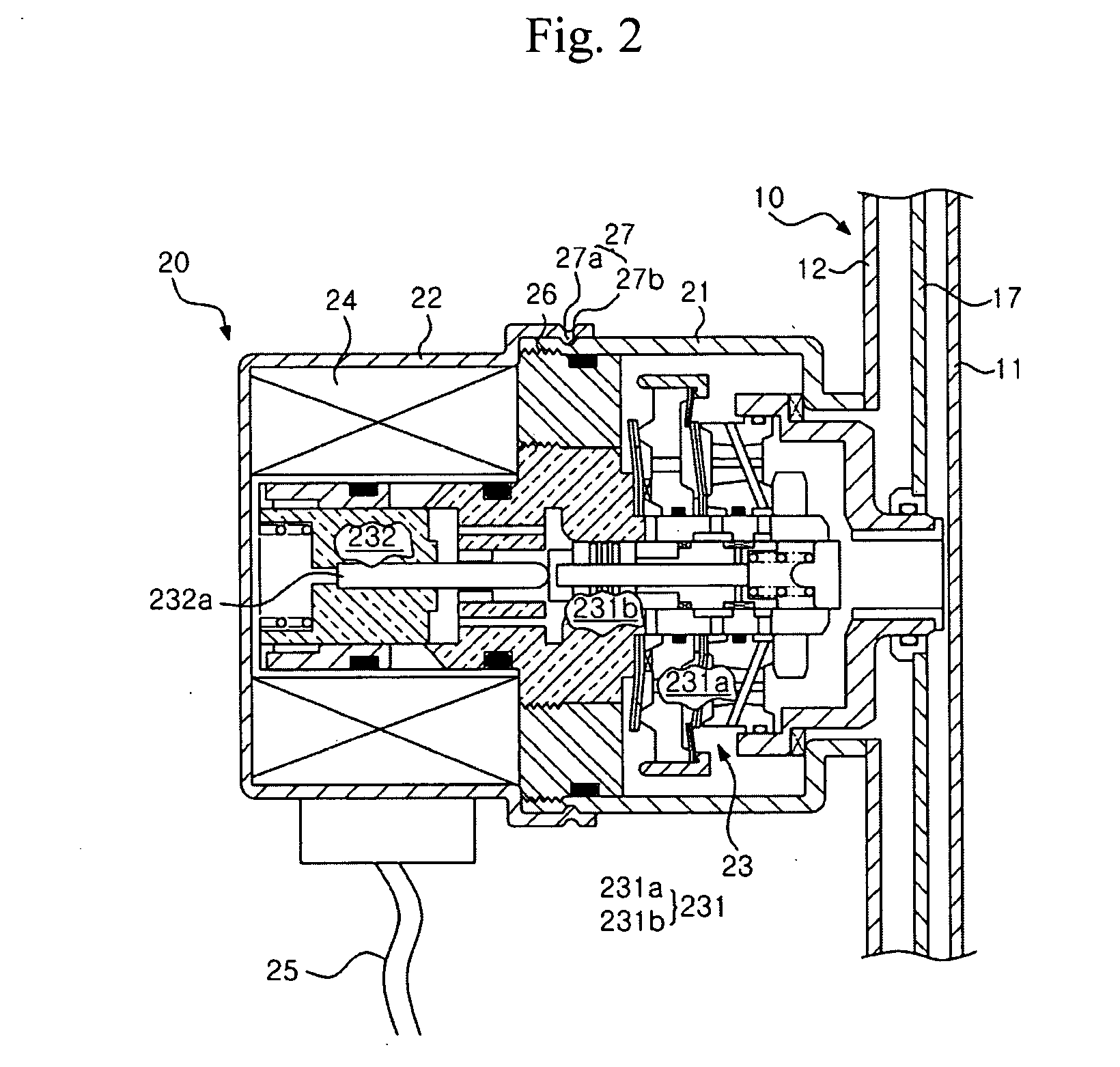

Solenoid valve assembly of variable damping force damper and method of assembling the same

InactiveUS20090200503A1Simple and inexpensive mannerEasy to fixOperating means/releasing devices for valvesSpringsBobbinSolenoid valve

A solenoid valve assembly of a variable damping force damper and a method of assembling the same are disclosed. The method includes coupling a valve housing to one side of a damper, accommodating an embedded assembly within the valve housing, the embedded assembly including a variable fluid path component and a solenoid operator, disposing a bobbin housing such that an inner circumference of the bobbin housing partially overlaps an outer circumference of the valve housing, while adjusting orientation of a power line connected to a bobbin accommodated in the bobbin housing, and fastening the bobbin housing to the valve housing, with the orientation of the power line adjusted.

