Patents

Literature

139results about "Gas solvent extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes and apparatus for extraction of active substances and enriched extracts from natural products

InactiveUS20040147767A1Reduce the temperatureAvoid expensive laggingBiocideOrganic chemistryNatural productChemistry

Processes for preparing extracts of natural products such as plant material, and for preparing purified extracts from crude extracts of natural products, by extraction with hot gas. Apparatus suitable for use in preparing extracts of natural products are also described.

Owner:GW PHARMA LTD

Method and apparatus for extracting botanical oils

ActiveUS10159908B2Fast and effective and inexpensiveHigh purityEssential-oils/perfumesEvaporationProcess engineeringSolvent

Owner:NATURAL EXTRACTION SYST LLC

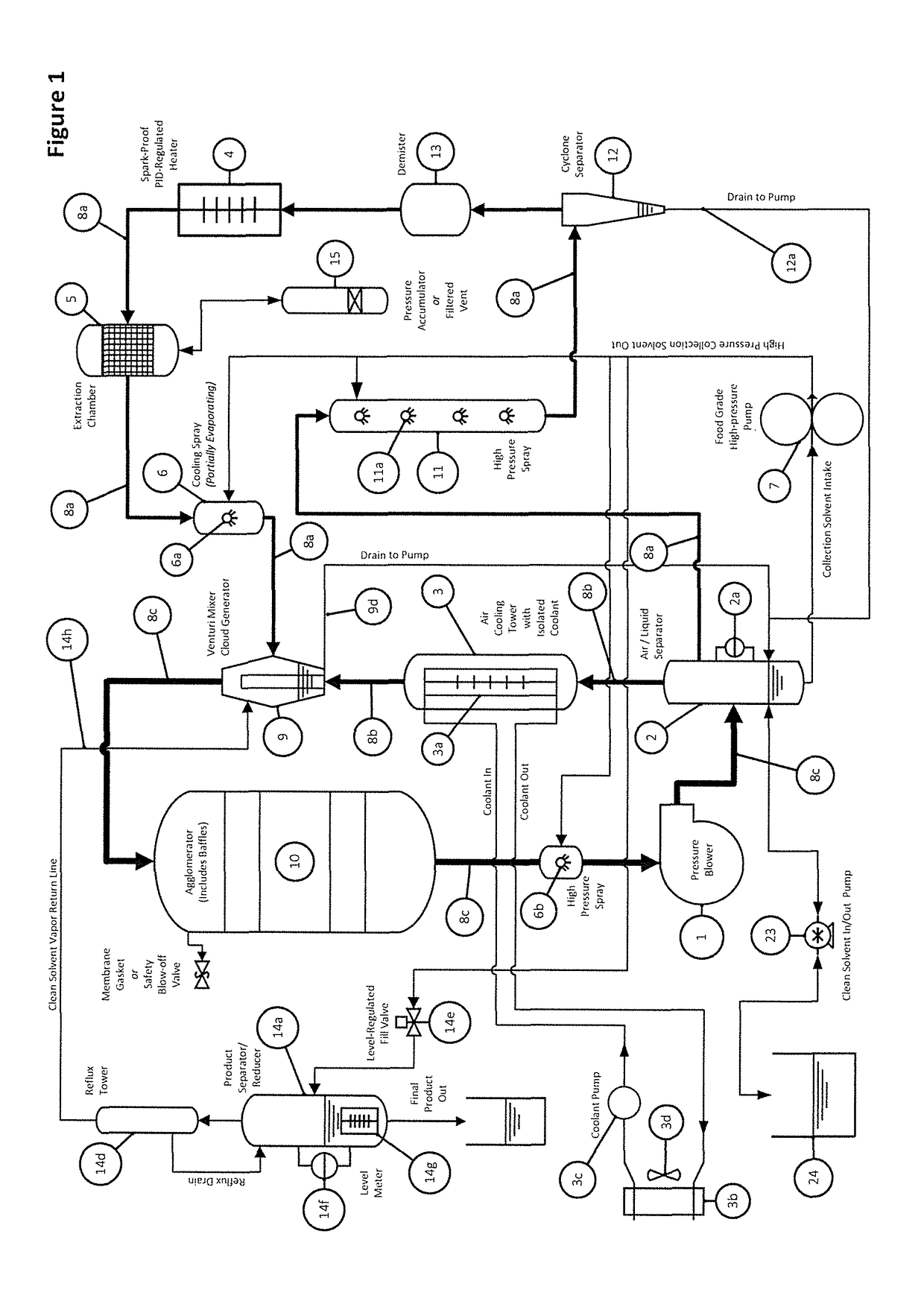

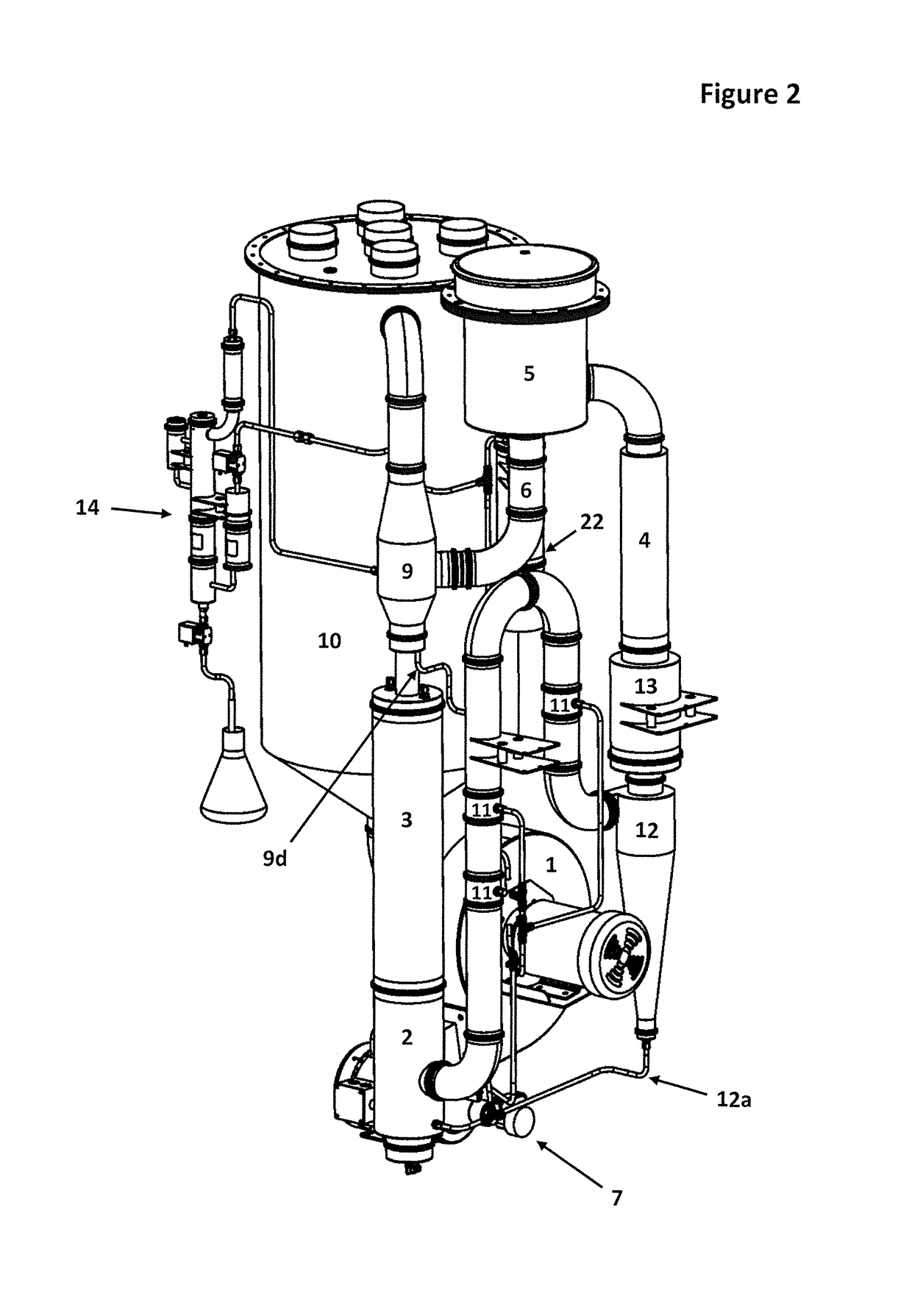

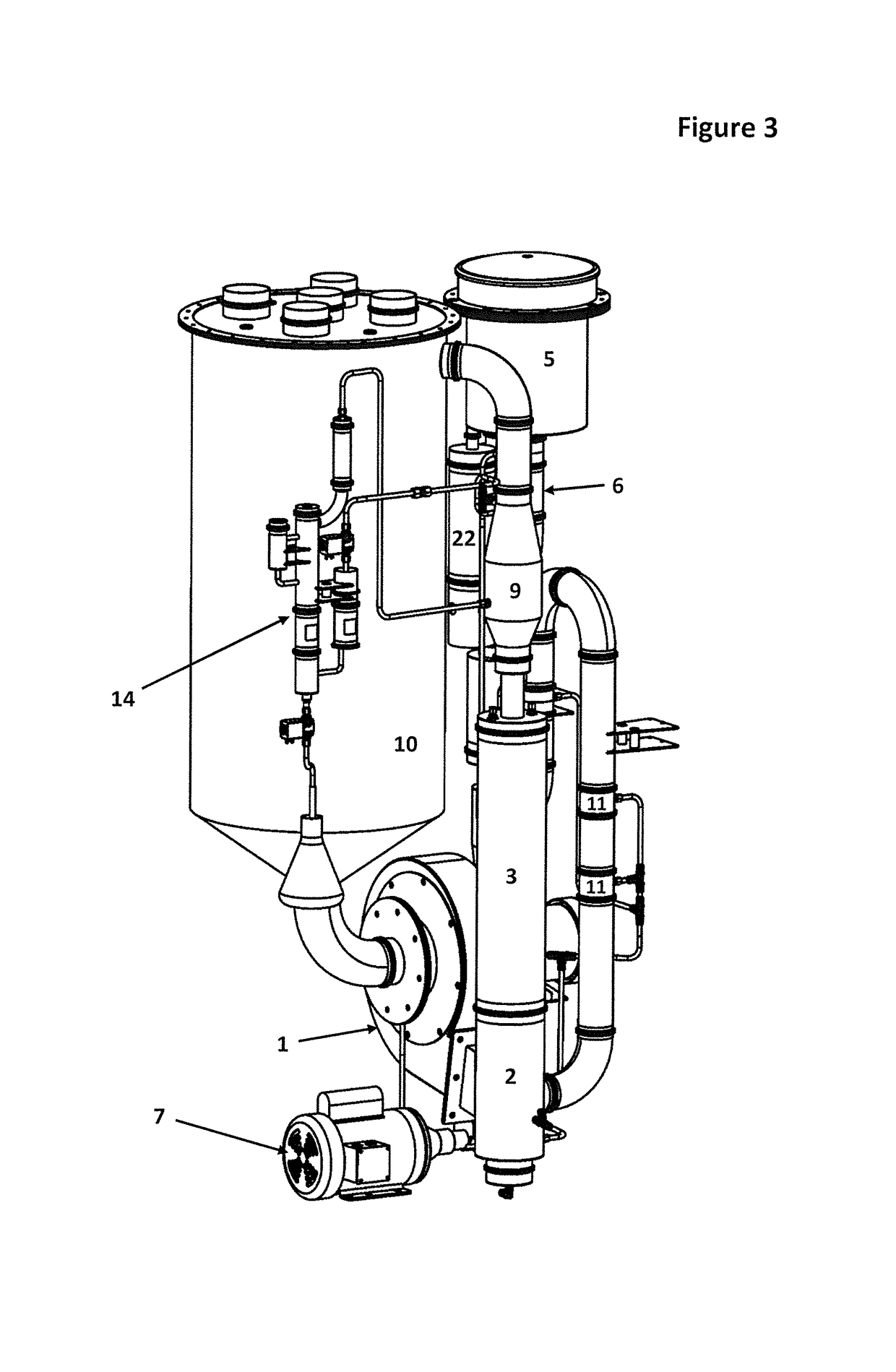

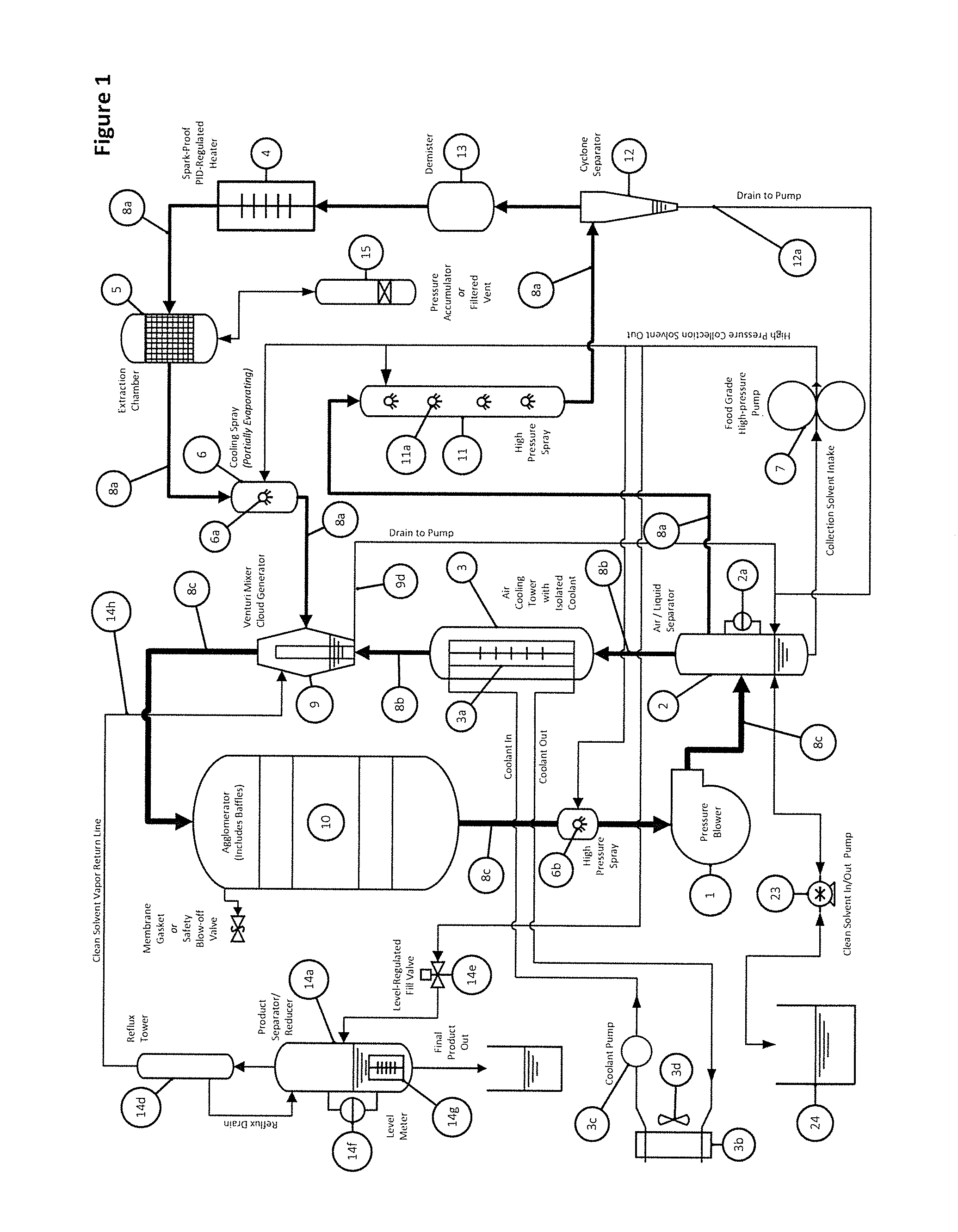

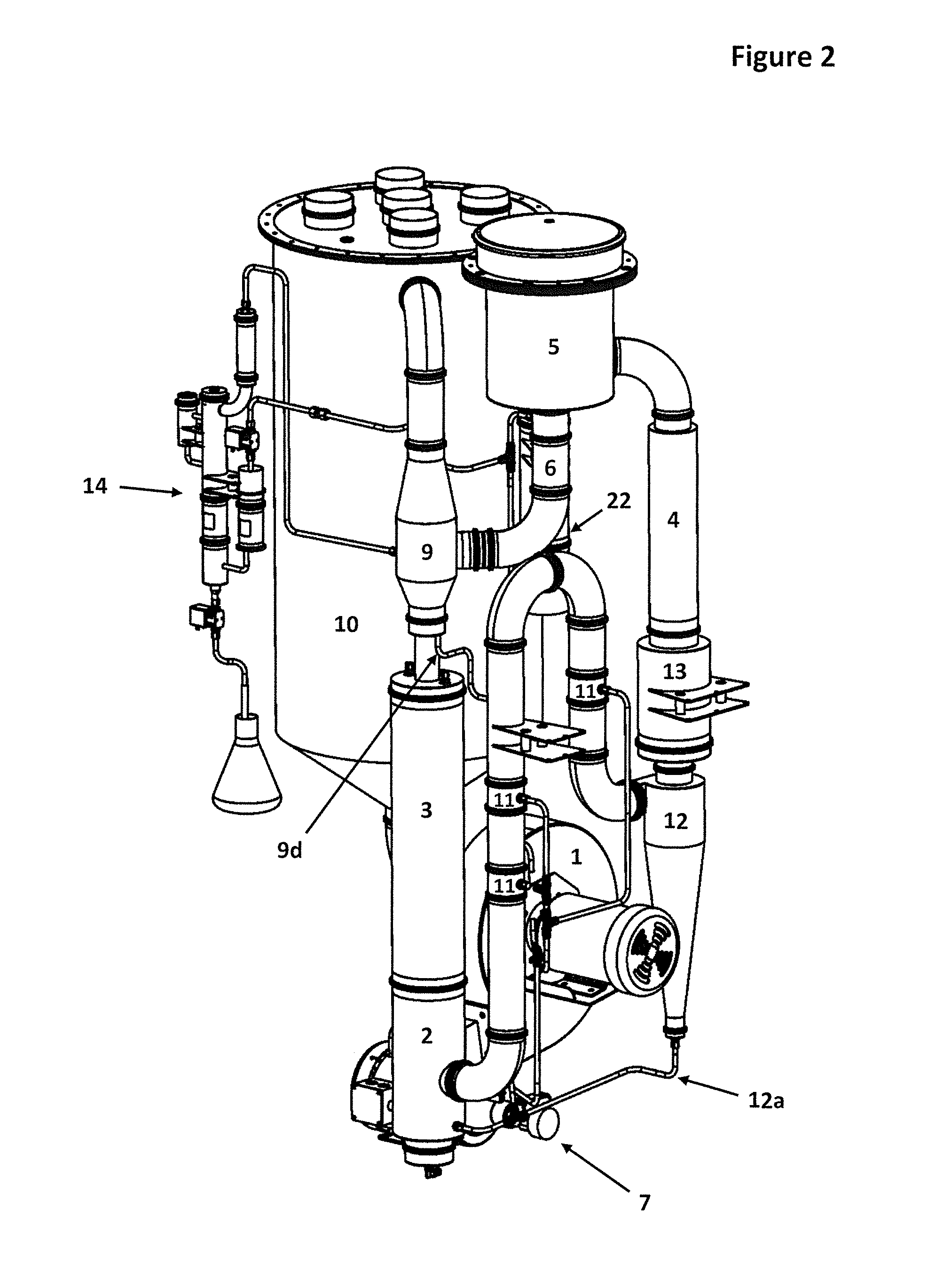

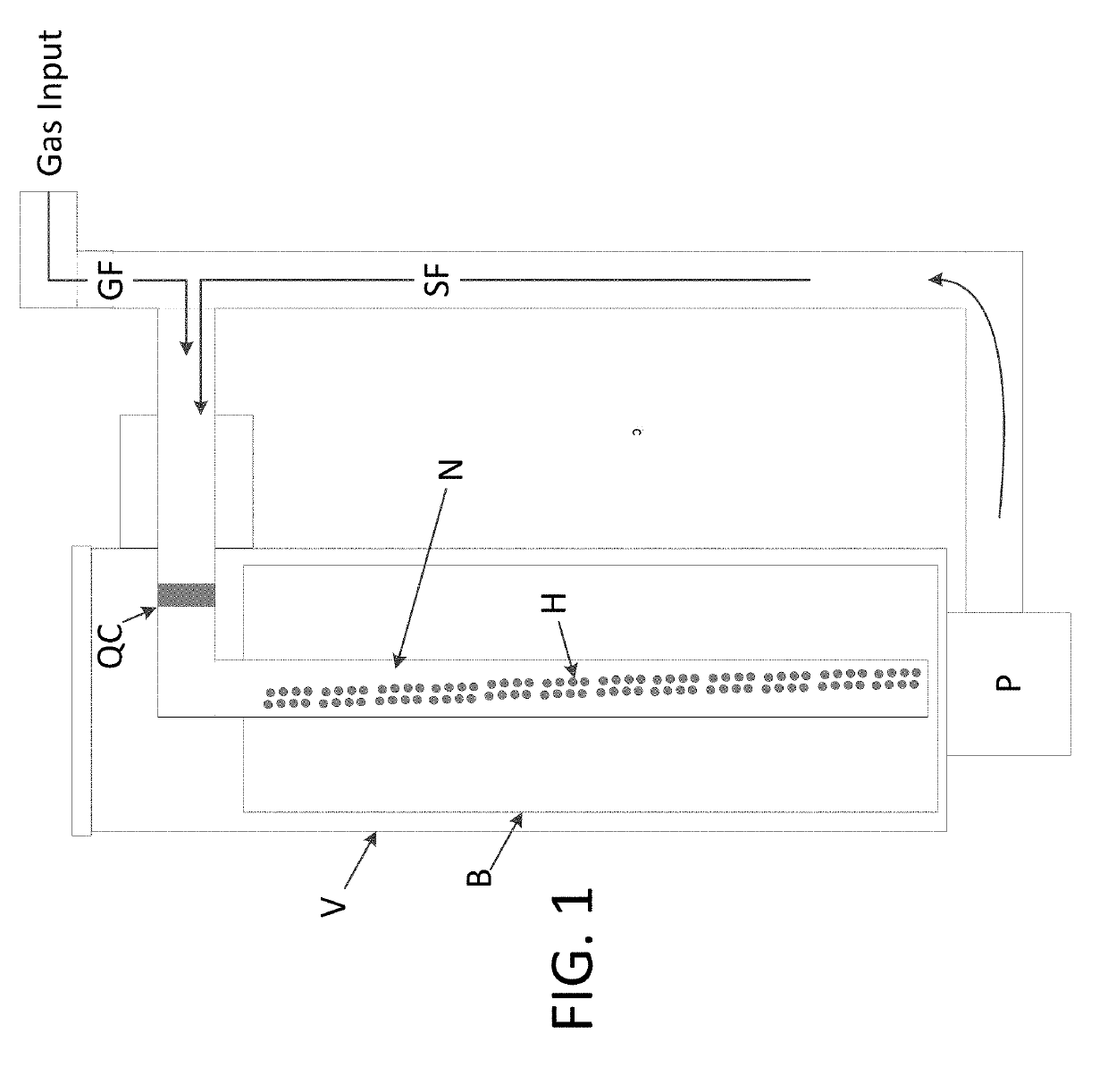

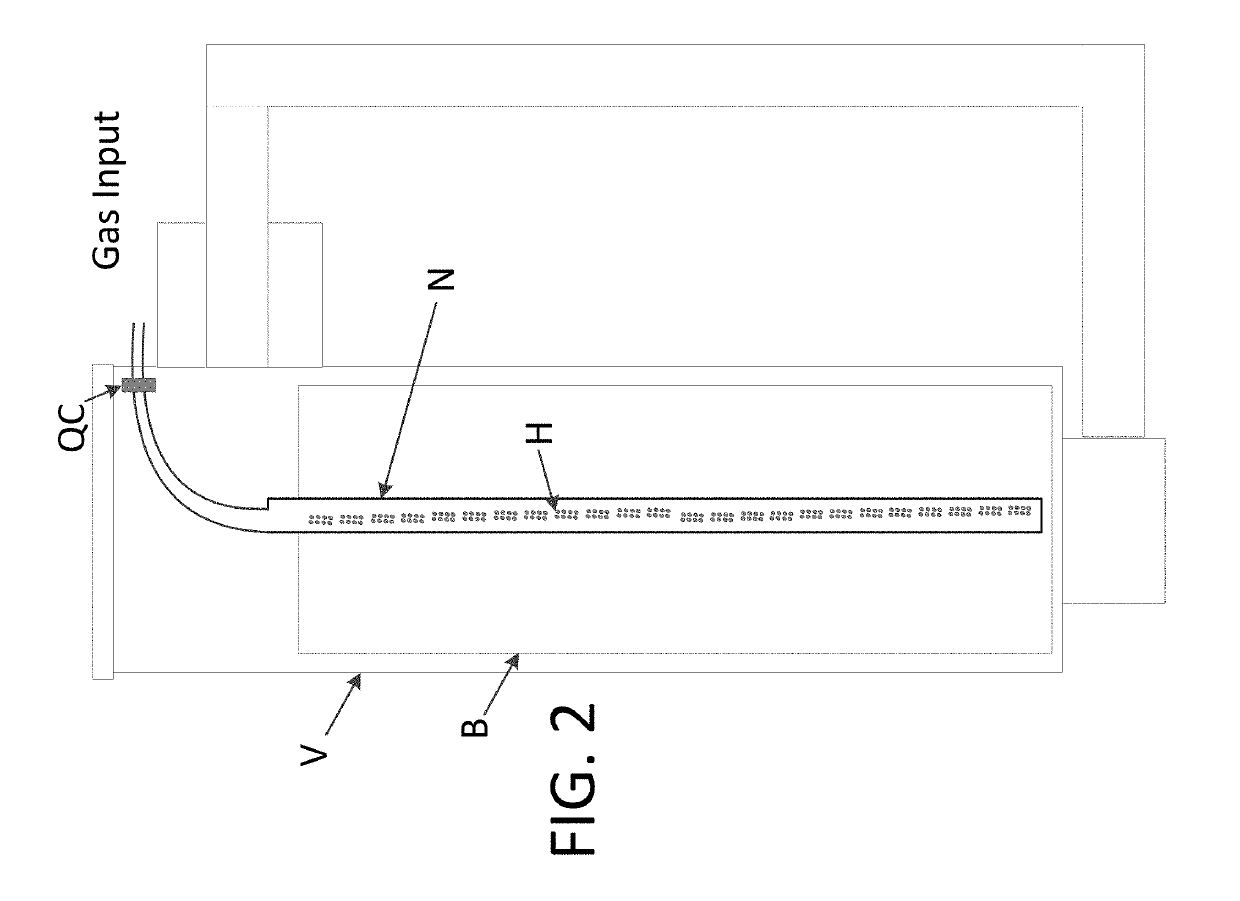

Method and apparatus for extracting botanical oils

ActiveUS20160250564A1Safe cosmetic useSafe human consumptionEssential-oils/perfumesEvaporationProcess engineeringSolvent

An apparatus for extracting an oil from plant material includes an extraction chamber for plant material. The plant material is exposed to a heated gas stream with a temperature sufficient to volatilize on oil from the plant material. The gas stream is rapidly cooled to liquefy the oil into entrained droplets. The oil is collected with a collection solvent.

