Method for extracting rosemary essential oil and antioxidant from rosemary

A technology for rosemary essential oil and antioxidants, which is applied in the directions of essential oils/spice, chemical instruments and methods, separation methods, etc., can solve the problems of complicated operation, low yield of essential oil, low yield and content of antioxidants, etc. The distillation temperature is low, the yield of essential oils is improved, and the effect of protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

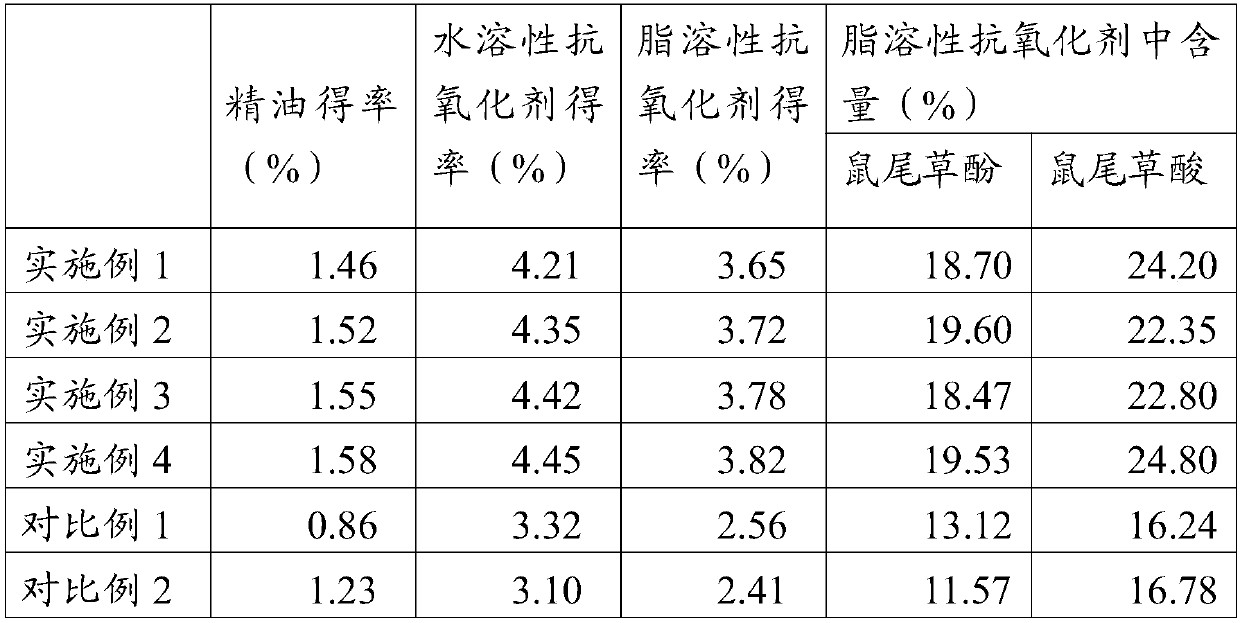

Examples

Embodiment 1

[0059] Take 150 kg of rosemary branches and leaves picked for 48 hours, wash the soil on the surface, add 150 kg of deionized water to soak for 3 hours at room temperature, and then use a refiner at a speed of 12000 r / min to beat for 4 minutes to obtain rosemary slurry. Adjust the pH value of the obtained rosemary slurry to 4.5 with acetic acid, add 0.15 kg of cellulase with an enzyme activity of 350,000 U / g, and perform enzymatic hydrolysis at 30° C. for 5 hours to obtain an enzymatic hydrolysis solution.

[0060] The obtained enzymatic hydrolysis solution is fed into the spinning cone distillation tower at a rate of 100L / h from the feed port of the spinning cone distillation tower, and water at a temperature of 95°C is passed into the bottom of the spinning cone distillation tower at a flow rate of 80Kg / h Steam, keeping the rotational speed of the rotating cone at 150r / min, condensing the steam at the top of the rotating cone distillation tower to obtain a rosemary oil-water ...

Embodiment 2

[0062] Take 150 kg of rosemary branches and leaves that have been picked for 15 hours, wash the surface soil, add 450 kg of deionized water to soak for 1 hour at room temperature, and then use a refiner at a speed of 15000 r / min to beat for 6 minutes to obtain rosemary slurry. Adjust the pH value of the obtained rosemary slurry to 7 with acetic acid, add 0.75 kg of amylase with an enzyme activity of 800,000 U / g, and perform enzymolysis at 65° C. for 3 hours to obtain an enzymolysis solution.

[0063] The obtained enzymatic hydrolysis solution is fed into the rotating cone distillation tower at a rate of 300L / h from the feed port of the rotating cone distillation tower, and water at a temperature of 110°C is passed into the bottom of the rotating cone distillation tower at a flow rate of 10Kg / h Steam, keeping the rotational speed of the rotating cone at 600r / min, condensing the steam at the top of the rotating cone distillation tower to obtain a rosemary oil-water mixture, and s...

Embodiment 3

[0065] Take 150 kg of rosemary branches and leaves that have been picked for 36 hours, wash the surface soil, add 200 kg of deionized water, soak for 2 hours at room temperature, and then use a refiner at a speed of 13000 r / min to beat for 5.5 minutes to obtain rosemary slurry. Adjust the pH of the obtained rosemary slurry to 6 with acetic acid, add 0.40 kg of papain with an enzyme activity of 1 million U / g, and perform enzymatic hydrolysis at 50° C. for 4 hours to obtain an enzymatic hydrolysis solution.

[0066] The obtained enzymatic hydrolysis solution is fed into the spinning cone distillation tower at a rate of 250L / h from the feed port of the spinning cone distillation tower, and water at a temperature of 105°C is passed from the bottom of the spinning cone distillation tower at a flow rate of 60Kg / h Steam, keeping the rotational speed of the rotating cone at 300r / min, condensing the steam at the top of the rotating cone distillation tower to obtain a rosemary oil-water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com