Owner:HL MANDO CORP

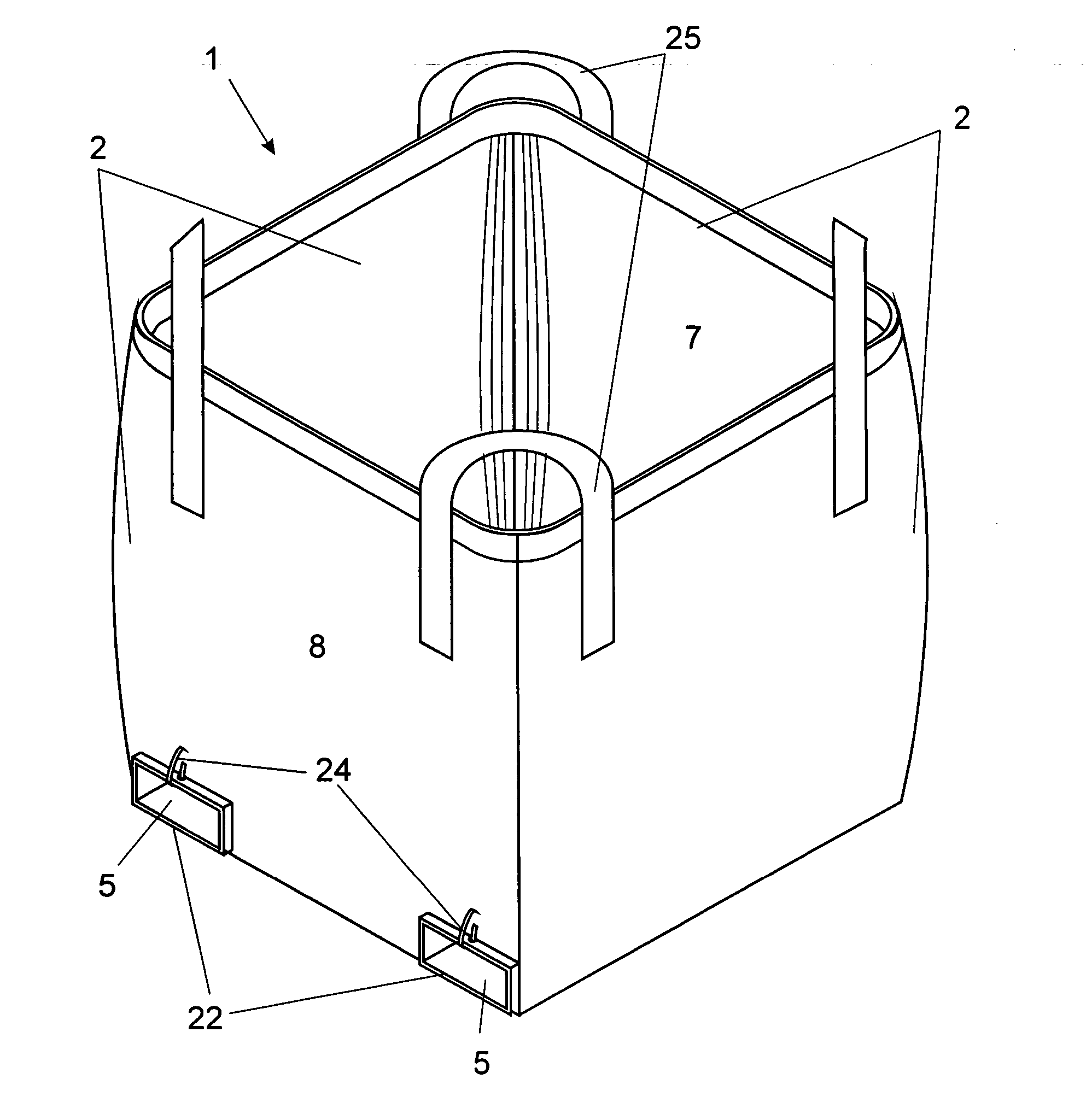

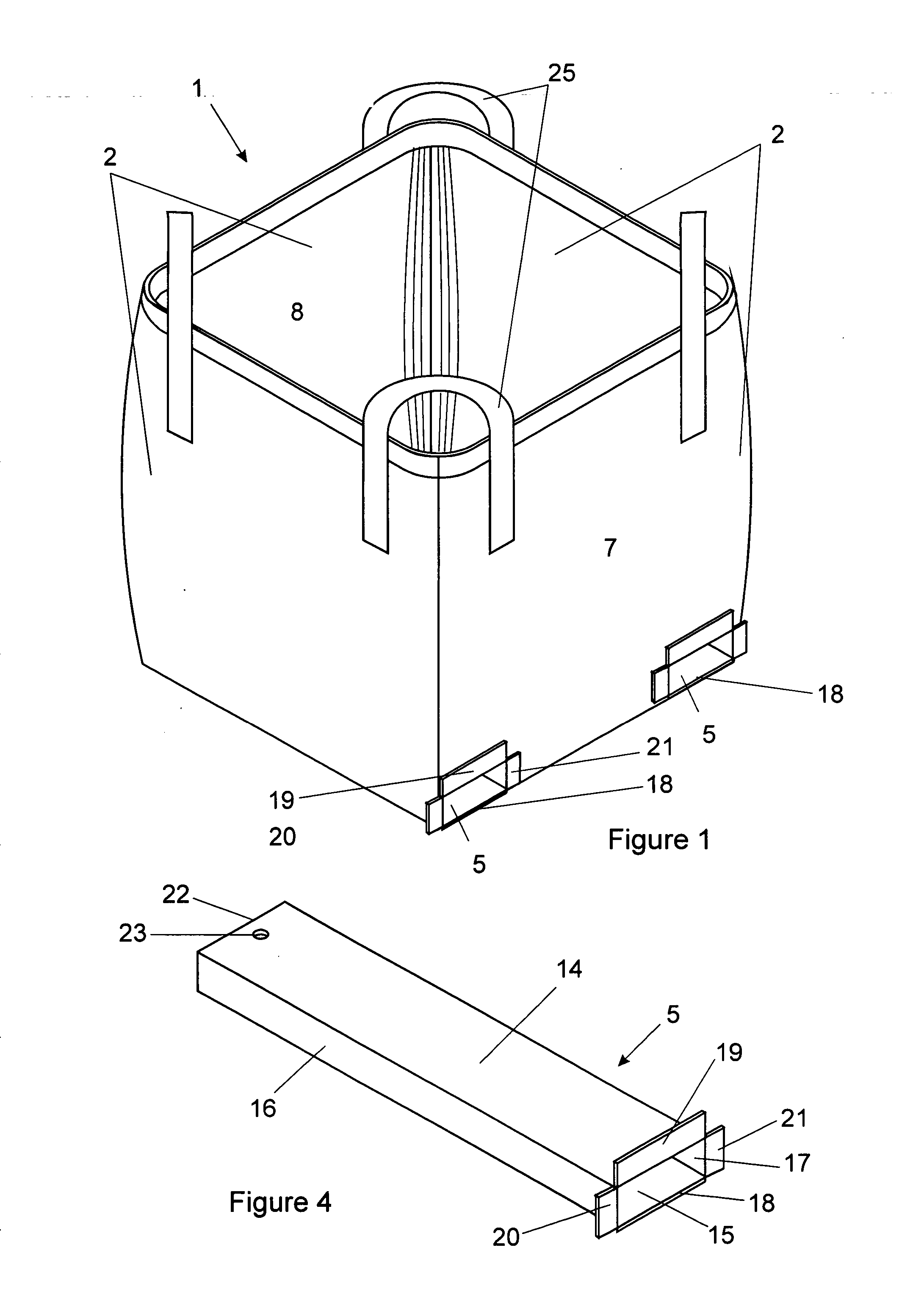

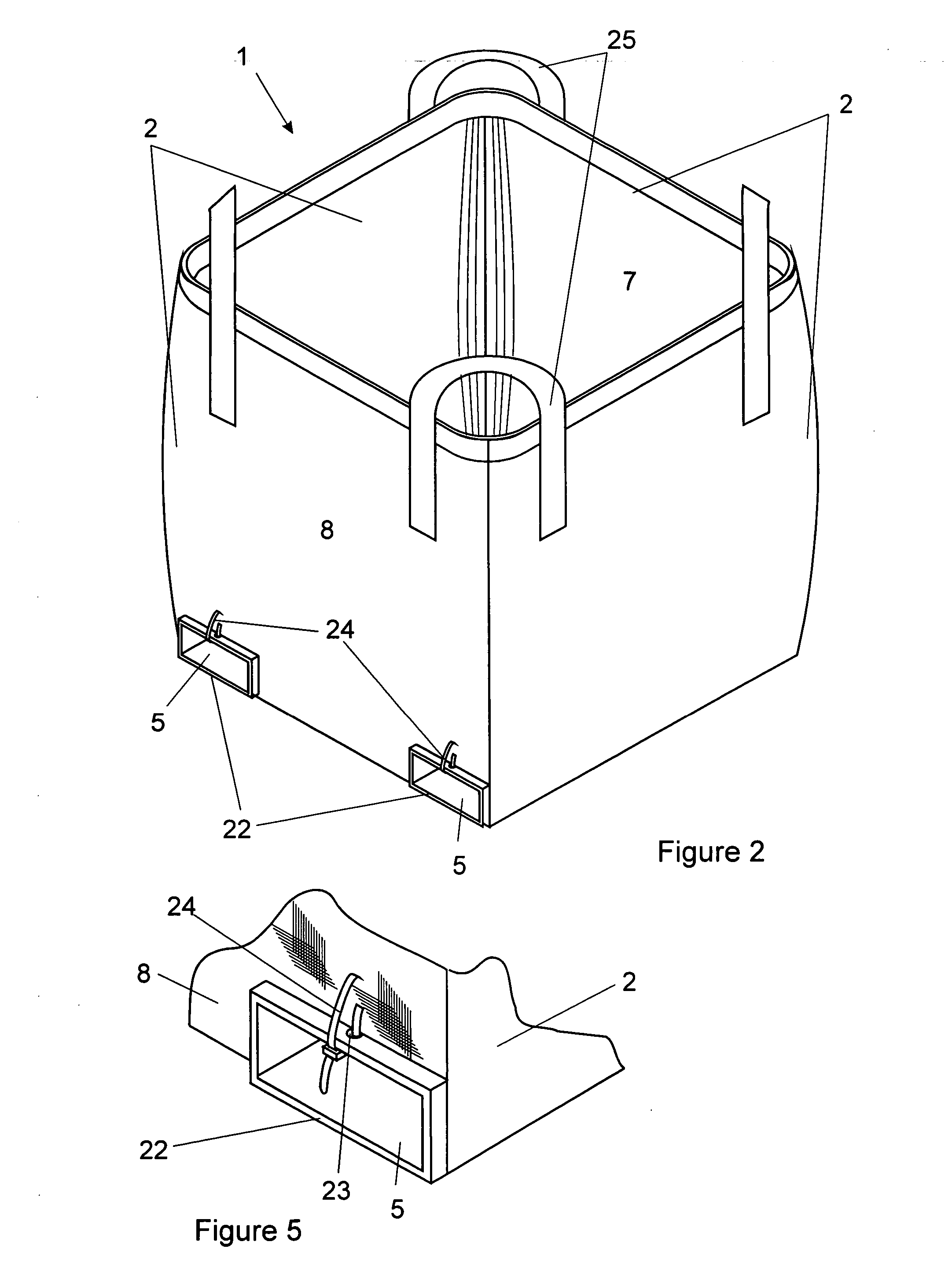

Bulk bag

ActiveUS20040159565A1Simple to produceSimple and inexpensive mannerBagsLarge containersEngineeringPlastic materials

A bulk bag having side walls; and a bottom wallis provided wherein a pair of laterally spaced generally flexible sleeves are associated with the bottom wall with each sleeve operatively receiving a generally rigid tubular element adapted to receive a tine of a forklift truck, in use. Each tubular element preferably has, at one end thereof, outwardly directed flange formations for preventing movement of the said end into the sleeve, in use, and means at the other end for inhibiting movement of said other end into the sleeve, in use. The tubular element is preferably made to a generally rectangular cross-sectional configuration from a flat sheet of material bent along the corners to define said tubular element. The flat sheet of material is preferably an extruded sheet of plastics material having a series of integral spaced parallel webs or ribs of material strengthening the sheet in which case bends defining the corners of said generally rectangular cross-sectional configuration extend at substantially right angles to the length of said webs or ribs.