Owner:NATURAL EXTRACTION SYST LLC

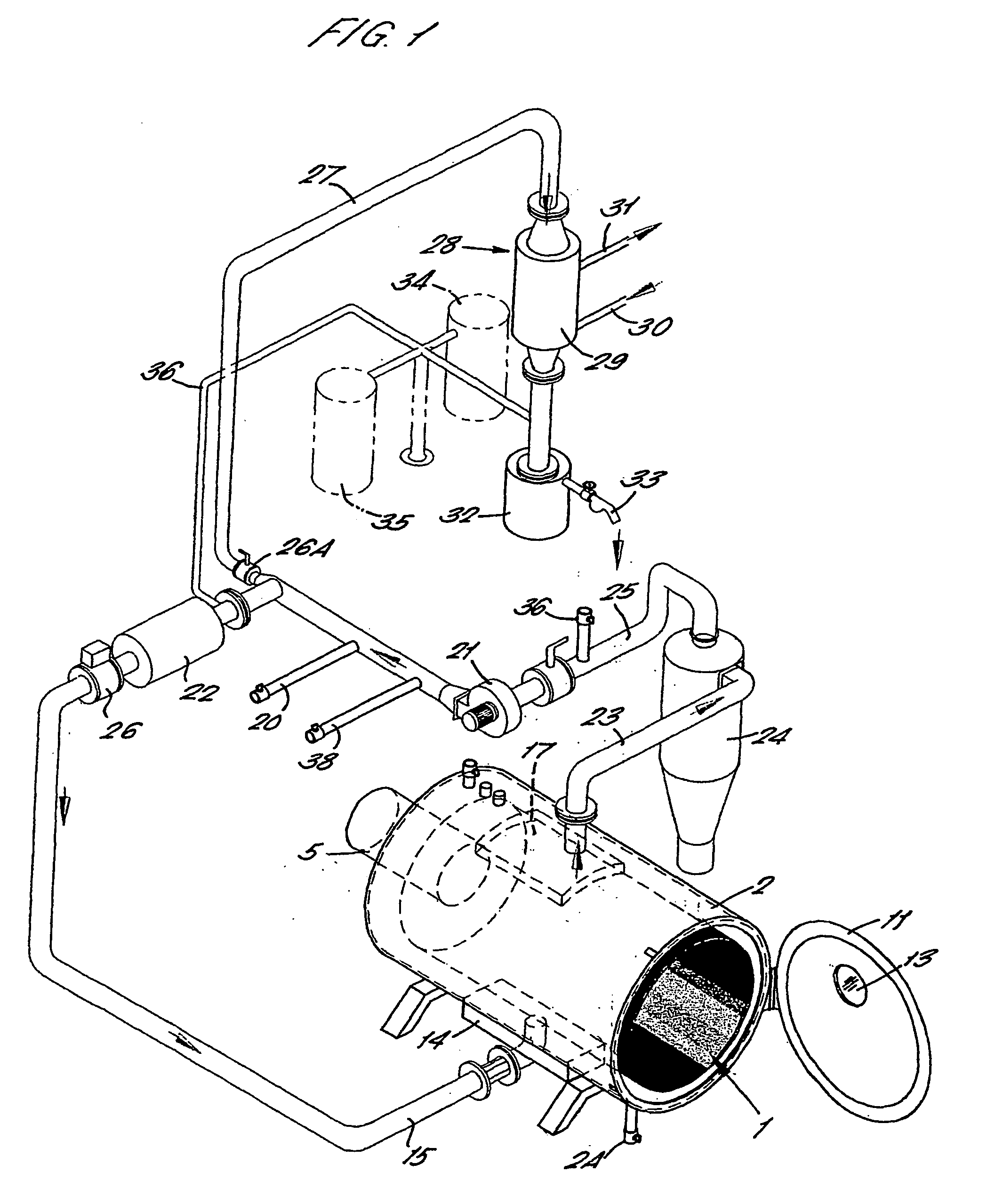

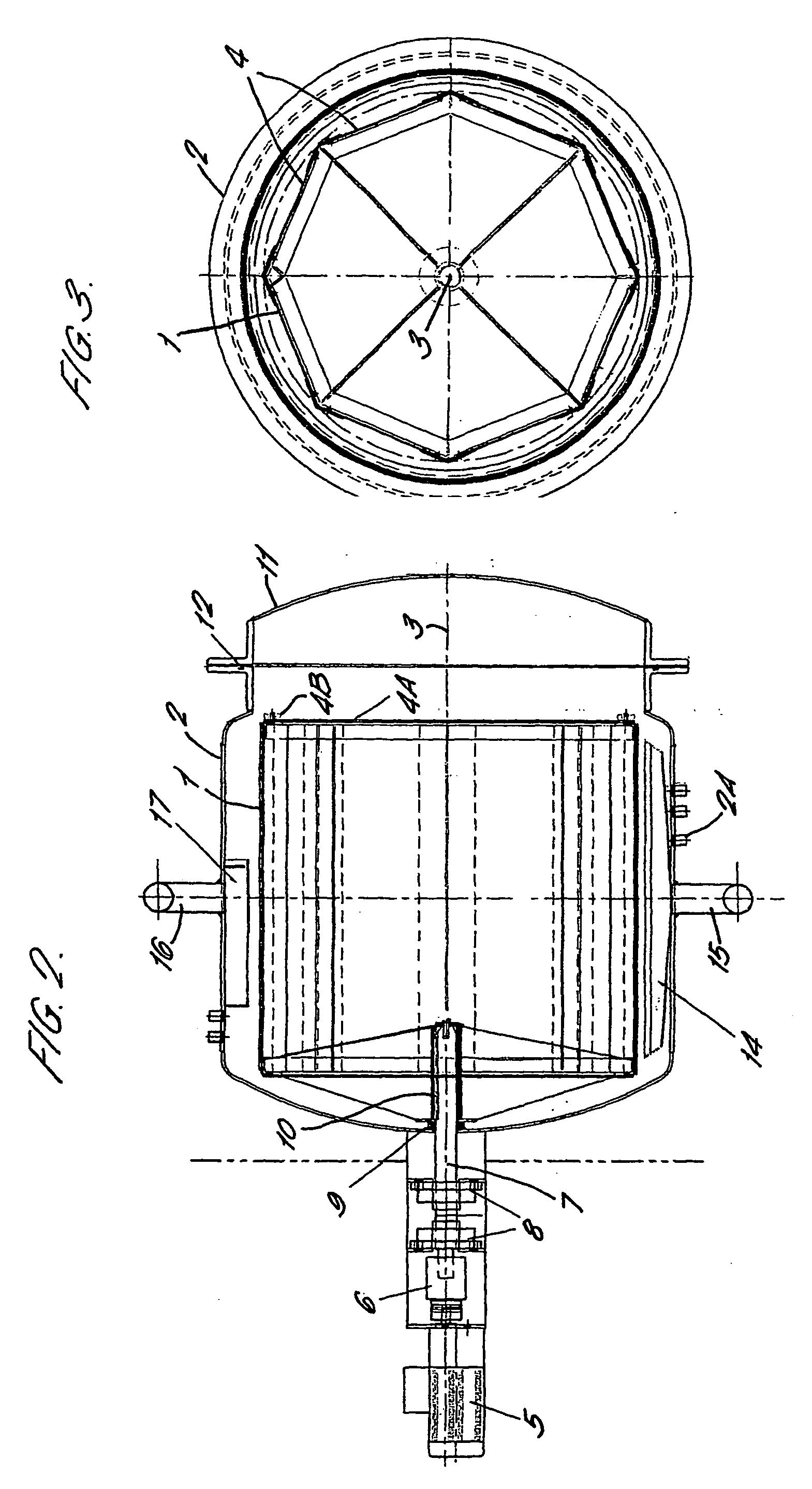

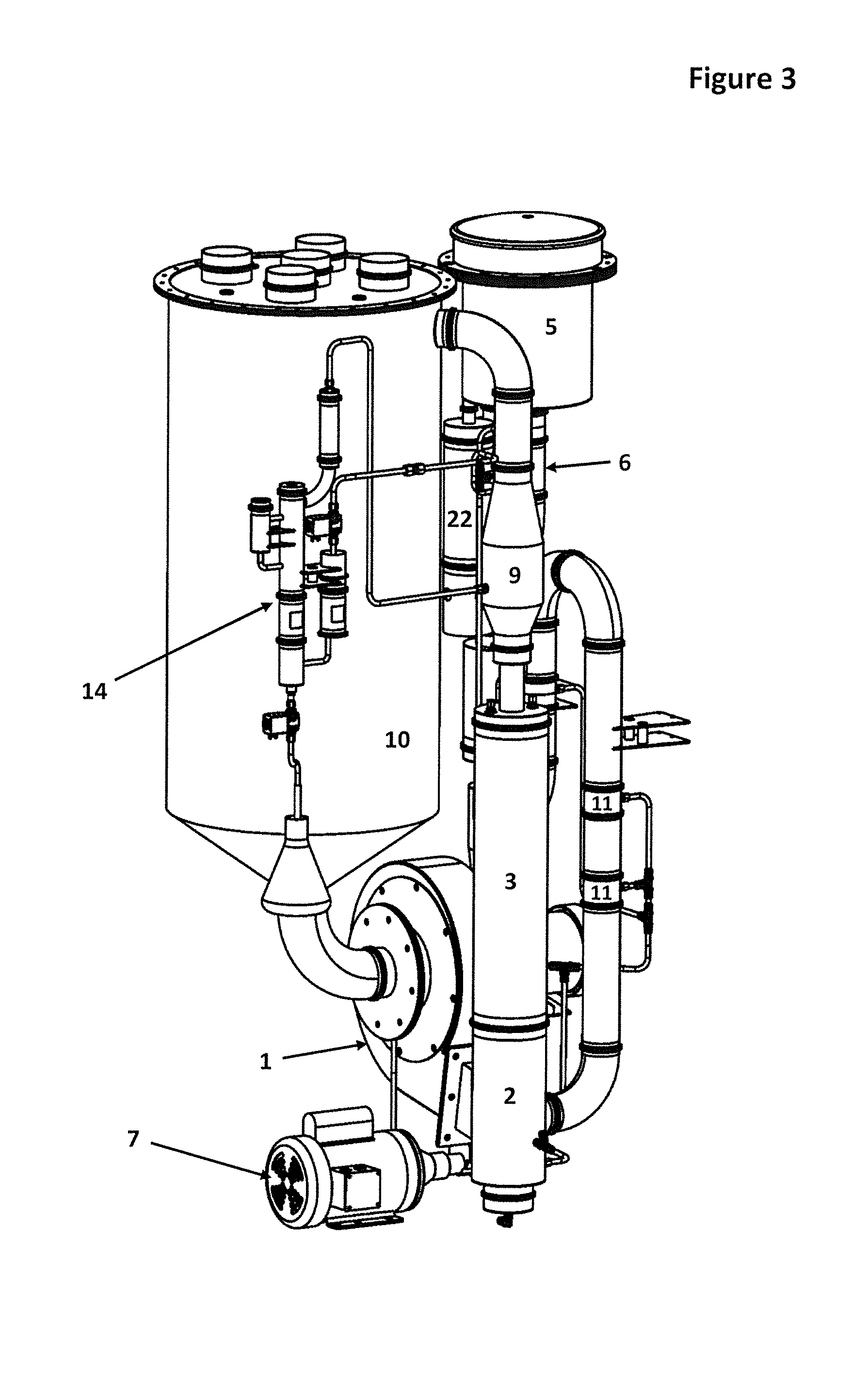

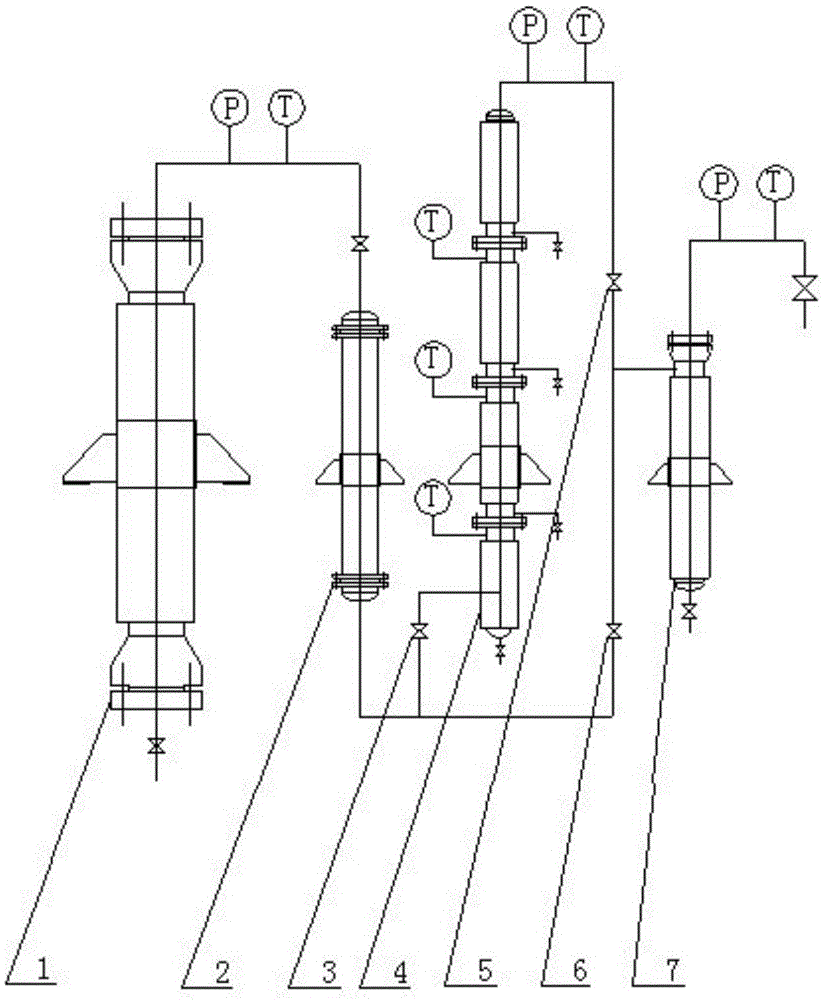

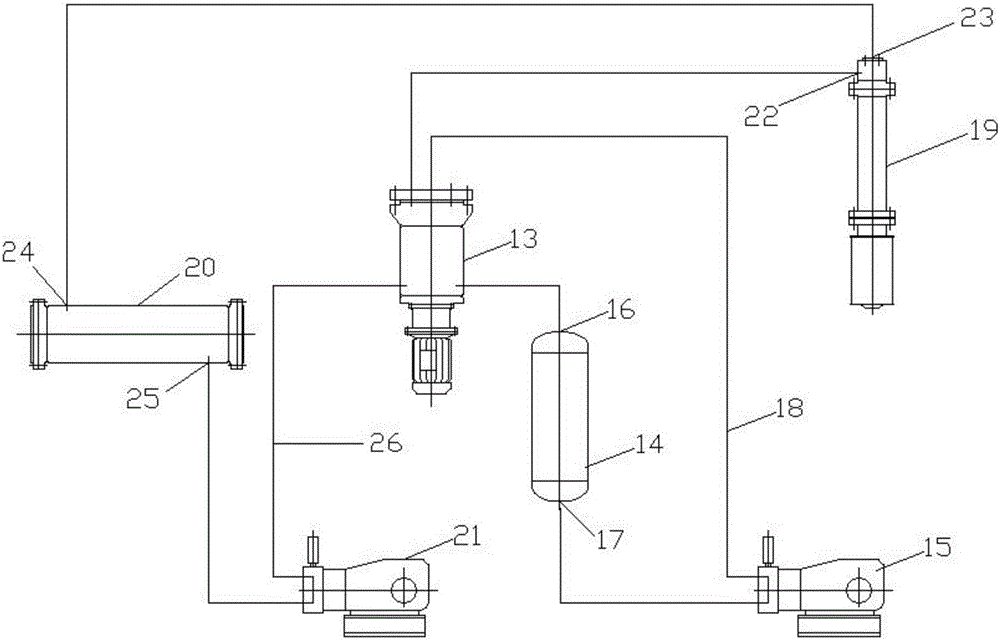

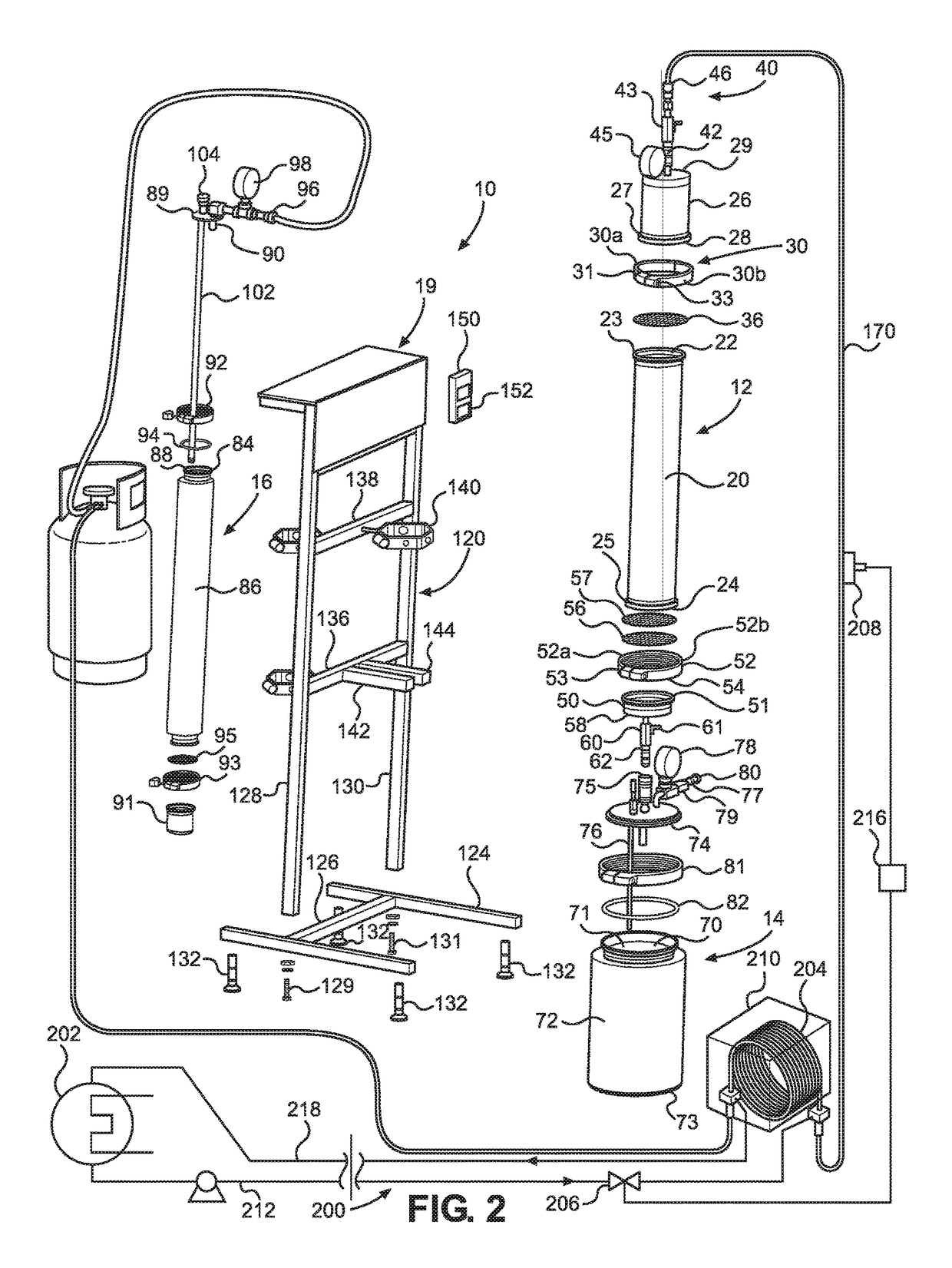

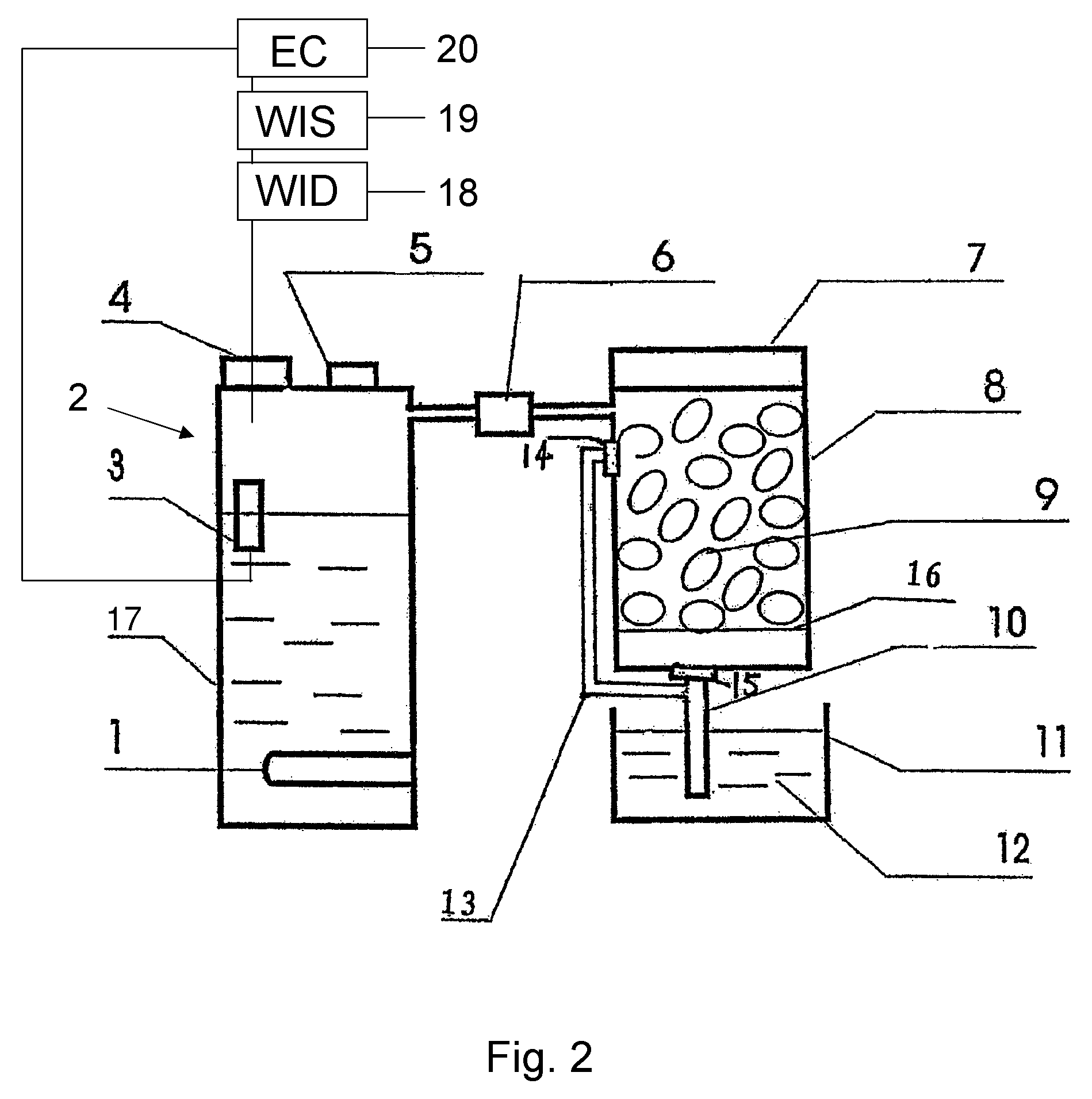

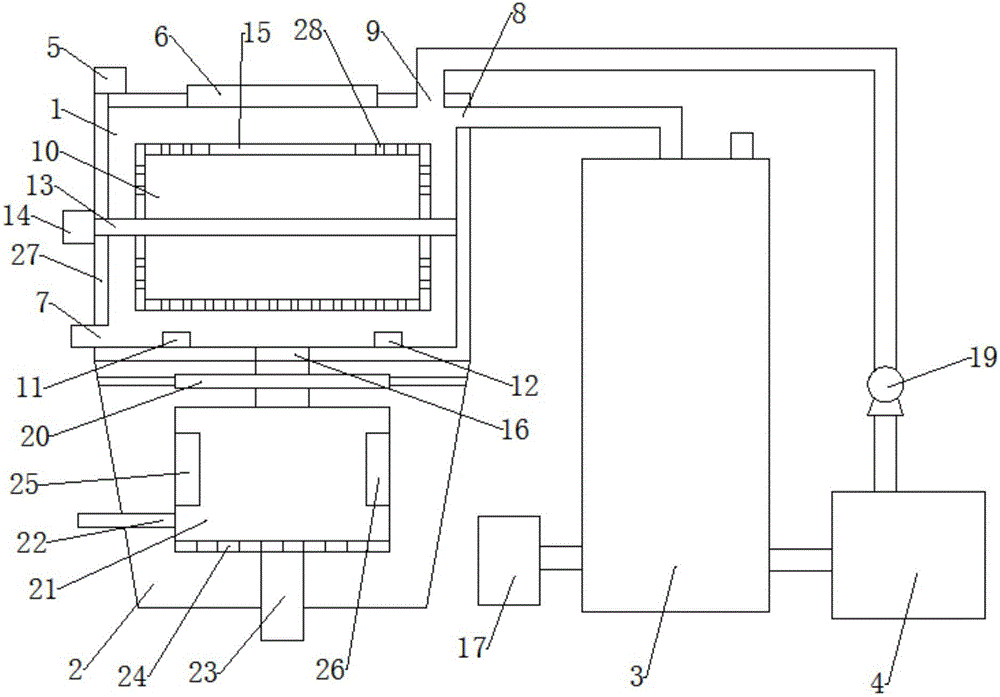

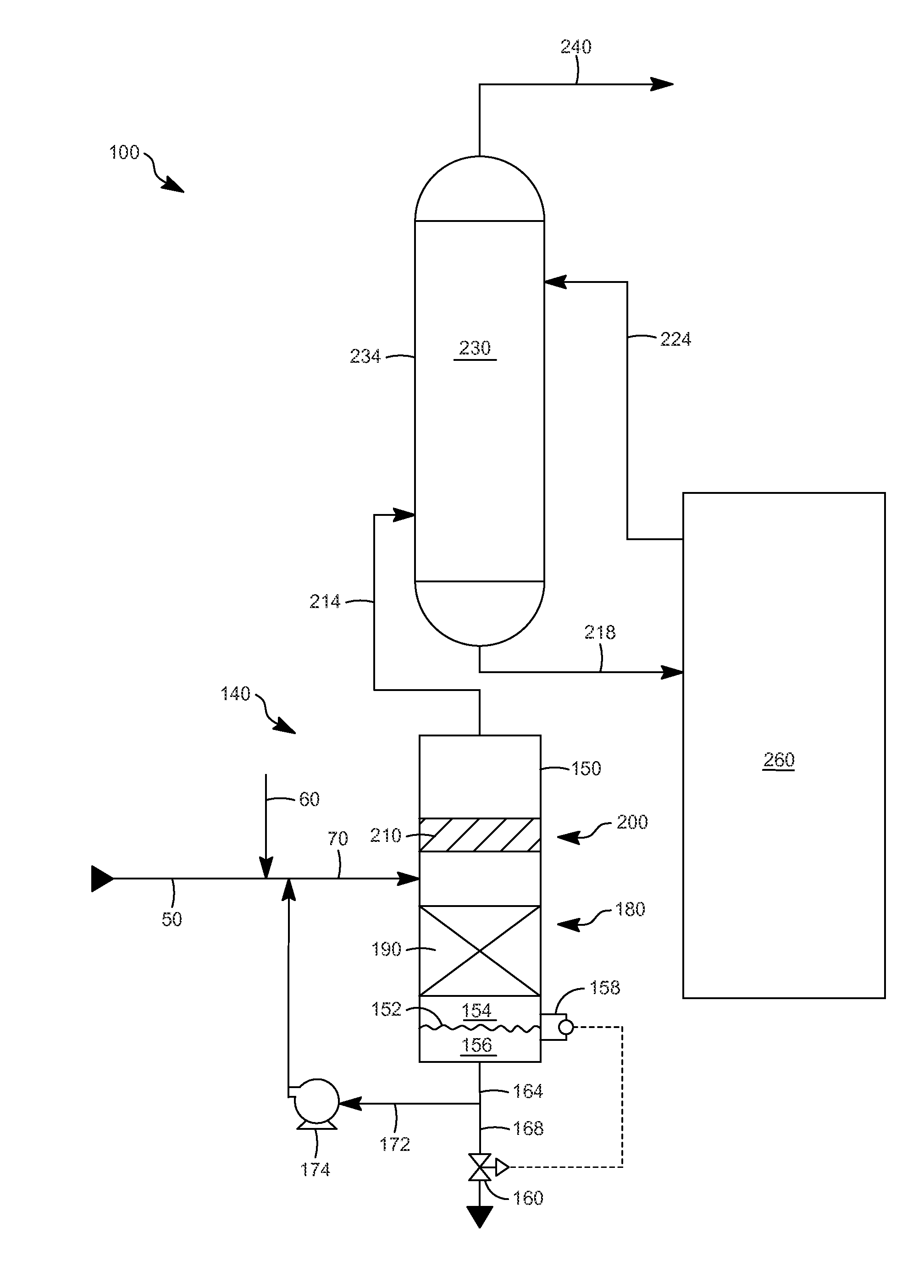

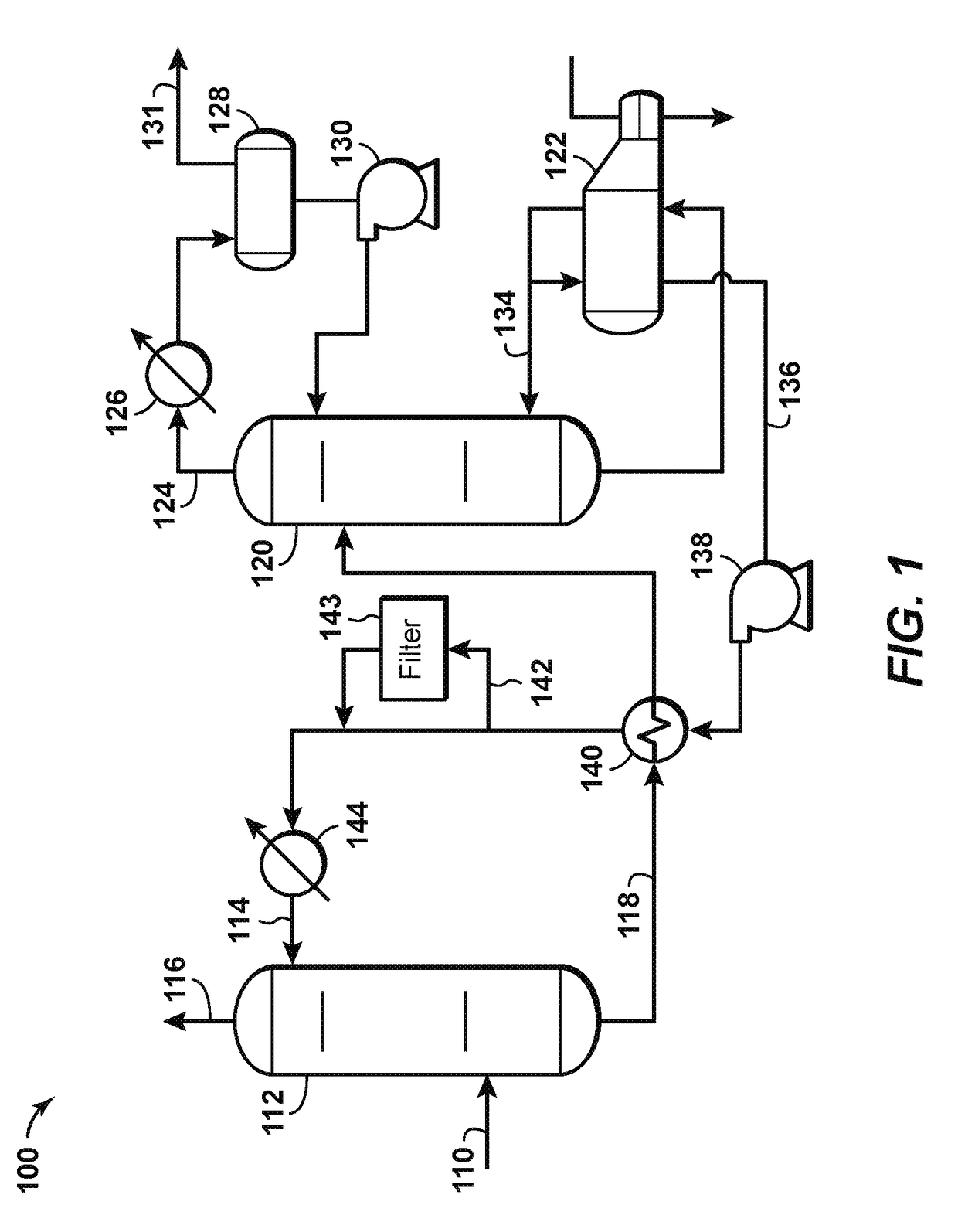

Apparatus for extracting oil from oil-bearing plants

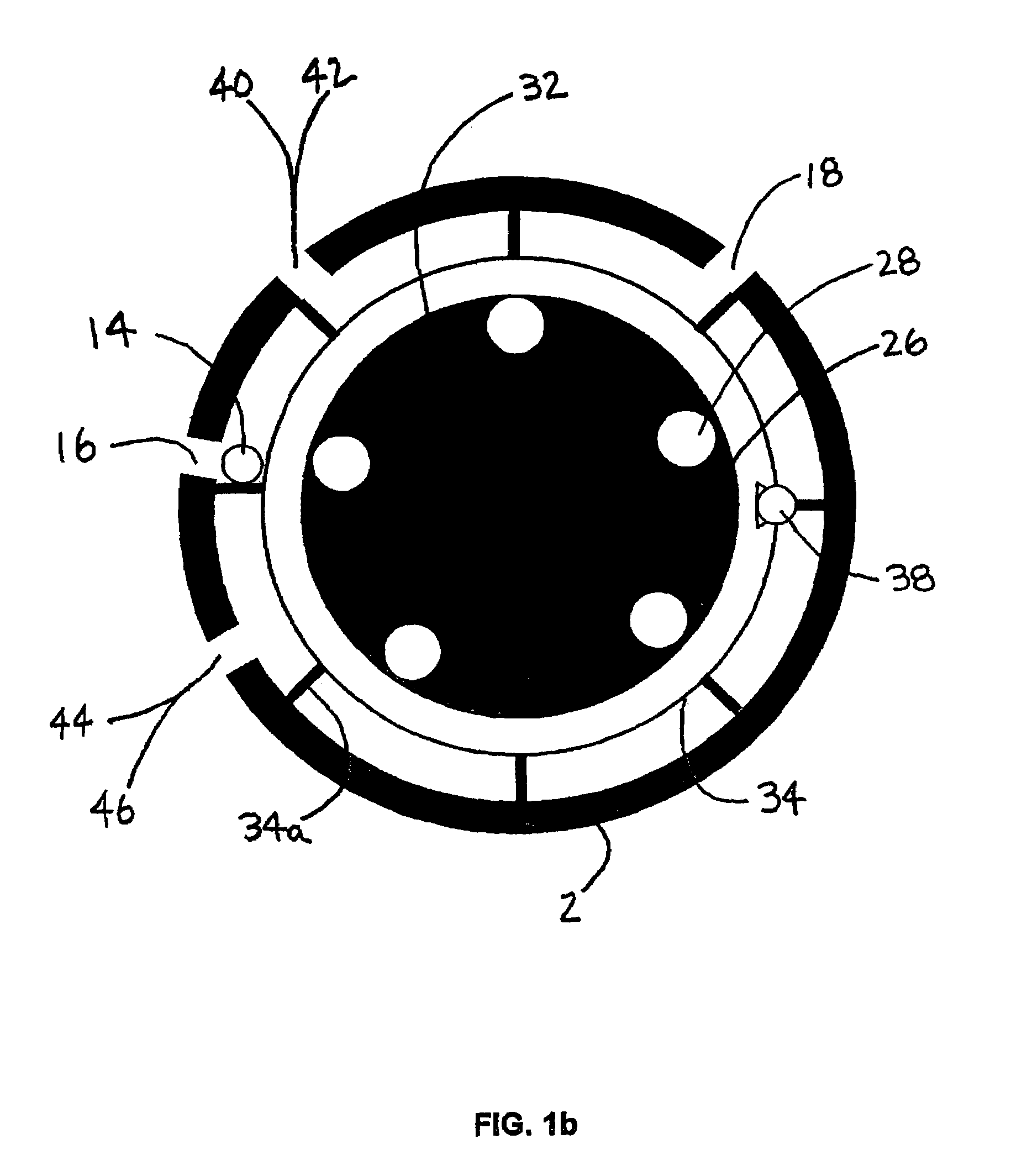

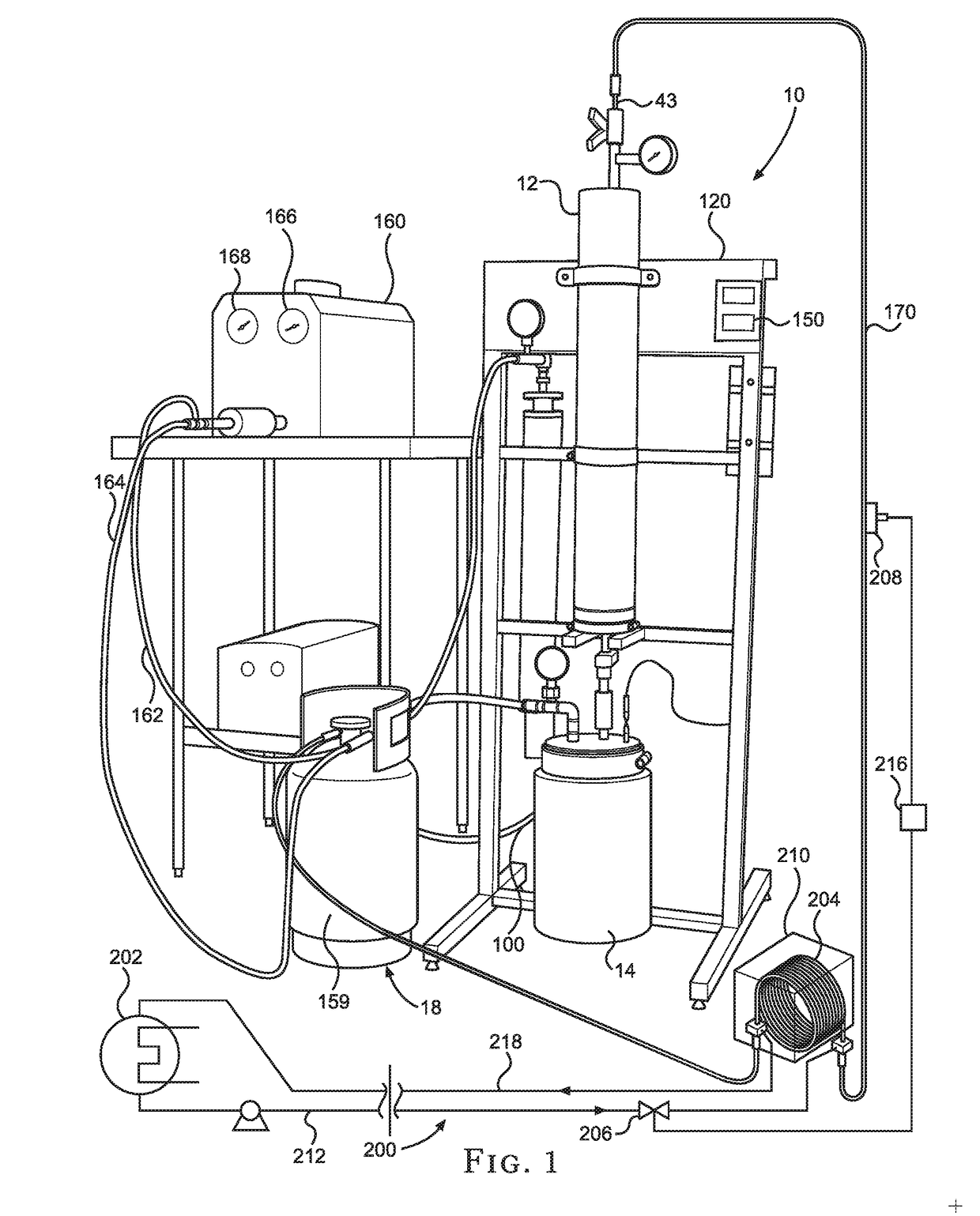

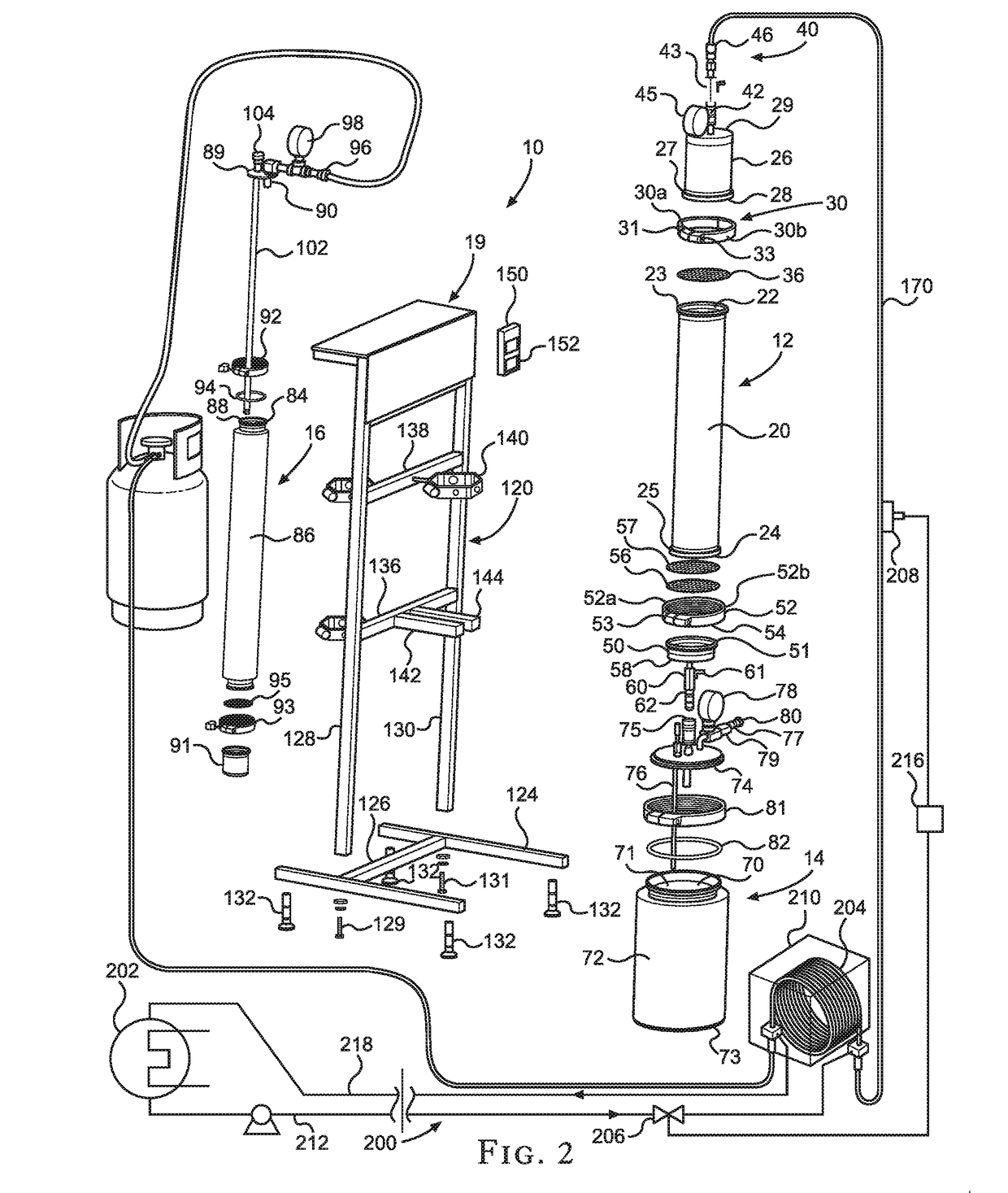

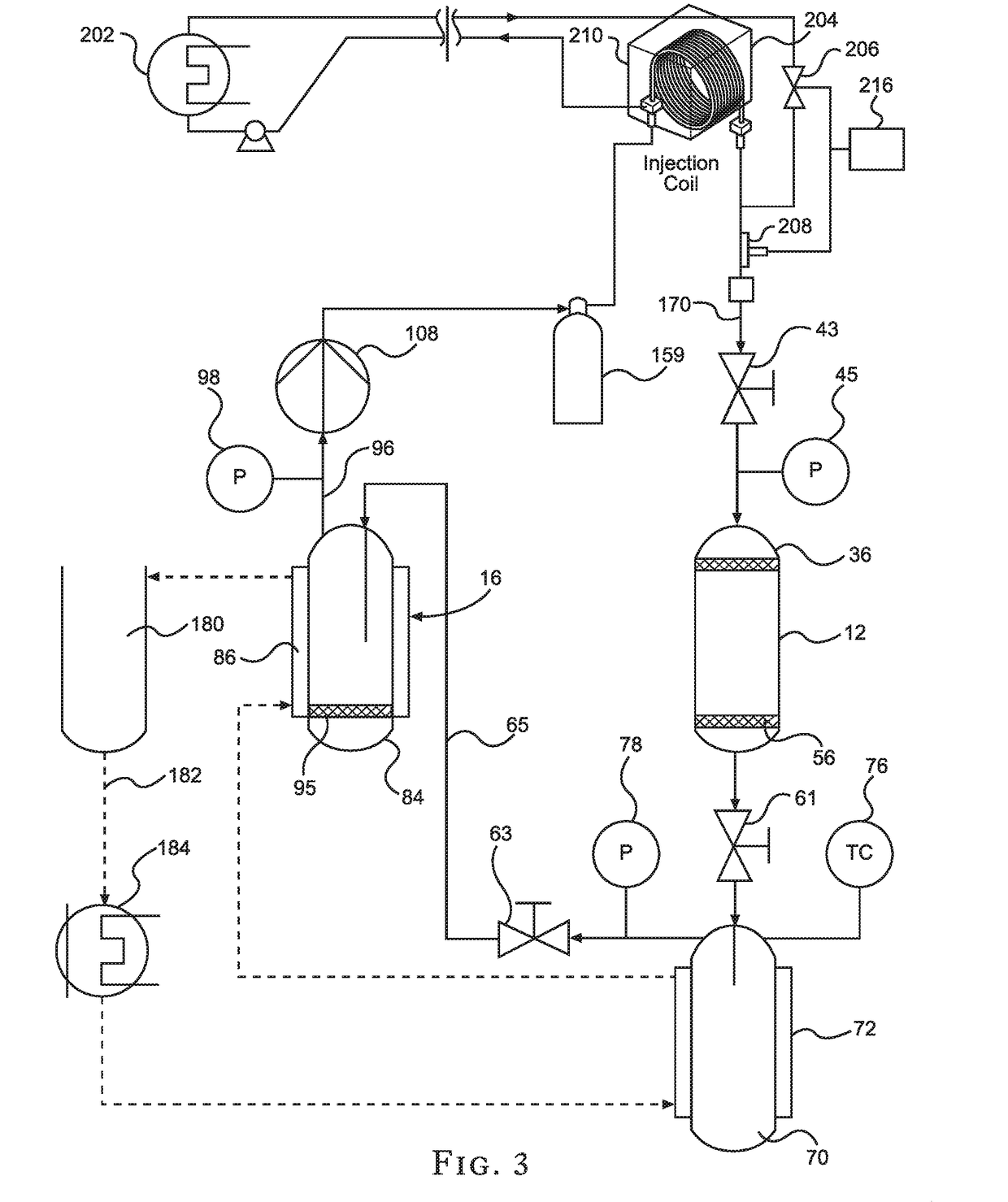

ActiveUS20160303490A1Simple and inexpensive mannerGas solvent extractionFatty-oils/fats productionHydrocarbon solventsTemperature control

A system for extracting oil from oil-bearing plant parts has an extraction vessel supported by an upright stand, a separator vessel mounted below the extraction vessel, and an expansion filter vessel mounted downstream from the separator vessel. A source of hydrocarbon solvent supplies liquid gas to the top of the extraction vessel, while a recycling pump connected to the separator vessel facilitates transport of the solvent through the plant material in the extraction vessel. The solvent is recovered and re-circulated, while extracted oil is removed from the separator. A computer-based temperature control assembly having a cooling device and a jacketed injection coil regulates temperature of the solvent delivered to the extraction assembly. A thermal