Tea tree essential oil extracting method and tea tree essential oil composition

A tea tree essential oil, extraction method technology, applied in the directions of detergent composition, surface active detergent composition, separation method, etc., can solve the problems of high price, skin damage, side effects, etc., and achieves convenient use, good use effect, less irritating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of tea tree essential oil: select fresh tea tree leaves and fresh tender shoots 10kg, join CO in the supercritical extractor, ethanol is as entrainer, and entrainer accounts for 5% by volume of total extraction solvent, extraction pressure 20MPa, temperature 40°C, CO2 flow rate 2m1 / g crude drug min, extraction time 160min, tea tree essential oil was obtained.

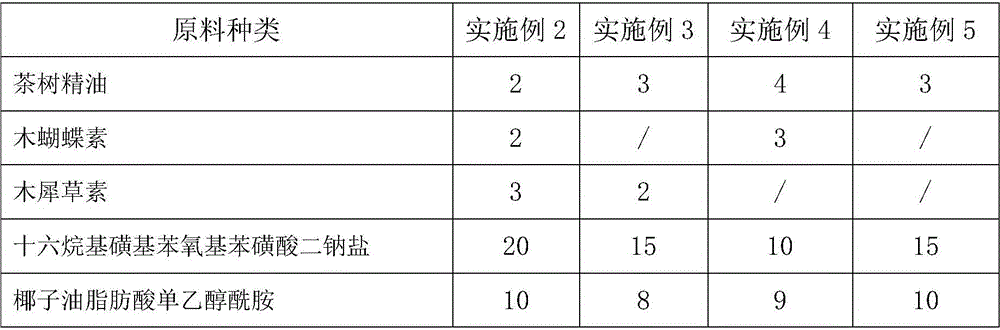

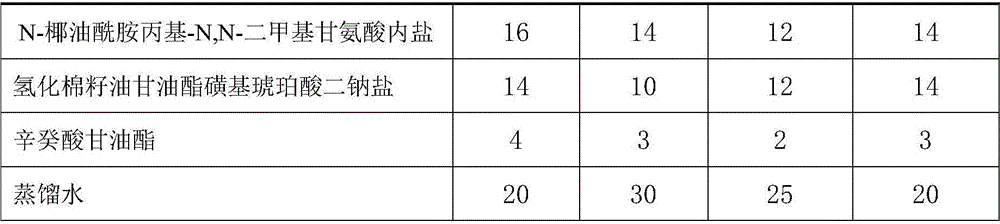

Embodiment 2

[0028] Embodiment 2: Prepare raw materials according to the above table, and the preparation method includes the following steps: (a) kneading and mixing: the various raw materials of the above components (tea tree essential oil is prepared by the method of the above-mentioned embodiment 1) are weighed in proportion Add it to a kneader for conventional soap making, knead and stir to mix evenly. (b) Grinding: Put the kneaded and stirred material into a grinder for soap body grinding. (c) Vacuum layering: put the ground soap body into a vacuum layering machine for vacuum layering. (d) Printing: The long soap body extruded by the plodder directly enters the printer for printing to obtain a shaped soap body.

Embodiment 3

[0029] Embodiment 3: according to above table, prepare raw material, preparation method, comprise the following steps: (a) kneading and mixing material: the various raw materials of above-mentioned components (tea tree essential oil is prepared by the method of above-mentioned embodiment 1) are weighed in proportion Take it and add it to a kneader for conventional soap making, knead and stir to mix evenly. (b) Grinding: Put the kneaded and stirred material into a grinder for soap body grinding. (c) Vacuum layering: put the ground soap body into a vacuum layering machine for vacuum layering. (d) Printing: The long soap body extruded by the plodder directly enters the printer for printing to obtain a shaped soap body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com