Owner:TELLAP

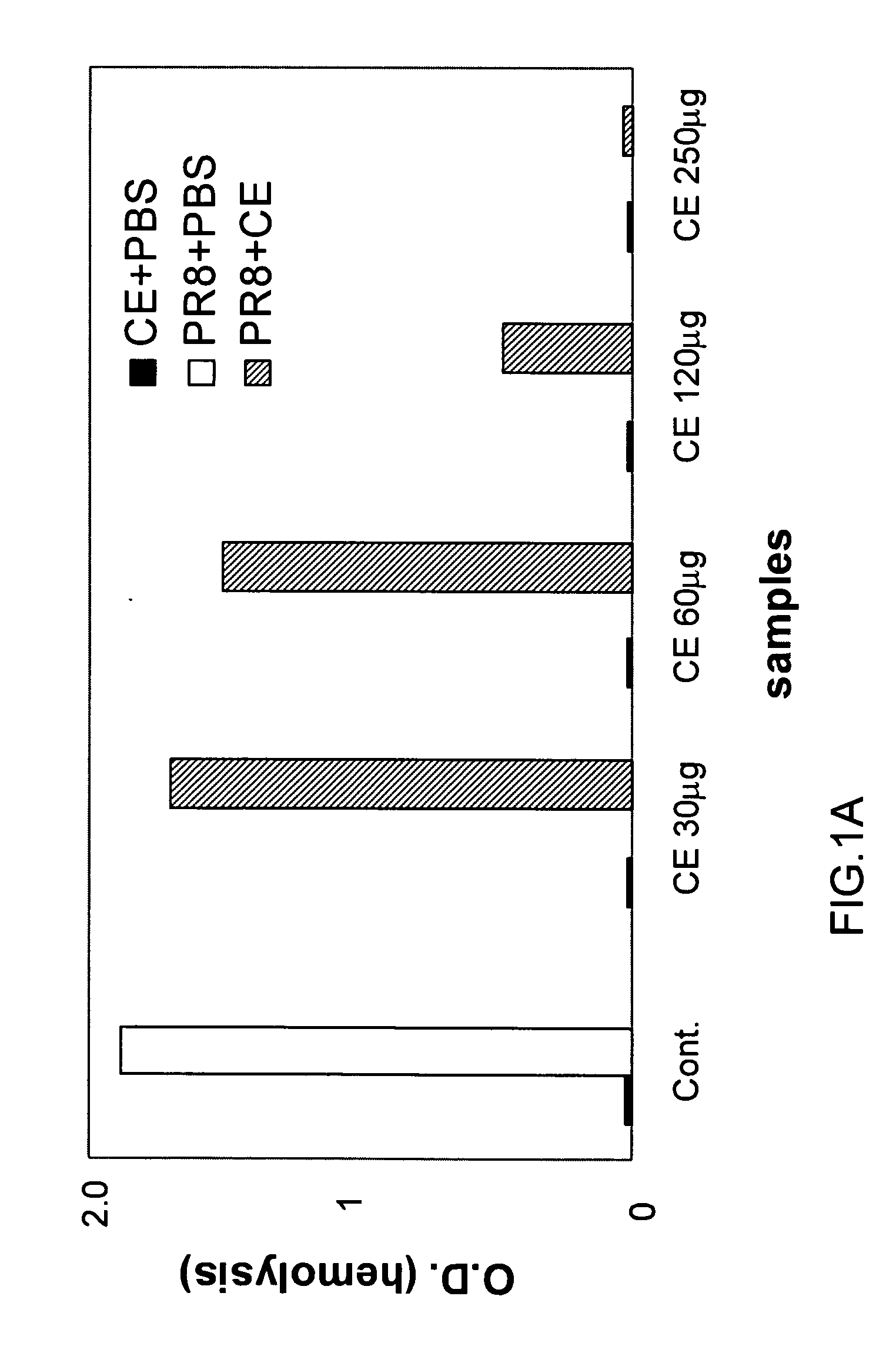

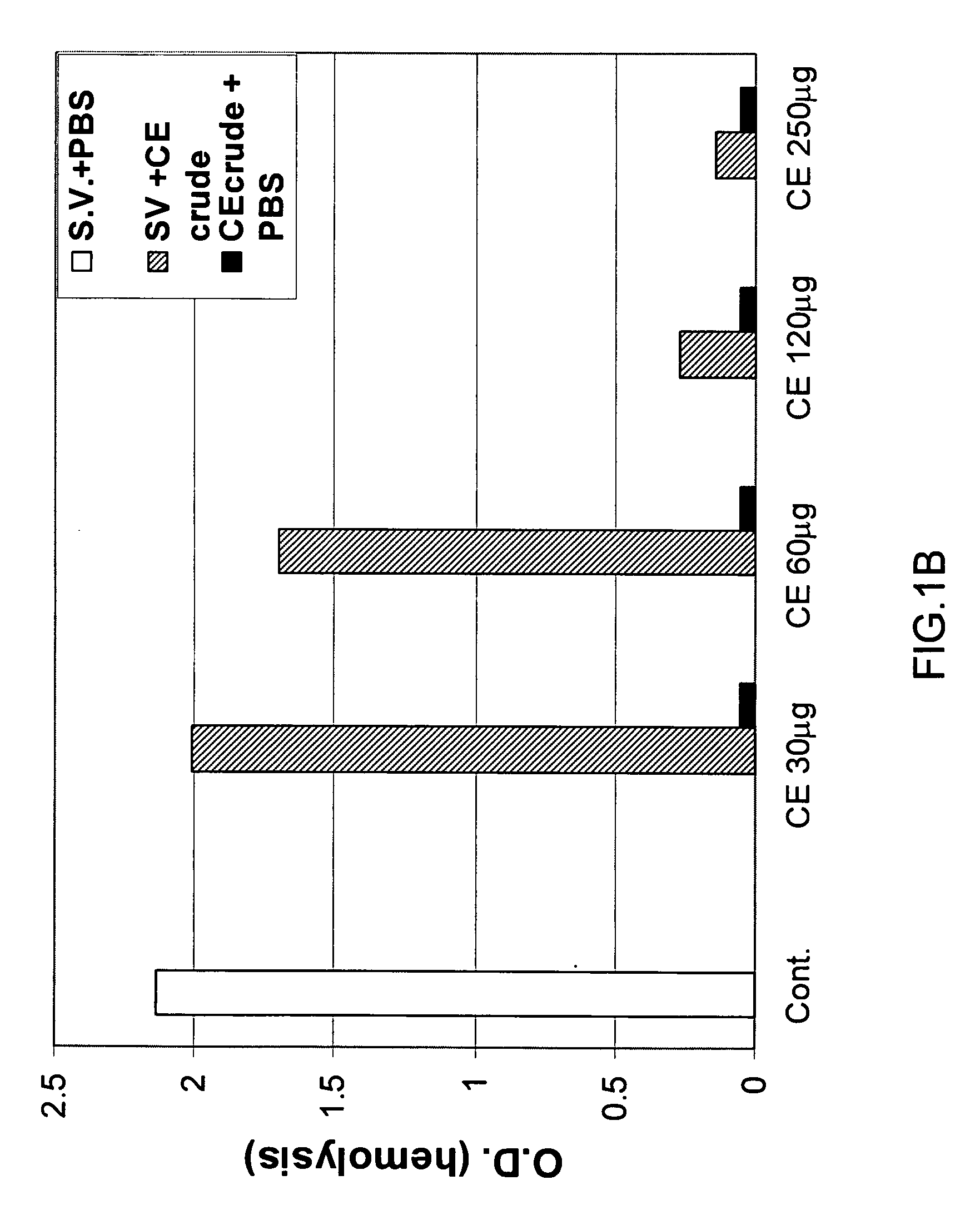

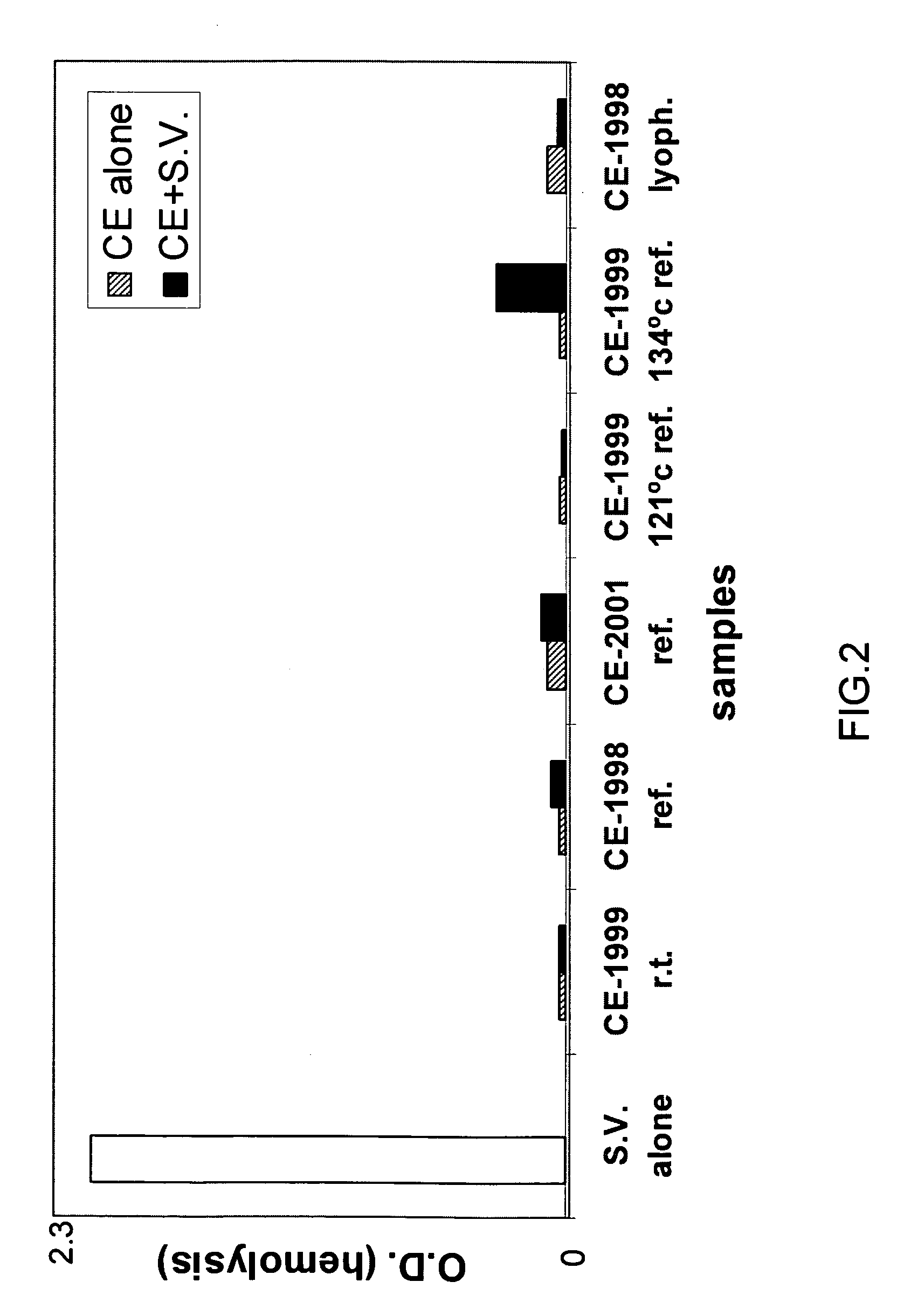

Antiviral preparations obtained from a natural cinnamon extract

The present application provides a natural aqueous extract obtainable from a cinnamon bark (Cinnamon sp.) which has antiviral activity against enveloped viruses including influenza A, Parainfluenza (Sendai) virus and HSV-1 viruses, as well as in vivo activity in inhibition of Influenza A and Parainfluenza viruses. The present application also concerns a method for the extraction of said cinnamon extract and applications thereof.

Owner:RAMOT AT TEL AVIV UNIV LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com