jacket is mounted on each of the separator vessel and the expansion filter vessel, with the thermal jackets supplying heat and cold to the interior of the separator vessel and the expansion filter vessel and helping evaporate and condense the solvent.

Owner:ELLIS MATTHEW

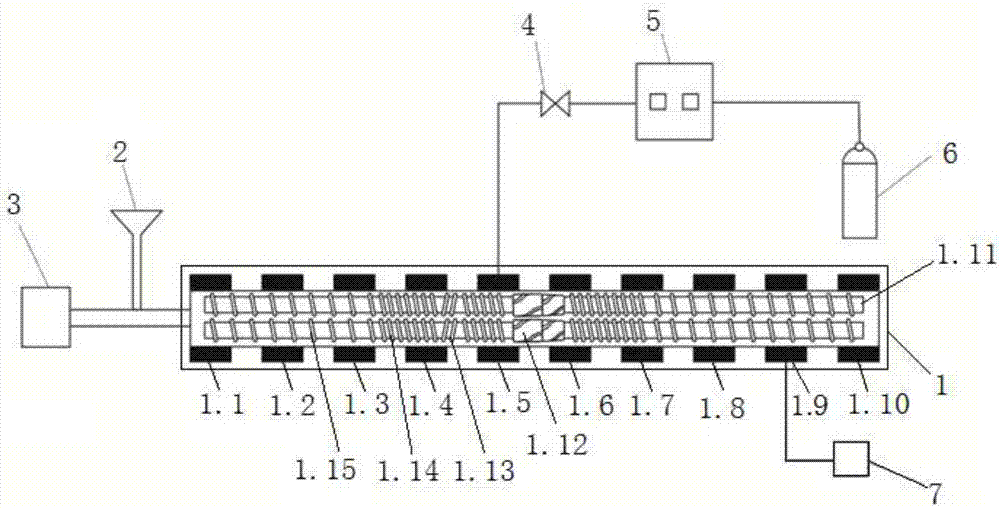

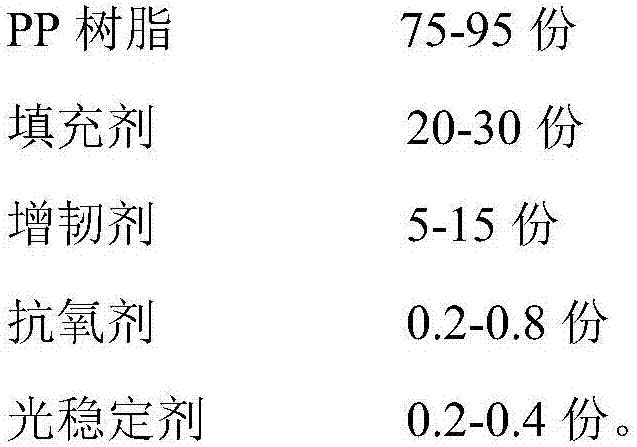

Method for preparing supercritical low-odor and low-emission polypropylene material

ActiveCN107090128AReduce performanceReduced performance (tensile strengthLiquid solutions solvent extractionGas solvent extractionMolten statePolymer science

The invention discloses a method for preparing a supercritical low-odor and low-emission polypropylene material. The method comprises the steps of mixing the polypropylene material and adding the mixed polypropylene material to a vacuumized twin-screw extruder; and introducing supercritical carbon dioxide to the middle of the twin-screw extruder, and carrying out mixing melting and extruding on the supercritical carbon dioxide and the polypropylene material in an air-tight high-pressure screw cylinder to prepare the supercritical low-odor and low-emission polypropylene material. By adopting an SCF-CO2 extraction method, small molecule volatile matters can be extracted when the material is in a molten state, and then evacuated, so that the odor level of the material is reduced to a 3.5 level from a 4.5 level, the total carbon content can be reduced by over 90%, and meanwhile, the method does not have influence on the performance of the material basically.

Owner:ORINKO NEW MATERIAL CO LTD

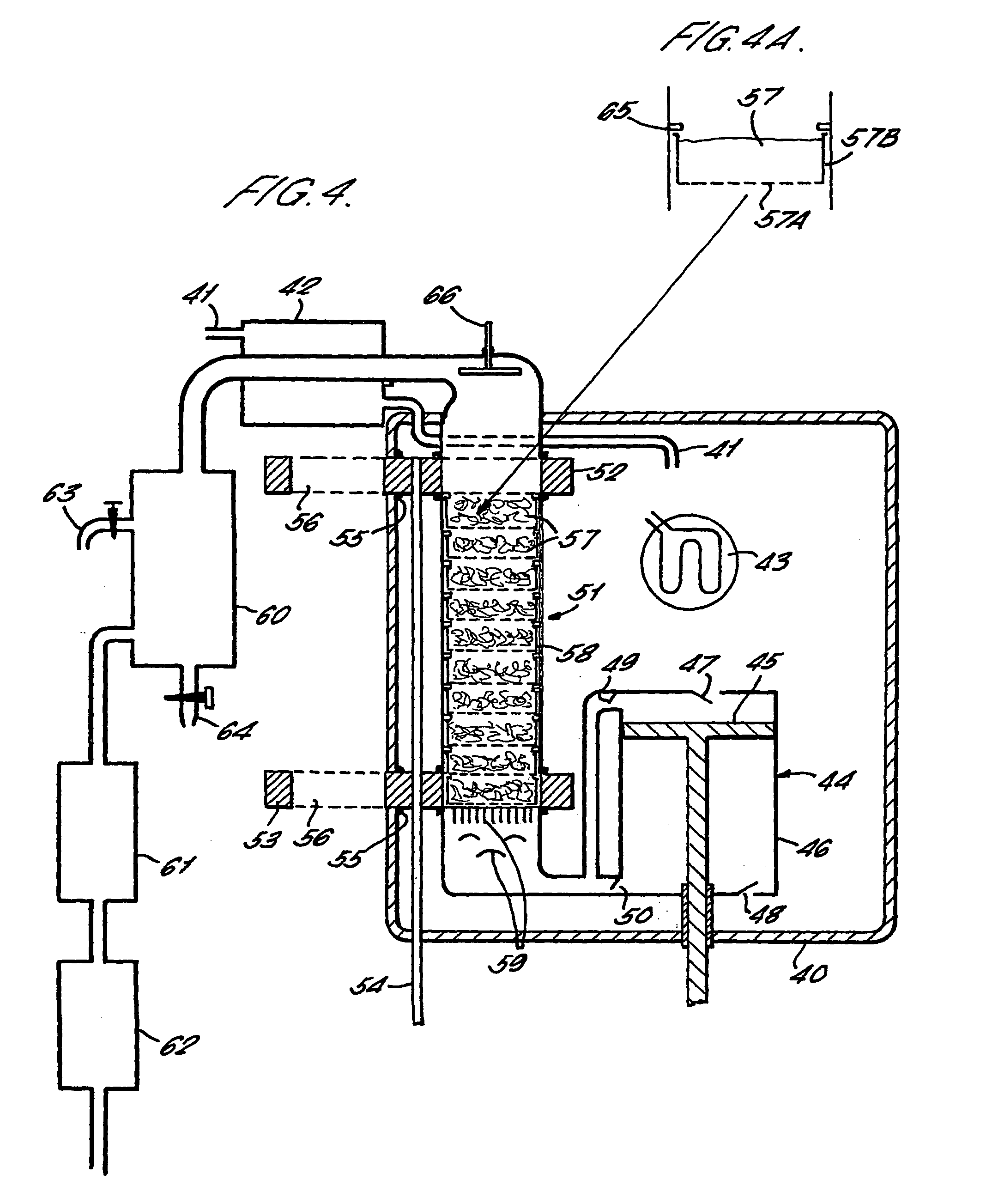

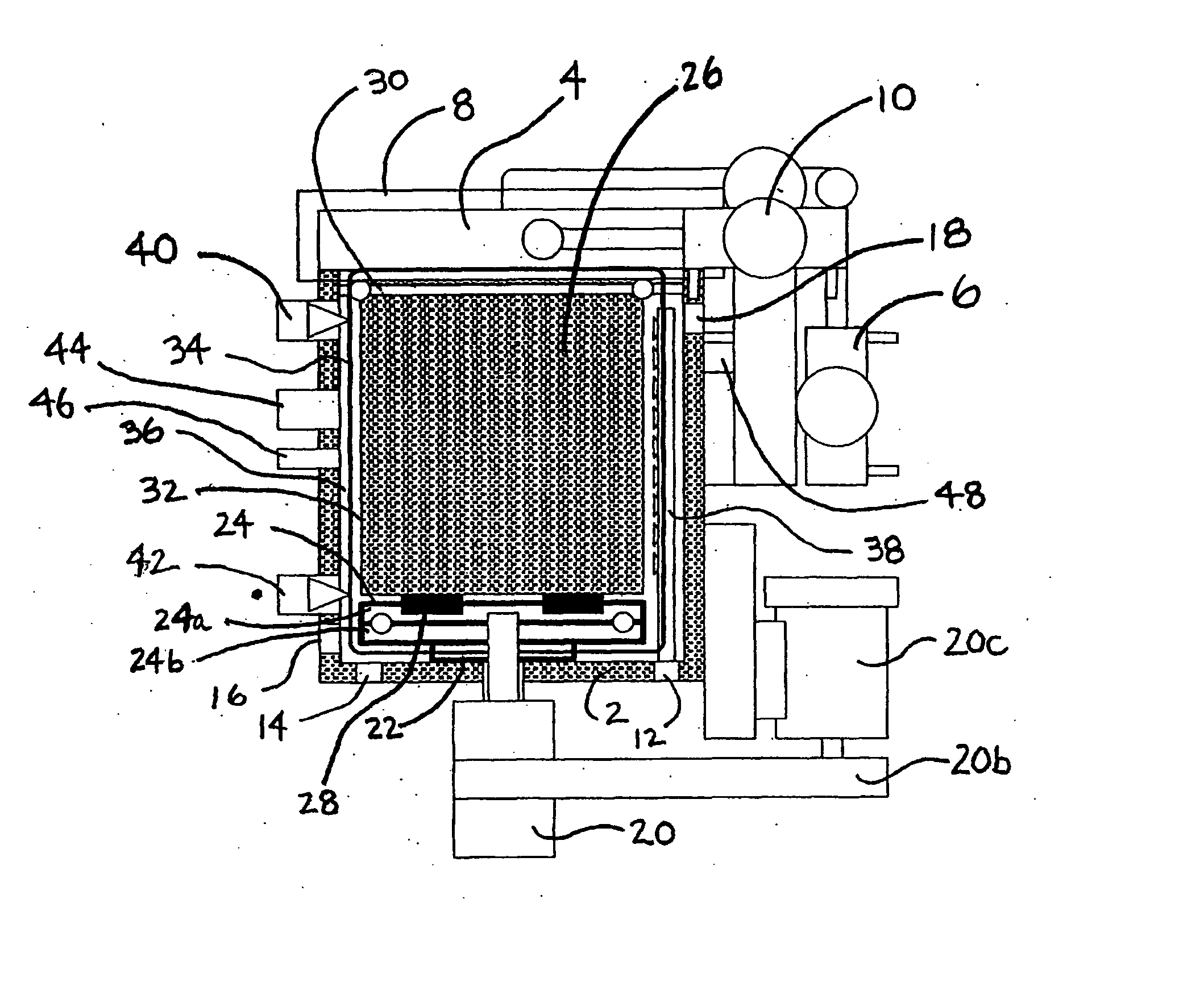

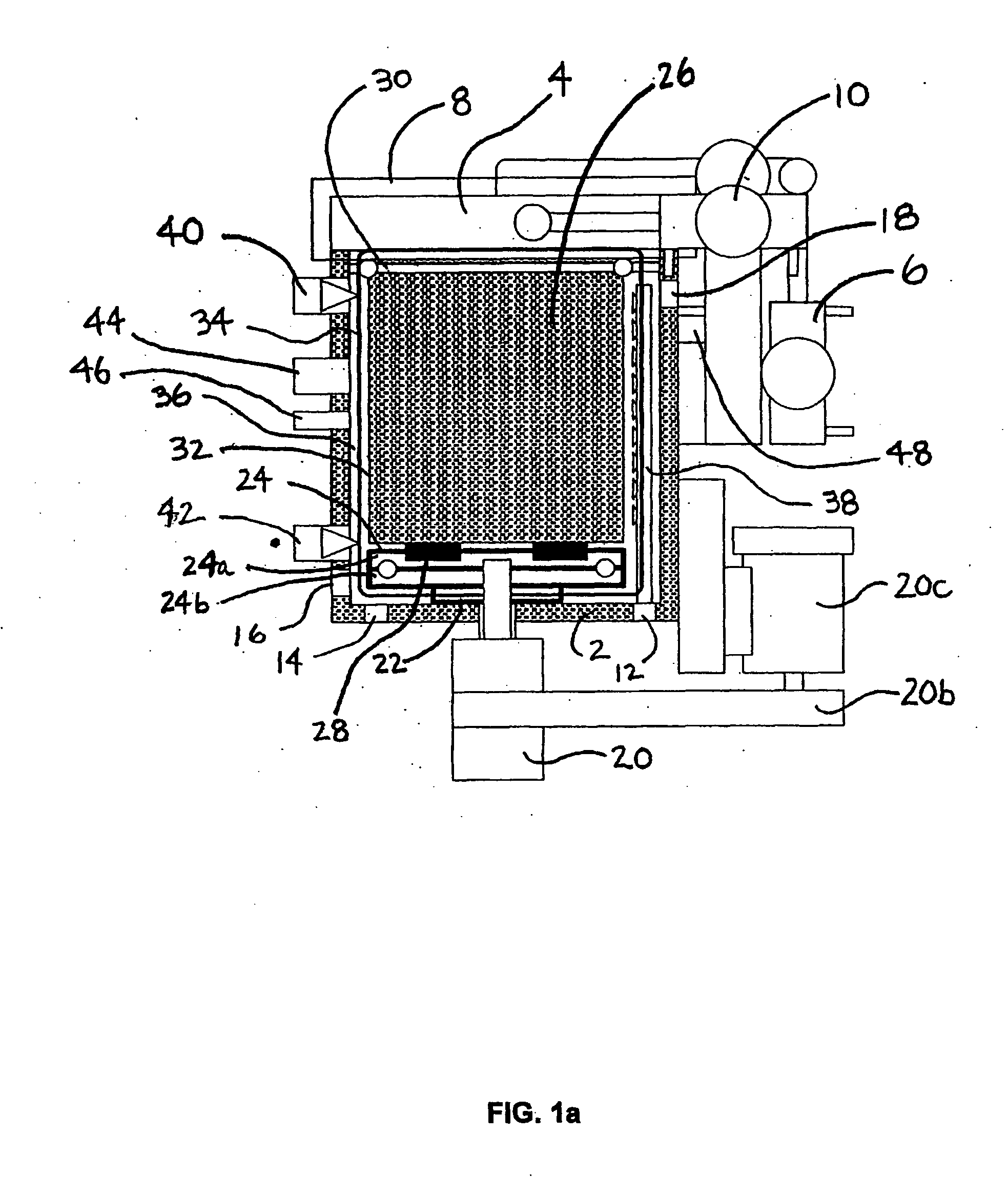

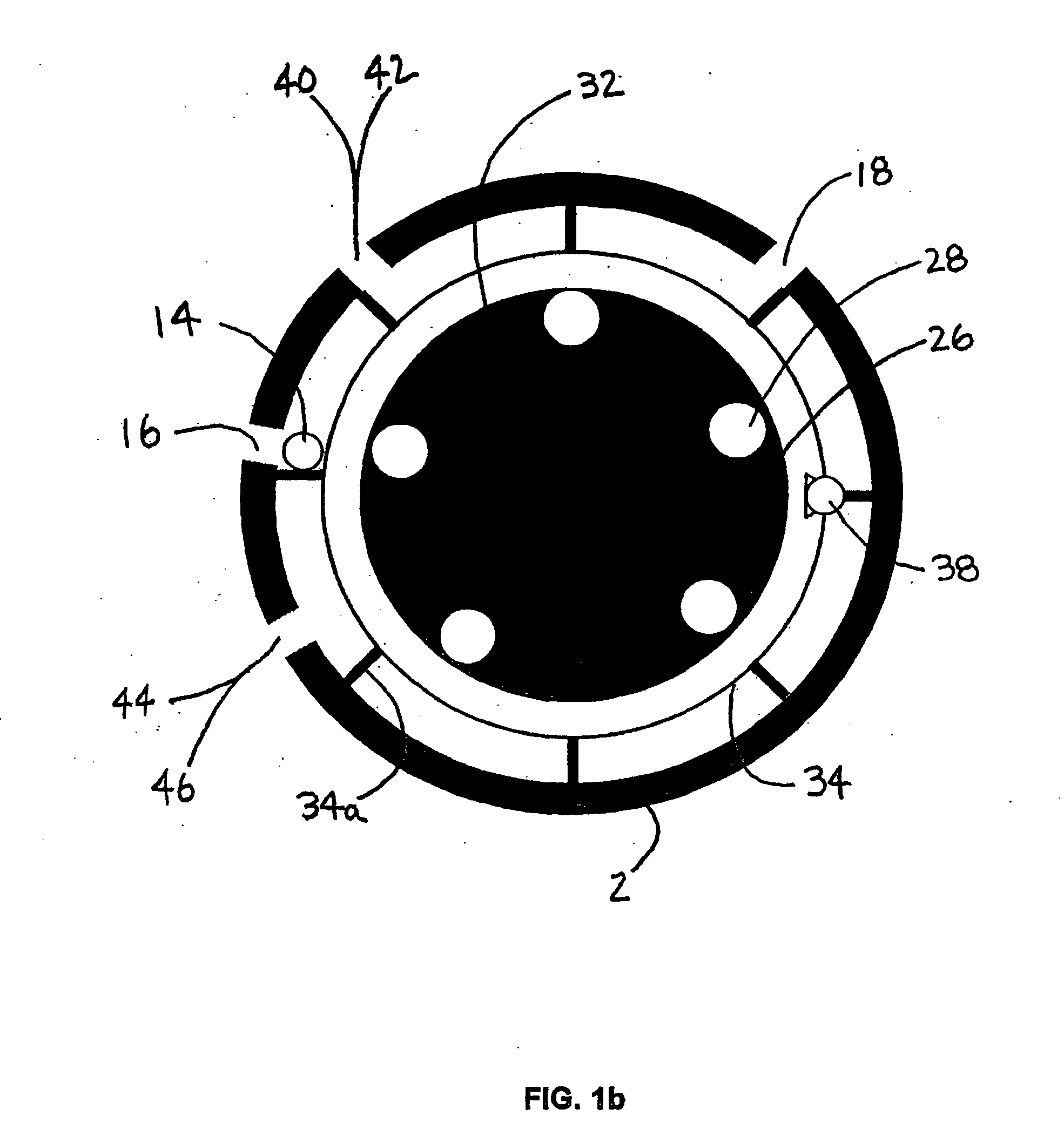

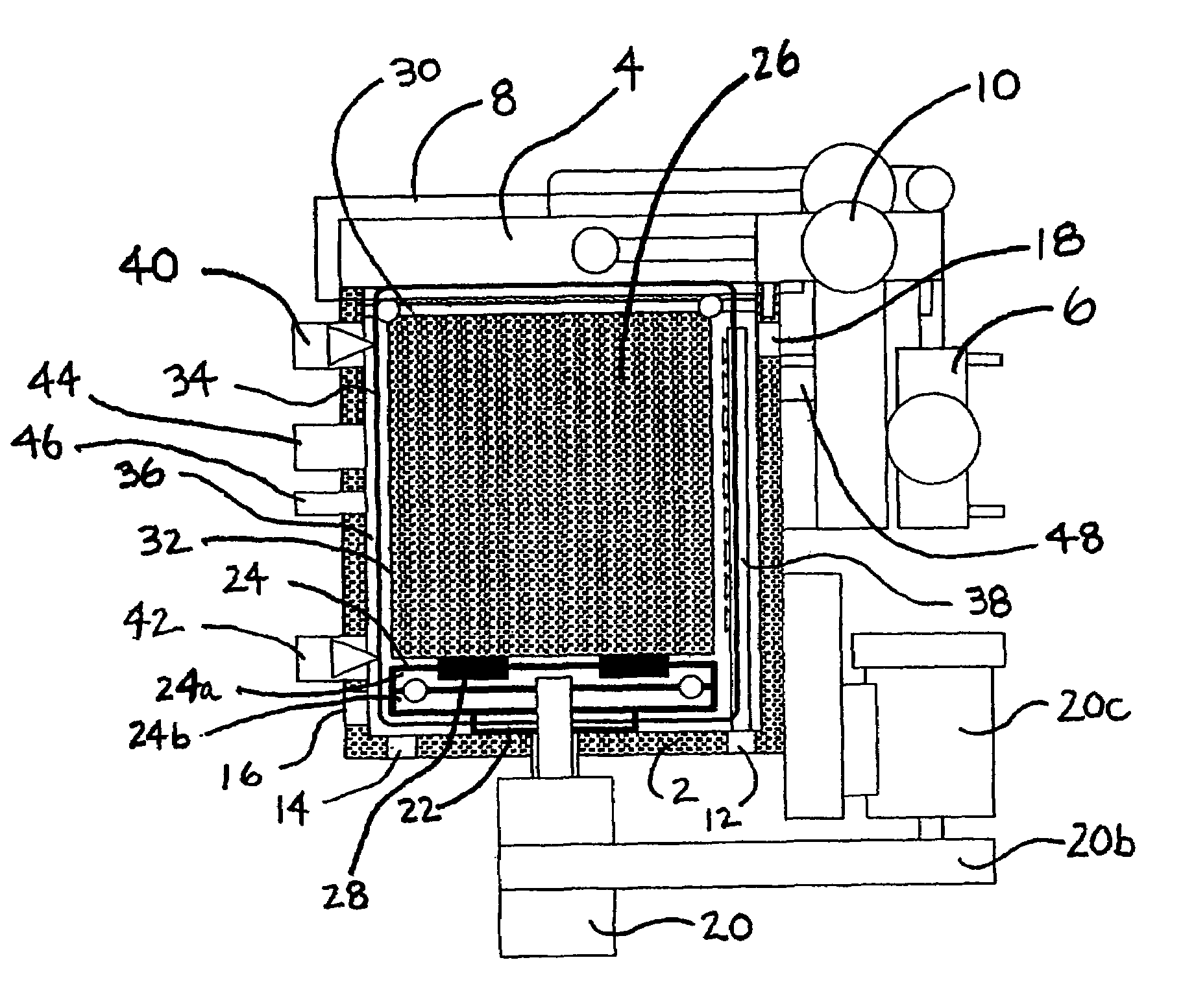

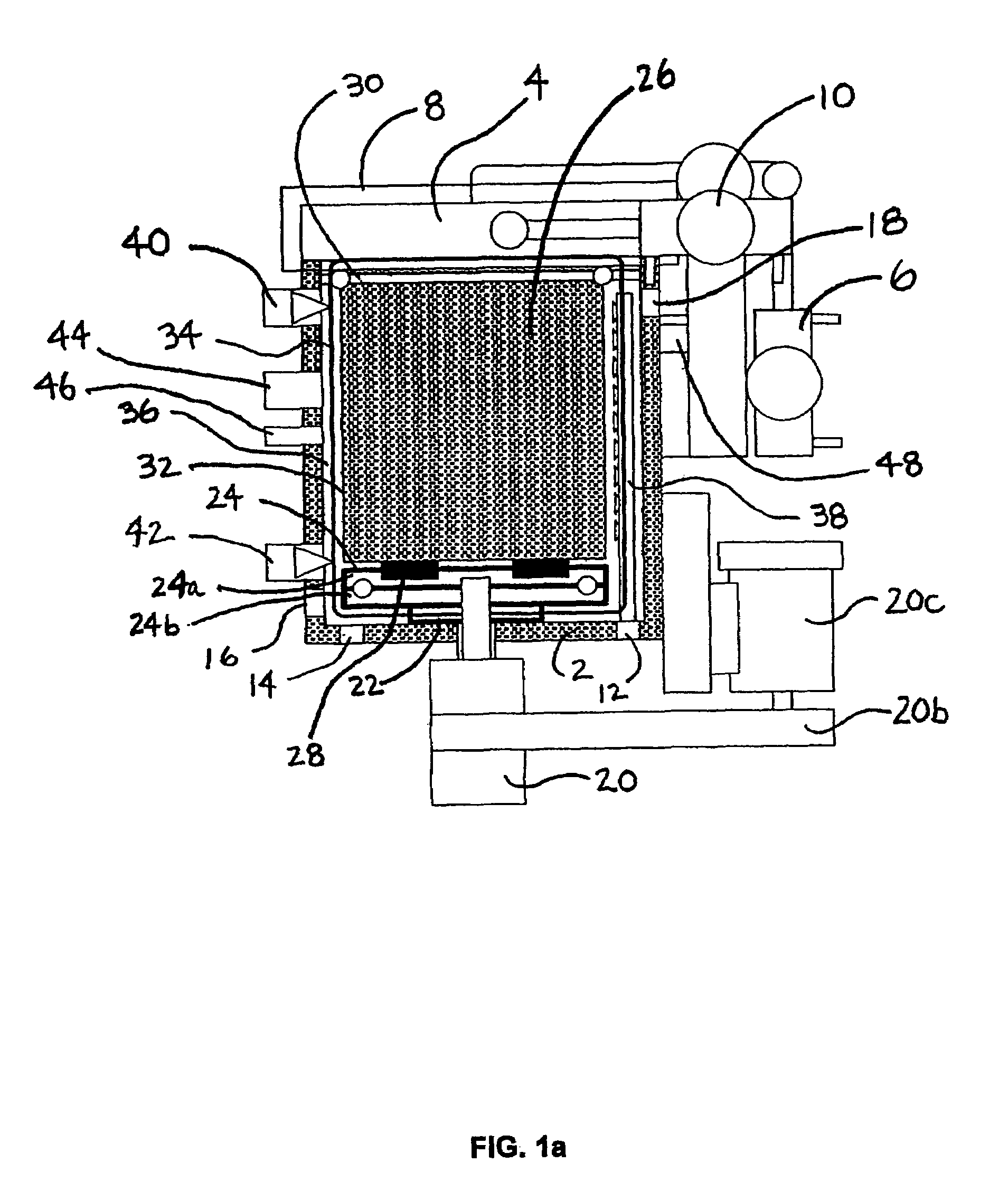

Dense fluid cleaning centrifugal phase shifting separation process and apparatus

InactiveUS20070259766A1Prevent redepositionIncrease speedDispersed particle separationCentrifugal force sediment separationEngineeringProcess conditions

The present invention is an apparatus and process for cleaning substrates using fluids, including dense fluids. A perforated centrifuge drum operates within a pressure vessel. A dense fluid cleaning and management system including suitable process condition sensors provides for exchanging fluid with the pressure vessel.

Owner:HITACHI HIGH-TECH CORP

Dense fluid cleaning centrifugal phase shifting separation process and apparatus

InactiveUS7601112B2Prevent redepositionIncrease speedDispersed particle separationCentrifugal force sediment separationEngineeringProcess conditions

The present invention is an apparatus and process for cleaning substrates using fluids, including dense fluids. A perforated centrifuge drum operates within a pressure vessel. A dense fluid cleaning and management system including suitable process condition sensors provides for exchanging fluid with the pressure vessel.

Owner:HITACHI HIGH-TECH CORP

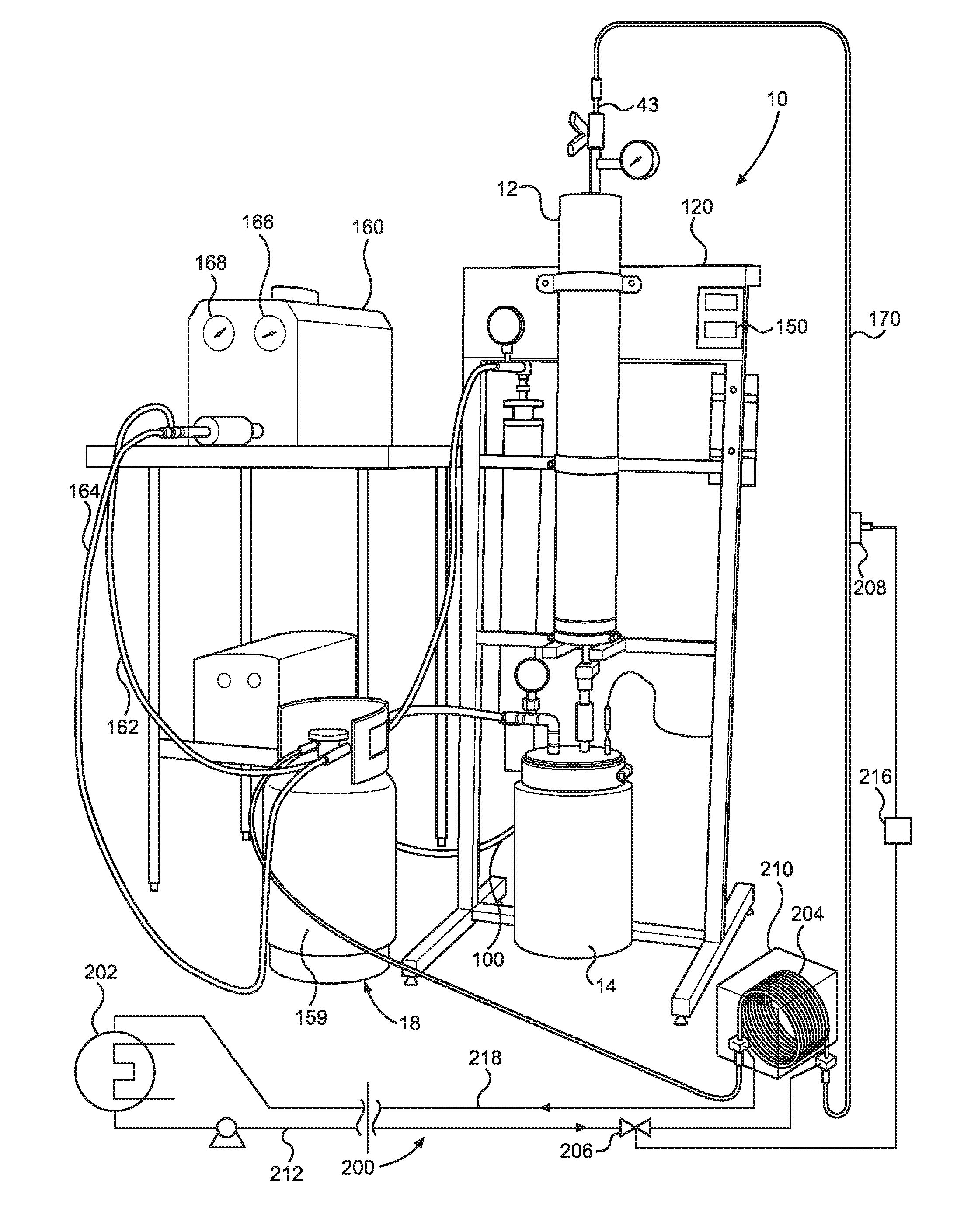

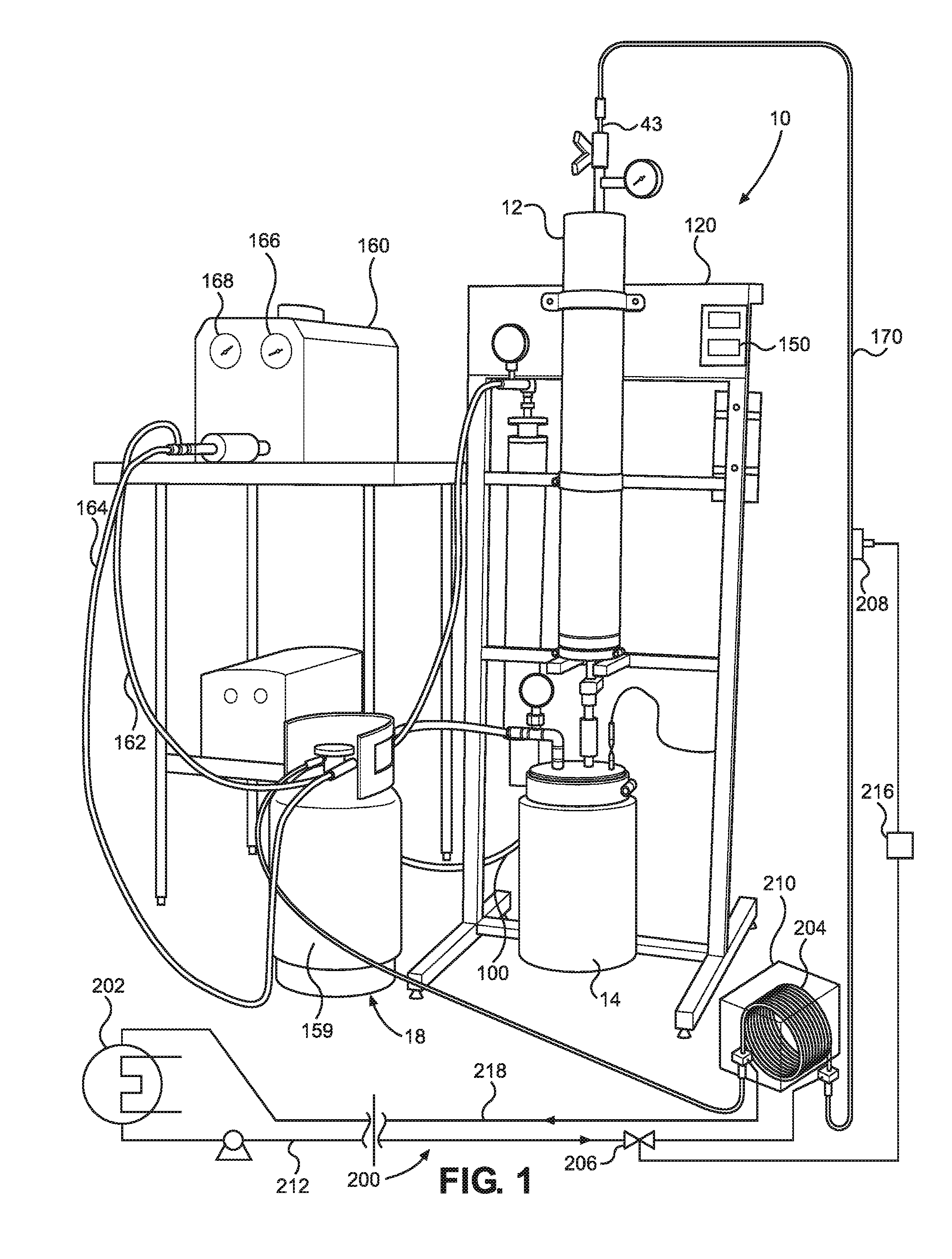

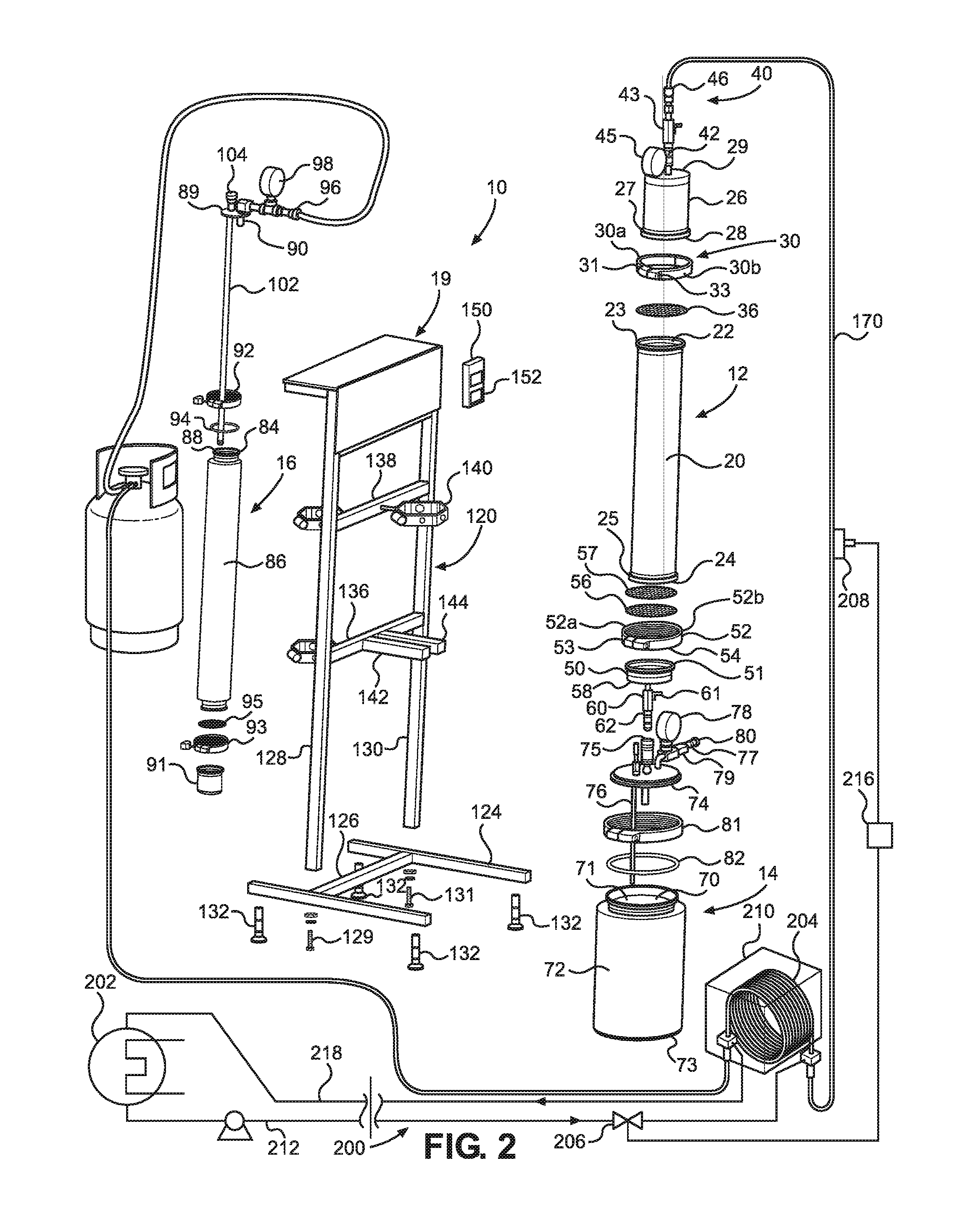

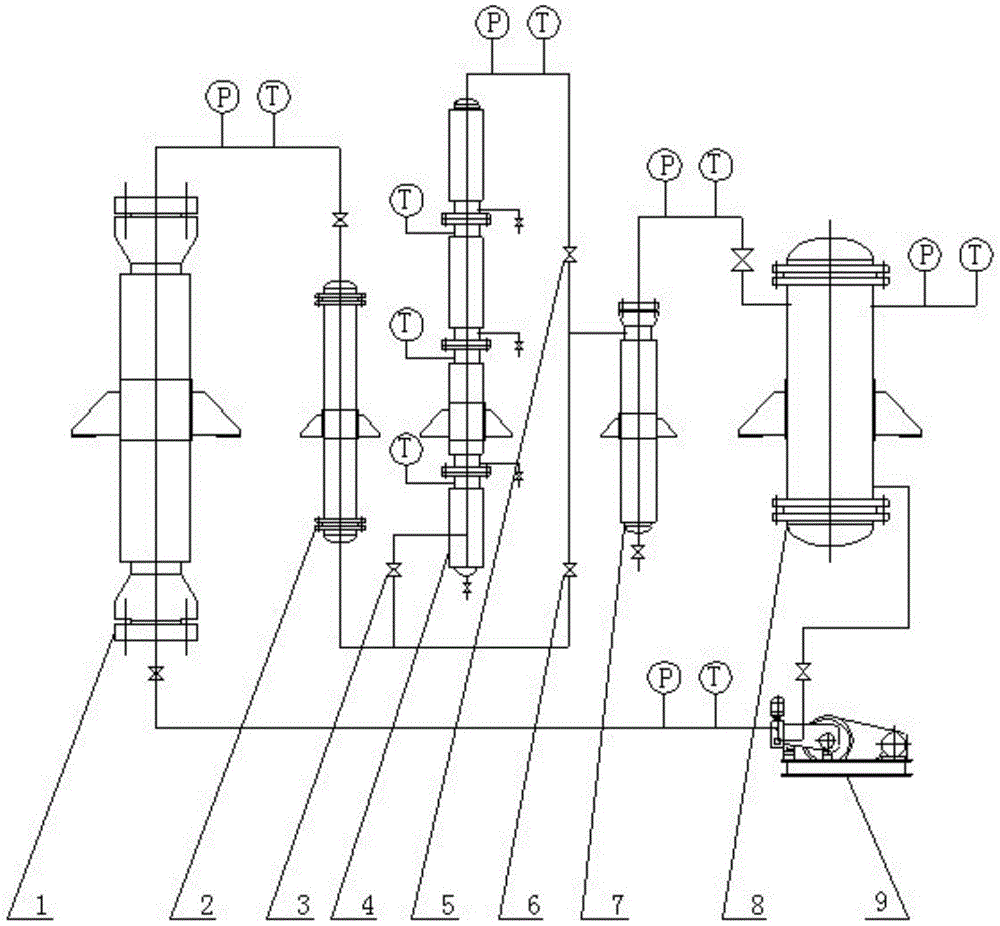

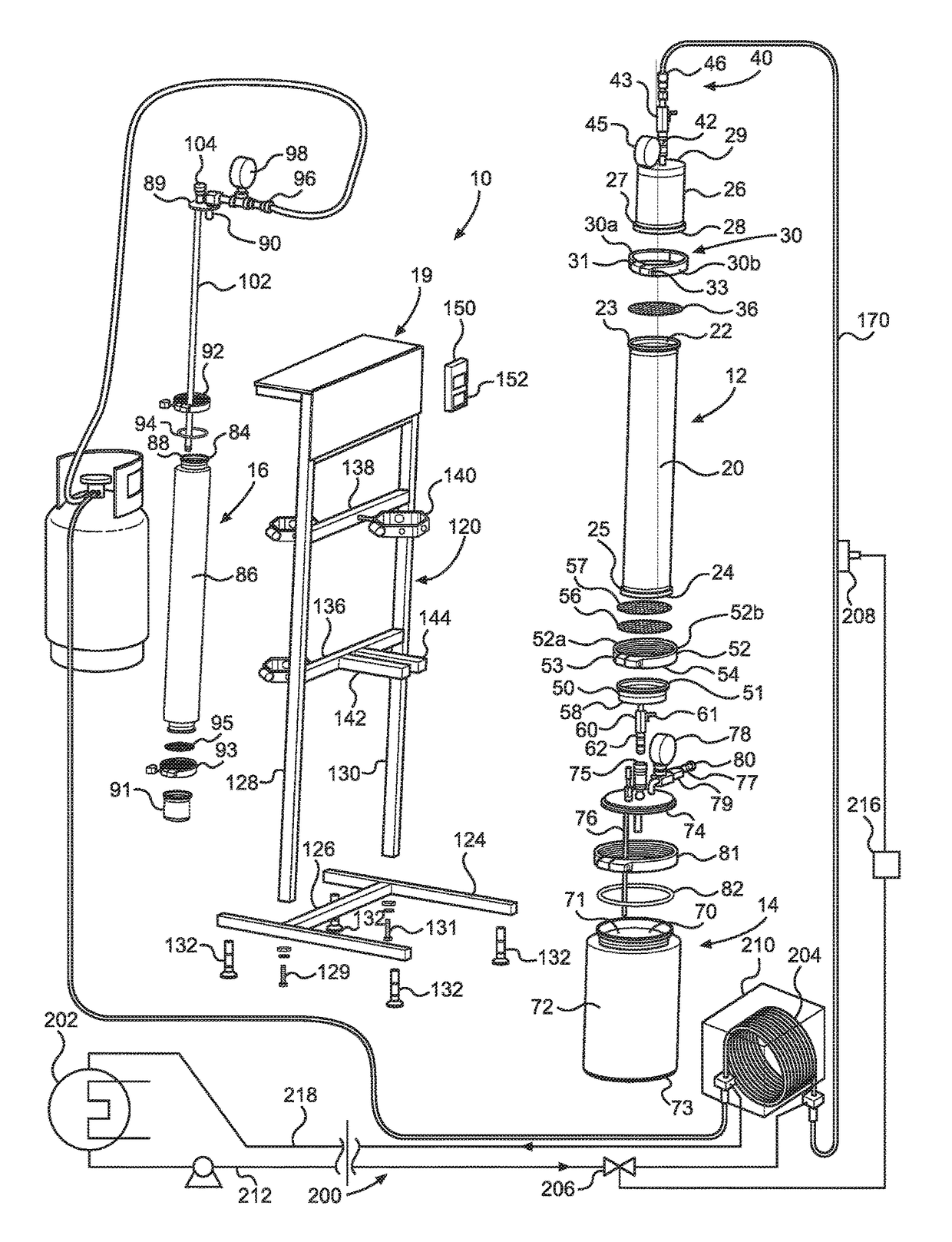

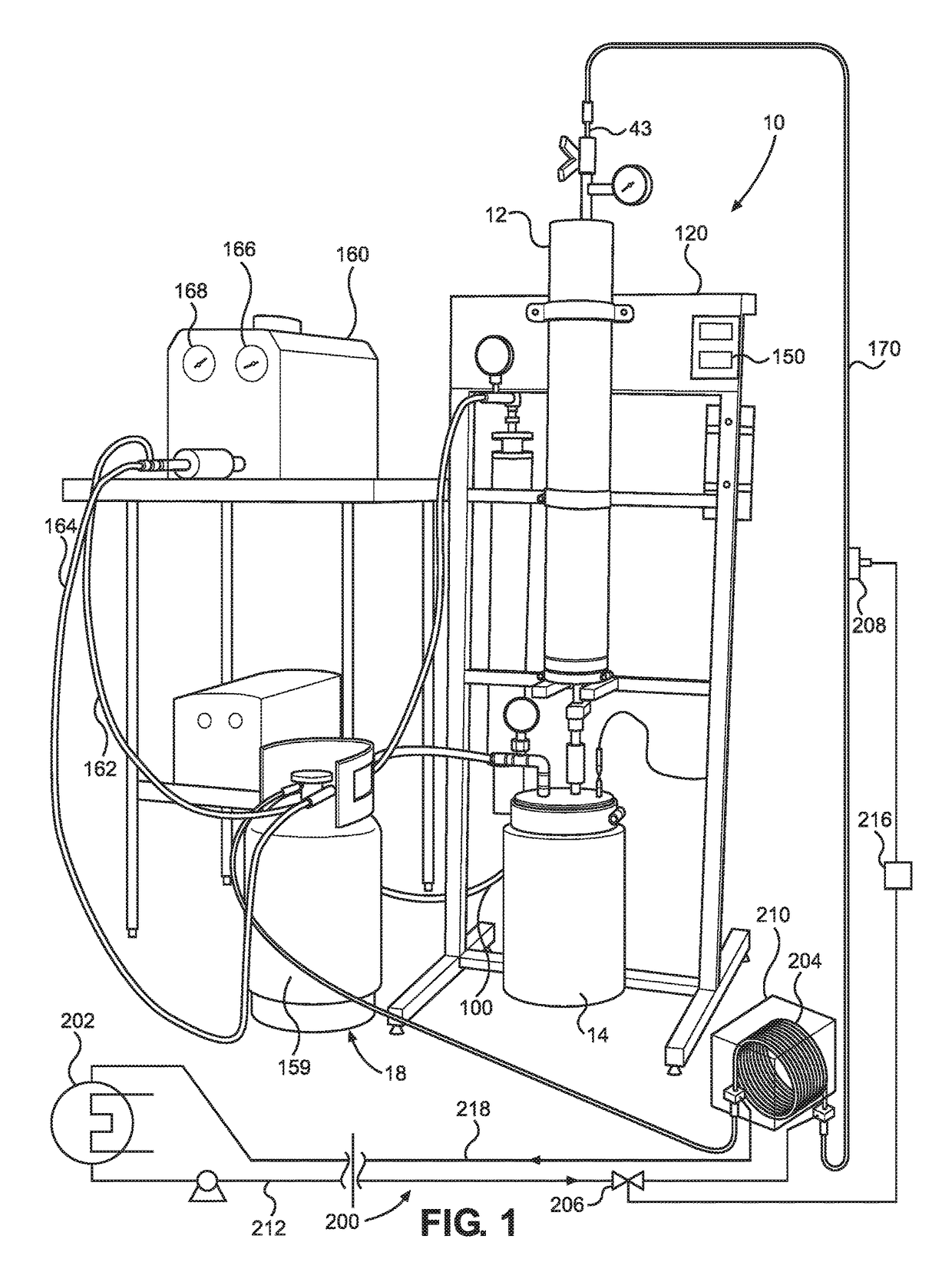

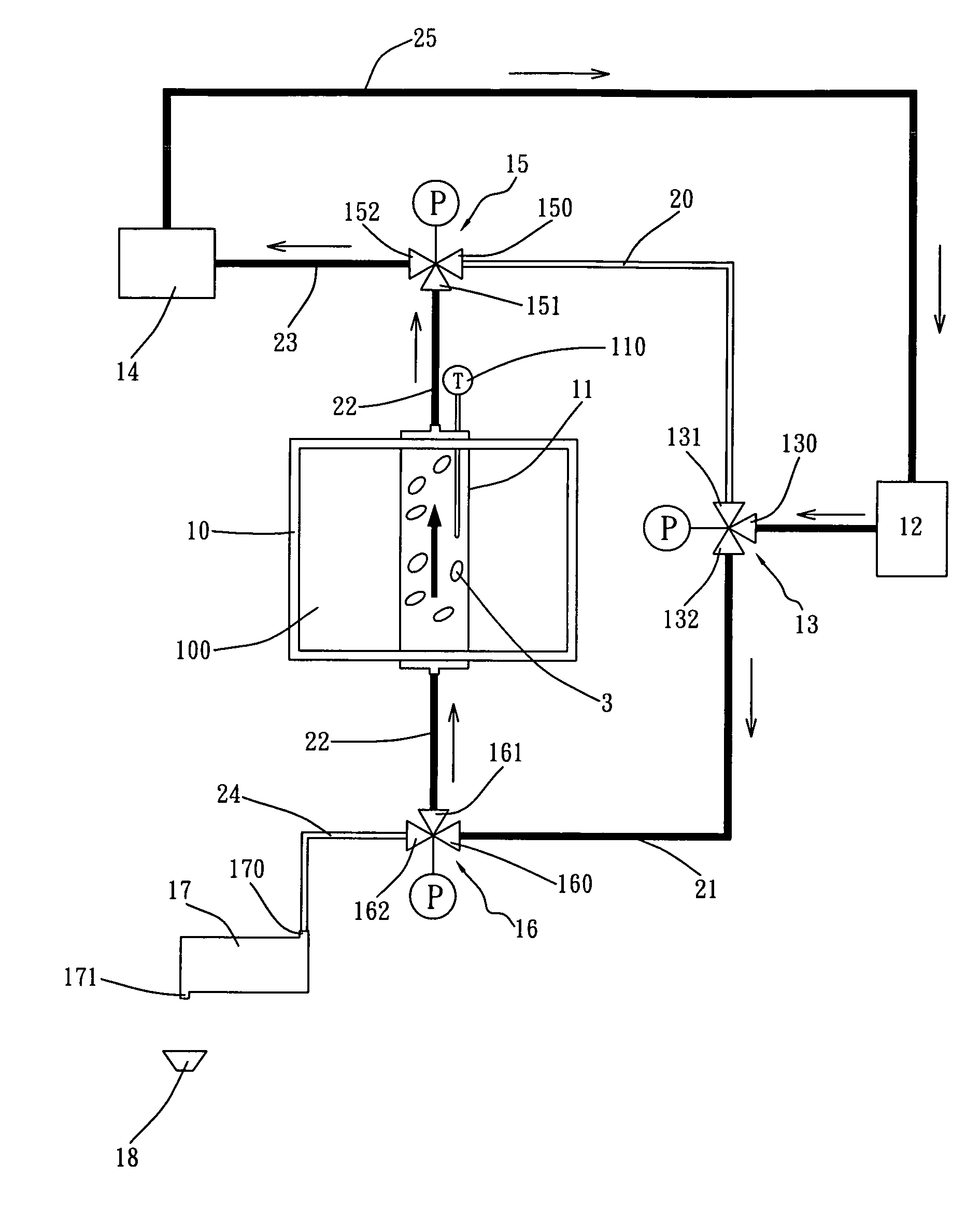

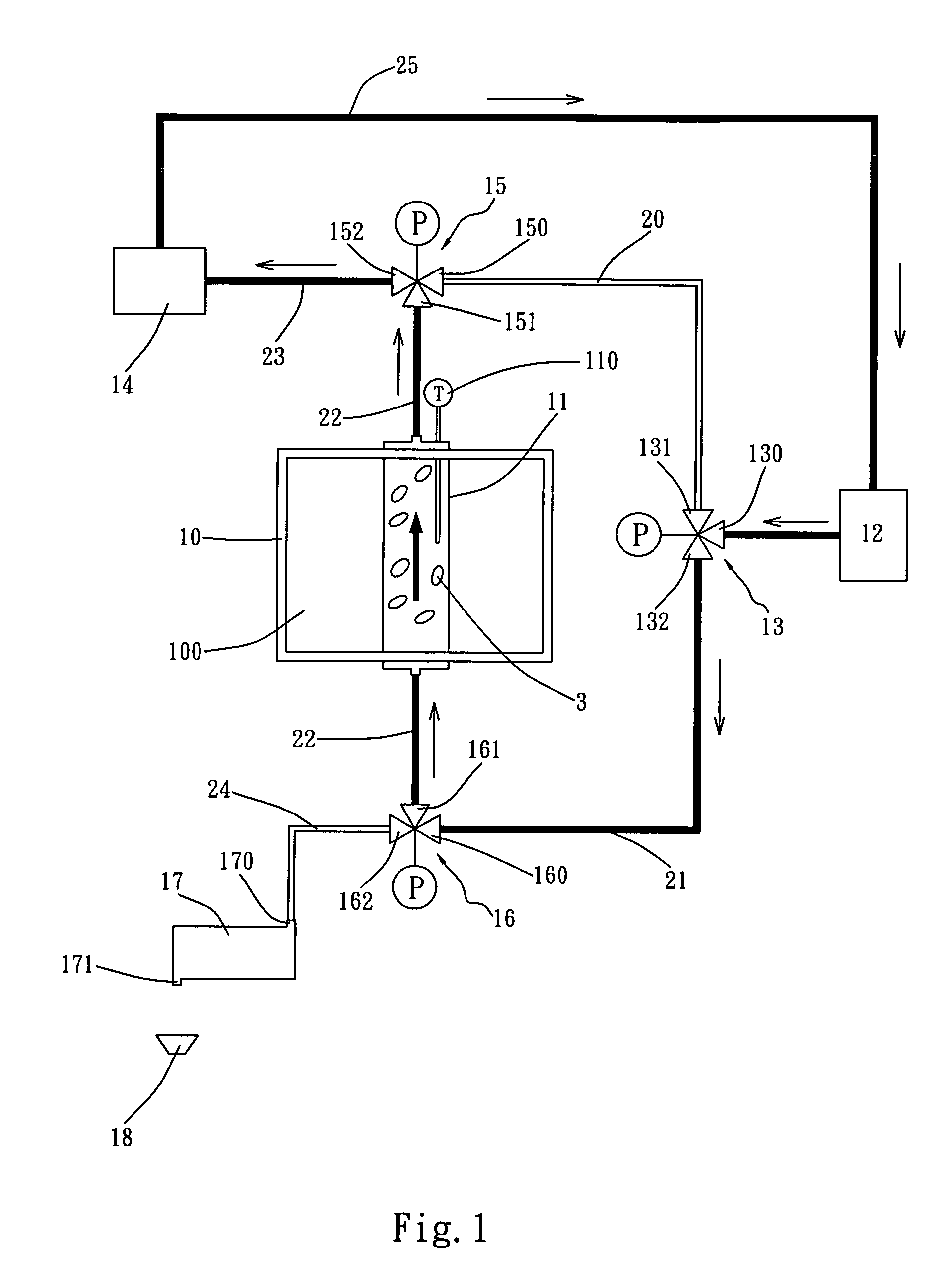

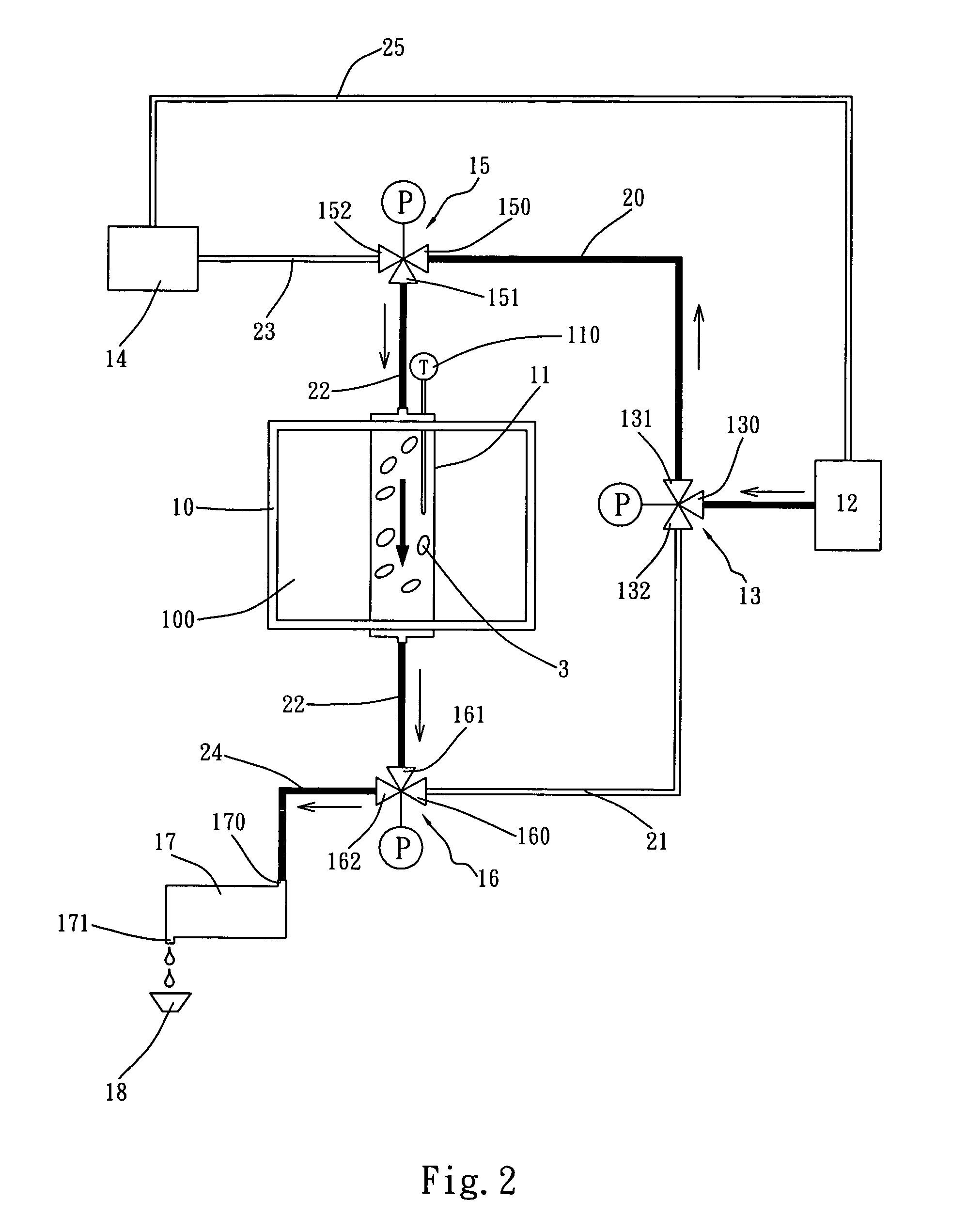

Continuous-flow extraction system and method

A continuous-flow extraction system and method for extracting oil from oil-bearing plant parts, or biomass, with liquid-phase hydrocarbon solvent in a continuous process, providing more than one extraction vessel so that one or more extraction vessels can be cleared of exhausted biomass and reloaded with biomass, while another one or more extraction vessels are undergoing the extraction process, optionally providing a de-waxer for use when needed, providing a primary jacketed separator vessel for flashing hydrocarbon solvent to a vapor phase and precipitating and collecting liquid plant extract, providing at least one secondary jacketed separator vessel for purification and refinement of vapor-phase hydrocarbon solvent and providing for re-liquefication of the solvent for the purpose of re-circulating and reusing the solvent, and providing for the heating, cooling, and pumping necessary to carry out the various steps.

Owner:ELLIS MATTHEW

Method for separating ginger essential oil from gingerol-rich oleoresin ginger through low-pressure supercritical CO2 extraction

ActiveCN105597367AHigh purityReduce the temperatureEssential-oils/perfumesGas solvent extractionOleoresinGingerol

The invention relates to a method for separating ginger essential oil from gingerol-rich oleoresin ginger through low-pressure supercritical CO2 extraction. The method comprises the steps of extracting ginger powder with high-pressure low-temperature CO2 fluid under low extraction pressure and at low temperature to prepare first CO2 extract liquid in which effective ingredients of ginger are dissolved; performing heat exchange and heating on the first CO2 extract liquid and separating directly to obtain oleoresin ginger resin containing extracts of full ingredients of ginger; carrying out extraction, heat exchange and heating, rectification and separation on the oleoresin ginger resin containing extracts of full ingredients of ginger sequentially to obtain high-purity ginger essential oil and gingerol-rich oleoresin ginger respectively, thereby achieving effective separation of the two effective ingredients. According to the method, while the extraction temperature and the extraction pressure are effectively reduced, the two effective ingredients, gingerol-based oleoresin ginger and ginger essential oil, in ginger are effectively separated, and finally, high-purity ginger essential oil and gingerol-rich oleoresin ginger are prepared.

Owner:QINGDAO H EXTRACT CO LTD

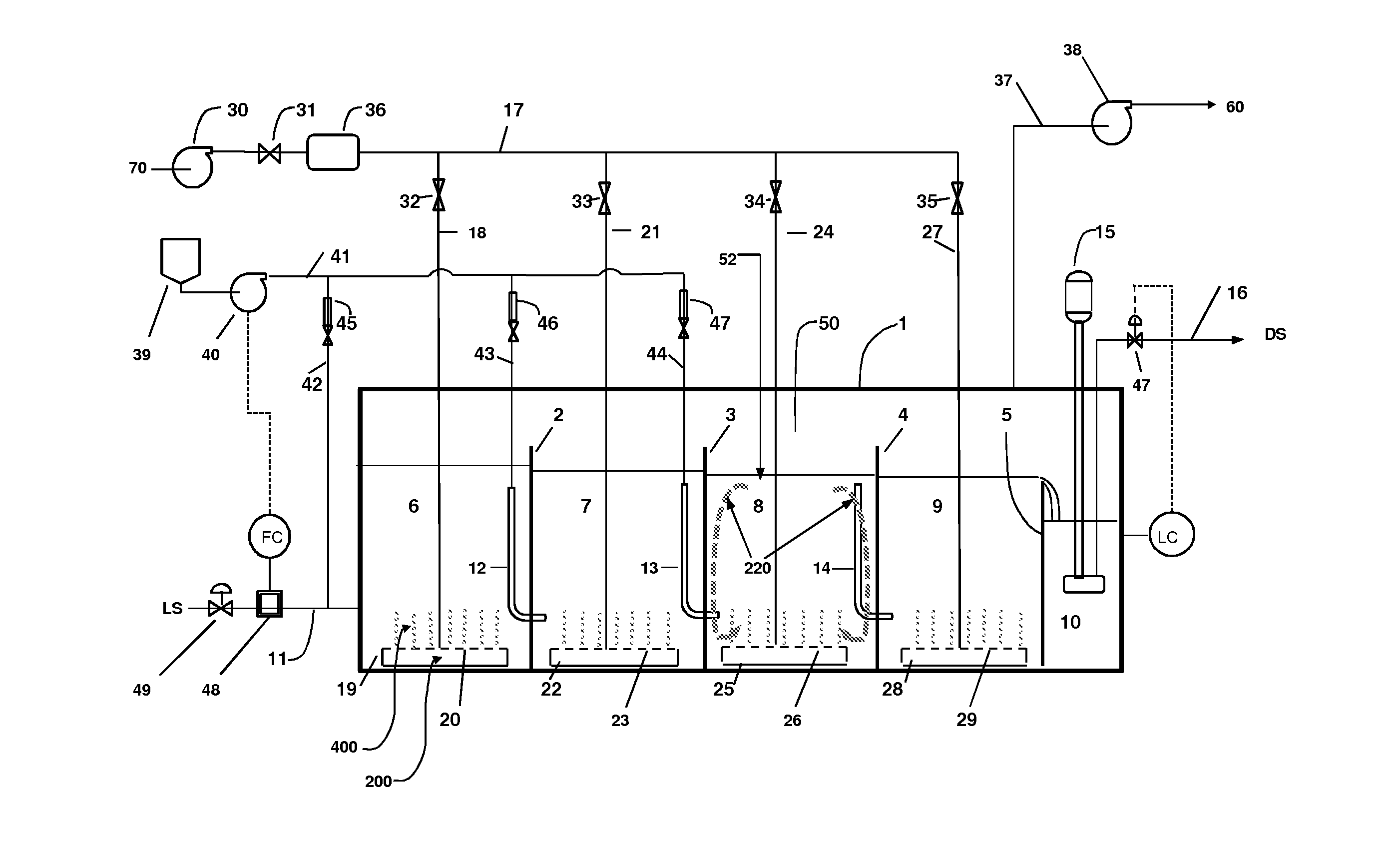

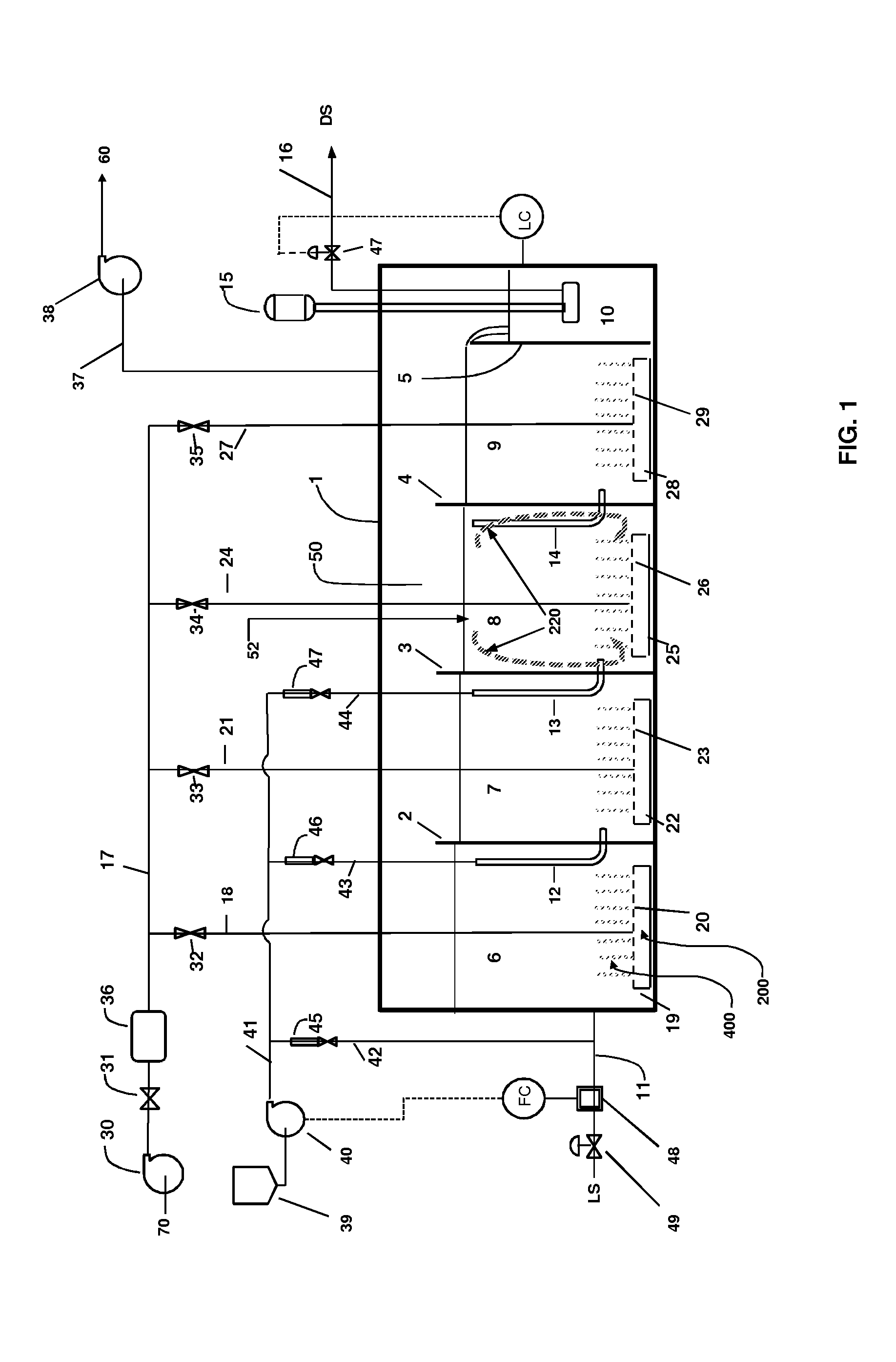

Sulfur degasser apparatus and method

ActiveUS20140065057A1Easy to removeIncrease surface areaLiquid degasificationLighting and heating apparatusHydrogenDegasser

A novel system and method for degassing H2S and H2Sx from liquid sulfur (sulphur) is disclosed. The system includes a degassing vessel with a plurality of cells. The cells include a sparging gas mat with a perforated surface at the bottom of the cell to allow the release of air bubbles (or sparging gas) into the cells. A catalyst may be used during the process. As a result, hydrogen sulfide and hydrogen polysulfide are efficiently and effectively removed from the liquid sulfur.

Owner:IPCO US LLC

Extraction apparatus and method of extracting essential oils, essence, and pigments from odorous raw material by microwave heating under sub-critical conditions

ActiveUS20100288620A1Improve efficiencyIncrease temperatureFunctional valve typesDrying solid materials with heatEngineeringMicrowave irradiation

The invention relates to extraction apparatus and method for obtaining essential oils and essence and pigments from odorous raw materials by microwave radiation heating under sub-critical conditions, which has advantages of easy operation, higher extracting temperature and efficiency. The microwave chamber has a power level of 100 W to 1,500 W and its microwave radiation has a frequency at 915 MHz or 2,450 MHz. The extraction process can be performed without any preheating necessary. A condenser unit is operated at temperatures between −20° C. and 15° C. for cooling the gas extractive flowing out of the extraction unit. Because both volatile aromatic compounds and pigments of the odorous raw materials can be extracted successfully, the extracted essence is colorful. Since the extraction process by microwave radiation heating is free from adding any organic solvent and / or any artificial chemical compound, the extraction apparatus and method applied are really environmentally friendly.

Owner:JOINTEK

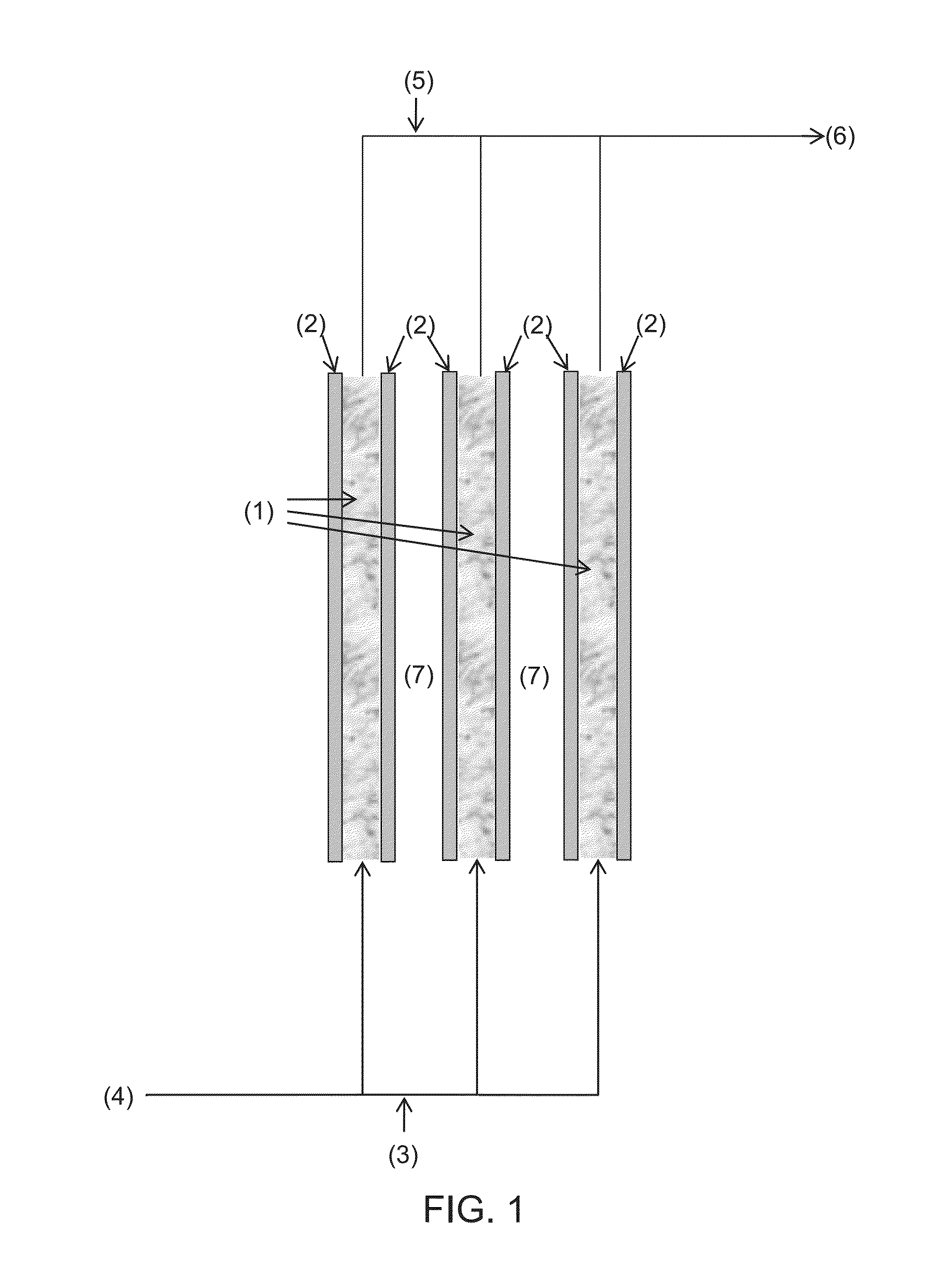

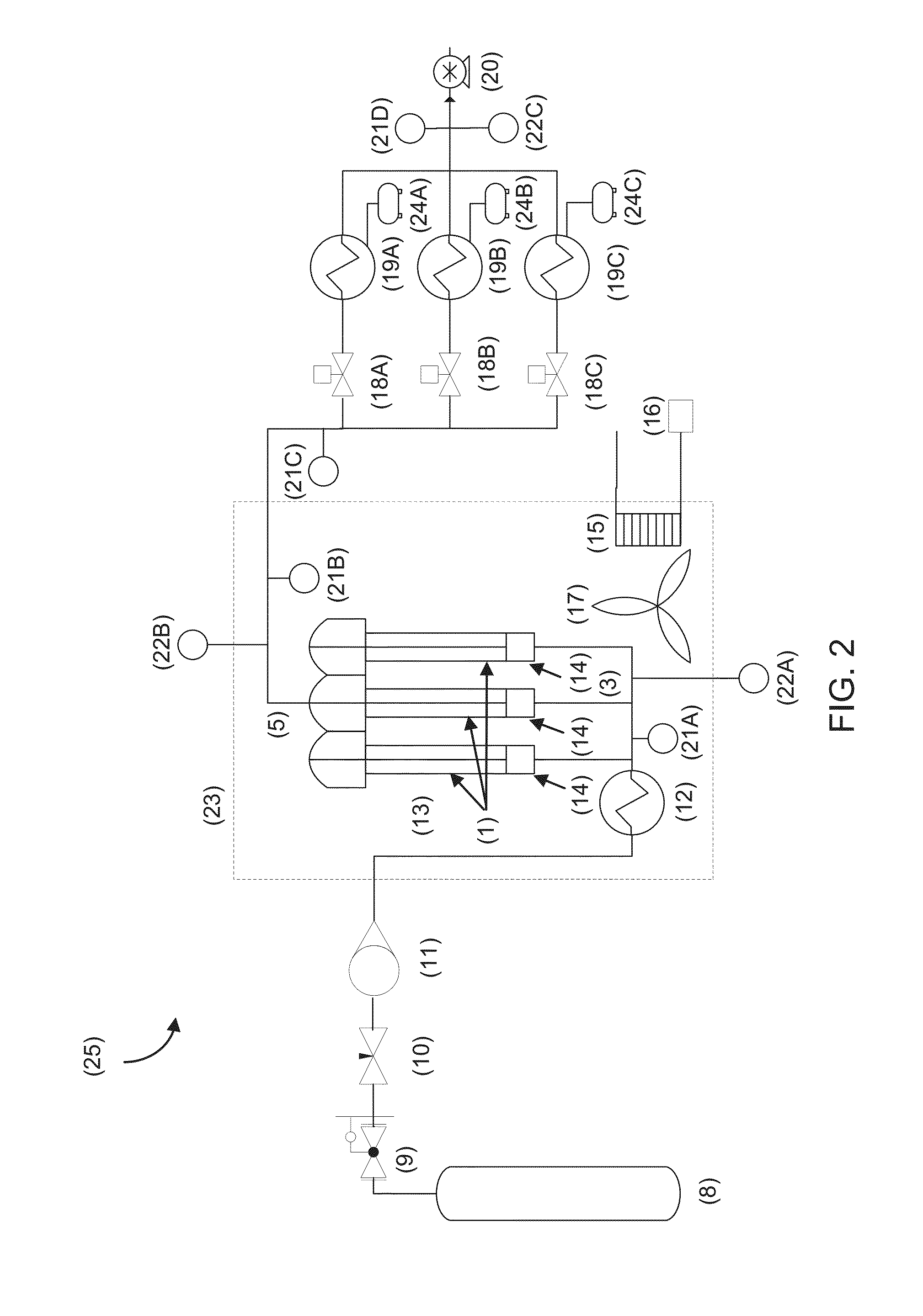

Thermal Fractionation Of Plant Material

InactiveUS20160243460A1Hydrocarbon active ingredientsHydroxy compound active ingredientsHigh rateDistillation

A highly controllable thermal distillation reactor system (25) and method (30) allow volatile compounds to be efficiently removed from the plant matter without use of solvents, and can separate compounds with different vapor pressure characteristics. The system has a Thermal Distillation Reactor (TDR) (13) into which the plant material is charged. The TDR provides for high rates of heat transfer coupled with small thermal diffusion length scales to allow substantially all of the plant material to be within a narrow temperature range, which enhances the separation purity cuts. The system provides high removal efficiencies whilst minimizing any impurities resulting from pyrolysis or thermal destruction to the cellulose, hemi-cellulose or lignin within the plant material.

Owner:BIOFRACT LLC

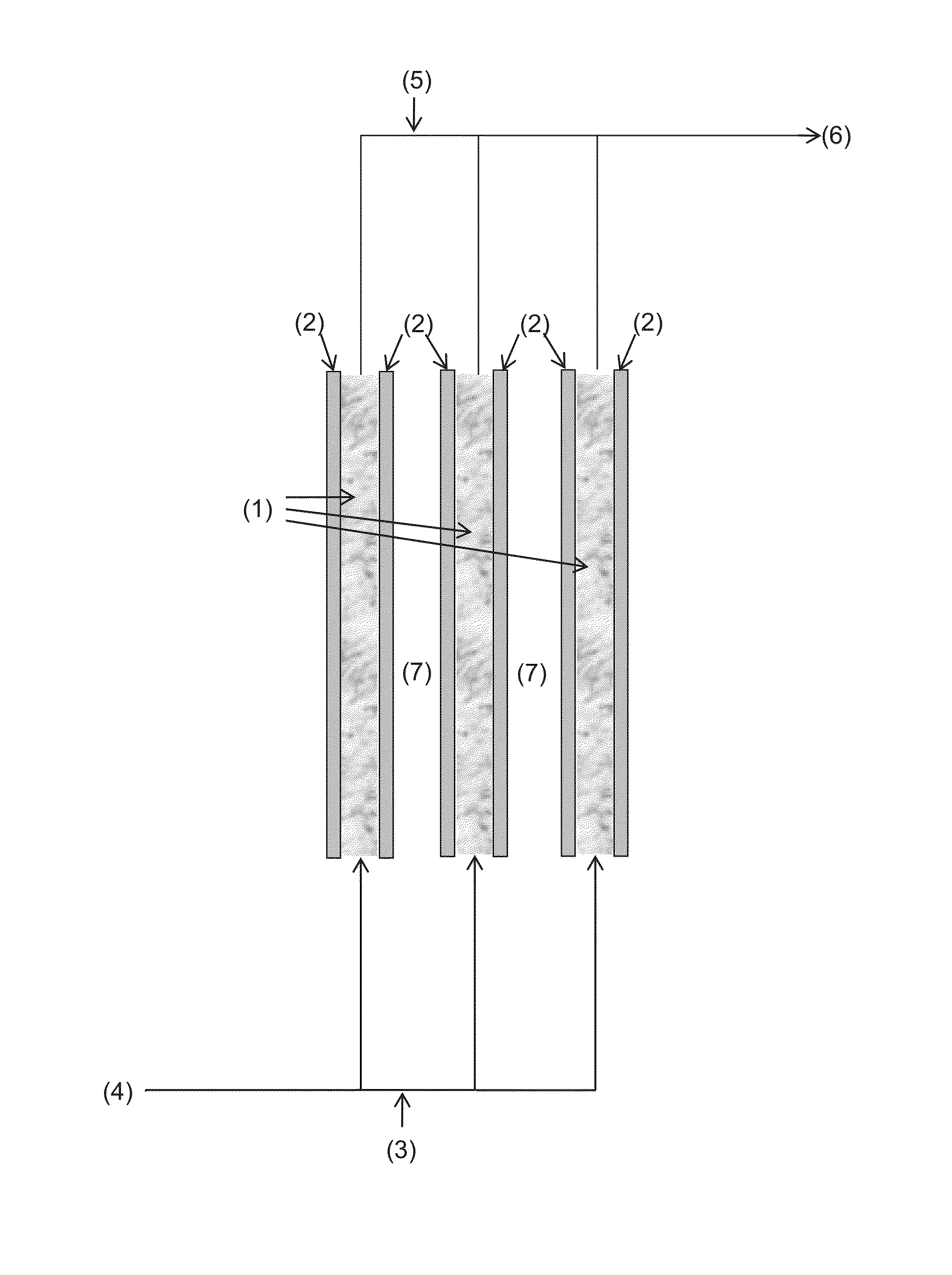

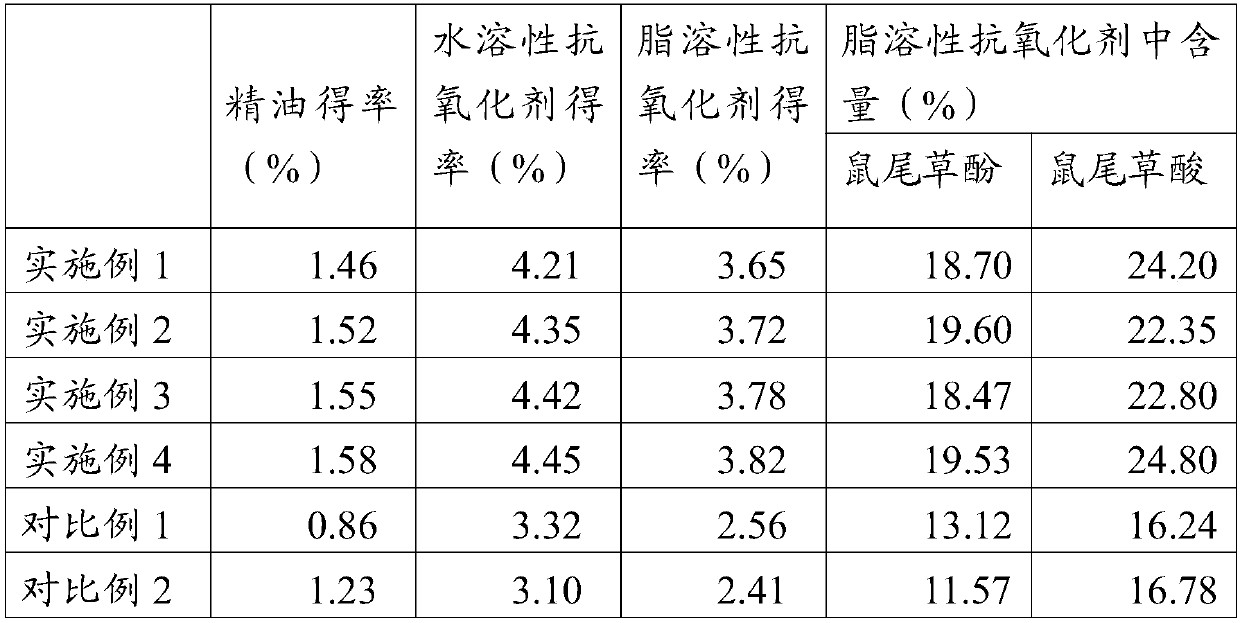

Method for extracting rosemary essential oil and antioxidant from rosemary

ActiveCN107686773AEfficient use ofRealize continuous productionEssential-oils/perfumesGas solvent extractionAntioxidantWater vapor

The invention provides a method for extracting a rosemary essential oil and an antioxidant from rosemary, and belongs to the technical field of plant extraction. The rosemary essential oil is extracted under the conditions that fresh rosemary branches and leaves are used as the raw materials and are processed through a rotating cone distillation column, the revolving speed of a rotating cone is 150-600 r / min, the feed rate of a wall-broken rosemary pulp is 100-300 L / h, the temperature of water vapor is 95-110 DEG C, and the flow velocity of the water vapor is 10-80 kg / h. Compared with the traditional water vapor distillation extraction, the extraction method provided by the invention can continuously produce, the distillation time of the material is short, the running temperature is low, the degradation of the processing material is effectively avoided, and the yields of the essential oil and the antioxidant are high.

Owner:SOUTHWEST FORESTRY UNIVERSITY +1

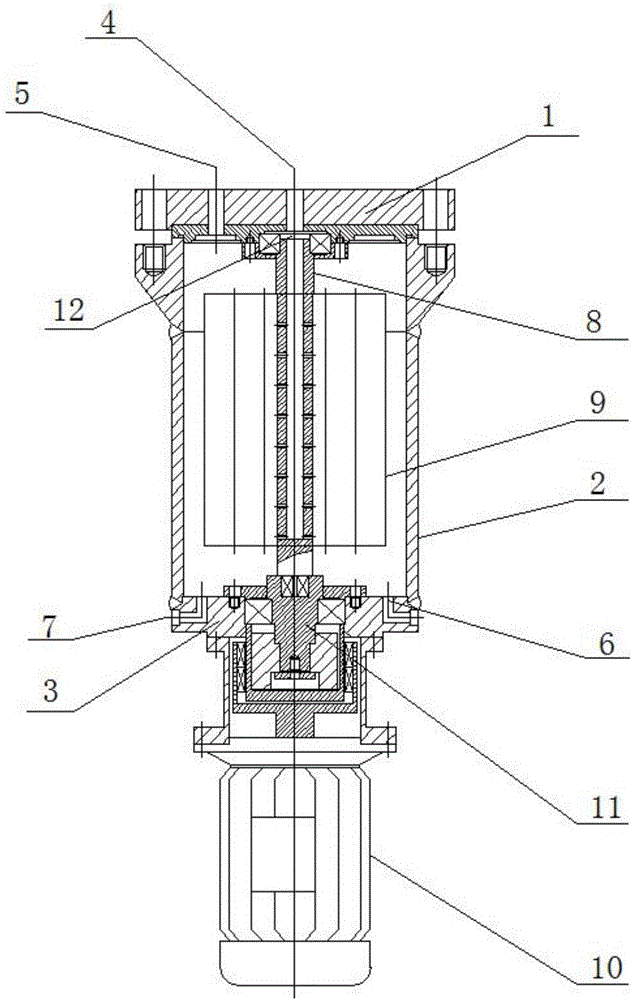

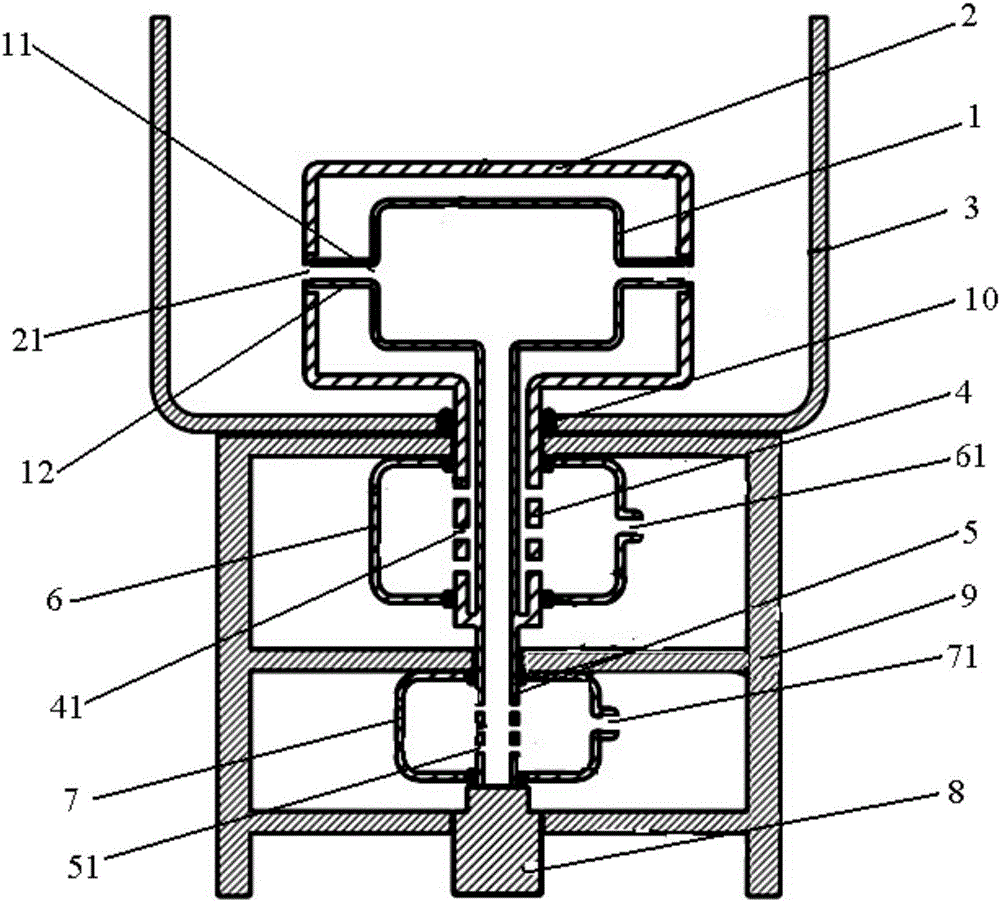

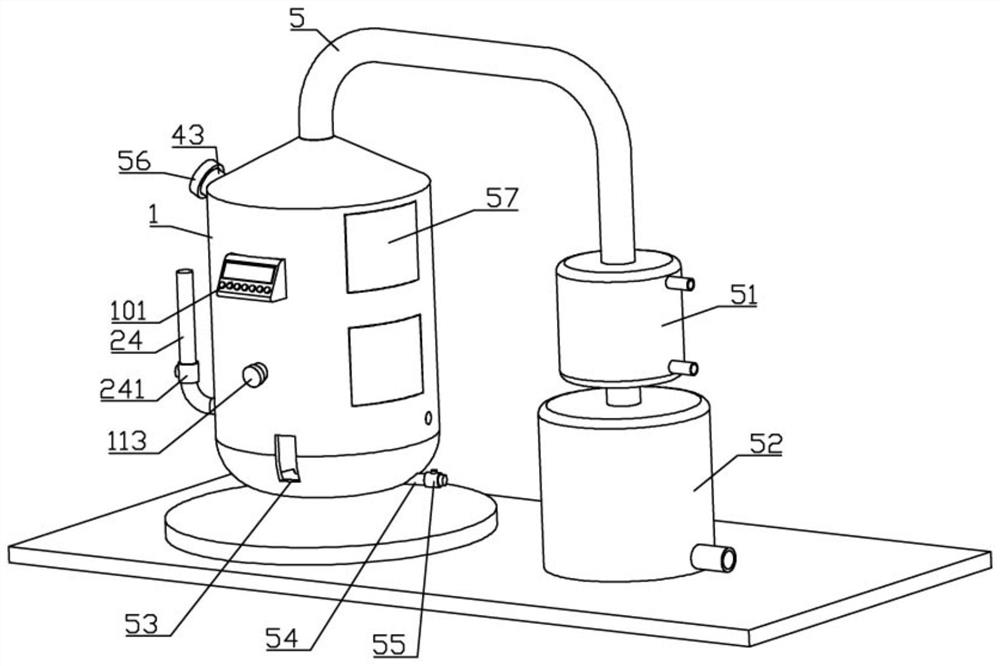

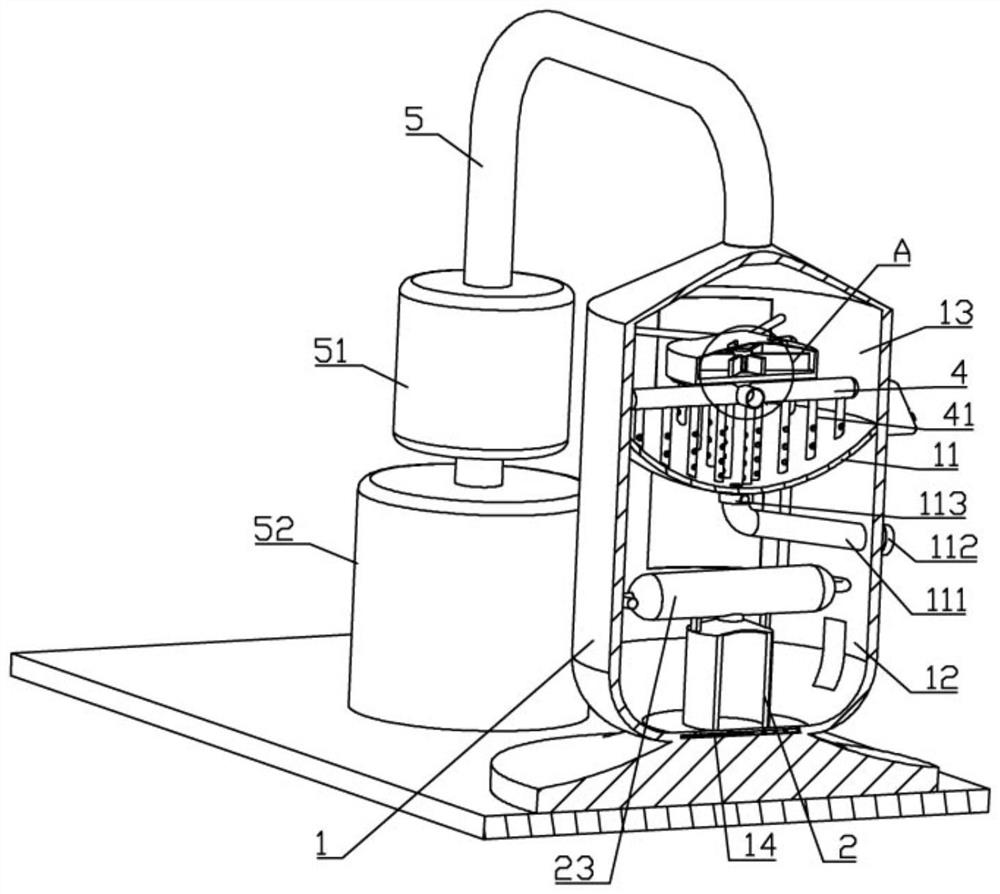

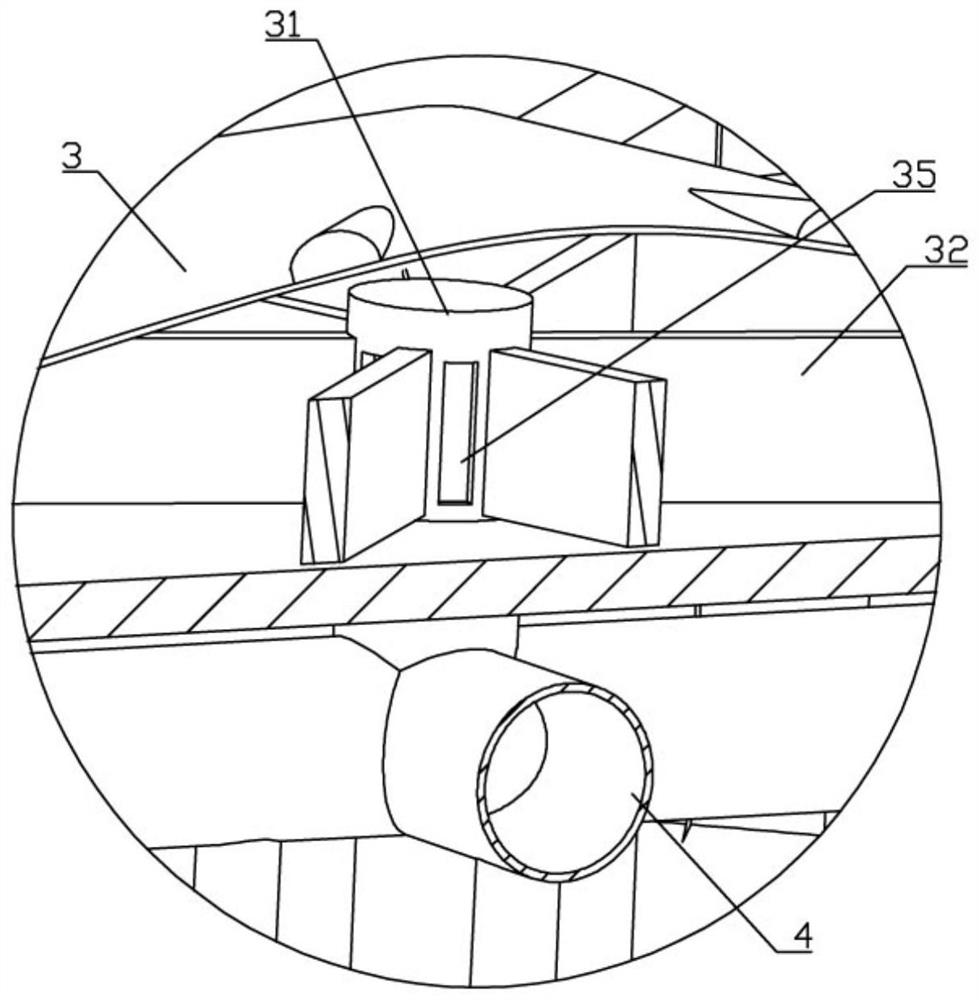

Supercritical carbon dioxide extraction tank and extraction system including same

ActiveCN105727585AIncrease contact areaIncrease productivityGas solvent extractionSolventSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide extraction tank. The supercritical carbon dioxide extraction tank comprises an extraction tank main body, a refining part and a power part, wherein the extraction tank main body sequentially comprises a top cover, a tank side wall and a base plate from top to bottom, a material inlet is formed in the center of the top cover, and a solvent outlet is formed beside the material inlet; a material outlet, a solvent inlet and a connecting hole are formed in the base plate in a penetration manner; the refining part comprises a feeding cylinder and a refining net, a plurality of discharging holes are formed in the side wall of the feeding cylinder in a penetration manner, and the feeding cylinder is externally sleeved with the refining net; and the power part comprises an electric motor, and the electric motor is fixedly connected with the lower end of the feeding cylinder. According to the supercritical carbon dioxide extraction tank, by virtue of a supergravity liquid drop refining manner, the contact area between a liquid material and a carbon dioxide solvent is increased, and the extraction efficiency is effectively improved. An extraction system including the supercritical carbon dioxide extraction tank can be used for solving the problem that the liquid material is difficultly continuously treated by virtue of a supercritical fluid extraction process.

Owner:QINGDAO H EXTRACT CO LTD

Apparatus for extracting oil from oil-bearing plants

ActiveUS9687754B2Simple and inexpensive mannerGas solvent extractionFatty-oils/fats productionTemperature controlHydrocarbon solvents

A system for extracting oil from oil-bearing plant parts has an extraction vessel supported by an upright stand, a separator vessel mounted below the extraction vessel, and an expansion filter vessel mounted downstream from the separator vessel. A source of hydrocarbon solvent supplies liquid gas to the top of the extraction vessel, while a recycling pump connected to the separator vessel facilitates transport of the solvent through the plant material in the extraction vessel. The solvent is recovered and re-circulated, while extracted oil is removed from the separator. A computer-based temperature control assembly having a cooling device and a jacketed injection coil regulates temperature of the solvent delivered to the extraction assembly. A thermal jacket is mounted on each of the separator vessel and the expansion filter vessel, with the thermal jackets supplying heat and cold to the interior of the separator vessel and the expansion filter vessel and helping evaporate and condense the solvent.

Owner:ELLIS MATTHEW

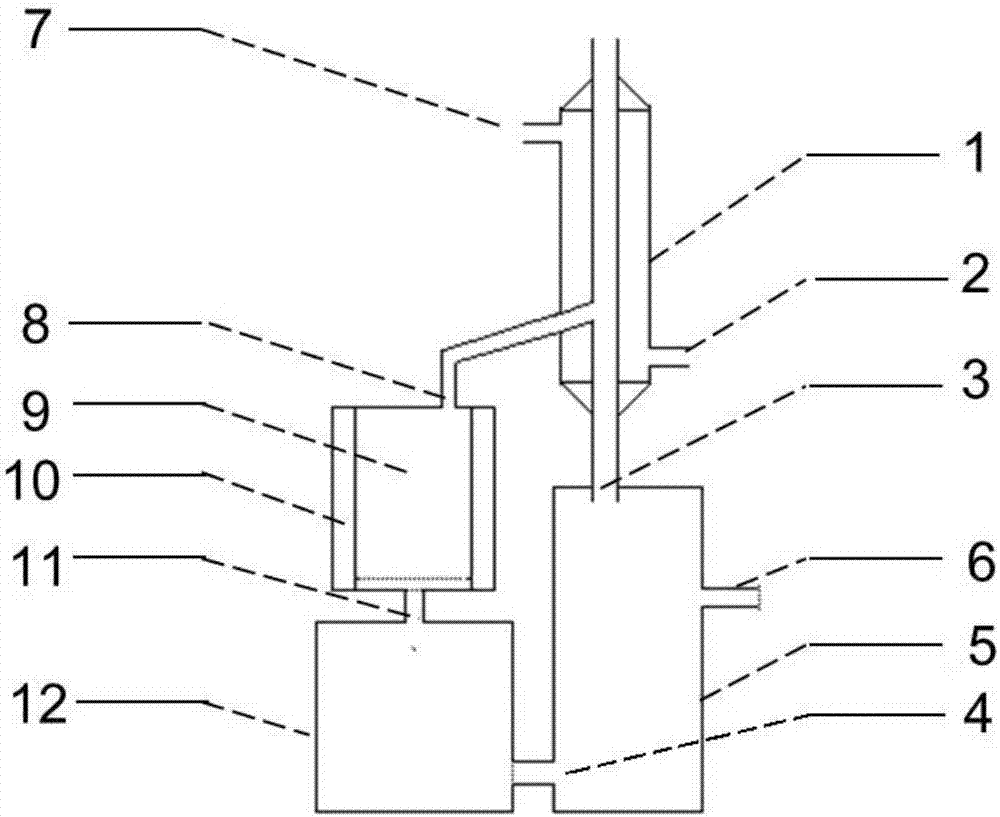

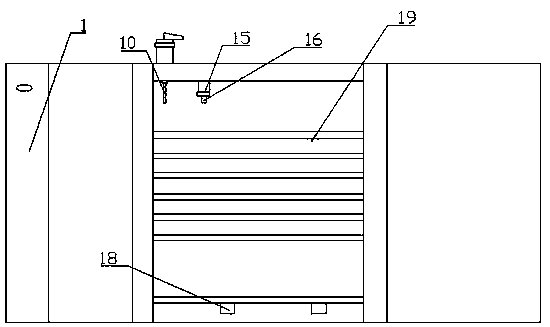

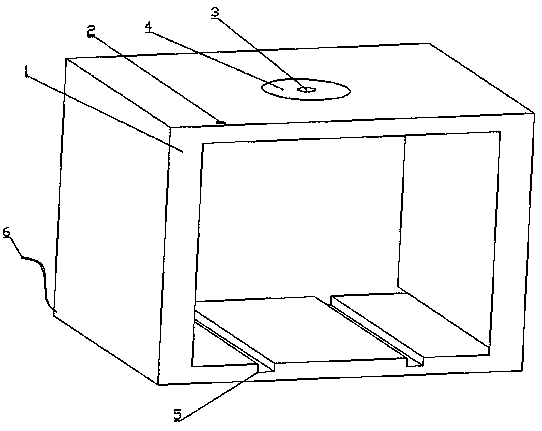

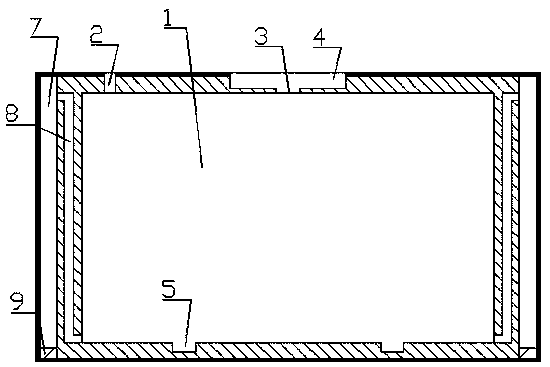

Device and method for extracting tobacco essence through superheated steam distillation

PendingCN106867673AIncrease productivityHigh yieldTobacco treatmentEssential-oils/perfumesSuperheated waterOil water

The invention discloses a device for extracting a tobacco essence through superheated steam distillation. The device comprises a distillation tank (9) and an oil-water separator (5), wherein a heating device (10) is arranged on the outer layer of the distillation tank (9); the upper end port of the distillation tank (9) is communicated with the lower part of a condenser pipe (1) through a distillation gas outlet (8); the lower end port of the distillation tank (9) is communicated with the upper end port of a superheated steam generation device (12) through a steam outlet (11); the upper end port of the oil-water separator (5) is communicated with the lower end port of the condenser pipe (1) through a condensed liquid outflow port (3); the middle upper part of the oil-water separator (5) is communicated with the upper part of the superheated steam generation device (12) through a water content outlet (4); an oil content outlet (6) is formed in the lower part of the oil-water separator (5). The invention also discloses a method for extracting the tobacco essence through the superheated steam distillation device.

Owner:CHINA TOBACCO YUNNAN IND

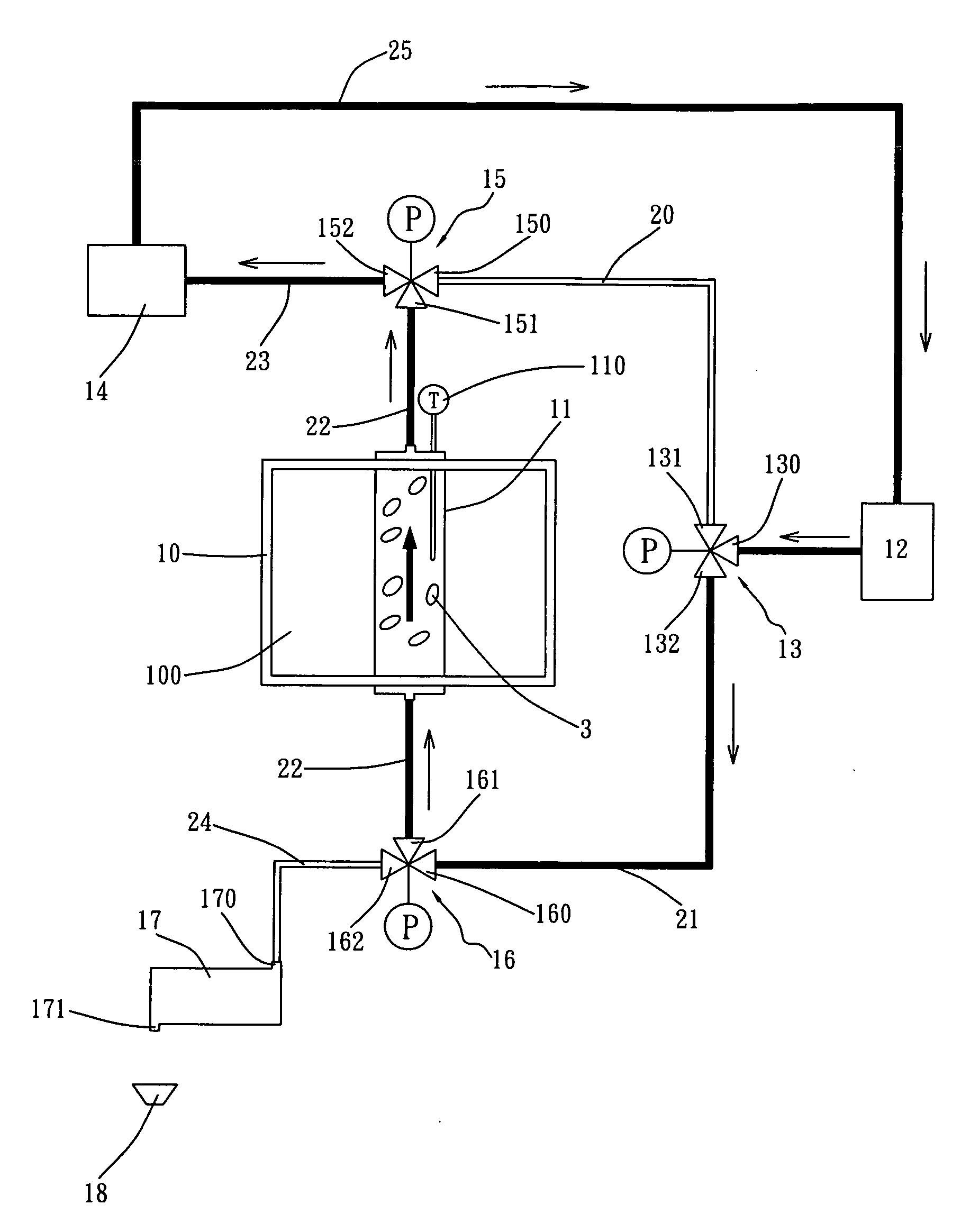

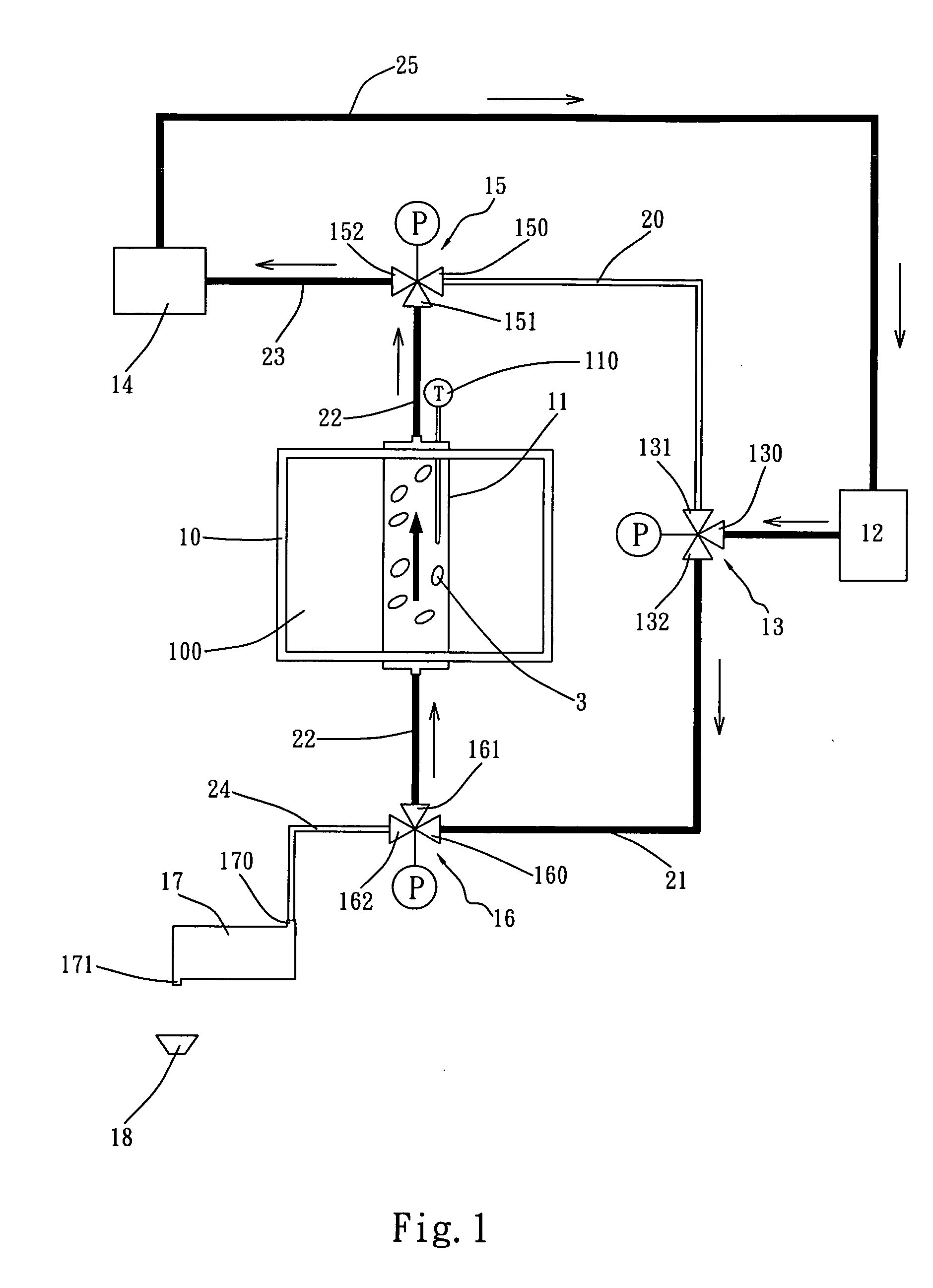

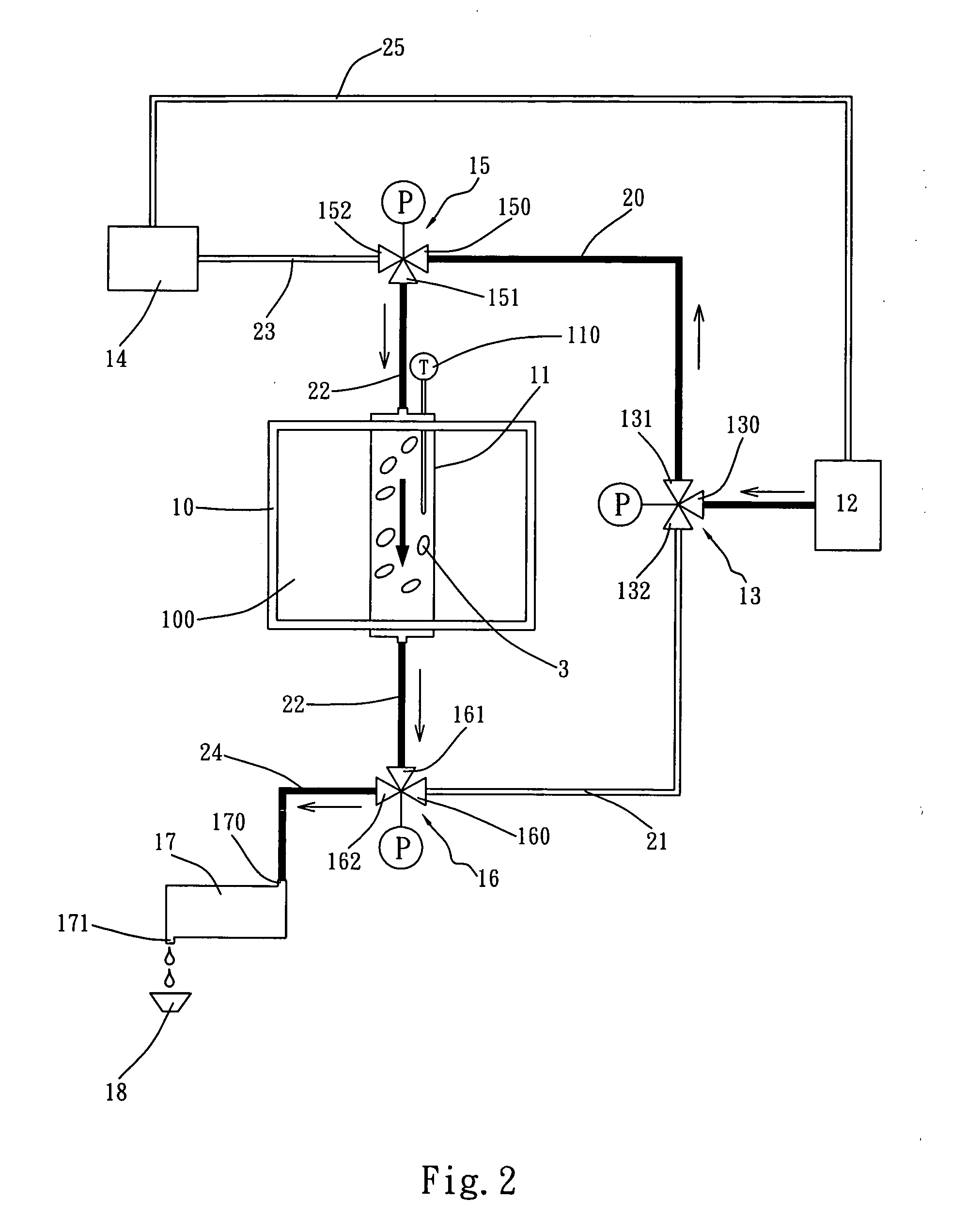

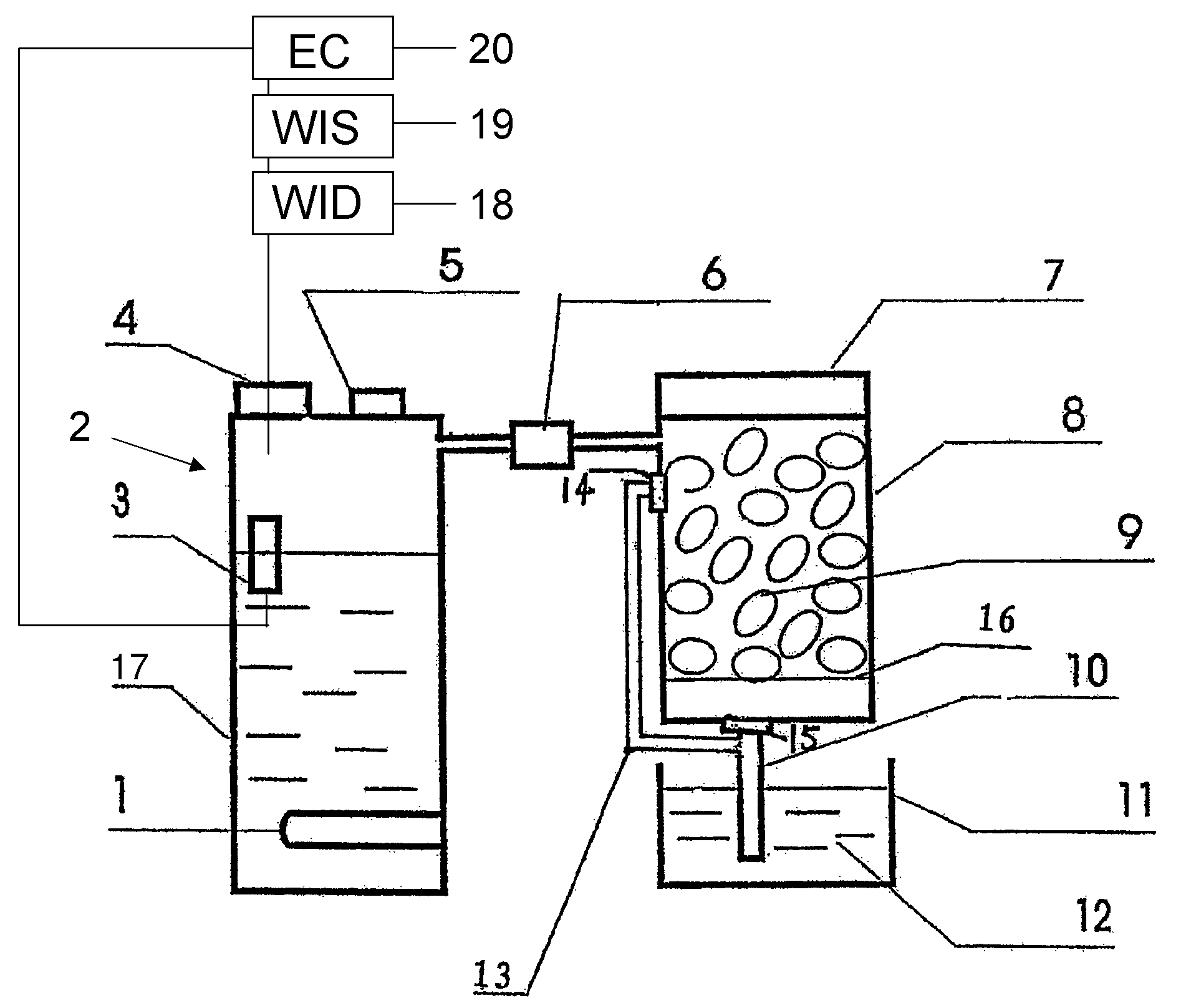

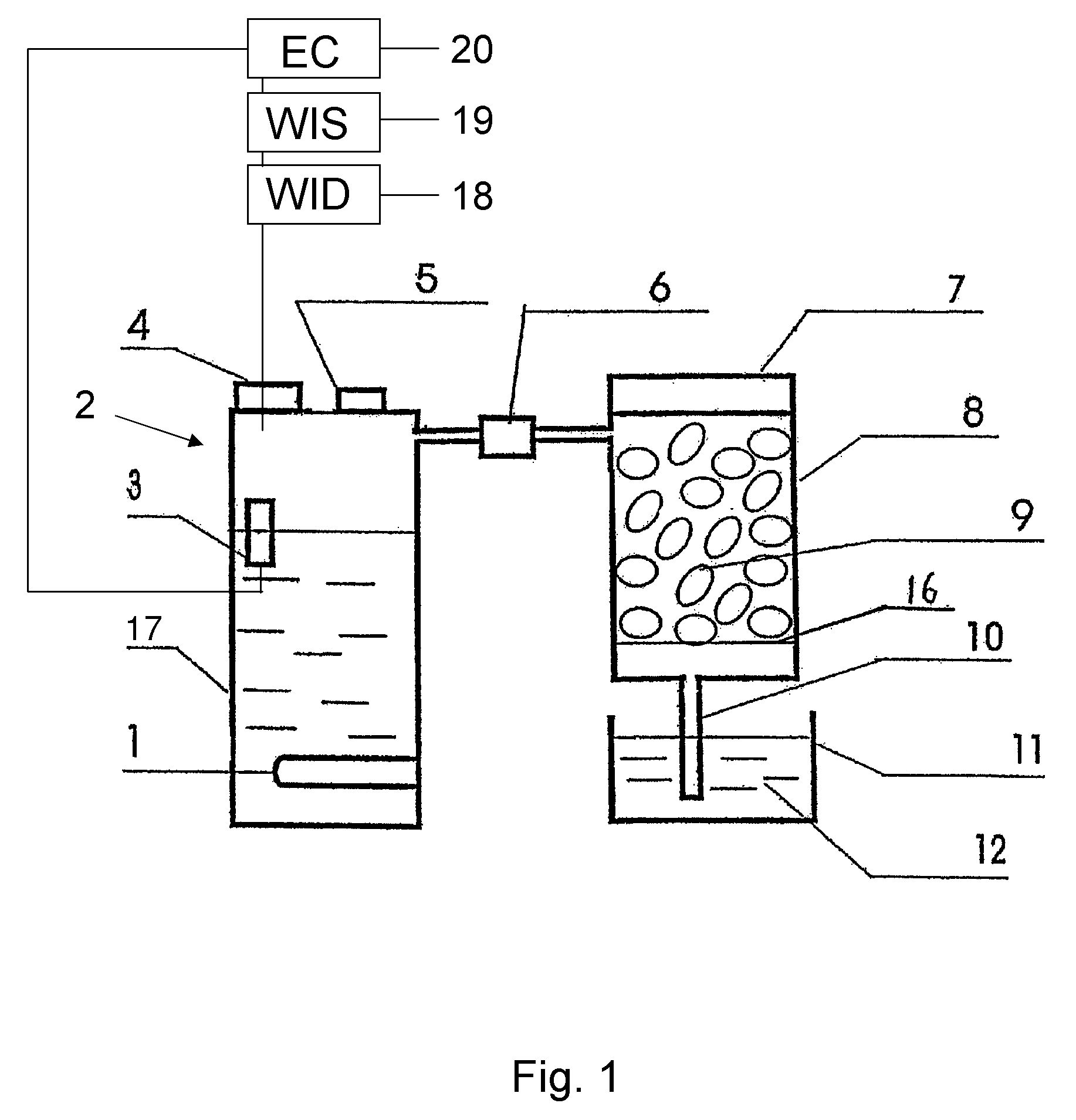

Method and device for preparing liquid

ActiveUS7770511B2Reduce the presence of hazardous substancesIncrease volumeFunctional valve typesCharging-discharging device combinationsDistillationHazardous substance

The invention relates to a device and method for preparing liquid from solid materials such as medicinal materials. It includes liquid and materials for preparing the liquid at the beginning and the end of the process. The device uses a steam generator, an intermediate switch valve and a material chamber, which are connected sequentially with pipes, and further includes an outlet pipe, which is at the bottom of the material chamber. The method involves the steps of: distillation and absorption; immersion; and repetition. The device and method for preparing liquid alternates the distillation and immersion steps, which reduces harmful substance in the prepared liquid that would otherwise occur by conventional methods. The method not only extracts soluble effective matter, but also reduces loss of volatile effective matter. Ultimately, the method makes the steps for preparing liquid simple and clear, and it can prepare liquid quantitatively, effectively and without pasty and shrinkable characteristics. The device may be automatically controlled by an electric control circuit, thereby avoiding operational errors that are common with manually operated, conventional devices.

Owner:SHENZHEN ZOFU TECH

Extraction apparatus and method of extracting essential oils, essence, and pigments from odorous raw material by microwave heating under sub-critical conditions

ActiveUS8282788B2Improve efficiencyIncrease temperatureFunctional valve typesDrying solid materials with heatEngineeringMicrowave irradiation

The invention relates to extraction apparatus and method for obtaining essential oils and essence and pigments from odorous raw materials by microwave radiation heating under sub-critical conditions, which has advantages of easy operation, higher extracting temperature and efficiency. The microwave chamber has a power level of 100 W to 1,500 W and its microwave radiation has a frequency at 915 MHz or 2,450 MHz. The extraction process can be performed without any preheating necessary. A condenser unit is operated at temperatures between −20° C. and 15° C. for cooling the gas extractive flowing out of the extraction unit. Because both volatile aromatic compounds and pigments of the odorous raw materials can be extracted successfully, the extracted essence is colorful. Since the extraction process by microwave radiation heating is free from adding any organic solvent and / or any artificial chemical compound, the extraction apparatus and method applied are really environmentally friendly.

Owner:JOINTEK

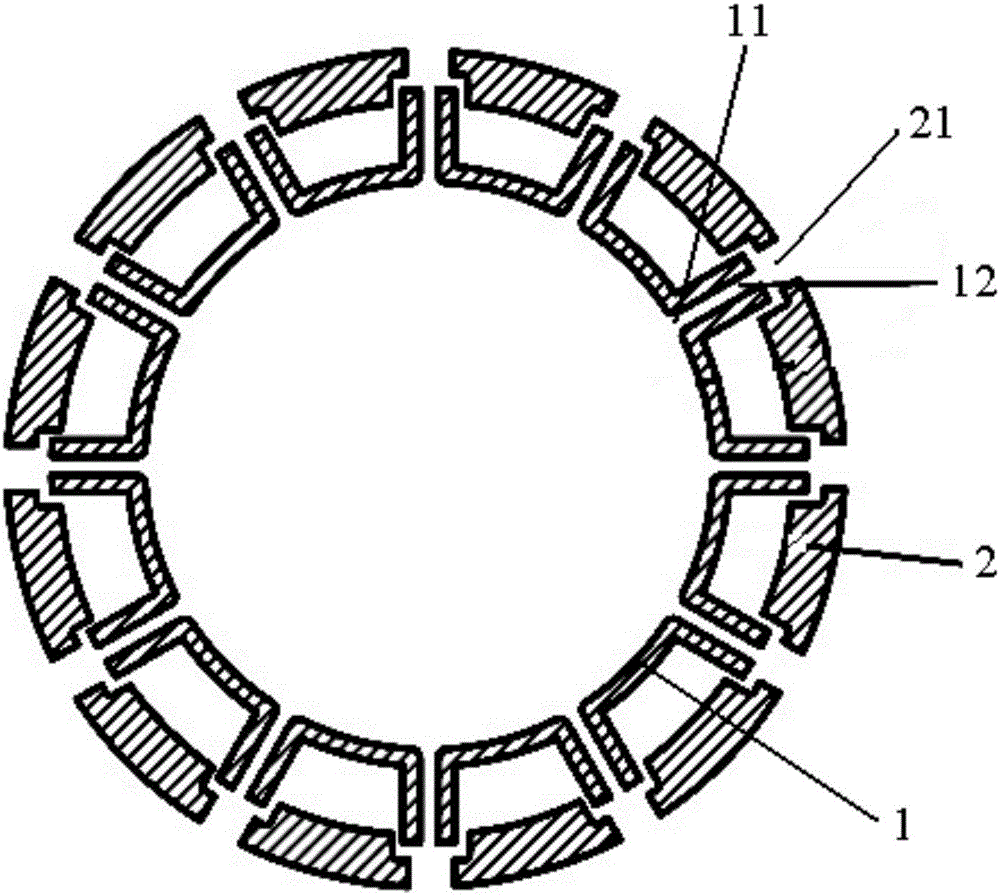

Traditional Chinese medicine extracting device

InactiveCN106823449AIncrease contact rateEasy extractionGas solvent extractionSolid solvent extractionProgrammable logic controllerWater storage tank

The invention provides a traditional Chinese medicine extracting device which comprises a cooking chamber, a membrane separation chamber, a condenser and a water storage tank, wherein the cooking chamber is positioned above the membrane separation chamber; the cooking chamber is communicated with the membrane separation chamber; the cooking chamber is connected with the condenser and the water storage tank through pipelines; a programmable logic controller, a sealing door, an air inlet, an air outlet and a water inlet are arranged on the cooking chamber; a roller, a heater and a temperature sensor are arranged in the cooking chamber; the roller is fixed to a rotating shaft; the rotating shaft is connected with an output shaft of a motor; the motor is fixed to the exterior of the cooking chamber; the interior of the roller is communicated with the interior of the cooking chamber; an openable door is arranged in a position on the roller opposite to the sealing door; the heater, the temperature sensor and the motor are electrically connected with the programmable logic controller; and a screen is arranged at the communicated part between the bottom of the cooking chamber and the membrane separation chamber. The traditional Chinese medicine extracting device provided by the invention is capable of increasing the extraction efficiency of effective constituents and saving energy.

Owner:TIANJIN HENGTIAN BIOLOGICAL TECH CO LTD

Extraction apparatus

InactiveCN106669224AEvenly distributedIncrease contact timeLiquid solutions solvent extractionGas solvent extractionSolventAir bubble

The invention discloses an extraction apparatus, belongs to the technical field of extraction, and is designed for solving the problem of nonuniform distribution of extractant in the prior apparatus. The extraction apparatus comprises an air chamber and a first solvent chamber which is sleeved outside the air chamber, the air chamber and the first solvent chamber are placed in a second solvent chamber, the first solvent chamber is used for containing a light phase extractant, the second solvent chamber is used for containing a heavy phase liquid to be extracted, the first solvent chamber and a extractant source which is positioned outside the solvent chamber are communicated, and the air chamber and a gas source which is positioned outside the second solvent chamber are communicated; a side wall of the air chamber is circumferentially and uniformly provided with several gas outlets, a side wall of the first solvent chamber corresponding to the position of the gas outlets is uniformly provided with several first outlets, and each gas outlet is communicated to the inner side of the corresponding first outlet or into the first outlet. In the extraction apparatus, oil gas bubble generation points are uniformly distributed, so that the extractant can be uniformly distributed in the liquid to be extracted with good extraction effects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

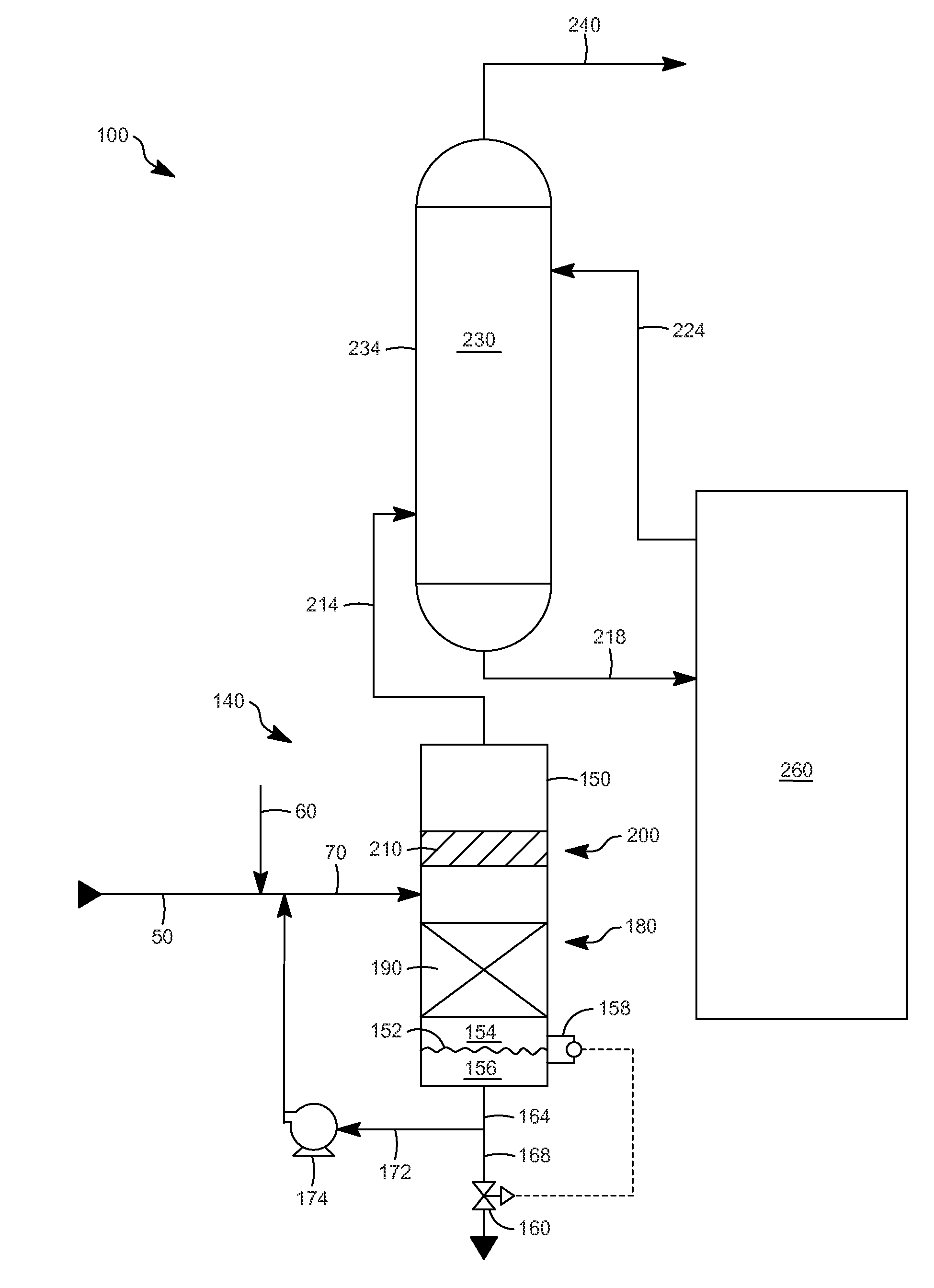

Process for removing carbonyl sulfide in a gas phase hydrocarbon stream and apparatus relating thereto

ActiveUS20140371508A1Operational flexibilityLow costHydrocarbonsLiquid solutions solvent extractionGas phaseCarbonyl sulfide

One exemplary embodiment can be a process for removing carbonyl sulfide in a gas phase hydrocarbon stream. The process may include combining the gas phase hydrocarbon stream with another stream including an alkali and an alkanolamine, and passing the combined stream to a prewash zone including a vessel. The gas phase hydrocarbon may include carbonyl sulfide, and the alkali can include at least one of potassium hydroxide, sodium hydroxide, and ammonia. Usually, the vessel contains a contacting zone and a coalescing zone for removing the carbonyl sulfide.

Owner:UOP LLC

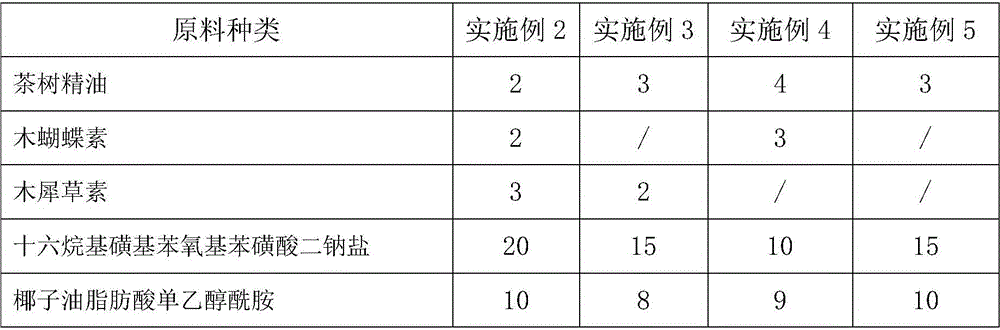

Tea tree essential oil extracting method and tea tree essential oil composition

InactiveCN106010795AMild performancePromote environmental protectionNon-ionic surface-active compoundsEssential-oils/perfumesShootSolvent

The invention provides a tea tree essential oil extracting method, comprising the steps: selecting fresh tea leaves and fresh tender shoots, adding to a CO2 supercritical extractor, using ethanol as an entrainer accounting for 4-6% by weight of a total extracting solvent, extracting under a pressure of 15-30 Mpa, at a temperature of 30-50 DEG C and at a CO2 flow of 1-3 ml / g raw drug per min, and extracting for 150-180 min to obtain the tea tree essential oil; soap made with the tea tree essential oil can diminish inflammation, is effective to use and is handy.

Owner:NANJING ZHENGKUAN MEDICAL TECH

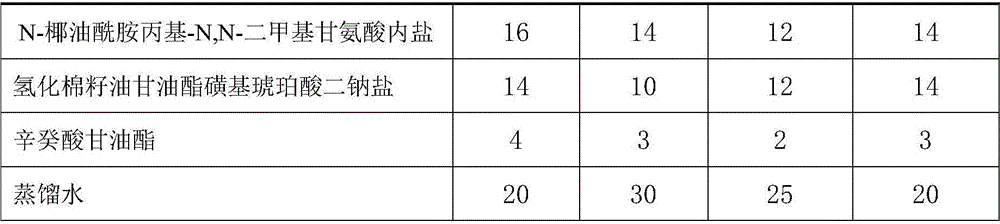

Method for removing organic solvent residue from bulk drug

InactiveCN105344128AAvoid destructionAvoid secondary pollutionGas treatmentSeparation devicesOrganic solventSorbent

The invention discloses a method for removing organic solvent residue from a bulk drug. The method includes: under a temperature of 35-80DEG C and a pressure of 10-40MPa, firstly performing static extraction for 0.5-2h, and then conducting dynamic extraction for 0.5-6h so as to obtain a bulk drug finished product with the organic solvent residue meeting the limit standard in an extraction kettle; carrying out pressure reduction separation on the carbon dioxide flowing out of the extraction kettle at a pressure of 4-7MPa and a temperature of 25-45DEG C, collecting the precipitate in a separation kettle, recovering the bulk drug, and loading the bulk drug into the extraction kettle for application. An adsorbent is employed to conduct adsorption separation on the carbon dioxide flowing out of the separation kettle, and the obtained carbon dioxide is introduced into the extraction kettle for cycle use. The bulk drug finished product obtained by the method has the organic solvent residue meeting the limit standard, the bulk drug yield is high, and the carbon dioxide can be recycled. The method provided by the invention has the advantages of simple process, stable operation, economical efficiency and high efficiency, and is suitable for industrial application.

Owner:SHANDONG GUANGTONGBAO PHARMA

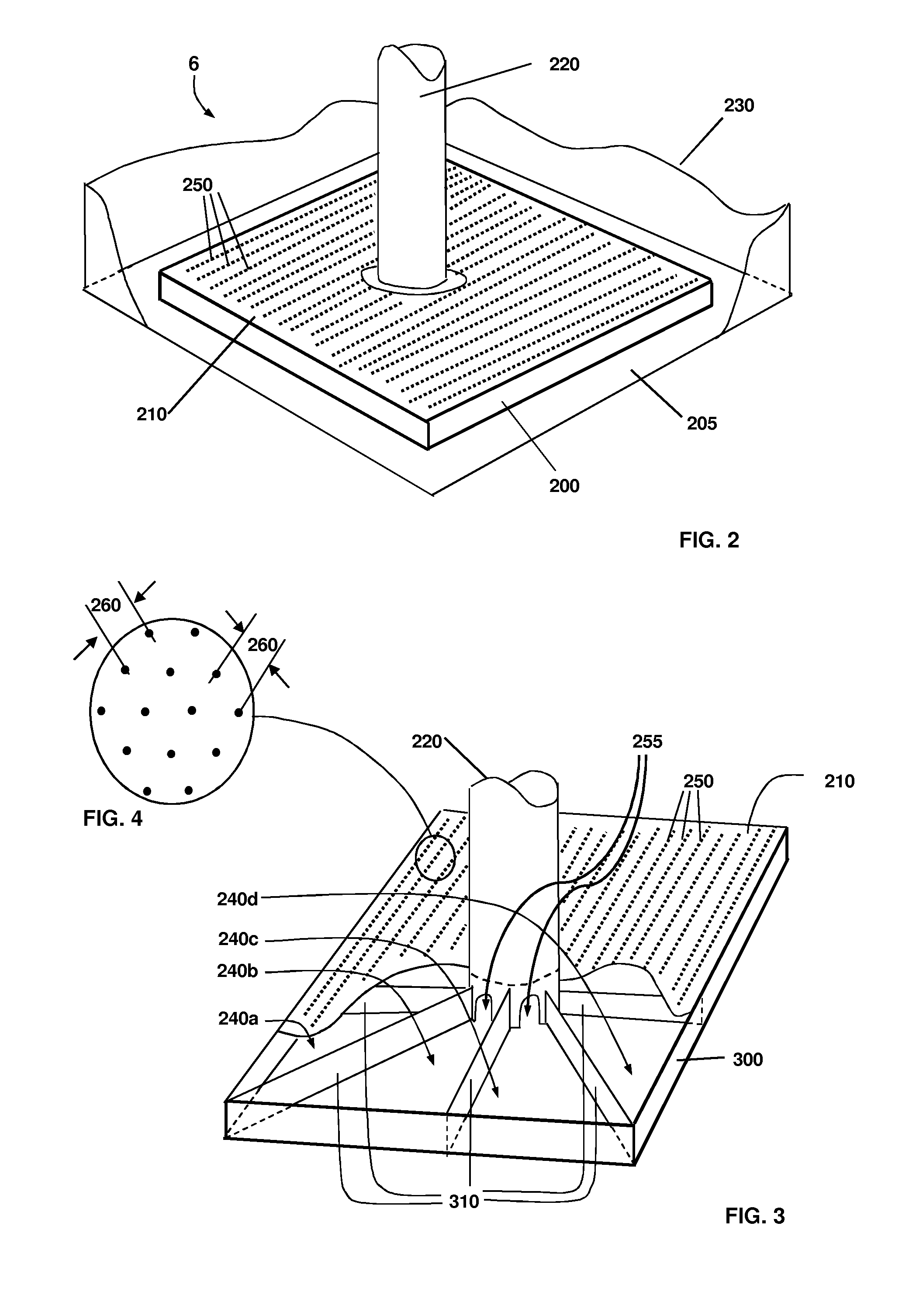

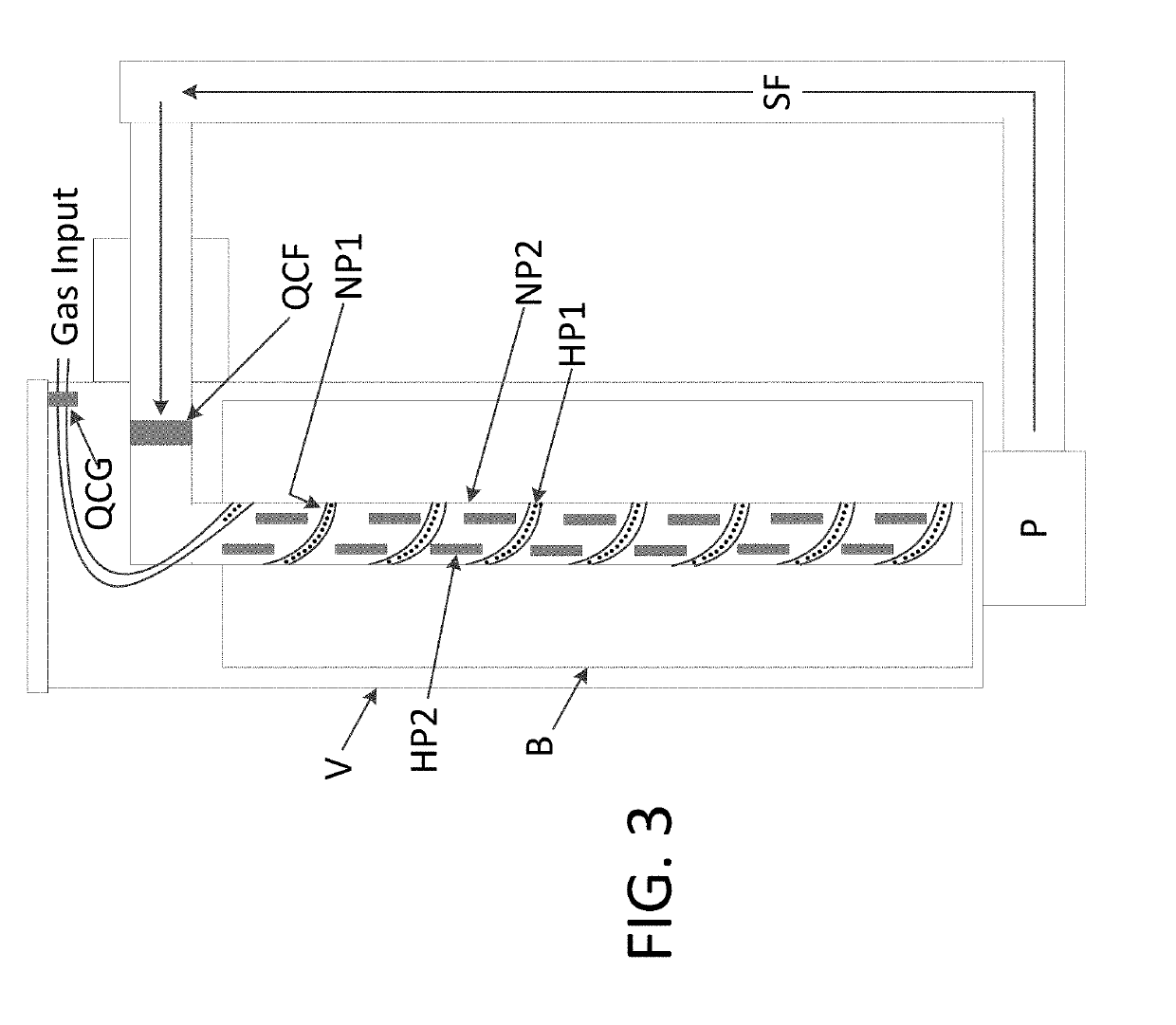

Nozzles for Essential Element Extraction Method and Apparatus

The present disclosure includes a nozzle and methods for using the nozzle in ways that may increase the efficiency of extraction of essential elements from plant matter. The nozzle may also be used to increase the efficiency of drying solvent saturated plant matter after an extraction has been completed. The nozzle may include an elongated tube with a plurality of holes that allow solvent and / or a gas to be provided or pumped / provided into an apparatus that includes plant matter. Nozzles consistent with the present disclosure may be optimized for extracting cannabis from cannabis plant matter or from other types of plants that include cannabinoids. In certain instances, nozzles may also be used when processing cannabinoid containing concentrates that were extracted from plant matter using any type of extraction technique.

Owner:RAPP ROBERT JAMES

Method for extracting ganoderma spore oil

PendingCN106318611AImprove oil yieldExtended shelf lifeFatty-oils/fats refiningGas solvent extractionSporeGrape seed

The invention discloses a method for extracting ganoderma spore oil. Grape seeds are used as antioxidant donors, excellent anti-oxidation effects can be realized after the grape seeds and ganoderma spore powder are collaboratively matched with one another, oxidation and rancidity of effective components in the ganoderma spore powder with broken walls can be effectively prevented, the oil yield of the ganoderma spore powder can be increased, the purity and the content of effective components in the ganoderma spore oil can be guaranteed, and the shelf life of the ganoderma spore oil can be prolonged; the ganoderma spore oil is extracted from the granulated ganoderma spore powder by the aid of supercritical carbon dioxide fluid; ganoderma spores are arranged in a supercritical fluid extraction device during extraction, and the ganoderma spore oil can be acquired by means of heating and injecting the CO2 fluid and boosting the pressures until the fluid is in a supercritical state and higher states. Compared with the prior art, the method has the obvious technical advantages that the method includes simple processes, is low in cost and high in ganoderma spore oil yield and can be widely applied to the field of technologies for extracting ganoderma spore oil from ganoderma spores, and the like.

Owner:开平市民丰食品有限公司

Traditional Chinese medicinal material preparation device and traditional Chinese medicinal material preparation method

InactiveCN111035959ASimple structureGood conditionPharmaceutical product form changeDomestic articlesAtomizer nozzleDistilled water

The invention relates to a traditional Chinese medicinal material preparation device and a traditional Chinese medicinal material preparation method. The device comprises a box body and a rhizoma polygonati placing frame arranged in the box body, wherein a distilled water tank, a yellow rice wine tank and an ultrasonic wave transmitter are arranged on the box body, a heating block is arranged in the distilled water tank, the distilled water tank communicates with the interior of the box body, the yellow rice wine tank is connected with an atomizing nozzle extending into the box body, the atomizing nozzle is located above the rhizoma polygonati placing frame, and is arranged towards the rhizoma polygonati placing frame, and the ultrasonic wave transmitter is arranged towards the rhizoma polygonati placing rack. The traditional Chinese medicinal material preparation device is simple in structure, can solve the problem that manual steaming is not easy to control, avoids too high temperature and too high pressure, and is high in steaming efficiency and good in steaming effect.

Owner:PINGDINGSHAN UNIVERSITY

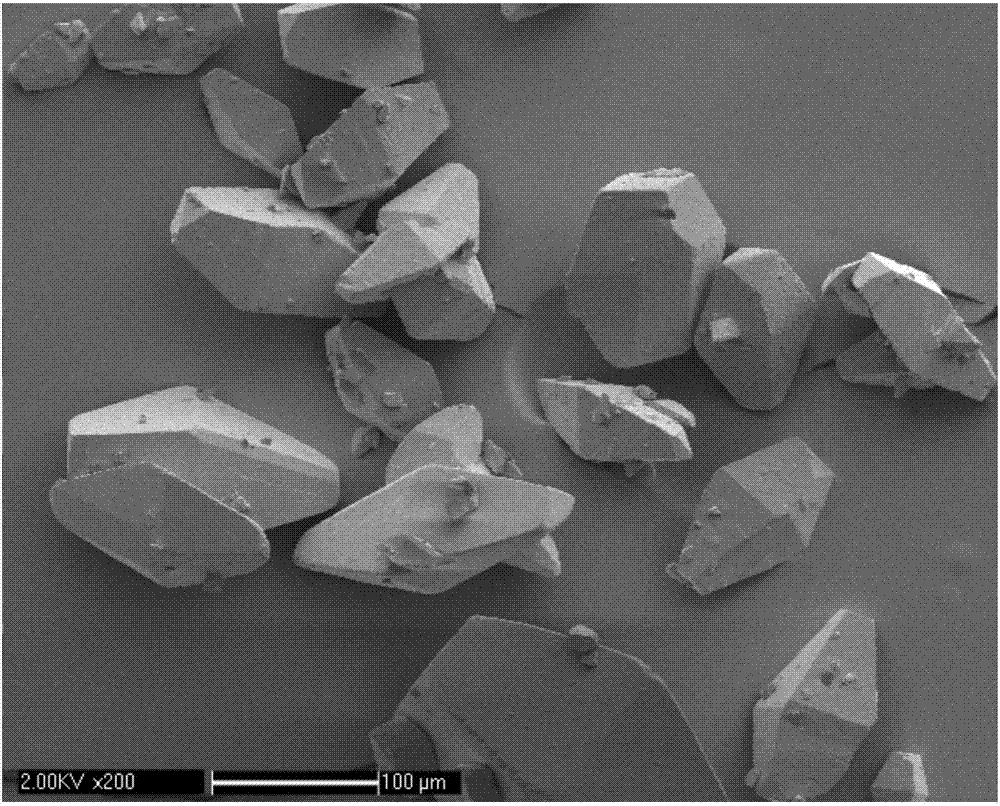

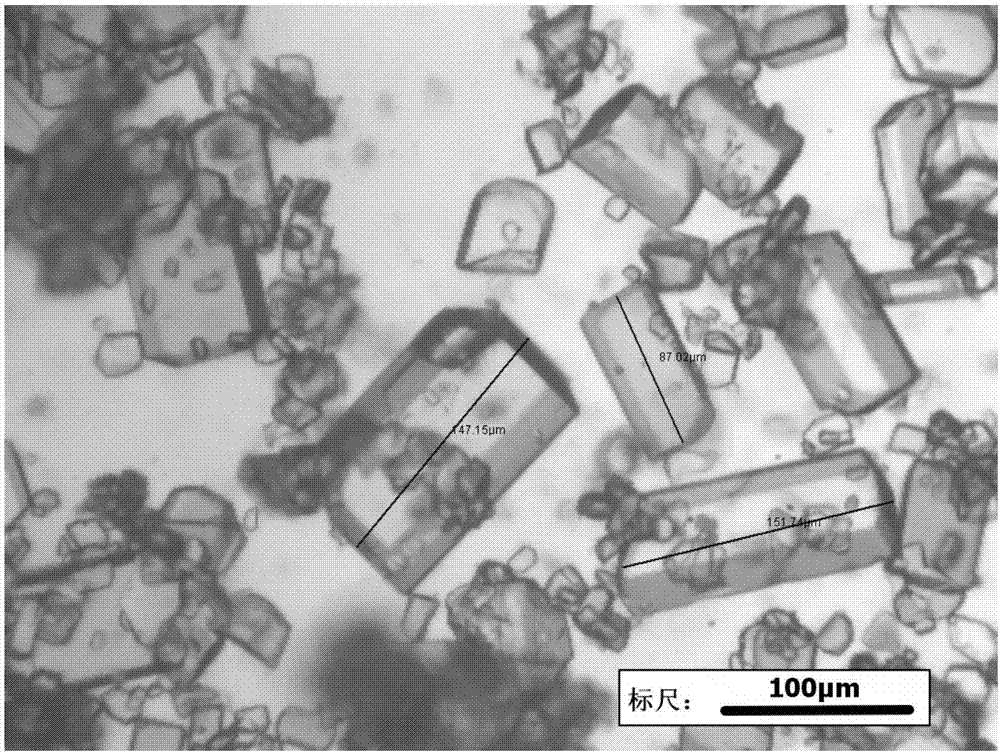

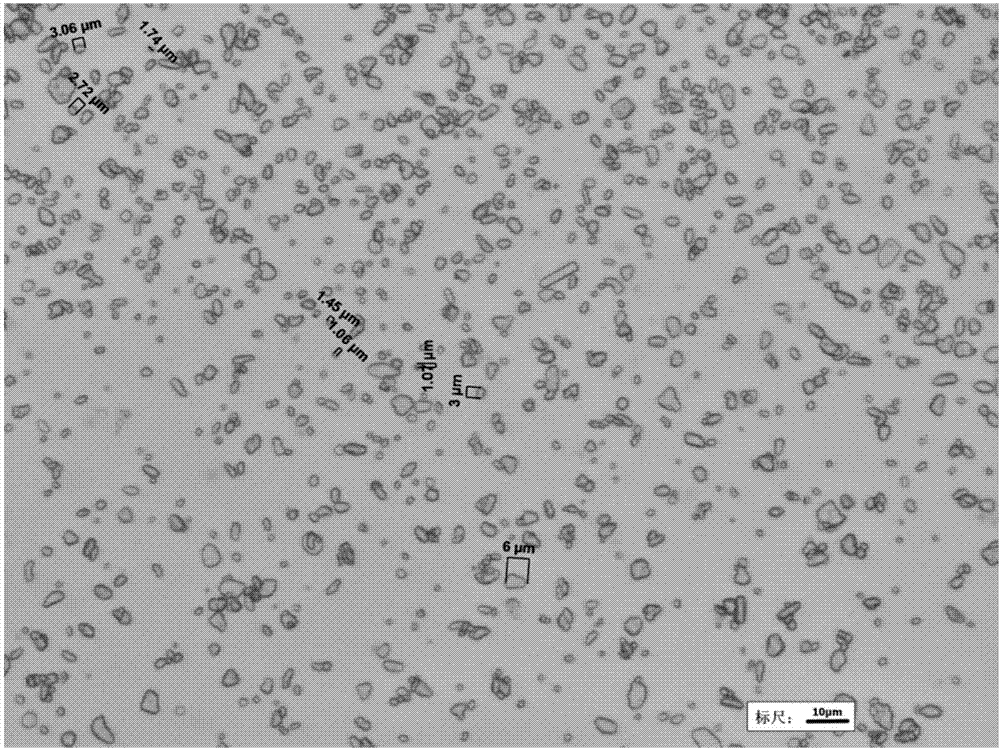

CL-20 explosive crystal refinement method based on counter solvent ultrasonic extraction technology

ActiveCN106861234AEasy to removeParticle Size Control RefinementCrystallization separationGas solvent extractionApparent densitySolvent molecule

The invention discloses a CL-20 explosive crystal refinement method based on a counter solvent ultrasonic extraction technology. The method comprises the following steps: complexing a raw material CL-20 and solvent to prepare CL-20 solvent compound crystals; adding the CL-20 solvent compound crystals into counter solvent, and simultaneously performing ultrasonic treatment; and after solvent molecules of the CL-20 solvent compound crystals are removed, stopping ultrasonic treatment, then filtering, washing, and drying to obtain refined CL-20 crystals. The refined CL-20 crystals have a favorable particle shape, the crystals are in an epsilon crystal form, the average particle diameter is smaller than 5 mu m, the crystal purity is greater than 99.6%, and the apparent density of the crystals reaches 99.5% or above of the theoretical density of the crystals.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Extraction device for shampoo production

ActiveCN111974019AImprove reaction efficiencyEasy extractionChemical/physical/physico-chemical stationary reactorsGas solvent extractionWater storageWater storage tank

The invention belongs to the technical field of shampoo production and extraction, and in particular relates to an extraction device for shampoo production. The extraction device comprises a distillation box and a control panel, wherein an arc-shaped ventilating plate is assembled in the distillation box; a first electromagnetic valve is assembled on a discharging pipe; the distillation box is divided into a water storage cavity and a placement cavity by the arc-shaped ventilating plate; a water storage tank is arranged at the bottom of the water storage cavity; the upper side of the water storage tank is connected with a gas storage tank through a pipeline; a plurality of impact plates are annularly and uniformly arranged on a hollow shaft; a rotating box is provided with two high-pressure air valves with separate circumferences; a plurality of hollow stirring rods matched with the arc-shaped surface of the arc-shaped ventilating plate are assembled on the four sides of a cross-shapedhollow pipe; according to the extraction device, in the herbaceous plant distillation process, water vapor drives the plurality of the hollow stirring rods to overturn and stir herbaceous plants, thereaction efficiency of the herbaceous plants and the water vapor is improved, the water vapor is directly poured into the stacked herbaceous plants through air holes, and the reaction efficiency of the herbaceous plants and the water vapor is improved.

Owner:广州德谷个人护理用品有限公司

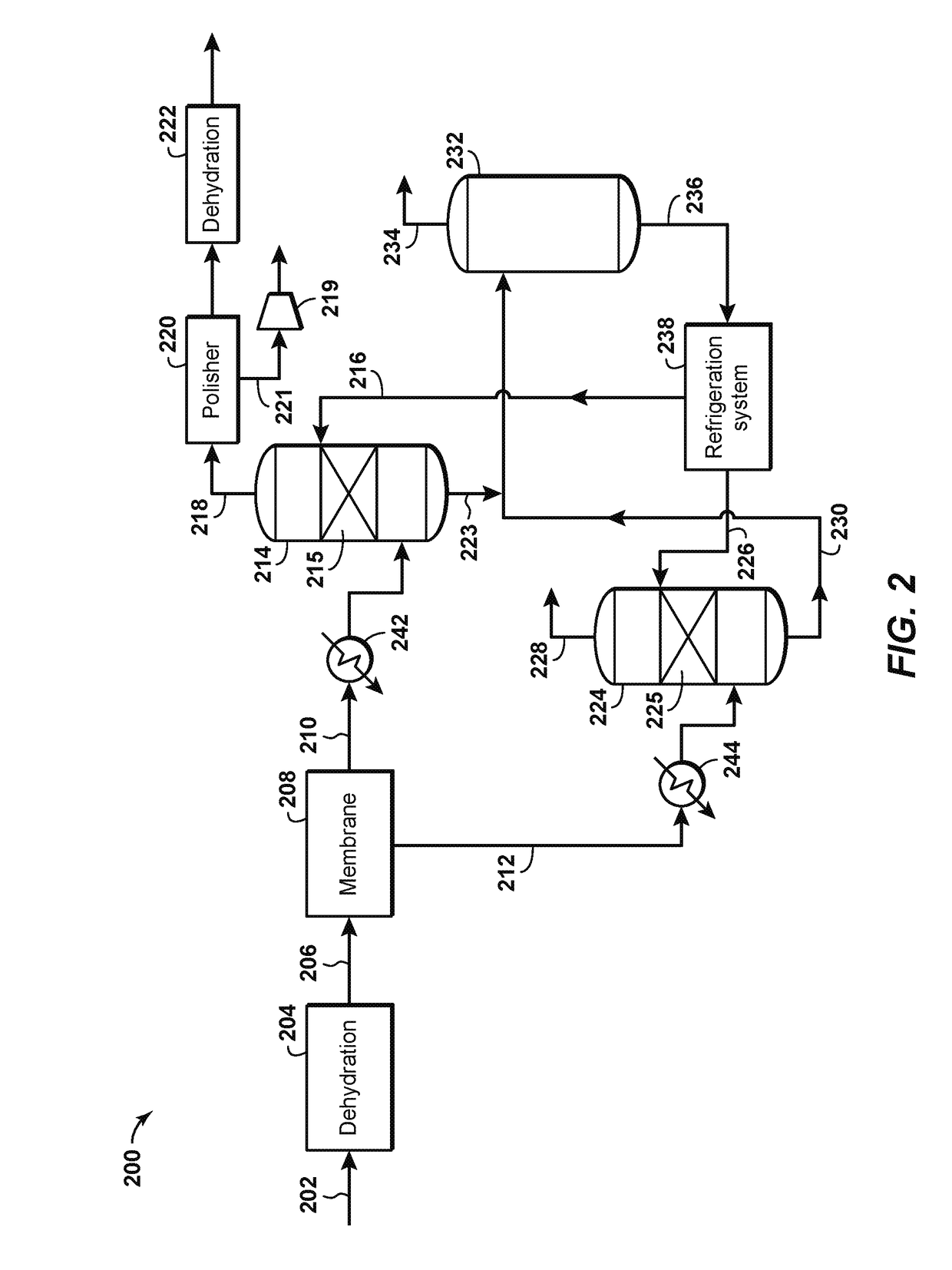

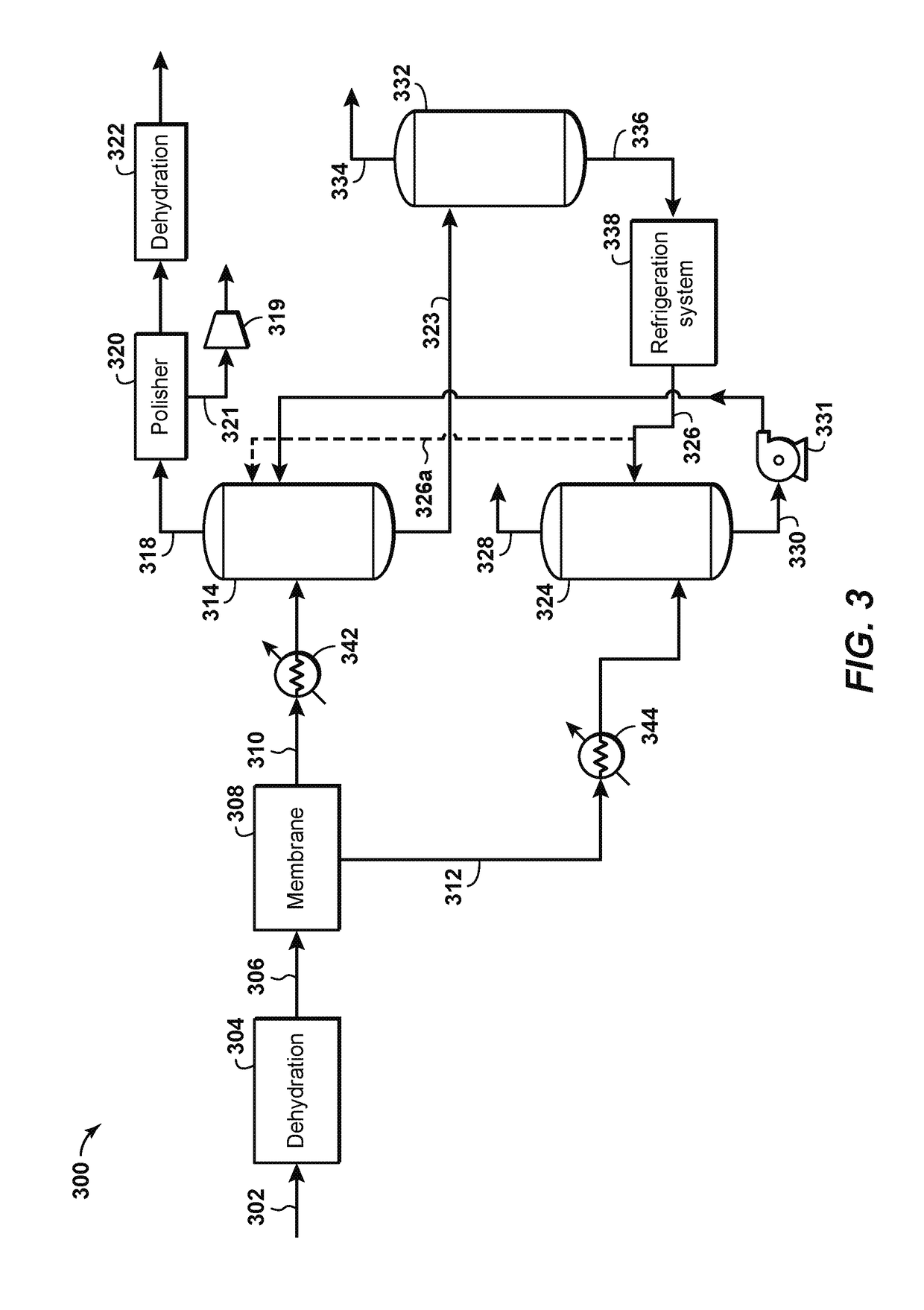

Integration of Cold Solvent and Acid Gas Removal

A method of separating impurities from a natural gas stream. CO2 and H2S are separated from the natural gas stream in a membrane separation system, thereby creating a partially-treated gas stream and a permeate gas stream, both of which are at a lower temperature than the natural gas stream. The partially-treated gas stream is contacted with a first lean solvent stream in a first contactor to separate H2S from the partially-treated gas stream, thereby producing a first rich solvent stream and a fully-treated gas stream. The permeate gas stream is contacted with a second lean solvent stream in a second contactor to separate H2S therefrom to produce a second rich solvent stream and a CO2 gas stream. H2S and CO2 are removed from the first and second rich solvent streams, thereby producing the first and second lean solvent streams.

Owner:EXXONMOBIL TECH & ENG CO

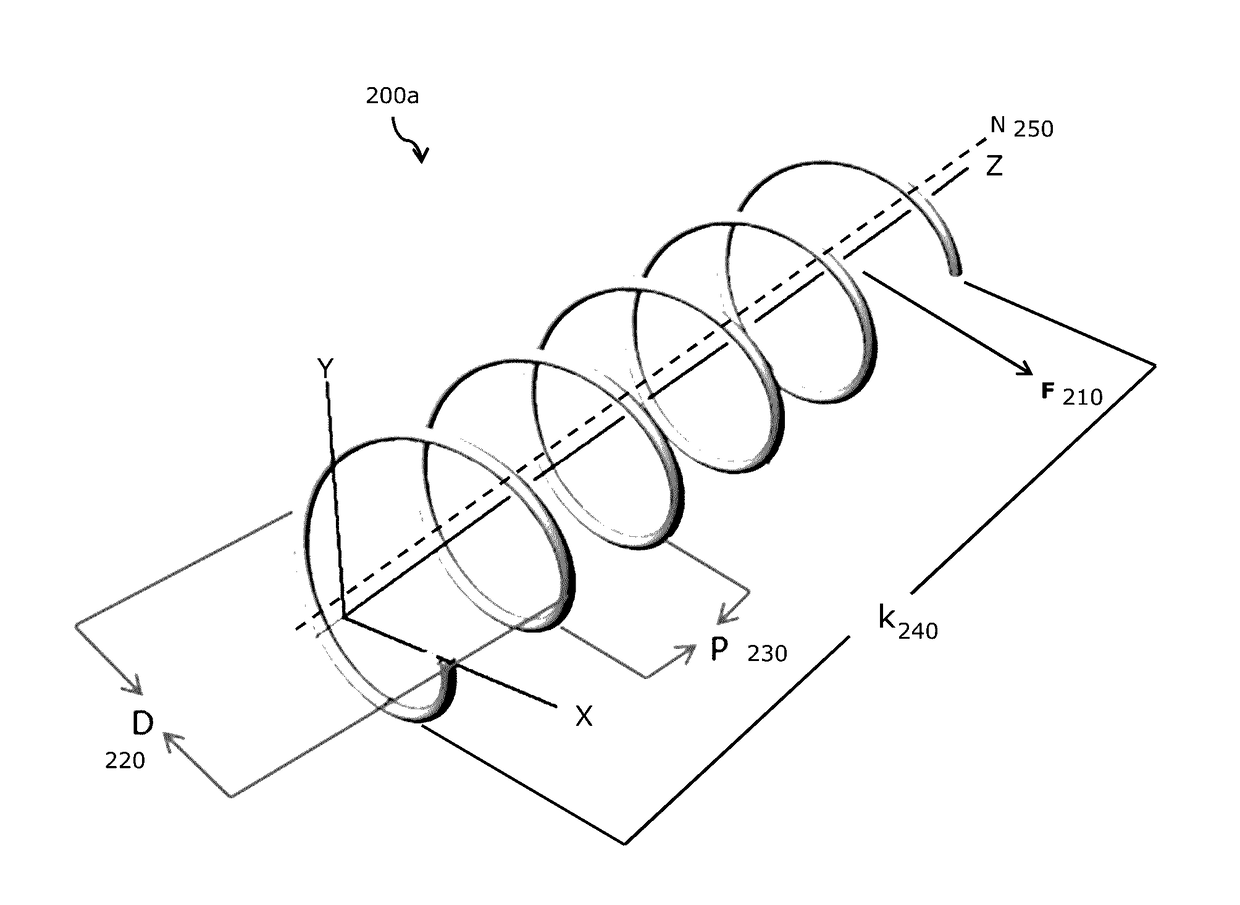

Low dispersion gas-liquid separator

ActiveUS20170113171A1Easy to separateMinimize cross contaminationLiquid degasificationComponent separationVapor–liquid separatorProduct gas

The present technology relates to methodologies, systems and apparatus for separating a liquid and a gas from a multi-phase flow stream. In particular, a gas-liquid separator having a curvilinear flow path sized is described. The flow path is designed to create a shift in the axial velocity of the primary flow field through the gas-liquid separator and generate a secondary flow field effect perpendicular to the primary flow field. The curvilinear flow path can minimize additional dispersion and provide improved efficiencies in fraction collection.

Owner:WATERS TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com